Page 1

QUICK REFERENCE GUIDE

Digital Display Menus

A AMPS

See back for recommended Amperage Values

Pulser

0-20 Pulses per second

(default = off)

• Alternating peak and background current controls heat input.

• Minimize material distortion

TIP: Lower pulse frequency provides a reference for adding filler metal,

making you a better TIG welder faster.

(pulsing: 0.5 - 2.0 pulses per second)

AC Balance

Range 60 - 90% Electrode Negative (default = 75%)

AC Frequency

Range 60 - 150 Hz (default = 90 Hz)

DC TIG

Steel Alloys

Stainless Steels

Nickel Alloys

Copper Alloys

Titanium

AC TIG

Aluminum

Magnesium

DC+ STICK

See back for suggested Amperage Values

®

TIG 200

SQUARE WAVE

Push button to choose between

Pulse (DC- & AC TIG), AC

Frequency (AC TIG) and AC

Balance (AC TIG). Rotate knob

to make adjustments to each

setting.

TIG

100%

Argon

Stick

Polarity based on consumable and penetration

Showing Positive Polarity setup

A lower AC Balance (%EN)

results in an arc with increased

cleaning action.

A lower AC frequency results in

a wider bead.

A higher AC Balance (%EN)

results in an arc with

higher penetration.

A higher AC frequency results in

a more focused bead.

or

Insert & twist

to lock

A lower AC frequency results in

a wider bead.

AC Frequency

Range 60 - 150 Hz (default = 90 Hz)

A higher AC frequency results in

a more focused bead.

