Page 1

Pro-MIG 140

MANUAL DEL OPERADOR

OPERATOR’S MANUAL

IM884

April, 2006

For use with machine Code Number:

Para el uso con número del código automático:

Pro-MIG™ 140

• Sales and Service through Subsidiaries and Distributors Worldwide •

TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

• World's Leader in Welding and Cutting Products •

Copyright © 2006 Lincoln Global Inc.

™

Safety Depends on You

Lincoln arc welding and cutting equipment

is designed and built with safety in mind.

However, your overall safety can be

increased by proper installation ... and

thoughtful operation on your part. DO NOT

INSTALL, OPERATE OR REPAIR THIS

EQUIPMENT WITHOUT READING THE

OPERATORS MANUAL WHICH IS PROVIDED WITH YOUR MACHINE AND THE

SAFETY PRECAUTIONS CONTAINED

THROUGHOUT. And, most importantly,

think before you act and be careful.

La seguridad depende de usted

El equipo de soldadura por arco y corte de

Lincoln está diseñado y construido teniendo

en mente la seguridad. Sin embargo, la

seguridad general puede ser mejor si instala

y opera la máquina adecuadamente.

NO

INSTALE, NO PONGA EN FUNCIONAMIENTO NI REPARE ESTE EQUIPO

SIN LA LECTURA DEL MANUAL DE LOS

OPERADORES QUE SE PROPORCIONA

CON SU MÁQUINA Y LAS MEDIDAS DE

SEGURIDAD CONTENIDAS EN EL MISMO.

Lo más importante, piense antes de actuar

y tenga cuidado.

}

11288

RETURN TO MAIN MENU

Page 2

i

SAFETY

i

Mar ‘95

ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information, it is strongly recommended that you purchase a copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American Welding

Society, P.O. Box 351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding

Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio

44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

WARNING

ARC RAYS can burn.

2.a. Use a shield with the proper filter

and cover plates to protect your

eyes from sparks and the rays of

the arc when welding or observing

open arc welding. Headshield and

filter lens should conform to ANSI

Z87. I standards.

2.b.Use suitable clothing made from durable flameresistant material to protect your skin and that of

your helpers from the arc rays.

2.c. Protect other nearby personnel with suitable,

non-flammable screening and/or warn them not

to watch the arc nor expose themselves to the

arc rays or to hot spatter or metal.

FOR ELECTRICALLY

powered equipment.

1.a. Turn off input power using the disconnect switch at the fuse box

before working on the equipment.

1.b.Install equipment in accordance with the U.S.

National Electrical Code, all local codes and the

manufacturer’s recommendations.

1.c. Ground the equipment in accordance with the

U.S. National Electrical Code and the manufacturer’s recommendations.

ELECTRIC AND MAGNETIC

FIELDS may be dangerous

3.a. Electric current flowing through

any conductor causes localized

Electric and Magnetic Fields

(EMF). Welding current creates

EMF fields around welding cables

and weldingmachines

3.b.EMF fields may interfere with some pacemakers, and welders having a pacemaker should

consult their physician before welding.

3.c. Exposure to EMF fields in welding may have

other health effects which are now not known.

3.d.All welders should use the following procedures

in order to minimize exposure to EMF fields from

the welding circuit:

3.d.1. Route the electrode and work cables together

- Secure them with tape when possible.

3.d.2. Never coil the electrode lead around your

body.

3.d.3. Do not place your body between the electrode

and work cables. If the electrode cable is on

your right side, the work cable should also be

on your right side.

3.d.4. Connect the work cable to the workpiece as

close as possible to the area being welded.

3.d.5. Do not work next to welding power source.

Page 3

ii

SAFETY

ii

WELDING SPARKS can

cause fire or explosion.

4.a.

Remove fire hazards from the

welding area.

If this is not possible, cover them to prevent the

welding sparks from starting a fire.

Remember that welding sparks

and hot materials from welding

can easily go through small cracks

and openings to adjacent areas.

Avoid welding near hydraulic lines.

Have a fire extinguisher readily

available.

4.b.Where compressed gases are to be used at the

job site, special precautions should be used to

prevent hazardous situations. Refer to “Safety in

Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment

being used.

4.c. When not welding, make certain no part of the

electrode circuit is touching the work or ground.

Accidental contact can cause overheating and

create a fire hazard.

4.d.Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to

insure that such procedures

will not cause flammable or toxic vapors from substances inside.

They can cause an explosion even

though

they

have been “cleaned”. For information, purchase

“Recommended Safe Practices for the

Preparation

for Welding and Cutting of

Containers and Piping That Have Held

Hazardous Substances”, AWS F4.1 from the

American Welding Society

(see address above).

4.e.Vent hollow castings or containers before heating, cutting or welding. They may explode.

4.f.

Sparks and spatter are thrown from the welding

arc. Wear oil

free protective garments such as

leather gloves, heavy shirt, cuffless trousers, high

shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined

places. Always wear safety glasses with side

shields when in a welding area.

4.g.Connect the work cable to the work as close to

the welding area as practical. Work cables connected to the building framework or other locations away from the welding area increase the

possibility of the welding current passing through

lifting chains, crane cables or other alternate circuits. This can create fire hazards or overheat

lifting chains or cables until they fail.

ELECTRIC SHOCK can kill.

5.a.The electrode and work (or ground)

circuits are electrically “hot” when the

welder is on. Do not touch these

“hot” parts with your bare skin or wet

clothing. Wear dry, hole-free gloves

to insulate hands.

5.b. Insulate yourself from work and ground using dry

insulation. Make certain the insulation is large

enough to cover your full area of physical contact

with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or

while wearing wet clothing; on metal structures

such as floors, gratings or scaffolds; when in

cramped positions such as sitting, kneeling or

lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or

ground) use the following equipment:

• Semiautomatic DC Constant Voltage (Wire)

Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

5.c. In semiautomatic or automatic wire welding, the

electrode, electrode reel, welding head, nozzle or

semiautomatic welding gun are also electrically

“hot”.

5.d. Always be sure the work cable makes a good electrical connection with the metal being welded. The

connection should be as close as possible to the

area being welded.

5.e. Ground the work or metal to be welded to a good

electrical (earth) ground.

5.f. Maintain the electrode holder, work clamp, welding

cable and welding machine in good, safe operating

condition. Replace damaged insulation.

5.g. Never dip the electrode in water for cooling.

5.h. Never simultaneously touch electrically “hot” parts

of electrode holders connected to two welders

because voltage between the two can be the total

of the open circuit voltage of both welders.

5.i. When working above floor level, use a safety belt

to protect yourself from a fall should you get a

shock.

5.j. Also see Items 4.c. and 1.

MAR95

Page 4

iii

SAFETY

iii

FUMES AND GASES

can be dangerous.

6.a.Welding may produce fumes and gases hazardous to health. Avoid breathing these fumes

and gases.When welding, keep your head out of

the fume. Use enough

ventilation and/or exhaust

at the arc to keep

fumes and gases away from

the breathing zone. When welding with elec-

trodes which require special ventilation such

as stainless or hard facing (see instructions

on container or MSDS) or on lead or cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep

exposure as low as possible and below

Threshold Limit Values (TLV) using local

exhaust or mechanical ventilation. In confined spaces or in some circumstances, outdoors, a respirator may be required.

Additional precautions are also required

when welding on galvanized steel.

6.b.

Do not weld in locations near chlorinated hydrocarbon

vapors coming from degreasing, cleaning or spraying operations. The heat and rays

of the arc can react with solvent vapors

to

form

phosgene, a highly toxic gas, and other irritating products.

6.c.Shielding gases used for arc welding can displace air and cause injury or death. Always use

enough ventilation, especially in confined areas,

to insure breathing air is safe.

6.d.Read and understand the manufacturer’s

instructions for this equipment and the consumables to be used, including the material safety

data sheet (MSDS) and follow your employer’s

safety practices. MSDS forms are available from

your welding distributor or from the manufacturer.

MAR95

CYLINDER may explode if

damaged.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b.Always keep cylinders in an upright position

securely

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

•Away from areas where they may be struck or

subjected to physical damage.

•A safe distance from arc welding or cutting

operations and any other source of heat,

sparks, or flame.

7.d.Never allow the electrode, electrode holder or

any other electrically “hot” parts to touch a cylinder.

7.e.Keep your head and face away from the cylinder

valve outlet when opening the cylinder valve.

7.f. Valve protection caps should always be in place

and hand tight except when the cylinder is in

use or connected for use.

7.g.Read and follow the instructions on compressed

gas cylinders, associated equipment, and CGA

publication P-l, “Precautions for Safe Handling

of Compressed Gases in Cylinders,” available

from the Compressed Gas Association 1235

Jefferson Davis Highway, Arlington, VA 22202.

Page 5

iviv

Thank You

for selecting a QUALITY product by Lincoln Electric. We want you

to take pride in operating this Lincoln Electric Company product

••• as much pride as we have in bringing this product to you!

Read this Operators Manual completely before attempting to use this equipment. Save this manual and keep it

handy for quick reference. Pay particular attention to the safety instructions we have provided for your protection.

The level of seriousness to be applied to each is explained below:

WARNING

This statement appears where the information must be followed exactly to avoid serious personal injury or

loss of life.

This statement appears where the information must be followed to avoid minor personal injury or damage to

this equipment.

CAUTION

Please Examine Carton and Equipment For Damage Immediately

When this equipment is shipped, title passes to the purchaser upon receipt by the carrier. Consequently, Claims

for material damaged in shipment must be made by the purchaser against the transportation company at the

time the shipment is received.

Please record your equipment identification information below for future reference. This information can be

found on your machine nameplate.

Product _________________________________________________________________________________

Model Number ___________________________________________________________________________

Code Number or Date Code_________________________________________________________________

Serial Number____________________________________________________________________________

Date Purchased___________________________________________________________________________

Where Purchased_________________________________________________________________________

Whenever you request replacement parts or information on this equipment, always supply the information you

have recorded above. The code number is especially important when identifying the correct replacement parts.

On-Line

Product Registration

- Register your machine with Lincoln Electric either via fax or over the Internet.

• For faxing: Complete the form on the back of the warranty statement included in the literature packet

accompanying this machine and fax the form per the instructions printed on it.

• For On-Line Registration: Go to our

WEB SITE at www.lincolnelectric.com. Choose “Quick Links” and then

“Product Registration”. Please complete the form and submit your registration.

Page 6

v

v

TABLE OF CONTENTS FOR ALL SECTIONS

Page

Installation .......................................................................................................Section A

Technical Specifications ........................................................................................A-1

Identify and Locate Components...........................................................................A-2

Select Suitable Location ........................................................................................A-3

Output Connections...............................................................................................A-3

Input Connections..................................................................................................A-6

Code Requirements ..............................................................................................A-6

________________________________________________________________________

Operation .........................................................................................................Section B

Safety Precautions ................................................................................................B-1

General Description...............................................................................................B-1

Design Features ....................................................................................................B-1

Welding Capability.................................................................................................B-2

Limitations..............................................................................................................B-2

Controls and Settings ............................................................................................B-2

Welding Operations ...............................................................................................B-3

Overload Protection...............................................................................................B-6

Application Chart ...................................................................................................B-7

________________________________________________________________________

Accessories.....................................................................................................Section C

Accessories ...........................................................................................................C-1

Replacement Parts................................................................................................C-2

________________________________________________________________________

Maintenance ....................................................................................................Section D

Safety Precautions ................................................................................................D-1

Items Requiring No Maintenance ..........................................................................D-1

Routine Maintenance.............................................................................................D-1

Gun and Cable Maintenance.................................................................................D-2

Component Replacement Procedures ..................................................................D-3

Changing Liner ......................................................................................................D-4

Gun Handle Parts..................................................................................................D-4

________________________________________________________________________

Troubleshooting..............................................................................................Section E

Safety Precautions.................................................................................................E-1

How to Use Troubleshooting Guide.......................................................................E-1

Troubleshooting Guide.............................................................................E-2 thru E-4

________________________________________________________________________

Wiring Diagrams..............................................................................................Section F

Wiring Diagram ......................................................................................................F-1

________________________________________________________________________

Español ..................................................................................Sección A por Sección F

