Page 1

INVERTEC® V450-PRO

RETURN TO MAIN MENU

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However,

your overall safety can be

increased by proper installation

. . . and thoughtful operation on

your part. DO NOT INSTALL,

OPERATE OR REPAIR THIS

EQUIPMENT WITHOUT READING THIS MANUAL AND THE

SAFETY PRECAUTIONS CONTAINED THROUGHOUT. And,

most importantly, think before you

act and be careful.

RETURN TO MAIN INDEX

SVM199-A

July, 2010

For use with machine code number: 11212

View Safety Info View Safety Info View Safety Info View Safety Info

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Cleveland, Ohio 44117-1199 U.S.A. TEL: 888.935.3877 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

SERVICE MANUAL

Copyright © Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Page 2

i i

SAFETY

WARNING

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer, birth defects, and other reproductive harm.

The Above For Diesel Engines

ARC WELDING can be hazardous. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information, it is strongly recommended that you

purchase a copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American Welding Society, P.O. Box 351040,

Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the

Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

The Above For Gasoline Engines

FOR ENGINE

powered equipment.

1.a. Turn the engine off before troubleshooting and maintenance

work unless the maintenance work requires it to be running.

____________________________________________________

1.b.Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

____________________________________________________

1.c. Do not add the fuel near an open flame welding arc or when the engine is running. Stop

the engine and allow it to cool before refueling to prevent spilled fuel from vaporizing on

contact with hot engine parts and igniting. Do

not spill fuel when filling tank. If fuel is spilled,

wipe it up and do not start engine until fumes

have been eliminated.

____________________________________________________

1.d. Keep all equipment safety guards, covers and devices in position and in good repair.Keep hands, hair, clothing and tools

away from V-belts, gears, fans and all other moving parts

when starting, operating or repairing equipment.

____________________________________________________

1.e. In some cases it may be necessary to remove safety

guards to perform required maintenance. Remove

guards only when necessary and replace them when the

maintenance requiring their removal is complete.

Always use the greatest care when working near moving

parts.

___________________________________________________

1.f. Do not put your hands near the engine fan.

Do not attempt to override the governor or

idler by pushing on the throttle control rods

while the engine is running.

1.h. To avoid scalding, do not remove the

radiator pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS

may be dangerous

2.a. Electric current flowing through any conductor causes

localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and

welding machines

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1.

Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and

work cables. If the electrode cable is on your right

side, the work cable should also be on your right side.

___________________________________________________

1.g. To prevent accidentally starting gasoline engines while

turning the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

2.d.4. Connect the work cable to the workpiece as close as

possible to the area being welded.

2.d.5. Do not work next to welding power source.

INVERTEC® V450-PRO

Page 3

ii ii

SAFETY

ELECTRIC SHOCK can kill.

3.a. The electrode and work (or ground) circuits

are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare

skin or wet clothing. Wear dry, hole-free

gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

must be performed under electrically hazardous

conditions (in damp locations or while wearing wet

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic

welding gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection

should be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical

(earth) ground.

3.f.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see Items 6.c. and 8.

ARC RAYS can burn.

4.a. Use a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. Headshield and filter lens

should conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

can be dangerous.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases.When welding, keep

your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing zone. When

welding with electrodes which require special

ventilation such as stainless or hard facing (see

instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure as

low as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or mechanical ventilation. In confined spaces or in some circumstances,

outdoors, a respirator may be required. Additional precautions are also required when welding on galvanized

steel.

5. b. The operation of welding fume control equipment is affected

by various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure level should be checked upon installation and periodically thereafter to be certain it is within applicable OSHA PEL

and ACGIH TLV limits.

5.c.

Do not weld in locations near chlorinated hydrocarbon

coming from degreasing, cleaning or spraying operations.

The heat and rays of the arc can react with solvent vapors

form phosgene, a highly toxic gas, and other irritating products.

vapors

to

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

5.d. Shielding gases used for arc welding can displace air and

cause injury or death. Always use enough ventilation,

especially in confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your

employer’s safety practices. MSDS forms are available from

your welding distributor or from the manufacturer.

5.f. Also see item 1.b.

INVERTEC® V450-PRO

Page 4

iii iii

SAFETY

WELDING and CUTTING

SPARKS can

cause fire or explosion.

6.a.

Remove fire hazards from the welding area.

If this is not possible, cover them to prevent

Remember that welding sparks and hot

materials from welding can easily go through small cracks

and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site,

special precautions should be used to prevent hazardous

situations. Refer to “Safety in Welding and Cutting” (ANSI

Standard Z49.1) and the operating information for the

equipment being used.

6.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact can

cause overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances

inside. They can cause an explosion even

been “cleaned”. For information, purchase “Recommended

Safe Practices for the

Containers and Piping That Have Held Hazardous

Substances”, AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

Sparks and spatter are thrown from the welding arc. Wear oil

6.f.

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a

welding area.

6.g. Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

increase the possibility of the welding current passing

through lifting chains, crane cables or other alternate circuits.

This can create fire hazards or overheat lifting chains or

cables until they fail.

6.h. Also see item 1.c.

the welding sparks from starting a fire.

though

they have

Preparation

for Welding and Cutting of

CYLINDER may explode

if damaged.

7.a. Use only compressed gas cylinders

containing the correct shielding gas for the

process used and properly operating

regulators designed for the gas and

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

7.b. Always keep cylinders in an upright position securely

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected to

physical damage.

• A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

7.g. Read and follow the instructions on compressed gas

cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in

Cylinders,” available from the Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202.

FOR ELECTRICALLY

powered equipment.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accordance with the U.S. National

Electrical Code, all local codes and the manufacturer’s

recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention

During Welding, Cutting and Other Hot Work”, available from

NFPA, 1 Batterymarch Park,PO box 9101, Quincy, Ma

022690-9101.

6.j. Do not use a welding power source for pipe thawing.

Refer to http://www.lincolnelectric.com/safety for additional safety information.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INVERTEC® V450-PRO

Page 5

iv iv

SAFETY

PRÉCAUTIONS DE SÛRETÉ

Pour votre propre protection lire et observer toutes les instructions

et les précautions de sûreté specifiques qui parraissent dans ce

manuel aussi bien que les précautions de sûreté générales suivantes:

Sûreté Pour Soudage A L’Arc

1. Protegez-vous contre la secousse électrique:

a. Les circuits à l’électrode et à la piéce sont sous tension

quand la machine à souder est en marche. Eviter toujours

tout contact entre les parties sous tension et la peau nue

ou les vétements mouillés. Porter des gants secs et sans

trous pour isoler les mains.

b. Faire trés attention de bien s’isoler de la masse quand on

soude dans des endroits humides, ou sur un plancher metallique ou des grilles metalliques, principalement dans

les positions assis ou couché pour lesquelles une grande

partie du corps peut être en contact avec la masse.

c. Maintenir le porte-électrode, la pince de masse, le câble de

soudage et la machine à souder en bon et sûr état defonctionnement.

d.Ne jamais plonger le porte-électrode dans l’eau pour le

refroidir.

e. Ne jamais toucher simultanément les parties sous tension

des porte-électrodes connectés à deux machines à souder

parce que la tension entre les deux pinces peut être le total

de la tension à vide des deux machines.

f. Si on utilise la machine à souder comme une source de

courant pour soudage semi-automatique, ces precautions

pour le porte-électrode s’applicuent aussi au pistolet de

soudage.

2. Dans le cas de travail au dessus du niveau du sol, se protéger

contre les chutes dans le cas ou on recoit un choc. Ne jamais

enrouler le câble-électrode autour de n’importe quelle partie du

corps.

3. Un coup d’arc peut être plus sévère qu’un coup de soliel, donc:

6. Eloigner les matériaux inflammables ou les recouvrir afin de

prévenir tout risque d’incendie dû aux étincelles.

7. Quand on ne soude pas, poser la pince à une endroit isolé de

la masse. Un court-circuit accidental peut provoquer un

échauffement et un risque d’incendie.

8. S’assurer que la masse est connectée le plus prés possible de

la zone de travail qu’il est pratique de le faire. Si on place la

masse sur la charpente de la construction ou d’autres endroits

éloignés de la zone de travail, on augmente le risque de voir

passer le courant de soudage par les chaines de levage,

câbles de grue, ou autres circuits. Cela peut provoquer des

risques d’incendie ou d’echauffement des chaines et des

câbles jusqu’à ce qu’ils se rompent.

9. Assurer une ventilation suffisante dans la zone de soudage.

Ceci est particuliérement important pour le soudage de tôles

galvanisées plombées, ou cadmiées ou tout autre métal qui

produit des fumeés toxiques.

10. Ne pas souder en présence de vapeurs de chlore provenant

d’opérations de dégraissage, nettoyage ou pistolage. La

chaleur ou les rayons de l’arc peuvent réagir avec les vapeurs

du solvant pour produire du phosgéne (gas fortement toxique)

ou autres produits irritants.

11. Pour obtenir de plus amples renseignements sur la sûreté, voir

le code “Code for safety in welding and cutting” CSA Standard

W 117.2-1974.

PRÉCAUTIONS DE SÛRETÉ POUR

LES MACHINES À SOUDER À

TRANSFORMATEUR ET À

REDRESSEUR

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

a. Utiliser un bon masque avec un verre filtrant approprié ainsi

qu’un verre blanc afin de se protéger les yeux du rayonnement de l’arc et des projections quand on soude ou

quand on regarde l’arc.

b. Porter des vêtements convenables afin de protéger la peau

de soudeur et des aides contre le rayonnement de l‘arc.

c. Protéger l’autre personnel travaillant à proximité au

soudage à l’aide d’écrans appropriés et non-inflammables.

4. Des gouttes de laitier en fusion sont émises de l’arc de

soudage. Se protéger avec des vêtements de protection libres

de l’huile, tels que les gants en cuir, chemise épaisse, pantalons sans revers, et chaussures montantes.

5. Toujours porter des lunettes de sécurité dans la zone de

soudage. Utiliser des lunettes avec écrans lateraux dans les

zones où l’on pique le laitier.

