Page 1

SAE-400 SEVERE DUTY

RETURN TO MAIN MENU

For use with machine code numbers 10856, 11199, 11408

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However,

your overall safety can be

increased by proper installation

. . . and thoughtful operation on

your part. DO NOT INSTALL,

OPERATE OR REPAIR THIS

EQUIPMENT WITHOUT READING THIS MANUAL AND THE

SAFETY PRECAUTIONS CONTAINED THROUGHOUT. And,

most importantly, think before

you act and be careful.

SVM187-A

October, 2008

View Safety Info View Safety Info View Safety Info View Safety Info

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Cleveland, Ohio 44117-1199 U.S.A. TEL: 888-935-3877 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

SERVICE MANUAL

Copyright © Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Page 2

i i

SAFETY

WARNING

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer, birth defects, and other reproductive harm.

The Above For Diesel Engines

ARC WELDING can be hazardous. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information, it is strongly recommended that you

purchase a copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American Welding Society, P.O. Box 351040,

Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the

Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

The Above For Gasoline Engines

FOR ENGINE

powered equipment.

1.a. Turn the engine off before troubleshooting and maintenance

work unless the maintenance work requires it to be running.

____________________________________________________

____________________________________________________

____________________________________________________

1.d. Keep all equipment safety guards, covers and devices in posi-

tion

away from V-belts, gears, fans and all other moving parts

when starting, operating or repairing equipment.

____________________________________________________

1.e. In some cases it may be necessary to remove safety

guards

guards only when necessary and replace them when the

maintenance requiring their removal is complete.

Always use the greatest care when working near moving

parts.

___________________________________________________

1.b.Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

1.c. Do not add the fuel near an open flame weldarc or when the engine is running. Stop

ing

the engine and allow it to cool before refueling to prevent spilled fuel from vaporizing on

contact with hot engine parts and igniting. Do

not spill fuel when filling tank. If fuel is spilled,

wipe it up and do not start engine until fumes

have been eliminated.

and in good repair.Keep hands, hair, clothing and tools

to perform required maintenance. Remove

1.f. Do not put your hands near the engine fan.

Do not attempt to override the governor or

idler by pushing on the throttle control rods

while the engine is running.

1.h. To avoid scalding, do not remove the

radiator pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS

maybedangerous

2.a. Electric current flowing through any conductor causes

localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and

welding machines

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1.

Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and

work cables. If the electrode cable is on your right

side, the work cable should also be on your right side.

___________________________________________________

1.g. To prevent accidentally starting gasoline engines while

turning

the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

2.d.4. Connect the work cable to the workpiece as close as

possible to the area being welded.

2.d.5. Do not work next to welding power source.

Mar ‘95

SAE-400 SEVERE DUTY

Page 3

ii ii

SAFETY

ELECTRIC SHOCK can kill.

3.a. The electrode and work (or ground) circuits

are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare

skin or wet clothing. Wear dry, hole-free

gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

must be performed under electrically hazardous

conditions (in damp locations or while wearing wet

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic

welding gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection

should be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical

(earth) ground.

3.f.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see Items 6.c. and 8.

ARC RAYS can burn.

4.a. Use a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. Headshield and filter lens

should conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

can be dangerous.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases.When welding, keep

your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing zone. When

welding with electrodes which require special

ventilation such as stainless or hard facing (see

instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure as

low as possible and below Threshold Limit Values (TLV)

using local exhaust or mechanical ventilation. In

confined spaces or in some circumstances, outdoors, a

respirator may be required. Additional precautions are

also required when welding on galvanized steel.

5. b. The operation of welding fume control equipment is affected

by various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure level should be checked upon installation and periodically thereafter to be certain it is within applicable OSHA PEL

and ACGIH TLV limits.

5.c.

Do not weld in locations near chlorinated hydrocarbon

coming from degreasing, cleaning or spraying operations.

The heat and rays of the arc can react with solvent vapors

form phosgene, a highly toxic gas, and other irritating products.

5.d. Shielding gases used for arc welding can displace air and

cause injury or death. Always use enough ventilation,

especially in confined areas, to insure breathing air is safe.

vapors

to

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your

employer’s safety practices. MSDS forms are available from

your welding distributor or from the manufacturer.

5.f. Also see item 1.b.

Aug ‘06

SAE-400 SEVERE DUTY

Page 4

iii iii

SAFETY

WELDING and CUTTING

SPARKS can

cause fire or explosion.

6.a.

Remove fire hazards from the welding area.

If this is not possible, cover them to prevent

Remember that welding sparks and hot

materials from welding can easily go through small cracks

and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site,

special precautions should be used to prevent hazardous

situations. Refer to “Safety in Welding and Cutting” (ANSI

Standard Z49.1) and the operating information for the

equipment being used.

6.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact can

cause overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances

inside. They can cause an explosion even

been “cleaned”. For information, purchase “Recommended

Safe Practices for the

Containers and Piping That Have Held Hazardous

Substances”, AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

Sparks and spatter are thrown from the welding arc. Wear oil

6.f.

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a

welding area.

6.g. Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

increase the possibility of the welding current passing

through lifting chains, crane cables or other alternate circuits.

This can create fire hazards or overheat lifting chains or

cables until they fail.

6.h. Also see item 1.c.

the welding sparks from starting a fire.

though

they have

Preparation

for Welding and Cutting of

CYLINDER may explode

if damaged.

7.a. Use only compressed gas cylinders

containing the correct shielding gas for the

process used and properly operating

regulators designed for the gas and

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

7.b. Always keep cylinders in an upright position securely

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected to

physical damage.

• A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

7.g. Read and follow the instructions on compressed gas

cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in

Cylinders,” available from the Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202.

FOR ELECTRICALLY

powered equipment.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accordance with the U.S. National

Electrical Code, all local codes and the manufacturer’s

recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention

During Welding, Cutting and Other Hot Work”, available from

NFPA, 1 Batterymarch Park,PO box 9101, Quincy, Ma

022690-9101.

6.j. Do not use a welding power source for pipe thawing.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Jan ‘07

SAE-400 SEVERE DUTY

Page 5

iv iv

SAFETY

PRÉCAUTIONS DE SÛRETÉ

Pour votre propre protection lire et observer toutes les instructions

et les précautions de sûreté specifiques qui parraissent dans ce

manuel aussi bien que les précautions de sûreté générales suivantes:

Sûreté Pour Soudage A LʼArc

1. Protegez-vous contre la secousse électrique:

a. Les circuits à l’électrode et à la piéce sont sous tension

quand la machine à souder est en marche. Eviter toujours

tout contact entre les parties sous tension et la peau nue

ou les vétements mouillés. Porter des gants secs et sans

trous pour isoler les mains.

b. Faire trés attention de bien s’isoler de la masse quand on

soude dans des endroits humides, ou sur un plancher metallique ou des grilles metalliques, principalement dans

les positions assis ou couché pour lesquelles une grande

partie du corps peut être en contact avec la masse.

c. Maintenir le porte-électrode, la pince de masse, le câble de

soudage et la machine à souder en bon et sûr état defonctionnement.

d.Ne jamais plonger le porte-électrode dans l’eau pour le

refroidir.

e. Ne jamais toucher simultanément les parties sous tension

des porte-électrodes connectés à deux machines à souder

parce que la tension entre les deux pinces peut être le total

de la tension à vide des deux machines.

f. Si on utilise la machine à souder comme une source de

courant pour soudage semi-automatique, ces precautions

pour le porte-électrode s’applicuent aussi au pistolet de

soudage.

6. Eloigner les matériaux inflammables ou les recouvrir afin de

prévenir tout risque d’incendie dû aux étincelles.

7. Quand on ne soude pas, poser la pince à une endroit isolé de

la masse. Un court-circuit accidental peut provoquer un

échauffement et un risque d’incendie.

8. S’assurer que la masse est connectée le plus prés possible de

la zone de travail qu’il est pratique de le faire. Si on place la

masse sur la charpente de la construction ou d’autres endroits

éloignés de la zone de travail, on augmente le risque de voir

passer le courant de soudage par les chaines de levage,

câbles de grue, ou autres circuits. Cela peut provoquer des

risques d’incendie ou d’echauffement des chaines et des

câbles jusqu’à ce qu’ils se rompent.

9. Assurer une ventilation suffisante dans la zone de soudage.

Ceci est particuliérement important pour le soudage de tôles

galvanisées plombées, ou cadmiées ou tout autre métal qui

produit des fumeés toxiques.