Page 2

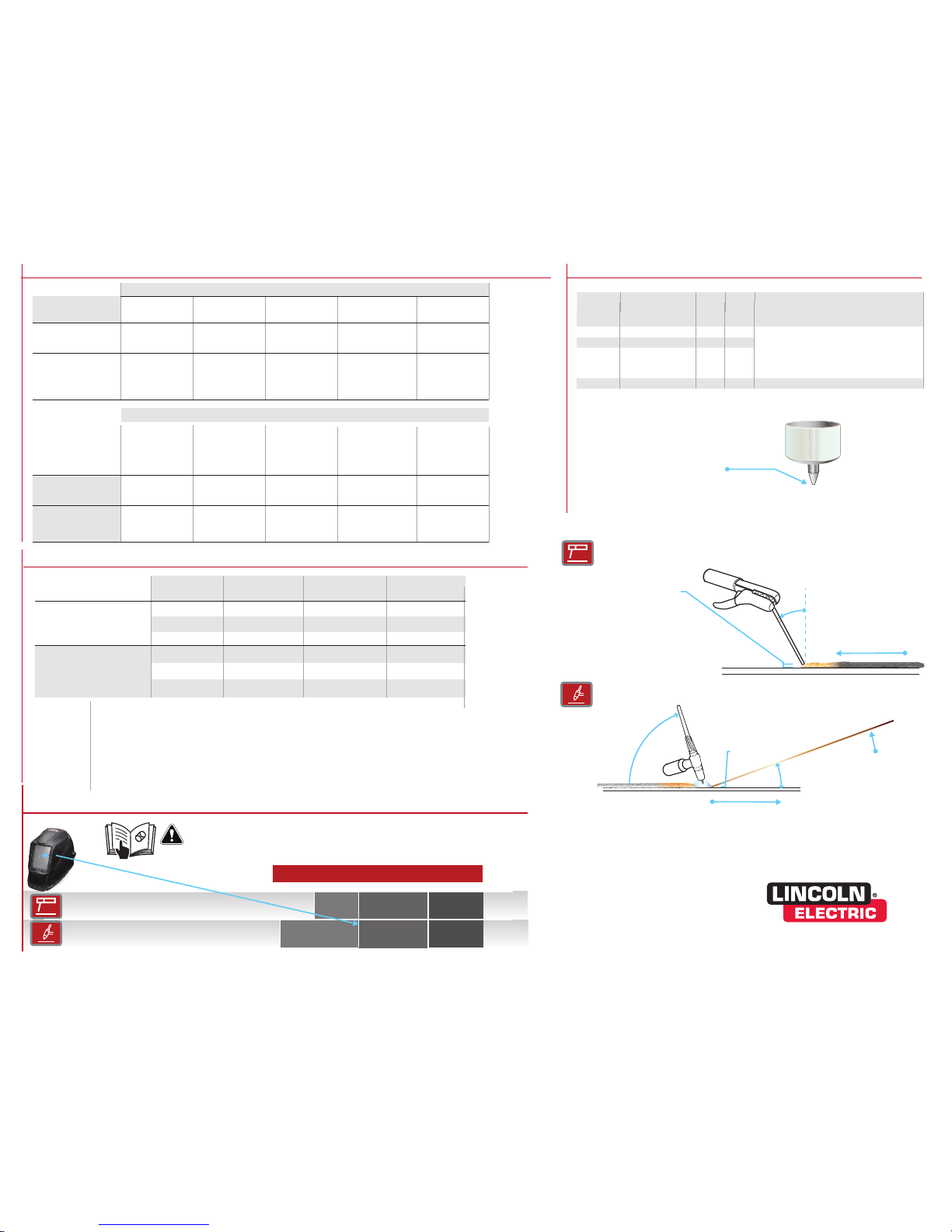

Tungsten -

Tungsten Preparation

Pure Tungsten is NOT Recommended

Tungsten should have a blunt tip.

TIG Amperage Values

STICK Amperage Values

Material Type

Material Thickness

Material Thickness

24 Ga (0.024 in)

(0.6 mm)

16 Ga (0.060 in)

(1.5 mm)

12 Ga (0.105 in)

(2.7 mm)

10 Gauge (0.135 in)

(3.4 mm)

3/16"

(4.8 mm)

Steel (DC -) 25-35 A 70-85 A 80-100 A 90-120 A 130-160 A

Stainless Steel (DC -) 25-35 A 70-85 A 80-100 A 90-120 A 130-160 A

24 Ga (0.024 in)

(0.6 mm)

1/16" (0.62 in)

(1.6 mm)

0.090"

(2.3 mm)

1/8" (0.125 in)

(3.2 mm)

3/16"

(4.8 mm)

24 Ga (0.024 in)

(0.6 mm)

1/16" (0.62 in)

(1.6 mm)

16 Ga (0.060 in)

(1.5 mm) or

12 Ga (0.105 in)

(2.7 mm) or

10 Ga (0.135 in)

(3.4 mm) or

0.090"

(2.3 mm)

1/8" (0.125 in)

(3.2 mm)

3/16"

(4.8 mm)

Aluminum (AC) 25-35 A 75-85 A 85-110 A 120-135 165-195 A

Suggested Tungsten

Diameter

1/16"

(1.6mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

Suggested Filler

Metal Diameter

1/16"

(1.6mm)

1/16"

(1.6 mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

1/8"

(3.2mm)

Stick Electrode

Diameter

12 Gauge

(0.105 in) (2.7 mm)

10 Gauge

(0.135 in) (3.4 mm)

3/16"

(4.7 mm)

Steel E6011 / E6013 (DC +)

3/32" (2.4 mm) 50-70A 60-80A -

1/8" (3.2 mm) 65-85A 75-95A 90-110A

5/32" (4.0 mm) 90-110A 115-135A 130-150A

Steel E7018 (DC +)

3/32" (2.4 mm) 70-90A 80-100A 90-110A

1/8" (3.2 mm) 90-110A 105-125A 115-135A

5/32" (4.0 mm) 105-125A 115-135A 140-160A

E6011 Deeper penetrating electrode that can be used in all positions. Frequently used for joining pipe.

E6013

Shallower penetrating electrode that can be used in all positions. Commonly used for wide root openings,

or conditions of poor fit up.

E7018

Low hydrogen electrode used for joints involving high-strength (structural), high carbon,

or low alloy steels. Smooth arc with medium arc penetration. Can be used in all positions.

Stick Drag Technique

TIG Push Technique

Correct Arc Length

1/16” to 1/8”

(1.6 to 3.2 mm)

Correct Tungsten to workpiece distance

1/16” to 1/8”

(1.6 to 3.2 mm)

20º

70º

15º to 20º

Filler Rod

L16988 © Lincoln Global Inc. All Rights Reserved.

Recommended Helmet Shade Lens Settings

Before you weld - refer to http://www.lincolnelectric.com/safety for

additional safety information.

Stick

TIG

10 20 40 60 80 120 160 180 200

7 8-10

8-12

10-12

8-10 10-14

AMPS

Color Tungsten Types AC

PolarityDCPolarity

Applications

Gold 1.5% Lanthanated

X

Blue 2% Lanthanted

X X

Good all around choice for both AC and DC, in welding

low alloyed & non-corroding steels, aluminum, magnesium, titanium, nickel, and copper.

