Page 1

WIRE FEEDER/WELDERS

CV

CC

DC

1

PHASE

60

Hz

Power MIG®350MP

Power MIG®. The Professional’s ChoiceSM.

When you need more than just a MIG machine, the Power MIG®350MP is

the choice for you. Lincoln Chopper Technology

processes—MIG and flux-cored, along with excellent stick welding, TIG and

advanced processes such as Power Mode

™

and Pulse-on-Pulse®. In addition,

future waveforms of special or improved welding processes can be downloaded into the Power MIG, making it expandable. This means the welder

you buy today won’t be obsolete tomorrow. Factor in the simplicity and

sophistication of synergic control, and you’ll agree—no other power

source in this category offers so much!

Processes

Stick, TIG, MIG, Pulsed, Flux-Cored

Advantage Lincoln

Arc Performance:

• Lincoln Chopper Technology®delivers high quality welds by

increasing the control over the welding arc.

• Multi-Process capable — Welds MIG, flux-cored, stick, TIG,

pulsed MIG, and advanced processes like Pulse-On-Pulse

Power Mode

• Pulse-on-Pulse™improves cleaning action when welding aluminum

and delivers a TIG-like appearance to the weld beads.

• Power Mode

on thin material – great arc length control for aluminum welding.

• Synergic control of voltage with wire feed speed allows you

to set weld procedures with only one control for simplicity.

®

.

®

maintains a stable, smooth arc for short arc welding

®

delivers more welding

™

and

Superb Quality:

• Rugged cast aluminum industrial wire drive features dual driven

rolls, easy-turn numeric tension indicator, brass-to-brass gun connections and Lincoln’s 100% wire-supporting split wire guide system.

• Three-year warranty on parts and labor (90 days warranty on gun).

Professional Features:

• Push-Pull or Spool Gun Ready — The Power MIG

electronics built-in to drive either a spool gun or push-pull gun giving

you more ways to feed aluminum.

• 115V auxiliary receptacle to power a grinder or other auxiliary

equipment in your work area.

• A second gas solenoid is built-in for spool gun use or TIG welding.

• Dual Procedure capable — Easily select between either two welding

procedures or two welding modes.

Output

Input

®

350MP has the

TECHNICAL SPECIFICATIONS

Product Product Rated Output Input Current @ H x W x D Net Weight

Name Number Input Power Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

®

Power MIG

One-Pak

Power MIG

(1)

40% on 208V input.

350MP

Push-Pull K2451-2 5-350 Amps

®

Model 50-700 ipm WFS 31.8 x 18.9 x 38.8 255

®

350MP K2403-1 Max. OCV 67V

Push Model

208/230/460/575/1/60 300A/32V/60%

(1)

76/64/37/29A (1.3-17.7 m/min) (808 x 480 x 985) (116)

Dimensions

Publication E7.57 9/07

Web Update 9/08

www.lincolnelectric.com

Page 2

A CLOSER LOOK

Push-Pull Gun Ready

ARC PERFORMANCE

Multi-Process/Multi-Feed Capability

One machine does it all! Stick

Flux-Cored

Spool Gun

Push-Pull

Advanced Nextweld

Innovations like Pulse-On-Pulse™and Power Mode

are designed to address specific or difficult

applications, including aluminum and

low amperage short arc welding.

3 Ways To Feed Aluminum

No PC board add-ons required.

Load in updated or additional welding waveforms as

your needs expand to other materials. Built-in D-shell

computer connector makes upgrades easy.

®

Processes

• Standard Push Gun

• Spool Gun

• Push-Pull

Expandability

MIG

Pulsed

®

TIG

Spool Gun

Ready

MIG/Cored

Push Gun

TIG

Stick

What is Nextweld®?

Nextweld®integrates Lincoln’s technologies,

processes and products to create a comprehensive,

flexible, user-friendly welding system that can

increase efficiency and reduce fabrication costs.

Waveform Control Technology®and digital

Lincoln Chopper Technology

Provides a smooth, stable arc with easy starts, low spatter and

excellent bead appearance.