10. Ne pas souder en présence de vapeurs de chlore provenant

d’opérations de dégraissage, nettoyage ou pistolage. La

chaleur ou les rayons de l’arc peuvent réagir avec les vapeurs

du solvant pour produire du phosgéne (gas fortement toxique)

ou autres produits irritants.

11. Pour obtenir de plus amples renseignements sur la sûreté, voir

le code “Code for safety in welding and cutting” CSA Standard

W 117.2-1974.

2. Dans le cas de travail au dessus du niveau du sol, se protéger

contre les chutes dans le cas ou on recoit un choc. Ne jamais

enrouler le câble-électrode autour de n’importe quelle partie du

corps.

3. Un coup d’arc peut être plus sévère qu’un coup de soliel, donc:

a. Utiliser un bon masque avec un verre filtrant approprié ainsi

qu’un verre blanc afin de se protéger les yeux du rayonnement de l’arc et des projections quand on soude ou

quand on regarde l’arc.

b. Porter des vêtements convenables afin de protéger la peau

de soudeur et des aides contre le rayonnement de l‘arc.

c. Protéger l’autre personnel travaillant à proximité au

soudage à l’aide d’écrans appropriés et non-inflammables.

4. Des gouttes de laitier en fusion sont émises de l’arc de

soudage. Se protéger avec des vêtements de protection libres

de l’huile, tels que les gants en cuir, chemise épaisse, pantalons sans revers, et chaussures montantes.

5. Toujours porter des lunettes de sécurité dans la zone de

soudage. Utiliser des lunettes avec écrans lateraux dans les

zones où l’on pique le laitier.

PRÉCAUTIONS DE SÛRETÉ POUR

LES MACHINES À SOUDER À

TRANSFORMATEUR ET À

REDRESSEUR

1. Relier à la terre le chassis du poste conformement au code de

l’électricité et aux recommendations du fabricant. Le dispositif

de montage ou la piece à souder doit être branché à une

bonne mise à la terre.

2. Autant que possible, I’installation et l’entretien du poste seront

effectués par un électricien qualifié.

3. Avant de faires des travaux à l’interieur de poste, la debrancher à l’interrupteur à la boite de fusibles.

4. Garder tous les couvercles et dispositifs de sûreté à leur place.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Mar ‘93

SAE-400 SEVERE DUTY

Page 6

v v

SAFETY

Electromagnetic Compatibility (EMC)

Conformance

Products displaying the CE mark are in conformity with European Community Council Directive of 3 May

1989 on the approximation of the laws of the Member States relating to electromagnetic compatibility

(89/336/EEC). It was manufactured in conformity with a national standard that implements a harmonized

standard: EN 60974-10 Electromagnetic Compatibility (EMC) Product Standard for Arc Welding Equipment.

It is for use with other Lincoln Electric equipment. It is designed for industrial and professional use.

Introduction

All electrical equipment generates small amounts of electromagnetic emission. Electrical emission may be

transmitted through power lines or radiated through space, similar to a radio transmitter. When emissions

are received by other equipment, electrical interference may result. Electrical emissions may affect many

kinds of electrical equipment; other nearby welding equipment, radio and TV reception, numerical controlled

machines, telephone systems, computers, etc. Be aware that interference may result and extra precautions

may be required when a welding power source is used in a domestic establishment.

Installation and Use

The user is responsible for installing and using the welding equipment according to the manufacturer’s

instructions. If electromagnetic disturbances are detected then it shall be the responsibility of the user of the

welding equipment to resolve the situation with the technical assistance of the manufacturer. In some cases

this remedial action may be as simple as earthing (grounding) the welding circuit, see Note. In other cases

it could involve construction of an electromagnetic screen enclosing the power source and the work complete with associated input filters. In all cases electromagnetic disturbances must be reduced to the point

where they are no longer troublesome.

Note: The welding circuit may or may not be earthed for safety reasons according to national

codes. Changing the earthing arrangements should only be authorized by a person who is

competent to access whether the changes will increase the risk of injury, e.g., by allowing

parallel welding current return paths which may damage the earth circuits of other equipment.

Assessment of Area

Before installing welding equipment the user shall make an assessment of potential electromagnetic problems in the surrounding area. The following shall be taken into account:

a) other supply cables, control cables, signaling and telephone cables; above, below and adjacent to the

welding equipment;

b) radio and television transmitters and receivers;

c) computer and other control equipment;

d) safety critical equipment, e.g., guarding of industrial equipment;

e) the health of the people around, e.g., the use of pacemakers and hearing aids;

f) equipment used for calibration or measurement

g) the immunity of other equipment in the environment. The user shall ensure that other equipment being

used in the environment is compatible. This may require additional protection measures;

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

h) the time of day that welding or other activities are to be carried out.

L10093 3-1-96H

SAE-400 SEVERE DUTY

Page 7

vi vi

SAFETY

Electromagnetic Compatibility (EMC)

The size of the surrounding area to be considered will depend on the structure of the building and other

activities that are taking place. The surrounding area may extend beyond the boundaries of the premises.

Methods of Reducing Emissions

Mains Supply

Welding equipment should be connected to the mains supply according to the manufacturer’s recommendations. If interference occurs, it may be necessary to take additional precautions such as filtering of the

mains supply. Consideration should be given to shielding the supply cable of permanently installed welding

equipment, in metallic conduit or equivalent. Shielding should be electrically continuous throughout its

length. The shielding should be connected to the welding power source so that good electrical contact is

maintained between the conduit and the welding power source enclosure.

Maintenance of the Welding Equipment

The welding equipment should be routinely maintained according to the manufacturer’s recommendations.

All access and service doors and covers should be closed and properly fastened when the welding equipment is in operation. The welding equipment should not be modified in any way except for those changes

and adjustments covered in the manufacturers instructions. In particular, the spark gaps of arc striking and

stabilizing devices should be adjusted and maintained according to the manufacturer’s recommendations.

Welding Cables

The welding cables should be kept as short as possible and should be positioned close together, running at

or close to floor level.

Equipotential Bonding

Bonding of all metallic components in the welding installation and adjacent to it should be considered.

However, metallic components bonded to the work piece will increase the risk that the operator could

receive a shock by touching these metallic components and the electrode at the same time. The operator

should be insulated from all such bonded metallic components.

Earthing of the Workpiece

Where the workpiece is not bonded to earth for electrical safety, not connected to earth because of its size

and position, e.g., ships hull or building steelwork, a connection bonding the workpiece to earth may reduce

emissions in some, but not all instances. Care should be taken to prevent the earthing of the workpiece

increasing the risk of injury to users, or damage to other electrical equipment. Where necessary, the connection of the workpiece to earth should be made by a direct connection to the workpiece, but in some

countries where direct connection is not permitted, the bonding should be achieved by suitable capacitance, selected according to national regulations.

Screening and Shielding

Selective screening and shielding of other cables and equipment in the surrounding area may alleviate

problems of interference. Screening of the entire welding installation may be considered for special applica-

1

tions.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

_________________________

1

Portions of the preceding text are contained in EN 60974-10: “Electromagnetic Compatibility (EMC)

product standard for arc welding equipment.”

SAE-400 SEVERE DUTY

L10093 3-1-96H

Page 8

vii vii

RETURN TO MAIN MENU

- MASTER TABLE OF CONTENTS FOR ALL SECTIONS -

RETURN TO MAIN INDEX

Page

Safety ...........................................................................i-iv

Installation..................................................................SectionA

Operation ..................................................................SectionB

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section C

Maintenance ................................................................SectionD

TheoryofOperation ..........................................................SectionE

Troubleshooting and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section F

ElectricalDiagrams ..........................................................SectionG

PartsManual ...................................................................P-530

SAE-400 SEVERE DUTY

Page 9

A-1 A-1

Installation.............................................................................A-1

TechnicalSpecifications ................................................................A-2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Location/Ventilation ..................................................................A-3

Stacking ............................................................................A-3

AngleOfOperation ...................................................................A-3

Lifting ..............................................................................A-3

High Altitude Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

VehicleMounting .....................................................................A-4

TABLE OF CONTENTS - INSTALLATION SECTION

Pre-OperationEngineService ...........................................................A-4

EngineBreak-In ......................................................................A-5

Engine Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

BatteryConnection....................................................................A-5

Spark Arrestor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Welding Output Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Machine Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...............A-6

