Lincoln Electric V350-PRO, SVM152-A User Manual

SVM152-A

JULY, 2000

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However,

your overall safety can be

increased by proper installation

. . . and thoughtful operation on

your part. DO NOT INSTALL,

OPERATE OR REPAIR THIS

EQUIPMENT WITHOUT READING THIS MANUAL AND THE

SAFETY PRECAUTIONS CONTAINED THROUGHOUT. And,

most importantly, think before

you act and be careful.

SERVICE MANUAL

For use with machine code numbers 10651, 10669

INVERTEC V350-PRO

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet con

sectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam e

r

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Lorem ipsum dolor sit amet consectetuer adipiscing

elit, ed diam non

umm

y nibh euismod tincidunt ut

laoreet dolore magna aliquam er

at

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

View Safety Info View Safety Info View Safety Info View Safety Info

RETURN TO MAIN INDEX

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

• World's Leader in Welding and Cutting Products •

Copyright © 2000 Lincoln Global Inc.

A

AMPS

V

VOLTS

A

W

A

R

N

IN

G

OUTPUT

INVERTEC V350-PRO

R

E

M

O

T

E

O

N

O

F

F

WELD TERMINALS

SELECT

P

O

W

E

R

LINCOLN

ELECTRIC

!

WARNING

!

WARNING

L

o

r

e

e

m

lit, e

ip

su

la

d

m

o

d

re

L

d

ia

o

e

o

re

m

t d

lo

e

m

n

r s

o

lit, e

ip

o

lo

n

it a

re

s

la

u

u

m

d

m

m

m

o

d

m

re

e

d

a

L

ia

t co

y

g

e

o

o

n

m

n

t d

re

lo

a

ib

n

n

e

m

r s

a

o

h

s

o

lo

lit, e

ip

e

e

liq

n

it a

c

re

u

u

s

la

te

u

m

is

u

m

m

a

d

tu

m

o

m

m

m

d

e

a

re

e

d

t c

y

o

e

ia

g

r a

n

d

e

o

n

r

m

o

tin

t d

L

a

lo

a

ib

d

n

o

n

t

a

ip

r s

h

s

o

re

c

o

e

e

liq

lo

is

id

e

n

m

it a

c

u

c

r

te

u

u

u

e

lit, e

ip

in

is

m

a

n

m

m

tu

m

m

g

t u

s

m

la

e

e

u

a

o

e

d

t c

r

y

t

m

g

d

o

d

n

r

a

n

tin

re

a

d

o

d

ia

a

ib

t

n

e

ip

o

a

m

h

s

t d

lo

e

e

liq

L

n

r s

o

o

u

u

o

re

lo

is

a

n

it a

re

m

e

m

m

u

m

m

o

lit, e

m

ip

e

d

m

e

r

s

a

la

a

t c

y

u

g

t

d

n

m

n

o

L

d

o

a

re

ib

o

d

n

ia

a

re

h

s

e

o

m

e

e

liq

t d

e

m

lo

c

n

u

lit, e

te

r s

ip

u

o

is

o

a

lo

tu

s

m

n

it a

m

la

re

u

u

e

d

o

e

m

o

m

r a

d

m

m

d

re

r

d

tin

m

a

ia

e

d

a

e

t

o

t c

y

ip

m

g

t d

lo

c

n

n

is

n

id

o

r s

a

ib

o

c

n

u

o

a

lo

in

h

s

n

n

it a

e

L

e

liq

re

t u

u

c

o

m

u

m

te

m

u

re

t

is

a

m

tu

e

e

m

a

m

m

t c

y

g

e

lit, e

ip

o

n

e

n

r a

o

L

d

a

ib

r

s

la

n

tin

a

o

a

u

d

h

s

d

t

m

ip

re

o

e

e

liq

d

c

e

re

c

is

d

id

u

ia

te

u

m

e

c

is

lit, e

o

u

a

m

in

tu

t d

lo

n

m

m

ip

la

n

g

t u

e

r s

o

e

o

r

o

d

lo

s

a

o

L

re

o

re

e

m

lit, e

ip

la

o

d

re

d

e

ia

t d

m

o

lo

re

m

t

r

n

d

it a

tin

a

u

re

d

u

d

t

ip

m

m

m

m

c

e

is

ia

m

id

e

d

a

t d

c

t c

u

y

m

g

in

n

o

n

n

o

g

t u

o

n

lo

a

ib

n

a

lo

h

s

t

r sit a

o

s

e

e

liq

re

n

c

u

u

te

u

um

m

is

m

a

tu

m

m

d

e

m

o

e

m

a

r a

d

o

g

r

e

tin

y n

a

n

lo

d

n

t

t c

ip

a

r sit a

o

c

is

id

ib

a

n

o

c

u

u

h

n

in

liq

n

m

e

se

g

t u

u

m

m

a

u

t

c

a

g

ism

e

te

y n

m

n

t c

tu

a

e

ib

o

a

o

e

r

d

a

h

n

r a

liq

tin

t

e

s

e

u

d

u

c

a

cid

ip

ism

te

m

is

tu

u

e

cin

o

n

e

r

d

t u

a

r a

g

tin

t

t

d

c

ip

id

is

u

c

n

in

t u

g

t

L

o

re

e

m

lit, e

ip

la

la

L

s

o

d

L

o

u

re

d

o

m

e

re

e

ia

e

d

lit, e

t d

m

m

lit, e

o

la

ip

o

n

lo

la

d

o

lo

r s

o

re

s

o

d

re

n

u

e

re

d

it a

u

t d

m

m

m

e

iam

o

d

t d

lo

m

m

a

o

g

e

y

o

n

lo

n

n

t c

lo

a

r s

o

ib

a

re

n

o

it a

u

h

n

liq

m

m

e

s

e

u

m

m

a

u

a

g

ism

e

y n

m

n

t c

a

e

ib

o

a

o

r

d

a

h

n

liq

t

e

se

u

u

cte

a

is

m

m

tu

e

o

e

r

d

a

r a

tin

t

d

c

id

u

n

t u

!

c

is

id

c

c

u

te

in

n

g

t u

tu

e

t

r a

tin

c

id

u

n

t u

g

la

L

e

lit, e

o

re

r

e

e

m

t d

ip

o

s

u

d

ia

m

n

o

re

m

a

g

n

c

te

tu

e

r a

tin

c

id

u

ip

isc

in

t

ATTENTION

d

ip

is

c

!

in

g

t

AVISO DE

PRECAUCION

L

o

re

e

m

lit, e

ip

s

la

u

d

m

o

d

re

L

d

ia

o

e

o

re

m

t d

lo

e

m

n

r s

o

lit, e

ip

o

lo

n

it a

re

s

la

u

u

m

d

m

m

m

o

d

m

re

e

d

a

L

ia

t c

y

g

e

o

o

n

m

n

t d

re

lo

o

a

ib

n

n

e

m

r s

a

o

h

s

o

lo

lit, e

ip

e

e

liq

n

it a

cte

re

u

u

s

la

u

m

L

is

u

m

m

a

d

tu

o

m

o

m

m

m

d

e

re

a

r

e

d

t co

y

e

o

e

ia

g

r a

e

m

n

e

d

o

n

r

m

t

tin

a

lit, e

lo

ip

a

ib

d

n

d

n

t

a

ip

r s

h

s

o

s

la

c

o

e

e

liq

lo

is

u

id

d

n

it a

c

m

o

u

c

re

d

te

u

u

u

re

in

is

d

m

a

n

m

ia

m

tu

m

m

g

t u

e

o

m

m

e

e

t d

a

o

lo

e

t c

y

r a

t

n

g

d

L

r s

n

r

o

n

tin

a

o

o

o

d

lo

a

ib

t

re

n

n

it a

ip

a

re

h

u

c

s

e

m

is

id

e

e

m

liq

m

m

c

c

lit, e

ip

u

u

m

te

u

in

e

n

a

is

a

t c

s

y

la

g

t u

tu

g

m

u

m

n

d

n

e

o

m

o

o

d

t

e

a

ib

r a

n

re

d

d

a

h

ia

s

r

L

tin

a

e

e

e

o

liq

d

o

m

t

t d

c

lo

ip

re

u

te

u

c

n

r s

is

is

e

m

id

o

a

tu

o

m

lo

c

m

u

lit, e

ip

n

it a

in

e

n

re

o

e

u

r a

g

s

t u

d

m

m

m

r

u

tin

a

d

m

d

m

t

o

e

t

d

a

ip

re

t c

y

d

cid

g

ia

n

is

n

e

o

o

m

c

a

ib

t d

u

lo

n

in

a

n

n

h

s

r s

o

g

t u

e

e

liq

o

lo

c

n

it a

u

t

te

u

re

u

is

a

m

tu

m

m

m

m

m

e

e

o

o

e

a

r a

t c

y

re

d

g

r

n

tin

a

n

m

d

o

t

a

ib

ip

n

ip

a

c

h

s

is

id

e

e

liq

su

c

c

u

u

in

d

te

u

n

m

is

d

a

g

t u

tu

d

m

m

ia

e

t

o

o

e

m

r a

lo

d

r

n

tin

r s

a

d

o

t

lo

ip

n

it a

c

m

re

is

u

id

m

c

d

m

m

u

in

m

n

o

e

a

g

t u

lo

t c

y

g

n

r s

n

t

o

a

ib

n

n

it a

a

h

s

u

e

e

liq

m

m

c

u

m

te

u

e

is

a

t c

y

tu

m

m

n

e

o

o

e

a

ib

r a

n

d

a

r

h

s

tin

a

d

e

e

liq

t

ip

c

u

c

te

u

is

is

id

a

tu

c

m

m

u

in

e

n

o

e

r

g

t u

d

a

r

tin

a

t

d

t

ip

c

d

is

id

ip

c

u

in

n

is

g

t u

c

nt u

t

in

g

t

g

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

i

SAFETY

i

FOR ENGINE

powered equipment.

