Page 1

APPLICATION

WAVEFORM CONTROL TECHNOLOGY

TM

Tandem MIG

High-Speed and High-Deposition Welding

Low cost and profitability are key

business objectives, whether the

product offering is a wheel, a

water tank, or a truck frame. It

used to be thought that on the

road to lower cost, quality had to

be sacrificed. That’s no longer

true with Tandem MIG welding.

The following factors affect

pricing per welded part:

• Capital Equipment

• Overhead

• Labor cost

• Part production rates

Lincoln Tandem MIG welding

systems are designed to produce

quality welds at welding speeds

well above accepted single

wire processes. The unique

engineered output control of the

Tandem MIG dual wire process

is designed to overcome the

barriers limiting the travel speed

capabilities of conventional single

wire GMAW processes.

Increased deposition

on thicker materials

reduces welding time

and distortion.

TM

Fast travel speeds on thin

lap welds increase the

number of parts per day.

advantages

The future of welding is here.

INCREASED TRAVEL SPEEDS

• The combined contribution of two separate welding arcs in one weld pool

provides the control to overcome the lack of follow tendencies of single

arc processes.

INCREASED DEPOSITION

• Two small diameter Tandem MIG wire electrodes provide higher melt-off

rates per current drawn when compared to a single larger diameter wire

electrode at similar current draws.

IMPROVED THROUGHPUT

• Higher travel speeds and higher deposition rates reduce part welding

time cycles.

®

NX-3.70 10/05© Copyright 2005 The Lincoln Electric Company. All rights reserved.

Page 2

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

What Is It?

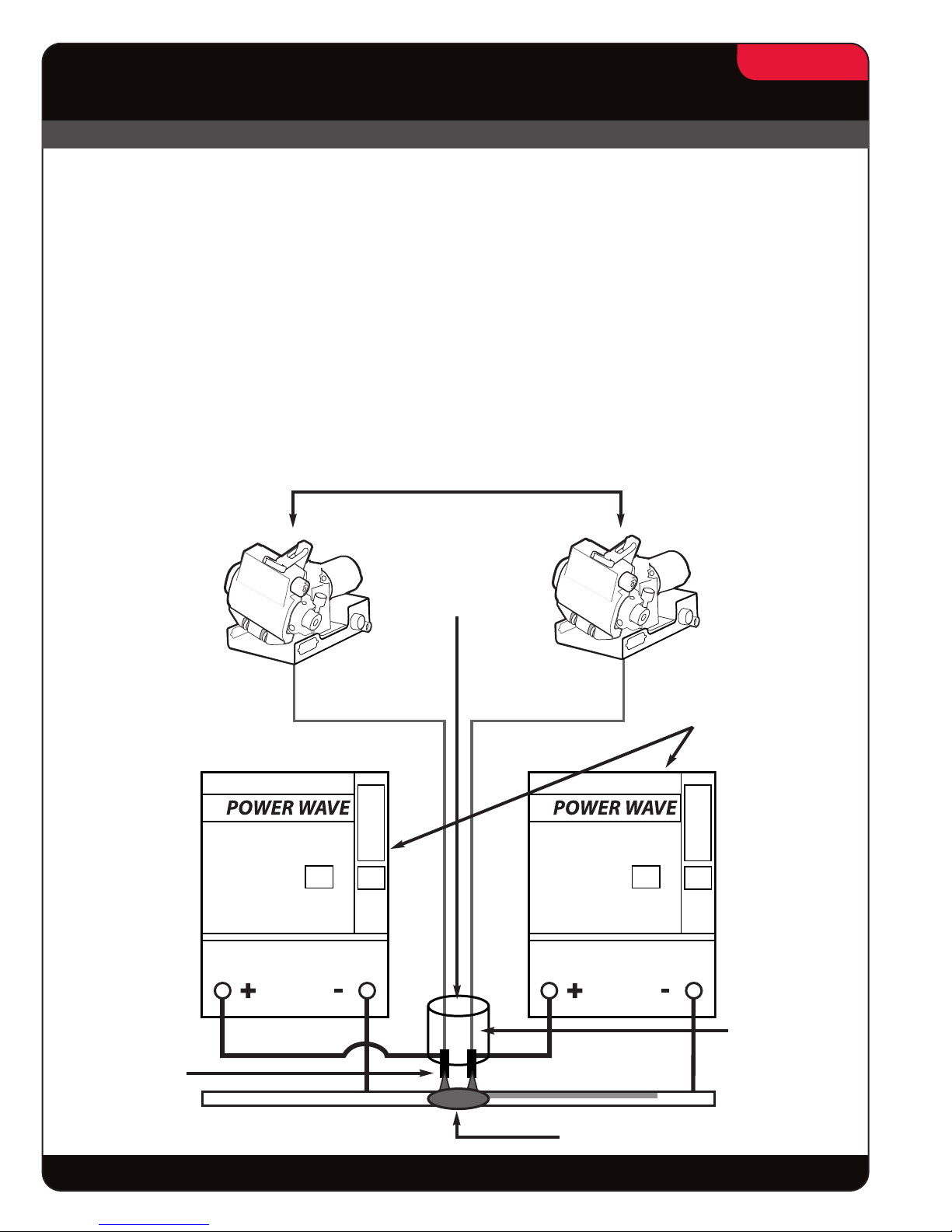

Tandem MIG is a dual wire GMAW process that is

used in automated welding applications to improve

welding productivity and part throughput. The process

utilizes two welding power sources and two wire

feeders acting in tandem to deliver two wire electrodes

through a single welding torch. The dual wire welding

torch, capable of often doubling the welding output of

a single wire torch, is used in hard automation and

robotic arc welding cells in the same manner as a

single wire welding torch would be. The two welding

arcs that are generated in the Tandem MIG process

are electrically isolated from one another and are

Tandem MIG Configuration

Two Wire Feeders

2/16

controlled independently. The welding arcs work

together, generally separated by less than 0.50 inches,

in the same weld pool. The independent control of the

two welding arcs is used to control the thermal and

fluid dynamics of the weld pool to further enhance

welding performance. The added deposit rate achieved

by the dual wire delivery and the added weld pool

control is used to overcome single wire limitations to

produce high travel speeds and electrode melt-off

rates (weld metal deposition). Special power source

welding software is used to allow the two welding arcs

to operate in unison.