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 10

A-2 A-2

INSTALLATION

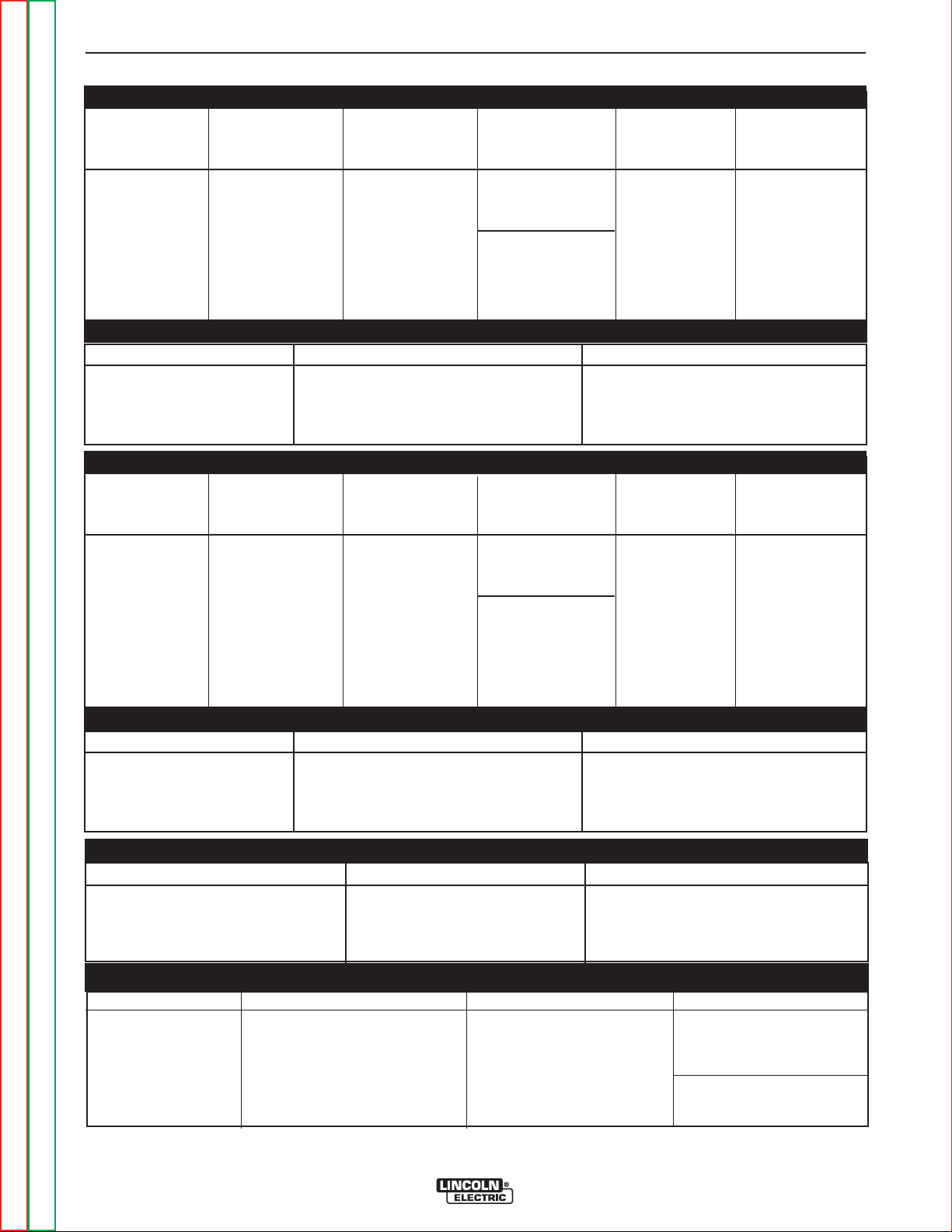

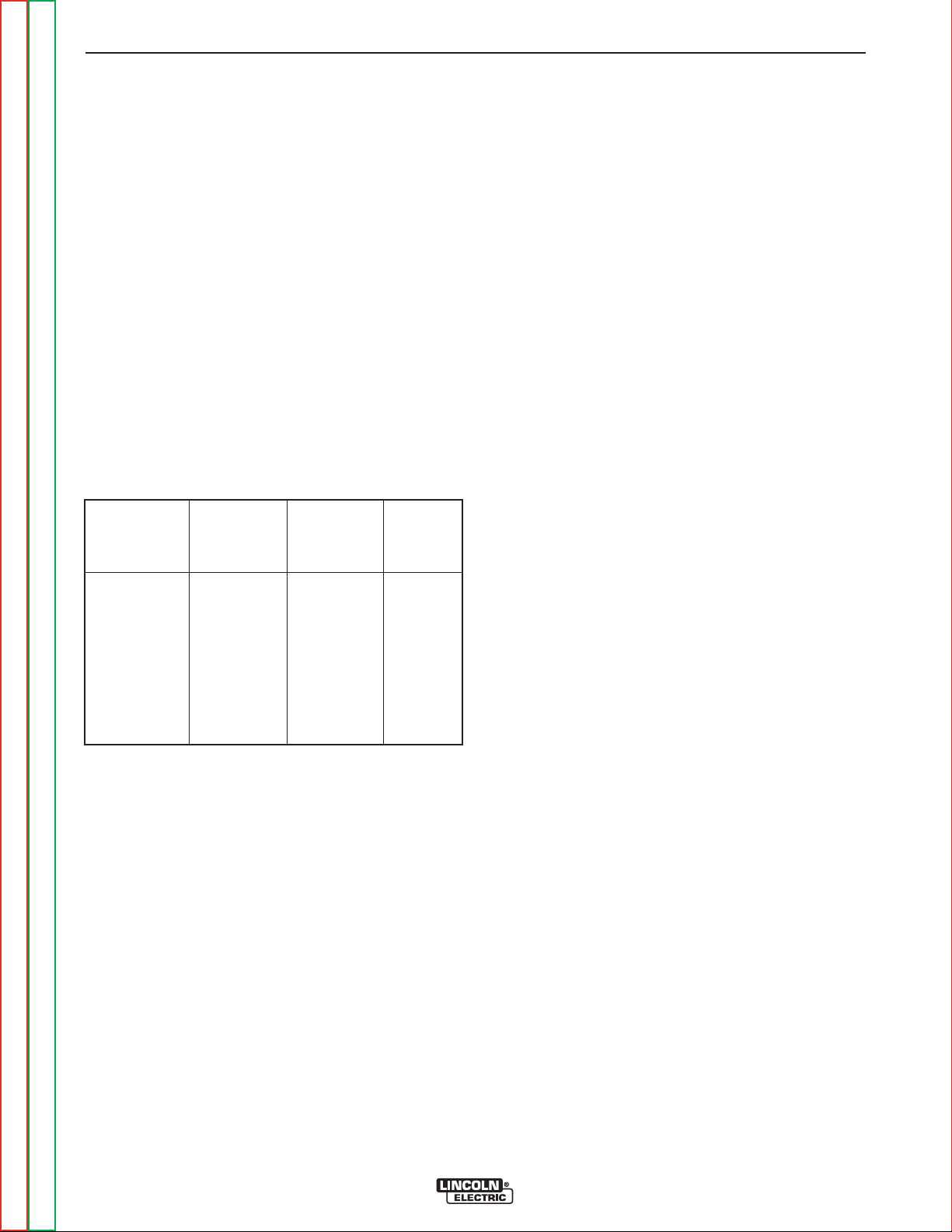

TECHNICAL SPECIFICATIONS - SAE-400 SEVERE DUTY

INPUT - DIESEL ENGINE CODE 10856

-

Make/Model Description Speed (RPM) Displacement Starting Capacities

System

Perkins 4 cylinder High Idle 1800 256 cu. in

1104.42 Diesel 71 HP @ Low Idle 1100 (4.2 L)

Engine 1725 RPM Full Load 1725

Bore x Stroke Oil: 8.5 Qts.

3.875” x 5.00”

(98.4 mm x 127.0mm) Coolant: 3.6 gal.

12VDC batteries

(2

) & Starter 85.1 L

Fuel: 22.5 gal.

8.04 L

13.63 L

RATED OUTPUT - WELDER CODES 10856

Duty Cycle

60% (NEMA) 400 amps 36 volts

60% (Lincoln Plus) 400 amps 40 volts

100% (Lincoln Plus) 400 amps 40 volts

(1)

Welding Output Volts at Rated Amps

INPUT - DIESEL ENGINE CODE 11199 &11408

Make/Model Description Speed (RPM) Displacement Starting Capacities

System

Perkins 4 cylinder High Idle 1800 269 cu. in

1104C-44 Diesel 68.4 HP @ Low Idle 1100 (4.2 L)

Engine 1725 RPM Full Load 1725

Bore x Stroke Oil: 10.1 Qts.