Chopper Technology

extremely fast response for

smoother output control.

®

for

®

Chopper Technology

CV-Wire Mode

®

communications provide the foundation for Nextweld

®

innovations

like Pulse-On-Pulse™, Power Mode®. Look for Nextweld®products

for ultimate arc control, high efficiency/reliability and seamless

system integration.

Traditional weld control is more

variable around the desired

output.

Traditional Reactor Technology

CV-Wire Mode

Power MIG®350MP

[2]

www.lincolnelectric.com

Page 3

A CLOSER LOOK

TIME

WELDING CURRENT

Background

Peak

Ramp Up

Tail Out

Step Off

PULSE FREQUENCY

Low Heat

(Background)

High Heat

(Peak)

ARC PERFORMANCE, CON’T.

Lincoln Nextweld®Innovations for Challenging Applications

Waveform Control Technology®makes it possible to take advantage of Lincoln innovations like these patented processes using the

Power MIG

®

350MP power source:

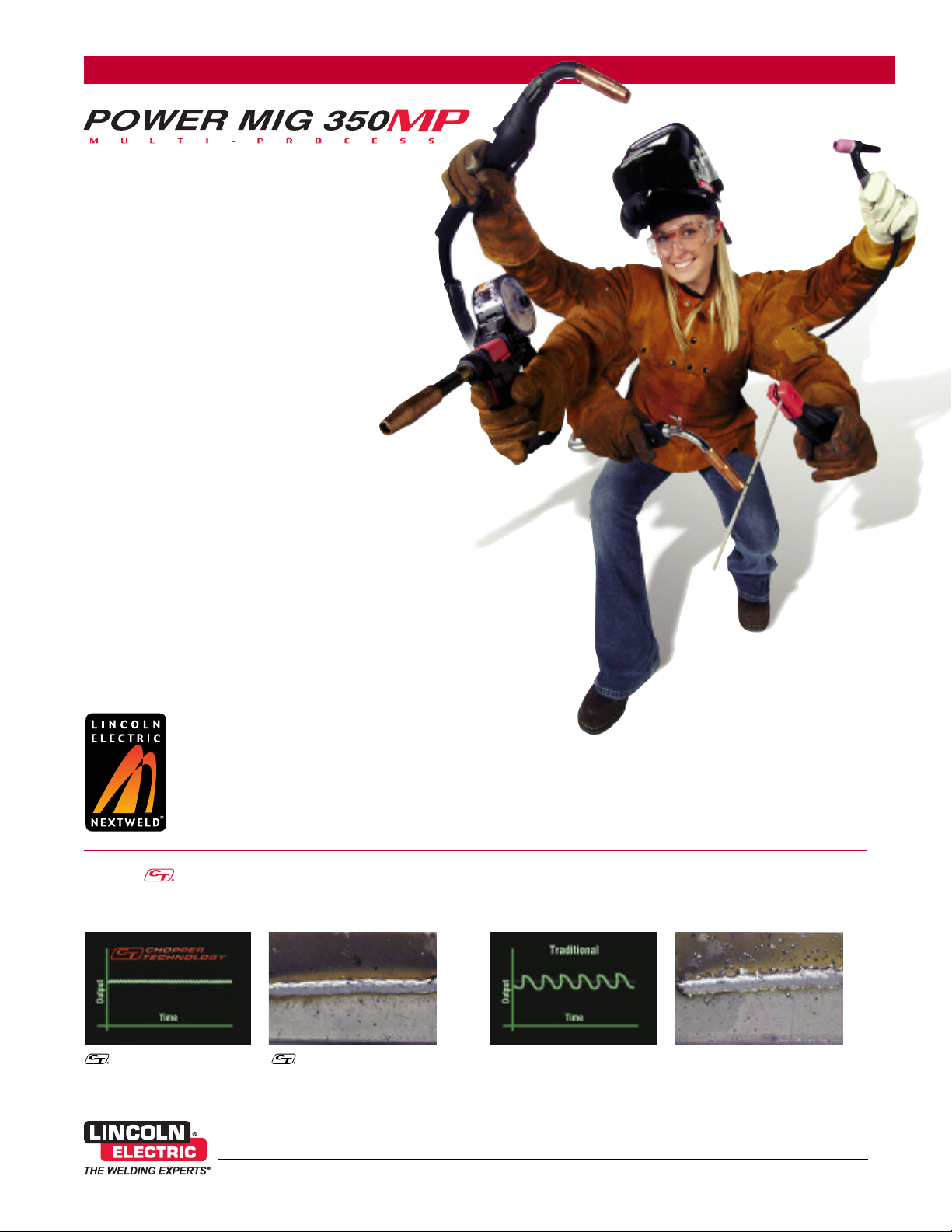

Pulse-On-Pulse

a TIG-like bead appearance and excellent weld properties when MIG welding

aluminum. Pulse-On-Pulse

it easier to achieve good penetration.

For more information see Nextweld

Pulse-On-Pulse™on 3 mm Aluminum

Power Mode

power to deliver extremely fast response to changes in

the arc, for example, when using a whip technique. The

result is improved MIG welding performance, including

low spatter, very uniform, consistent bead wetting and

controlled penetration. Power Mode benefits are especially

apparent on low voltage applications on thin steel and

stainless steel material less than 20 gauge (0.7 mm). It

also delivers excellent arc characteristics on aluminum

and other alloys such as silicon bronze and nickel alloys.

For more information see Nextweld®Document NX-2.60

®

uses high-speed regulation of output

™

uses a sequence of varying pulse wave shapes to produce

™

controls arc length and heat input together, making

®

Document NX-2.10

Power Mode reduces spatter and

improves bead appearance,

even for low voltage

procedures on stainless.

Power Mode aids bead

wetting and penetration

on aluminum.