Two Separate

Welding Arcs

Shielding Gas

Two

Power Sources

One

Welding Torch

The future of welding is here.

One Weld Pool

®

Page 3

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

How Does It Work?

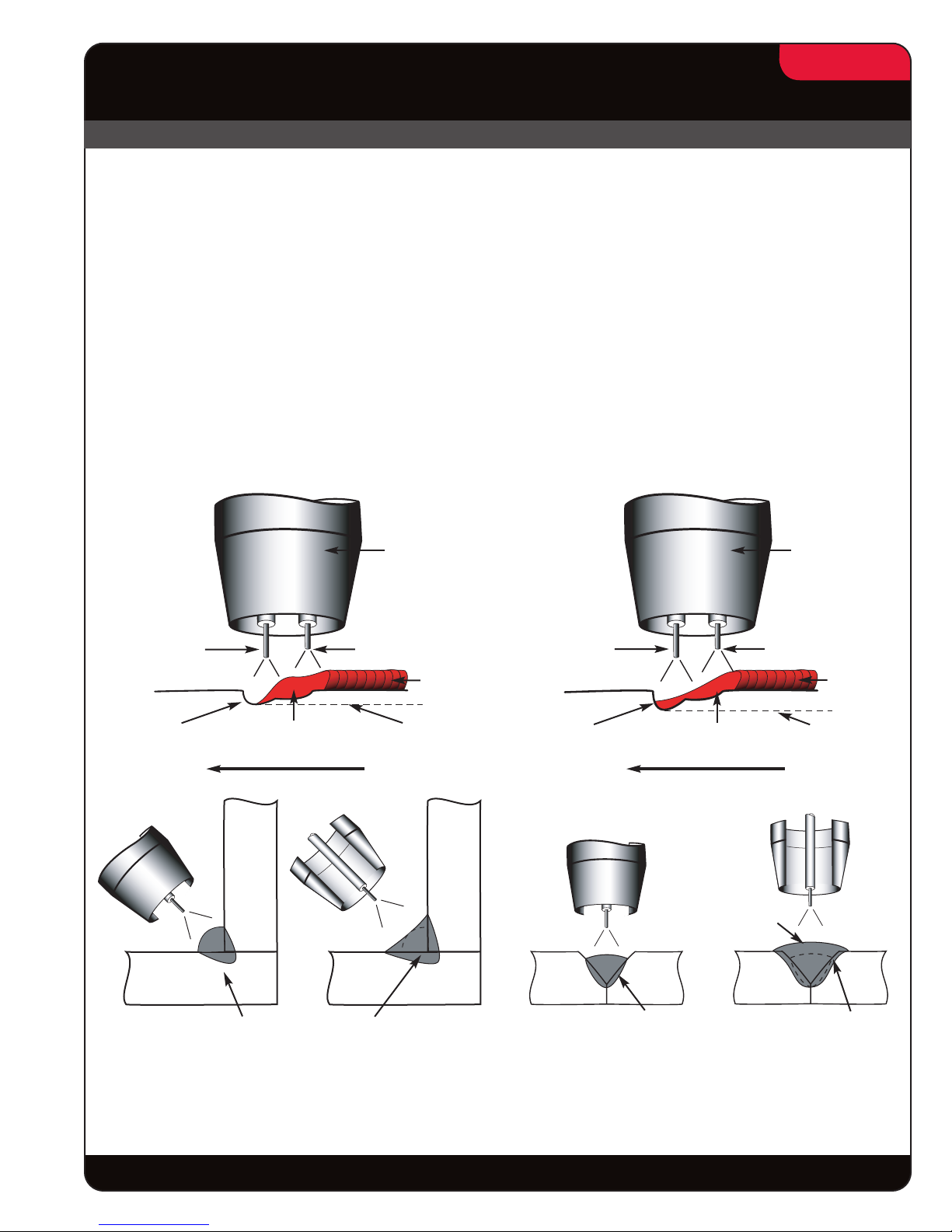

The two welding arcs common to the Tandem MIG

process have distinct functions. The lead arc (the

first arc in the direction of torch travel) is operated in

a spray transfer mode. The mode may be either a

special Tandem MIG pulse mode, an adaptive

constant voltage mode or a Tandem MIG power mode.

The lead arc’s primary function is to establish initial

root penetration and develop a molten weld pool for

the trail wire. While performing these functions the

lead wire typically accounts for 60% or more of the

total weld metal deposited. The trail arc or second arc

Lead and Trail arc functions for high speed welding

Trail arc is focused on the crest of the pool

created by the lead.

Gas Nozzle

3/16

is operated in a special Tandem MIG pulse mode.

The trail arc’s function is to add filler metal to the weld

pool and control the bead characteristics such as edge

wetting, physical contour, side-wall penetration and

weld pool follow speed. The trail arc should be kept

directly in line with the lead arc and focused on the

center of the weld pool. The trail wire melting rate

typically represents approximately 40% of the

process deposition rate. The Tandem MIG trail pulse

waveforms are designed to operate at low voltages

to limit arc interaction and minimize arc blow.

