Lincoln Electric RANGER 405D Operating Manual

IMA 608D

September 2004

OPERATING MANUAL

THE LINCOLN ELECTRIC COMPANY

(AUSTRALIA) PTY. LTD.

A.B.N. 36 000 040 308

SYDNEY. AUSTRALIA

A Subsidiary of

THE LINCOLN ELECTRIC CO. U.S.A.

Associated Subsidiaries in Australasia, Asia, Canada, Europe, North and South America.

THE WORLD’S LEADER IN WELDING AND CUTTING PRODUCTS

SAFETY DEPENDS ON YOU

Lincoln Electric welders are designed and built with safety in mind. However, your overall safety can be

increased by proper installation and thoughtful operation on your part. Read and observe the general safety

precautions on page 2 and follow specific installation and operating instructions included in this manual.

Most importantly, think before you act and be careful.

RANGER 405D

Part No. KA1453

Multi Process DC Welder & three phase 15 kVA

Auxiliary Power Generator - Diesel Engine driven

Engine - Kubota / Perkins

P R OTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. READ AND

U N D E R S TAND BOTH THE SPECIFIC INFORMATION GIVEN IN THE OPERATING MANUAL FOR THE

WELDER AND/OR OTHER EQUIPMENT TO BE USED AS WELL AS THE FO L L OW I N G GENERAL

ARC WELDING SAFETY PRECAUTIONS

1. a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do not touch

these “hot” parts with your bare skin or wet clothing.

Wear dry, hole-free gloves to insulate hands.

b. In semi-automatic and automatic wire welding, the

electrode, electrode reel, welding head and nozzle or

semi-automatic welding gun are also electrically “hot”.

c. Insulate yourself from work and ground using dry

insulation. When welding in damp locations, on metal

framework such as floors, gratings or scaffolds, and

when in positions such as sitting or Lying, make certain

the insulation is large enough to cover your full area of

physical contact with work and ground.

d. Always be sure the work cable makes a good electrical

connec tion with the metal being welded. T h e

connection should be as close as possible to the area

being welded.

e. Ground the work or metal to be welded to a good

electrical (earth) ground.

f. Maintain the electrode holder, work clamp, welding

cable and welding machine in good, safe operating

condition. Replace damaged insulation.

g. Never dip the electrode holder in water for cooling.

h. Never simultaneously touch electrically “hot” parts of

electrode holders connected to two welders because

voltage between the two can be the total of the open

circuit voltage of both welders.

i. When working above floor level, protect yourself from

a fall should you get a shock.

j. Also see items 4c and 6.

2. a. Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. When

welding, keep your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep fumes and

gases away from the breathing zone. When welding

on galvanised, lead or cadmium plated steel and other

metals which produce toxic fumes, even greater care

must be taken.

b. Do not weld in locations near chlorinated hydrocarbon

vapours coming from degreasing, cleaning or spraying

operations. The heat and rays of the arc can react with

solvent vapours to form phosgene, a highly toxic gas,

and other irritating products.

c. Shielding gases used for arc welding can displace air

and cause injury or death. Always use enoug h

ventilation, especially in confined areas, to ensure

breathing air is safe.

d. Read and understand the manufacturer ’ s instructions

for this equipment and the consumables to be used,

including the material safety data sheet (MSDS) and

follow your employer’s safety practices.

e. Also see Item 7b.

3. a. Use a shield with the proper filter and cover plates to

protect your eyes from sparks and the rays of the arc

when welding or observing open arc welding.

Headshield and filter lens should conform to A S

1674.2-1990 standards.

b. Use suitabl e clothing made from durable flame

resistant material to protect your skin and that of your

helpers from the arc rays.

c. Protect other nearby personnel with suitable non

flammable screening and/or warn them not to watch

the arc or expose themselves to the arc rays or to hot

spatter or metal.

4. a. Remove fire hazards from the welding area. If this is

not possible, cover them to prevent the welding sparks

from starting a fire. Remember that welding sparks

and hot materials from welding can easily go through

small cracks and openings to adjacent areas. Have a

fire extinguisher readily available.

b. Where compressed gases are to be used at the job

site, special precautions should be used to prevent

hazardous situations. Refer to AS1674 Parts 1 & 2

“Safety in Welding and Allied Processes”, WTIA

Technical Note 7 “Health and Safety in Welding” and

the operating information for the equipment being

used.

c. When not welding, make certain no part of the

electrode circuit is touching the work or ground.

Accidental contact can cause overheating and create

a fire hazard.

d. Do not heat, cut or weld tanks, drums or containers

until the proper steps have been taken to insure that

such procedures will not cause flammable or toxic

vapours from substances inside. These can cause an

explosion even though the vessel has been “cleaned”.

For information purchase AS 1674-1990.

e. Vent hollow castings or containers before heating,

cutting or welding. They may explode.

f. Sparks and spatter are thrown from the welding arc.

Wear oil free protective garments such as leather

gloves, heavy shirt, cuffless trousers, high shoes and

a cap over your hair. Wear ear plugs when welding out

of position or in confined places. Always wear safety

glasses with side shields when in a welding area.

g. Connect the work cable to the work as close to the

welding area as possible. Work cables connected to

the building framework or other locations away from

the welding area increase the possibility of the welding

current passing through lifting chains, crane cables or

other alternate circuits. This can create fire hazards or

overheat lifting chains or cables until they fail.

h. Also see Item 7c.

ELECTRIC SHOCK can kill

FUMES AND GASES

can be dangerous

A R C RAYS can burn

WELDING SPARKS can

cause fire or explosion

5. a. Use only compressed gas cylinders containing the

correct shielding gas for the proce ss used and

properly operating regulators, designed for the gas

and pressure used. All hoses, fittings, etc. should be

suitable for the application and maintained in good

condition.

b. Always keep cylinders in an upright position and

securely chained to an undercarriage or fixed support.

c. Cylinders should be located :

• Away from areas where they may be struck or

subjected to physical damage.

• A safe distance from arc welding or cutting

operations and any other source of heat, sparks or

flame.

d. Never allow the electrode, electrode holder, or any

other electrically “hot” parts to touch a cylinder.

e. Keep your head and face away from the cylinder valve

outlet when opening the cylinder valve.

f. Valve protection caps should always be in place and

hand-tight except when the cylinder is in use or

connected for use.

g. Read and follow the instructions on compressed gas

cylinders and associated equipment, and AS 2030

Parts 1 & 2.

6. a. Turn off input power using the disconnect switch at the

fuse box before working on the equipment.

b. Install equipment in accordance with the SAA Wiring

Rules, all local codes an d the manufac turer’s

recommendations.

c. Ground the equipment in accordance with the SAA

Wirin g Rules and the manufactur er’s

recommendations.

7. a. Turn the engine off before troubleshooting

and maintenan ce work unless the

maintenance work requires it to be running.

b. Operate engines in open, well ventilated

areas or vent the engine exhaust fumes

outdoors.

c. Do not add fuel near an open flame,

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refuelling to prevent spilled fuel from

vaporizing on contact with hot engine

parts and igniting. Do not spill fuel when

filling tank. If fuel is spilled, wipe it up and

do not start engine until fumes have been

eliminated.

d. Keep all equipment, safety guards, covers

and devices in position and in good repair.

Keep hands, hair, clothing and tools away

from V-belts, gears, fans and all other

moving parts when starting, operating or

repairing equipment.

e. In some cases it may be necessary to

remove safety guards to perform required

maintenance. Remove guards only when

necessary and replace them when the

maintenance requiring their removal is

complete. Always use the greatest care

when working near moving parts.

f. Do not put your hands near the engine

fan. Do not attempt to over ride the

governor or idler by pushing on the throttle

control rods while the engine is running.

g. To prevent accidentally starting petrol

engines while tur ning the engine or

welding generator during maintenance

work, disconnect the spark plug wires,

distributor cap or magneto wi re as

appropriate.

h. To avoid scalding do not remove the

radiator pressure cap when the engine is

hot.

CYLINDER may explode if

damaged

FOR ELECTRICALLY

powered equipment

FOR ENGINE

powered equipment

HAVE ALL INSTALLATIONS, OPERATION, MAINTENANCE AND REPAIR WORK PERFORMED BY QUALIFIED PEOPLE

HOW TO ORDER REPLACEMENT PARTS

To ensure that you receive the correct replacement part the following procedure should be followed:

1. Quote Serial Number and Code Number.

2. Quote the Description, Item Number and Parts List Number of the desired part. When ordering parts for items carrying brand names

of other companies, such as fan motors, drive shafts, etc., be sure to include the other company’s name and part number and other

relevant information.

3. Should the primary cord be damaged, a special cord is required, and is available from Lincoln Electric.

4. Parts should be ordered from Lincoln, its offices or the nearest Authorised Field Service Shop. (The “Lincoln Service Directory” listing

these shops geographically is available on request.)

Note: “Hardware” in the Lincoln Parts Lists are not Lincoln stock items but can be obtained via the Field Service Shop network.

Component parts of assemblies such as stator coils or armature coils, etc., which require electrical testing or locating fixtures are not

considered replaceable items. This is to ensure that the customer receives parts which will keep the welder in the best operating condition.

BUY ONLY GENUINE REPAIR PARTS

For more detailed information it is strongly recommended that you purchase a copy of “Safety in Welding and Cutting - ANSI Standard Z

49.1” and WTIA Technical Note 7. All WTIA publications and ANSI/AWS Standards are available from the Welding Technology Institute of

Australia, P.O. Box 6165, Silverwater NSW 2128. For copies of various Australian Standards contact your local S.A.A. office.

VRD - VOLTAGE REDUCTION DEVICES

What are VRD & ROCV Devices?

VRD's are gaining popularity as a "must have" safety accessory

especially where welding applications are being carried out in an

environment with a high-risk of electric shock such as wet areas

and hot humid sweaty conditions.

VRD & ROCV are the abbreviations of two different naming

conventions used to describe safety device fitted to welding

power source to help protect the operator from electric shocks.