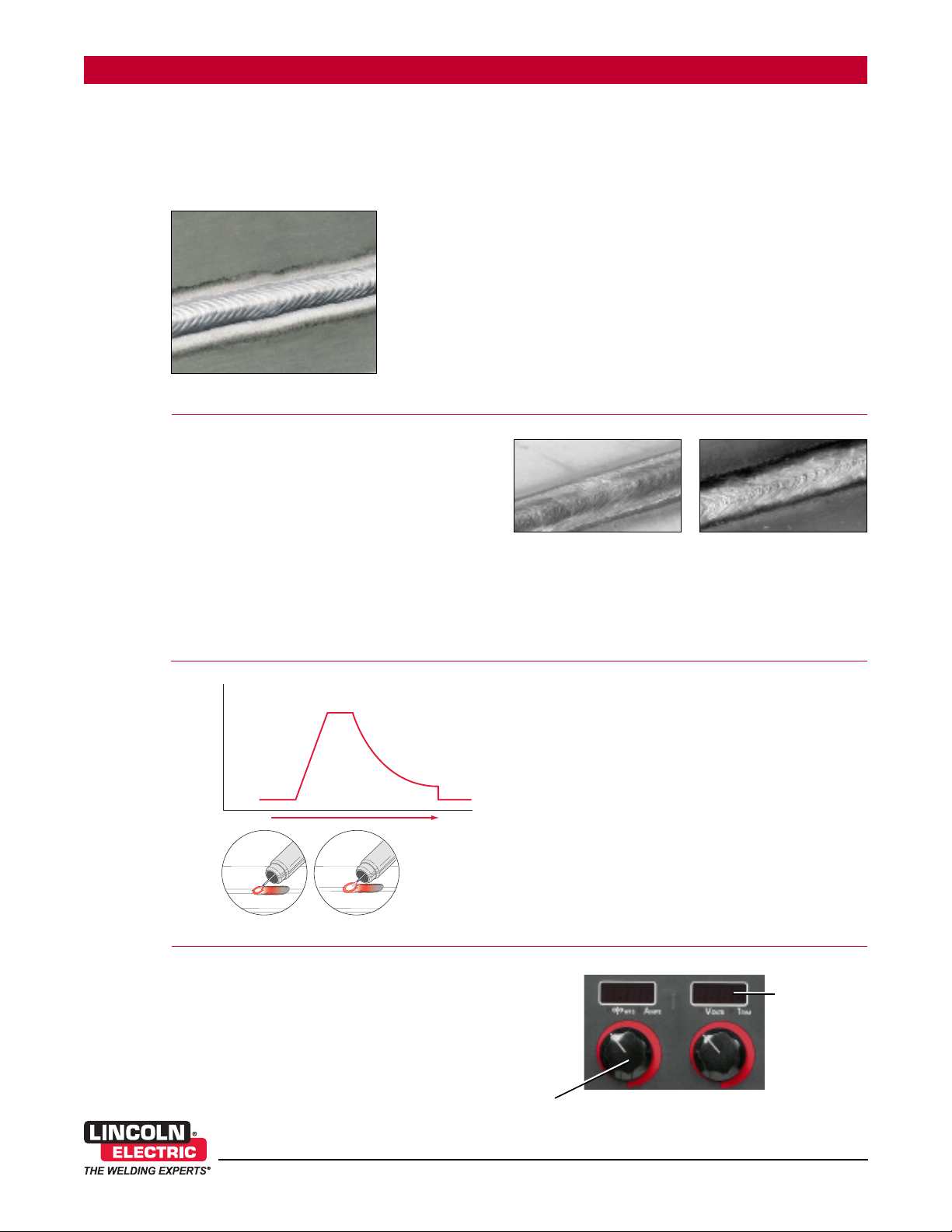

Synergic MIG

Synergic control of voltage and wire feed speed allows you

to set weld procedures with only one control for simplicity

and ease of use.

Set the wire feed speed and your voltage is automatically

set. Override the setting with the voltage/trim control for

personal preference.

[3]

Pulsed MIG varies weld current between peak (high heat)

and background (low heat) current to provide better control of

heat input, which minimizes warping and burnthrough on thin

materials. Pulsed MIG also enables flat, horizontal, vertical up,

or overhead welding without a slag system. It can be used in

hard automation, robotic, and high production semiautomatic

applications. Optimized GMAW-P waveforms are readily available to use on aluminum, carbon steel, high strength low alloy

steel, stainless steel, and nickel alloys.

For more information see Nextweld®Document NX-2.70

2. Voltage is automatically set.

1. Use one

knob to set

procedures.

Power MIG®350MP

www.lincolnelectric.com

Page 4

A CLOSER LOOK

FEATURES

Compare These Innovations – Make the Professional’s ChoiceSM!

115 Volt AC Auxiliary Power

Easy Load Gas Cylinder Platform

Professional Heavy Duty Wire Drive System

Internal tachometer feedback drive system

