Page 1

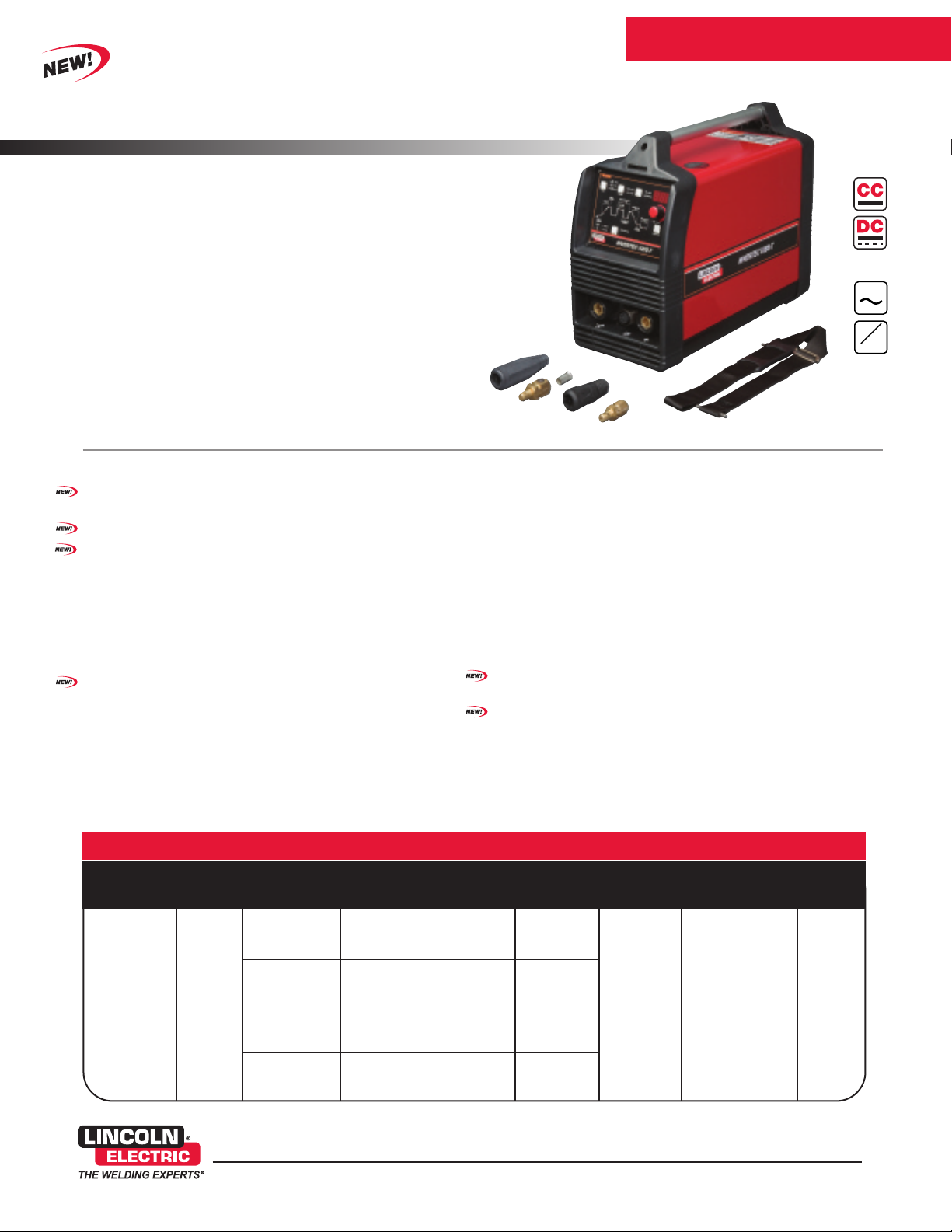

Invertec®V205-T DC

1

PHASE

60

5

0

H

z

For TIG and Stick Welding

The Invertec®V205-T DC is a compact, TIG power source intended for

critical DC TIG welding. From maintenance to production fabrication,

to motorsports, aerospace, nuclear piping and shipbuilding, this feature-packed inverter is flexible enough for almost any job!