Lead and Trail arc functions for high deposition welding

The trail arc is focused on the middle of the weld pool

to create additional fill.

Gas Nozzle

Lead Arc Trail Arc

Lead Arc

Penetration

Lead

Arc

Partial

Fill

Penetration Past the Root

The Lead Arc generates the

majority of the penetration

and leaves joint requiring

additional fill.

Molten Weld

Pool

Travel Travel

Completes

Fill

downward and forward

pressure on the weld pool

for better pool follow and

Weld

Bead

Penetration

Trail

Arc

Wets Edges

The Trail Arc places a

wetting along the

bead edges.

Lead Arc Trail Arc

Lead Arc

Penetration

Penetration

The Lead Arc creates the

initial root penetration and

the majority of the joint fill.

Molten Weld

Pool

Lead

Arc

Completed

Fill

Root

The Trail Arc is focused in

the weld pool providing

additional joint side-wall

penetration and joint fill.

Weld

Bead

Penetration

Trail

Arc

Sidewall

Penetration

The future of welding is here.

®

Page 4

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Using Tandem MIG

For High-Speed Applications

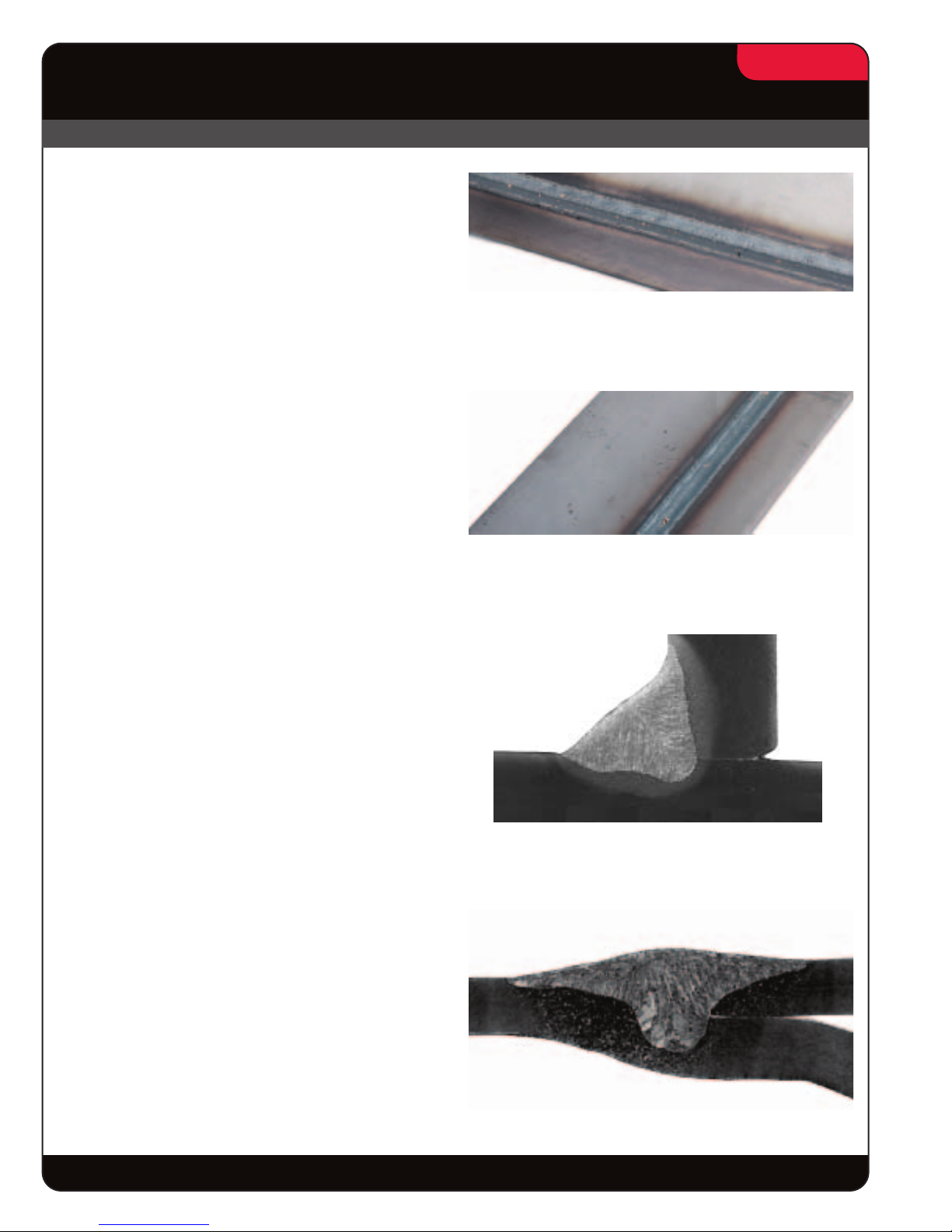

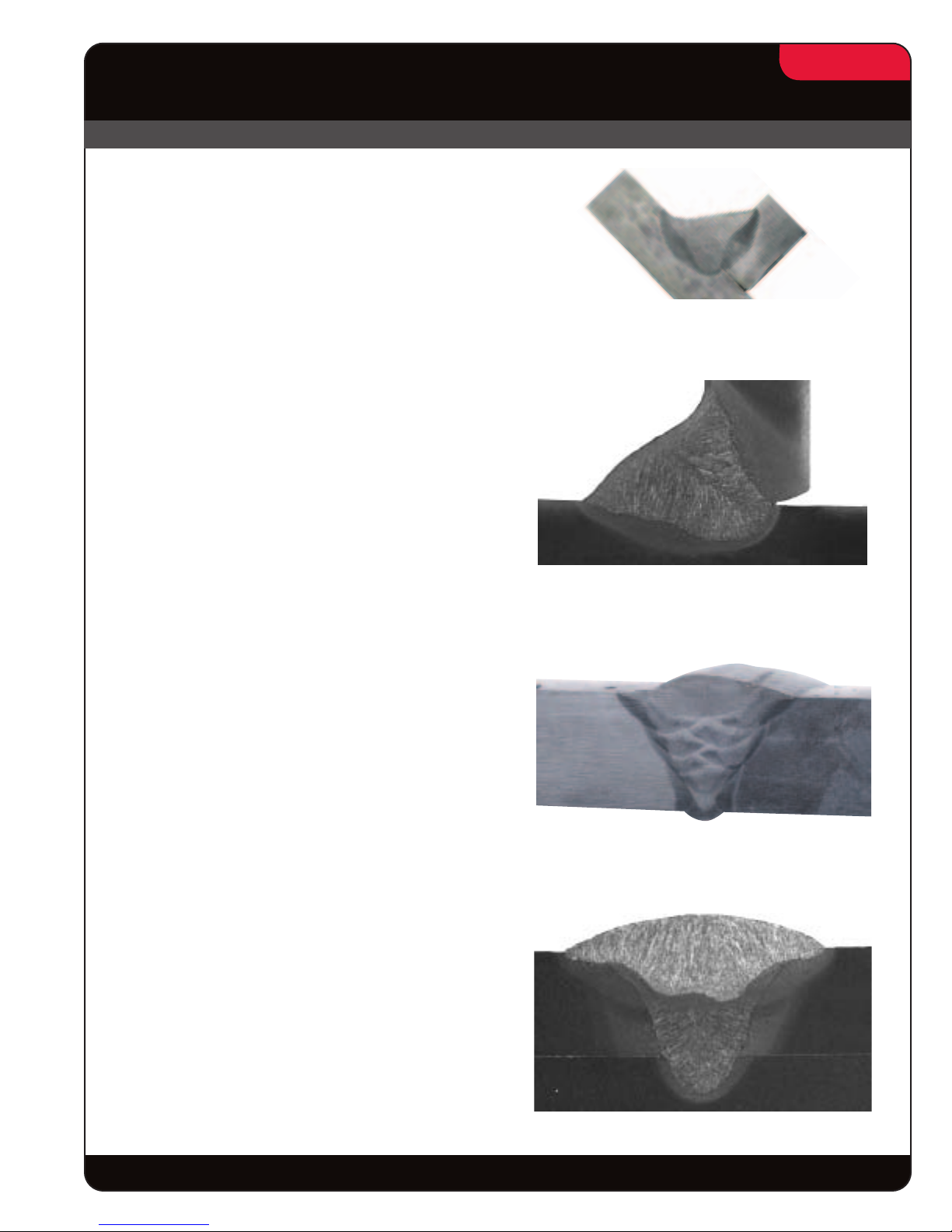

Flat and Horizontal Lap Welds

1.5 mm - 5 mm

Automotive, Tank Fabrication

Flat and horizontal lap welds common to automotive

components like control arms, stub or full chassis

frames, cross members, shock absorbers, struts,

stabilizer arms and flex axles are performed at welding

travel speeds ranging from 70 - 130 ipm. On thinner

components with metal thickness ranging from

1.5 - 3 mm, flat and horizontal lap welds are made with

(2) .035” diameter electrodes at travel speeds ranging

from 100 - 130 ipm. Thicker components with metal

thickness from 3 - 5 mm are performed with (2) .045”

diameter electrodes at travel speeds ranging from

70 - 100 ipm.

4/16

This thin gauge lap weld was made at a

travel speed of 100 ipm

Flat and Horizontal Fillet Welds