INVERTEC® V450-PRO

1. Relier à la terre le chassis du poste conformement au code de

l’électricité et aux recommendations du fabricant. Le dispositif

de montage ou la piece à souder doit être branché à une

bonne mise à la terre.

2. Autant que possible, I’installation et l’entretien du poste seront

effectués par un électricien qualifié.

3. Avant de faires des travaux à l’interieur de poste, la debrancher à l’interrupteur à la boite de fusibles.

4. Garder tous les couvercles et dispositifs de sûreté à leur place.

Page 6

v v

SAFETY

Electromagnetic Compatibility (EMC)

Conformance

Products displaying the CE mark are in conformity with European Community Council Directive of 15 Dec

2004 on the approximation of the laws of the Member States relating to electromagnetic compatibility,

2004/108/EC. It was manufactured in conformity with a national standard that implements a harmonized

standard: EN 60974-10 Electromagnetic Compatibility (EMC) Product Standard for Arc Welding Equipment.

It is for use with other Lincoln Electric equipment. It is designed for industrial and professional use.

Introduction

All electrical equipment generates small amounts of electromagnetic emission. Electrical emission may be

transmitted through power lines or radiated through space, similar to a radio transmitter. When emissions

are received by other equipment, electrical interference may result. Electrical emissions may affect many

kinds of electrical equipment; other nearby welding equipment, radio and TV reception, numerical controlled

machines, telephone systems, computers, etc. Be aware that interference may result and extra precautions

may be required when a welding power source is used in a domestic establishment.

Installation and Use

The user is responsible for installing and using the welding equipment according to the manufacturer’s

instructions. If electromagnetic disturbances are detected then it shall be the responsibility of the user of the

welding equipment to resolve the situation with the technical assistance of the manufacturer. In some cases

this remedial action may be as simple as earthing (grounding) the welding circuit, see Note. In other cases

it could involve construction of an electromagnetic screen enclosing the power source and the work complete with associated input filters. In all cases electromagnetic disturbances must be reduced to the point

where they are no longer troublesome.

Note: The welding circuit may or may not be earthed for safety reasons according to national

codes. Changing the earthing arrangements should only be authorized by a person who is

competent to access whether the changes will increase the risk of injury, e.g., by allowing

parallel welding current return paths which may damage the earth circuits of other equipment.

Assessment of Area

Before installing welding equipment the user shall make an assessment of potential electromagnetic problems in the surrounding area. The following shall be taken into account:

a) other supply cables, control cables, signaling and telephone cables; above, below and adjacent to the

welding equipment;

b) radio and television transmitters and receivers;

c) computer and other control equipment;

d) safety critical equipment, e.g., guarding of industrial equipment;

e) the health of the people around, e.g., the use of pacemakers and hearing aids;

f) equipment used for calibration or measurement

g) the immunity of other equipment in the environment. The user shall ensure that other equipment being

used in the environment is compatible. This may require additional protection measures;

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

h) the time of day that welding or other activities are to be carried out.

INVERTEC® V450-PRO

Page 7

vi vi

SAFETY

Electromagnetic Compatibility (EMC)

The size of the surrounding area to be considered will depend on the structure of the building and other

activities that are taking place. The surrounding area may extend beyond the boundaries of the premises.

Methods of Reducing Emissions

Mains Supply

Welding equipment should be connected to the mains supply according to the manufacturer’s recommendations. If interference occurs, it may be necessary to take additional precautions such as filtering of the

mains supply. Consideration should be given to shielding the supply cable of permanently installed welding

equipment, in metallic conduit or equivalent. Shielding should be electrically continuous throughout its

length. The shielding should be connected to the welding power source so that good electrical contact is

maintained between the conduit and the welding power source enclosure.

Maintenance of the Welding Equipment

The welding equipment should be routinely maintained according to the manufacturer’s recommendations.

All access and service doors and covers should be closed and properly fastened when the welding equipment is in operation. The welding equipment should not be modified in any way except for those changes

and adjustments covered in the manufacturers instructions. In particular, the spark gaps of arc striking and

stabilizing devices should be adjusted and maintained according to the manufacturer’s recommendations.

Welding Cables

The welding cables should be kept as short as possible and should be positioned close together, running at

or close to floor level.

Equipotential Bonding

Bonding of all metallic components in the welding installation and adjacent to it should be considered.

However, metallic components bonded to the work piece will increase the risk that the operator could

receive a shock by touching these metallic components and the electrode at the same time. The operator

should be insulated from all such bonded metallic components.

Earthing of the Workpiece

Where the workpiece is not bonded to earth for electrical safety, not connected to earth because of its size

and position, e.g., ships hull or building steelwork, a connection bonding the workpiece to earth may reduce

emissions in some, but not all instances. Care should be taken to prevent the earthing of the workpiece

increasing the risk of injury to users, or damage to other electrical equipment. Where necessary, the connection of the workpiece to earth should be made by a direct connection to the workpiece, but in some

countries where direct connection is not permitted, the bonding should be achieved by suitable capacitance, selected according to national regulations.

Screening and Shielding

Selective screening and shielding of other cables and equipment in the surrounding area may alleviate

problems of interference. Screening of the entire welding installation may be considered for special applica-

1

tions.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

_________________________

1

Portions of the preceding text are contained in EN 60974-10: “Electromagnetic Compatibility (EMC)

product standard for arc welding equipment.”

INVERTEC® V450-PRO

Page 8

I I

RETURN TO MAIN MENU

- MASTER TABLE OF CONTENTS FOR ALL SECTIONS -

Page

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i-iv

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section A

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section B

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section C

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section D

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section E

Troubleshooting and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section F

Electrical Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section G

Parts Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-525

INVERTEC® V450-PRO

Page 9

A-1 A-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Lifting, Stacking & Machine Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

High Frequency Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Input Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Input Fuse and Supply Wire Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Negative Electrode Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

TABLE OF CONTENTS - INSTALLATION SECTION

Connections of Wire Feeders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Parallel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INVERTEC® V450-PRO