VRD stands for ‘Voltage Reduction Device’ and ROCV stands for

‘Reduced Open Circuit Voltage’ both devices are either fitted as

an after market addition or part of the integral design of a

machine. They reduce the voltage at the welding output terminals

whilst not welding to a no load voltage of no more than 35V for dc

welding and for AC welding 35V peak 25V a.c. rms, when the

resistance of the output circuit is below 200Ø (ohms). The lower

reactivation resistance is of the device the higher the safety level

but also requires that the welding cable connections be keep in

good electrical condition.

Having good electrical connections also limit the possibility of

other safety issues such as heat-generated damage, burns and

fires.

Welding Power Sources

Welding power sources generally have an Open Circuit Voltage

(i.e. the voltage at the welding output terminals whilst not welding)

in the ranges of 35 – 115VDC. Welding machines for stick

welding (MMAW) and similar constant current (CC) processes,

supply a higher open circuit voltage between the electrode and

the work when the welding machine is switch on and ready to

commence welding. These welding machines have a drooping

characteristic, with the open circuit voltage higher (typically

60-80V) than when the arc is established and welding current is

drawn (20-35V).

Consequently, the greatest danger occurs when handling the

electrodes and the electrode holder between welding operations,

such as when changing electrodes.

Welding machines for MIG (GMAW & FCAW) have a flat constant

voltage (CV) characteristic, generally with a lower open circuit

voltage (30-60V). Also, the current is turned on & off by a gun

trigger, which also controls the wire feed. Therefore, the welder is

not exposed to open circuit voltage, unless the trigger is turned on

and the wire is feeding. Also, electrodes are not changed as

frequently as for stick welding (MMAW).

For these reasons VRD/ROCV’s are more common ly

incorporated into the stick welding mode (CC) of welding

machines being used in environments with high-risk of electric

shock.

All multi-process CC/CV machines which are fitted with VRD’s do

not offer low voltage protection in CV modes. If the multi-process

machine has a “WELD TERMINAL ENABLE SWITCH” enabled,

the weld outpu t terminals will be electrically ‘HOT’ a n d

potentially High Voltage present.

Only ‘ACROSS THE ARC’ type wire feeders with a internal

contactor fitted should be used in this configuration.

Arc air gouging is not recommended in CV. Due to ‘CV MODE’

not offering VRD protection.

This reduction of the voltage supplies a safer level of voltage

when an arc is not being struck or when an electrical resistance

less than the welder’s body resistance have been detected.

All VRD’s are only an aid to safety and personal protective

equipment and safe working practices must be observed at all

times. The risk of electric shock during welding from a correctly

installed and maintained welding machine is negligible, provided

that sensible precautions are taken by the user and correct safe

working procedures are followed. All parts of the output circuit

should be considered electrically alive, and consequently welders

should ensure that no part of their body is placed in such a

position as would complete a path through it for the passage of

electric current. Safe working procedures should always be

followed whether a VRD is fitted or not.

Operation

Due to inherit low voltage safety features of the VRD’s to reduce

the possibility of electric shock to the operator. A very slight delay

during striking of the electrode may be experienced. The high

voltage that is available on units without VRD’s allows them to

penetrate and burn through dirty, painted and heavily mill scale

plate. Units fitted with VRD’s cannot penetrate and are required

to register the correct resistance, which switches the safety

device into weld mode. Unlike other VRD’s Lincoln uses micro

processor control to monitor and establish the arc without the

sticking and shorting of the electrode to the job as seen in many

other VRD installations. Due to the requirement of the resistance

in the c ircuit to be low for a VRD to ope rate, a good

metal-to-metal contact must be made between the metal core of

the electrode and the job. A damaged or poor connection

anywhere in the output circuit may limit the operation of the VRD.

Some electrodes form a cone at the end of the electrode after the

welding arc has been broken, particularly iron powder and low

hydrogen electrodes. This cone will need to be broken off in order

to have the metal core of the electrode to make contact.

Safe working procedures should always be followed whether

a VRD is fitted or not.

W A R N I N G

WELDING, EMF & PACEMAKERS

All welders should follow safe practices that minimise their

exposure to electric and magnetic fields (EMF).

For welders wearing implanted pacemaker s, safe welding

practices are particularly important and additional procedures

should be followed by those who have decided to continue to

weld. (Hopefully in keeping with a doctor’s advice).

The following procedures will not eliminate exposure to EMF or

the possibility of arc welding having an effect on a pacemaker,

however if followed, they will significantly reduce exposure to

electric and magnetic fields. Electric and magnetic fields are

created any time electric current flows through a conductor,

however it is not clear whether such exposure affects ones

health.

Some researchers have reported that exposure to EMF may

cause leukemia or other illnesses. These claims originally arose

in relation to high voltage electric power lines and are very much

in dispute in the medical and scientific arena, however the best

advice is to minimise your exposure to EMF to protect your health

should doctors eventually decide there is a risk.

There are four fundamental facts about EMF:

• With direct current (DC), the field strength is relatively

constant and does not change.

• With alternating current (AC), the field strength constantly

changes.

• The greater the current flow, i.e. the higher the amps, the

stronger the field created by the current

• The closer the conductor or electrical device is to the body,

the greater the exposure to the field.

Minimising exposure

All welders should use the following procedures to minimise EMF

exposure.

• Route electrode or gun and work cables together. Secure

them with tape if possible.

• Never coil the electrode lead around your body.

• Do not place your body between the electrode and work

cables. If your electrode cable is on your right side the work

cable should also be on your right side.

• Connect the work cable to the work piece as close as

possible to the area being welded. (This is also a good

practice to eliminate a common problem on welding - a poor

work connection.

• Do not work next to the welding power source.

Welders with pacemakers

There is no question that the fields in arc welding can interfere

with a pacemakers function. Generally the interference does not

permanently damage the pacemaker. Once the wearer leaves the

arc welding environment or stops welding, the pacemaker returns

to normal functioning. The welding arc has little or no effect on the

operation of some pacemakers, especially designs that are bipolar or designed to filter out such interference.

For a welder or anyone working around electrical equipment the

selection of a pacemaker is very important. Get a doctor’s advice

about which pacemaker is the least sensitive to interference from

welding while still being medically suitable.

In addition to the normal safety precautions, the following

additional procedures should be adopted by welder s with

pacemakers.

• Use gas welding when the application is suitable.

• Use the lowest current settin g appropriate for the

application. Do not exce ed 400 amps . Low current

(75-200 amps) direct current (DC) welding should be used if

arc welding is necessary. Do not TIG weld with high

frequency.

• Do not use repeated, short welds. Wait about ten seconds

between stopping one weld and starting the next. When

having difficulty starting an electrode, do not re-strike the rod

repeatedly.

• If you feel light headed, dizzy or faint, immediately stop

welding. Lay the electrode holder down so that it does not

contact the work and move away from any welding being

performed. Arrange your work in advance so that, if you

become dizzy and drop the electrode holder, the electrode

holder will not fall on your body or strike the work.

• Do not work on a ladder or other elevated position or in a

cramped, confined place.

• Do not work alone. Work only in the presence of an

individual who underst ands these precautions and the

possible effect welding may have on your pacemaker.

• Do not work near spot welding equipment.

• If you have a pacemaker and wish to continue arc welding,

discuss this and any other questions you may have with your

physician and follow his or her advice. The doctor may wish

to contact the pac emaker manufac turer for a

recommendation. As mentioned before, the design of the

pacemaker significantly affects the degree to which it is

subject to interference from a welding circuit. Do not rely on

the fact that you know another welder with a pacemaker who

has welded for years without experiencing a problem. That

welder and his or her pacemaker may be quite different from

you and your pacemaker.

Conformance

Products displaying the C-Tick mark are in conformity with

Australian/ New Zealand requirements for Elec tromagnet ic

Compatibility (EMC). They are:

• manufactured in conformity with Australian/New Zealand

Standa rd (Emission):- AS/NZS 36 52 ‘Electromagnet ic

Compatibility - Arc Welding Equipment’ (Identical to and

reproduced from British Standard EN 50199)

• for using with other Lincoln Electric/LiquidArc equipment.

• designed for industrial and professional use.

Introduction

All electrical equipment generates small amounts of electromagnetic emission. Electrical emission may be transmitted through

power lines or radiated through space, similar to a radio

transmitter. When emissions are received by other equipment,

electrical interference may result. Electrical emissions may effect

many kinds of electrical equipment: other nearby welding

equipment, radio and TV transmitters and receivers, numerical

controlled machines, telephone systems, computers, etc. Be

aware that interference may result and extra precautions may be

required when a welding power source is used in a domestic

establishment.

Installation and Use

The purchaser/user is responsible for installing and using the

welding equipment according to the manufacturer’s instructions.

If electromagnetic disturbances are detected then it shall be the

responsibility of the purchaser/user of the welding equipment to

resolve the situation with the technical assi stanc e of the

manufacturer. In some cases this remedial action may be as

simple as earthing (grounding) the welding circuit (see note

below). In other cases it could involve constructing an electromagnetic screen enclosing the power source and the work

complete with associated input filters. In all cases electromagnetic disturbances must be reduced to the point where they are no

longer troublesome.

Note: The welding circuit may or may not be earthed for safety

reasons according to national codes. Changing the earthing

arrangements should only be authorised by a person who is

competent to assess whether the changes increase the risk of

injury, eg. by allowing parallel welding current return paths which

may damage the earth circuits of other equipment.

Assessment of Area

Before installing welding equipment the purchaser/user shall

make an assessment of potential problems in the surrounding

area.

The following shall be taken into account:

a. Other supply cables, control cables, signalling and telephone

cables above, below and adjacent to the welding equipment;

b. Radio and television transmitters and receivers;

c. Computer and other control equipment;

d. Safety critical safety equipment, eg. guarding of industrial

equipment;

e. The health of people around, eg. the use of pacemakers and

hearing aids;;

f. Equipment used for calibration or measurement;

g. The immunity of other equipment in the environment. The

purchaser/user shall ensure that other equipment being used

in the environment is compatible. This may require additional

protection measures;

h. The time of the day that welding or other activities are to be

carried out.

The size of the surrounding area to be considered will depend on

the structure of the building and other activities that are taking

place. The surrounding area may extend beyond the boundaries

of the premises.