allows you to maintain constant wire feed

speed for consistent welds.

Split guides support the wire through the entire

drive system to minimize feeding problems.

Reliable brass-to-brass gun receiver bushings provide

connectivity to Magnum or competitive guns. Easier

interchangeability, better mechanical support and

dditional Gas Solenoid – connect

A

-piece TIG torch or control gas flow

2

to a spool gun.

Accessible Wire Compartment

electrical current transfer.

xtra Length 15 ft. (4.5 m) gun

E

Handy MIG gun expendables chart

Lockable Storage Compartment

ith Tool Tray

w

Easy turn

numeric tension

indicator with optimized ranges for

different

wire types.

Built-in gun holder

onveniently stores

c

welding gun.

Wide idler arm

hinge provides

improved drive

roll clamping

pressure.

Input bushing

protects the wire

from damage.

Two gear driven

rolls. No tools

needed to swap

rolls on or off.

DRIVE ROLL KITS

Wire Size Order Number

Solid .035" (0.9 mm) KP1696-035S

Cored

Aluminum

.023"-.030" (0.6-0.8 mm) KP1696-030S

.035/.045 Combination KP1696-1

.040" (1.0 mm) KP1696-2

.045" (1.2 mm) KP1696-045S

.035" (0.9 mm) KP1697-035C

.045" (1.2 mm) KP1697-045C

.035" (0.9 mm) KP1695-035A

3/64" (1.2 mm) KP1695-3/64A

Separate drive

gear reduces

pressure on

motor shaft for

long life.