1.a. Turn the engine off before troubleshooting and maintenance

work unless the maintenance work requires it to be running.

____________________________________________________

1.b.Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

____________________________________________________

1.c. Do not add the fuel near an open flame welding arc or when the engine is running. Stop

the engine and allow it to cool before refueling to prevent spilled fuel from vaporizing on

contact with hot engine parts and igniting. Do

not spill fuel when filling tank. If fuel is spilled,

wipe it up and do not start engine until fumes

have been eliminated.

____________________________________________________

1.d. Keep all equipment safety guards, covers and devices in position and in good repair.Keep hands, hair, clothing and tools

away from V-belts, gears, fans and all other moving parts

when starting, operating or repairing equipment.

____________________________________________________

1.e. In some cases it may be necessary to remove safety

guards to perform required maintenance. Remove

guards only when necessary and replace them when the

maintenance requiring their removal is complete.

Always use the greatest care when working near moving

parts.

___________________________________________________

1.f. Do not put your hands near the engine fan.

Do not attempt to override the governor or

idler by pushing on the throttle control rods

while the engine is running.

___________________________________________________

1.g. To prevent accidentally starting gasoline engines while

turning the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information, it is strongly recommended that you

purchase a copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American Welding Society, P.O. Box 351040,

Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the

Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

WARNING

Mar ‘95

ELECTRIC AND

MAGNETIC FIELDS

may be dangerous

2.a. Electric current flowing through any conductor causes

localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and

welding machines

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1.

Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and

work cables. If the electrode cable is on your right

side, the work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as

possible to the area being welded.

2.d.5. Do not work next to welding power source.

1.h. To avoid scalding, do not remove the

radiator pressure cap when the engine is

hot.

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer, birth defects, and other reproductive harm.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

The Above For Diesel Engines

The Above For Gasoline Engines

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

ii

SAFETY

ii

ARC RAYS can burn.

4.a. Use a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. Headshield and filter lens

should conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

ELECTRIC SHOCK can kill.

3.a. The electrode and work (or ground) circuits

are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare

skin or wet clothing. Wear dry, hole-free

gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

must be performed under electrically hazardous

conditions (in damp locations or while wearing wet

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic

welding gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection

should be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical

(earth) ground.

3.f.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see Items 6.c. and 8.

FUMES AND GASES

can be dangerous.

5.a.Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases.When welding, keep

your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing zone. When

welding with electrodes which require special

ventilation such as stainless or hard facing (see

instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure as

low as possible and below Threshold Limit Values (TLV)

using local exhaust or mechanical ventilation. In

confined spaces or in some circumstances, outdoors, a

respirator may be required. Additional precautions are

also required when welding on galvanized steel.

5.b.

Do not weld in locations near chlorinated hydrocarbon

vapors

coming from degreasing, cleaning or spraying operations.

The heat and rays of the arc can react with solvent vapors

to

form phosgene, a highly toxic gas, and other irritating

products.

5.c. Shielding gases used for arc welding can displace air and

cause injury or death. Always use enough ventilation,

especially in confined areas, to insure breathing air is safe.

5.d. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your

employer’s safety practices. MSDS forms are available from

your welding distributor or from the manufacturer.

5.e. Also see item 1.b.

Mar ‘95

SAFETY

iii iii

V350-PRO

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FOR ELECTRICALLY

powered equipment.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accordance with the U.S. National

Electrical Code, all local codes and the manufacturer’s

recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

CYLINDER may explode

if damaged.

7.a. Use only compressed gas cylinders

containing the correct shielding gas for the

process used and properly operating

regulators designed for the gas and

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

7.b. Always keep cylinders in an upright position securely

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

•Away from areas where they may be struck or subjected to

physical damage.

• A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

7.g. Read and follow the instructions on compressed gas

cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in

Cylinders,” available from the Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202.

Mar ‘95

WELDING SPARKS can

cause fire or explosion.

6.a.

Remove fire hazards from the welding area.

If this is not possible, cover them to prevent

the welding sparks from starting a fire.

Remember that welding sparks and hot

materials from welding can easily go through small cracks

and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site,

special precautions should be used to prevent hazardous

situations. Refer to “Safety in Welding and Cutting” (ANSI

Standard Z49.1) and the operating information for the

equipment being used.

6.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact can

cause overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances

inside. They can cause an explosion even

though

they have

been “cleaned”. For information, purchase “Recommended

Safe Practices for the

Preparation

for Welding and Cutting of

Containers and Piping That Have Held Hazardous

Substances”, AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f.

Sparks and spatter are thrown from the welding arc. Wear oil

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a

welding area.

6.g. Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

increase the possibility of the welding current passing

through lifting chains, crane cables or other alternate circuits.

This can create fire hazards or overheat lifting chains or

cables until they fail.

6.h. Also see item 1.c.

SAFETY

iv iv

V350-PRO

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

PRÉCAUTIONS DE SÛRETÉ

Pour votre propre protection lire et observer toutes les instructions

et les précautions de sûreté specifiques qui parraissent dans ce

manuel aussi bien que les précautions de sûreté générales suivantes:

Sûreté Pour Soudage A L’Arc

1. Protegez-vous contre la secousse électrique:

a. Les circuits à l’électrode et à la piéce sont sous tension

quand la machine à souder est en marche. Eviter toujours

tout contact entre les parties sous tension et la peau nue

ou les vétements mouillés. Porter des gants secs et sans

trous pour isoler les mains.

b. Faire trés attention de bien s’isoler de la masse quand on

soude dans des endroits humides, ou sur un plancher metallique ou des grilles metalliques, principalement dans

les positions assis ou couché pour lesquelles une grande

partie du corps peut être en contact avec la masse.

c. Maintenir le porte-électrode, la pince de masse, le câble de

soudage et la machine à souder en bon et sûr état defonctionnement.

d.Ne jamais plonger le porte-électrode dans l’eau pour le

refroidir.

e. Ne jamais toucher simultanément les parties sous tension

des porte-électrodes connectés à deux machines à souder

parce que la tension entre les deux pinces peut être le total

de la tension à vide des deux machines.

f. Si on utilise la machine à souder comme une source de

courant pour soudage semi-automatique, ces precautions

pour le porte-électrode s’applicuent aussi au pistolet de

soudage.

2. Dans le cas de travail au dessus du niveau du sol, se protéger

contre les chutes dans le cas ou on recoit un choc. Ne jamais

enrouler le câble-électrode autour de n’importe quelle partie du

corps.

3. Un coup d’arc peut être plus sévère qu’un coup de soliel, donc:

a. Utiliser un bon masque avec un verre filtrant approprié ainsi

qu’un verre blanc afin de se protéger les yeux du rayonnement de l’arc et des projections quand on soude ou

quand on regarde l’arc.

b. Porter des vêtements convenables afin de protéger la peau

de soudeur et des aides contre le rayonnement de l‘arc.

c. Protéger l’autre personnel travaillant à proximité au

soudage à l’aide d’écrans appropriés et non-inflammables.

4. Des gouttes de laitier en fusion sont émises de l’arc de

soudage. Se protéger avec des vêtements de protection libres

de l’huile, tels que les gants en cuir, chemise épaisse, pantalons sans revers, et chaussures montantes.

5. Toujours porter des lunettes de sécurité dans la zone de

soudage. Utiliser des lunettes avec écrans lateraux dans les

zones où l’on pique le laitier.

6. Eloigner les matériaux inflammables ou les recouvrir afin de

prévenir tout risque d’incendie dû aux étincelles.

7. Quand on ne soude pas, poser la pince à une endroit isolé de

la masse. Un court-circuit accidental peut provoquer un

échauffement et un risque d’incendie.

8. S’assurer que la masse est connectée le plus prés possible de

la zone de travail qu’il est pratique de le faire. Si on place la

masse sur la charpente de la construction ou d’autres endroits

éloignés de la zone de travail, on augmente le risque de voir

passer le courant de soudage par les chaines de levage,

câbles de grue, ou autres circuits. Cela peut provoquer des

risques d’incendie ou d’echauffement des chaines et des

câbles jusqu’à ce qu’ils se rompent.