3 mm - 6 mm

General Light Gauge Steel Fabrication,

Shipbuilding, Railroad

Light gauge steel fabrication of 3 - 4 mm fillet welds

used to weld structural trusses, farm implements,

residential and commercial storage systems,

trash-hauling containers and similar components are

welded with (2) .035” diameter electrodes to produce

welds at travel speeds ranging from 80 - 100 ipm.

Larger 4 - 6 mm fillet welds common to structural

beams, light earth moving equipment, ship stiffeners,

rail cars and similar components are welded with

(2) .045” electrodes at travel speeds ranging from

50 - 80 ipm.

Joggle Joints 1.5 mm - 4 mm

Tanks and General Fabrication

Joggle joints require a careful balance of joint fill and

controlled penetration. Tandem MIG provides the

independent control of both, providing needed joint fill

without excessive penetration. Joggle welds between

1.5 and 3 mm, common to the light tank, truck bodies,

trash-hauling containers and similar components are

welded at travel speeds ranging from 80 - 120 ipm

using (2) .035” diameter electrodes. Larger 3 - 4 mm

joggle joints used in larger tanks and thicker

containers are performed at welding speeds ranging

from 40 - 80 ipm using (2) .045” diameter electrodes.

3/16” (4.8 mm) Horizontal Lap Weld

6mm Horizontal Fillet

Joggle Weld

The future of welding is here.

®

Page 5

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Using Tandem MIG

For High-Deposition Applications

Flat and Horizontal Fillet Welds

6 mm and Larger

Railroad, Structural, Industrial

Equipment, Ship Building, Off Road

Wheel Manufacturing

Flat and horizontal fillets common to structural

building components, offshore platforms, railcar

haulers, machine bases, large vehicle wheels,

undercarriages/truck suspensions and other fabricated

components of metal thickness of 6 mm and greater

are performed at deposition rates ranging from

21 - 35 lbs./hr.