________________________________________________________________________

Parts Lists ..................................................................................P526 Series, P202-E.1

________________________________________________________________________

Page 7

A-1

Pro-MIG 140

A-1

Fuse or

Output Mode Input Voltage Breaker Size1Input Amps Power Cord Extension Cord

Three Conductor

#14 AWG

(2.1 mm

2

) or Larger

RATED 120V/60Hz 20 Amp 20 15 Amp, 125V,

Up to 25 Ft. (7.6 mm)

Three Prong Plug Three Conductor

(NEMA Type 5-15P) #12 AWG

(3.3 mm2) or Larger

Up to 50 Ft. (15.2 mm)

INSTALLATION

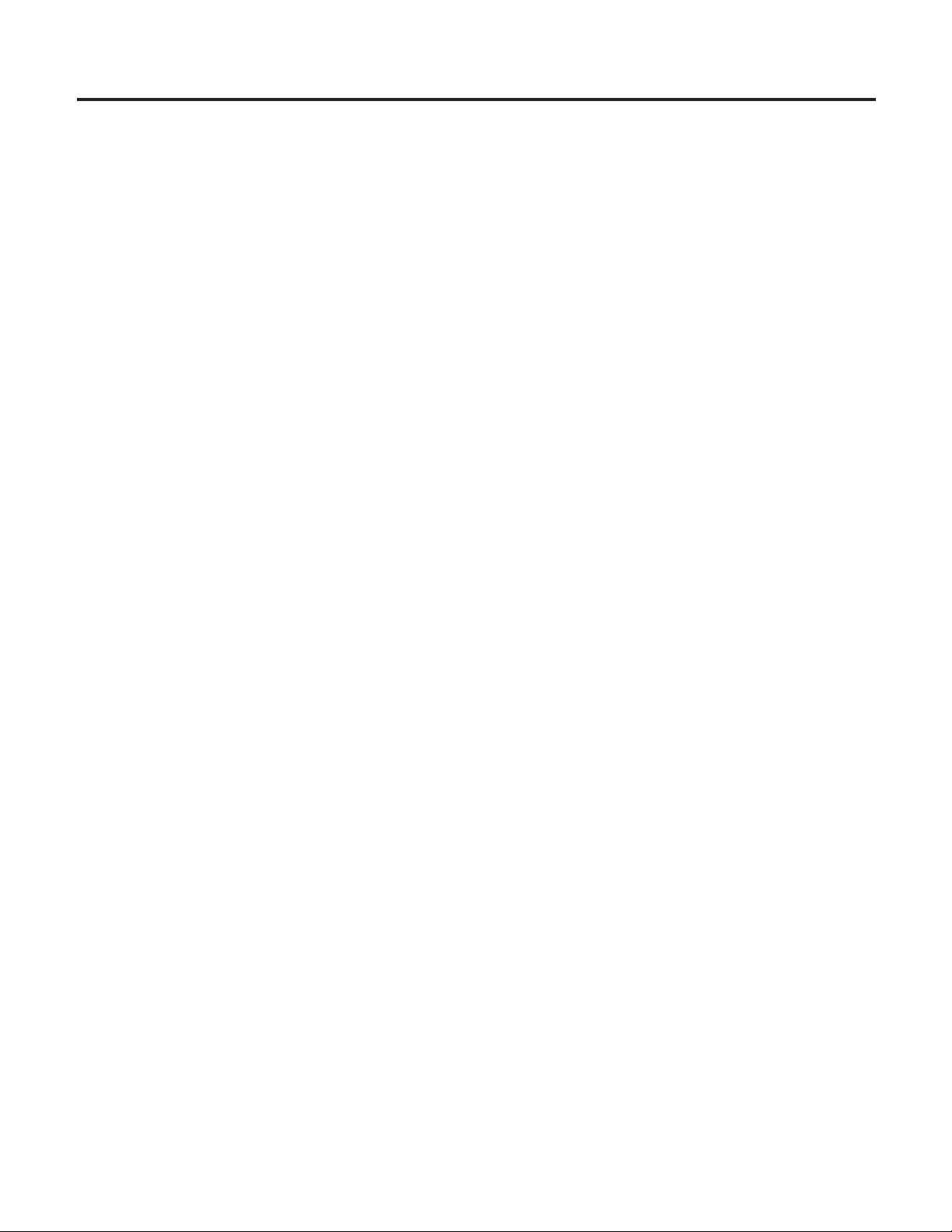

TECHNICAL SPECIFICATIONS – Pro-MIG 140

INPUT – SINGLE PHASE ONLY

RATED OUTPUT

OUTPUT

RECOMMENDED INPUT CABLE AND FUSE SIZES

Height Width Depth Weight

12.0 in 9.75 in 16.5 in 48 Ibs

305 mm 248 mm 419 mm 21.8 kg

PHYSICAL DIMENSIONS

Standard Voltage/Frequency Input Current

120V/60Hz 20 Amps - Rated Output

Duty

Cycle Current Voltage

20% Duty Cycle 90 Amps 19 V

Welding Current Range Maximum-Open Circuit Voltage Wire Speed Range

25-140 Amps 29V 50 - 300 in/min.

(1.3 - 7.6 m/min.)

1

If connected to a circuit protected by fuses use Time Delay Fuse marked “D”.

Page 8

A-2

INSTALLATION

Pro-MIG 140

A-2

Read entire installation section before starting

installation.

SAFETY PRECAUTIONS

IDENTIFY AND LOCATE

COMPONENTS

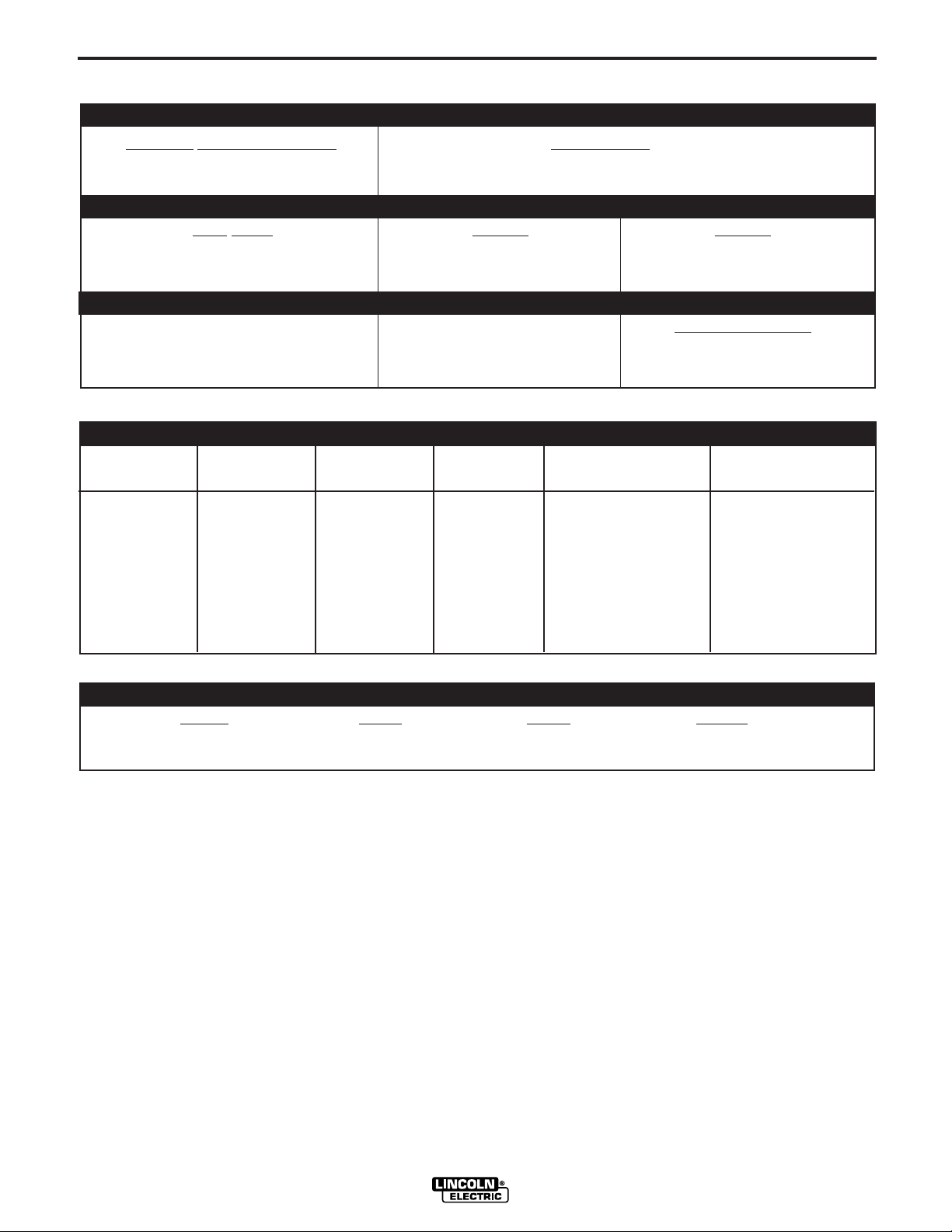

If you have not already done so, unpack the Pro-MIG

140 from its carton and remove all packing material

around the Pro-MIG 140. Remove the following loose

items from the carton (see Figure A.1):

1. Pro-MIG 140

2. Gun and cable assembly

(1)

3. Literature and miscellaneous including:

a) This operating manual

b) 3 extra .023"-.025” (0.6 mm) contact tips

c) 2 extra .035” (0.9 mm) contact tips

d) Hex key wrench for removal of drive roll.

4. 10 ft (3.0 m) work cable.

5. Work clamp.

6. a) 2lb. spool of .025” (0.6 mm) Super Arc L-56

MIG wire.

b) Sample spool of Innershield .035” (0.9 mm)

NR-211-MP.

7. Welding Helmet.

8. Adjustable mixed-Gas Regulator & Hose.

9. Instructional video.

10. Nozzle.

For available options and accessories refer to the

Accessories Section of this manual.

1)

As shipped from the factory, the Pro-MIG 140 gun

liner is ready to feed .023” (0.6 mm) -.035 (0.9 mm)

wire.

ELECTRIC SHOCK can kill.

• Only qualified personnel should perform

this installation.

• Only personnel that have read and understood the Pro-MIG 140 Operating Manual

should install and operate this equipment.

• Machine must be plugged into a receptacle

which is grounded per any national, local

or other applicable electrical codes.

• The Pro-MIG 140 power switch is to be in

the OFF (“O”) position when installing

work cable and gun and when connecting

power cord to input power.