9. Assurer une ventilation suffisante dans la zone de soudage.

Ceci est particuliérement important pour le soudage de tôles

galvanisées plombées, ou cadmiées ou tout autre métal qui

produit des fumeés toxiques.

10. Ne pas souder en présence de vapeurs de chlore provenant

d’opérations de dégraissage, nettoyage ou pistolage. La

chaleur ou les rayons de l’arc peuvent réagir avec les vapeurs

du solvant pour produire du phosgéne (gas fortement toxique)

ou autres produits irritants.

11. Pour obtenir de plus amples renseignements sur la sûreté, voir

le code “Code for safety in welding and cutting” CSA Standard

W 117.2-1974.

PRÉCAUTIONS DE SÛRETÉ POUR

LES MACHINES À SOUDER À

TRANSFORMATEUR ET À

REDRESSEUR

1. Relier à la terre le chassis du poste conformement au code de

l’électricité et aux recommendations du fabricant. Le dispositif

de montage ou la piece à souder doit être branché à une

bonne mise à la terre.

2. Autant que possible, I’installation et l’entretien du poste seront

effectués par un électricien qualifié.

3. Avant de faires des travaux à l’interieur de poste, la debrancher à l’interrupteur à la boite de fusibles.

4. Garder tous les couvercles et dispositifs de sûreté à leur place.

MASTER TABLE OF CONTENTS FOR ALL SECTIONS

v v

V350-PRO

Page

Safety.................................................................................................................................................i-iv

Installation.............................................................................................................................Section A

Operation...............................................................................................................................Section B

Accessories...........................................................................................................................Section C

Maintenance .........................................................................................................................Section D

Theory of Operation .............................................................................................................Section E

Troubleshooting and Repair.................................................................................................Section F

How to Use Troubleshooting Guide............................................................................................F-2

Troubleshooting Guide................................................................................................................F-4

Test Procedures ........................................................................................................................F-15

Replacement Procedures .........................................................................................................F-51

Electrical Diagrams..............................................................................................................Section G

Parts Manual....................................................................................................................P-369 Series

RETURN TO MAIN INDEX

SectionA-1 Section A-1

V350-PRO

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TABLE OF CONTENTS

- INSTALLATION SECTION -

Installation

Technical Specifications .............................................................................................................A-2

Input Grounding Connections....................................................................................................A-3

Power Cord Connection.............................................................................................................A-3

Single Phase Input ...............................................................................................................A-3

Three Phase Input.............................................................................................................. ..A-3

Parallel Operation.......................................................................................................................A-3

Quick Disconnect Plugs .............................................................................................................A-3

V350-PRO

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

A-2

INSTALLATION

A-2

TECHNICAL SPECIFICATIONS -

INVERTEC V350-PRO

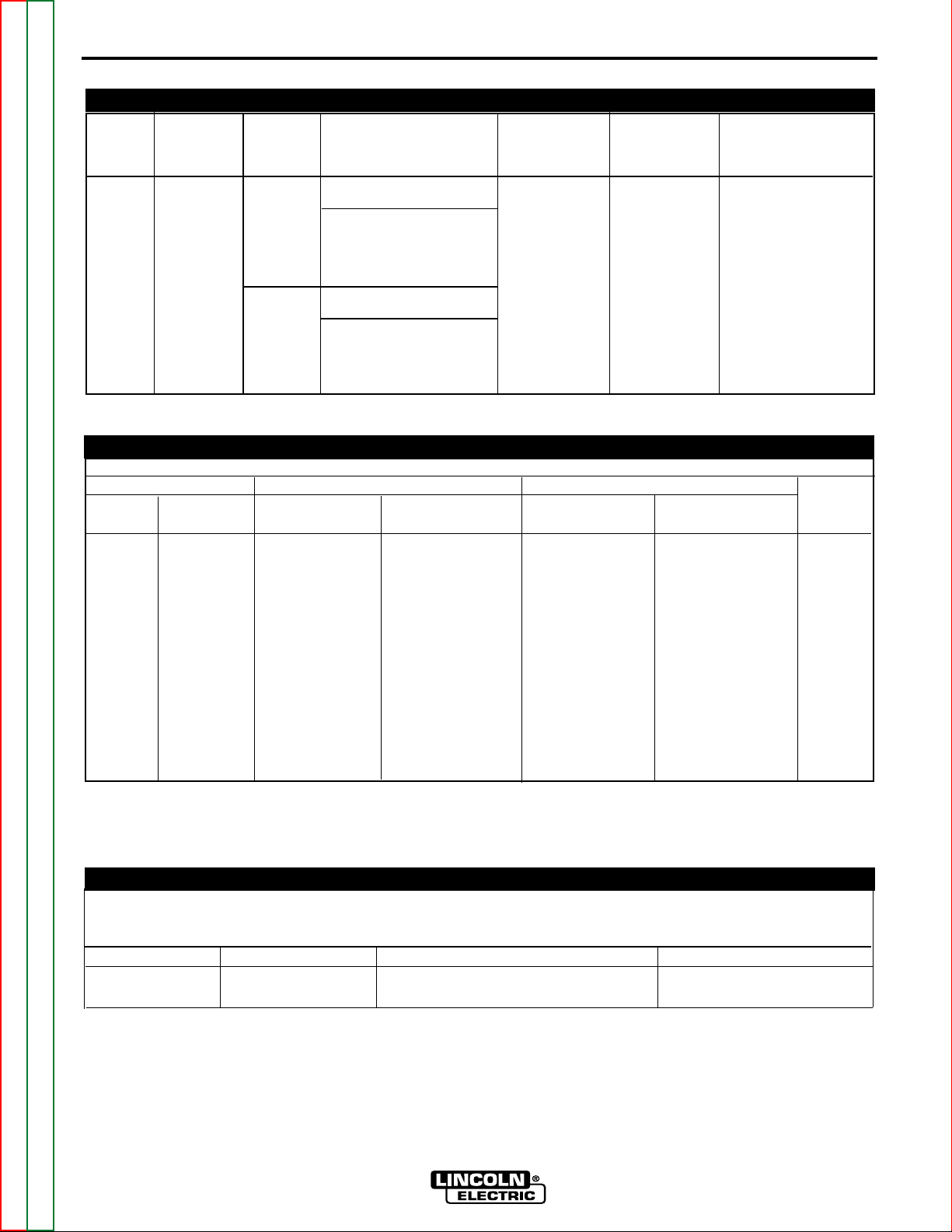

INPUT AC VOLTAGE & DC OUTPUT

OUTPUT CABLES, CONNECTIONS AND LIMITATIONS

Product Ordering Input AC Rated DC Output Output Weight

Name Information Voltage Amps/Volts/Duty Cycle Range with Cord HxWxD

(continuous)

K1728-1 200-230 / 200-230/ 350A / 34V / 60%

Factory 380-415/ Factory

460-480/ 275A / 31V / 100% 82.5lbs 14.7”x12.5”x

Invertec 575 (37.4 kg) 27.8”*

V350- K1728-2 3 Phase AMPS (373x318x

PRO Construction 60/50 Hz 5-425 Construction 706*)mm

60/50 Hz

81.5lbs

208-230/ 350A / 34V / 60% (36.9 kg) * Includes

K1728-3 415/ handles

“CE” 460-480/ 275A / 31V /100%

575

1 Phase

* Overall Length Including Handle, 27.8” (706mm) without handle.

Select the output cable size based upon the following chart.

Cable sizes for Combined Length of Electrode and Work Cable (Copper) 75C rated:

DUTY CYCLE CURRENT LENGTH UP 61m (200 FT) 61-76m (200-250 FT)

100% 275 1/0 1/0

60% 350 1/0 2/0

V350-PRO INPUT CURRENT

1. When operating on these inputs, the line cord should be changed to an input conductor of 6 AWG or larger.

Recommended Fuse Sizes Based On The U.S. National Electrical Code And Maximum Machine Outputs

Input 50/60 Hz Output Recommended

Voltage Phases 275Amps@ 350Amps@ Line Cord Size Fuse Size Notes

31Volts(100%) 34Volts(60%)

208 1 70 94 2 125A Note 1

230 1 62 85 4 125A Note 1

415 1 38 54 6 80A Note 1

460 1 34 42 8 70A

575 1 27 37 8 50A

200 3 37 50 8 80A Note 1

208 3 36 50 6 80A Note 1

230 3 31 42 8 70A

380 3 21 28 8 50A

400 3 20 27 8 50A

415 3 19 26 8 50A

460 3 17 23 8 50A

575 3 14 18 8 35A

INSTALLATION

A-3 A-3

V350-PRO

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INPUT AND GROUNDING CONNECTIONS

1. Only a qualified electrician should connect the

Invertec V350-PRO. Installation should be made

in accordance with the U.S. National Electrical

Code, all local codes and the information detailed

below.

2. When received directly from the factory, multiple

voltage machines are internally connected for

460VAC. If 460VAC is the desired input, then the

machine may be connected to the power system

without any setup required inside the machine.