Methods of Reducing Emissions

Mains Supply

Welding equipment should be connected to the mains supply

according to the manufacturer’s recommendations.If interference

occurs, it may be necessary to take additional precautions such

as filtering the mains supply. Consideration should be given to

shielding the supply cable of permanently installed welding

equipment in metallic conduit or equivalent. Shielding should be

electrically continuous throughout its length. The shielding should

be connected to the welding power source so that good electrical

contact is maintained between the conduit and the welding power

source enclosure.

Maintenance of the Welding Equipment

The welding equipment should be routinely maintained according

to the manufacturer’s recommendations. All access and service

doors and covers should be closed and properly fastened when

the welding equipment is in operation. The welding equipment

should not be modified in any way except for those changes and

adjus tmen t c overed in the m anufactu rer ’s instructions. In

particular, the spark gaps of arc initiation and stabilising devices

should be adjusted and maintained ac cording to the

manufacturer’s recommendations.

Welding Cables

The welding cables should be kept as short as possible and

should be positioned close together, running at or close to the

floor level.

Equipotential Bonding

Bonding of all metallic components in the welding installation and

adjac ent to it should be considered. Howev er, met allic

components bonded to the work piece will increase the risk that

the operator could receive a shock by touching these metallic

components and the electrode at the same time. The operator

should be insulated from all such bonded metallic components.

Earthing of the workpiece

Where the workpiece is not bonded to earth for electrical safety,

nor connected to earth because of its size and position, eg. ship’s

hull or building steelwork, a connection bonding the workpiece to

earth may reduce emissions in some, but not all instances. Care

should be taken to prevent the earthing of work pieces increasing

the risk of injury to users, or damage to other electrical

equipment. Where necessary, the connection of the workpiece to

earth should be made by direct connection to the workpiece, but

in some countries where direct connection is not permitted, the

bonding should be achieved by suitable capacitance, selected

according to national regulations.

Screening and Shielding

Selective screening and shielding of other cables and equipment

in the surrounding area may alleviate problems of interference.

Screening of the entire welding installation may be considered for

special applications.*

* Portions of the preceding text are cont ained in A S / N Z S 3 6 5 2 :

‘Electromagnetic Compatibility - Arc Welding Equipment’.

INSTRUCTIONS FOR ELECTROMAGNETIC COMPATIBILITY

This welding machine must be used by trained operators

only. Read this manual carefully before attempting to use

the welding machine.

W A R N I N G

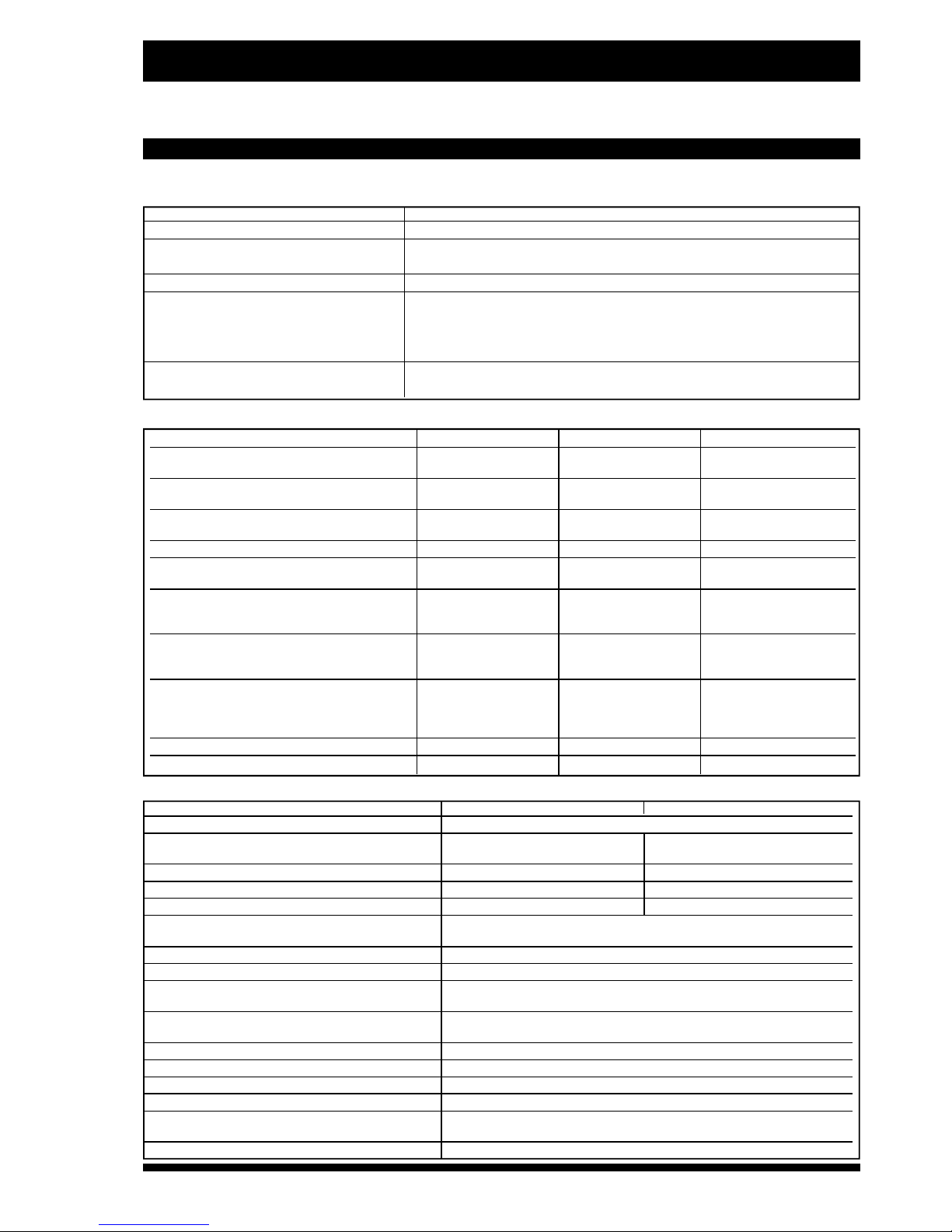

PRODUCT DESCRIPTION

The Ranger 405D is a diesel engine driven alternator power source for multi-process DC welding and for 115/230-240/400-415VAC

auxiliary* and standby power. It is housed in a sound reduced enclosure for quiet operation.

* Auxiliary outlets and circuit breakers depend on model purchased.

THE RANGER 405D IS NOT RECOMMENDED FOR PIPE THAWING

Part Number

KA1453-1, KA1453-2, KA1453-3, KA1453-4, KA1453-5, KA1453-6, KA1453-7, KA1453-20

DC Constant Current – Current Range 30 to 405 Amps

Maximum OCV – Reduced OCV (VRD) 62 Volts – Reduced < 8 Volts

Arc Force Control Factor x 1 to x 2.6

DC Constant Voltage – Open Circuit Range 15 to 49 Volts

Ratings:-

Low Inductance Receptacle 400 Amp @ 20 Volt 30% Duty Cycle

350Amp @ 30Volt 60% Duty Cycle

300Amp @ 32Volt 100% Duty Cycle

High Inductance Receptacle 335Amp @ 30Volt 50% Duty Cycle

250Amp @ 30Volt 100% Duty Cycle

Machine Specifications - Welding

Auxiliary Power - (When welding, maximum available auxiliary power is reduced)

Part Number KA1453-1,-4, -7 & -20 KA1453-2 &-5 KA1453-3 & -6

Ratings (Factory set) voltage regulation 415V (3 Ph) & 400V (3 Ph) & 230V (1 Ph) & 400V (3 Ph)

is within +/-7% @ all loads up to rated capacity) 240V (1 Ph) 230V (1 Ph) 115V (Centre Tapped Earth)

Total Loading (100% Duty Cycle) 15kVA @ Unity 14.4kVA @ Unity 14.4kVA @ Unity

12kW @ 0.8pf 11.5kW @ 0.8pf 11.5kW @ 0.8pf

Wire Feeder Supply 115V @ 5 Amps AC & 115V @ 5 Amps AC & 115V @ 5 Amps AC

42V @ 10 Amps AC 42V @ 10 Amps AC 42V @ 10 Amps AC

Frequency 50Hz 50Hz 50Hz

Automatic Electronic Voltage Regulator (AVR) 115/230/400V

Factory set for 240/415V Output 230/400V Output 115V Output

Protection & Receptacles

Residual Current Device (RCD) 4 Pole, 25 Amp, 4 Pole, 25 Amp, 4 Pole, 25 Amp

(30mA Trip Current) (30mA Trip Current) (30mA Trip Current)

Thermal / Magnetic Circuit Breakers 3 Ph 20 Amp x 1 & 3 Ph 20 A, x 1 & 3 Ph 20 Amp x 1

1 Ph 16 Amp x 3 1 Ph 16 Amp x 2 1 Ph 16 Amp x 1

2 Ph 20 Amp x 1

Receptacles 415V (3 Ph) x 1 400V (3 Ph) x 1 400V (3 Ph) x 1

240V (1 Ph) x 3 230V (1 Ph) x 2 230V (1 Ph) x 1

14 pin Amphenol x 1 14 pin Amphenol x 1 115V (1Ph) x 3

14 pin Amphenol x 1

Dimensions approx. L x W x H 1600 x 733 x 970 1665 x 733 x 970 1665 x 733 x 970

Weight approx. 550 kg 550kg 550kg

Make / Model Kubota / D1105 Perkins / 403C-11

Type 3 Cyl., Water cooled, 4 Cycle, Diesel

Combustion Chamber Spherical type; 3 Vortex Naturally aspirated

Combustion System Indirect injection

Bore & Stroke 78 x 78.4mm 77 x 81mm

Displacement 1124cc 1131cc

Power (SAE, J1349 net intermittent) 18.6kW @ 3000rpm 19.6kW @ 3000rpm

Electrical System 12V Battery & Starter, Key Start & Stop, Glow Plugs, Alternator

Battery Charger (internal regulator)

Governor Type Centrifugal (flywheel high speed mechanical)

Lubrication Forced feed full flow oil filter

Cooling System Pressurised (0.9 kg/cm2) Radiator. Pump forced circulation,

capacity is 4L and an overflow reservoir bottle.