4.13” x 5.00”

(105 mm x 127mm) Coolant: 3.4 gal.

12VDC batteries

(2

) & Starter 85.1 L

Fuel: 22.5 gal.

9.6 L

12.8 L

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Duty Cycle

35% (NEMA) 500 amps 40 volts

100% (Lincoln Plus) 400 amps 36 volts

100% (Lincoln Plus) 400 amps 40 volts

(1)

Welding Output Volts at Rated Amps

OUTPUT - WELDER AND GENERATOR

RATED OUTPUT - WELDER CODES 11199 &11408

Welding Range Open Circuit Voltage Auxiliary Power

80 - 575 Amps 97 Max. OCV 115/230 VAC

@ 1800 RPM 3000 Watts, 60 Hz.

100% Duty Cycle

PHYSICAL DIMENSIONS

HEIGHT WIDTH DEPTH WEIGHT

Codes

50.13 in. 28.00 in. 83.00 in. 11199 2,210 lbs.

11408 1002.4 kg

1273.3 mm 711.2 mm 2108.2 mm

10856 2178 lbs.

(1)

Based on a 10 minute period.

SAE-400 SEVERE DUTY

988.0 kg

Page 11

A-3 A-3

Read this entire installation section before you

start installation.

SAFETY PRECAUTIONS

WARNING

Do not attempt to use this equipment until you

have thoroughly read all operating and maintenance manuals supplied with your machine. They

include important safety precautions, detailed

engine starting, operating and maintenance

instructions and parts lists.

INSTALLATION

CAUTION

DO NOT MOUNT OVER COMBUSTIBLE SURFACES.

Where there is a combustible surface directly

under stationary or fixed electrical equipment, that

surface shall be covered with a steel plate at least

.06”(1.6mm) thick, which shall extend not less than

5.90”(150mm) beyond the equipment on all sides.

------------------------------------------------------------------------

STACKING

These machines cannot be stacked.

ANGLE OF OPERATION

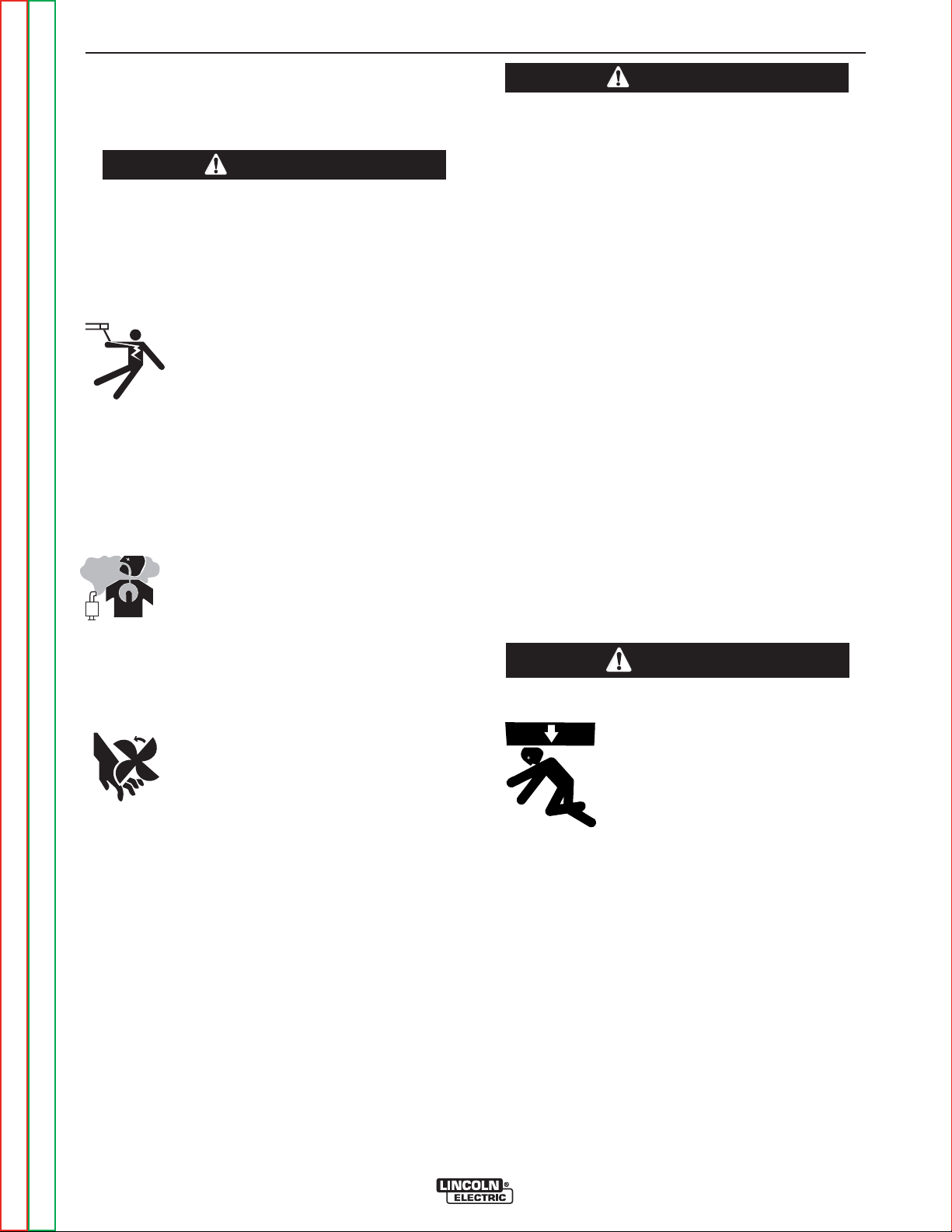

ELECTRIC SHOCK can kill.

•Do not touch electrically live parts

such as output terminals or internal

wiring.

•Insulate yourself from the work and

ground.

•Always wear dry insulating gloves.

------------------------------------------------------------------------

To achieve optimum engine performance the machine

should be run in a level position. The maximum angle

of operation for the Perkins engine is 30 degrees in all

directions. If the engine is to be operated at an angle,

provisions must be made for checking and maintaining

the oil level at the normal (FULL) oil capacity in the

engine crankcase. When operating the welder at an

angle, the effective fuel capacity will be slightly less

than the specified 22.5 gallons.

LIFTING

ENGINE EXHAUST can kill.

The equipment lift bail should be used to lift the

•

Use in open, well ventilated areas or

vent exhaust outside

machine.

•Do not stack anything near the

engine.

------------------------------------------------------------------------

MOVING PARTS can injure.

•

Do not operate with doors open or

guards off.

•Stop engine before servicing.

•Keep away from moving parts

------------------------------------------------------------------------

Only qualified personnel should install, use or

service

this equipment

LOCATION/VENTILATION

The welder should be located to provide an unrestricted

flow of clean, cool air to the cooling air inlets and to avoid

restricting the cooling air outlets. Also, locate the welder

so that the engine exhaust fumes are properly vented to

an outside area.

WARNING

• Lift only with equipment of

adequate lifting capacity.

• Be sure machine is stable

when lifting.

• Do not lift this machine using

lift bail if it is equipped with a

heavy accessory such as trailer or gas cylinder.

FALLING • Do not lift machine if lift bail is

damaged.

EQUIPMENT can • Do not operate machine while

cause injury. suspended from lift bail.

------------------------------------------------------------------------

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 12

A-4 A-4

HIGH ALTITUDE OPERATION

At higher altitudes, output derating may be necessary.

As a rule of thumb, derate the welder output 5% for

every 500 meters (1640 ft.) above 1000 meters (3280

ft.).

Contact a Perkins Service Representative for any

engine adjustments that may be required for high altitude operation.

INSTALLATION

• Only transport this equipment on serviceable vehicles which are rated and designed for such loads.

• Distribute, balance and secure loads so vehicle is

stable under conditions of use.

• Do not exceed maximum rated loads for components such as suspension, axles and tires.

• Mount equipment base to metal bed or frame of

vehicle.

• Follow vehicle manufacturerʼs instruction.

----------------------------------------------------------------------------

PRE-OPERATION ENGINE SERVICE

TOWING

The recommended trailers for use with this equipment

for in-plant and yard towing by a vehicle

K767-1 and K956-1. The K956-1 is also designed to be

used at highway speeds

(1)

.If the user adapts a nonLincoln trailer, he must assume responsibility that the

method of attachment and usage does not result in a

safety hazard or damage the welding equipment.