3. Initial 200VAC - 415VAC and 575VAC operation

will require an Input voltage panel setup.

• Open the access panel on the rear of the

machine.

• For 200 or 230: Position the large switch to 200-

230.

For higher voltages: Position the large switch to

380-575.

• Move the "A" lead to the appropriate terminal.

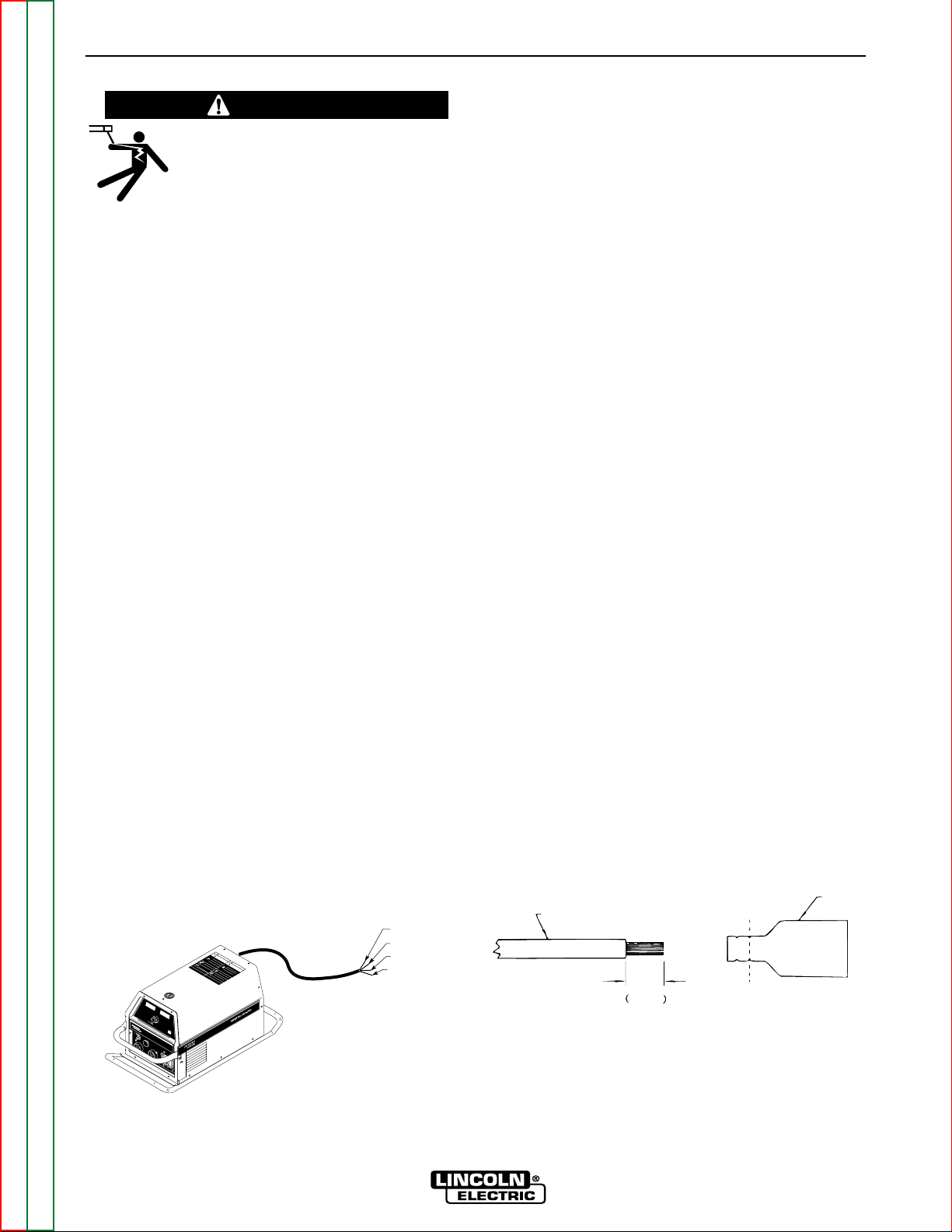

POWER CORD CONNECTION

A 10 ft. (3.0m) power cord is provided and wired into

the machine. Follow the power cord connection

instructions. Incorrect connection may result in equipment damage.

INSTALLATION

ELECTRIC SHOCK can kill.

• TURN THE INPUT POWER OFF AT

THE DISCONNECT SWITCH BEFORE

ATTEMPTING TO CONNECT OR DIS-

CONNECT INPUT POWER LINES, OUTPUT

CABLES, OR CONTROL CABLES.

• Only qualified personnel should perform this

installation.

• Connect the green lead of the power cord to

ground per U.S. National Electrical Code.

--------------------------------------------------------------------

WARNING

Single Phase Input

1. Connect green lead to ground per U.S. National

Electrical Code.

2. Connect black and white leads to power.

3. Wrap red lead with tape to provide 600V insulation.

Three Phase Input

1. Connect green lead to ground per U.S. National

Electric Code.

2. Connect black, red and white leads to power.

Install in accordance with all local and national

electric codes.

PARALLEL OPERATION

The V350-Pro are operable in parallel in CC mode.

For best results, the currents of each machine should

be reasonably well shared. As an example, with two

machines set up in parallel for a 400 amp procedure,

each machine should be set to deliver approximately

200 amps, not 300 amps from one and 100 amps

from the other. This will minimize nuisance shutdown

conditions. In general, more than two machines in

parallel will not be effective due to the voltage

requirements of procedures in that power range.

To set machine outputs, start with output control pots

and arc control pots in identical positions. Use the

output control pots to balance the currents and maintain the desired voltage or current. The arc control

pots should be kept identical on the two machines.