Fuel System Indirect injection pre fitted to fuel filter with shut off, lift pump, bypass valve

for easy bleeding.

Fuel Tank Capacity 45 litres

Air Cleaner Heavy Duty, 2 Stage dry cartridge type

Engine Idler Automatic (with manual over-ride)

Muffler Low Noise

Engine Protection System with ‘First Alarm’ Shutdown on - High electricals temperature, High coolant

latched LED indication temperature, Low oil pressure, welding output failure

Operating Speeds (approximate) High Idle - 3130rpm Low Idle - 1580rpm Full Load - 3000rpm

Engine Specifications

Technical Specifications

Before Starting your Welder

Pre-Operation Service

READ the engi ne operating and maintenanc e instructions

supplied with this machine.

Oil

The Ranger 405D is shipped with the engine crankcase filled with

the correct grade oil for the run-in period. Check the oil level

before starting the engine. If it is not up to the full mark on the dip

stick, add oil as required. Check the oil level every four hours of

running time during the first 35 running hours. Refer to the engine

Operator’s Manual for specific oil recommendations and run-in

information.

Fuel - use diesel fuel only

Fill the fuel tank with clean, fresh diesel fuel. The capacity is 45

litres. See engine Operator’s Manual for specific fuel recom-

mendations. Do not allow the Ranger 405D to run out of fuel.

This necessitates bleeding the injector system.

Engine Coolant

The welder is shipped with the engine and radiator filled with

engine coolant. Before starting the engine check coolant level in

the radiator, add more pre-mixed coolant if required. See

Maintenance Section and engine Operator’s Manual for more

information on coolant.

Battery

Important: In order that control electronics will function

correctly, the Ranger 405D must always have its battery

connected whenever its engine is running. The battery must

be in good condition, and fully charged.

GASES FROM BATTERY CAN EXPLODE.

• Keep sparks, flame and cigarettes away

from battery.

To prevent Explosion when:

• Installing a new battery - disconnect negative cable from

old battery first and connect to new battery last

• Connecting a battery charger - remove battery from welder

by disconnecting negative cable first, then positive cable and

battery clamp. When reinstalling, connect negative cable last.

Keep well ventilated.

• Using a booster - connect positive lead to battery first then

connect negative lead to the chassis/engine strap.

THE RANGER 405D IS FURNISHED WITH A

WET CHARGED BATTERY

Battery Connection Instructions

The Range r is shipped with the negat ive batter y cable

disconnected. Before you operate the machine, make sure the

Key Switch is in the OFF position and attach the disconnected

cable securely to the negative (-) battery terminal.

Note: This machine is furnished with a wet charged battery; if

unused for an extended time, the battery may require a booster

charge. Be sure to use the correct polarity when charging the

battery. (If the battery terminal voltage is less than 12.47 volts,

then it will need recharging

before

use).

• Battery electrolyte contains sulphuric acid which is corrosive

to skin and clothing.

• Batteries also discharge explosive gases.

• When charging provide adequate ventilation to allow the safe

escape of explosive gases.

• Do not do anything to cause sparks near the battery. Keep

naked flames and cigarettes away from battery.

• If acid contacts eyes or skin flush immediately with large

quantities of clean drinking water.

• In case of acid contacting eyes, consult a doctor immediately.

• After use wash out empty electrolyte bottles with water and

dispose of carefully - do not use empty electrolyte bottles for

any other purpose.

• Always keep batteries and electrolyte out of reach of children.

• Dispose of old batteries carefully.

Important Note: Battery must not be filled or “topped

up” whilst it is in normal operating position - always

remove from machine.

Battery acid can burn eyes and skin

•Wear gloves and eye protection and be

careful when working near battery.

•Follow instructions printed on battery.

DIESEL fuel

can cause fire or

explosion

• Stop engine when fuelling.

• Do not smoke when fuelling.

• Remove cap slowly to release pressure.

• Do not overfill tank.

• Wipe up spilled fuel and allow fumes to

clear before starting engine.

• Keep sparks and flame away from tank.

HOT COOLANT CAN BURN SKIN

Do not remove cap if radiator is hot.

W A R N I N G

W A R N I N G

W A R N I N G

W A R N I N G

Angle of Operation

Engines are designed to run in the level condition which

is where the optimum performance is achieved. The maximum

angle of operation for the Kubota engine and Perkins engine is

20° continuously in any direction. If the engine must be operated

at an angle, provisions must be made for checking and

maintaining the oil level at the normal (FULL) oil capacity in the

crankcase.

When operating the welder at an angle, the effective fuel capacity

will be slightly less than the specified 45 litres.

High Altitude Operation

At higher altitudes, output derating may be necessary. As a rule

of thumb, derate the welder output 0.4% for every 30m above

150m.

Contact Kubota/Perkins Service Representative for any engine

adjustments that may required.

Optional Field Installed Accessories

KA1373 Power Plug Kit (suits KA1453-1, -4, -7 & -20 415/240V

Australian plugs)

KA1373-3 Power Plug Kit (suits KA1452-5 400/380/230/220V

Provides a plug for each auxiliary power receptacle.

KIT400 Accessory Kit

Includes:- Electrode Holder, ground clamp, flip front Headshield,

supervisibility lens, Non-spat ter lens, wire brush, chipping

hammer.

KIT1600T Lead Kit

Includes:- One 10m & one 9m length of 50mm2cable with one

Twistmate connector fitted to each.

K857 Remote Control (Weld Control)

Portable control provides same dial range as the output control

on the welder from a location up to away from the welder. Has

convenient plug for easy connection to the welder. (Requires

K864 or K876 Adapter).

Refer Optional Equipment Section in this manual for cable length

and plug options.

K864 Remote Control Adapter

Plugs into the 14 pin remote output control plug base mounted on

the machine. It provides a 14 pin and a 6 pin remote output

connection. e.g. Used for K857 remote control and ‘plug’ cable

LN-7 connections.

K876 Remote Control Adapter

Plugs into the 14 pin remote output control plug base mounted on

the machine. It provides a 6 pin connector. e.g. Used for K857

remote control.

K867 Universal Adapter Plug

Plugs into the 14 pin remote output control plug base mounted on

the machine. It provides flying leads for connection to ‘lugged’

control cables. e.g. Used for K775 remote control and ‘lugged’

cable LN-7 connections.

K930-2 Hi-Freq TIG Module

High frequency unit with gas valve for TIG welding. Rating is 250

amp @ 80% duty cycle.

INSTALLATION INSTRUCTIONS

Location / Ventilation

Do not touch electrically live parts such as output terminals

or internal wiring

Use in open, well ventilated areas or vent exhaust outside.

• Do not operate with doors open or guards off.

• Stop engine before servicing.

Keep away from moving parts.

Only qualified personnel should install, use, or service this

equipment.

The welder should be located to provide an unrestricted flow of

clean, cool air to the cooling air inlets and to avoid heated air

coming out of the back of the welder recirculating back to the

cooling air inlets. Also, locate the welder so that the engine

exhaust fumes are properly vented to an outside area.

Machine Earthing

Standards Australia advise that "There is no need for an earth

electrode to be used with an engine driven welding power

service" E W Robson Projects Manager Committee EL/1 (7th

September 1998).

FALLING EQUIPMENT CAN CAUSE INJURY

• Do not lift this machine using lift bale if it

is equipped with a heavy accessory such

as trailer or gas cylinder.

• Lift only with equipment of adequate

lifting capacity.

• Be sure machine is stable when lifting

E N GINE EXHAUST

can kill

M O V I N G PA R TS

can injure

ELECTRIC SHOCK can kill

W A R N I N G

Do not attempt to use this equipment until you have

thoroughly read the engine manufacturer’s manual supplied

with your welder. It includes important safety precautions,

detailed engine starting, operating and maintenance

instructions, and parts lists.

W A R N I N G

High Frequency Generator for TIG Welding

Applications

The K930-2 TIG Module is suitable for use with the Ranger 405D.

The Ranger 405D and any high frequency generating equipment

must be properly grounded. See the K930-2 Operating Manual for

completed instruc tion s on installati on, operation, and

maintenance.

A T1224 6 BYPASS CAPA C I T OR A S S E M B L Y M U S T B E

I N S T ALLED IN THE RANGER 40 5D TO PROTECT T H E

RANGER 405D FROM DAMAGE.

Standby Power Connections

The Rang er 405D is suitable for tempor ary, standb y or

emergency power usi ng the eng ine manufac turer’s

recommended maintenance schedule.

The Ranger 405D can be permanently installed as a standby

power unit for:-

KA1453-1, -4 & -7 415/240V - 20 Amp service,

KA1453-2 & -5 400/230V - 20 Amp service

KA1453-3 & -6 400/230 and 115V (Centre Tapped Earth) - 20

Amp service.

Connections must be made by a licensed electrician who can

determine how the connections can be made to adapt to

particular installations and comply with all applicable electrical

codes, eg Australian Standard AS3000 Wiring Rules, and

maintain operation of the Residual Current Device.

Welding Output Cables

With the engine off, connect the electrode and work cables to the

appropriate receptacles.

Copper cables sizes listed below are recommended for the rated

current and duty cycle. Lengths stipulated are the distance from

the welder to work and back to the welder again. Cable sizes are

increased for gr eater lengths primarily for the purpose of

minimising cable voltage drop.

Remote Output Control

The Ranger 405D is fitted with a 14 pin remote control receptacle.

This receptacle is mounted between the output studs on the

control panel and is used for connection remote equipment, eg.

The control cable for an LN-21 wire feeder. Wen remote output

control is used the ‘local/remote’ toggle switch must be set at the

‘REMOTE’ position, otherwise set it at ‘LOCAL’ position for control

at machine nameplate.