Some of the factors to be considered are as follows:

1. Design capacity of trailer vs. weight of Lincoln

equipment and likely additional attachments.

2. Proper support of, and attachment to, the base of

the welding equipment so that there will be no

undue stress to the trailer’s framework.

3. Proper placement of the equipment on the trailer to

insure stability side to side and front to back when

being moved and when standing by itself.

4. Typical conditions of use, such as travel speed,

roughness of surface on which the trailer will be

operated, and environmental conditions.

5. Proper preventative maintenance of trailer.

6. Conformance with federal, state and local laws.

(1)

For highway use, consult applicable federal, state

and local laws regarding specific requirements for

use on public highways, such as brakes, lights, fenders, etc.

(1)

are Lincoln’s

1

VEHICLE MOUNTING

WARNING

READ the engine operating and maintenance instructions supplied with this machine.

ENGINE OIL

The engine is shipped with the engine crankcase filled

with high quality SAE 10W-30 oil (API class CD or better). Check the oil level before starting the engine. If it is

not up to the full mark on the dip stick, add oil as required.

Check the oil level every four hours of running time during

the first 35 running hours. Refer to the engine Operator’s

Manual for specific oil recommendations and break-in

information. The oil change interval is dependent on the

quality of the oil and the operating environment. Refer to

the engine Operator’s Manual for the proper service and

maintenance intervals.

FUEL USE DIESEL FUEL ONLY

WARNING

• Stop engine while fueling.

• Do not smoke when fueling.

• Keep sparks and flame away

from tank.

• Do not leave unattended while

fueling.

DIESEL FUEL

can cause fire.

• Wipe up spilled fuel and allow

fumes to clear before starting

engine.

• Do not overfill tank, fuel

expansion may cause overflow.

DIESEL FUEL ONLY

------------------------------------------------------------------------

Fill the fuel tank with clean, fresh diesel fuel.

The capacity of the fuel tank is 22.5 gallons (85.1 liters).

See engine Operator’s Manual for specific fuel recommendations.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Improperly mounted concentrated loads may cause

unstable vehicle handling and tires or other components to fail.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

NOTE:

fuel shutoff valve is open.

SAE-400 SEVERE DUTY

Before attemting to start the engine, be sure the

Page 13

A-5 A-5

ENGINE BREAK-IN

Lincoln Electric selects high quality, heavy-duty industrial engines for the portable welding machines we

offer. While it is normal to see a small amount of

crankcase oil consumption during initial operation,

excessive oil use, wetstacking (oil or tar like substance

at the exhaust port), or excessive smoke is not normal.

Larger machines with a capacity of 350 amperes and

higher, which are operated at low or no-load conditions

for extended periods of time are especially susceptible

to the conditions described above. To accomplish successful engine break-in, most diesel-powered equipment needs only to be run at a reasonably heavy load

within the rating of the welder for some period of time

during the engine’s early life. However, if the welder is

subjected to extensive light loading, occasional moderate to heavy loading of the engine may sometimes be

necessary. Caution must be observed in correctly

loading a diesel/generator unit.

1. Connect the welder output studs to a suitable resistive load bank. Note that any

attempt to short the output studs by connecting the welding leads together, direct

shorting of the output studs, or connecting

the output leads to a length of steel will

result in catastrophic damage to the generator and voids the warranty.

INSTALLATION

BATTERY CONNECTION

WARNING: Use caution as the electrolyte is a strong

acid that can burn skin and damage eyes.

Remove and discard the insulating caps from the negative battery terminals. Attach and tighten negative

battery cable terminals.

NOTE:

batteries; if unused for several months, the batteries

may require a booster charge. Be careful to charge the

batteries with the correct polarity. Make sure that the

batteries are level while charging.

To prevent EXPLOSION when:

● INSTALLING A NEW BATTERY — disconnect

● CONNECTING A BATTERY CHARGER —

This machine is furnished with wet charged

negative cable from old battery first and

connect to new battery last.

remove battery from welder by disconnecting

negative cable first, then positive cable and

battery clamp. When reinstalling, connect

negative cable last. Keep well ventilated.

WARNING

GASES FROM BATTERY can explode.

● Keep sparks, flame and cigarettes

away from battery.

2. Set the welder controls for an output current and voltage within the welder rating

and duty cycle. Note that any attempt to

exceed the welder rating or duty cycle for

any period of time will result in catastrophic

damage to the generator and voids the

warranty.

3. Periodically shut off the engine and check

the crankcase oil level.

ENGINE COOLING SYSTEM

The cooling system has been filled at the factory with

a 50-50 mixture of ethylene glycol antifreeze and

water. Check the radiator level and add a 50-50 solution as needed. (See Engine Manual or antifreeze

container for alternate antifreeze recommendation.)

● USING A BOOSTER — connect positive lead to

battery first then connect negative lead to negative battery lead at the lower control panel

support.

BATTERY ACID can burn eyes and

skin.

● Wear gloves and eye protection

and be careful when working near

battery.

● Follow instructions printed on battery.

IMPORTANT: To prevent ELECTRICAL DAMAGE

WHEN:

a) Installing new batteries.

b) Using a booster.

Use correct polarity — Negative Ground.

To prevent BATTERY BUCKLING, tighten nuts on batteries only until snug. DO NOT OVERTIGHTEN.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 14

A-6 A-6

SPARK ARRESTOR

INSTALLATION

MACHINE GROUNDING

WARNING

WARNING

Some federal, state or local laws may require that

diesel engines be equipped with exhaust spark

arrestors when they are operated in certain locations

where unarrested sparks may present a fire hazard.

SAE-400 Severe Duty machines are factory equipped

with either a muffler that qualifies as a spark arrestor or

with a separate Spark Arrestor Unit.

Qualified mufflers have a clean out service plug, and

will have “USDA FS 51001C QUALIFIED SPARK

ARRESTOR” stamped on the muffler shell. If a spark

arrestor is required, and the muffler is not stamped,

secure the separate spark arrestor to the outlet tube of

the muffler using the clamp provided.

Any type of spark arrestor must be serviced and properly maintained.

• Spark Arrestor and Muffler may be hot!

Allow engine to cool before

Do not operate engine while

servicing spark arrestor!

servicing spark arrestor!

CAUTION

An incorrect spark arrester may lead to damage to

the engine or adversely affect performance.

---------------------------------------------------------------------

Because this portable engine driven welder creates its

own power, it is not necessary to connect its frame to

an earth ground, unless the machine is connected to

premises wiring (home, shop, etc.).

To prevent dangerous electric shock, other equipment

powered by this engine driven welder must:

a) be grounded to the frame of the welder using a

grounded type plug,

or

b) be double insulated.

When this welder is mounted on a truck or trailer, its

frame must be securely connected to the metal frame

of the vehicle. When this engine driven welder is connected to premises wiring such as that in a home or

shop, its frame must be connected to the system earth

ground. See the article on grounding in the latest U.S.

National Electrical Code and the local code.

In general, if the machine is to be grounded, it should

be connected with a #8 or larger copper wire to a solid

earth ground such as a metal water pipe going into the

ground for at least ten feet and having no insulated

joints, or to the metal framework of a building which

has been effectively grounded. The U.S. National

Electrical Code lists a number of alternate means of

grounding electrical equipment. A machine grounding

stud marked with the symbol is provided on the

welding generator frame foot.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

WELDING OUTPUT CABLES

With the engine off, connect the electrode and work

cables to the studs provided. These connections

should be checked periodically and tightened if necessary.

Listed in Table A.1 are copper cable sizes recommended for the rated current and duty cycle. Lengths

stipulated are the distance from the welder to work and

back to the welder again. Cable sizes are increased

for greater lengths primarily for the purpose of minimizing cable voltage drop.

Table A.1 Combined Length of Electrode and

Work Cables.

TOTAL COMBINED LENGTH OF ELEC-

TRODE AND WORK CABLES

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

AMPS

@60%

Duty Cycle

400

Up to 100 FT.

(Up to 30m)

2/0 AWG

100-200 FT.

(30m-61m)

3/0 AWG

200-250 FT.