Page 10

A-2 A-2

INSTALLATION

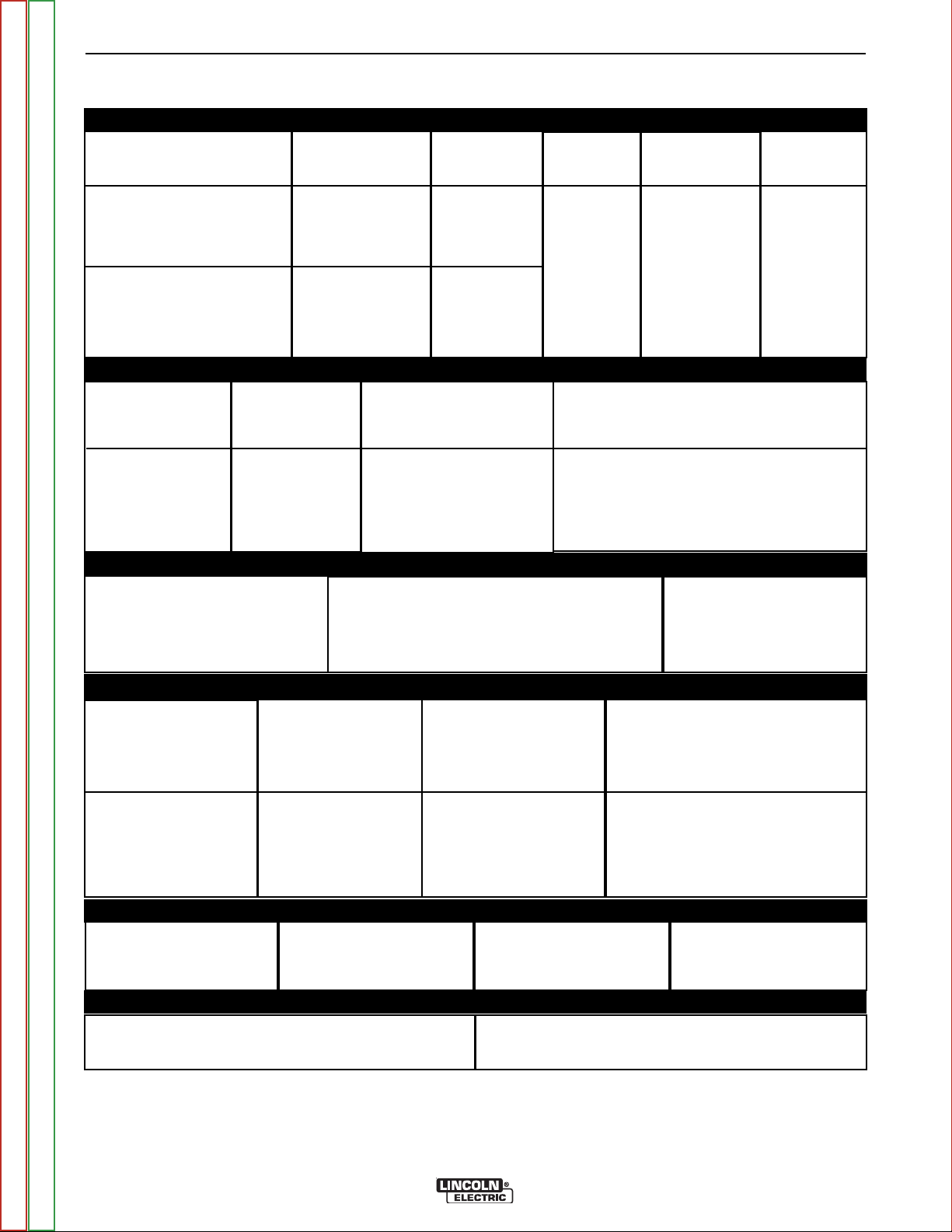

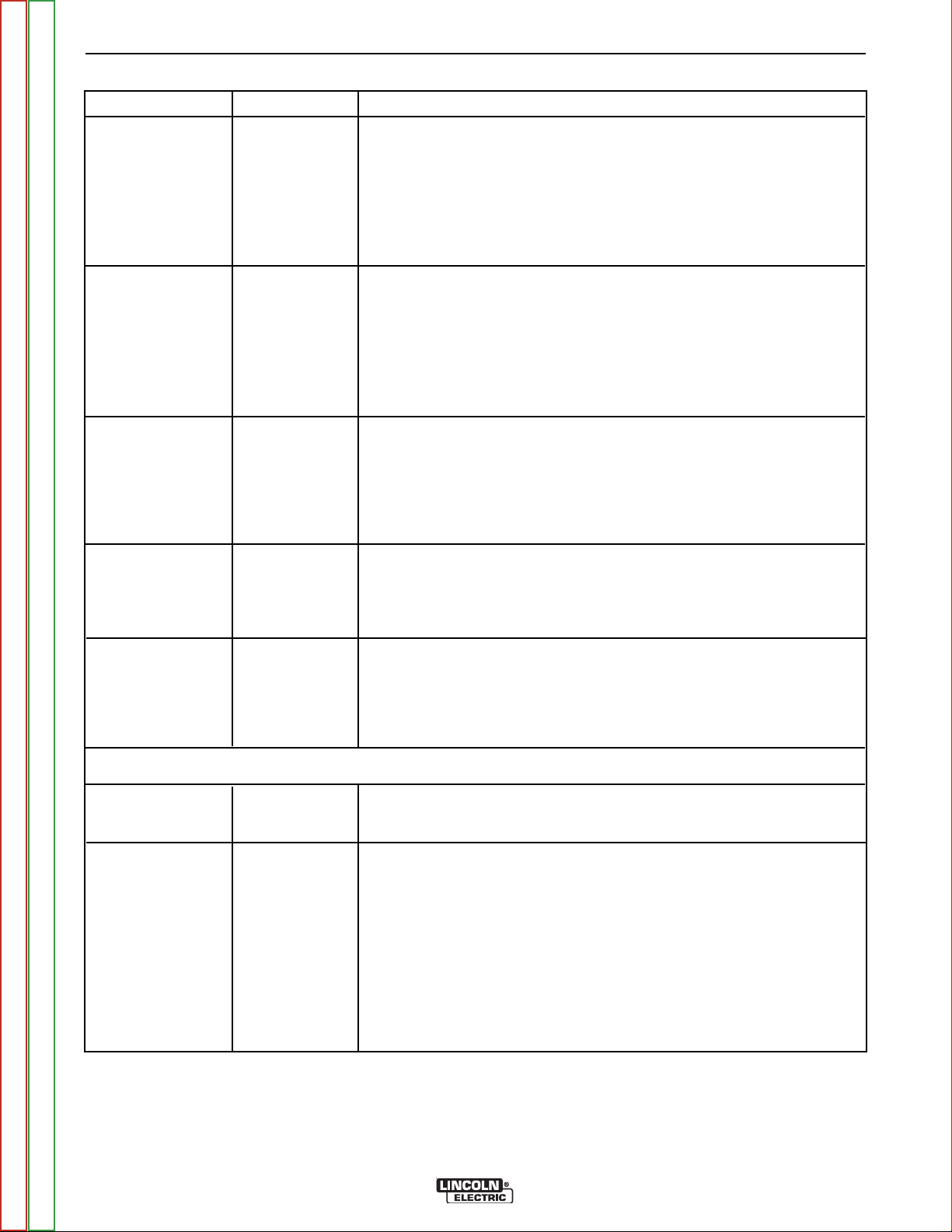

TECHNICAL SPECIFICATIONS -

INVERTEC® V450-PRO

INPUT AT RATED OUTPUT - THREE PHASE ONLY

INPUT VOLTS-

FREQUENCY

208/230/460/575V - 60HZ.

200/220/440/575V - 50HZ.

OUTPUT

CONDITIONS

AMPS / VOLTS / DUTY CYCLE

450A@38V.100%

570A@43V. 60%

400A@36V.100%

500A@40V. 60%

INPUT

CURRENT

AMPS

58/53/25/22

82/78/37/31

49/45/23/18

67/61/31/25

IDLE

POWER

400 Watts

Max.

POWER FACTOR

@ RATED OUTPUT

.95 MIN.

EFFICIENCY

@ RATED

OUTPUT

88%

OUTPUT

PULSE

FREQUENCY

0.15 - 1000 Hz

PULSE

VOLTAGE

RANGE

5 - 55 VDC

PULSE AND

BACKGROUND

TIME RANGE

100 MICRO SEC. -3.3

SEC.

(CIRCUIT BREAKER PROTECTED)

AUXILIARY POWER

24VAC

42VAC AT

10 AMPS

115VAC AT

15* AMPS

OPEN CIRCUIT VOLTAGE PROCESS CURRENT RANGE (DC) CURRENT

30-76

76

76

18-76

76

MIG/MAG

FCAW

SMAW

GTAW

Pulse

50-570 Average Amps

40-570 Average Amps

55-570 Average Amps

5-570 Average Amps

5-750 Peak Amps

RECOMMENDED INPUT WIRE AND FUSE SIZES FOR MAXIMUM RATED OUTPUT

INPUT

VOLTAGE /

FREQUENCY

208/50/60HZ

230/50/60HZ

460/50/60HZ

575/50/60HZ

TYPE 75°C

COPPER WIRE IN

CONDUIT AWG(MM2)

SIZES

4(25)

4(25)

8(10)

10(6)

TYPE 75°C

GROUND WIRE IN

CONDUIT AWG(MM2)

SIZES

8(10)

8(10)

10(6)

10(6)

TYPE 75°C

(SUPER LAG)

OR BREAKER

SIZE (AMPS)

100

100

50

40

PHYSICAL DIMENSIONS

HEIGHT

26.10 in

663 mm

WIDTH

19.86 in

505 mm

DEPTH

32.88 in

835 mm

WEIGHT

293 lbs.

133 kg.

TEMPERATURE RANGES

OPERATING TEMPERATURE RANGE

-20°C to +40°C

* Earlier models used 10 amps circuit breaker.

STORAGE TEMPERATURE RANGE

-40°C to +40°C

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INVERTEC® V450-PRO

Page 11

A-3 A-3

INSTALLATION

SAFETY PRECAUTIONS

Read

start installation.

this entire installation section before you

WARNING

ELECTRIC SHOCK can kill.

• Only qualified personnel should

perform this installation.

• Turn the input power OFF at the

disconnect switch or fuse box

before working on this equipment. Turn off the input

power to any other equipment connected to the

welding system at the disconnect switch or fuse

box before working on the equipment.

• Do not touch electrically hot parts.

• Always connect the V450-PRO grounding lug

(located inside the reconnect input access door)

to a proper safety (Earth) ground.

--- -- --- - ---- -- --- - ---- -- --- - ---- -- --- - ---- -- --- - ---- -- ---

SELECT SUITABLE LOCATION

Do not use the Invertec® in outdoor environments without appropriate protection. The V450-PRO power

source should not be subjected to falling water, nor

should any parts of it be submerged in water. Doing so

may cause improper operation as well as pose a safety hazard. The best practice is to keep the machine in a

dry, sheltered area.

LIFTING

Lift the machine by the lift bail only. The lift bail is

designed to lift the power source only. Do not attempt

to lift the V450-PRO with accessories attached to it.

STACKING

V450-PRO machines can be stacked to a maximum of

3 high.

CAUTION

The bottom machine must always be placed on a

firm, secure, level surface. There is a danger of

machines toppling over if this precaution is not

taken.

MACHINE GROUNDING

The frame of the welder must be grounded. A ground

terminal marked with the symbol is located inside

the reconnect/input access door for this purpose. See

your local and national electrical codes for proper

grounding methods.

HIGH FREQUENCY PROTECTION

Locate the V450-PRO away from radio controlled

machinery.

WARNING

Do not mount the V450-PRO over combustible surfaces. Where there is a combustible surface directly under stationary or fixed electrical equipment,

that surface shall be covered with a steel plate at

least .060" (1.6mm) thick, which shall extend not

less than 5.90" (150mm) beyond the equipment on

all sides.

------------------------------------------------------------------------

Place the welder where clean cooling air can freely circulate in through the rear louvers and out through the

case sides and bottom. Water, Dirt, dust, or any foreign

material that can be drawn into the welder should be

kept at a minimum. Failure to observe these precautions can result in excessive operating temperatures

and nuisance shutdowns.

Machines are equipped with F.A.N. (fan as needed) circuitry. The fan runs whenever the output is enabled,

whether under loaded or open circuit conditions. The

fan also runs for a period of time (approximately 5 minutes) after the output is disabled, to ensure all components are properly cooled.

If desired, the F.A.N. feature can be disabled (causing

the fan to run whenever the power source is on). To disable F.A.N., connect leads 444 and X3A together at the

output of the solid state fan control relay, located on the

back of the Control PC board enclosure. (See Wiring

Diagram)

CAUTION

The normal operation of the V450-PRO may

adversely affect the operation of RF controlled

equipment, which may result in bodily injury or

damage to the equipment.

INPUT CONNECTION

WARNING

Only a qualified electrician should connect the

input leads to the V450-PRO. Connections should

be made in accordance with all local and national

electrical codes and the connection diagram located on the inside of the reconnect/input access

door of the machine. Failure to do so may result in

bodily injury or death.

------------------------------------------------------------------------

Use a three-phase supply line. A 1.75 inch (45 mm)

diameter access hole for the input supply is located on

the upper left case back next to the input access door.