The 115/230V input voltage auto-reconnect makes the V205-T DC

extremely useful almost anywhere in the shop or in the field.

Processes

Stick, TIG

Advantage Lincoln

TIG WELDERS

Output

Input

Precision Arc Performance

• Added Stick Crisp Mode for exceptional Fleetweld®5P and 5P+ (E6010)

Performance.

• Improved TIG Starting. Now starts DC(-) to maintain a sharp tungsten.

• Adjustable DC Strike mode – Allows adjustment of a hotter or colder

start depending on the tungsten diameter.

• DC inverter for TIG with advanced inverter technology to optimize arc

performance.

• High quality stick welding with such popular Lincoln

Fleetweld

®

5P, 35, 37, 180 and Excalibur®7018.

®

electrodes as

Professional Features

• Voltage Reduction Device (VRD). When enabled from the set up

menu reduces the open circuit voltage in STICK mode for use in

electrically hazardous conditions or when the use of a VRD

is required.

• 200 amps @ 40% duty cycle is the highest output rating in this

machine class.

• Weighs in at a mere 38 lbs. (17.3 kg) making it easy to carry around the

shop or job site.

Simple Controls

• Full featured TIG control –including pulse, upslope, downslope, start

and finish current.

• Easy to read sequence diagram with LEDs displays selected parameter

for easy setting with a single knob.

• Selectable high frequency TIG starting for easy arc ignition or

Touch-Start™ TIG starting capability on DC for areas where high

frequency emissions are a concern.

Outstanding Quality

• Newly designed using the latest power electronic technology for

improved reliability.

• Fan-As-Needed (F.A.N.) fan only operates when needed to reduce power

consumption, noise and dust in machine.

• CSA C/US Certified.

• Three-Year Lincoln

®

Warranty on parts and labor.

• Auto-reconnects for single phase 115/230V 50/60 Hz input allows the

flexibility to weld in the shop or take in the field where 230V may not be

available.

TECHNICAL SPECIFICATIONS

Product Product Rated Output Current @ Output H x W x D Net Weight

Name Number Input Power Current/Voltage/Duty Cycle Rated Output

®

Invertec

V205-T DC K2629-1 115V/1/50/60 120A/14.8V/60% TIG 25.0A

230V/1/50/60

115V/1/50/60 90A/23.6V/60% Stick 28.0A 53.7

230V/1/50/60

(1) Input amps on 60Hz input. (2) Also operates on 208 input volts.

(2)

(2)

150A/16.0V/40% TIG 34.0A

100A/14.0V/100% TIG 20.0A

200A/18.0V/40% TIG 30.0A

170A/16.0V/60% TIG 18.0A 6-200 A

140A/15.6V/100% TIG 15.0A DC 15.0 x 8.5 x 19.0 38

110A/24.4V/35% Stick 34.0A Max. OCV: (381 x 216 x 483) (17.3)

70A/22.8V/100% Stick 20.0A

180A/27.2V/35% Stick 30.0A

150A/26.0V/60% Stick 23.0A

130A/25.2V/100% Stick 19.0A

Input Dimensions

(1)

Range inches (mm) lbs.(kg)

Publication E3.110.1 06/07

Web Update 06/08

www.lincolnelectric.com

Page 2

A CLOSER LOOK

PERFORMANCE

TIG Welding

Full featured TIG control with adjustable starting parameters for

excellent starting and pulse control for excellent heat control.

FEATURES

• Selectable high frequency TIG starting for easy arc ignition or

Touch-Start™ DC TIG starting for areas where high frequency

emissions are a concern.

• Hidden start up menu offers the following additional controls:

– Preflow time for purging gas lines is adjustable between 0 and

25 seconds. Factory preset at 0.5 seconds.

Key Controls

Stick Welding

The Invertec®V205-T DC is also an excellent DC stick welder

with such popular Lincoln®electrodes such as Fleetweld®5P

and 5P+, Fleetweld®35, Fleetweld®37, Fleetweld®180 and

Excalibur®7018.

– High frequency is standard starting method for TIG.

Touch-Start™ TIG may be selected for DC.

– Adjustable DC TIG strike current.

– Adjustable Arc Force for stick mode only.

– Adjustable Hot Start for stick mode only.