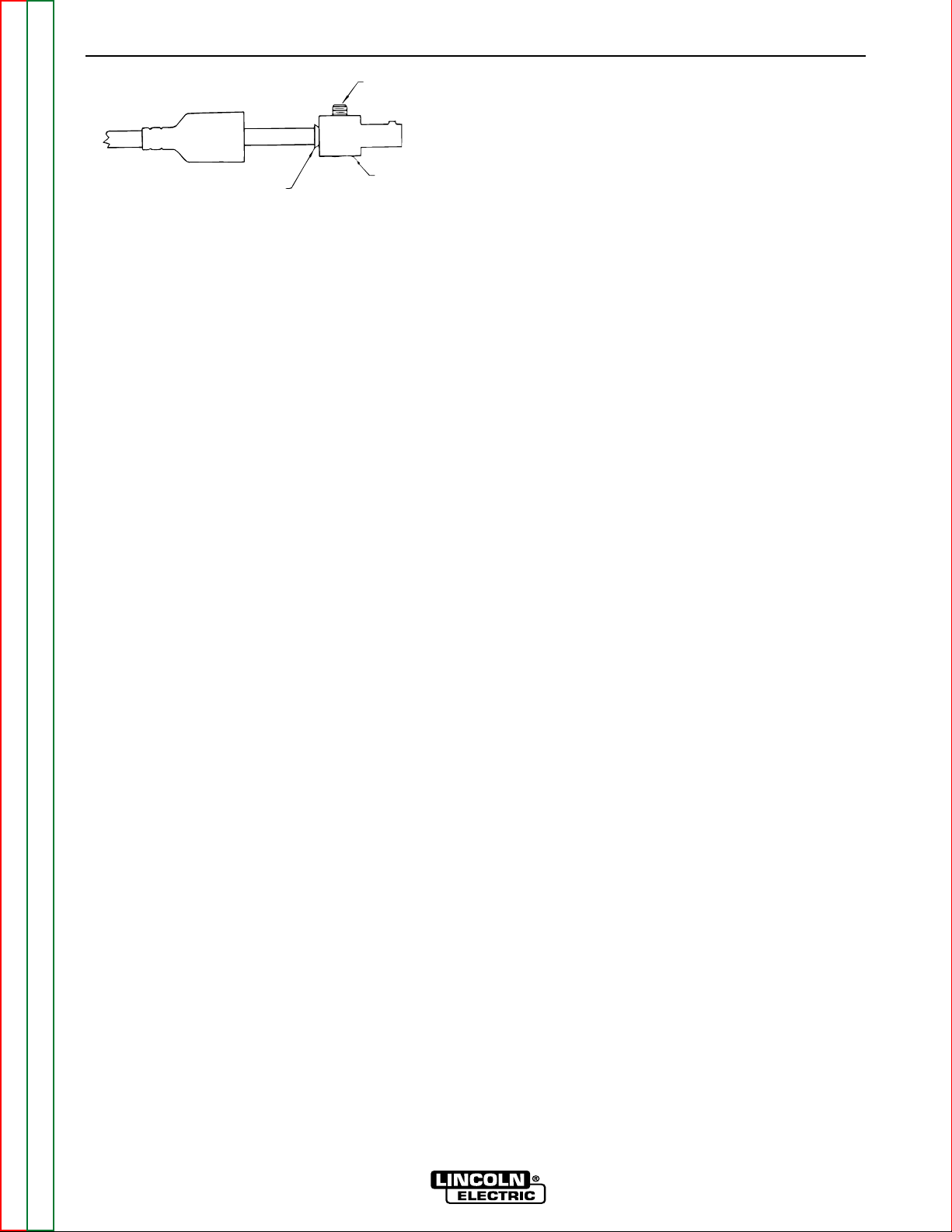

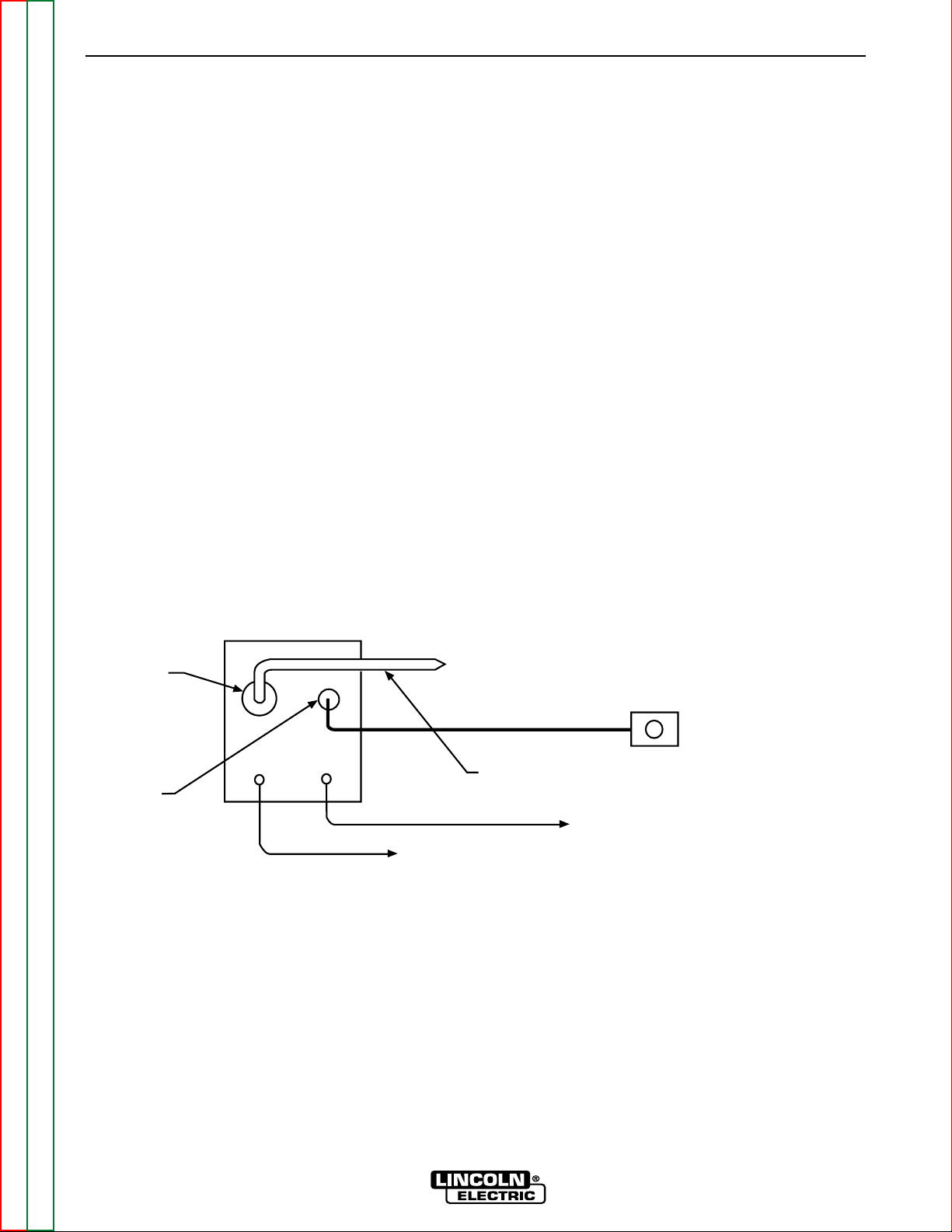

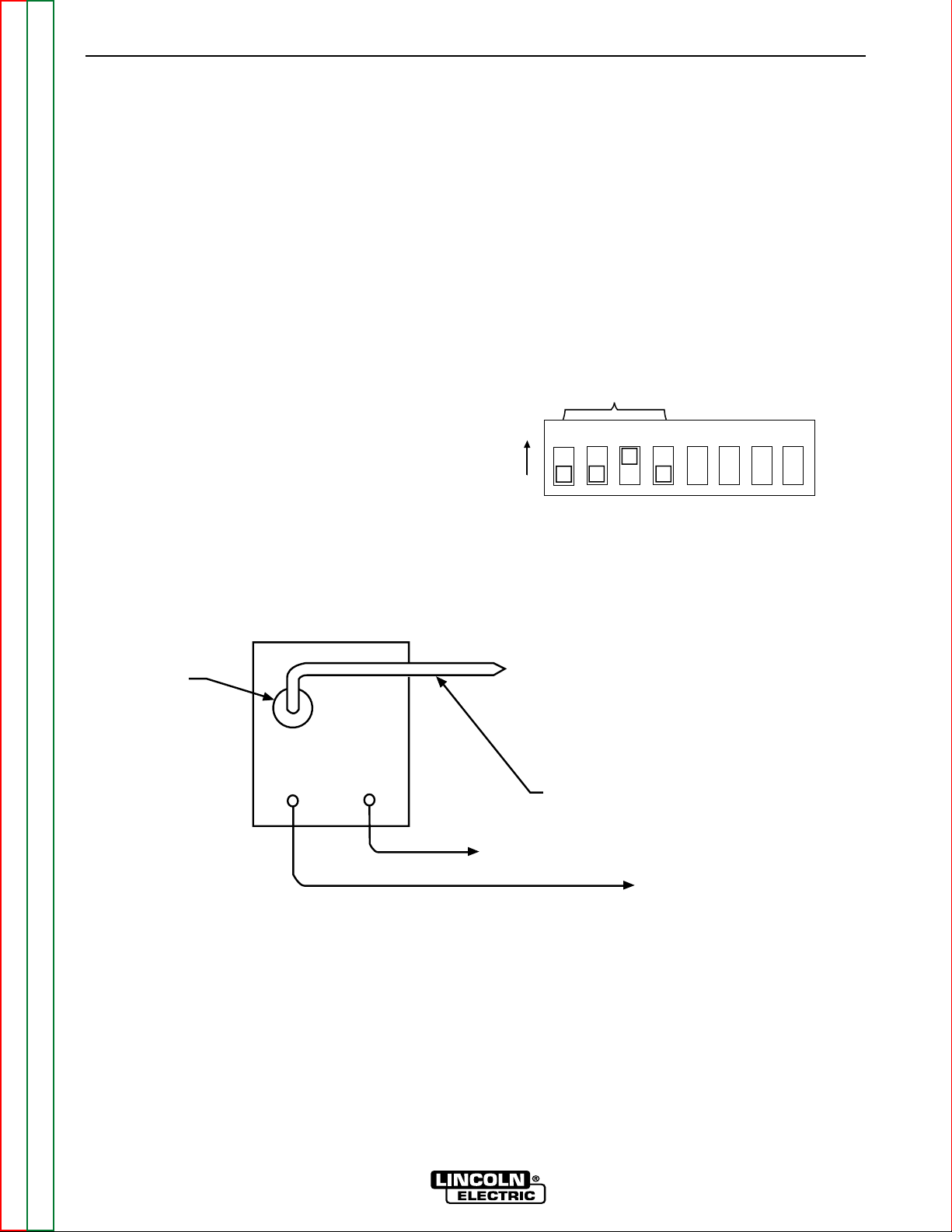

QUICK DISCONNECT PLUGS

A quick disconnect system is used for the welding

cable connections. The welding plug included with the

machine is designed to accept a welding cable size of

1/0 to 2/0.

1. Remote 25mm (1 in.) of welding cable insulation.

2. Slide rubber boot onto cable end. The boot end

may be trimmed to match the cable diameter.

Soap or other lubricant will help to slide the boot

over the cable.

3. Slide the copper tube into the brass plug.

4. Insert cable into copper tube.

W

A

R

N

IN

G

R

E

M

O

T

E

P

O

W

E

R

O

F

F

O

N

A

A

M

P

S

A

V

V

O

LT

S

WELD TERMINALS

SELECT

O

U

T

P

U

T

LIN

CO

LN

ELECTRIC

INVERTEC V350-PRO

WARNING

WARNING

AVISO DE

PRECAUCION

ATTENTION

!

!

!

!