WARNING

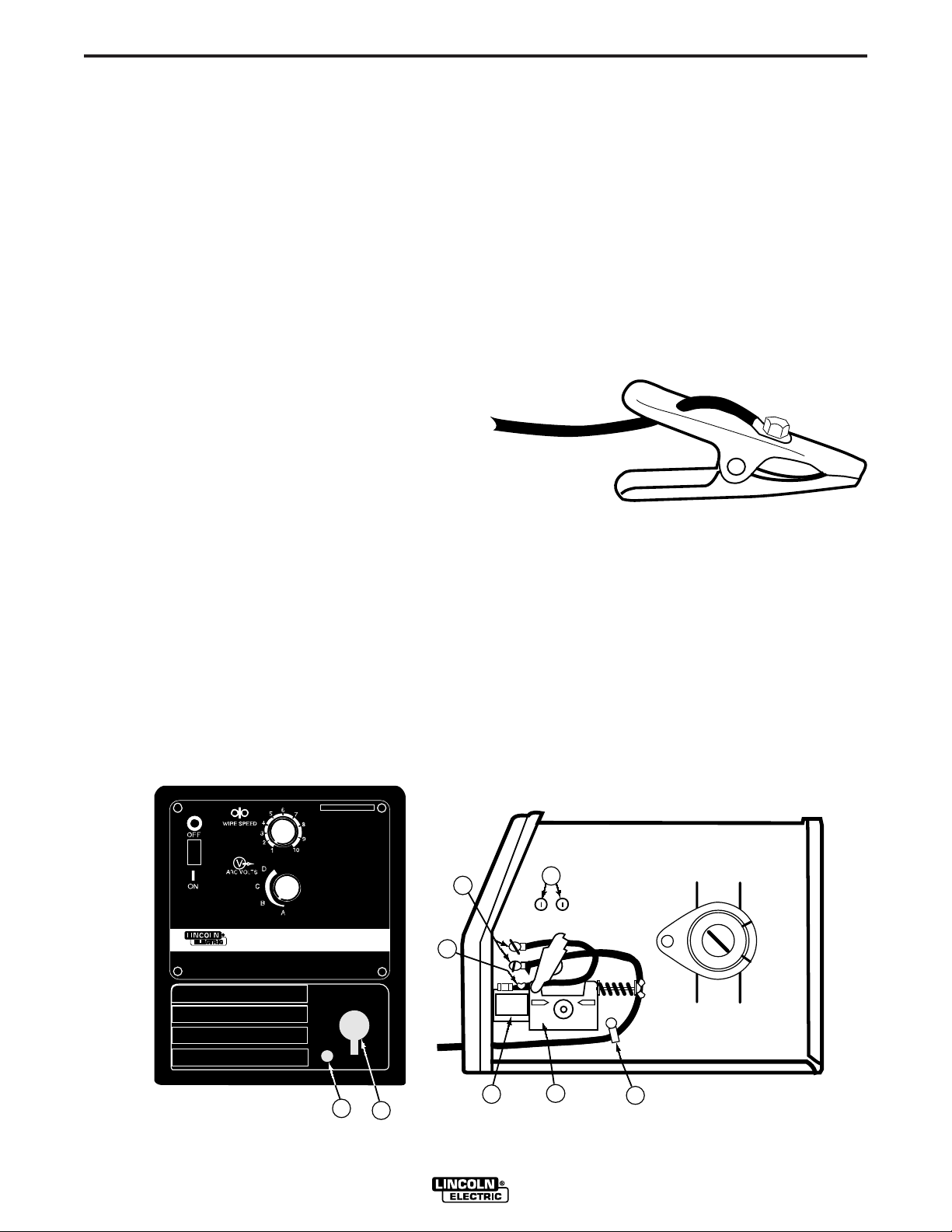

FIGURE A.1

Pro-MIG

140

1

P

ro

-M

IG

™ 1

4

0

3

5

7

9

2

4

6

8

10

Page 9

A-3

INSTALLATION

Pro-MIG 140

A-3

Pro-MIG“ 140

4

5

8

3

6

7

1

2

DO NOT SWITCH

WHEN WELDING

+

-

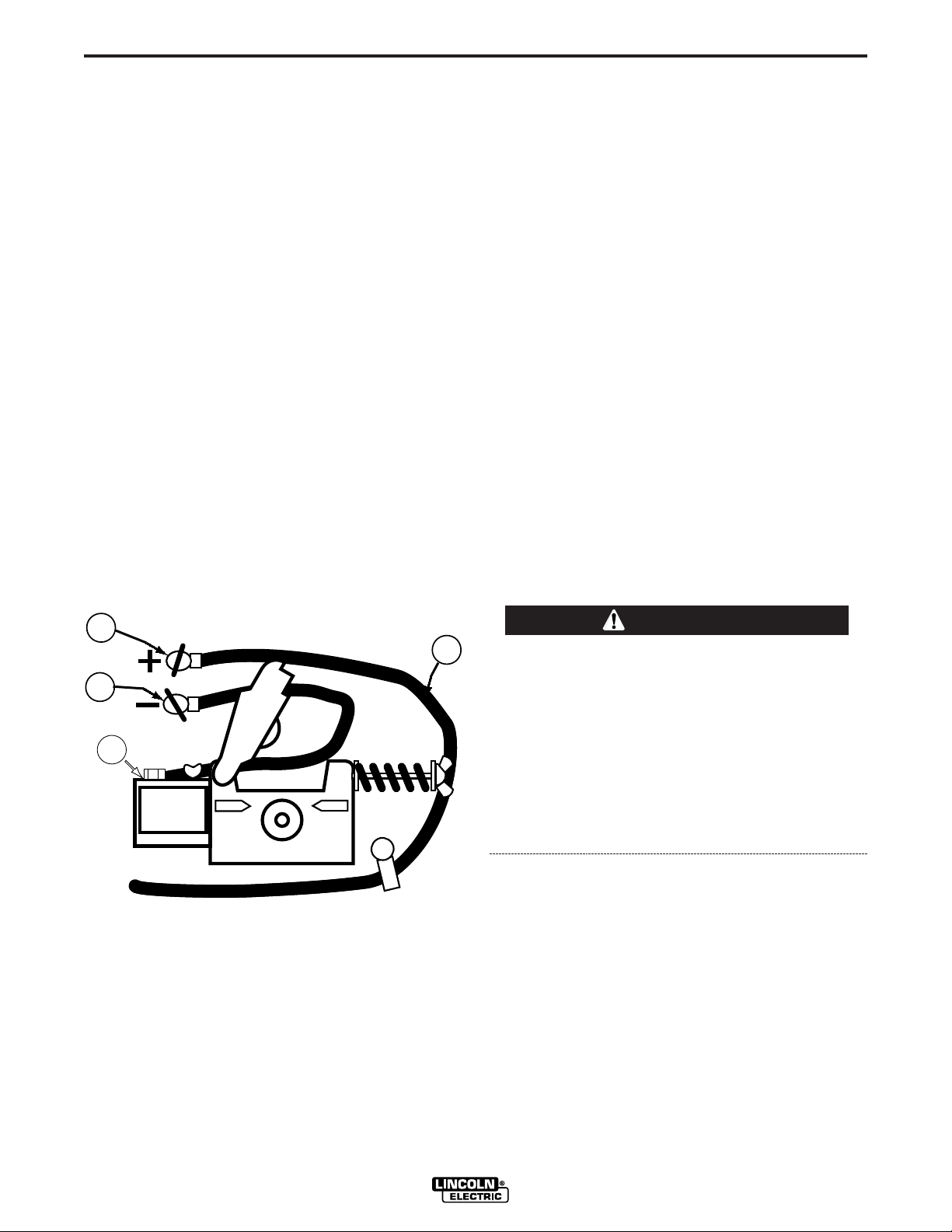

FIGURE A.2

Work Clamp Installation

Attach the work clamp per the following:

1. Unplug the machine or turn the power switch to the

“OFF” position.

2. Insert the work cable terminal lug with the larger

hole through the strain relief hole in the work clamp

as shown in Figure A-3.

3. Fasten securely with the bolt and nut provided.

FIGURE A.3

SELECT SUITABLE LOCATION

Locate the welder in a dry location where there is free

circulation of clean air into the louvers in the back and

out the front of the unit. A location that minimizes the

amount of smoke and dirt drawn into the rear louvers

reduces the chance of dirt accumulation that can block

air passages and cause overheating.

STACKING

Pro-MIG 140’s cannot be stacked.

TILTING

Each machine must be placed on a secure, level surface, directly or on recommended cart. The machine

may topple over if this procedure is not followed.

OUTPUT CONNECTIONS

Refer to Figure A.2.

1. Work Cable Access Hole.

2. Gun Cable and Control Lead Access Hole.

3. Connector Block.

4. Gun Trigger Lead Connectors.

5. Positive (+) and negative (–) output terminals.

6. Wire Feed Gearbox.

7. Cable Hanger.

8. Thumbscrew.

Strain Relief Hole

Nut & Bolt

Work Clamp

Work Cable

Page 10

Work Cable Installation

Refer to Figure A.2.

1. Open the wire feed section door on the right side of

the Pro-MIG 140.

2. Pass the end of the work cable that has the terminal lug with the smaller hole through the Work

Cable Access Hole (1) in the case front.

3. Route the cable under and around the back of the

Wire Feed Gearbox (6).

4. For GMAW Only: Refer to Figure A.2. This is the

appropriate configuration for the GMAW (MIG)

process. To complete installation, use the provided

wing nut to connect the work cable’s terminal lug to

the negative (–) output terminal (5) located above

the Wire Feed Gearbox (6). Make sure that both

wing nuts are tight.

5. For Innershield Only: Refer to Figure A.4. As

delivered, the machine is connected for negative

electrode polarity. To wire for negative polarity

(required for the Innershield process), connect the

short cable attached to the connector block (1) to

the negative (–) output terminal (2) and the work

cable (3) to the positive (+) terminal (4).

A-4

INSTALLATION

Pro-MIG 140

A-4

Connecting Gun Cable to the Pro-MIG 140

1. Refer to Figure A.2. Unplug the machine or turn

power switch to the OFF “O” position.

2. Pass the insulated terminals of the gun trigger control leads, one at a time, through the Gun Cable

and Control Lead Access Slot (2) in the case front.

The leads are to be routed under the Wire Feed

Gearbox (6) and through the Cable Hanger (7) on

the inner panel.

3. Insert the connector on the gun conductor cable

through the Gun Cable Access Hole (2) in the ProMIG 140 case front. Make sure the connector is all

the way into the brass connector block. Unscrew

the thumbscrew on the connector block a few turns

if gun connector will not insert fully. Rotate the connector so control leads are on the underside and

tighten the Thumbscrew (8) in the connector block.

4. Connect the gun trigger control lead terminals to

the two insulated 1/4" (6.4 mm) tab terminal connector bushings located below the “Gun Trigger

Connection” decal in the wire feed section (4).

Either lead can go to either connector. Form the

leads so that they are as close as possible to the

inside panel.

If the gun trigger switch being used is other than

that supplied with the Pro-MIG 140, the switch

must be a normally open, momentary switch. The

terminals of the switch must be insulated from the

welding circuit. Malfunction of the Pro-MIG 140

may result if this switch shorts to the Pro-MIG 140

welding output circuit or is common to any electrical circuit other than the Pro-MIG 140 trigger circuit.

GAS CONNECTION

When using the GMAW process, a cylinder of shielding gas, must be obtained. For more information about

selecting gas cylinders for use with the Pro-MIG 140

refer to the ACCESSORIES section.

2

4

3

1

FIGURE A.4

GUN INSTALLATION

As shipped from the factory, the Pro-MIG 140 is ready

to feed .035" (0.9 mm) Innershield flux-cored wire. If

.023" – .025" (0.6 mm) solid wire is to be used, use

the appropriate contact tip , diffuser and Nozzle.