1) Weld Mode

2) Up-Slope Time

3) Pre-settable Amperage

4) Down-Slope Time

5) Finish Current

6) Pulse Frequency

7) Pulse Background

Current

8) % On-Time Pulse

9) Adjustable post-flow time

10) Digital output current

display

11) 2-Step and 4-Step

operation modes

12) Local/Remote switch

allows for remote current

controls in TIG welding

mode

13) Starting Current

14) 6-pin MS-Type remote

connector (not shown)

15) Integral Twist-Mate™ gas

and power connections

(not shown)

QUALITY AND RELIABILITY

• Thermal and voltage overload protection for long life of internal

components.

®

• Three year Lincoln

warranty on parts and labor.

SYSTEM SELECTION

One-Pak®Welding Packages

Order a Lincoln®One-Pak®and get everything you need to

complete a welding package – all with one order number.

Just add shielding gas.

1

11

12

7

6

3

2

13

8

• Line voltage compensation gives you the option to use remote

generator power.

5

10

4

9

Invertec®V205-T DC One-Pak®Package —

One product number (K2671-1) gets you all this:

Package Contains These Separate Items:

• Invertec®V205-T DC (115/230/1/50/60). . . . . K2629-1

• TIG-Mate™ 17 Air-Cooled . . . . . . . . . . . . . . . K2266-1

TIG Torch Starter Pack

• Foot Amptrol®. . . . . . . . . . . . . . . . . . . . . . . . K870

[2]

K2266-1

K2629-1

K870

Invertec®V205-T DC

www.lincolnelectric.com

Page 3

RECOMMENDED OPTIONS

TICK OPTIONS

S

Stick Electrode Holder, Work

Clamp, Cable & Twist-Mate™ Set

Includes 200A stick electrode

holder, #4 welding cable, work

cable and Twist-Mate™ set.

Order K2394-1

TIG OPTIONS

TIG-Mate™ 9 Air-Cooled TIG

Torch Starter Pack

Get everything you need for TIG

welding in one complete easy-toorder kit packaged in its own

portable carrying case. Includes:

PTA-9 Ultra-FlexTMtorch, gas lens

parts kit, Harris®flowmeter/regulator, Twist-MateTMadapter, gas hose,

work clamp and cable.

Order K2413-1

TIG-Mate™ 17 Air-Cooled

TIG Torch Starter Pack

Get everything you need for TIG

welding in one complete easy-toorder kit packaged in its own

portable carrying case. Includes:

PTA-17 Ultra-FlexTMtorch, parts

kit, Harris®flowmeter/regulator, 10

ft. gas hose, PTA-17 Twist-Mate

adapter, and work clamp and

10 ft. cable.

Order K2266-1

TIG-Mate™ 20 Water-Cooled

TIG Torch Starter Pack

Get everything you need for TIG

welding in one complete easy-toorder kit packaged in its own

portable carrying case. Includes:

PTW-20 torch, parts kit, Harris

flowmeter/regulator, 10 ft. gas

hose, PTW-20 Twist-Mate

adapter, work clamp and cable

and 10 ft. water hose.

Order K2267-1

Additional or alternate torches

may be ordered:

Pro-Torch™ TIG Torches

One-piece air-cooled PTA-9 or -17

TIG torches may be connected

directly with the included K1622-1

TIG Torch Adapter.

Order K1781-1 for PTA-9,

12.5 ft., 1-cable.

Order K1782-1 for PTA-17,

12.5 ft., 1-cable.

One-piece air-cooled PTA-26

TIG torches may be connected

with an optional K1622-3

Twist-Mate™ adapter.

Order K1783-1 for PTA-26,

12.5 ft., 1-cable.

Order K1622-3 PTA-26 adapter

PTW-20 water-cooled torch may

be connected with an optional

K1622-4 Twist-Mate™ adapter.

TM

TM

Order K1784-3 for PTW-20, 12.5 ft.

Order K1622-4 PTW-20 adapter

A full line of TIG torches and parts

kits in various lengths and types

are available.

Request Lincoln®Publication

E12.150 for more information.

Foot Amptrol

®

Provides 25 ft. (7.6m) of remote

current control for TIG welding.