Grey 2% Ceriated

X X

Chartreuse or

Purple (E3®)

1.5% Lanthanum,

0.08% Zirconium,

0.08% Yttrium

X X

White 0.08% Zirconiated

X

A very good choice for aluminum or magnesium alloys.

Good choice for welding titanium, nickel,

copper, mild steel and stainless steel.

Page 3

GUÍA DE REFERENCIA RÁPIDA

Menús de Pantalla Digital

A AMPS

Consulte el reverso para conocer los Valores de Amperaje recomendados

Pulsador

0-20 pulsos por segundo

(default = off)

• La alternancia entre la corriente pico y la de respaldo controla la entrada

de calor.

• Minimizar la distorsión del material

TIP: Baja frecuencia de pulsación proporciona una referencia para agregar

metal de relleno convirtiéndote en un mejor soldador TIG más rápido.

(pulsación: 0.5 - 2.0 pulsaciones por segundo)

Balance de AC

Rango 60 - 90% Electrodo Negativo (predeterminado = 75%)

Frecuencia de AC

Rango 60 - 150 Hz (predeterminado = 90 Hz)

DC TIG

Aleaciones de acero

Aceros Inoxidables

Aleaciones de Níquel

Aleaciones de cobre

Titanio

AC TIG

Aluminio

Magnesio

DC+ ELECTRODO

Ver reverso para conocer los Valores de

Amperaje sugeridos

®

TIG 200

SQUARE WAVE

Presione el botón para seleccionar entre Pulsación (DC- &

AC TIG), Frecuencia de AC (AC

TIG) y balance de AC (AC TIG.)

Gire la perilla para ajustar cada

conguración.

TIG

100%

Argon

Stick

La polaridad se basa en consumibles y penetración

Muestra de conguración de Polaridad Positiva

Un equilibrio de AC menor(%EN)

resulta en un arco con mayor

acción de limpieza.

Una frecuencia de AC menor

resulta en un cordón más amplio.

Un equilibrio de AC mayor

(%EN) resulta en un arco con

mayor penetración.

Una frecuencia de AC mayor

resulta en un cordón más enfocado.

o

Insertar y girar

Una frecuencia de AC menor

resulta en un cordón más amplio.

Rango 60 - 150 Hz (predeterminado = 90 Hz)

Una frecuencia de AC mayor

resulta en un cordón más enfocado.

Entrada Entrada

Page 4

Tungsteno – NO se recomienda Tungsteno puro

El Tungsteno debe tener una

punta de cono truncado.

Valores de Amperaje TIG

Valores de Amperaje de la VARILLA

Tipo de material

Espesor de material

Espesor de material

Cal 24 (0.024”)

(0.6 mm)

Cal 16 (0.060”)

(1.5 mm)

Cal 12 (0.105”)

(2.7 mm)

Cal 10 (0.135”)

(3.4 mm)

3/16"

(4.8 mm)

Acero (DC -) 25-35 A 70-85 A 80-100 A 90-120 A 130-160 A

Acero Inoxidable (DC -) 25-35 A 70-85 A 80-100 A 90-120 A 130-160 A

Cal 24 (0.024”)

(0.6 mm)

1/16" (0.62”)

(1.6 mm)

0.090"

(2.3 mm)

1/8" (0.125”)

(3.2 mm)

3/16"

(4.8 mm)

Cal 24 (0.024”)

(0.6 mm)

1/16" (0.62”)

(1.6 mm)

Cal 16 (0.060”)

(1.5 mm) or

Cal 12 (0.105”)

(2.7 mm) or

Cal 10 (0.135”)

(3.4 mm) or

0.090"

(2.3 mm)

1/8" (0.125”)

(3.2 mm)

3/16"

(4.8 mm)

Aluminio (AC) 25-35 A 75-85 A 85-110 A 120-135 165-195 A

Diámetro de

Tungsteno Sugerido

1/16"

(1.6mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

Diámetro de Metal

de relleno Sugerido

1/16"

(1.6mm)

1/16"

(1.6 mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

1/8"

(3.2mm)

Diámetro de

Electrodo Revestido

Calibre 12

(0.105”) (2.7 mm)

Calibre 10

(0.135”) (3.4 mm)

3/16"

(4.7 mm)

Acero E6011 / E6013

(DC +)

3/32" (2.4 mm) 50-70A 60-80A -

1/8" (3.2 mm) 65-85A 75-95A 90-110A

5/32" (4.0 mm) 90-110A 115-135A 130-150A

Acero E7018 (DC +)

3/32" (2.4 mm) 70-90A 80-100A 90-110A

1/8" (3.2 mm) 90-110A 105-125A 115-135A

5/32" (4.0 mm) 105-125A 115-135A 140-160A

E6011 Se puede utilizar un electrodo con penetración más profunda en todas las posiciones. Se utiliza frecuentemente para tubería de unión.