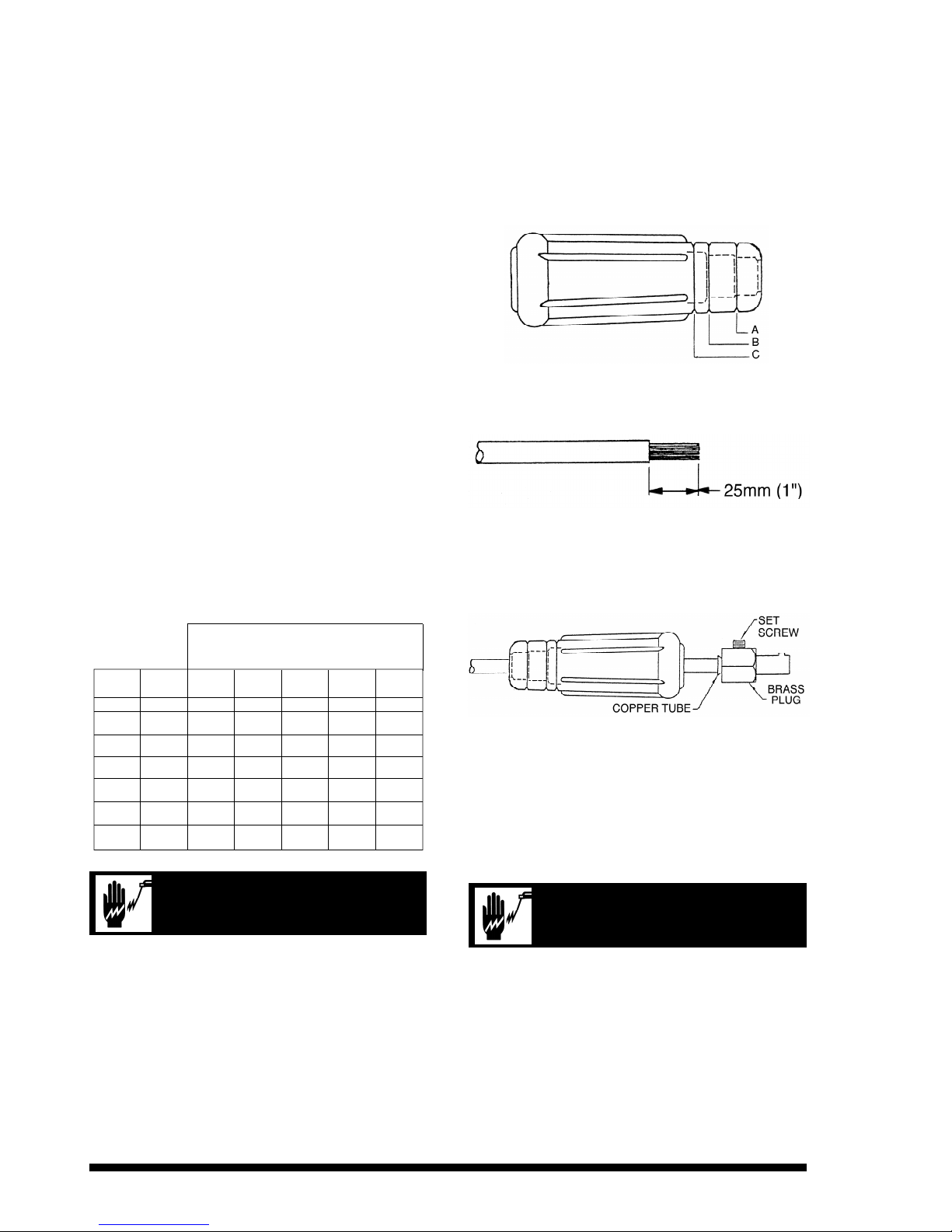

Twist-Mate Welding Cable Plug

Installation Instructions

Turn the engine “OFF” before connecting or disconnecting plugs

to welding power source.

1. The connector is suitable for cable sizes 25 to 95mm2.

2. Trim rubber boot as required (see diagram).

25/35mm2Cable: No trim

50mm2Cable: Trim at “A”

70mm2Cable: Trim at “B”

95mm2Cable: Trim at “C”

3. Slide rubber boot on to cable end (soap or other lubricant may

be required to help slide the boot over the cable).

4. Strip the outer sheath of the welding cable 25mm.

5. Slide the copper tube into the brass plug. (Use only the

largest dia. tube for 95mm2cable. Use both tubes for all other

cable sizes).

6. Insert cable into copper tube.

7. Tighten set screw to collapse copper tube. Screw must apply

pressure against welding cable. The top of the set screw will

be well below the surface of the brass plug after tightening.

8. Slide rubber boot over brass plug. The rubber boot must be

positioned to completely cover all electrical surfaces after the

plug is locked into the receptacle.