(61m-76m)

4/0 AWG

SAE-400 SEVERE DUTY

Page 15

B-1 B-1

Operation..............................................................................B-1

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Additional Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

GeneralDescriptions ..................................................................B-2

Welder .............................................................................B-2

Auxiliary Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

DesignFeaturesAndAdvantages ........................................................B-3

Duty Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....B-3

Engine Controls: Function / Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

TABLE OF CONTENTS - OPERATION SECTION

WelderControls:Function/Operation.....................................................B-5

RemoteControl ......................................................................B-5

Auxiliary Power Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Engine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

StartingInstructions ...................................................................B-6

TypicalFuelConsumption ..............................................................B-7

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 16

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

B-2 B-2

OPERATION

OPERATING INSTRUCTIONS

WELDING SPARKS can cause

Read and understand this entire section before operating your equipment.

SAFETY INSTRUCTIONS

Do not attempt to use this equipment until you have

thoroughly read all operating and maintenance manuals supplied with your machine. They include important

safety precautions, detailed engine starting, operating

and maintenance instructions and parts lists.

WARNING

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrodes with your skin or wet clothing.

• Insulate yourself from the work and

ground.

• Always wear dry insulating gloves.

• Do not use AC welder if your clothing, gloves or

work area is damp or if working on, under or

inside workpiece.

Use the following equipment:

• Semiautomatic DC constant voltage

(wire) welder.

• DC manual (stick) welder.

• AC welder with reduced voltage control.

------------------------------------------------------------------------

ARC RAYS can injure eyes and

burn skin.

• Wear eye, ear, and body protection.

----------------------------------------------------------

• Only qualified personnel should install, use or

service this equipment.

• Consult instruction manual before operating.

----------------------------------------------------------------------

Before operating, read and understand the manufacturerʼs instructions for this equipment and the

consumables to be used including the Material

Safety Data Sheet (MSDS) and follow your

employerʼs safety practices.

------------------------------------------------------------------------

FUMES AND GASES can be

dangerous to your health.

• Keep your head out of fumes.

• Use enough ventilation or exhaust

at the arc, or both, to keep the fumes

and gases from your breathing zone

and general area.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

------------------------------------------------------------------------

ADDITIONAL SAFETY PRECAUTIONS

Always operate the welder with the hinged doors

closed as these provide maximum protection from

moving parts and insure proper cooling air flow.

Read carefully the Safety Precautions page in the

Instruction Manual before operating this machine.

Always follow these and any other safety procedures

included in this manual and in the engine and compressor instruction manuals.

GENERAL DESCRIPTION

The SAE-400 SEVERE DUTY is a diesel engine driven

welding power source. The machine uses a DC generator for DC stick electrode welding and an AC exciter

for 115/230 VAC auxiliary power. As a generator it can

supply up to 3,000 watts of 115/230 volt AC power. As

a welder it provides up to 575 amps of DC constant

current output.

The engine is a 4-cylinder water cooled diesel made by

Perkins.

RECOMMENDED APPLICATIONS

WELDER

The SAE-400 SEVERE DUTY provides excellent constant current DC welding output for stick (SMAW) welding.

AUXILIARY POWER

The SAE-400 SEVERE DUTY provides 3 KW of

115/230 VAC output for auxiliary power and emergency standby power.

SAE-400 SEVERE DUTY

fire or explosion.

• Do not weld near flammable material .

• Do not weld on containers that have

held flammable material.

---------------------------------------------

MOVING PARTS can injure.

• Keep away from moving parts

• Do not operate with doors open or

guards off.

• Stop engine before servicing.

-------------------------------------------------------

ENGINE EXHAUST can kill.

• Use

in open, well ventilated areas or

vent exhaust outside.

Page 17

B-3 B-3

DESIGN FEATURES AND ADVANTAGES

OPERATION

DUTY CYCLE

FOR STICK WELDING

• Excellent DC constant current output for stick welding applications.

• Continuous adjustment of both voltage and current

for unsurpassed welds on demanding jobs.

• Remote control capability standard.

FOR AUXILIARY POWER

• 3,000 watts of 115/230 VAC, 60 Hz auxiliary power.

• One 20 amp 115 VAC duplex receptacle for up to 26

amps of 115 VAC power.

• One 15 amp, 230 VAC duplex receptacle for up to 13

amps of 230 VAC power.

• Weld and AC auxiliary power at the same time (with-

in the limits shown on the chart below).

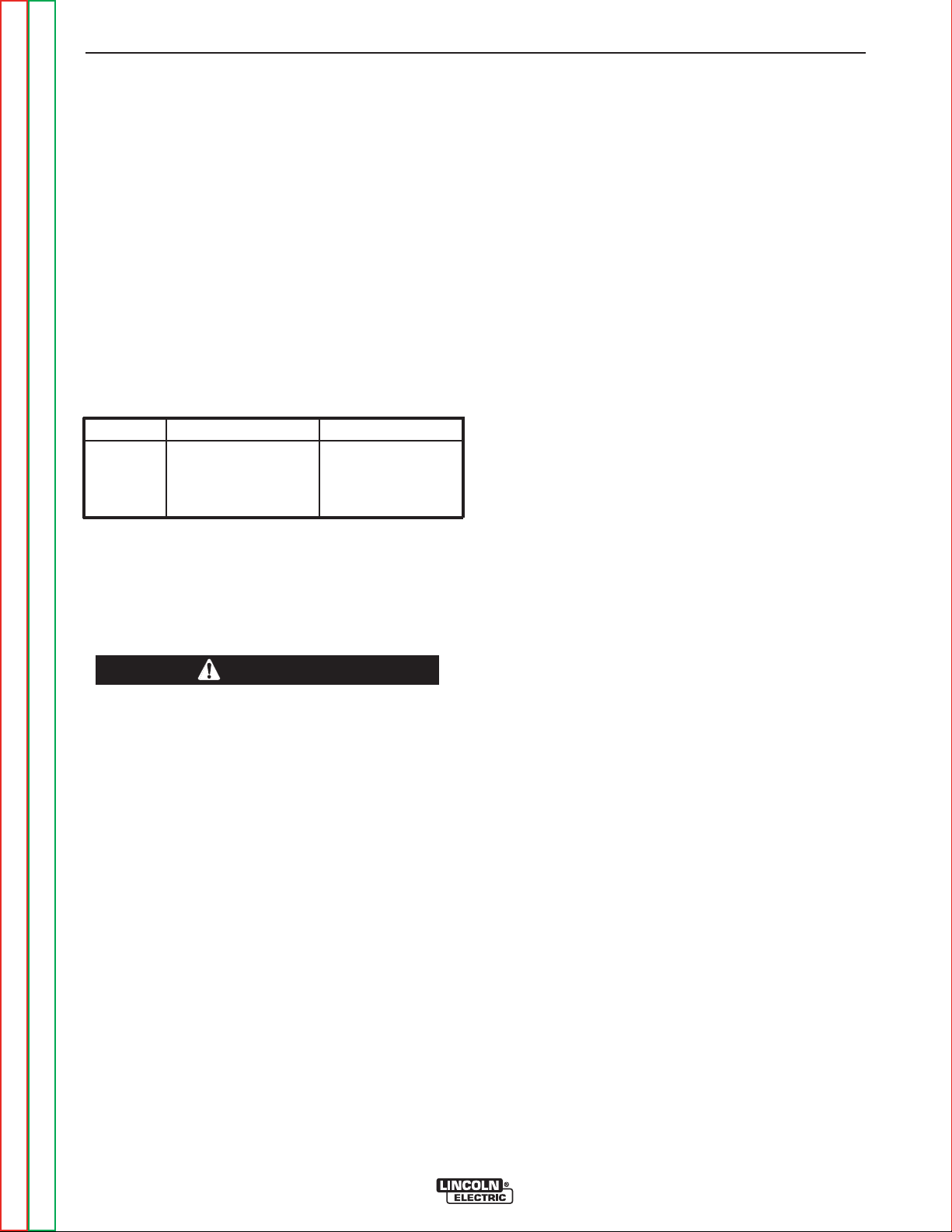

Welding Using Only Using Only Total

Current, Amps 115V Circuit, 230V Circuit, Aux.

@ NEMA Arc Amps Amps kVA

Vol ts

Duty cycle is the percentage of time the load is being

applied in a 10 minute period. For example a 60% duty

cycle, represents 6 minutes of load and 4 minutes of

no load in a 10 minute period.

026133.0

100 19.5 9.75 2.25

200 13 6.5 1.5

300 6.5 3.25 0.75

400 0 0 0

500• 0 0 0

* Codes 11199 and 11408

OTHER FEATURES

• Perkins 4-cylinder, water cooled diesel engine.