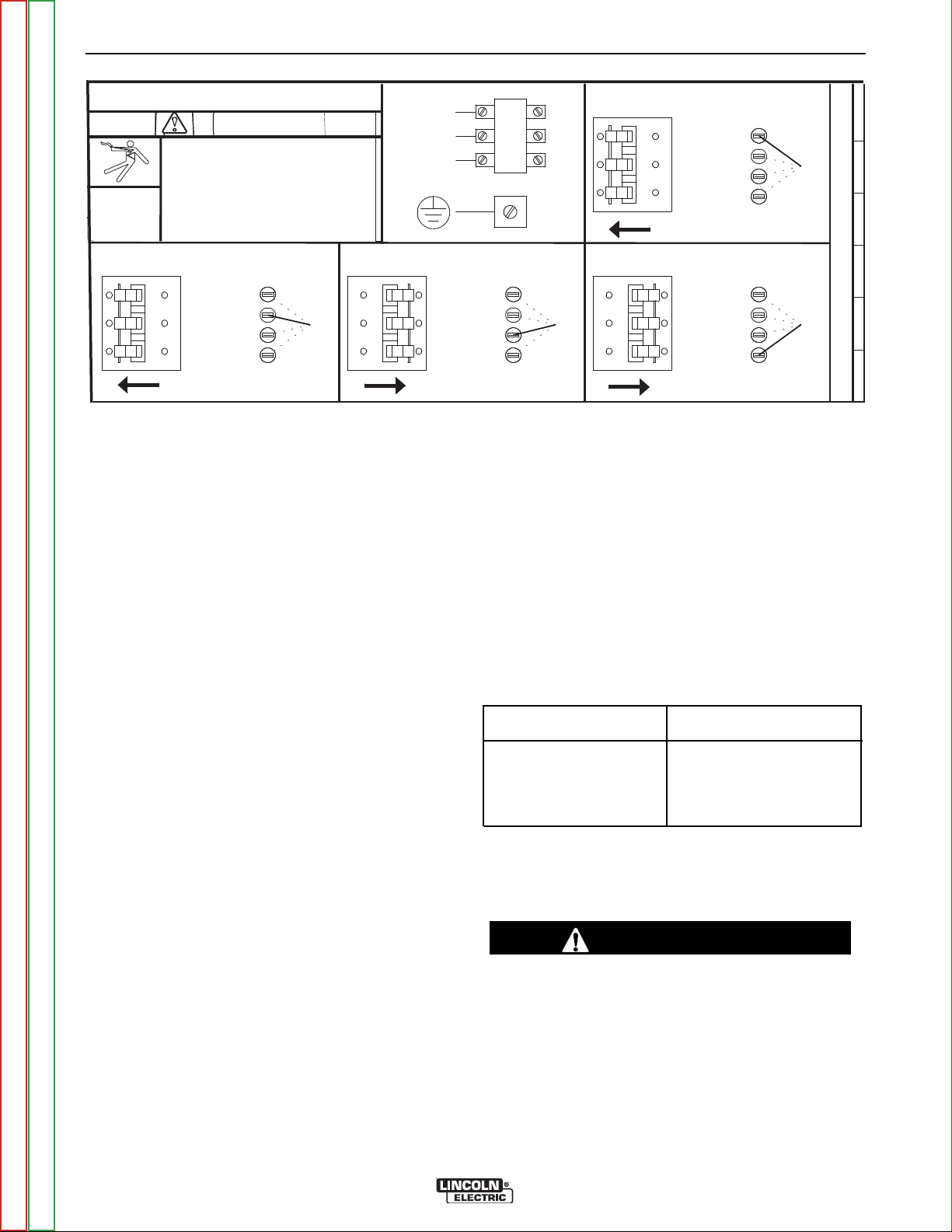

Connect L1, L2, L3 and ground according to the Input

Supply Connection Diagram decal located on the

inside of the input access door or refer to Figure A.1 on

the following page.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INVERTEC® V450-PRO

Page 12

A-4 A-4

200-208V

220-230V

440-460V

550-575V

200-208V

220-230V

=

220-230V

220-230V

200-208V

220-230V

440-460V

550-575V

200-208V

U / L1

550-575V

440-460V

'A'

'A'

= 440-460V

'A'

S25198

VOLTAGEVOLTAGE

VOLTAGE

VOLTAGE

=

200-208V

THE LINCOLN ELECTRIC CO. CLEVELAND, OHIO U.S.A.

XA

'A'

= 550-575V

C

R1

W / L

3

V / L

2

440-460V

550-575V

.

inspecting or servicing machine.

Do not operate with covers

.

r

emoved.

Do not touch electrically live parts.

.

Only qualied persons should install,

use or service this equipment.

.

Disconnect input power before

INPUT SUPPLY CONNECTION DIAGRAM

WARNING

ELECTRIC

SHOCK

CAN KILL

200-208V

220-230V

440-460V

550-575V

200-208V

220-230V

=

220-230V

220-230V

200-208V

220-230V

440-460V

550-575V

200-208V

U / L1

550-575V

440-460V

'A'

'A'

= 440-460V

'A'

S25198

VOLTAGEVOLTAGE

VOLTAGE

VOLTAGE

=

200-208V

THE LINCOLN ELECTRIC CO. CLEVELAND, OHIO U.S.A.

XA

'A'

= 550-575V

C

R1

W / L

3

V / L

2

440-460V

550-575V

.

inspecting or servicing machine.

Do not operate with covers

.

r

emoved.

Do not touch electrically live parts.

.

Only qualied persons should install,

use or service this equipment.

.

Disconnect input power before

INPUT SUPPLY CONNECTION DIAGRAM

WARNING

ELECTRIC

SHOCK

CAN KILL

INSTALLATION

FIGURE A.1 - CONNECTION DIAGRAM ON CONNECTION/INPUT ACCESS DOOR

NOTE: Turn main input power to the machine OFF before performing connection procedure. Failure to do

so will result in damage to the machine.

INPUT FUSE AND SUPPLY WIRE

CONSIDERATIONS

Refer to the Technical Specifications at the beginning

of this Installation section for recommended fuse and

wire sizes. Fuse the input circuit with the recommended super lag fuse or delay type breakers (also called

“inverse time” or “thermal/magnetic” circuit breakers).

Choose an input and grounding wire size according to

local or national electrical codes. Using fuses or circuit

breakers smaller than recommended may result in

“nuisance” shut-offs from welder inrush currents, even

if the machine is not being used at high currents.

INPUT VOLTAGE CHANGE OVER (FOR

MULTIPLE INPUT VOLTAGE

MACHINES ONLY)

Welders are shipped connected for the highest input

voltage listed on the rating plate. To move this connection to a different input voltage, see the diagram located on the inside of the input access door. If the main

reconnect switch or link position is placed in the wrong

position, the welder will not produce output power.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

If the Auxiliary (A) lead is placed in the wrong position,

there are two possible results. If the lead is placed in a

position higher than the applied line voltage, the welder

may not come on at all. If the Auxiliary (A) lead is

placed in a position lower than the applied line voltage,

the welder will not come on, and the two circuit breakers or fuses in the reconnect area will open. If this

occurs, turn off the input voltage, properly connect the

(A) lead, reset the breakers, and try again. For

machines equipped with a fuse in the reconnect area,

turn off the input voltage and replace the fuse with the

spare fuse that is attached to the reconnect switch pin.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INVERTEC® V450-PRO

ELECTRODE AND WORK CABLE

CONNECTIONS

Connect a work lead of sufficient size and length (Per

Table 1) between the proper output terminal on the

power source and the work. Be sure the connection to

the work makes tight metal-to-metal electrical contact.

To avoid interference problems with other equipment

and to achieve the best possible operation, route all

cables directly to the work and wire feeder. Avoid

excessive lengths and do not coil excess cable.

Minimum work and electrode cable sizes are as follows:

TABLE A.1

(Current (60% Duty Cycle)

400 Amps 2/0 (67 mm2)

500 Amps 3/0 (85 mm2)

600 Amps 3/0 (85 mm2)

NOTE: K1796 coaxial welding cable is recommended

to reduce the cable inductance in long cable lengths.

This is especially important when Pulse welding up to

350 amps.

When using inverter type power sources like the

V450-PRO, use the largest welding (electrode and

work) cables that are practical. At least 2/0 (67

2

) copper wire - even if the average output cur-

mm

CAUTION

rent would not normally require it. When pulsing,

the pulse current can reach very high levels.

Voltage drops can become excessive, leading to

poor welding characteristics, if undersized welding

cables are used.

------------------------------------------------------------------------

MINIMUM COPPER

WORK CABLE SIZE AWG

Up To-100 Ft. Length (30 m)