Single pass 5/16” flat fillets are commonly welded

at 24 - 30 ipm with (2) .045” diameter electrodes.

5/16

1/2” Flat Fillet at 20 ipm

Single pass 5/16” flat fillets are commonly welded

at 27 - 40 ipm with (2) .052” diameter electrodes.

Bevel and “V” Groove Joints

Heavy Plate Fabrication, Structural

Members and Industrial Equipment

Single and multi-pass beveled butt welds used

in industries fabricating ship hulls, earth moving

equipment, structural platforms, pressure vessels,

beams and similar heavy plate weldments are

performed at deposition rates ranging from

22 - 35 lbs./hr. Welds are commonly performed using

like electrode diameters, either .045 or .052 inch

diameter. The lead electrode provides root penetration,

the trail electrode adds to sidewall penetration.

“J” and “U” Groove Butt Welds

Earth Moving Equipment and

Heavy Plate Fabrication

Single and multi pass “J” and “U” groove joints

common to undercarriages, rollover protection

equipment, sticks, booms, fifth wheels, frames,

hydraulic cylinders, pant legs and similar earth

moving equipment components are welded at

deposition rates ranging from 22 - 35 lbs./hr. Welds

are performed at a 30 - 50% reduction in heat input

when compared to larger diameter single electrode

processes. Lower heat input can substantially reduce

post weld straightening activity caused by distortion.

8 mm Horizontal Fillet

Multi-pass Butt Weld

2 Pass “J” Groove

The future of welding is here.

®

Page 6

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Comparing High-Speed Tandem MIG

To Single Wire GMAW Processes

Better Weld Metal Follow Characteristics:

Problem - Single Wire GMAW

As higher travel speeds are explored with conventional

single solid and metal cored wire GMAW processes

one of the factors that limits obtainable travel speeds

is a phenomenon referred to as “bead humping” or

lack of follow. The lack of follow occurs as a number

of physical metal flow requirements break down. The

coalescent properties of the weld pool are not strong

enough to pull the puddle along while, at the same

time, the higher travel speeds limit the heating of the

plate that would normally allow the weld pool to wet

or flow along the weld bead edges.

Solution - Tandem MIG

The spacing of the two arcs of the Tandem MIG

process is designed to overcome the lack of follow

associated with single wire GMAW processes. The

lead arc provides initial penetration into the base plate

and a preheating of the plate for the trail arc. The trail

arc rides the pool created by the lead electrode, the

pressure from the trail arc flattens the created weld

pool to eliminate the tendency for the pool to rise and

hump. The applied weld pool pressure from the trail

arc is used to not only limit the tendency of the lead

weld pool to hump and lose follow capability, but the

pressure is adjustable, allowing the bead contour to be

modified to meet application requirements.

6/16

12 Gauge Lap Weld

at 120 ipm travel

Reduced Tendency Towards Burn-through and Undercut

Problem - Single Wire GMAW

Increased travel speeds require the use of larger wire

diameters or higher wire feed speeds. Both choices

will cause an increase in current draw. The added

current draw creates added penetration that must

be managed. With a single wire GMAW process the

penetration is most intense at the point where the

axial flow of material from the welding wire is directed

on to the plate. This area is focused to a small area

that is generally the cross-sectional area of the

welding wire diameter. In order to manage the

additional finely focused penetration wire placement

becomes more demanding, joint fit-up becomes

more critical. If joint alignment is not maintained and

the welding arc wanders off the seam, concentrating

the arc on a single metal thickness, burn-through is a

common result. If joint fit-up is not maintained welds

often penetrate well into the open joint creating an

unacceptable undercut. If the penetration is not

successfully managed the common result is costly

increased rework or scrap.

Solution - Tandem MIG

The Tandem MIG process is able to achieve the

high wire feed requirements of high speed welding

without creating excessive penetration. The required

wire feed total for high speed welding is shared by

the two electrodes forming the Tandem MIG process.

The shared wired feed speed not only reduces the

current draw on each individual arc but disperses

the total welding energy over two separate focal

points. The separation of the two focal penetration

points allows more metal to be deposited without

excessive penetration. The lead arc is focused on

the plate while the trail arc is focused on the molten

pool created by the lead arc. The trail wire energy is

applied to the pool and not directly onto the plate. This

limits the overall penetration and allows the process

to be tolerant of joint misalignment and joint gaps.

The future of welding is here.

®

Page 7

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Comparing High-Speed Tandem MIG

To Single Wire GMAW Processes

Travel Speed Comparison

Typical Travel Speeds

Travel

Speed

(ipm)

140

120

100

80

60

40

Single Wire GMAW vs Tandem MIG

7/16

Single Wire GMAW

Tandem MIG

2mm 2.5mm 3mm 4mm 5mm

Lap Weld Size

Comparing High-Deposition Tandem MIG

To Single Wire GMAW Process

Higher Deposition rates

Problem - Single Wire GMAW

A conventional single wire GMAW process has an

optimum operating range based primarily on wire

diameter, shielding gas and wire feed speed.

Attempting to maximize deposition rates for a given

wire diameter requires increasing the wire feed rate

to the top or beyond its defined operating range. As

the process is pushed to its limit, arc instability is often

a result. Arc instability creates increased spatter levels

and weld porosity. The elevated welding currents

create weld pool turbulence that can cause root

porosity, or porosity just below the surface of the

weld bead.

Solution - Tandem MIG

The two-wire electrode configuration of the Tandem

MIG process allows a higher total wire feed rate,

creating a higher deposition rate. Each electrode in

the Tandem configuration can be operated within an

optimum operating range as defined by a single wire

process. Both the lead and the trail electrode may be

operated in a stable operating range, while the

combined wire feed speed of the two electrodes often

exceed a useable single wire process by 35-80%.