CAUTION

Page 11

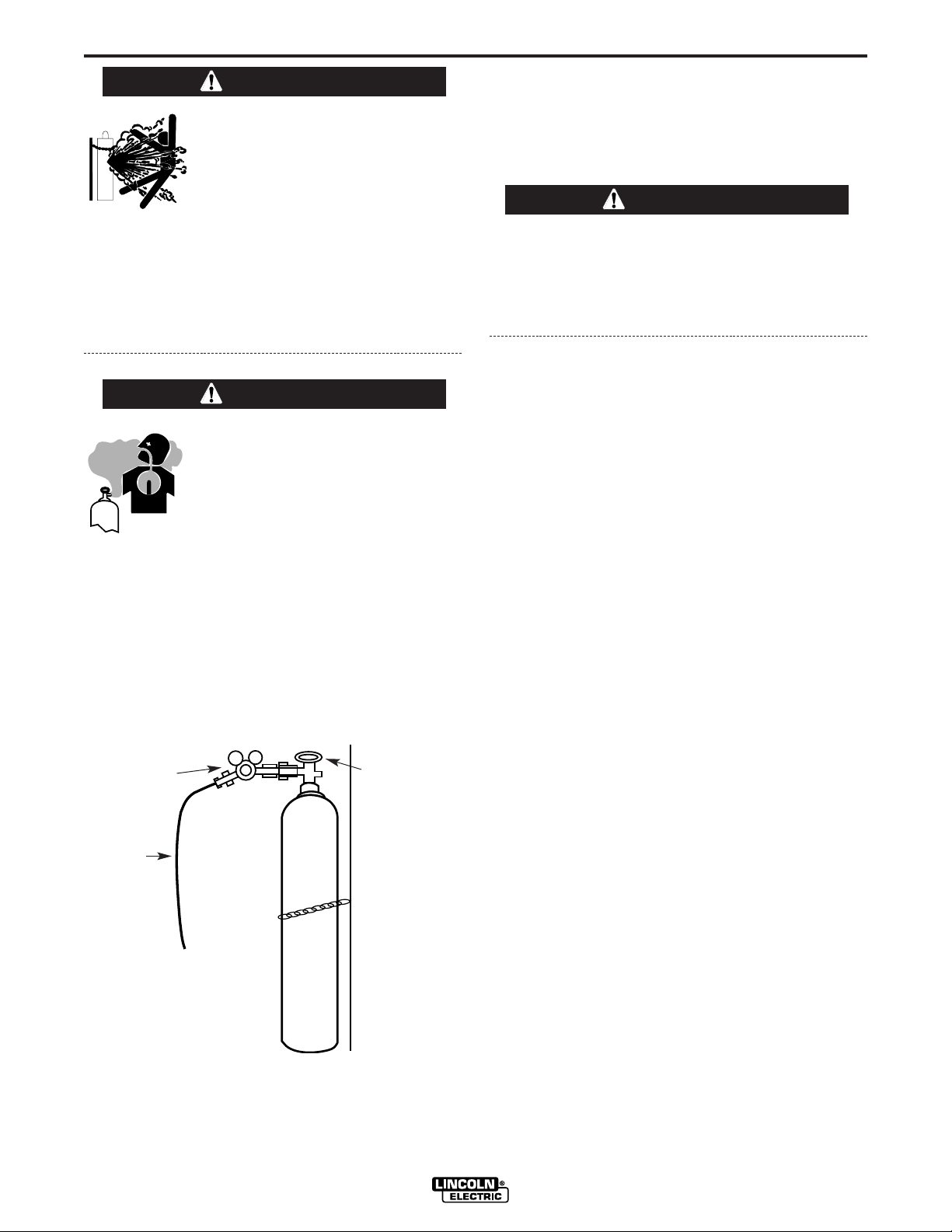

CYLINDER may explode if damaged. Keep cylinder upright and

chained to support

• Keep cylinder away from areas

where it may be damaged.

• Never lift welder with cylinder

attached.

• Never allow welding electrode to

touch cylinder.

• Keep cylinder away from welding

or other live electrical circuits.

BUILDUP OF SHIELDING GAS may

harm health or kill.

• Shut off shielding gas supply

when not in use.

• SEE AMERICAN NATIONAL

STANDARD Z-49.1, “SAFETY IN

WELDING AND CUTTING” PUBLISHED BY THE AMERICAN

WELDING SOCIETY.

1. Chain the cylinder to a wall or other stationary support to prevent the cylinder from falling over.

Insulate the cylinder from the work circuit and earth

ground. Refer to Figure A.5.

FIGURE A.5

A-5

INSTALLATION

Pro-MIG 140

A-5

WARNING

Cylinder Valve

Gas Hose

Flow Regulator

WARNING

2. With the cylinder securely installed, remove the

cylinder cap. Stand to one side away from the outlet and open the cylinder valve very slightly for an

instant. This blows away any dust or dirt which may

have accumulated in the valve outlet.

BE SURE TO KEEP YOUR FACE AWAY FROM

THE VALVE OUTLET WHEN “CRACKING” THE

VALVE. Never stand directly in front of or behind

the flow regulator when opening the cylinder

valve. Always stand to one side.

3. Attach the flow regulator to the cylinder valve and

tighten the union nut securely with a wrench.

NOTE: If connecting to 100% CO2cylinder, make

certain the plastic washer is seated in the fitting

that attaches to the CO2cylinder.

4. Refer to Figure A.6. Attach one end of inlet gas

hose to the outlet fitting of the flow regulator and

tighten the union nut securely with a wrench.

Connect the other end to the Pro-MIG 140 Gas

Solenoid Inlet Fitting (5/8-18 female threads — for

CGA — 032 fitting). Make certain the gas hose is

not kinked or twisted.

WARNING

Page 12

A-6

INSTALLATION

Pro-MIG 140

A-6

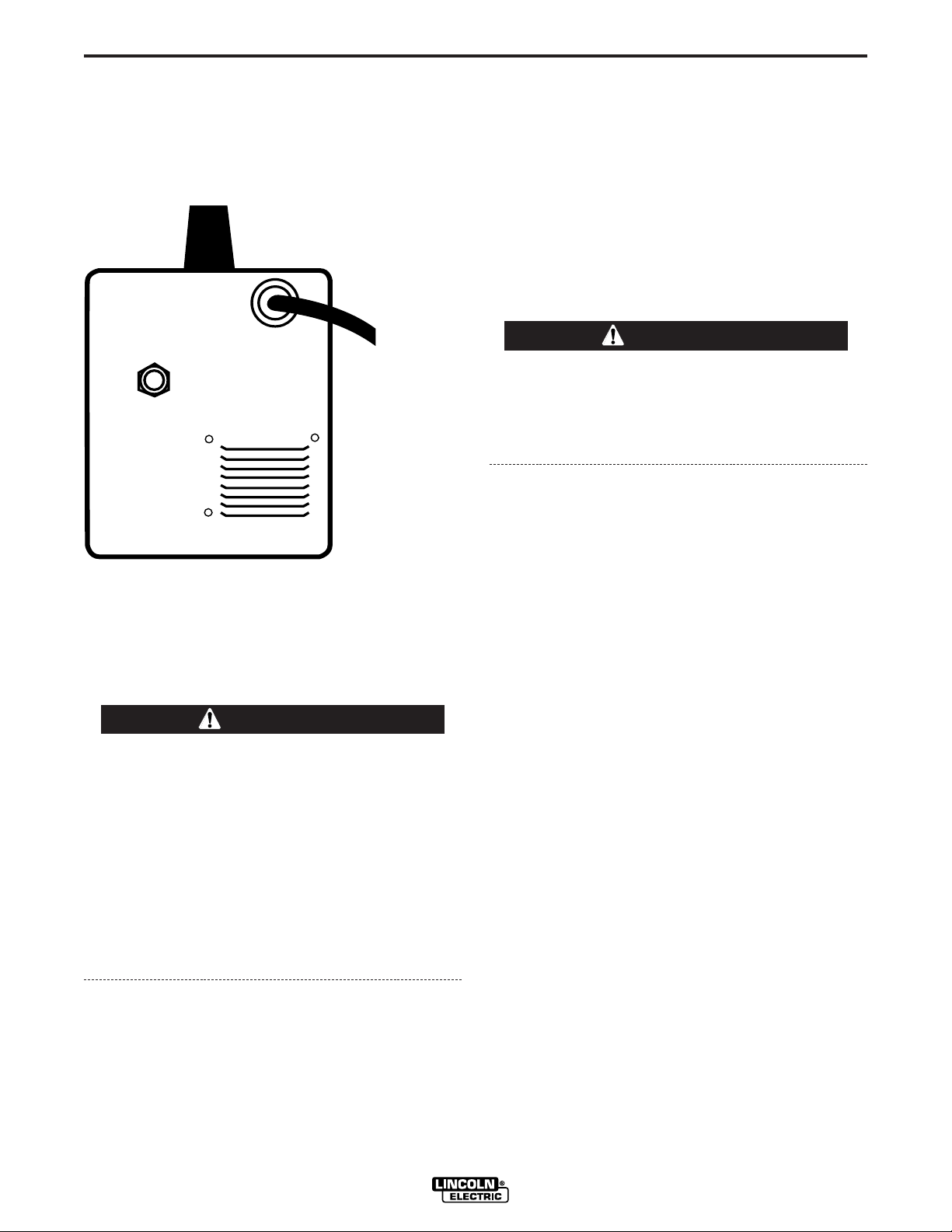

INPUT CONNECTIONS

Refer to Figure A.6.

The Pro-MIG 140 has a power input cable located on

the rear of the machine.

FIGURE A.6

CODE REQUIREMENTS FOR INPUT

CONNECTIONS

This welding machine must be connected to a

power source in accordance with applicable electrical codes.

The National Electrical Code provides standards

for amperage handling capability of supply conductors based on duty cycle of the welding

source.

If there is any question about the installation

meeting applicable electrical code requirements,

consult a qualified electrician.

Requirements For Rated Output

A power cord with a 15 amp, 125 volt, three prong

plug (NEMA Type 5-15P) is factory installed on the

Pro-MIG 140. Connect this plug to a mating grounded

receptacle which is connected to a 20 amp branch circuit with a nominal voltage rating of 115 to 125 volts,

60 Hertz, AC only.

The rated output with this installation is 90 amps,19

Volts, 20% duty cycle (2 minutes of every 10 minutes

used for welding).

Do not connect the Pro-MIG 140 to an input power

supply with a rated voltage that is greater than 125

volts.

Do not remove the power cord ground prong.

POWER INPUT

CABLE

GAS SOLENOID

INLET FITTING

WARNING

CAUTION

Page 13

B-1

OPERATION

B-1

Pro-MIG 140

Read entire operation section before

operating the Pro-MIG 140.

ELECTRIC SHOCK can kill.

• Do not touch electrically live

parts or electrode with skin or

wet clothing. Insulate yourself

from work and ground.

• Always wear dry insulating

gloves.

FUMES AND GASES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing

zone.

WELDING SPARKS can

cause fire or explosion.

• Keep flammable material away.

• Do not weld on closed contain-

ers.

ARC RAYS can burn eyes

and skin.

• Wear eye, ear and body protection.

Observe all safety information throughout

this manual.

WARNING

GENERAL DESCRIPTION

The Pro-MIG 140 is a complete semiautomatic constant-voltage DC wire feeder / power source arc

welder. It has been designed for workshop, hobby,

automotive and light maintenance. Included is a tapswitch controlled, single phase constant voltage transformer / rectifier power source and a wire feeder welding gun for feeding .023 - .025” (0.6 mm) through

.030” (0.8 mm) solid steel electrode. An optional kit is

available for feeding .035” (0.9 mm) Innershield®NR211-MP flux-cored wire.

The Pro-MIG 140 is ideally suited for individuals having access to 120 volt AC input power, and wanting

the ease of use, quality and dependability of both gas

metal arc welding or GMAW (also known as MIG

welding) and the Innershield electrode process (self

shielded flux cored or FCAW). The Pro-MIG 140 is a

rugged and reliable machine that has been designed

for dependable service and long life.

RECOMMENDED PROCESSES

The Pro-MIG 140 can be used for welding mild steel

using the Gas Metal Arc Welding (GMAW or MIG,

Metal Inert Gas) single pass process, which requires a

supply of shielding gas, or the flux-cored arc welding

(FCAW) process using Innershield®electrode wire.

The Pro-MIG 140 is configured for use with the FCAW

process as delivered from the factory.

OPERATIONAL CONTROLS

The Pro-MIG 140 has the following controls as standard: Control Power ON/OFF Switch, Voltage Control,

Wire Speed Control, Trigger Switch, and a Circuit

Breaker.

DESIGN FEATURES

● Operates on 120 volt input

● “Cold electrode” until gun trigger is pressed for an

added measure of safety.

● Overload protection — incorporates both a thermo-

stat and a circuit breaker.

● Quality wire drive with electronic overload protec-

tion.

● “Quick Release” idle roll pressure arm is easily

adjusted.

● Reversible, dual groove drive roll. Drive roll will

feed .023 – .025” (0.6 mm) and .030" - .035" (0.8 -

0.9 mm) diameter wire.

Page 14

B-2

OPERATION

B-2

Refer to Figure B.1b.

4. Circuit Breaker – Protects machine from damage if

maximum output is exceeded. Button will extend

out when tripped (Manual reset).

5. Gun Trigger - Activates welding output, wire feed,

and gas solenoid operation. Releasing the trigger

deactivates welding and simultaneously activates

the “burnback” function so that the welding wire

does not stick in the weld puddle.

FIGURE B.1a

FIGURE B.1b

● No external shielding gas is required when used

with Lincoln Innershield .035” (0.9 mm) NR®-211MP electrode.

● Accommodates both 4” (100 mm) diameter and 8”

(200 mm) diameter spools of wire.

WELDING CAPABILITY

The Pro-MIG 140 is rated at 90 amps, 19 volts, at

20% duty cycle on a ten minute basis. It is capable of

higher output currents at lower duty cycles.

LIMITATIONS

Arc Gouging cannot be performed with the Pro-MIG

140. The Pro-MIG 140 is not recommended for pipe

thawing or TIG welding.