Page 13

A-5 A-5

B

A

C

FIGURE A.2

WORK

V450-PRO

A

C

B

FIGURE A.3

K1796 COAXIAL CABLE

MEASURE FROM END

OF OUTER JACKET OF

CABLE

C

A

B

WORK

SLIDING

WORK

V

450-PRO

A

C

B

FIGURE A.3

K1796 COAXIAL CABLE

MEASURE FROM END

OF OUTER JACKET OF

CABLE

C

A

B

WORK

SLIDING

WORK

V

450-PRO

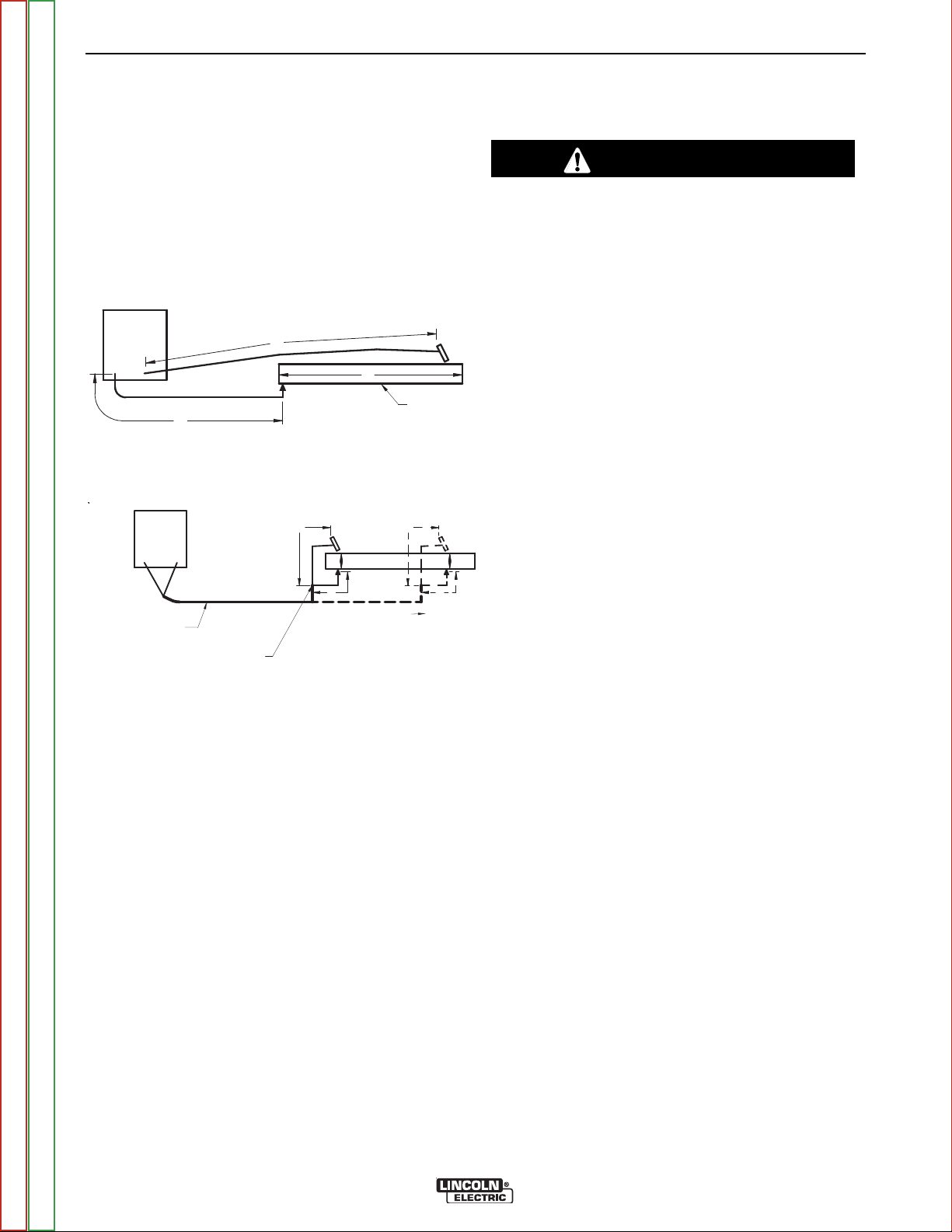

CABLE INDUCTANCE, AND ITS EFFECTS

ON PULSE WELDING

For Pulse Welding processes, cable inductance will

cause the welding performance to degrade. For the

total welding loop length less than

tional welding cables may be used without any effects

on welding performance. For the total welding loop

length greater than

50 ft. (15.24m), the K1796 Coaxial

Welding Cables are recommended. The welding loop

length is defined as the total of electrode cable length

(A) + work cable length (B) + work length (C) (See

Figure A.2).

50 ft.(15.24m), tradi-

INSTALLATION

For additional Safety information regarding the electrode and work cable set-up, See the standard "SAFETY INFORMATION" located in the front of the

Instruction Manuals.

CAUTION

Excessive voltage drops caused by poor work

piece connections often result in unsatisfactory

welding performance.

------------------------------------------------------------------------

NEGATIVE ELECTRODE POLARITY

When negative electrode polarity is required, such as in

some Innershield applications, switch the output connections at the power source (electrode cable to the

negative (-) stud, and work cable to the positive (+)

stud.

For long work piece lengths, a sliding ground should be

considered to keep the total welding loop length less

50 ft.(15.24m). (See Figure A.3.)

than

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Output connections on some V450-PRO are made via

1/2-13 threaded output studs located beneath the

spring-loaded output cover at the bottom of the case

front.

Most welding applications run with the electrode being

positive (+). For those applications, connect the electrode cable between the wire feeder and the positive

(+) output stud on the power source (located beneath

the spring loaded output cover near the bottom of the

case front). Connect the other end of the electrode

cable to the wire drive feed plate. The electrode cable

lug must be against the feed plate. Be sure the connection to the feed plate makes tight metal-to-metal

electrical contact. The electrode cable should be sized

according to the specifications given in the work cable

connections section. Connect a work lead from the

negative (-) power source output stud to the work

piece. The work piece connection must be firm and

secure, especially if pulse welding is planned.

INVERTEC® V450-PRO

Page 14

A-6 A-6

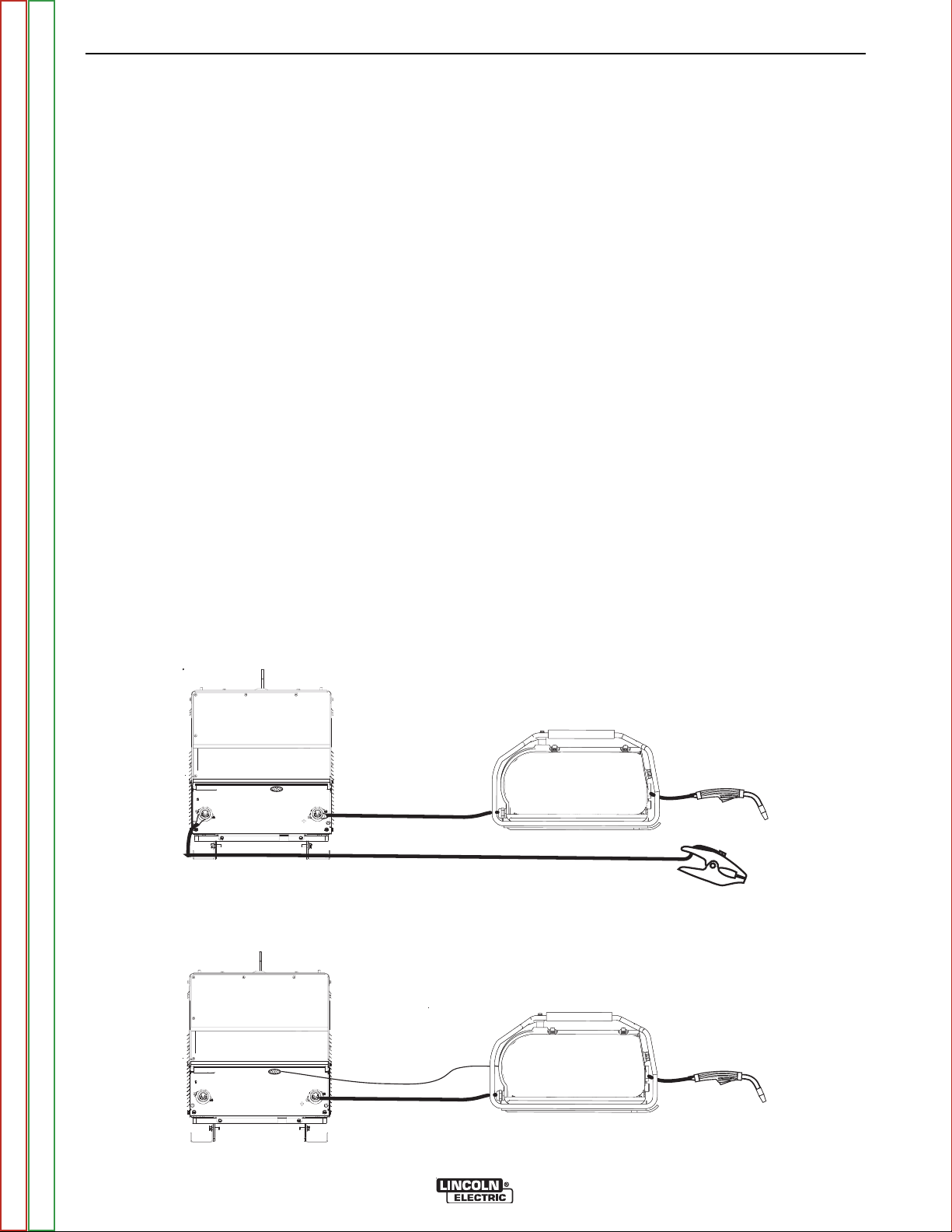

14-PIN

STUD

WORK CLAMP

ELECTRODE CABLE

V450-PRO

ACROSS THE ARC MODEL

CONROL CABLE MODEL

OUTPUT TERMINALS

ALWAYS HOT.

POWER SOURCE CONTACTOR

SWITCH MUST BE IN THE

“ON” POSITION OR USE A

K848 JUMPER PLUG KIT.

MAGNUM GUN

AND CABLE

ASSEMBLY

LN-15

SEMIAUTOMATIC

WIRE FEEDER

K1870-1

14-PIN

STUD

ELECTRODE CABLE

V450-PRO

K1819-10

CONTROL CABLE

MAGNUM GUN

AND CABLE

ASSEMBLY

LN-15

SEMIAUTOMATIC

WIRE FEEDER

K1871-1 MODEL

14-PIN

STUD

WORK CLAMP

ELECTRODE CABLE

V450-PRO

ACROSS THE ARC MODEL

CONROL CABLE MODEL

OUTPUT TERMINALS

ALWAYS HOT.

POWER SOURCE CONTACTOR

SWITCH MUST BE IN THE

“ON” POSITION OR USE A

K848 JUMPER PLUG KIT.

MAGNUM GUN

AND CABLE

ASSEMBLY

LN-15

SEMIAUTOMATIC

WIRE FEEDER

K1870-1

14-PIN

STUD

ELECTRODE CABLE

V450-PRO

K1819-10

CONTROL CABLE

MAGNUM GUN

AND CABLE

ASSEMBLY

LN-15

SEMIAUTOMATIC

WIRE FEEDER

K1871-1 MODEL

INSTALLATION

CONNECTIONS OF WIRE FEEDERS TO V450-PRO

LF-72, 74 Connection Instructions

• Turn the Invertec® power switch "off".

• Connect the K1797-[ ] control cable from the LF-72, 74

to the 14-pin MS-style connector.

• Connect the electrode cable to the output terminal of the

polarity required by electrode. Connect the work lead to

the other terminal.

• If a remote control such as K857 is to be used with the

LF-72, 74 the remote can be connected directly to the 6pin MS-style connector on the front of the Invertec® or

use a K864 adapter to connect the LF-72, 74 and the

remote to the 14-pin MS-style connector.

LN-10, DH-10 Connection Instructions

• Turn the Invertec® power switch "off"

• Connect the K1505 control cable from the LN-10 to the

14-pin MS-style connector.

• Connect the electrode cable to the output terminal of

polarity required by the electrode. Connect the work lead

to the other terminal.

• Set the meter polarity switch on the front of the Invertec®

to coincide with wire feeder polarity used.