The future of welding is here.

®

Page 8

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Comparing High-Deposition Tandem MIG

To Single Wire GMAW Process

Reduced Heat Input and Improved Bead Profiles

Problem - Single Wire GMAW

A single wire GMAW process has a useable weld

metal deposition rate based on wire feed speed and

wire diameter. In an attempt to increase weld metal

deposit rates, rather than push a given wire diameter

to unstable wire feed speeds, it is often common

practice to increase the wire diameter and operate

within stable wire feed ranges. The increase in wire

diameter increases the required current draw

associated with a given weld metal deposit rate.

Increased current draw produces higher heat inputs

leading to part distortion and a large fluid weld pool

that is difficult to control.

Solution - Tandem MIG

With the Tandem MIG process the two smaller

diameter electrodes produce a lower heat input and

improved weld pool control when compared to a larger

single electrode process attempting to perform similar

welds. When compared to larger diameter electrode

processes,Tandem MIG typically reduces heat input

by as much as 30-50%. The trail electrode in the

Tandem MIG process is operated in a special Tandem

MIG pulse mode designed to cool the weld pool

created by the lead electrode. The combination of

lower total heat input and the cooling affect of the trail

electrode, allows the trail electrode to be used to help

control weld bead contour. This provides the ability

to better stack horizontal weld beads and produce

flatter horizontal fillets while working at higher

deposition rates.

8/16

REDUCED HEAT INPUT EXAMPLE

5/16” Horizontal Fillet Weld

PROCESS

GMAW - 1/16” dia. - ER70S - 6 470 31 17.8 17.7 49.4

FCAW - 3/32” dia. - ER70T - 1 435 29.5 15.8 15.7 49.0

GMAW - 3/32” dia. - ER70C - 6M 500 34 16.2 16.1 63.3

Lead .045” dia. ER70S - 6 300 23

Trail .045” dia. ER70S - 6 250 24

CURRENT

DRAW

(amps)

ARC

VOLTAGE

(DC+)

Tandem MIG

DEPOSIT

RATE

(lbs./hr)

23.3 23.1 33.5

TRAVEL SPEED

(ipm)

HEAT INPUT

Kj/in

The future of welding is here.

®

Page 9

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Comparing High-Deposition Tandem MIG

To Single Wire GMAW Process

Deposition Rate Comparison

Weld Metal Deposition Rate Single Wire GMAW vs Tandem MIG

Lbs./Hr.

Single Wire GMAW

40

30

9/16

Tandem MIG

20

10

1/4”

Horizontal

Fillet

5/16”

Horizontal

Fillet

3/8”

Flat

Fillet

Joint Type

5/8”

J Groove

Multi-Pass

Beveled Butt

The future of welding is here.

®

Page 10

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

10/16

High-Speed and High-Deposition Welding

Using Tandem MIG

Understanding Operating Variables

The general rules governing operating variables for single wire GMAW arc welding also apply to Tandem MIG

welding. However there are additional considerations that must be kept in mind when welding with multiple arcs.

Since the two arcs will interact, the type of power fed to each arc, the wire feed speed ratio between lead and trail,

the arc lengths, the wire positioning, and torch angles must be set correctly. The enclosed procedures are starting

points and may need to be altered based on specific application conditions. Adherence to the following guidelines

will assist in achieving the maximum potential of the process.

Lead Arc

The lead arc creates the majority of the penetration and should represent the majority of the total deposition

rate of the process. When using like diameter electrodes for the lead and the trail, the lead should represent

approximately 60% of the total wire feed. In the case where a larger wire diameter is used as a lead (for added

penetration) the lead should represent approximately 60% or more of the total deposition. The lead arc can be

operated in a Tandem pulse, CV or Power mode. Pulse is recommended for the high deposition procedures.

Power mode or CV may be used for greater lead arc stability in high travel speed applications.

Trail Arc

The trail arc is used to cool the weld pool and control the bead contour and is always operated in the Tandem

pulse mode. The trail should be kept directly in line with the lead arc and focused on the center of the weld pool.

The trail wire should represent approximately 40 % of the process deposition rate. The Tandem MIG trail pulse

waveforms are designed to operate at low voltages to limit arc interaction and minimize arc blow.

Torch Positioning

Torch positioning may be altered for specific applications. A 5-degree push angle is recommended for high

deposition welding. A (0-5)-degree angle is recommended for high speed welding.

Travel Angle

Push Angle

Push Angle

Travel

Travel

Directionl

Direction

(Beveled Butt, Fillets, Laps

Flat Welds

45°

Joint Angle

90°

65°

Horizontal Welds

Lap

1/2” Wire Dia.

40°

A 5-degree push angle

is recommended

The future of welding is here.

Horizontal Welds

Small Fillet

Horizontal Welds

Large Fillet

®

Page 11

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

11/16

High-Speed and High-Deposition Welding

Using Tandem MIG

Understanding Operating Variables

Shielding Gas

The lead and trail shielding gas should be of the same mixture and supplied through separate flow regulators. Gas

flow per electrode should be a minimum of 40-cfh each. High deposition procedures may require flow rates as

high as 70 cfh per electrode. High deposition multi-pass applications may require that a trailing gas is applied to

eliminate nitrogen pick-up. The Tandem MIG process requires a binary gas mixture capable of supporting a spray

transfer. Argon/Carbon dioxide or Argon/ Oxygen are the preferred mixtures.