L

o

r

e

m

i

p

s

u

m

d

o

l

o

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

ip

i

s

c

in

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

i

t

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

i

b

h

e

u

i

s

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

l

a

o

r

e

e

t

d

o

lo

r

e

m

a

g

n

a

a

li

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

i

p

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

ip

i

s

c

in

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

i

t

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

i

b

h

e

u

i

s

m

o

d

t

i

n

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

l

a

o

r

e

e

t

d

o

lo

r

e

m

a

g

n

a

a

liq

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

ip

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

i

p

is

c

i

n

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

i

t

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

i

s

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

la

o

r

e

e

t

d

o

l

o

r

e

m

a

g

n

a

a

l

i

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

ip

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

i

p

i

s

c

i

n

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

li

t

,

e

d

d

ia

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

is

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

l

a

o

r

e

e

t

d

o

lo

r

e

m

a

g

n

a

a

l

iq

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

ip

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

ip

is

c

i

n

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

i

t

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

i

s

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

l

a

o

r

e

e

t

d

o

lo

r

e

m

a

g

n

a

a

li

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

i

p

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

ip

i

s

c

i

n

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

i

t

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

i

s

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

la

o

r

e

e

t

d

o

l

o

r

e

m

a

g

n

a

a

li

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

i

p

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

ip

is

c

in

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

i

t

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

is

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

la

o

r

e

e

t

d

o

l

o

r

e

m

a

g

n

a

a

li

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

i

p

s

u

m

d

o

l

o

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

ip

is

c

in

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

i

t

,

e

d

d

ia

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

i

s

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

l

a

o

r

e

e

t

d

o

l

o

r

e

m

a

g

n

a

a

li

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

i

p

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

ip

is

c

in

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

it

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

is

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

la

o

r

e

e

t

d

o

l

o

r

e

m

a

g

n

a

a

li

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

i

p

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

i

p

is

c

i

n

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

i

t

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

i

b

h

e

u

i

s

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

la

o

r

e

e

t

d

o

lo

r

e

m

a

g

n

a

a

li

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

i

p

s

u

m

d

o

l

o

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

ip

i

s

c

in

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

it

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

i

b

h

e

u

i

s

m

o

d

t

i

n

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

la

o

r

e

e

t

d

o

l

o

r

e

m

a

g

n

a

a

li

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

i

p

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

i

p

is

c

i

n

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

i

t

,

e

d

d

ia

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

i

s

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

la

o

r

e

e

t

d

o

lo

r

e

m

a

g

n

a

a

li

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

ip

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

i

p

is

c

i

n

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

li

t

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

i

b

h

e

u

is

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

la

o

r

e

e

t

d

o

lo

r

e

m

a

g

n

a

a

li

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

re

m

ip

s

u

m

d

o

lo

r s

it a

m

e

t c

o

n

s

e

c

te

tu

e

r a

d

ip

is

c

in

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

lit, e

d

d

ia

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

is

m

o

d

tin

c

id

u

n

t u

t

y nibh euismod tincidunt ut

la

o

re

e

t d

o

lo

re

m

a

g

n

a

a

liq

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

re

m

ip

s

u

m

d

o

lo

r s

it a

m

e

t c

o

n

s

e

c

te

tu

e

r a

d

ip

is

c

in

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

lit, e

d

d

ia

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

is

m

o

d

tin

c

id

u

n

t u

t

y nibh euismod tincidunt ut

la

o

re

e

t d

o

lo

re

m

a

g

n

a

a

liq

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

re

m

ip

s

u

m

d

o

lo

r s

it a

m

e

t c

o

n

s

e

c

te

tu

e

r a

d

ip

is

c

in

g

Lorem ipsum dolor sit amet conse

ctetuer adipiscing

e

lit, e

d

d

ia

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

is

m

o

d

tin

c

id

u

n

t u

t

y nibh euismod tincidunt ut

la

o

re

e

t d

o

lo

re

m

a

g

n

a

a

liq

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

re

m

ip

s

u

m

d

o

lo

r s

it a

m

e

t c

o

n

s

e

c

te

tu

e

r a

d

ip

is

c

in

g

Lorem ipsum dolor

sit amet consectetuer adipiscing

e

lit, e

d

d

ia

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

ib

h

e

u

is

m

o

d

tin

c

id

u

n

t u

t

y nibh euismod tincidunt ut

la

o

re

e

t d

o

lo

re

m

a

g

n

a

a

liq

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

i

p

s

u

m

d

o

lo

r

s

i

t

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

ip

is

c

in

g

Lorem ipsum dolor sit amet consectetuer adipi

scing

e

l

i

t

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

i

b

h

e

u

is

m

o

d

t

in

c

i

d

u

n

t

u

t

y nibh euismod tincidunt ut

la

o

r

e

e

t

d

o

lo

r

e

m

a

g

n

a

a

l

i

q

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

L

o

r

e

m

i

p

s

u

m

d

o

lo

r

s

it

a

m

e

t

c

o

n

s

e

c

t

e

t

u

e

r

a

d

ip

is

c

i

n

g

Lorem ipsum dolor sit amet consectetuer adipiscing

e

l

i

t

,

e

d

d

i

a

m

n

o

n

elit, ed diam nonu

m

m

ummy

n

i

b

h

e

u

i

s

m

o

d

t

in

c

id

u

n

t

u

t

y nibh euismod tincidunt ut

la

o

r

e

e

t

d

o

l

o

r

e

m

a

g

n

a

a

l

iq

u

a

m

e

r

laoreet dolore magna aliquam era

t

at

GREEN

RED

BLACK

WHITE

25 mm

1 in.

WELDING CABLE

BOOT

TRIM

INSTALLATION

A-4 A-4

V350-PRO

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

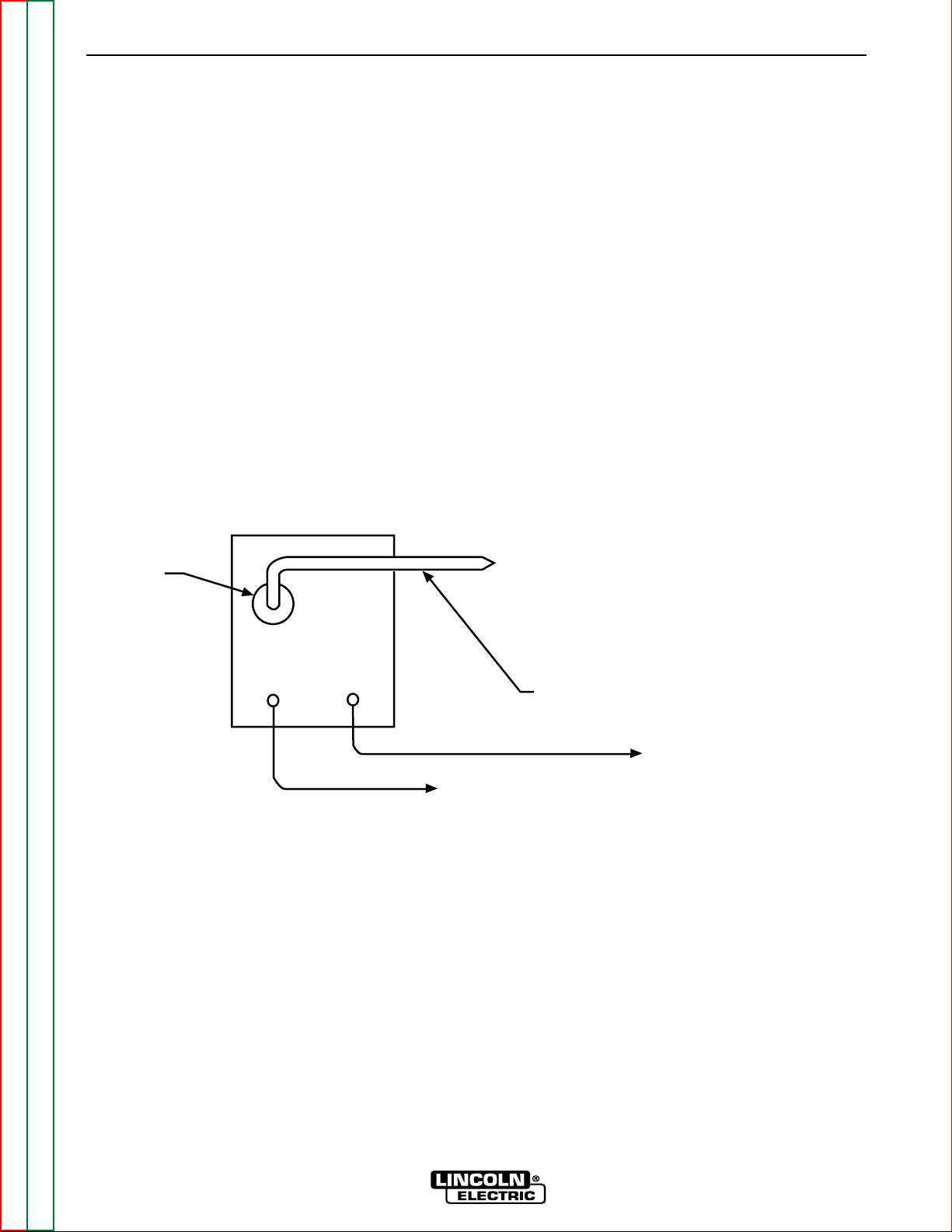

5. Tighten set screw to collapse copper tube. Screw

must apply pressure against welding cable. The

top of the set screw will be well below the surface

of the brass plug after tightening.