(1)

(2)(3)

(1) Included with K2403-1 Push model and K2451-2 Push-Pull One-Pak®model.

(2) Included in the K2153-1 Aluminum Feeding Kit.

(3) Included with K2451-2 Push-Pull One-Pak

®

model.

Removable outer

wire guide for

easy access.

Power MIG®350MP

[4]

www.lincolnelectric.com

Page 5

A CLOSER LOOK

FEATURES, CON’T.

Key Controls

Easy to use controls for high productivity and accurate settings.

A. Continuous WFS/Amps Control – In wire feed welding, adjusts

wire feed speed. In stick or TIG modes, adjusts amperage.

B. Continuous Volts/Trim Control – Adjusts voltage when MIG

welding. Adjusts the arc length (trim) when Pulse-MIG welding.

Professional’s Choice – weld with traditional manual control or take

advantage of the included MSP3 digital panel for high tech weld

features:

1. Weld Mode – Many synergic modes to select from for simple

one-knob control.

2. Preflow – Adjustable timer to initiate gas flow before the arc.

3. Post-Flow – Further protect your weld integrity by automatically

setting the gas to run a few seconds after the trigger is released.

4. Run-In – Adjustable speed at which wire strikes the plate to

enhance starting.

5. Start Procedure – Set start procedure, wire feed speed and volts

for an adjustable starting time.

6. Arc Control – Set arc control to crisp or soft depending on your

preference and application. In pulsed MIG, this control varies

the pulse frequency and background current. In Stick mode, it

adjusts the arc force.

7. Crater Control – Adjusts the ending weld procedure and ramp

down time.

A

B

1-9

1

8. Burnback – Adjustable time delay between turning off the arc

and the wire feed to prevent wire sticking to the puddle.

9. Spot Timer – Adjustable arc time for repetitive tack and spot

welds.

3 Ways To Feed Aluminum

Better BestGood

Push Gun

Good for occasional

aluminum work

Python®-Plus Air-Cooled Push-Pull Guns

Features the same Magnum®back end as the Magnum®300 gun,

eliminating the need for the K2154-1 adapter. Effortless, fast

changes between Magnum®300 MIG gun and Python®-Plus

push-pull gun.

• 15 ft. (4.5 m) Order K2447-1

• 25 ft. (7.6 m) Order K2447-2

• 50 ft. (15.2 m) Order K2447-3

Base Unit Includes:

Push Model (K2403-1): Power MIG

Regulator and Hose, Work Clamp and Cable, 230V Input Cord and Plug.

Push-Pull One-Pak

®

Model (K2451-2): Includes Power MIG®350MP (K2403-1) push model, Python®-Plus push-pull gun 25 ft. (K2447-2), 3/64

Aluminum Drive Roll Kit (KP1695-3/64A).

®

350MP, Magnum®300 Gun 15 ft. (4.5 m), .035" (0.9 mm)/.045" (1.2 mm) Drive Rolls and Guide for Steel,

Spool Gun

Better feeding with

integrated 2 lb. spools

Push-Pull Gun

Best performance for production

aluminum welding - Use larger spools.

(Note: Standard air-cooled and water-cooled Python®, CobraMax™and

®

XL push-pull guns still require the K2154-1 connection kit.)

Prince

[5]

Power MIG®350MP

www.lincolnelectric.com

Page 6

RECOMMENDED OPTIONS

ENERAL OPTIONS

G

Dual Cylinder Mounting Kit

Permits side-by-side mounting of

two full size gas cylinders, with

easy loading. Attaches easily to

Power MIG undercarriage.

Order K1702-1

Canvas Cover

Protect your Power MIG®when not

in use. Made from attractive red

canvas that is flame retardant,

mildew resistant and water repellent. Fits any Power MIG®machine

with or without a gas cylinder in

the cylinder rack. Will not fit if

spool gun holder is attached to the

machine.