1. 90/10%, Ar/CO

2. 82-95% argon with a Ar/C02 binary mixture is a useable range, The higher CO2% will promote added

penetration but may produce added spatter. The lower CO

3. 95/5%, Ar/O2is recommended for high speed welding of thin gage material under 3mm. The

mixture will provide improved wetting at bead edges and reduced tendency to erode away

edges of lap welds.

Work Lead Connection

Tandem MIG welding should be performed welding in the direction from the work lead connection. Welding

towards the work lead connection may cause a convex weld bead and undercut.

is preferred for most welding applications.

2

% will produce less spatter.

2

Joint Selection

The Tandem MIG process is ideal for many joint configurations. A joint application rating is as follows:

Excellent

1. Lap welds in the flat, horizontal, 3 o'clock position.

2. Fillet welds in the flat and horizontal positions.

3. Joggle welds in the flat position.

4. Beveled butt welds in flat position.

5. "J" Groove welds.

6. Rotated roundabouts, lap and joggle welds.

Good

1. Beveled butt welds in horizontal position.

2. Horizontal flare joint.

Poor

1. Seamer applications.

2. Joints known to be subject to arc blow.

3. Weld joints that have multiple or severe turns in direction or contour.

4. Thin gage square edge butt welds.

The future of welding is here.

®

Page 12

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Configuring Tandem MIG

Hard Automation Systems

Models: AD1202 - 1 and AD1202 - 2

H

C

12/16

B

G

A

F

I

Item Component AD1202-1 AD1202-2 Qty

A Power Source Tandem MIG Power Wave 455M Robotic or K2262-1-TM 2

Tandem MIG Power Wave 655 Robotic K1519-1-TM 2

B Wire Feeder Power Feed 10R Wire Feeder K1780-2 K1780-2 2

C Interface Controller G3207-185 G3207-185 1

D DeviceNet Tee S23383-3 S23383-3 2

Terminating Resistor S23383-5 S23383-5 1

E DeviceNet Communication Cables (drops) (20 in.) S23383-4 S23383-4 2

F DeviceNet Communication Cables (trunk line) (19.5 ft.) S23383-2 S23383-2 1

G Communication cables. Power source to wire feeders (25 ft.) K1785-25 K1795-25 2

Cable jumper, 22 pin to 14 pin (18 inch) K1804-2 2

800 amp Tandem MIG torch

H

900 amp Tandem MIG torch

I 4/0 Work (ground) cable (25 ft.) L-4/0-25-14-14 L-4/0-25-14-14 2

Not Shown Drive Roll Kit KP1505-XX KP1505-XX 2

or

D

S22693-XXX

E

or

G3494-XA

A

S22693-XXX

or

G3494-XA

1

Not Shown Wire Straightener K1733-1 K1733-1 2

Not Shown Process Sense Leads K940-25 K940-25 2

Not Shown 4/0 Electrode Cable (25 ft.) L-4/0-25-14-14 L-4/0-25-14-14 2

Not Shown Torch water cooling package AD1013-3 AD1013-3 1 or 3*

* S22693-XXX series torches require (1) water cooling package per torch, G3494-XA series torches require (3)

The future of welding is here.

®

Page 13

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Configuring Tandem MIG

Robotic Systems

Models: AD1201 - 1 and AD1201 - 2

G

E

13/16

H

B

D

A

F

C

A

Item Component AD1201-1 AD1201-2 Qty

A Power Source Tandem MIG Power Wave 455M Robotic or K2262-1-TM 2

A Tandem MIG Power Wave 655 Robotic K1519-1-TM 2

B Wire feeder Power Feed 10R wire feeder K1780-2 K1780-2 2

C ArcLink cables, Power source to robot controller (25 ft.) S23394-18 S23394-18 2

D Communication cables, Power source to wire feeders (25 ft.) K1785-25 K1795-25 2

Cable jumper, 22-pin to 14-pin (18 in.) K1804-2 2

E 4/0 Work (ground) cable (25 ft.) L-4/0-25-14-14 L-4/0-25-14-14 2

Fanuc RJ3iB robot and controller

F

Arc tool software 6.4 or above

Dual channel DeviceNet board S23319-62 S23319-62 1

24 Volt Power cable S23394-9 S233394-9 1

800 amp Tandem MIG torch

G

900 amp Tandem MIG torch

H 9 ft. Boom for wire feeder mounting AD1038-3 AD1038-3 1

Not Shown Reaming Station M18426-1 M18426-1 1

Not Shown Drive Roll Kit KP1505-XX KP1505-XX 2

Not Shown Wire Straightener K1733-1 K1733-1 2

Not Shown Process Sense Leads K940-25 K940-25 2

Not Shown 4/0 Electrode Cable (25 ft.) L-4/0-25-14-14 L-4/0-25-14-14 2

Not Shown Torch water cooling package AD1013-3 AD1013-3 1 or 3*

or

100 or 120 Series

RJ3iB Controller

S22693-XXX

or

G3494-XA

100 or 120 Series

RJ3iB Controller

S22693-XXX

or

G3494-XA

1

1

* S22693-XXX series torches require (1) water cooling package per torch, G3494-XA series torches require (3)

The future of welding is here.

®

Page 14

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Lincoln Welding Systems Featuring Tandem MIG

14/16

Power Feed 10R Wire Feeder

Compact Wire Drive System for Automation

The Power Feed 10R is a high performance,

digitally controlled wire feeder designed to be a part

of a modular, multi-process welding system. It is

specifically designed to mount to a robot arm or to

use in hard automation applications. Modular systems

can be arranged in a variety of ways for optimum,

customized performance and easy maintenance. This

four drive roll feeder operates on 40VDC input power

and is designed to be used with ArcLink™ Robotic

Power Wave

the feeder, power source and existing equipment

creates the foundation for a system with superior

welding performance and reliability.