6. Slide rubber boot over brass plug. The rubber

boot must be positioned to completely cover all

electrical surfaces after the plug is locked into the

receptacle.

SET SCREW

BRASS PLUG

COPPER TUBE

Section B-1 Section B-1

V350-PRO

TABLE OF CONTENTS

- OPERATION SECTION -

Operation...............................................................................................................................Section B

Operating Instructions................................................................................................................B-2

Product Description .............................................................................................................B-2

Duty Cycle............................................................................................................................B-2

Operational Features and Controls ............................................................................................B-2

Upper Control Panel...................................................................................................................B-2

Amps Meter ..........................................................................................................................B-2

Volt Meter.............................................................................................................................B-2

Output Control......................................................................................................................B-2

Weld Terminals.....................................................................................................................B-2

Thermal.................................................................................................................................B-3

Control Remote....................................................................................................................B-3

Hidden Middle Control Panel .....................................................................................................B-3

Weld Mode Select................................................................................................................B-3

CC-Stick Soft..................................................................................................................B-3

CC-Stick Crisp ................................................................................................................B-3

TIG GTAW.......................................................................................................................B-4

CV-Wire...........................................................................................................................B-4

CV-Flux Cored ................................................................................................................B-4

Hot Start & Arc Control........................................................................................................B-4

Lower Case Front.......................................................................................................................B-4

CV Modes.............................................................................................................................B-4

TIG Mode ....................................................................................................................... ......B-5

CC-Stick Modes................................................................................................................. ..B-5

Types of Remote Output Control ................................................................................................B-5

Types of Remote Weld Terminal Control ....................................................................................B-5

Design Features and Advantages...............................................................................................B-5

Auxiliary Power................................................................................................................ ...........B-6

Limitations...................................................................................................................................B-6

Recommended Processes..........................................................................................................B-6

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

B-2

B-2

V350-PRO

OPERATION

OPERATING INSTRUCTIONS

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and

ground.

• Always wear dry insulating gloves.

------------------------------------------------------------------------

FUMES AND GASES can be dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to remove

fumes from breathing zone.

-------------------------------------------------------

-----------------

WELDING SPARKS can cause fire or

explosion.

• Keep flammable material away.

• Do not weld on closed containers.

------------------------------------------------------------------------

ARC RAYS can burn eyes and skin.

• Wear eye, ear and body

protection.

------------------------------------------------------------

See additional warning information at

front of this operators manual.

-----------------------------------------------------------

WARNING

GENERAL DESCRIPTION

PRODUCT DESCRIPTION

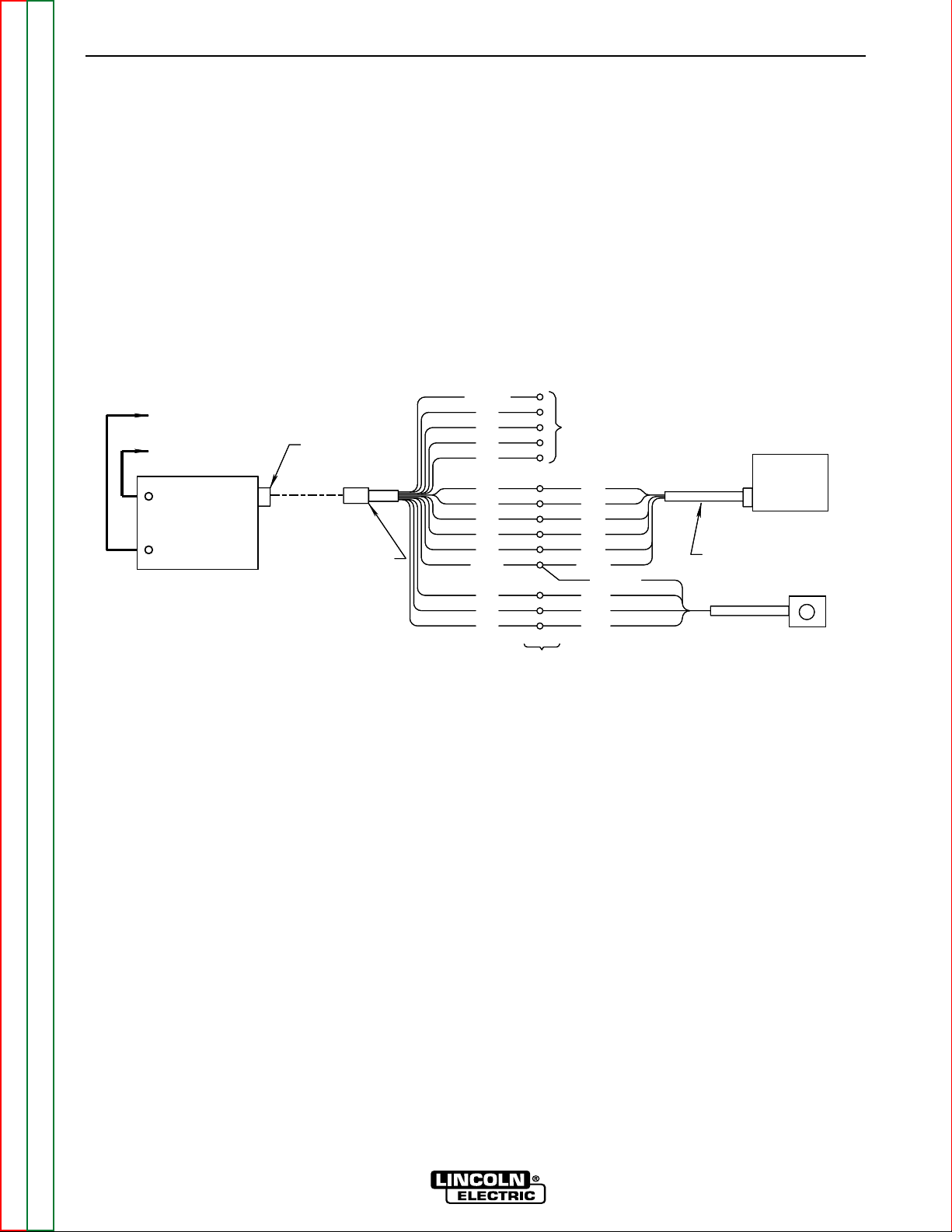

The Invertec V350-Pro offers multi mode CV and CC

DC welding and is rated 350 amps, 34 volts at a 60%

duty cycle. The V350-Pro is available in European and

Rest of the World (North America and Export) versions.

Differences between these versions are input ratings

and CE noise filtering. In the different configurations,

the V350-Pro is available in either a construction version (no wire feeder connection and auxiliary power)

and a factory version (includes wire feeder connection

and related power).

DUTY CYCLE

The V350-Pro is rated at 350 amps, 60% duty cycle

(based on a 10 minute cycle). It is also rated at 275

amps, 100% duty cycle.

OPERATIONAL FEATURES and CONTROLS:

UPPER CONTROL PANEL

1. AMPS Meter

• Prior to STICK or TIG operation (current flow), the

meter displays preset current value (either 2 amps or

+/- 3% (e.g. 3 amps on 100), whichever is greater).

• Prior to CV operation, the meter displays four dashes indicating non-presetable AMPS.

• During welding, this meter displays actual average

amps.

• After welding, the meter holds the actual current

value for 5 seconds. Output adjustment while in the

"hold" period results in the "prior to operation" characteristics stated above. The displays blink indicating that the machine is in the "Hold" period.

2. VOLT METER

• Prior to CV operation (current flow), the meter displays desired preset voltage value (+/- .5V).

• Prior to STICK or TIG operation, the meter displays

the Open Circuit Voltage of the Power Source or

four dashes if the output has not been turned on.

• During welding, this meter displays actual average

volts.

• After welding, the meter holds the actual voltage

value for 5 seconds. The displays blink indicating

that the machine is in the "Hold" period.

• Output adjustment while in the "hold" period results

in the "prior to operation" characteristics stated

above.

3. OUTPUT CONTROL

• Output control is conducted via a single turn potentiometer.

• Adjustment is indicated by the meters as stated

above.

• When in TIG modes, this control sets the maximum

welding current. Full depression of a foot or hand

Amptrol results in the preset level of current.