E6013

En todas las posiciones se puede utilizar el electrodo de penetración superficial. Se utiliza comúnmente en separaciones de raíz

amplias, o condiciones de adherencia deficiente.

E7018

El Electrodo de bajo hidrógeno se utiliza en uniones que implican gran fuerza (estructural), alto carbón, o aceros de aleación baja.

Arco suave con penetración de arco media. Se puede utilizar en todas las posiciones.

Técnica de Arrastre de Varilla

Técnica de Empuje TIG

Longitud de Arco correcta

1/16” to 1/8”

(1.6 to 3.2 mm)

Distancia correcta entre el Tungsteno

y la pieza de trabajo.

1/16” to 1/8”

(1.6 to 3.2 mm)

20º

70º

15º to 20º

Varilla de Relleno

L16988 © Lincoln Global Inc. Todos los derechos reservados.

Configuraciones Recomendadas de Careta con Oscurecimiento

Antes de soldar

Visite http://www.lincolnelectric.com/ para conocer información de seguridad adicional.

Varilla

TIG

10 20 40 60 80 120 160 180 200

7 8-10

8-12

10-12

8-10 10-14

AMPS

Color Tipos de Tungsteno AC

PolaridadDCPolaridad

Dorado 1.5% Lantaneado

X

Azul 2% Lantaneado

X X

Buena elección en general tanto para AC como para DC

en soldadura de aceros de baja aleación y no corrosivos,

aluminio, magnesio, titanio, níquel y cobre.

Gris 2% Ceriado

X X

Chartreuse or

Púrpura (E3®)

1.5% Lantano

0.08% Zirconio

0.08% Itrio

X X

Blanco 0.08% Zirconio

X

Muy buena elección para aleaciones de aluminio o magnesio.

Aplicaciones

Buena elección para soldadura de titanio, níquel,

cobre, acero fundido.

Page 5

GUIDE DE RÉFÉRENCE RAPIDE

Menus de l’Écran Numérique

A AMPS

Voir au verso les Valeurs d’Intensité recommandées.

Générateur d’Impulsions

0-20 Impulsions par seconde (par défaut = éteint)

• L’alternance entre le courant de crête et le courant de fond contrôle

l’apport de chaleur.

• Minimise la déformation du matériau.

ASTUCE : Une fréquence d’impulsions plus faible fournit une référence

pour l’ajout de métal de remplissage, ce qui fera plus vite de vous un

meilleur soudeur TIG. (Impulsion : 0,5 – 2,0 impulsions par seconde)

Équilibrage AC

Registre 60 - 90% Électrode Négative (par défaut = 75%)

Fréquence AC

Registre 60 - 150 Hz (par défaut = 90 Hz)

DC TIG

Alliages d’Acier

Aciers Inoxydables

Alliages de Nickel

Alliages de Cuivre

Titane

AC TIG

Aluminium

Magnésium

DC+ BAGUETTE

Voir au verso les Valeurs d’Intensité

recommandées.

®

TIG 200

SQUARE WAVE

Appuyer sur le bouton pour

choisir entre Impulsion (DC- &

AC TIG), Fréquence AC (AC TIG)

et Équilibrage AC (AC TIG).

Faire tourner le bouton pour

ajuster chaque réglage.

TIG

100%

Argon

Stick

La polarité se base sur le matériel consommable

et la pénétration. Illustration du réglage de la Polarité Positive.

Un Équilibrage AC moins faible

(%EN) donne un arc ayant une

action de nettoyage accrue.

Une fréquence AC plus faible donne

un cordon de soudure plus large.

Un Équilibrage AC moins élevé

(%EN) donne un arc ayant plus de

pénétration.

Une fréquence AC plus élevée

donne un cordon plus focalisé.

o

Insérer & tourner

Une fréquence AC plus faible donne

un cordon de soudure plus large.

Registre 60 - 150 Hz (par défaut = 90 Hz)

Une fréquence AC plus élevée

donne un cordon plus focalisé.

Page 6

Tungstène - Le Tungstène pur n’est PAS Recommandé.