Order K2378-1

STICK OPTIONS

Parts Kits

Magnum®Parts Kits provide all

the torch accessories you need to

start welding. Parts kits provide

collets, collet bodies, a back cap,

alumina nozzles and tungstens in

a variety of sizes, all packaged in

an easy to carry reclosable box.

Order KP508 for PTA-17

Order KP509 for PTA-26

Foot Amptrol

®

Provides 25 ft. (7.6 m) of remote

current control for TIG welding.

(6-pin plug connection).

Order K870

Hand Amptrol

®

Provides 25 ft. (7.6 m) of remote

current control for TIG welding.

(6-pin plug connection)

Order K963-3

Accessory Kit

Complete kit for stick

welding. Includes 30 ft. (9.1 m)

electrode cable, 25 ft. (7.6 m)

work cable, headshield,

work clamp and electrode

holder.

Order K875 for 150 amps

Order K704 for 400 amps

Remote Output Control

Consists of a control box with

choice of two cable lengths.

Permits remote adjustment of

output.

Order K857 for 25 ft. (7.6 m)

Order K857-1 for 100 ft. (30.5 m)

TIG OPTIONS

PTA-17 150 Amp Air-Cooled

TIG Torch

Order K1782-2

for 12.5 ft. (3.8 m) length, 2-cable

Order K1782-4

for 25 ft. (7.6 m) length, 2-cable

Arc Start Switch

Needed if an Amptrol®is not used

when TIG welding. Comes with a

25 ft. (7.6 m) cable. Attaches to

the TIG torch for convenient finger

control.

Order K814

Cut Length Consumables

TIG welding filler metals are available for welding stainless steel,

mild steel, aluminum and copper

alloys.

See publication C9.10

WIRE FEEDER OPTIONS

Aluminum Feeding Kit

Conversion kit for welding with

3/64" (1.2 mm) aluminum wire.

Includes drive rolls, contact tips

(qty. 2), polished wire guides and

cable liner.

Order K2153-1

PTA-26 200 Amp Air-Cooled

TIG Torch

Order K1783-2

for 12.5 ft. (3.8 m) length, 2-cable

Order K1783-4

for 25 ft. (7.6 m) length, 2-cable

[6]

Fast-Mate™Adapter

Allows guns with a Fast-Mate

type back end to plug into a

Power MIG®.

Order K489-8

Power MIG®350MP

www.lincolnelectric.com

™

Page 7

RECOMMENDED OPTIONS

Dual Procedure Switch

Easily mounts to gun using

convenient velcro straps to allow

welding operators to select

between two preset welding

procedures or modes. Plugs into

the gun trigger connector on the

wire feeder.

Order K2449-1

®

Magnum

250LX™Spool Gun

280 amps, 60% duty cycle. Feeds

.025"-3/64" (0.6-1.2 mm) diameter

aluminum wire on 2 lb. (0.9 kg)

spools. With remote wire feed

speed control. 25 ft. (7.6 m) cable.

Order K2490-1

Magnum

®

250LX™Spool Gun

Control Cable Extension

Extend your spool gun reach with

a 25 ft. (7.6 m) Control Cable

Extension. Features a 7-pin

female MS-type connector on the

spool gun end and a 7-pin male

MS-type connector on the power

source end.

Order K2519-1

Spool Gun Holder

Provides neat storage of spool

gun cable, and gas hose on

Power MIG.

Order K1738-1

®

Python

-Plus Air-Cooled

Push-Pull Gun

The Python®-Plus push-pull gun

features the same great performance and ergonomics as the standard Python®gun but features a

Magnum®style back end for easy

connection to a Lincoln®Power

MIG®without an adapter. The

ergonomic handle design, fingertip controls and foolproof set-up

make the Python®the most

advanced gooseneck gun on the

market. The Python®-Plus gun

with standard air-cooled barrel is

rated 200A @100% duty cycle,

250A @50% duty cycle.