• See the LN-10 manual for details on accessing Control

DIP Switch. Dip Switches for the V350 and the same settings may be used for the V450.

LN-15 Connection Instructions

(See Figure A.4)

• Turn the Invertec® power switch "off".

• Connect the electrode cable to the output terminal of polarity required by electrode. (See Figures below)

• Set the meter polarity switch on the front of the Invertec®

to coincide with wire feeder polarity used.

LN-25 Connection Instructions

• Turn the Invertec® power switch "off".

• Connect the electrode cable to the output terminal of polarity required by electrode. Connect the work lead to the

other terminal.

• LN-25 with Remote Control 6-Pin (K444-1) and 14-pin

(K444-2) remotes can be connected directly to the 6-pin &

14-pin MS-style connectors. The 42 Volt Remote Voltage

and Output Control (K624-1) Kit can be connected to the

V450’s 14-pin MS-style connector using Remote Control

Cable assembly K627- [ ]. LN-25s with a K431-1 remote kit

can be connected to the V450’s 14-pin MS-style connector

using a K432 cable and K876 adapter. (See connection

diagram S19899). Or the K432 cable could be modified

with a K867 Universal Adapter Plug (See connection diagram S19405) to connect it to the V450’s 14-pin MS-style

connector.

FIGURE A.4

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

INVERTEC® V450-PRO

Page 15

A-7 A-7

INSTALLATION

LN-742 Connection Instructions

• Turn the Invertec® power switch "off"

• A K1819-1 Input cable assembly is required to connect the LN-742 to the Invertec®.

• Connect the control cable from the LN-742 to the

14-pin MS-style connector.

• Connect the electrode cable to the output terminal

of the polarity required by electrode. Connect the

work lead to the other terminal.

• Set the meter polarity switch on the front of the

Invertec® to coincide with wire feeder polarity used.

The wire feeder will now display the welding voltage.

• If a remote control such as K857 is to be used with the

LN-742, the remote can be connected directly to the 6-pin

MS-style connector on the front of the Invertec® or use a

K864 adapter to connect the LN-742 and the remote to

the 14-pin MS-style connector.

Cobramatic Connection Instructions

• Turn the Invertec® power switch "off"

• Connect the control cable from the Cobramatic to

the 14-pin MS-style connector.

• Connect the electrode cable to the output terminal

of the polarity required by electrode. Connect the

work lead to the other terminal.

• Set the meter polarity switch on the front of the

Invertec® to coincide with wire feeder polarity used.

• If a remote control such as K857 is to be used with

the Cobramatic, the remote can be connected

directly to the 6-pin MS-style connector on the front

of the Invertec® or use a K864 adapter to connect

the cobramatic and the remote to the 14-pin MSstyle connector.

General Instructions for Connection of Wire

Feeders to V450-Pro

Wire feeders other than those listed above may be

used provided that the auxiliary power supply rating of

the V450-Pro is not exceeded and the V450-PRO output is not actively controlled by the wire feeder. (Like

an LN-9). K867 universal adapter plug is required. See

connection diagram S24985 in Operator Manual.

REMOTE CONTROL OF INVERTEC®

Remote Control K857, Hand Amptrol K963 and Foot

Amptrol K870 may be used.

PARALLEL OPERATION

The V450-Pro are operable in parallel in CC mode. For

best results, the currents of each machine should be

reasonably equally balanced. As an example, with two

machines set up in parallel for a 800 amps procedure,

each machine should be set to deliver approximately

400 amps, not 450 amps from one and 350 amps from

the other. This will minimize nuisance shutdown conditions. In general, more than two machines in parallel

will not be effective due to the voltage requirements of

procedures in that power range.

To set machine outputs, start with output control pots

and arc control pots in identical positions. Use the output control pots to balance the currents and maintain

the desired current. The arc control pots should be

kept identical on the two machines.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

TIG Module K930-2

The TIG Module connects to the Factory and Advanced

Process

control cable. Connect the K936-1 to the 14-Pin MSstyle connector.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

V450-Pro versions with a K936-1 (9-14 pin)

INVERTEC® V450-PRO

Page 16

A-8 A-8

NOTES

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INVERTEC® V450-PRO

Page 17

B-1 B-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Case Front Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Hidden Middle Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

TIG GTAW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

CV-Innershield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Weld Mode Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Memory Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

TABLE OF CONTENTS - OPERATION SECTION

Weld Mode Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Pulse Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Remote Control Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-9

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-10

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INVERTEC® V450-PRO

Page 18

B-2 B-2

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and

ground.

• Always wear dry insulating gloves.

------------------------------------------------------------------------

FUMES AND GASES can be dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to remove

fumes from breathing zone.

-------------------------------------------------------

-----------------

WELDING SPARKS can cause fire or

explosion.

• Keep flammable material away.

• Do not weld on closed containers.

OPERATION

• After welding, the meter holds the actual current

value for 5 seconds. Output adjustment while in the

"hold" period results in the "prior to operation" characteristics stated above. The displays blink indicating that the machine is in the "Hold" period.

3. VOLT METER

• Prior to CV operation (current flow), the meter displays desired preset voltage value (+/- .5V).

• Prior to STICK or TIG operation, the meter displays

the Open Circuit Voltage of the Power Source or four

dashes if the output has not been turned on.

• During welding, this meter displays actual average

volts.

• After welding, the meter holds the actual voltage

value for 5 seconds. The displays blink indicating

that the machine is in the "Hold" period.

• Output adjustment while in the "hold" period results

in the "prior to operation" characteristics stated

above.

------------------------------------------------------------------------

ARC RAYS can burn eyes and skin.

• Wear eye, ear and body

protection.

------------------------------------------------------------

See additional warning information at

front of this operator’s manual.

-----------------------------------------------------------

GENERAL DESCRIPTION

The Invertec® V450-Pro offers multi-process CV, CC,

and DC welding and is rated 570 amps, 43 volts at a

60% duty cycle.

DUTY CYCLE

The V450-Pro is rated at 570 amps, 60% duty cycle

(based on a 10 minute cycle). It is also rated at 450

amps, 100% duty cycle.

OPERATIONAL FEATURES and CONTROLS:

UPPER CONTROL PANEL

1. ON, OFF- SWITCH

4. OUTPUT CONTROL

• Output control is conducted via a single turn potentiometer.

• Adjustment is indicated by the meters as stated

above.

• When in TIG modes, this control sets the maximum

welding current. Full depression of a foot or hand

Amptrol results in the preset level of current.

5. WELD TERMINALS-REMOTE / ON

• Two status lights indicate the location of trigger control as determined by the "WELD TERMINALS" push

button.

• If trigger control is local "weld terminals on", the ON

display will be lit.

• If trigger control is remote "weld terminals remotely

controlled", the REMOTE display will be lit.

• The unit will power up in "pre-determined preferred"

trigger modes.

STICK = ON

CV = REMOTE

TIG = REMOTE if remote output controls are attached

to the machine.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

2. AMPS Meter

• Prior to STICK or TIG operation (current flow), the

meter displays preset current value (either +/- 2

amps or +/- 3% (e.g. 3 amps on 100), whichever is

greater).

• Prior to CV operation, the meter displays four dashes indicating AMPS unable to be preset.

• During welding, this meter displays actual average

amps.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TIG = ON if remote output controls are not attached to

the machine.

For all versions, these trigger modes can be over-ridden

(switched) with the WELD TERMINALS push button. When

changed, the unit will power up in the configuration it was in

INVERTEC® V450-PRO

Page 19

B-3 B-3

OUTPUTOUTPUT

MPSMPS

AA

O

LTSOLTS

VV

REMOTEREMOTE

LOCALLOCAL

CONTROLCONTROL

SELECTSELECT

SOFT

C

RIP

HI-FREQ

TIG

TOUCH

S

TART

TIG

OUTPUTOUTPUT

MPSMPS

AA

O

LTSOLTS

VV

REMOTEREMOTE

LOCALLOCAL

CONTROLCONTROL

SELECTSELECT

SOFT

C

RIP

HI-FREQ

TIG

TOUCH

S

TART

TIG

6.

THERMAL

• This status light indicates when the power source has been

driven into thermal overload. If the output terminals were

OPERATION

CC-STICK SOFT: The Stick Soft process features contin-

uous control ranging from 5 to 570 amps. This mode was

intended for most SMAW applications, and Arc Gouging.

"ON", the "ON" light will blink indicating that the output will

be turned back on once the unit cools down to an acceptable temperature level. If the unit was operating in the

"REMOTE" mode, the trigger will need to be opened

before or after the thermal has cleared and closed after the

machine has cooled down to an acceptable temperature to

establish output.

• Arc Gouging: Setting the output of the Stick Soft

mode to 570 amps or setting the arc control to maximum will enable the arc-gouging mode. The actual output current will depend on the size of carbon used. The

recommended maximum size carbon is 3/8"(9.5mm).

• The Hot Start control regulates the starting current at

arc initiation. Hot Start can be adjusted from minimum

7.

CONTROL-REMOTE / LOCAL

• Two status lights indicate the location of output control as

pre-determined by the power sources auto-configure system.

• The LOCAL display will be lit when control is at the power

source.

• The REMOTE display will be lit when a remote pot/control

is detected.

These Output Control configurations can be overridden

(switched) with the CONTROL push button. When changed,

the unit will power up in the configuration it was in when it

was last powered down.

(0), with no additional current added at arc start, to

maximum (10), with double the preset current or 570

amps (max of machine) added for the first second after

arc initiation.

• The Arc Control regulates the Arc Force to adjust the

short circuit current. The minimum setting (-10) will produce a "soft" arc and will produce minimal spatter. The

maximum setting (+10) will produce a "crisp" arc and

will minimize electrode sticking.

CC-STICK CRISP:The Stick Crisp mode features continuous control from 5 to 570 amps with a crisp shorting

response optimized for E6010 type electrodes.