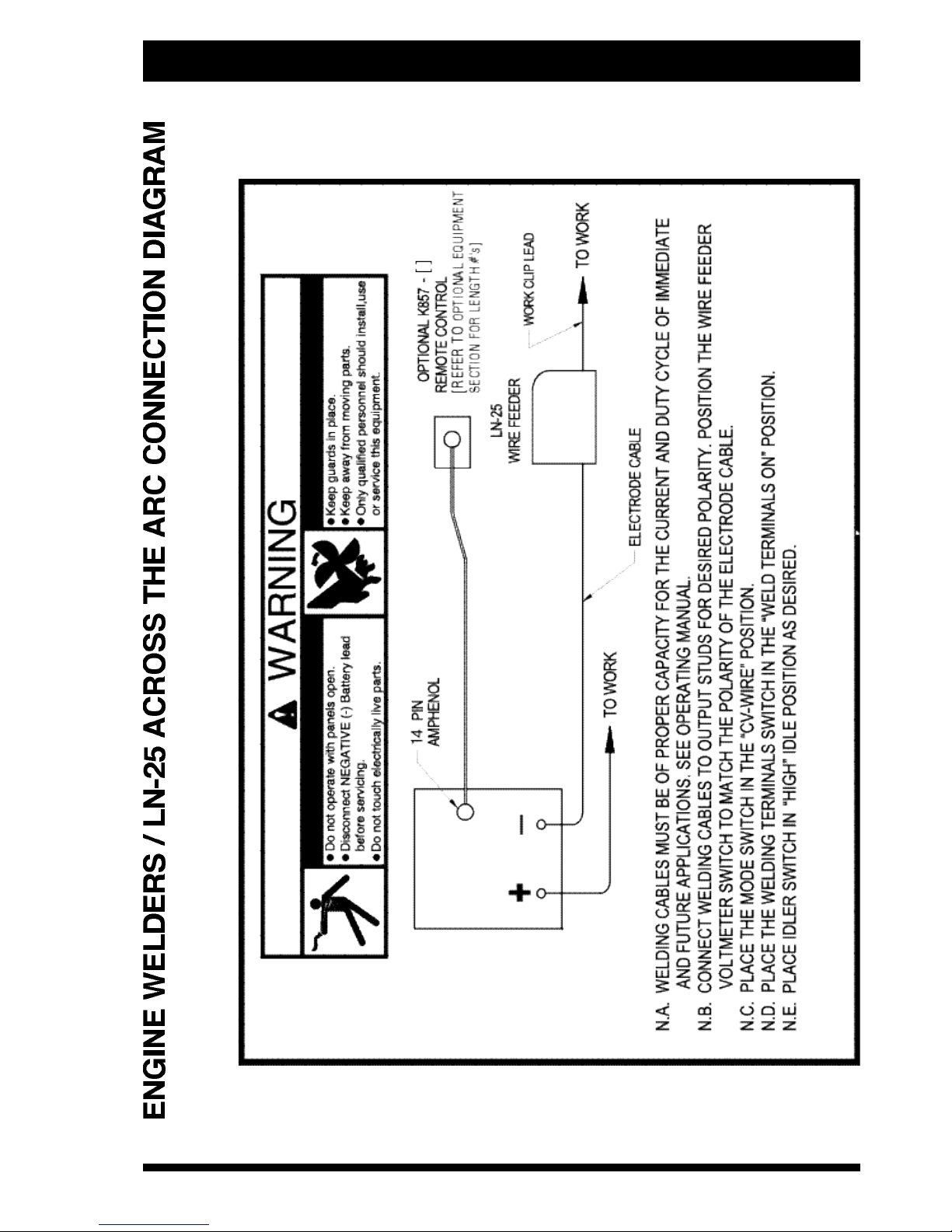

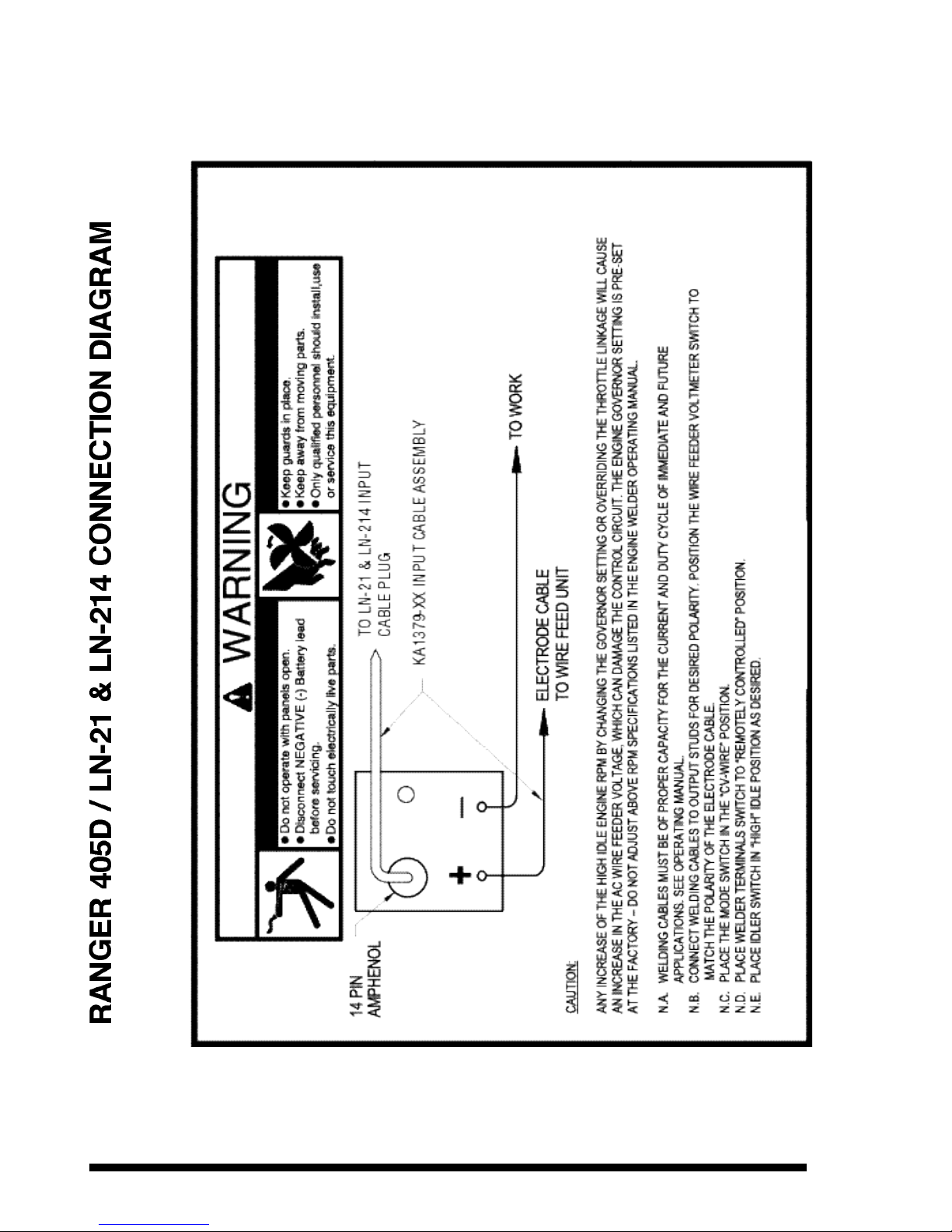

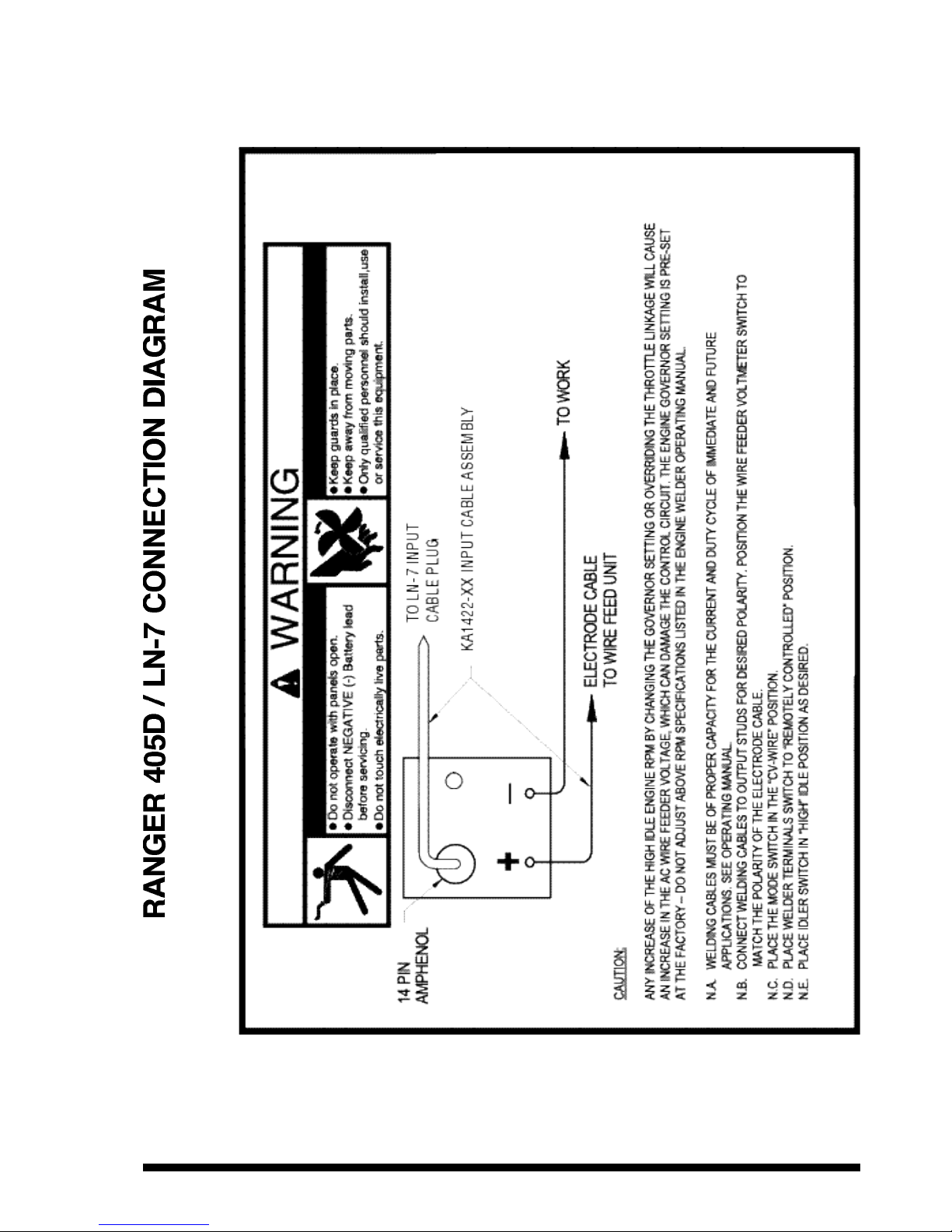

Connection of Lincoln Electric Wire Feeders

• Do not operate with covers removed.

• Disconnect power source before servicing.

• Do not touch electrically live parts.

• Only qualified persons should install, use or service this

machine.

Note:- The (–)ve “High Inductance” output receptacle is for

stick welding only, all other cases covered in this section use

the “Low Inductance” receptacle.

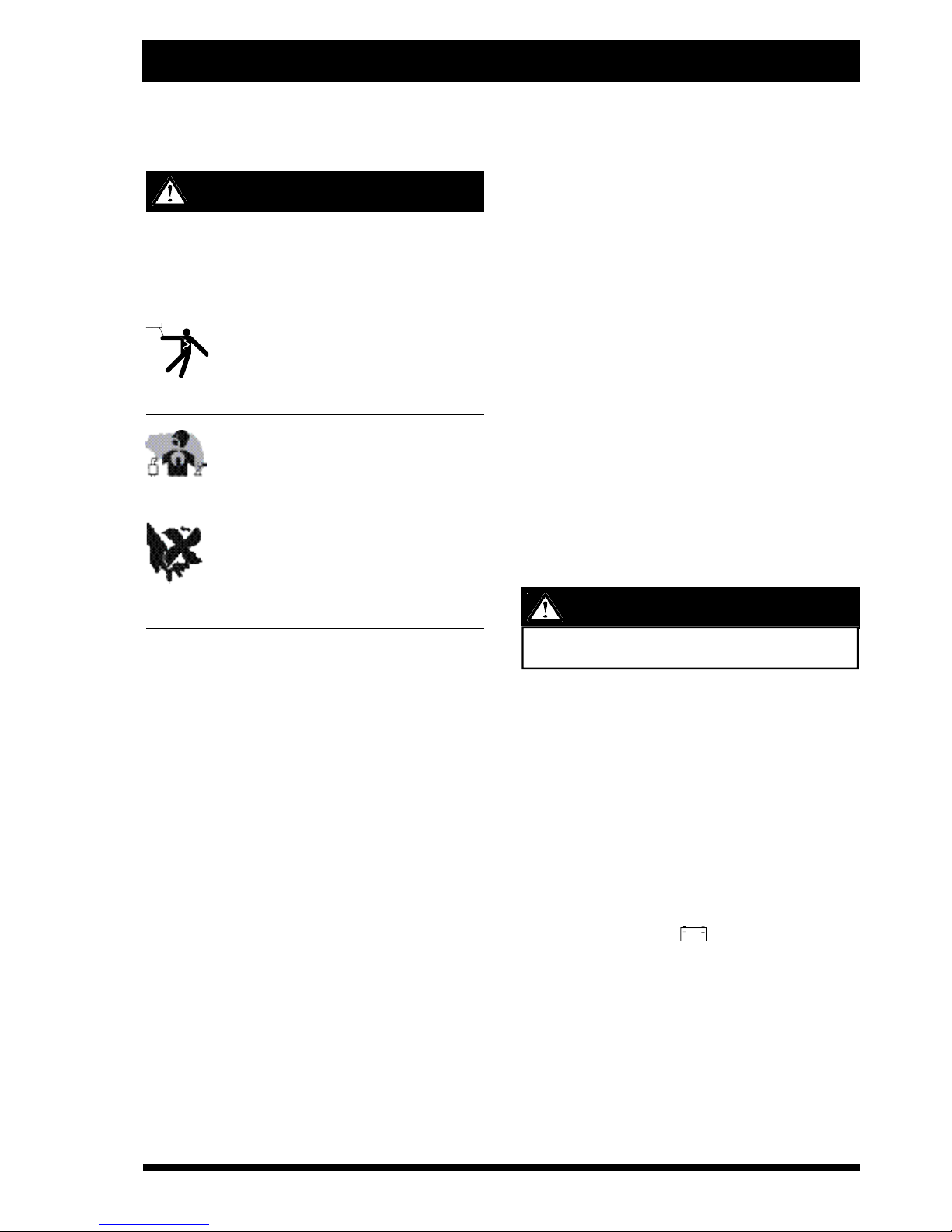

AMPS DUTY 0 - 15 15 - 30 30 - 45 45 - 60 60 - 75

CYCLE m m m m m

250 40 35mm235mm250mm250mm250mm

2

250 100 50mm250mm250mm250mm250mm

2

300 40 50mm250mm250mm250mm250mm

2

300 60 50mm250mm250mm250mm270mm

2

300 100 70mm270mm270mm295mm295mm

2

350 60 50mm250mm270mm270mm295mm

2

400 30 50mm250mm250mm270mm270mm

2

TOTAL COMBINED LENGTH OF

ELECTRODE & WORK CABLE

ELECTRIC SHOCK can kill

ELECTRIC SHOCK can kill

OPERATING INSTRUCTIONS

Safety Instructions

Read and understand this entire section before operating your

Vantage.

Do not attempt to use this equipment until you have

thoroughly read all operating and maintenance manuals

supplied with your machine. They include important safety

preca utions, detailed en gine starting, operating and

maintenance instructions and parts lists.