Designed for long life, easy maintenance and excellent fuel economy.

• Engine protection system shuts the engine down for

low engine oil pressure or high coolant temperature,

alternator failure, or broken belt.

• Electronic Engine Idler. Engine automatically goes to

low idle in 10 to 14 seconds after welding or use of

auxiliary power stops. Includes high idle switch.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

• Gauges for engine oil pressure, coolant temperature

and battery charging ammeter.

• Engine hour meter standard.

• Extended range 22.5 gallon (85.1 L) fuel tank.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 18

B-4 B-4

OPERATION

ENGINE CONTROLS

ENGINE PROTECTION SYSTEM

IGNITION SWITCH

The engine protection system shuts down the engine

When placed in the “ON” position, this switch energizes the fuel solenoid. When placed in the “OFF” position, the flow of fuel to the injection pump is stopped to

shut down the engine.

“IDLER” SWITCH

The idler switch has two positions, “HIGH” and

“AUTO”.

When in “HIGH” ( ) position, the engine will run

continuously at high idle.

When in “AUTO” ( / ) idle position, the idler

operates as follows:

a. Welding

When the electrode touches the work, the welding

arc is initiated and the engine accelerates to full

speed.

After welding ceases (and no auxiliary power is

being drawn), the engine will return to low idle after

approximately 10 to 14 seconds.

under high coolant temperature, low engine oil pres-

sure, broken belt or alternator failure conditions by

allowing the fuel solenoid valve to close.

AIR INTAKE SHUT-OFF

Code 10856:

This code uses an air intake shut-off device that is

manually engaged and blocks all intake air from enter-

ing the engine.

To shut down the engine, simply pull the emergency

stop handle on the lower control panel.

This air intake shut-off device must be reset manually

inside of the welder.

• Place the Ignition toggle switch in the “off” position.

• Manually turn the air intake shut-off reset handle such

that the handle is in-line with the air intake hoses. The

air intake shut-off is located on the top of the engine

between the muffler and the air filter.

Codes 11199 and 11408:

b. Auxiliary Power

With the engine running at low idle and auxiliary

power for lights or tools is drawn (approximately

100-150 watts or greater) from the receptacles, the

engine will accelerate to high speed. If no power is

being drawn from the receptacles ( and not welding) for 10-14 seconds, the idler reduces the engine

speed to low idle.

ENGINE TEMPERATURE GAUGE

Displays the coolant temperature in the engine block.

ENGINE OIL PRESSURE GAUGE

Displays the oil pressure to the engine. When the

engine starts running, watch for the oil pressure to

build up. If no pressure shows within 30 seconds, stop

the engine and consult the engine instruction manual.

BATTERY CHARGING AMMETER

Displays the current going from the charging alternator

into the batteries. It is normal for charging current to be

high (above 15 amps) after starting or when the batteries are ‘low’ on charge.

These codes have an automatic/manual device that

blocks all intake air from entering the engine.

The automatic feature of this shut-off device will

engage should excessive over speeding occur. The

valve is calibrated at the factory to shutdown before

damage occurs to the engine or generator.

To manually shut down the engine, simply pull the

emergency stop handle on the lower control panel.

This air intake shut-off device will reset automatically,

generally within one minute.

IMPORTANT: Before restarting engine, verify that the

air intake shut-off is in the open position. DO NOT

ATTEMPT TO START ENGINE WITH THE AIR

INTAKE SHUT-OFF IN THE CLOSED POSITION.

WARNING

•

Muffler and Engine may be hot!

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

ENGINE HOUR METER

The engine hour meter records the total running time

on the engine in hours. It can be used to keep a record

of maintenance on the engine and or welder.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

This may cause severe damage to the engine.

SAE-400 SEVERE DUTY

Page 19

B-5 B-5

WELDER CONTROLS

POLARITY SWITCH

Turn the Arc Polarity switch to electrode positive or

electrode negative as required for each particular

application.

CONTROL OF WELDING CURRENT

Purpose of Controls

The continuous “Current Control” is the main current

adjuster. The “Job Selector” is both a fine current

adjuster and the continuous Open Circuit Voltage

adjuster. Open Circuit Voltage (OCV) controls the arc

characteristics.

OPERATION

4. If you want a little more current, turn the “Job

Selector” up (counterclockwise) to increase current. If you want a little less current, turn the “Job

Selector” down (clockwise) to decrease current.

5. If dialing the desired current with the “Job

Selector” moves the setting outside the black

range causing undesirable arc characteristics, turn

the “Job Selector” back to the center of the black

range. Then turn the “Current Control” up or down

a little as needed. Readjust the “Job Selector” for

the exact characteristics and current desired.

REMOTE CONTROL

“Job Selector”

The “Job Selector” dial is divided into four colored sections providing OCV ranges as follows:

Color Title OCV Range

White Large Electrodes High OCV

Black Normal Welding Medium OCV

Red Overhead & Vertical Low OCV

Grey Special Applications Extra-Low OCV

The “Job Selector” is usually set in the black range

because it provides a soft “Buttering “ arc desired for

most welding. Some operators prefer to set the “Job

Selector” in the red range for a snappy “Digging” arc

when welding vertical up or overhead.

“Current Control”

CAUTION

Do not adjust the “Current Control” while welding

because this can damage the control.

------------------------------------------------------------------------

The “Current Control” dial is calibrated in amperes on

three

separate colored dials corresponding to the

white, black and red ranges of the “Job Selector” dial.

For example: when the “Job Selector” is set on the

black range, the approximate welding current is indicated on the black scale of the “Current Control” dial.

A receptacle and “Local/Remote” control switch on the

lower front control panel and a remote control box with

100 ft. (30.5 m) of cord for adjusting the OCV at the

welding site are standard. Putting the switch in the

“REMOTE” position allows fine current control at the

remote control box while placing the switch in the

“LOCAL” position allows fine current control at the “Job

Selector” on the machine.

AUXILIARY POWER CONTROLS

Note: GFCI receptacles are an option and if installed,

see the “MAINTENANCE SECTION” for detailed

information on testing and resetting the GFCI

receptacle.

115 VAC Receptacle

One 20 amp, 115 VAC duplex receptacle provides 115

VAC for auxiliary power. A total of 26 amps can be

drawn from this receptacle.

230 VAC Receptacle

One 15 amp, 230 VAC duplex receptacle provides 230

VAC for auxiliary power. A total of 13 amps can be

drawn from this receptacle.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

HowtoSettheControls

Assume you want a normal soft arc and about 135

amps, using a 5/32” (4.0 mm) electrode:

1. Set the “Job Selector” at the center of the black

range.

2. Set the “Current Control” to read 135 amps on the

black dial.

3. Start to weld.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Circuit Breakers

The circuit breakers provide separate overload current

protection for each half of the 115 V duplex receptacle.

The circuit breakers provide overload current protection in both current carrying wires of the 230 V duplex

receptacle.

Ground Stud

Provides a connection point for connecting the

machine to earth ground. For the safest grounding procedure refer to “Machine Grounding” in the INSTAL-

LATION section of this manual.

SAE-400 SEVERE DUTY

Page 20

B-6 B-6

ENGINE OPERATION

WARNING

Do not attempt to use this equipment until you

have thoroughly read the engine manufacturerʼs

manual supplied with your welder. It includes

important safety precautions, detailed engine

starting, operating and maintenance instructions,

and parts lists.

-----------------------------------------------------------------------ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and

ground

• Always wear dry insulating gloves.

-----------------------------------------------------------------------ENGINE EXHAUST can kill.

• Use in open, well ventilated areas or

vent exhaust outside.

OPERATION

5. Observe the oil pressure. If no pressure shows

within 30 seconds, stop the engine and consult the

engine operating manual. To stop the engine, turn

the “IGNITION” switch to “OFF”.

6. If the engine protection warning light comes on

during cranking or after start up, the “IGNITION”

switch must be turned “OFF” to reset the engine

protection system.

7. Allow the engine to run at high idle speed for several minutes to warm the engine. Stop the engine

and recheck the oil level, after allowing sufficient

time for the oil to drain into the pan. If the level is

down, fill it to the full mark again. The engine controls were properly set at the factory and should

require no adjusting when received.

COLD WEATHER STARTING

WARNING

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

-----------------------------------------------------------------------MOVING PARTS can injure.

• Do not operate with doors open or

guards off.

• Stop engine before servicing.

•Keepawayfrommovingparts.

------------------------------------------------------------------------

See additional warning information at the

front of this operatorʼs manual.