CONTROLS AND SETTINGS

Refer to Figure B.1a.

1. Control Power ON/OFF Switch

— When the power is on the

fan motor will run and air will be

exhausted out the louvers in the

front of the machine. The welding output and wire feeder

remain off until the gun trigger

is pressed.

2. Wire Speed Control —

Controls the wire feed speed

from 50 – 300 in /min. (1.3 –

7.6 m/min.). The control can

be preset on the dial to the

setting specified on the ProMIG 140 Application Chart

located on the inside of the

wire feed section door.

3. Voltage Control — A 4-position tap selector switch gives

full range adjustment of

power source output voltage.

Do not switch while welding

as damage to switch may

occur.

Pro-MIG 140

OFF

ON

ARC VOLTS

WIRE SPEED

Pro-MIG™ 140

DO NOT SWITCH

WHEN WELDING

3

2

1

Page 15

B-3

OPERATION

B-3

WELDING OPERATIONS

SEQUENCE OF OPERATION

Wire Loading

Refer to Figures B.2 and B.3.

The machine power switch should be turned to the

OFF (“O”) position before working inside the wire feed

enclosure.

The welder is shipped from the factory ready to feed

8" (200 mm) diameter spools with 2.2" (56 mm) maximum width. These spools fit on a 2" (51 mm) diameter

spindle that has a built in, adjustable friction brake to

prevent overrun of the spool and excess slack in the

wire.

Note:When loading and removing the 8” Spools

make

sure that the wing nut (inside the wire spool spindle

hub) is turned 90° from the wire spool spindle locking

tab. If the wing nut is positioned in line with the locking

tab, the tab cannot be depressed to load or unload the

wire spool.

FIGURE B.2

Load an 8” (200 mm) diameter spool on the wire spool

spindle shown in Figure B.2.

To use 4” (100 mm) diameter spools, the 2” (50 mm)

diameter spindle must be removed (See Figure B.3).

Remove the wing nut and spacer at the end of the

shaft and remove the outside plastic wire spool spindle. The spindle can be stored in the wire feed compartment. A 4” (100 mm) diameter spool is mounted

directly on the 5/8” (16 mm) diameter shaft and held in

place with the previously removed hardware. Also

make certain the start end of the wire, which may protrude through the side of the spool does not contact

any metallic case parts.

FIGURE B.3

Pro-MIG 140

Wire Spindle Shaft

To Wire Drive

4" Wire Spool

Wing Nut

and Spacer

Wire Spool must be pushed all the way on the spindle so that the

spindles tab will hold it in place. The Wire Spool will rotate clockwise when wire is dereeled.

Be sure that this stud engages

the hole in the wire spool.

To Wire Drive

Wire Spool Spindle

8” Wire Spool

Page 16

B-4

OPERATION

B-4

Friction Brake Adjustment

With wire spool installed on the spindle shaft and the

wing nut loose, turn the spool by hand while slowly

tightening the wing nut until a light drag is felt. Tighten

the wing nut an additional 1/4 turn.

Note: When properly adjusted, the brake should provide only enough drag to prevent overrun of the spool

and excess slack in the wire. Too much drag may

result in wire feeding problems, and may cause premature wear of wire drive system components.

Wire Threading

Refer to Figure B.4

1. Release the Spring Loaded Pressure Arm (1)

rotate the Idle Roll Arm (2) away from. the Wire

Feed Drive Roll (3). Ensure that the groove size in

the feeding position on the drive roll matches the

wire size being used.

2. Carefully detach the end of the wire from the

spool. To prevent the spool from unwinding,

maintain tension on the wire until after step 5.

3. Cut the bent portion of wire off and straighten the

first 4” (100 mm).

4. Thread the wire through the In-going guide tube

(4), over the drive roll (3), and into the out-going

guide tube (5).

5. Close the idle roll arm (2) and latch the spring

loaded pressure arm (1) in place. Rotate the spool

counterclockwise if required in order to take up

extra slack in the wire.

6. The idle roll pressure adjustment wing nut is factory set to approximately five full turns from where

the wing nut first engages the threads of the pressure arm (1). If feeding problems occur because

the wire is flattened excessively, turn the pressure

adjustment counter-clockwise to reduce distortion

of the wire. Slightly less pressure may be required

when using 0.023 – 0.025" (0,6 mm) wire. If the

drive roll slips while feeding wire, the pressure

should be increased until the wire feeds properly.

When inching the welding wire, the drive rolls, the

gun connector block and the gun contact tip are

electrically energized relative to work and ground

and remain energized for several seconds after

the gun trigger is released.

FIGURE B.4

7. Refer to Figure B.5. Remove gas nozzle and contact tip from end of gun.

8. Turn the Pro-MIG 140 ON (“I”).

9. Straighten the gun cable assembly.

10. Depress the gun trigger switch and feed welding

wire through the gun and cable. (Point gun away

from yourself and others while feeding wire.)

Release gun trigger after wire appears at end of

gun.

11. Turn the Pro-MIG 140 OFF (“O”).

12. Replace contact tip and gas nozzle.

13. Refer to Figure B-6. Cut the wire off 3/8” – 1/2” (10

– 13 mm) from the end of the tip. The Pro-MIG

140 is now ready to weld.

FIGURE B.5

Pro-MIG 140

WARNING

The Wire Drive Feed Roll can

accommodate two wire sizes

by flipping the wire drive feed

roll over.

1

2

3

4

5

Gun Handle

Gas Diffuser/

Contact Tip

Gas Nozzle

Page 17

B-5

OPERATION

B-5

FIGURE B.6

Making A Weld

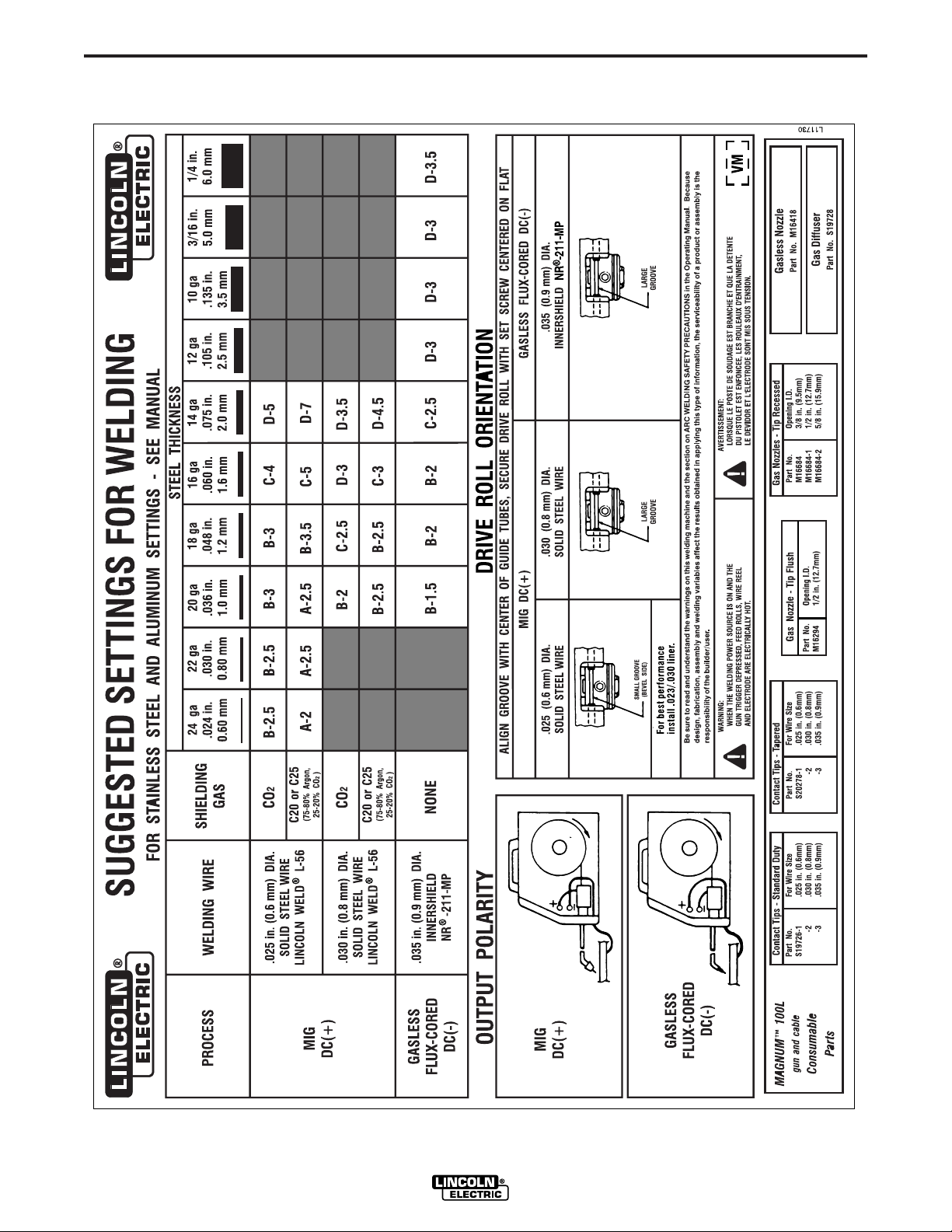

1. See “Process Guidelines” in this section for selection of welding wire and shielding gas and for

range of metal thicknesses that can be welded.

2. See the Application chart on the inside of the wire

feed compartment door for information on setting

the Pro-MIG 140 controls. Refer to Table B.1 for

aluminum and stainless wire.

3. Set the Voltage (“V”) and Wire Speed (“olo’”) controls to the settings suggested for the welding wire

and base metal thickness being used, refer to

Applications chart on the inside of the wire drive

compartment door.

4. Check that the polarity is correct for the welding

wire being used and that the gas supply, if

required, is turned on.

5. When using Innershield electrode, remove the gas

nozzle and install the gasless nozzle. This will

improve visibility of the arc and protect the gas diffuser from weld spatter. Refer to the MAINTENANCE section for details on nozzle replacement.

FIGURE B.7

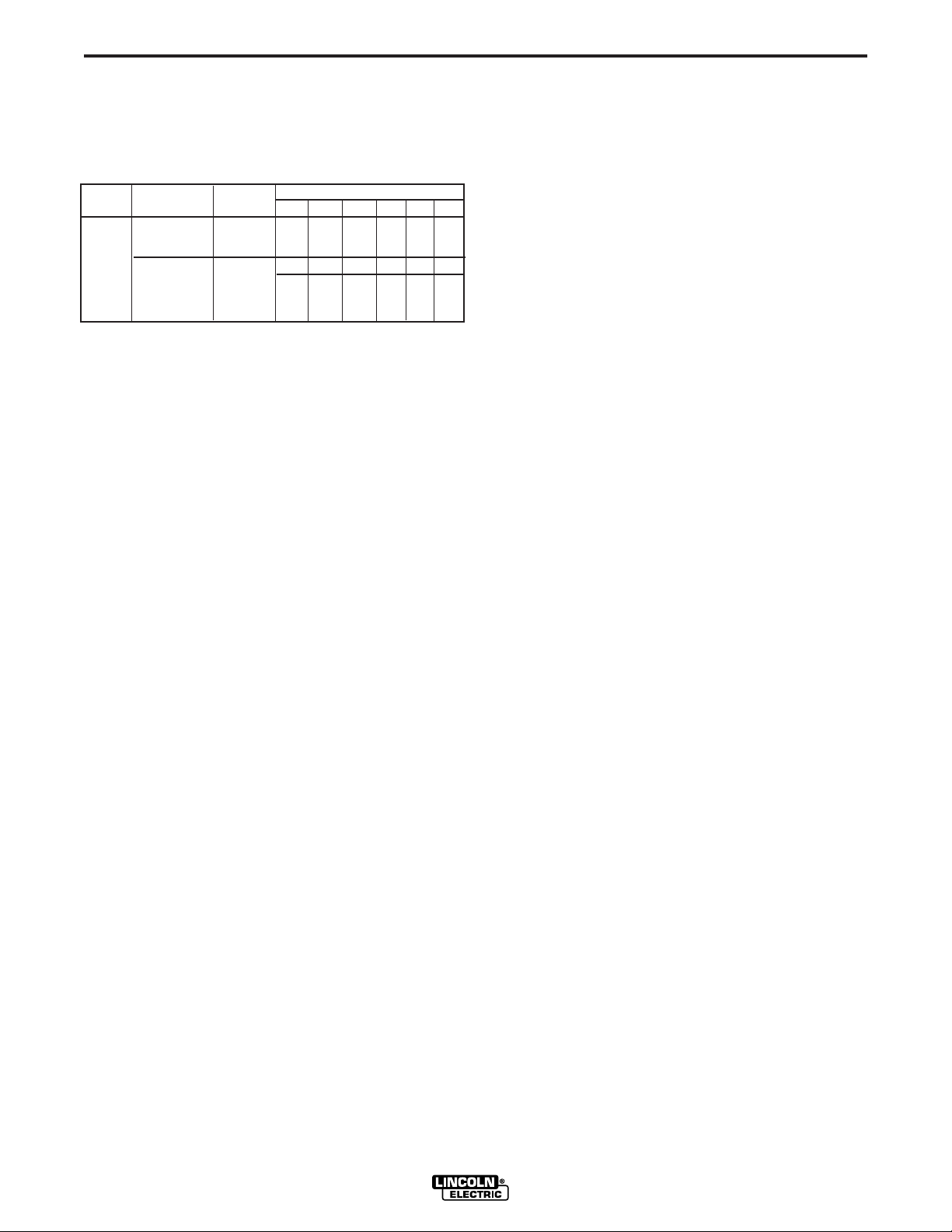

6. Refer to Figure B.7. Connect work clamp to metal

to be welded. Work clamp must make good electrical contact to the workpiece. The workpiece

must also be grounded as stated in “Arc Welding

Safety Precautions” in the beginning of this manual.