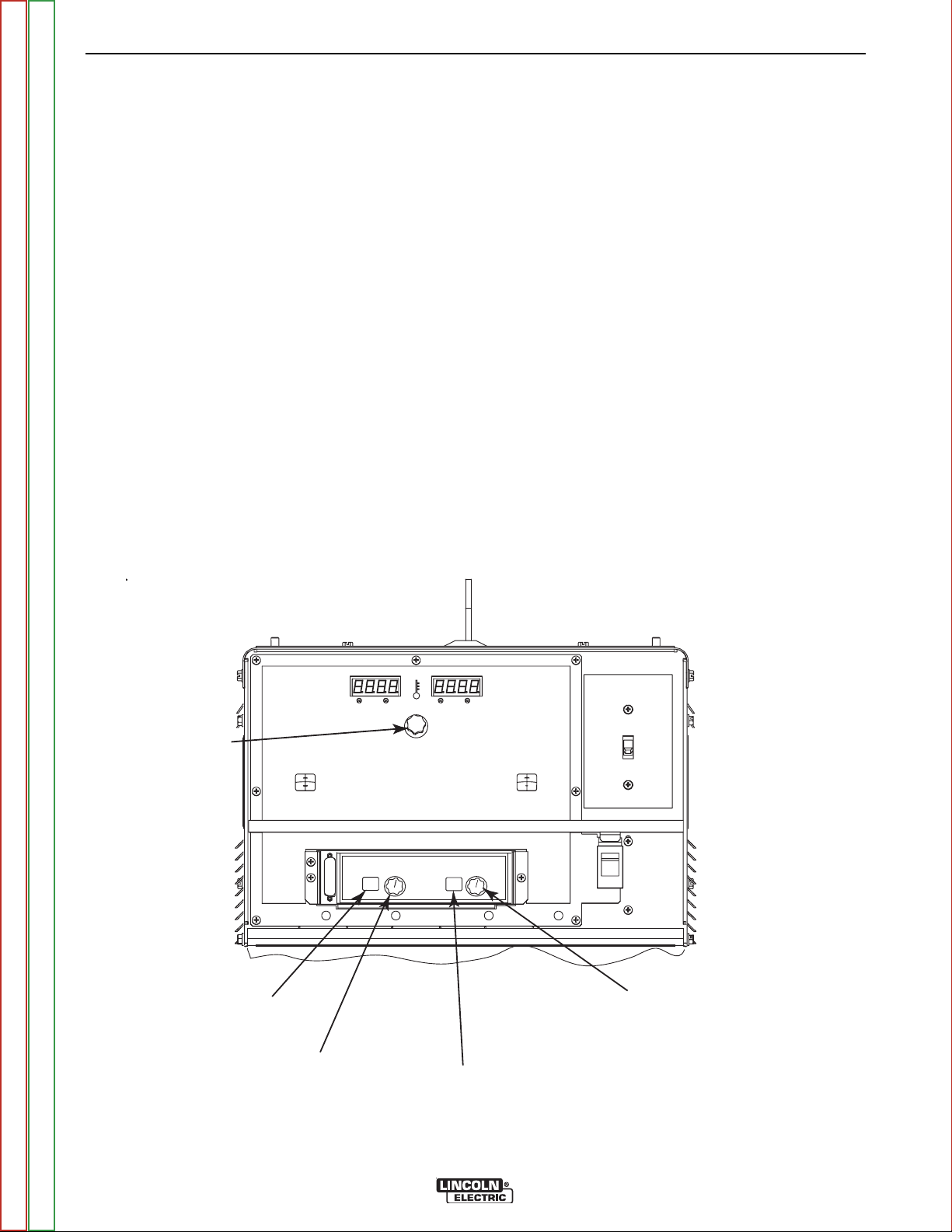

Hidden Middle Control Panel – Process Set Up

Panel

The middle control panel is removable to allow for

upgrades (see Field Installed Options/Accessories).

Additionally, this panel is hidden by an access door to

provide protection to the controls.

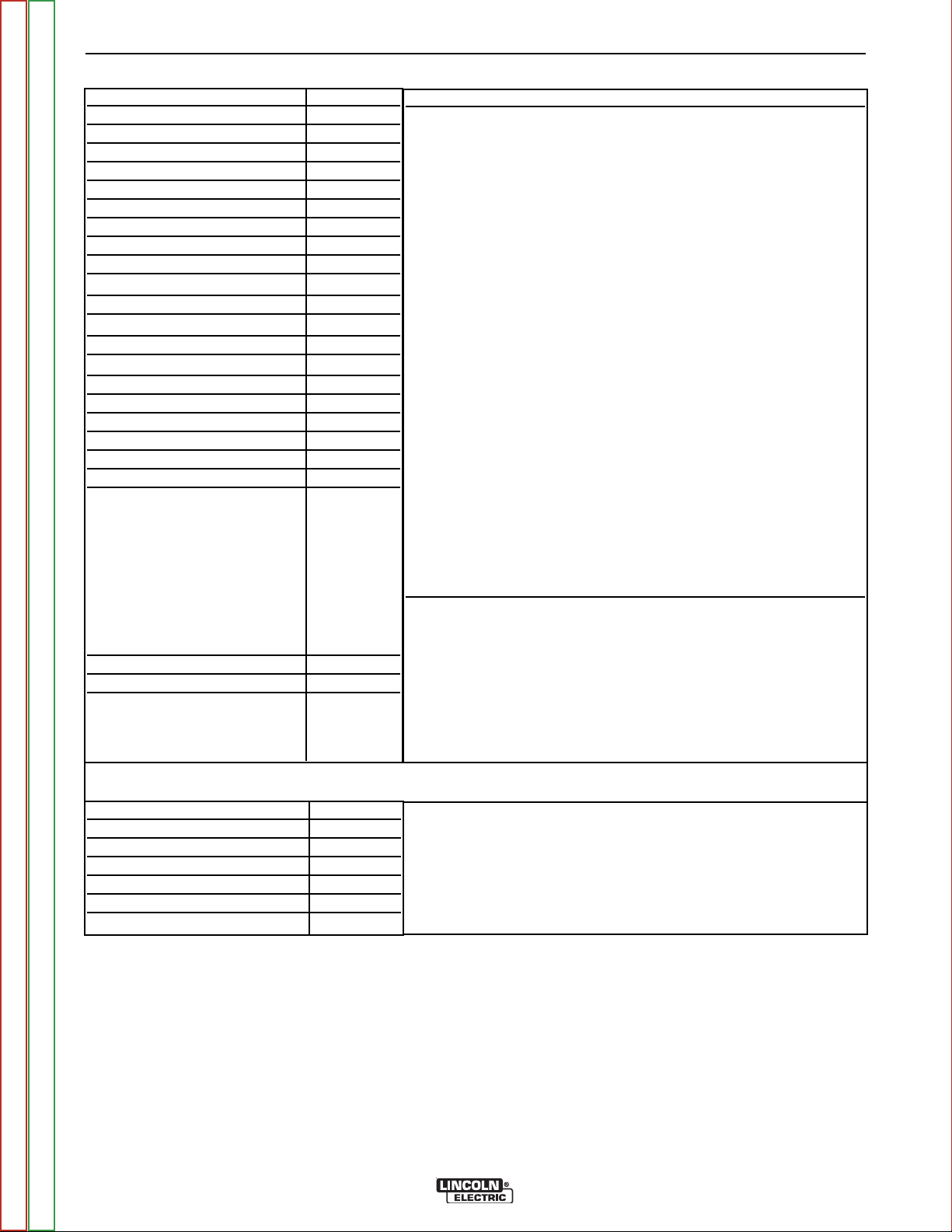

8. WELD MODE SELECT - STANDARD (See

Figure B.1)

The Mode Control button selects from the following

welding modes.

2

6

7

8

9

• Arc Gouging: Setting the output of the Crisp mode to

570 amps or setting the arc control to maximum will

enable the arc-gouging mode. The actual output current will depend on the size of carbon used. The recommended maximum size carbon is 3/8"(9.5mm).

• The Hot Start control regulates the starting current at

arc initiation. Hot Start can adjust starting current up or

down by 25% of the preset value. The recommended

setting for Hot Start is 5 where the initial current is

equal to the preset current.

FIGURE B.1

3

4

1

5

10

13

14

12

11

15

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

INVERTEC® V450-PRO

Page 20

B-4 B-4

• The Arc Control regulates the Arc Force to adjust the

short circuit current. The minimum setting (-10) will

produce a "soft" arc and will produce minimal spatter. The maximum setting (+10) will produce a "crisp"

arc and will minimize electrode sticking.

TIG GTAW: The TIG mode features continuous control

from 5 to 570 amps. The TIG mode can be run in either

the TIG touch start or high frequency (optional equipment required) assisted start mode.

• The Hot Start control selects the starting mode

desired. A setting of less than 5, the TIG lift start

mode is selected. The OCV is controlled below 10v

and the short circuit "TIG touch" current is maintained at 25 amps independent of the preset current.

When the tungsten is lifted, an arc is initiated and

the output is regulated at the preset value. Hot start

settings between 0 and 5 regulate the arc initiation

current. A setting of 5 results in the most positive arc

initiation. A setting of 0 reduces hot start.

• Hot Start settings between 5 and 10, select high frequency assisted starting TIG mode. In this range,

the OCV of the machine is controlled between 50

and 70 volts. If using the Lincoln K930-1 TIG

Module, set the Hot start to 10 for maximum OCV.

• The Arc Control is not used in the TIG mode.

OPERATION

CV-WIRE: The CV-WIRE mode features continuous

control from 10 to 40 volts. This mode was intended for

most GMAW, FCAW, and MCAW applications.

• The Hot Start control is not used in the CV-WIRE

mode.

• The Arc Control regulates pinch effect. At the minimum setting (-10), minimizes pinch and results in a

soft arc. Low pinch settings are preferable for welding with gas mixes containing mostly inert gases. At

the maximum setting (+10), maximizes pinch effect

and results in a crisp arc. High pinch settings are

preferable for welding FCAW and GMAW with CO

CV-INNERSHIELD: The CV-INNERSHIELD mode

features continuous control from 10 to 45 volts. This

mode was designed for self-shielded flux cored wires

that require tight voltage control.

• The Hot Start control is not used in the CV-INNERSHIELD mode.