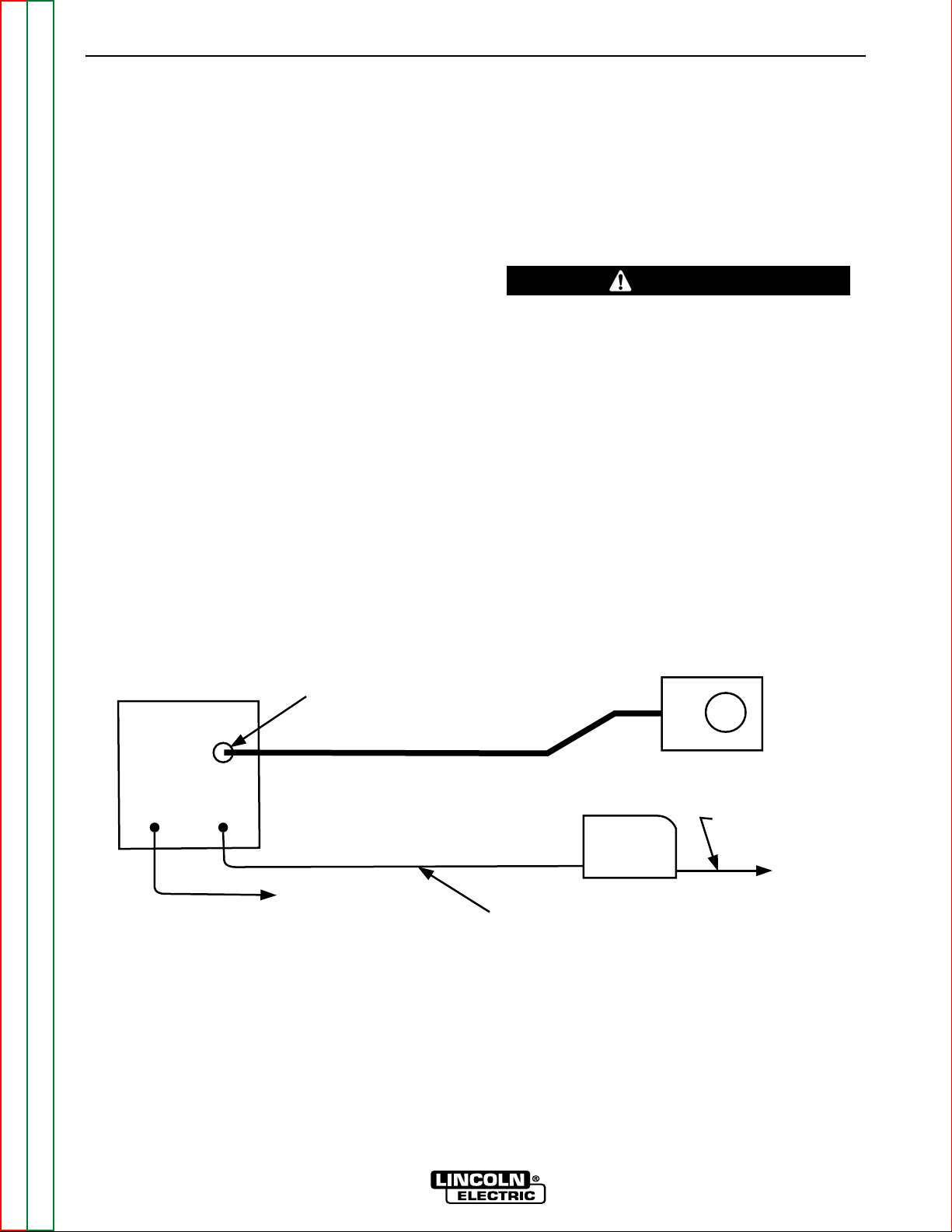

4. WELD TERMINALS-REMOTE , ON

• Two status lights indicate the location of trigger

control as determined by the "WELD TERMINALS"

push button.

• If trigger control is local "weld terminals on", the ON

display will be lit.

• If trigger control is remote "weld terminals remotely

controlled", the REMOTE display will be lit.

• The unit will power up in "pre-determined preferred"

trigger modes.

For the Construction version all modes ON.

For the Factory version

STICK = ON

TIG and CV = ON or REMOTE depending if remote

output controls are connected to the machine.

OPERATION

B-3 B-3

V350-PRO

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

For both the Construction and Factory versions,

these trigger modes can be over-ridden (switched)

with the WELD TERMINALS push button. When

changed, the unit will power up in the configuration it

was in when it was last powered down.

5. THERMAL

• This status light indicates when the power source

has been driven into thermal overload. If the output

terminals were "ON", the "ON" light will blink indicating that the output will be turned back on once

the unit cools down to an acceptable temperature

level. If the unit was operating in the "REMOTE"

mode, the trigger will need to be opened before or

after the thermal has cleared and closed after the

machine has cooled down to an acceptable temperature to establish output.

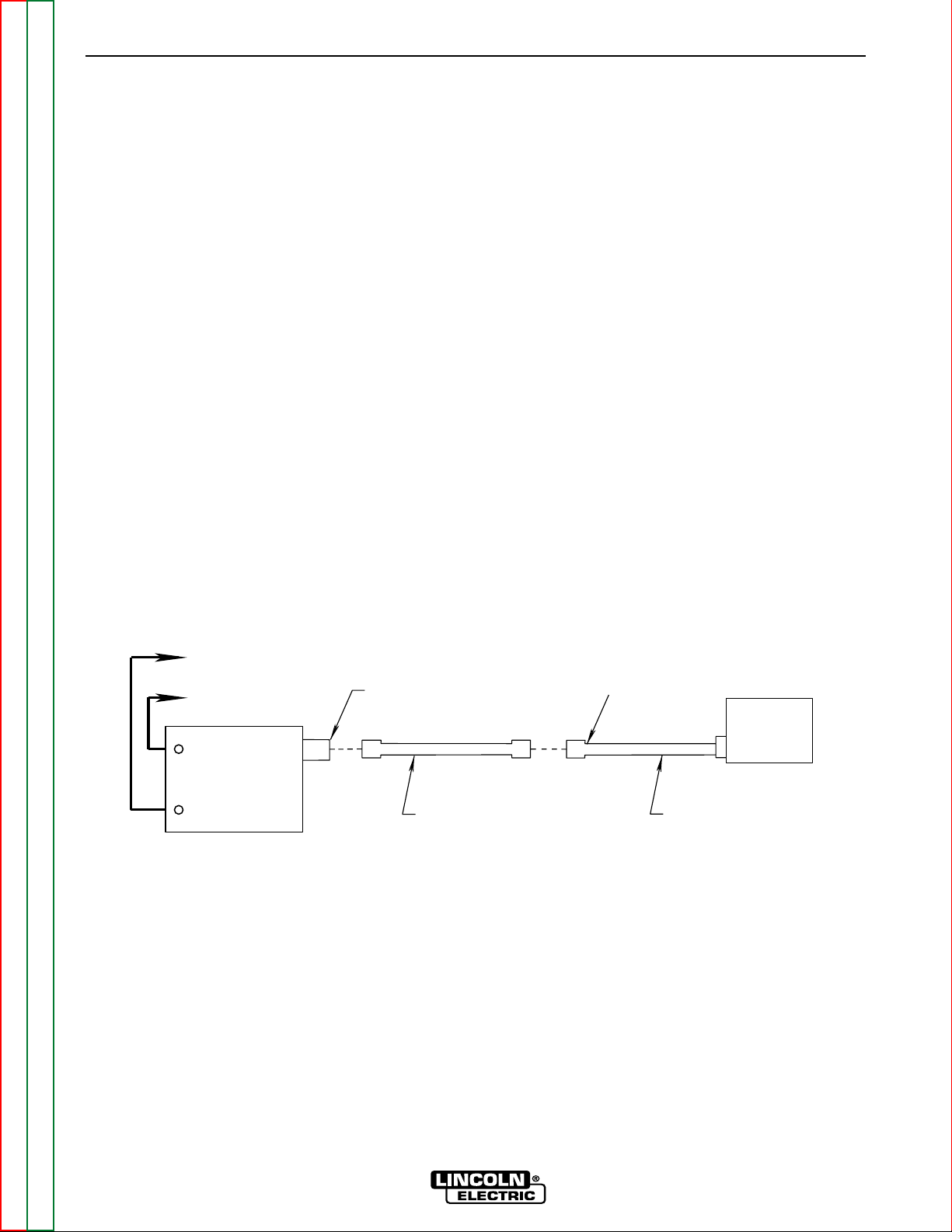

6. CONTROL-REMOTE , LOCAL

• Two status lights indicate the location of output

control as pre-determined by the power sources

auto-configure system.

• The LOCAL display will be lit when control is at the

power source.

• The REMOTE display will be lit when a remote

pot/control is detected.

These Output Control configurations can be overridden (switched) with the CONTROL push button.

When changed, the unit will power up in the configuration it was in when it was last powered down.

Hidden Middle Control Panel – Process

Set Up Panel

The middle control panel is removable to allow for

upgrades (see Field Installed Options/Accessories).

Additionally, this panel is hidden by an access door

to reduce appeared complexity and provide protection

to the controls.

7. WELD MODE SELECT

The Mode Control button selects the following welding modes desired.

CC-STICK SOFT: The Stick Soft process features

continuous control ranging from 5 to 425 amps. This

mode was intended for most SMAW applications, and

Arc Gouging.

• Arc Gouging: Setting the output of the Stick Soft