7. Position gun over joint. End of wire may be lightly

touching the work.

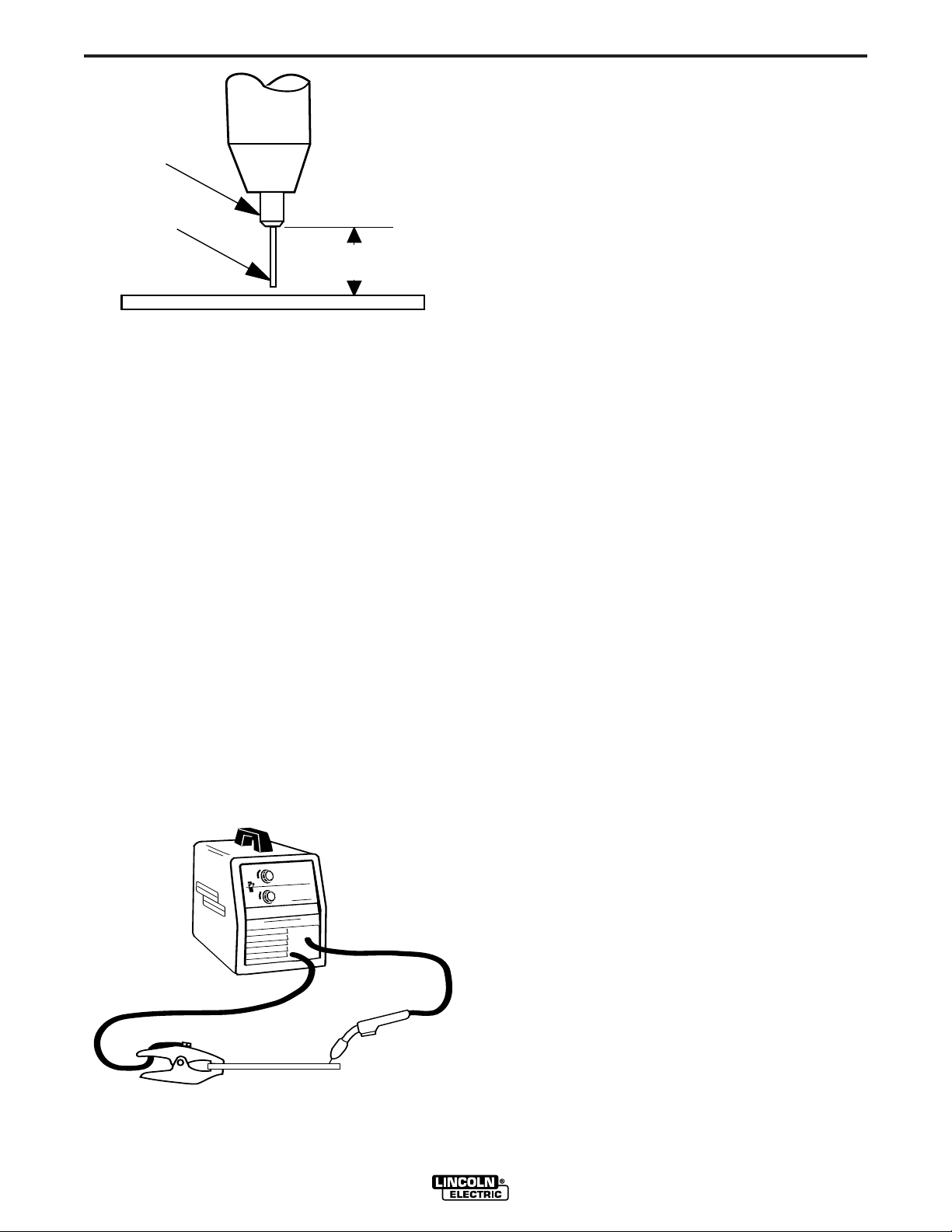

8. Place hand shield in front of face, close gun trigger, and begin welding. Hold the gun so the contact tip to work distance is about 3/8 inch (10 mm).

9. To stop welding, release the gun trigger and then

pull the gun away from the work after the arc goes

out.

10. When no more welding is to be done, close valve

on gas cylinder (if used), momentarily operate gun

trigger to release gas pressure, and turn off the

Pro-MIG 140.

Cleaning Tip And Nozzle

Clean the contact tip and nozzle to avoid arc bridging

between the nozzle and contact tip which can result in

a shorted nozzle, poor welds and an overheated gun.

Hint: Anti-stick spray or gel, available from a welding

supply distributor, may reduce buildup and aid in spatter removal.

PROCESS GUIDELINES

The Pro-MIG 140 can be used for welding mild steel

using the GMAW, single pass process which requires

a supply of shielding gas or it can be used for the selfshielded, Innershield®process (FCAW).

The recommended gases and electrodes for GMAW

are welding grade CO2gas or an argon-CO2blended

gas (75 to 80% argon and 25 to 20% CO2) and .025"

(0.6 mm) diameter Lincoln Super Arc L-56 mild-steel

welding wire, supplied on 12-1/2 lb (5.7 kg) spools.

The recommended electrode for the self-shielded

process is .035” (0.9 mm) diameter Lincoln

Innershield®NR-211-MP. This electrode can be used

for all position welding of 20 gauge (1.0 mm) through

5/16" (8 mm) steel. Thickness of 1/4" (6 mm) and

5/16" (8 mm) require multiple passes. This wire can

also be used for the welding of galvanized coated

sheet metal.

Pro-MIG 140

Contact Tip

Wire Electrode

WORKPIECE

GUN CABLE

ARC

WORK CLAMP

Pro-MIG

™ 140

3/8"– 1/2"(10-13mm) Contact

Tip to Work Distance(CTWD)

Page 18

B-6

OPERATION

B-6

The Pro-MIG 140 is suitable for .035" aluminum wire

and .030" stainless wire. Refer to Table B.1 for recommended procedure settings.

TABLE B.1

NOTE:

NR - Not Recommended

CHANGING MACHINE OVER TO

FEED OTHER WIRE SIZES

The Pro-MIG 140 is shipped from the factory ready to

feed .035” (0.9 mm) diameter wire. To operate the

Pro-MIG 140 with other sizes of wire, it is necessary

to change the appropriate contact tip, diffuser, nozzle

and change the drive roll over to other sizes. Refer to

Changing the Contact Tip and Changing the Drive

Roll, in the MAINTENANCE section, for specific information on these procedures.

WELDING WITH GMAW (MIG)

Shielding Gas

When using the GMAW process, the correct drive roll

and electrode polarity must be used. See Work Cable

Installation in INSTALLATION section for changing

the polarity.

When using the GMAW process, obtain and install a

gas regulator and hose kit. If using CO2a CO

2

adapter is required, sold separately.

1. For CO2, open the cylinder very slowly. For argonmixed gas, open cylinder valve slowly a fraction of

a turn. When the cylinder pressure gauge pointer

stops moving, open the valve fully.

2. If using a regulator with an adjustable flow meter,

close the gun trigger and adjust the flow to give 15

– 20 cubic ft per hour (CFH) (7 – 10 I/min.) [use 20

– 25 CFH (10 – 12 I/min.) when welding out of

position or in a drafty location for CO2]. For argon

mixed gas, trigger to release gas pressure, and

adjust the flow to give 25 – 30 CFH (12 – 14

I/min.).

3. Keep the cylinder valve closed, except when using

the Pro-MIG 140. When finished welding:

a) Close the cylinder valve to stop gas flow.

b) Depress the gun trigger briefly to release the

pressure in the gas hose.

c) Turn off the Pro-MIG 140.

WELDING WITH FCAW (Innershield)

When using the FCAW process, the correct drive roll

and electrode polarity must be used. See Work Cable

Installation in INSTALLATION section for changing

the polarity.

OVERLOAD PROTECTION

Output Overload

The Pro-MIG 140 is equipped with a circuit breaker

and a thermostat which protects the machine from

damage if maximum output is exceeded. The circuit

breaker button will extend out when tripped. The circuit breaker must be manually reset.

Thermal Protection

The Pro-MIG 140 has a rated output duty cycle of

20%. If the duty cycle is exceeded, a thermal protector

will shut off the output until the machine cools to a

reasonable operating temperature. This is an automatic function of the Pro-MIG 140 and does not

require user intervention. The fan continues to run

during cooling.

Electronic Wire Drive Motor Protection

The Pro-MIG 140 has built-in protection for wire drive

motor overload.

Pro-MIG 140

Shielding

Voltage/Wire Speed

Process Welding Wire Gas 22 ga 16 ga 12 ga 1/8” 3/16” 1/4”

.035 Dia(0.9mm 100% Argon A-4.5 C-8.5 D-10 NR NR NR

4043 Aluminum

Wire

MIG DC+

18 ga 16 ga 14 ga 12 ga 10ga

.030 Dia 98% Argon/ B-6 C-6.5 D-7.5 NR NR

308L Stainless 2% Oxygen

Steel Wire

Page 19

B-7

APPLICATION CHART

B-7

Pro-MIG 140

Page 20

C-1

ACCESSORIES

C-1

OPTIONAL ACCESSORIES

1. K664-2 Aluminum Feeding Kit — This kit is rec-

ommended for welding with .035 Aluminum wire.

This kit may also be used for feeding .035 stainless

wire. Included with this kit are a drive roll, liner and

contact tip. It is important when changing

between welding with steel wire and aluminum

to exchange these components due to the

lubricant applied to steel wire. Failure to do so

may result in contaminated welds when welding aluminum.

2. K520 Utility Cart — Designed to transport the

Lincoln family of small welders. Has provisions for

mounting a single gas cylinder. Has front casters

and large rear wheels. Handle height is easily

adjustable. Bottom tray provided for tools and

accessories. Easy assembly required; takes less

than 15 minutes.

3. K586-1 Deluxe Adjustable Gas Regulator &

Hose Kit

Accommodates CO2 or mixed Gas Cylinders.

Pro-MIG 140

Page 21

C-2

ACCESSORIES

C-2

INNERSHIELD (FCAW)

CONVERSION

Several changes are needed to convert the unit for

operation with the Innershield (FCAW) process:

1. Change the output polarity to DC(–). See “Work

Cable Installation” in Installation section for details.

2. Install proper drive roll for the wire size selected.

See “Changing Drive Roll” in Maintenance section

for details.

3. Install the proper gun liner

1

and tip for the wire size

selected. See “Component Replacement” in

Maintenance section for details.