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts such

as output terminals or internal wiring.

• Insulate yourself from the work and

ground.

• Always wear dry insulating gloves.

ENGINE EXHAUST can kill.

• Use in open, well ventilated areas or vent

exhaust outside.

• Do not stack anything near the engine.

MOVING PARTS can injure.

• Do not operate with doors open or guards

off.

• Stop engine before servicing.

• Keep away from moving parts.

Only qualified personnel should operate this equipment.

VRD (Voltage Reduction Device)

Welding power sources generally have an Open Circuit Voltage

(i.e. the voltage at the welding output terminals whilst not welding)

in the ranges of 35-115VDC. Welding machines for stick welding

(MMAW) and similar constant current (CC mode) processes,

supply a higher open circuit voltage between the electrode and

the work when the welding machine is switch on and ready to

commence welding. These welding machines have a drooping

characteristic, with the open circuit voltage higher (typically

60-80V) than when the arc is established and welding current is

drawn (20-35V).

Consequently, the greatest danger occurs when handling the

electrodes and the electrode holder between welding operations,

such as when changing electrodes.

Welding machines for MIG (GMAW & FCAW) have a flat constant

voltage (CV) characteristic, generally with a lower open circuit

voltage (30-60V). Also, the current is turned on & off by a gun

trigger, which also controls the wire feed. Therefore, the welder is

not exposed to open circuit voltage, unless the trigger is turned on

and the wire is feeding. Also, electrodes are not changed as

frequently as for stick welding (MMAW).

For th ese reasons VRD/ROCV’s are more com monly

incorporated into the stick welding mode (CC) of welding

machines being used in environments with high-risk of electric

shock.

Safety

This reduction of the voltage supplies a safer level of voltage

when an arc is not being struck or when an electrical resistance

less than the welder’s body resistance have been detected. All

V R D ’s are only an aid to safety and personal protective

equipment and safe working practices must be observed at all

times. The risk of electric shock during welding from a correctly

installed and maintained welding machine is negligible, provided

that sensible precautions are taken by the user and correct safe

working procedures are followed. All parts of the output circuit

should be considered electrical alive, and consequently welders

should ensure that no part of their body is placed in such a

position as would complete a path through it for the passage of

electric current. Safe working procedures should always be

followed whether a VRD is fitted or not.

Additional Safety Precautions

Always operate the welder with the hinged door closed and

the side panels in place as these provide maxim um

protection from moving parts and insure proper cooling air

flow.

Engine Operation

Engine Control – Function and Operation

Key Switch

The key switch incorporates:

a) ‘Pre heat’ position:- Turn the key anticlockwise and hold for

15 seconds (30 seconds if temperature is below 0°C).

b) OFF position:- the vertical position where the key can be

inserted & removed, shown “OFF”. When in this position the

fuel flow to the injector pump is stopped to shut the engine

down.

c) “RUN” position:- turn the key clockwise to position shown

“RUN”. When in this position the fuel solenoid & other

electrical accessories are energised.

d) ‘Start’ position:- turn key clockwise past the on position. When

in this position the starter motor is energised. Hold in this

position until the engine starts and then release the key. Do

not engage this position while the engine is running as this

can cause damage to the ring gear and/or starter motor.

(Also see ‘Starting and Stopping the Engine’ section in this

manual).

Battery charge light

The yellow battery charger light is off when battery charging

system is functioning normally. If the light turns on while the

engine is running, the fan be lt may be broken or the

alternator/regulator may be defective.

Engine Hour Meter

Allows machine maintenance procedures to be adhered to by

recording engine operating hours.

Fuel Gauge

Provides indication of the amount of fuel in the fuel tank.

W A R N I N G

W A R N I N G

Under no circumstances should ether or other starting

fluids be used in this engine.

Engine Protection and Engine Idler

Engine Protection

System

+ Oil pressure light

+ Water temperature light

+ Welding Output failure

+ Electrical temperature light.

(Also see ‘Welder Control’ section of this manual.)

If any of the above red lights are illuminated a fault has been

detected in that area of engine/alternator operation and the

engine shuts down automatically.

The first light to come on remains illuminated until the key switch

is turned to the “off” position*. This enables the operator to

determine what initiated the engine shut down.

* The electrical temperature light remains illuminated until the

thermostat resets.

The engine protection system is over-ridden for the first 10

seconds (approx) after the engine is started, to enable the oil

pressure to build up. Therefore if a fault is still present the engine

will stop again after approx 10 seconds.

The key switch turned to the start position ‘resets’ the oil pressure

fault light. If the engine stops again after the timer period check

the oil in the engine.

• Have qualified personnel do maintenance and

troubleshooting work

• If possible, turn the engine off and disconnect the battery

before working inside the machine

• Remove guards only when necessary to perform

maintenance, and replace them when the maintenance

requiring their removal is complete

• Keep hands, hair, clothing and tools away from

V-belts, gears, fans and all other moving parts

• If fan guards are missing from a machine, obtain

replacements from a Lincoln Distributor. (See

Operating Manual Parts List.)

• Read the Safety Precautions in front of this manual and the

engine instruction manual before working on this machine

Engine Idler System

Upon starting the engine the “idler” holds the engine speed at low

idle for (approx) 10 seconds. Then, depending on the idler switch

position low idle is held or high idle speed is engaged.

“Idler” Switch

The idler switch has two positions, “High” and “Auto”.

When in “High” ( ) idle position, the unit operates continuously

at high idle.

When in “Auto” ( ) idle position, the idler operates as

follows:

a) Auxiliary Power:- At low idle speed the Auxiliary output

voltages are approximately half of their rated values. Drawing

a current of 0.5amp or greater will cause the engine to

accelerate to high idle. (Note if using Aux Power with the

output contactor switch in the “I” (output on) position, the

welder terminals will be “hot” in constant voltage mode only.

In constant current the ROCV device maintains less than 8v

across the output studs. They will also be “hot” if the output

contactor switch is in the remote switching “ ” position and

the the wire feeder gun trigger is pressed).

High idle speed is maintained until approx 12 seconds after

the Auxiliary load is removed (providing no welding load is

applied).

Note:- If two phase Aux power is used the idler may not

sense automatically. If this happens, change to another

combination of two phases.

b) Welding:- At low idle speed the welding OCV is approx 8V

DC. Drawing a current of 20 amps or more will cause the

engine to accelerate to high idle. This is accomplished by

striking the electrode to the work.

High idle speed is maintained until approx 12 seconds after

the welding load is removed (providing no auxiliary load is

applied).

Also see sect ion “Connection of Linc oln Electric Wi r e

Feeders” in this manual to determine idler switch settings.

Starting & Stopping the Engine

Starting

1) Check for proper oil level on dip stick & check for proper

coolant level in radiator reservoir bottle. Check fuel gauge to

ascertain fuel level in fuel tank (never allow Ranger 405D to

run out of fuel). Be sure engine compartment door is closed.

2) Be sure all auxiliary loads are turned off.

3) Set “Idler” switch to position.

4) Turn the key to the “preheat” position. Observe that the

battery charging light is on.

Preheat for 15 seconds, (30 seconds if below 0°C). Maximum

allowable preheat time is 30 seconds.

5) Turn the key to the “start” position then release when the

engine starts, the key will automatically return to the “RUN”

position

6) If the engine doesn’t start after 30 seconds of cranking,

release key switch, wait 2 minutes then repeat steps (4) & (5).

Don’t crank longer than 30 seconds & allow at least 2 minutes

between crankings to allow the starter mot or to cool.

Excessive cranking may overheat and damage the Ranger

405D electrical system. If the engine fails to start on second

attempt, check fuel supply to make sure the fuel system has

been properly primed. Consult trouble shooting guide if

engine still will not start.

7) After 10 seconds running, check that battery charge light is

off. If not, stop engine to check for the fault.

8) Allow the engine to warm up at low idle for several minutes

before applying a load and/or switching to high idle. Allow a

longer warm up time in cold weather.

9) Never disconnect the battery after starting as the controlling

PCBs may not function correctly (or at all).

Note: If at any time during starting the engine the “Welding

Output Failure” light illuminates, immediately return the key

switch to the “OFF” position before continuing to crank the

engine.

Stopping

Return engine to the idle position for several minutes before

stopping.

Turn the key switch to the “off” position. This turns off the voltage

to the stop solenoid mounted in the engine injector pump.

Running-in

All diesel engines require some additional care for about the first

50 hours of operation. While maximum load can be applied to a

new engine as soon as it is put into service and the coolant

temperature has reached at least 60°C, care should be taken that

the engine is not run at very light loads (say less than 2.4kVA, or

a 10 amp radiator) for extended periods, as this can lead to

glazing of the cylinder bores. Do not operate at high speeds

without a load, and do not overload the engine. Cylinder glazing

can lead to excessive oil consumption and smoky exhaust, while

overloading during the first few hours can lead to excessive wear

and shorten the life of the engine.

HOT COOLANT CAN BURN SKIN

Do not remove cap if radiator is hot.

W A R N I N G

Welder Operation

• Do not touch electricity live parts or electrode with skin

or wet clothing.

• Insulate yourself from work and ground.

• Always wear dry insulating gloves.

• Keep your head out of fumes.

• Use ventilation or exhaust fan to remove fumes from

breathing zone.

• Keep flammable material away.

• Do not weld upon containers which have held

combustibles.

• Wear eye, ear and body protection.

Stick/TIG (Constant Current) Welding

Connect welding cables to the positive and negative output studs

as appropriate to process being performed. The high inductance

negative output receptacle “ ” is for stick/TIG welding. The

rating of this receptacle is 335amps @ 50% duty cycle. Thermal

protection is provided for this output. Start the engine, set the idler

switch to the desired operating mode, and set the C.V./C.C.

switch to C.C. Set the “Output Control” dial to the desired welding

current and the machine is ready for welding. Adjustment of the

welding current can be made with the “Output Control” dial or a

“Remote Output Control” using K857 and K864 remote control kit.