For added safety always operate the welder with the

doors closed. Further, leaving the doors open changes

the designed air flow and may cause engine, generator overheating.

CAUTION

Do not adjust the high idle engine speed (rpm)

above the factory setting specification as this will

void warranty.

------------------------------------------------------------------------

STARTING INSTRUCTIONS

Be sure all Pre-Operation Maintenance has been

performed. (See INSTALLATION section of this

manual).

1. Turn the “IDLER” switch to “HIGH”.

2. Turn the “IGNITION” switch to “ON”.

3. Press the Glow Plug button for 20 to 30 seconds.

(maximum 60 seconds). (codes 11199 and 11408

only).

4. Press the Glow Plug and the Start buttons at the

same time. When the engine starts running,

release buttons. If the engine fails to start in 20

seconds, wait 30 seconds and repeat the above

procedure. Press the Start button only for code

10856.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Under NO conditions should ether or other starting

fluids be used!

-----------------------------------------------------------------------Code 10856

When overnight temperatures are between 10oF(12oC)

and freezing, use the standard “Thermostart” starting

system installed on all engines. Follow the instructions

on the start panel nameplate and in the engine manual shipped with the welder. With fully charged batteries

and the proper weight oil, the “Themostart” system

operates satisfactorially even down to about 0

o

C).

18

Codes 11199 and 11408

With a fully charged battery and the proper weight oil,

the engine should start satisfactorily even down to

about -5°F (-20°C). It maybe desirable to install coldstarting aides at lower temperatures.

Note: Extreme cold weather staring may require longer

glow plug operation.

STOPPING THE ENGINE

1. Turn the “IGNITION” switch to “OFF”

At the end of each day’s welding, check the crankcase

oil level, drain accumulated dirt and water from the

water separator and refill the fuel tank to minimize

moisture condensation in the tank. Also, running out of

fuel tends to draw dirt into the fuel system.

When hauling the welder between job sites, close the

fuel shut-off valve.

If the fuel supply is cut off or runs out while the fuel

pump is operating, air may be entrapped in the fuel distribution system. If this happens, bleeding of the fuel

system may be necessary. Use qualified personnel to

do this per the instructions in the MAINTENANCE section of this manual.

SAE-400 SEVERE DUTY

o

F(-

Page 21

B-7 B-7

OPERATION

TYPICAL FUEL CONSUMPTION

The typical fuel consumption of the SAE-400 for various operating scenarios is shown below:

11199 + 11408 10856

Low Idle - No Load .30 gal./ hr. .35 gal./hr

1100 RPM (1.12 L./hr.) (1.32 L/hr)

High Idle - No Load .69 gal./hr. .75 gal./hr

1800 RPM (2.61 L./hr.) (2.84 L/hr)

Welding Load 1.79 gal./hr. 1.92 gal./hr

400 Amps, 40 Volts (6.76 L./hr.) (7.27 L/hr)

Welding Load 2.43 gal./hr.

500 Amps, 40 Volts (9.19 L./hr.)

Auxiliary Power .71 gal./hr. .96 gal./hr

3000VA (3.68 L./hr.) (3.63 L/hr)

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 22

B-8 B-8

NOTES

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 23

C-1 C-1

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Optional Field Installed Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

TABLE OF CONTENTS - ACCESSORIES SECTION

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 24

C-2 C-2

ACCESSORIES

OPTIONAL FIELD INSTALLED

ACCESSORIES

K802-D Power Plug Kit - Kit includes male plugs for

20 Amp receptacle.

K2641-1 Trailer - A 4-wheel steerable trailer for in-

(1)

plant and yard towing

with E78-14 load range (B)

tubeless tires. Mounts directly to welder base.(Not for

use on the highway.)

Comes standard with a Duo-Hitch™, a

2” Ball and Lunette Eye combination Hitch.

K2637-1 Trailer - A 2-wheel trailer designed for road

(1)

off road, in-plant and yard towing. Trailer mounts

directly to welder base.

Comes standard with a Duo-Hitch™,

a 2” Ball and Lunette Eye combination Hitch.

Order:

K2637-1 Trailer

K958-1 Ball Hitch

K958-2 Lunette Eye Hitch

K2639-1 Fender & Light Kit.

K2640-1 Cable Storage Rack

1

For highway use, consult applicable federal, state and local laws regarding

possible requirements for brakes, lights, fenders, etc.

K704 Standard Accessory Kit - Includes electrode

and work cables, headshield, work clamp and electrode holder.

K1690-1 GFCI RECEPTACLE KIT

Includes one UL approved 120V ground fault circuit

interrupter duplex type receptacle with cover and

installation instructions. Replaces the factory installed

120V duplex receptacle. Each receptacle of the GFCI

Duplex is rated at 20 Amps, the maximum total current

from the GFCI Duplex is limited to the 20 Amps. See

the MAINTENANCE section for detailed information on

testing and resetting the GFCI receptacle.

,

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 25

D-1 D-1

Maintenance ...........................................................................D-1

RoutineMaintenance ..................................................................D-2

PeriodicMaintenance..................................................................D-2

EngineOilChange,EngineAirFilter ......................................................D-2

BearingCommutatorAndBrushMaintenance ..............................................D-3

Cooling System, Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3

WaterSeperator......................................................................D-4

SecondaryFuelFilter..................................................................D-4

Engine Maintenance Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......D-4

TABLE OF CONTENTS - MAINTENANCE SECTION

Spark Arrestor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

GFCIReceptacleTestingAndResetingProcedure...........................................D-5

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 26

D-2 D-2

●

●

●

●

●

●

●

MAINTENANCE

WARNING

ELECTRIC SHOCK can kill.

Do not touch electrically live parts

such as output terminals or internal wiring

ENGINE EXHAUST can kill.

Use in open, well ventilated areas

or vent exhaust outside

MOVING PARTS can injure.

Do not operate with doors open or

guards off

Stop engine before servicing

Keep away from moving parts

Remove guards only when necessary and

replace when work requiring removal is complete.

Only qualified personnel should install, use, or

service this equipment.

ROUTINE MAINTENANCE

At the end of each day’s welding, refill the fuel tank to

minimize moisture condensation in the tank. Also, running out of fuel tends to draw dirt into the fuel system.

Check the engine crankcase oil level.

If the fuel supply runs out while the fuel pump is operating, air may be entrapped in the fuel distribution system. If this happens, bleeding of the fuel system may

be necessary. See the engine instruction manual.

PERIODIC MAINTENANCE

1. Blow out the welder and controls with an air hose at least

once every two months. In particularly dirty locations, this

cleaning may be necessary once a week. Use low pressure air to avoid driving dirt into the insulation.

4. Belts tend to loosen after the first 30 or 40 hours of operation. Check the cooling fan belt and tighten if necessary.

DO NOT OVER TIGHTEN.

ENGINE OIL CHANGE

The SAE-400 SEVERE DUTY is equipped with a convenient

oil drain system. Drain the oil when the engine is warm to

assure rapid and complete draining.

• Remove the oil filler cap and dipstick.

• To open drain valve, push handle away from valve and turn

90°.

• Drain oil into a suitable container.

• To close drain valve, turn handle 90° till handle snaps in the

closed position.

• Refill engine with the recommended oil to the appropriate

level. Replace dipstick and tighten the oil filler cap securely.

Change the crankcase oil at regular intervals using the proper grade of oil as recommended in the Engine Operating

Manual. Wash your hands with soap and water after handling

used oil. Please dispose of used motor oil in a manner that is

compatible with the environment. We suggest you take it in a

sealed container to your local service station or recycling

center for reclamation. Do not throw it in the trash, pour it on

the ground or down a drain.

ENGINE AIR FILTER

The engine air filter element is a dry cartridge type. It

is located above the engine. It can be cleaned and reused; however, damaged elements should not be

washed or re-used. Remove loose dirt from element

with compressed air or water hose directed from inside

out. Compressed Air: 100 psi maximum. The filter

should never be removed while the engine is running.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

2. The current control reactor brushes are self-lubricating

and should not be greased. Keep the contacts clean. This

control should be moved from maximum to minimum daily

to prevent the controls from sticking.

3. See the engine Instruction Manual for periodic engine

maintenance information. Change the oil filter in accordance with the instructions in the engine operating manual. When the oil filter is changed add one quart of oil to

the crankcase to replace the oil held in the filter during

operation.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SAE-400 SEVERE DUTY

Page 27

D-3 D-3

MAINTENANCE

BEARING MAINTENANCE