4. Remove gas nozzle (if installed) and install the

gasless nozzle. To remove, simply unscrew.

5. Load wire into machine and thread into gun and

cable per “Welding Wire Loading” section.

1

The factory installed gun liner will feed up to .035

(0.9mm) wire.

REPLACEMENT PARTS

Complete Gun and Cable Assembly

L8311-6 (K530-4)

Contact Tip .025” (0.6 mm)

KP2039-1B1

Contact Tip .030” (0.8 mm)

KP2039-2B1

Contact Tip .035” (0.9 mm)

KP2039-3B1

Contact Tip-Tapered .025” (0.6 mm)

KP2052-1B1

Contact Tip-Tapered .030” (0.8 mm)

KP2052-2B1

Contact Tip-Tapered .035” (0.9 mm)

KP2052-3B1

Liner .025 - .035” (0.6 - 0.9 mm)

KP1937-3

Gas Diffuser

KP2040-1

Gas Nozzle

KP1938-1

Gas Nozzle-Tip Recessed 3/8” (9.5 mm)

Opening I.D.

KP1942-1

Gas Nozzle-Tip Recessed 1/2” (12.7 mm)

Opening I.D.

KP1942-2

Gas Nozzle-Tip Recessed 5/8” (15.9 mm)

Opening I.D.

KP1942-3

Spot Welding Nozzle

KP1956-1

Gasless Nozzle (Innershield Only)

KP1939-1

Pro-MIG 140

Page 22

MAINTENANCE

SAFETY PRECAUTIONS

ELECTRIC SHOCK can kill.

• Disconnect input power by removing

plug from receptacle before working

inside Pro-MIG 140. Use only grounded

receptacle. Do not touch electrically

“hot” parts inside Pro-MIG 140.

• Have qualified personnel do the mainte-

nance and trouble shooting work.

ROUTINE MAINTENANCE

POWER SOURCE COMPARTMENT

No user serviceable parts inside! Do not attempt to perform

service in the power source (fixed) side of the Pro-MIG 140.

Take the unit to an authorized Lincoln Service Center if you

experience problems. NO maintenance is required.

In extremely dusty locations, dirt may clog the air passages

causing the welder to run hot with premature tripping of thermal protection. If so, blow dirt out of the welder with low pressure air at regular intervals to eliminate excessive dirt and dust

build-up on internal parts.

WIRE FEED COMPARTMENT

1. When necessary, vacuum accumulated dirt from gearbox

and wire feed section.

2. Occasionally inspect the incoming guide tube and clean

inside diameter if necessary.

3. Motor and gearbox have lifetime lubrication and require no

maintenance.

FAN MOTOR

Has lifetime lubrication — requires no maintenance.

WIRE REEL SPINDLE

Requires no maintenance. Do not lubricate shaft.

D-1

MAINTENANCE

D-1

Pro-MIG 140

WARNING

Page 23

D-2

MAINTENANCE

D-2

Pro-MIG 140

GUN AND CABLE

MAINTENANCE

FOR MAGNUM™ 100L GUN

Gun Cable Cleaning

Clean cable liner after using approximately 300 lbs

(136 kg) of solid wire or 50 lbs (23 kg) of flux-cored

wire. Remove the cable from the wire feeder and lay it

out straight on the floor. Remove the contact tip from

the gun. Using low pressure air, gently blow out the

cable liner from the gas diffuser end.

Excessive pressure at the start may cause the dirt

to form a plug.

Flex the cable over its entire length and again blow

out the cable. Repeat this procedure until no further

dirt comes out.

Contact Tips, Nozzles, and Gun Tubes

1. Dirt can accumulate in the contact tip hole and

restrict wire feeding. After each spool of wire is

used, remove the contact tip and clean it by pushing a short piece of wire through the tip repeatedly.

Use the wire as a reamer to remove dirt that may

be adhering to the wall of the hole through the tip.

2. Replace worn contact tips as required. A variable

or “hunting” arc is a typical symptom of a worn contact tip. To install a new tip, choose the correct size

contact tip for the electrode being used (wire size is

stenciled on the side of the contact tip) and screw it

snugly into the gas diffuser.

3. Remove spatter from inside of gas nozzle and from

tip after each 10 minutes of arc time or as required.

4. Be sure the gas nozzle is fully screwed onto the

diffuser for gas shielded processes. For the

Innershield®process, the gasless nozzle should

be screws onto the diffuser.

5. To remove gun tube from gun, remove gas nozzle

or gasless nozzle and remove diffuser from gun

tube. Remove both collars from each end of the

gun handle and separate the handle halves.

Loosen the locking nut holding the gun tube in

place against the gun end cable connector.

Unscrew gun tube from cable connector. To install

gun tube, screw the locking nut on the gun tube as

far as possible. Then screw the gun tube into the

cable connector until it bottoms. Then unscrew (no

more than one turn) the gun tube until its axis is

perpendicular to the flat sides of the cable connector and pointed in the direction of the trigger.

Tighten the locking nut so as to maintain the proper

relationship between the gun tube and the cable

connector. Replace the gun handle, trigger and diffuser. Replace the gas nozzle or gasless nozzle.

CAUTION

Page 24

D-3

MAINTENANCE

D-3

Pro-MIG 140

COMPONENT

REPLACEMENT

PROCEDURES

CHANGING THE CONTACT TIP

1. Refer to Figure D.2. Remove the gas nozzle from

the gun by unscrewing counter-clockwise.

2. Remove the existing contact tip from the gun by

unscrewing counter-clockwise.

3. Insert and hand tighten desired contact tip.

4. Replace gas nozzle.

CHANGING DRIVE ROLL

The drive roll has two grooves; one for .023" – .025"

(0.6 mm) solid steel electrode and a larger groove for

.030" (0.8 mm) solid and .035" (0.9 mm) flux-cored

steel electrode. As shipped, the drive roll is installed in

the .035" (0.9 mm) position.

If .023"/.025" (0.6 mm) wire is to be used, the drive roll

must be reversed as follows:

1. Connect the machine to its rated input power per

instructions in Installation section.

2. Release the spring-loaded idle arm tensioner,Item 2, and

lift the idle roll arm,

Item 3,

away from the drive roll, Item

1. (See Figure D.1)

3. Turn the power switch to ON (marked “I”).

4. Set the wire speed to minimum and jog the drive

unit with the trigger switch until the drive roll set

screw is facing up.

When inching the welding wire, the drive rolls,

gun connector block, and gun contact tip are

energized relative to work and ground and remain

energized for several seconds after the gun trigger is released.

5. Turn the power switch to OFF (marked “O”).

6. Loosen the drive roll set screw with the 5/64" (2.0

mm) hex wrench supplied.

7. Remove the drive roll, flip over and reinstall with the

.023"/.025" (0.6 mm) groove (the smaller groove)

closest to the gearbox.

8. Push a length of straightened welding wire through

the wire feeder guide tubes and adjust the position

of the drive roll so that the groove is centered on

the wire. Make certain the set screw is located on

the flat portion of the shaft and tighten.

3

2

1

FIGURE D.1

CAUTION

Page 25

GUN HANDLE PARTS

The gun handle consists of two halves that are held

together with a collar on each end. To open up the

handle, turn the collars approximately 60 degrees

counter-clockwise until the collar reaches a stop. Then

pull the collar off the gun handle. If the collars are difficult to turn, position the gun handle against a corner,

place a screwdriver against the tab on the collar and

give the screwdriver a sharp blow to turn the collar

past an internal locking rib. See Figure D-3.

FIGURE D.3

➣

Counter-clockwise

D-4

MAINTENANCE

D-4

8. Screw the gas diffuser onto the end of the gun tube

and securely tighten.

9. Replace the contact tip and nozzle.

Pro-MIG 140

1-1/4 (31.8 mm)

Liner Trim Length

Gas Diffuser

Gas Nozzle or

Gasless Nozzle

Set Screw Brass Cable

Connector

Liner Assembly

(Liner bushing to be sealed tight

against brass cable connector)

FIGURE D.2

Liner trim length

CHANGING LINER

NOTICE: The variation in cable lengths prevents the

interchangeability of liners. Once a liner has been cut

for a particular gun, it should not be installed in another gun unless it can meet the liner cutoff length

requirement. Refer to Figure D.2.

1. Remove the gas nozzle from the gun by unscrewing counter-clockwise.

2. Remove the existing contact tip from the gun by

unscrewing counter-clockwise.

3. Remove the gas diffuser from the gun tube by

unscrewing counter-clockwise.

4. Lay the gun and cable out straight on a flat surface.

Loosen the set screw located in the brass connector at the wire feeder end of the cable. Pull the liner

out of the cable.

5. Insert a new untrimmed liner into the connector end

of the cable. Be sure the liner bushing is stenciled

appropriately for the wire size being used.

6. Fully seat the liner bushing into the connector.

Tighten the set screw on the brass cable connector.

At this time, the gas diffuser should not be installed

onto the end of the gun tube.

7. With the gas nozzle and diffuser removed from the

gun tube, be sure the cable is straight, and then

trim the liner to the length shown in the Figure D.2.

Remove any burrs from the end of the liner.

Page 26

E-1

TROUBLESHOOTING

E-1

Pro-MIG 140

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

This Troubleshooting Guide is provided to help you

locate and repair possible machine malfunctions.

Simply follow the three-step procedure listed below.

Step 1. LOCATE PROBLEM (SYMPTOM).

Look under the column labeled “PROBLEM (SYMPTOMS)”. This column describes possible symptoms

that the machine may exhibit. Find the listing that

best describes the symptom that the machine is

exhibiting.

Step 2. POSSIBLE CAUSE.

The second column labeled “POSSIBLE CAUSE” lists

the obvious external possibilities that may contribute

to the machine symptom.

Step 3. RECOMMENDED COURSE OF ACTION

This column provides a course of action for the

Possible Cause, generally it states to contact your

local Lincoln Authorized Field Service Facility.

If you do not understand or are unable to perform the

Recommended Course of Action safely, contact your

local Lincoln Authorized Field Service Facility.

HOW TO USE TROUBLESHOOTING GUIDE

Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel.

Unauthorized repairs performed on this equipment may result in danger to the technician and

machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical

Shock, please observe all safety notes and precautions detailed throughout this manual.

__________________________________________________________________________

WARNING

Page 27

E-2

TROUBLESHOOTING

E-2

Pro-MIG 140

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

PROBLEMS

(SYMPTOMS)

Major physical or electrical damage

is evident.

No wire feed, weld output or gas

flow when gun trigger is pulled. Fan

does NOT operate.

No wire feed, weld output or gas

flow when gun trigger is pulled.

Fan operates normally.

POSSIBLE

CAUSE

None

Contact your local Authorized Field

Service Facility.

1. Make sure correct voltage is

applied to the machine (115vac).

2. Make certain that power switch

is in the ON position.

3. Make sure circuit breaker is

reset.

1. The thermostat may be tripped

due to overheating. Let machine

cool. Weld at lower duty cycle.

2. Check for obstructions in air

flow. Check Gun Trigger connections. See Installation section.

3. Gun trigger may be faulty.

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service

Facility.

OUTPUT PROBLEMS

Observe all Safety Guidelines detailed throughout this manual

Page 28

E-3

TROUBLESHOOTING

E-3

Pro-MIG 140

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

PROBLEMS

(SYMPTOMS)

No wire feed when gun trigger is

pulled. Fan runs, gas flows and

machine has correct open circuit

voltage (32VDC maximum) – weld

output.

Low or no gas flow when gun

trigger is pulled. Wire feed, weld

output and fan operate normally.

POSSIBLE

CAUSE

1. If the wire drive motor is running

make sure that the correct drive

rolls are installed in the machine.

2. Check for clogged cable liner or

contact tip.

3. Check for proper size cable liner

and contact tip.

1. Check gas supply, flow regulator

and gas hoses.

2. Check gun connection to

machine for obstruction or leaky

seals.

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service

Facility.

FEEDING PROBLEMS

GAS FLOW PROBLEMS

Observe all Safety Guidelines detailed throughout this manual

Page 29

E-4

TROUBLESHOOTING

E-4

Pro-MIG 140

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

PROBLEMS

(SYMPTOMS)

Arc is unstable – Poor starting

POSSIBLE

CAUSE

1. Check for correct input voltage

to machine – 115vac.