Order K2447-1

for Air-Cooled 15 ft. (4.5 m)

Order K2447-2

for Air-Cooled 25 ft. (7.6 m)

Order K2447-3

for Air-Cooled 50 ft. (15.2 m)

®

Prince

XL Push-Pull Gun

The Prince®XL is the smallest,

lightest pistol grip push-pull gun

you can buy. Choose the standard

straight barrel or optional curved

barrel with ratings up to 225 amps

100% duty cycle. The patented

EZ-Lock system make rotating or

changing the barrel an easy notool twist of the wrist.

Order K2296-2

for Air-Cooled 25 ft. (7.6 m)

Push-Pull Gun Connection Kit

Required for aluminum welding

with the Prince®XL, Python®* and

CobraMax™air or water-cooled

push-pull guns. Includes power

block, gun bushing, gas hose

adapter, gun gas bypass valve

(required for Prince®XL Gun only),

and wire reel brake limiter.

Requires aluminum drive roll kit.

*Not required for Python®-Plus

Guns.

Order K2154-1

Spindle Adapter for

Small Spools

Permits 8" (200 mm) O.D. spools

to be mounted on 2" (51 mm)

O.D. spindles.

Order K468

Welding Fume Extractors

Lincoln offers a wide variety

of welding fume extraction

environmental system solutions,

ranging from portable systems

easily wheeled around the shop

to shop-wide central systems

servicing many dedicated welding

stations.

Request Publication E13.40

[7]

Power MIG®350MP

www.lincolnelectric.com

Page 8

OWER MIG

P

®

50MP ORDER FORM

3

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

OWER MIG

P

OWER MIG

P

®

50MP PUSH MODEL 208/230/460/575/1/60 K2403-1

3

®

50MP PUSH-PULL ONE-PAK

3

®

ODEL K2451-2

M

RECOMMENDED GENERAL OPTIONS

ual Cylinder Mounting Kit K1702-1

D

anvas Cover K2378-1

C

ECOMMENDED STICK OPTIONS

R

ccessory Kit:

A

150 amps K875

400 amps K704

emote Output Control:

R

5 ft. (7.6 m) K857

2

100 ft. (15.2 m) K857-1

ECOMMENDED TIG OPTIONS

R

Pro-Torch™TIG Torches See publication E12.150

Part Kits:

For PTA-17 KP508

For PTA-26 KP509

oot Amptrol

F

and Amptrol

H

®

®

870

K

963-3

K

Arc Start Switch K814

Cut Length Consumables See publication C9.10

RECOMMENDED WIRE FEEDER OPTIONS

Aluminum Feeding Kit K2153-1

Fast-Mate™Adapter K489-8

Dual Procedure Switch K2449-1

Magnum®250LX™Spool Gun K2490-1

Spool Gun Holder K1738-1

Python®-Plus Air-Cooled Push-Pull Gun

15 ft. (4.5 m) K2447-1

25 ft. (7.6 m) K2447-2

50 ft. (15.2 m) K2447-3

Prince®XL Push-Pull Gun Air-cooled, 25 ft. (7.6 m) K2296-2

Push-Pull Gun Connection Kit K2154-1

Spindle Adapter for Small Spools K468

Welding Fume Extractors See publication E13.40

TOTAL:

The business of The Lincoln Electric Company®is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of

our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for information or advice about their use of our products. Our employees respond to

inquiries to the best of their ability based on information provided to them by the customers and the knowledge they may have concer ning the application. Our employees, however, are not

in a position to verify the information provided or to evaluate the engineering requirements for the particular weldment. Accordingly, Lincoln Electric does not warrant or guarantee or assume

any liability with respect to such information or advice. Moreover, the provision of such information or advice does not create, expand, or alter any warranty on our products. Any express or

implied warranty that might arise from the information or advice, including any implied warranty of merchantability or any warranty of fitness for any customers’ particular purpose is

specifically disclaimed.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the

customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

C U S T O M E R A S S I S T A N C E P O L I C Y

TH E LI N C O LN E L E CT R I C C O M PA NY

®

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

Loading...

Loading...