While in Constant Current Mode the Open Circuit Voltage (OCV)

is held to a value less than 8 volts for added operator safety, Refer

to "Welder Controls – Function & Operation ROCV" for further

details

Stick Welding

The Ranger 405D can be used with any DC stick electrode within

the rating of the unit.

TIG Welding

The Ranger 405D can be used for a variety of DC tungsten inert

gas (TIG) welding applications. Arc initiation may be by “scratch”

starting, or by use the K930 Hi-Freq unit. Scratch starting is not

recommended for critical work, because of the risk of tungsten

inclusions in the weld, and there is also a risk of damage to the

tungsten electrode. For more information on TIG, (or GTAW

welding, as it is sometimes called) refer to JFLF 834, a Guidebook

on Gas Tungsten Arc Welding, available from The Lincoln Electric

Company.

The Hi-Freq unit must be installed per instructions in Installation

Instructions Section of this manual, and the Ranger 405D should

be set for High Idle for proper operation.

Thorium oxides are found in thoriated tungsten electrodes up to

4.2%. Thorium is radioactive and may present hazards by

external and internal exposure. If alternatives are technically

feasible, they should be used, however several studies carried out

on thoriated electrodes have shown that due to the type of

radiation generated, external radiation risks - during storage,

welding and disposal of residues - are negligible under normal

conditions of use.

On the contrary

, during grinding of electrode tips there is

generation of radioactive dust, with the risk of internal

exposure. It is therefore necessary to use local exhaust

ventilation to control the dust at its source, complimented if

necessary by respiratory protective equipment. The risk of internal

exposure during welding is considered negligible since the

electrode is consumed at a very slow rate.

Precautions must also be taken to control any risk of exposure

during the disposal of dust from any grinding devices.

Wire Feed (Constant Voltage) Welding

Connect a wire feeder to the Ranger 405D and set welder

controls acco rding to the in structions unde r the headi ng

“Connection of Lincoln Electric Wire Feeders”.

The Ranger 405D permits use of a broad range of Innershield,

Outershield & solid wire electrodes within the rating of the

machine.

ELECTRIC SHOCK can kill

FUMES AND GA S E S

can be dange r o u s

A R C RAYS can burn

W E L D I N G SPA R K S can

cause fi r e or ex p l o s i o n

W A R N I N G

Health aspects of the use of thoriated tungsten electrodes

Controls and Settings

All welder and engine controls are located on the case front panel. Refer to diagram and the explanations that follow.

1

10

13

20

14

9

7

65

3

2

22

4

8

11

12

13

15

16

17

18

18

1. Output Control Dial

Increase/Decrease of output “ ” (Voltage or Current)

The output control on the control panel is a continuous control of

the machine output. The control may be rotated from minimum to

maximum while under load to adjust the machine output.

2. Volt-Amp Meter Module and Switch

Output stud voltage is displayed on the Volt Meter Module. Output

current Amps is displayed on the Amp Meter Module (where

fitted).

3 & 4. Circuit Breaker

Five circuit breakers are mounted on the top of the control panel.

If they are activated, press them to reset. Refer trouble shooting

guide if tripping occurs. Their functions are (left to right looking at

the control panel).

1, 2 & 3) Field winding protection

4) Control +12V

5) Auxiliary 115/42V

5. VRD Operation Indicator

On the front panel of the Ranger 405D are two indicator lights. A

red light when lit indicates voltage >32V and a green light when

lit indicates voltage <32V.

These lights monitor the OCV at all times. In the CC mode when

the welding arc has stopped the green light will aluminate

indicating that the VRD has reduced the OCV to less than 32V.

During welding the red light will aluminate indicating that the OCV

is greater than 32V. During welding the red and green light may

flicker on and off. This is normal operation as the welding voltage

depending on the process and type of the electrodes being used

may produce less than 32V.

Should the red light remain illuminated after stopping welding in

the CC mode. Please refer to your local field service shop for

service.

6. Fuel Level Gauge

Displays the level of diesel fuel in the fuel tank. The operator must

watch the fuel level closely to prevent running out of fuel and

possibly having to bleed the system.

7. Switch: PREHEAT STOP RUN START

Toggle to preheat position to energize the glow plugs, then toggle

through to the start position and hold to crank the engine; release

as the engine starts. To stop the engine, toggle to the stop

position.

Note: When starting the engine the engine stop button must be

released. If the engine stop button is used to stop the engine, the

key switch must also be toggled to the stop position otherwise the

battery may be drained.

8. Battery Charging Light

The yellow engine alternator light is off when battery charging

system is functioning normally. If light turns on the alternator or

the voltage regulator may not be operating correctly. The light will

remain on when the engine is stopped and the run/stop switch is

in the run position.

9. Idler Switch

Has two positions as follows:

A) In the “High” position , the engine runs at the high idle speed

controlled by the governor.

B) In the “Auto” position, the idler operates as follows:

a. When switched from “High” to “Auto” or after starting the

engine, the engine will operate at full speed for

approximately 12 seconds and then go to low idle speed.

b. When the electrode touches the work or power is drawn

for lights or tools (approximately 100 Watts minimum) the

engine accelerates and operates at full speed.

c. When welding ceases and the AC power load is turned

off, a fixed time delay of approximately 12 seconds

starts.

d. If the welding or AC power load is not restarted before

the end of the time delay, the idler reduces the engine

speed to low idle speed.

e. The engine will automatically return to high idle speed

when the welding load or A.C. power load is reapplied.

Idler Operational Exceptions

When the WELDING TERMINALS switch is in the “Remotely

Controlled” position the idler will operate as follows:

• When the triggering device (Amptrol, Arc Start Switch, etc.)

is pressed the engine will accelerate and operate at full

speed prov ided a weldin g loa d is applie d within

approximately 12 seconds.

• If the triggering device remains pressed but no welding load

is applied within approximately 12 seconds the engine will

return to low idle speed.

• If the triggering device is released or welding ceases the

engine will return to low idle speed after approximately 12

seconds.

10. Hour Meter

The hour meter displays the total time that the engine has been

running. This meter is a useful indicator for scheduling preventive

maintenance.

11. Engine Protection

The engine protection lights remain off with proper oil pressure

and under normal operating temperatures. If a light turns on the

engine protection system will stop the engine. the illuminated light

will indicate the reason for the engine shutdown. Low oil pressure,

high coolant temperature, high electrical temperature or electrical

fault.

Welder Thermal Protection Light

The thermal protection light will be lit if either of the two

electrical protection thermostats have opened. This circuit is

combined with the engine protection circuit so that if over

temperature is sensed the engine is shut down. The engine

will restart & run for only approx 10 seconds if the high temp

light is still illuminated.

Welding Output Failure

Incorrect voltages and / or welding output malfunction will cause

the Welding Output Failure light to be illuminated. The engine will

not restart and run if the “Welding Output Failure” light is still

illuminated.

Oil Pressure Light

This circuit is combined with the engine protection circuit so that

if low oil pressure is sensed the engine will shut down. The engine

will restart and run for approx 10 seconds if the low oil light is

illuminated.

12. Arc Force Control

(effective only in C.C. mode)

Increase/Decrease short circuit current

The arc force dial should be set at approx mid-range for most

welding. Adjustments up or down can then be made

depending on the electrode, procedures and operator

preference. Higher settings will provide more short circuit

current giving a more forceful arc. Excessive spatter may

result if the control setting is too high. For most TIG welding

applications adjust this control to minimum for best operating

characteristics.

13. Weld Output Terminals + and -

These Twistmate plugs and sockets provide welding connection

points for the electrode and work cables. For positive polarity

welding the electrode cable connects to the “+” terminal and the

work cable connects to this “-” terminal. For negative polarity

welding the work cable connects to the “+” terminal and the

electrode cable connects to this “-” terminal.

14. Earth Connection

An earthing stud is provided on the control panel. Refer to

Installation Instructions Section this manual. “Machine Earthing”

and local regulations eg. Australian Standard AS3000.

15. 42V / 115V Wire Feeder Voltage Switch

Toggles output of 14-pin connector to voltage requirement of Wire

Feeder.

16. Remote Control Receptacle

Amphenol Receptacle

The Ranger 405D has one 14pin amphenol located on the

control panel. The receptacle is for connecting wire feeders,

it allows the welder output to be controlled at the wire feeder,

when the wire feeder includes this feature, and includes

115V AC 5amp & 42V AC 10amp auxiliary supplies. These

supplies are protected by a circuit breaker mounted on the

control panel.

17. Engine Stop Button

When depressed stops and disables restarting of the engine by

removing the power supply to the engine injection pump solenoid.

18. Remote Polarity Switch

Remote Voltmeter

Positive Electrode

+

Negative Electrode

–

The remote voltmeter polarity switch allows the electrode polarity

to be set for the remote (No. 21) work sensing lead of automatic

or semi-automatic equipment. Set ‘+’ for electrode positive and ‘–’

for electrode negative.

19. Output Terminal Switch (output contactor)

(effective only in CV mode)

Output (Voltage) “ ”

ON “I”

Remote Switching “ ”

The output terminals toggle switch controls the solid state output

contactor. Switched to the “I” position the contactor is closed and

the output studs are “hot” all the time. Switched to the “ ”

position the output studs only become “hot” when wires No. 2 & 4

are shorted together using the wire feeder gun trigger.

20. Output Control “Local-Remote” Switch

Remote Output Voltage or Current Control “ ”

Local Output Voltage or Current Control “ ”

The Local/Remote switch, mounted beside the output control dial,

gives the operator the option of controlling the output at the

machine control panel or at a remote station. For control at the

machine, switch to “ ” position. For remote control, switch to “

” position, in this position control is at the wire feeder (if so

constructed) or at a K857 control connected to the amphenol on

the control panel. (See ‘Optional Field Installed Accessories’).

21.Weld Mode Selector Switch

Constant Voltage position is shown as “ ”, ‘CV’.

Constant Current position is shown as “ ”, ‘CC’.

Caution:- Never change the CV/CC switch setting while

welding. This will cause severe damage to the

switch and other electrical components.

There is no VRD protection in the CV mode.

With the toggle switch in the “WELD T E R M I N A L O N ”

position the voltage at the output terminal maybe up

to 60V.

W A R N I N G

INSTALLATION INSTRUCTIONS

Loading...

Loading...