2. Check for proper electrode

polarity for process.

3. Check gun tip for wear or dam-

age and proper size – Replace.

4. Check for proper gas and flow

rate for process. (For MIG only.)

5. Check work cable for loose or

faulty connections.

6. Check gun for damage or

breaks.

7. Check for proper drive roll orien-

tation and alignment.

8. Check liner for proper size.

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service

Facility.

WELDING PROBLEMS

Observe all Safety Guidelines detailed throughout this manual

Page 30

F-1

DIAGRAMS

F-1

Pro-MIG 140

WARNING

HIGH VOLTAGE

can kill

Only qualified persons should install, use or service this machine.

Do not operate with covers removed.

Disconnect input power by unplugging power cord before servicing.

Do not touch electrically live parts

A

M20801

S1

SWITCH

D1

D3

D2

D4

204

204

204

203

203

203

C1

59,000 f

40V

203

204

-

+

ELECTRICAL SYMBOLS PER E1537

CAVITY NUMBERING SEQUENCE

( COMPONENT SIDE OF BOARD )

539

541

T1

GUN TRIGGER

THERMOSTAT

208

5K

WIRE SPEED

R2

(W)

(B)

N.C.

N.C. COMPONENT VIEWED FROM REAR.

ON-OFF

N.C.

209

WINDING

24V

AUXILIARY

FAN MOTOR

X1

202

X2

S2

SELECTOR

SWITCH

CIRCUIT

BREAKER

115V/60HZ

115V/60HZ

OUTPUT

CHOKE

X3

X4

X5

+

H1

H1

H2

F1

541

204

203

209

208

539

213

214

1234

LATCH

5

678910

1234

5

6

7

8910

GAS

SOLENOID

CONTROL P.C. BOARD

J1

J1

CR1

H1

H2

LS1

H2

H2

N.O.

214

N.B.

N.D.

N.A.

N.D.

TO EARTH GROUND PER

NATIONAL, LOCAL OR

OTHER APPLICABLE

ELECTRICAL CODES.

-

+

(MOUNTED TO

SEC. COIL)

WIRE

FEED

MOTOR

CASE

GROUNDING

STUD

N.A. DIODES D2 & D4 ARE MOUNTED

ON THE OUTSIDE HEATSINK.

N.B. DIODES D1 & D3 ARE MOUNTED

ON THE INSIDE HEATSINK, WHICH

IS CLOSEST TO THE CENTER PANEL.

N.D. BOLTED ALUMINUM CONNECTIONS

LEAD COLOR CODE:

B-BLACK

W-WHITE

REQUIRE T12837 JOINT COMPOUND

(DOW CORNING 340) WHEN REATTACHING.

213

TO

WORK

GUN CABLE

CONDUCTOR

BLOCK

WIRING DIAGRAM

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The

specific diagram for a particular code is pasted inside the machine on one of the enclosure panels.

Page 31

ESPAÑOL

i

SEGURIDAD

i

La SOLDADURA POR ARCO puede ser peligrosa. PROTEJASE USTED Y A LOS DEMAS CONTRA POSIBLES LESIONES GRAVES O LA MUERTE. NO PERMITA QUE LOS NIÑOS SE ACERQUEN. LAS PERSONAS CON MARCAPASOS DEBEN CONSULTAR A SU MEDICO ANTES DE USAR ESTE EQUIPO.

Lea y entienda los siguientes mensajes de seguridad. Para más información acerca de la seguridad, se

recomienda comprar un ejemplar de "Safety in Welding & Cutting - ANIS Standard Z49.1" de la Sociedad

Norteamericana de Soldadura, P.O. Box 351040, Miami, Florida 33135 ó CSA Norma W117.2-1974. Una ejemplar gratis del folleto "Arc Welding Safety" (Seguridad de la soldadura al arco) E205 está disponible de Lincoln

Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

ASEGURESE QUE TODOS LOS TRABAJOS DE INSTALACION, OPERACION, MANTENIMIENTO Y

REPARACION SEAN HECHOS POR PERSONAS CAPACITADAS PARA ELLO.

ADVERTENCIA

Los RAYOS DEL ARCO pueden quemar.

2.a. Colocarse una careta con el filtro y

cubiertas para protegerse los ojos de

las chispas y rayos del arco cuando

se suelde o se observe un soldadura

por arco abierta. El cristal del filtro y

casco debe satisfacer las normas

ANSI Z87.I.

2.b. Usar ropa adecuada hecha de material ignífugo

durable para protegerse la piel propia y la de los

ayudantes con los rayos del arco.

2.c. Proteger a otras personas que se encuentren

cerca con un biombo adecuado no inflamable y/o

advertirles que no miren directamente al arco ni

que se expongan a los rayos del arco o a las

salpicaduras o metal calientes.

Para equipos ELECTRICOS.

1.a. Cortar la electricidad entrante usando el interruptor de desconexión en

la caja de fusibles antes de trabajar

en el equipo.

1.b. Instalar el equipo de acuerdo con el Código

Eléctrico Nacional (EE.UU.), todos los códigos

locales y las recomendaciones del fabricante.

1.c. Conectar a tierra el equipo de acuerdo con el

Código Eléctrico Nacional (EE.UU.) y las

recomendaciones del fabricante.

LOS CAMPOS ELECTRICOS Y

MAGNETICOS

pueden ser peligrosos

3.a. La corriente eléctrica que circula por cualquiera de

los conductores causa campos eléctricos y magnéticos (EMF) localizados. La corriente para soldar

crea campos EMF alrededor de los cables y

máquinas soldadoras.

3.b. Los campos EMF pueden interferir con algunos

marcapasos, y los soldadores que tengan marcapaso deben consultar a su médico antes de manejar una soldadora.

3.c. La exposición a los campos EMF en soldadura

pueden tener otros efectos sobre la salud que se

desconocen.

3.d. Todo soldador debe emplear los procedimientos

siguientes para reducir al mínimo la exposición a

los campos EMF del circuito de soldadura:

3.d.1. Pasar los cables del electrodo y de trabajo

juntos - Atarlos con cinta siempre que sea

posible.

3.d.2. Nunca enrollarse el cable del electrodo

alrededor del cuerpo.

3.d.3. No colocar el cuerpo entre los cables del

electrodo y de trabajo. Si el cable del electrodo está en el lado derecho, el cable de

trabajo también debe estar en el lado derecho.

3.d.4. Conectar el cable de trabajo a la pieza de

trabajo lo más cerca posible del área que se

va a soldar.

3.d.5. No trabajar cerca del suministro eléctrico de

la soldadora.

MAR95

Page 32

ii

SEGURIDAD

ii

Las CHISPAS DE LA SOLDADURA

pueden causar incendio o

explosión.

4.a. Quitar todas las cosas que presenten riesgo de

incendio del lugar de soldadura. Si esto no es

posible, cubrirlas para impedir que las chispas

de la soldadura inicien un incendio. Recordar

que las chispas y los materiales calientes de la

soldadura puede pasar fácilmente por las grietas pequeñas y aberturas adyacentes al área.

No soldar cerca de tuberías hidráulicas. Tener

un extinguidor de incendios a mano.

4.b.En los lugares donde se van a usar gases com-

primidos, se deben tomar precauciones especiales para impedir las situaciones peligrosas.

Consultar la norma “Safety in Welding and

Cutting” (Norma ANSI Z49.1) y la información

de manejo para el equipo que se está usando.

4.c. No calentar, cortar o soldar tanques, tambores o

contenedores hasta haber tomado los pasos

necesario para asegurar que tales procedimientos no van a causar vapores inflamables o tóxicos de las sustancias en su interior. Pueden

causar una explosión incluso después de

haberse “limpiado”. Para información, comprar

“Recommended Safe Practices for the

Preparation for Welding and Cutting of

Containers and Piping That Have Held

Hazardous Substances”, AWS F4.1 de la

American Welding Society (ver la dirección más

arriba).

4.e.Ventilar las piezas fundidas huecas o contene-

dores antes de calentar, cortar o soldar. Pueden

explotar.

4.f. Las chispas y salpicaduras son lanzadas por el

arco de la soldadura. Usar vestimenta protectora libre de aceite tales como guantes de cuero,

camisa gruesa, pantalones sin bastillas, zapatos

de caña alta y un gorro. Ponerse tapones en los

oídos cuando se suelde fuera de posición o en

lugares confinados. Siempre usar gafas protectoras con escudos laterales cuando se esté en

un área de soldadura.

4.g.Conectar el cable de trabajo a la pieza de traba-

jo tan cerca del área de soldadura como sea

posible. Los cables de la pieza de trabajo

conectados a la estructura del edificio o a otros

lugares alejados del área de soldadura aumentan la posibilidad de que la corriente para soldar

pase por las cadenas de izar, cables de grúas u

otros circuitos alternativos. Esto puede crear

riesgos de incendio o sobrecalentar las cadenas

o cables de izar hasta hacer que fallen.

El ELECTROCHOQUE puede

causar la muerte.

5.a. Los circuitos del electrodo y pieza de trabajo (o

tierra) están eléctricamente “vivos” cuando la soldadora está encendida. No tocar esas piezas “vivas”

con la piel desnuda o ropa mojada. Usar guantes

secos sin agujeros para aislar las manos.

5.b.Aislarse de la pieza de trabajo y tierra usando

aislante seco. Asegurarse que el aislante sea lo

suficientemente grande para cubrir toda el área de

contacto físico con la pieza de trabajo y el suelo.

Además de las medidas de seguridad normales,

si es necesario soldar en condiciones eléctricamente peligrosas (en lugares húmedos o mientras se está usando ropa mojada; en las estructuras metálicas tales como suelos, emparrillados o andamios; estando en posiciones apretujadas tales como sentado, arrodillado o acostado, si existe un gran riesgo de que ocurra contacto inevitable o accidental con la pieza de trabajo o tierra, usar el equipo siguiente:

• Soldadora (de alambre) de voltaje constante

CD semiautomática.

• Soldadora (de varilla) manual CD.

• Soldadora CA con control de voltaje

reducido.

5.c. En la soldadura con alambre semiautomática o

automática, el electrodo, carrete del electrodo,

cabezal soldador, boquilla o pistola para soldar

semiautomática también están eléctricamente

“vivas”.

5.d.Siempre asegurar que el cable de trabajo tenga

una buena conexión eléctrica con el metal que

se está soldando. La conexión debe ser lo más

cerca posible del área que se va a soldar.

5.e.Conectar la pieza de trabajo o metal que se va

a soldar a una buena tierra eléctrica.

5.f. Mantener el portaelectrodo, pinza de trabajo,

cable de la soldadora y la soldadora en condiciones de trabajo buenas y seguras. Cambiar el

aislante si está dañado.

5.g. Nunca sumergir el electrodo en agua para enfri-

arlo.

5.h.Nunca tocar simultáneamente la piezas eléctricamente “vivas” de los portaelectrodos conectados a dos soldadoras porque el voltaje entre los

dos puede ser el total del voltaje de circuito

abierto de ambas soldadoras.

5.i. Cuando se trabaje sobre el nivel del suelo, usar

un cinturón de seguridad para protegerse de

una caída si llegara a ocurrir electrochoque.

5.j. Ver también las partidas 4.c. y 1.

MAR95

Page 33

ESPAÑOL

iii

SEGURIDAD

iii

Los HUMOS Y GASES

pueden ser peligrosos.

6.a. La soldadura puede producir humos y gases

peligrosos para la salud. No respirarlos.

Durante la soldadura, mantener la cabeza alejada de los humos. Tener bastante ventilación y/o

escape en el arco para mantener los humos y

gases lejos de la zona de respiración. Cuando

se suelde con electrodos que requieren ventilación especial tales como aceros inoxidables o revestimientos duros (ver las

instrucciones en el contenedor u hoja de

datos de seguridad del material, MSDS) o en

plomo o acero cadmiado y otros metales o

revestimientos que produzcan humos

hipertóxicos, mantener la exposición tan

baja como sea posible y por debajo de los

valores límites umbrales (TLV), utilizando un

escape local o ventilación mecánica. En

espacios confinados o en algunas situaciones, a la intemperie, puede ser necesario