• The Arc Control regulates pinch effect. At the minimum setting (-10), minimizes pinch and results in a

soft arc. At the maximum setting (+10), maximizes

pinch effect and results in a crisp arc. Most selfed wires work well at an Arc Control setting of 5.

2.

shield-

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INVERTEC® V450-PRO

Page 21

B-5 B-5

OUTPUT KNOBOUTPUT KNOB

REMOTEREMOTE

ONON

REMOTEREMOTE

LOCALLOCAL

WELD TERMINALSWELD TERMINALS

CONTROLCONTROL

SELECTSELECT

SELECTSELECT

MPSMPS

AA

OLTSOLTS

VV

ADVANCE PROCESS PANEL- MIDDLE SECTION OF WELDER (OPTIONAL)

MEMORYMEMORY

MEMORY BUTTON MEMORY BUTTON

(M1 THRU M8)(M1 THRU M8)

SELECT BUTTONSELECT BUTTON

(HOT START OR ARC CONTROL)(HOT START OR ARC CONTROL)

ADJUST KNOB ADJUST KNOB

(0 THRU +10 HOT START) (0 THRU +10 HOT START)

(-10 THRU 0 AND 0 THRU +10 ARC CONTROL)(-10 THRU 0 AND 0 THRU +10 ARC CONTROL)

SELECT KNOB SELECT KNOB

(SCOLLS WELDING PROCESSES)(SCOLLS WELDING PROCESSES)

SELECTSELECT

ADJUST ADJUST

SELECTSELECT

OUTPUT KNOBOUTPUT KNOB

REMOTEREMOTE

ONON

REMOTEREMOTE

LOCALLOCAL

WELD TERMINALSWELD TERMINALS

CONTROLCONTROL

SELECTSELECT

SELECTSELECT

MPSMPS

AA

OLTSOLTS

VV

ADVANCE PROCESS PANEL- MIDDLE SECTION OF WELDER (OPTIONAL)

MEMORYMEMORY

MEMORY BUTTON MEMORY BUTTON

(M1 THRU M8)(M1 THRU M8)

SELECT BUTTONSELECT BUTTON

(HOT START OR ARC CONTROL)(HOT START OR ARC CONTROL)

ADJUST KNOB AD JUS T K N OB

(0 THRU +10 HOT START) (0 THRU +10 HOT START)

(-10 THRU 0 AND 0 THRU +10 ARC CONTROL)(-10 THRU 0 AND 0 THRU +10 ARC CONTROL)

SELECT KNOB SELECT KNOB

(SCOLLS WELDING PROCESSES)(SCOLLS WELDING PROCESSES)

SELECTSELECT

ADJUST ADJUST

SELECTSELECT

OPERATION

8A. WELD MODE SELECT-FOR

MACHINES EQUIPPED WITH OPTIONAL

ADVANCED PROCESS PANEL

(See Figure B.2 UPPER AND MIDDLE SECTION)

See (WELD MODE DETAILS) in this section.

To program welding modes, the SELECT knob is used

to Scroll through all welding modes. The MEMORY

button is used to store and access welding modes into

locations M1 thru M8.

Modes:

In addition to the 5 welding modes described in SECTION 7, the Advance Process Panel allows you to

select the Following additional modes.

• Constant Power mode

In the Power Mode;

The work point will be in the Volts window. The Amp

window will have CP displayed indicating Constant

Power. Once current starts flowing and during the 5

second “Hold” feature the displays will show Volts

and Amps respectively.

• Gouge Mode

The gouging mode is specifically designed for carbon arc gouging with electrodes up to 3/8”.

• Pulsed Modes

In Pulse Modes;

The work point will be in the Amps window and

should be set close to the wire feed speed of the

wire feeder in inches per minute. The Volts window

will have SPd displayed indicating Wire Feed

Speed. Once current starts flowing and during the 5

second “Hold” feature the displays will show amps

and volts.

Pulse Mode features that are displayed while selecting

a Welding pulse mode are listed below:

Steel - .030”, .035”, .045”, .052”, 1/16” – Argon Blends

Stainless Steel - .030”, .035”, .045” – Argon Blends &

Helium/Argon Blends

Aluminum - .035”, 3/64”, 1/16” – 4043 & 5356

Metal Core - .045”, .052”, 1/16” – Argon Blends

Nickel - .035”, .045” – Argon/Helium blends

FIGURE B.2

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

INVERTEC® V450-PRO

Page 22

B-6 B-6

OPERATION

MEMORY SELECTIONS:

(See Figure B.2 for location of controls)

The MEMORY button and SELECT knob are used

together to select a welding process and store it in

memory (M1 thru M8). The SELECT knob scrolls

through the welding process modes and memory M1

thru M8. The MEMORY button stores the welding

process in memory.

• SELECT button" (The right button) selects between

the "Hot Start" or "Arc Control". The < will indicate the

active feature shown below.

Right Digital Window

"Hot Start" (-10 to 0 +10)

"Arc Control" (0 to 10) <

• The ADJUST knob adjusts the desired settings for

the Hot Start or Arc Control feature that is active.

WELDING PROCESS MODES AVAILABLE

Stick SMAW, TIG GTAW

Gouge CAG, CV MIG GMAW

CV Flux Core, Pulse MIG

ELECTRODE MATERIAL

Steel, Metal Core, Stainless, Aluminum, Nickel

EXAMPLE OF SAVING WELDING MODES TO MEMORY

The following example is how to select Pulse MIG

using .035 steel and store it into memory.

1. Turn the SELECT knob until welding process is dis-

played.

RIGHT WINDOW LEFT WINDOW

Pulse MIG Argon Blends

Steel .035

2. Wait two seconds and the right window will display

Arc Control on the second line on the right side.

Pulse MIG Argon Blends

Steel .035 Arc Cntrl ### <

3. SPd is displayed in the upper right Volts window.

The left Amps window matches the desired wire

feed speed that is set on the wire feeder. Adjust the

OUTPUT knob until desired number is displayed.

4. Start welding. If the arc length is too short, turn the

Output knob up. If the arc length is too long, turn

the Output knob down.

The Arc Control, which is displayed in the right digital window, can be used to fine-tune the arc length

and characteristics.

5. After all adjustments have been made press and

hold the MEMORY button until the display changes.

The right and the left window will display a memory

position, for example M1 (or turn knob to select

memory of your choice). To store in M1, push the

MEMORY button again to save the Pulse Mig mode

to memory M1.

6. The display in the digital windows read as follows:

M1 Pulse MIG Argon Blends

Steel .035 Arc Cntrl 1.2

7. To save a second welding mode to a memory position of your choice, turn the SELECT knob until the

desired welding process mode is displayed in right

digital window. Then follow steps 2 thru 6.

8. Adjust the output control to the correct wire feed setting and the V450-PRO is ready to weld again.

(NOTE: The wire feed speed setting is not stored in

memory and will need to be reset.)

9. Adjust the Arc Control and note that the M1 goes

away indicating that the V450-PRO settings no

longer match what is stored in memory. Going back

to the original settings will not bring the M1 back.

You will need to push the MEMORY button to recall

the original settings in M1.

NOTE: After all memory; M1 thru M8, are used and the

welder needs to store another welding process, a new

welding process will overwrite what was originally in

the memory and will read:

Save to MEM

M1 Overwrite

M1, which previously stored Pulse Mig, is now overwritten with the new welding process.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INVERTEC® V450-PRO

Page 23

B-7 B-7

OPERATION

WELD MODE DETAILS:

Mode Range Comments

Stick Soft 55 - 570 amps The stick soft mode is the best selection for general stick

applications.

Arc Control = Arc Force

Hot Start = Initial hot start current (min = start a match set amps, Max.

= greatest hot start current) During hot start, arc force is set

at high and is fast response.

For gouging applications: Turn current up to 570 amps.

Stick Crisp 55 - 570 amps The stick crisp mode features an aggressive arc force routine well suit-

ed for Exx10, Exx11 series electrodes.

Arc Control = Arc Force

Hot Start = Initial hot start current (Mid range = welding current and will

vary up and down with knob control.) During hot start, arc

force is set at high and is fast response.

For gouging applications: Turn current up to 570 amps.

GTAW (Tig mode) 5 - 570 amps The tig mode produces a soft, steady constant current waveform for

either touch start or high frequency assisted start DC GTAW applications.

Hot Start = Min to Mid range = Touch start with low OCV

Mid to Max range = High frequency assisted starting with adjustable

OCV up to 70 volts.

GMAW - CV 10 - 45 volts The GMAW - CV mode is the best selection for general MIG welding,

Metal core, and gas shielded applications.

Arc Control = Pinch (Min = min pinch, softest arc),

(Max = max pinch, crispest arc)

FCAW-SS 10 - 45 volts The FCAW-SS mode is designed for Self Shielded Innershield products

that require tight voltage control. For example; the NR 203 series or NR

207)

Arc Control = Pinch (Min = min pinch, softest arc),

(Max = max pinch, crispest arc)

ADVANCED PULSE PANEL WELDING PROGRAMS

Gouging 60 - 570 amps The gouging mode is specifically designed for carbon arc gouging with

electrodes up to 3/8”.

GMAW - Power 0.1 - 20 KW The GMAW - power mode is similar in operation to other GMAW

modes. The power mode features a very stable short arc performance,

which is especially good when welding small diameter (.025 and .030

steel and stainless) wires for low procedures. The short arc steel and

stainless applications, a fast response for spray applications, and a

drooper type spray mode characteristic for Aluminum.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INVERTEC® V450-PRO

Page 24

B-8 B-8

OPERATION

PULSE PROGRAMS:

MODE IPM*

.030 Steel 75 - 800

.035 Steel 50 - 800

.045 Steel 60 - 800

.052 Steel 60 - 750

1/16 Steel 60 - 600

.045 Metal Core 60 - 700

.052 Metal Core 60 - 500

1/16 Metal Core 60 - 500

.030 Stainless Ar Blends 100 - 800

.030 Stainless He Ar CO

2

100 - 800

.035 Stainless Ar Blends 70 - 800

.035 Stainless He Ar CO

2

70 - 700

.045 Stainless Ar Blends 50 - 700

.045 Stainless He Ar CO

2

60 - 700