Patented Drive Roll System

The Power Feed 10R is a basic wire feeder with an

optimized design, which consists of an industrial motor

driving the feeder mechanism in a sheet metal frame.

The logic for controlling the wire feeder resides in a

PC board inside the robotic power source.

®

power sources. Close integration of

Advantage Lincoln

• Digitally controlled by the Power Wave power source,

yielding the best performance in the industry.

• Use with Lincoln power sources featuring ArcLink, the

leading digital communications protocol for welding,

making it the best choice for seamless integration with

the power source and networked equipment.

• Tachometer feedback provides calibrated and precise

control of wire feed speed.

• Feeder brakes from maximum speed to zero in

milliseconds, minimizing the chance of wire sticking

in the puddle.

• Select standard or high speed gears for wide wire

feed speed range.

• Split wire guides provide trouble-free feeding and

offer fast, tool-less wire installation, changeover

and maintenance.

• Easy-to-read gauge for accurate drive roll tension.

• Brass-to-brass connections for good connectivity

between feeder and gun.

• Modular construction for easy servicing.

• Self loading wire feature for easy set-up.

The future of welding is here.

®

Page 15

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Lincoln Welding Systems Featuring Tandem MIG

15/16

Power Wave 455M

For welding thicker materials in robotics, hard

automation, PLC and semiautomatic applications,

choose the Power Wave 455M. The power source

features Waveform Control Technology for superior arc

performance on a variety of materials, including steel,

stainless steel, aluminum and nickel alloys. Custom

control of the arc for each wire type and size provide

consistent welds time after time. These Power Waves

are designed to be part of a modular, multi-process

welding system.

The future of welding is here.

Power Wave 655R

The Power Wave 655R was designed for Robotic and

Hard Automation applications that require extra power

(650 Amps at 100% Duty Cycle).

• Digital Communications enable the Power Wave to

connect seamlessly to robot controllers and hard

automation PLCs.

• The Ethernet/DeviceNet Gateway provides networking

capabilities and allows process and production monitoring.

• Software-based controls can be upgraded as new

features become available.

• The Power Wave 655R has an output range of

20-880 Amps.

®

Page 16

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Tandem MIG

High-Speed and High-Deposition Welding

Lincoln Consumables used with Tandem MIG

SuperArc®/SuperGlide

Lincoln’s SuperArc, our premium copper-coated MIG wire, and

SuperGlide, our premium bare wire, are the choice of welders

and welding decision-makers everywhere because of their

exceptional consistency, feedability, and arc action.

A better arc means less spatter, less clean-up, and improved

productivity – and premium SuperArc and SuperGlide deliver

the best arc in MIG welding.

Our MicroGuard™ Ultra surface treatment,

with proprietary arc enhancement agents,

facilitates excellent weld puddle control, very

good wetting action, straight bead edges, and

a wider operating range.

The exceptional feeding characteristics of

SuperGlide, made possible by MicroGuard Ultra

surface treatment, translate to reduced

down-time and high operator appeal.

Accu-Pak

100% Recyclable Patented Package — when the

wire is consumed, just remove the components,

collapse the box and throw into the recycle bin.

Lifting Strap for ease of movement from one location

to the next. Patented Ring Design.

Accu-Trak

This Accu-Trak Drum Payoff Kit is made of a

durable plastic for superior strength and integrity.

It also features two viewing windows 180° apart

from one another for easy viewing of the wire as

it is paying off.

A Payoff Kit must be used with Accu-Trak Drums

to ensure precise feeding. The fitting on top of the

Payoff Kit has a 1/2-14 NPT internal pipe thread

to facilitate the connection of the conduit to 500 lb.

Accu-Trak drums.

Customer Assistance Policy

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment,

consumables, and cutting equipment. Our challenge is to meet the needs of our customer and to exceed

their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their

use of our products. We respond to our customers based on the best information in our possession at that

time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with

respect to such information or advice. We expressly disclaim any warranty of any kind, including any

warranty of fitness for any customer’s particular purpose, with respect to such information or advice. As a

matter of practical consideration, we also cannot assume any responsibility for updating or correcting any

such information or advice once it has been given, nor does the provision of information or advice create,

expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by

Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many

variables beyond the control of Lincoln Electric affect the results obtained in applying these types of

fabrication methods and service requirement.

Subject to change - This information is accurate to the best of our knowledge at the time of printing.

Please refer to www.lincolnelectric.com for any updated information.

®

®

®

16/16

WHAT IS NEXTWELD?

The challenges facing industrial

fabricators today are increasingly

difficult. Rising labor, material, and

energy costs, intense domestic and

global competition,

a dwindling pool of

skilled workers,

more stringent and

specific quality

demands.

Through our

commitment to

extensive research

and investments in

product

development,

Lincoln Electric has

established an industry benchmark for

applying technology to improve the

quality, lower the cost and enhance the

performance of arc welding processes.

Advancements in power electronics,

digital communications and Waveform

Control Technology™ are the foundation

for many of the improvements.

NEXTWELD brings you a series of

Process, Technology, Application and

Success Story documents like this one.

NEXTWELD explains how technologies,

products, processes and applications are

linked together to answer the important

questions that all businesses face:

• How can we work faster, smarter,

more efficiently?

• How can we get equipment and

people to perform in ways they’ve

never had to before?

• How do we stay competitive?

NEXTWELD is the future of welding but

its benefits are available to you today.

Ask your Lincoln Electric representative

how to improve the flexibility, efficiency

and quality of your welding operations to

reduce your cost of fabrication.

THE LINCOLN ELECTRIC COMPANY

www.lincolnelectric.com

1.216.481.8100

The future of welding is here.

®

Loading...

Loading...