(6 pin plug connection)

Order K870

Hand Amptrol

Provides 25 ft. (7.6m) of remote

current control for TIG welding.

(6 pin plug connection).

Velcro straps secure torch.

Order K963-3 (one size fits all

Pro-Torch TIG torches).

Arc Start Switch

May be used in place of the Foot

or Hand Amptrol. Comes with a 25

ft. (7.6m) cable and 6-pin plug

connector. Attaches to the TIG

torch for convenient finger control

to start and stop the weld cycle at

the current set on the machine.

Order K814

Cool-Arc™ 40 Water Cooler

Energy efficient long life cooler for

water-cooled welding applications.

Order K1813-1 for 115V.

Order K2187-1 for 230V.

Water Cooler Hoses

(CGA to CGA)

For 5/8" LH CGA fitting applications at both cooler and wire

feeder. Kit contains two 25 ft.

hoses with 5/8" left hand CGA

fittings on both ends of hose.

Order K1859-2

Hose Coupler (11N18)

5/8" LH CGA female fitting on

both ends allows a water hose

from cooler to connect directly to

the water line of the TIG torch.

Order S19558-6

Cut Length Consumables

TIG welding filler metals are

available for welding stainless

steel, mild steel, aluminum and

copper alloys.

Request Lincoln®Publication

C9.10 for more information

GENERAL OPTIONS

Small Canvas Cover

Protect your machine when not in

use. Made from attractive red canvas that is flame retardant, mildew

resistant and water repellent.

Includes a convenient side pocket

to hold welding torch or gun.

Order K2377-1

[3]

Invertec®V205-T DC

www.lincolnelectric.com

Page 4

RECOMMENDED OPTIONS

ENERAL OPTIONS, CONT.

G

Welding Cart

Lightweight cart stores and transports welder, 80 cubic foot shielding gas cylinder, welding cables

and accessories. Includes an

angled top shelf for easy access

to welder controls, a lower tray for

added storage space, a sturdy

handle and a convenient cable

wrap hanger.

Order K2275-1

Utililty Cart

Heavy duty cart stores and transports welder, 150 cubic foot

shielding gas cylinder, welding

cables and accessories. Includes

stable platforms for welder and

gas bottle platform, lower tray for

added storage capacity and

adjustable height handle.

Order K520

INVERTEC®V205-T DC

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

Invertec®V205-T DC 115/230/1/50/60 K2629-1

Invertec®V205-T DC One-Pak®Package K2671-1

Recommended Stick Options

Stick Electrode Holder, Work Clamp, Cable & Twist-Mate™ Set K2394-1

Recommended TIG Options

TIG-Mate™ 9 Air-Cooled TIG Torch Starter Pack K2413-1

TIG-Mate™ 17 Air-Cooled TIG Torch Starter Pack K2266-1

TIG-Mate™ 20 Water-Cooled TIG Torch Starter Pack K2267-1

Pro-Torch™ TIG Torches: see publication E12.150

PTA-9 TIG Torch, 12.5 ft., 1-cable, 125 amps K1781-1

PTA-17 TIG Torch, 12.5 ft., 1-cable, 150 amps K1782-1

TIG Torch Adapter (required for PTA-9, -17) K1622-1

PTA-26 TIG Torch, 12.5 ft., 1-cable, 200 amps K1783-1

TIG Torch Adapter (required for PTA-26) K1622-3

PTW-20 TIG Torch, 12.5 ft., 250 amps K1784-3

TIG Torch Adapter (required for PTW-20) K1622-4

Foot Amptrol K870

Hand Amptrol K963-3

Arc Start Switch K814

Cool Arc™ 40 Water Cooler:

115/1/50/60 K1813-1

220-240/1/50/60 K2187-1

Water Cooler Hoses (CGA to CGA) K1859-2

Hose Coupler (11N18) S19558-6

Cut Length Consumables see publication C9.10

Recommended General Options

Small Canvas Cover K2377-1

Welding Cart K2275-1

Utility Cart K520

TOTAL:

C U S T O M E R A S S I S T A N C E P O L I C Y

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the

needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond

to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability,

with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to

such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has

been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsible manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility

of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

THE L INC OLN EL ECTRI C CO MPA NY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

Loading...

Loading...