Le Tungstène doit avoir

une pointe émoussée.

Valeurs de l’Intensité pour soudage TIG

Valeurs de l’Intensité pour soudage à la BAGUETTE

type d'ouvrage

Epaisseur du matériau

Epaisseur du matériau

24 Ga (0.024 in)

(0.6 mm)

16 Ga (0.060 in)

(1.5 mm)

12 Ga (0.105 in)

(2.7 mm)

10 Gauge (0.135 in)

(3.4 mm)

3/16"

(4.8 mm)

pour Acier Doux (DC -) 25-35 A 70-85 A 80-100 A 90-120 A 130-160 A

pour Acier Inoxydable (DC -) 25-35 A 70-85 A 80-100 A 90-120 A 130-160 A

24 Ga (0.024 in)

(0.6 mm)

1/16" (0.62 in)

(1.6 mm)

0.090"

(2.3 mm)

1/8" (0.125 in)

(3.2 mm)

3/16"

(4.8 mm)

24 Ga (0.024 in)

(0.6 mm)

1/16" (0.62 in)

(1.6 mm)

16 Ga (0.060 in)

(1.5 mm) or

12 Ga (0.105 in)

(2.7 mm) or

10 Ga (0.135 in)

(3.4 mm) or

0.090"

(2.3 mm)

1/8" (0.125 in)

(3.2 mm)

3/16"

(4.8 mm)

Aluminium (AC) 25-35 A 75-85 A 85-110 A 120-135 165-195 A

Diamètre de

Tungstène Suggéré

1/16"

(1.6mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

Diamètre de Métal

d'Apport suggéré

1/16"

(1.6mm)

1/16"

(1.6 mm)

3/32"

(2.4 mm)

3/32"

(2.4 mm)

1/8"

(3.2mm)

Diamètre de

l'Électrode

12 Gauge

(0.105 in) (2.7 mm)

10 Gauge

(0.135 in) (3.4 mm)

3/16"

(4.7 mm)

Acier E6011 / E6013 (DC +)

3/32" (2.4 mm) 50-70A 60-80A -

1/8" (3.2 mm) 65-85A 75-95A 90-110A

5/32" (4.0 mm) 90-110A 115-135A 130-150A

Acier E7018 (DC +)

3/32" (2.4 mm) 70-90A 80-100A 90-110A

1/8" (3.2 mm) 90-110A 105-125A 115-135A

5/32" (4.0 mm) 105-125A 115-135A 140-160A

E6011 Électrodes à pénétration plus profonde pouvant être utilisées dans toutes les positions. Fréquemment utilisées pour l’union de tuyauteries.

E6013

Électrodes à pénétration plus concave pouvant être utilisées dans toutes les positions. Communément utilisées pour les écartements

de bords larges, ou des conditions de mauvaise adhérence.

E7018

Électrodes à faible teneur en hydrogène utilisées pour des joints impliquant une grande force (structurelle), une haute teneur en carbone,

ou des aciers à faible alliage. Arc régulier avec pénétration d’arc moyenne. Peuvent être utilisées dans toutes les positions.

Technique de Traînage à la Baguette

Technique de Poussée TIG

Longueur d’Arc Correcte

1/16” to 1/8”

(1.6 to 3.2 mm)

Distance correcte entre le Tungstène et la pièce à souder

1/16” to 1/8”

(1.6 to 3.2 mm)

20º

70º

15º to 20º

Métal d'Apport

L16988 © Lincoln Global Inc. Tous les droits d’exécution réservés.

Voir au verso les Valeurs d’Intensité recommandées

Avant de souder- se reporter à http://www.lincolnelectric.com/safety pour des

informations supplémentaires en matière de sécurité.

BAGUETTE

TIG

10 20 40 60 80 120 160 180 200

7 8-10

8-12

10-12

8-10 10-14

AMPS

couleur Types de Tungstène PolaritéACPolaritéDCApplications

Or 1.5% Lanthanated

X

Bleu 2% Lanthanted

X X

Bon choix général pour AC et DC. ,Gris 2% Ceriated

X X

Chartreuse ou

Mauvé (E3®)

1.5% Lanthanum,

0.08% Zirconium,

0.08% Yttrium

X X

Blanc 0.08% Zirconiated

X

Un très bon choix pour les alliages d’aluminium ou de magnésium.

Bon choix pour souder du titane, du nickel, du cuivre,

de l’acier doux et de l’acier inoxydable.

Loading...

Loading...