Page 1

CV

DC

1

P

HASE

POWER MIG®215XT

POWER MIG®. The Professional’s ChoiceSM.

The POWER MIG®215XT offers the autobody and sheet metal fabrication

industries top welding performance and a host of professional features

not often found at this price. Featuring Diamond Core Technology

POWER MIG

action, a wide voltage sweet spot at a given wire feed speed and low spatter.

And, the MAXTRAC

®

215XT delivers a forgiving arc, excellent out-of-position arc

®

drive system with a patented Split Wire Guide system

and tachometer feedback ensures trouble-free wire delivery. The wide

30-250 amp output range, standard 15 foot gun cable, and 115 volt auxiliary

power receptacle are uncommon in this class. In addition, the 7 voltage tap

ranges make it easy to operate and the locking storage compartment keeps

our valuable tools secure. The POWER MIG

y

Lincoln’s light duty Magnum

truly The Professional’s Choice

®

100SG Spool Gun. The POWER MIG®215 XT—

SM

.

®

15XT is Spool Gun Ready for

2

™

, the

WIRE FEEDER/WELDERS

Output

Input

Spool Gun Ready

Spool Gun Capable

Light Duty Medium Duty Heavy Duty

Advantage Lincoln

Arc Performance:

• Diamond Core Technology™, a patented choke design, delivers a

forgiving arc, even with large stickout changes, excellent out-ofposition arc action, a wide voltage sweet spot at a given wire feed

speed for steel, stainless steel or aluminum and low spatter.

• More Output – Rated at 215 amps/22 volts @ 30% duty cycle, with

an amperage range of 30-250 amps DC, the POWER MIG

has the highest rating and widest amperage range in its class.

Superb Quality:

• MAXTRAC

®

cast aluminum industrial wire drive features dual driven

rolls, regulated wire feed speed control, easy-turn numeric tension

indicator, brass-to-brass connections and Lincoln’s 100% wire

supporting split wire guide system.

• Three-year warranty on parts and labor (90 days warranty on gun).

®

215XT

Processes

MIG, Flux-Cored

Professional Features:

• Generous 15 ft. (4.5m) gun and cable assembly makes it easy to

reach your work.

• Seven tapped voltage ranges make it easy to select the right

procedure for your application.

• Only machine in its class to feature a 115 volt auxiliary power

receptacle.

• Lincoln’s Innovative value-adding features include an easy-load gas

cylinder platform, a locking storage compartment with tool tray for

your personal tools and valuables, intuitive input reconnect panel and

easy-load wire spindle system with tool-less brake adjustment.

TECHNICAL SPECIFICATIONS

Product

Name

POWER MIG

(1)

(2)

®

215XT K2700-1 208/230/1/50/60

21V on 220V 50 Hz input.

Input current is at the rated output with the 115V auxiliary receptacle also drawing 15 amps.

Product

Number

Input Power

Rated Output

Current/Voltage/Duty Cycle

(1)

215A / 22V

190A / 23V / 40%

170A / 24V / 60%

/ 30%

Input Current @

Rated Output

45/41A

42/38A

39/35A

(2)

Output Range

30-250 Amps DC

50-700 ipm WFS

(1.3-17.7 m/min)

Max. OCV: 39V

Dimensions

H x W x D

inches (mm)

31.8 x 18.9 x 38.8

(808 x 408 x 985)

Net Weight

lbs. (kg)

210

(95)

Publication E7.51 7/08

www.lincolnelectric.com

Page 2

A CLOSER LOOK

PERFORMANCE

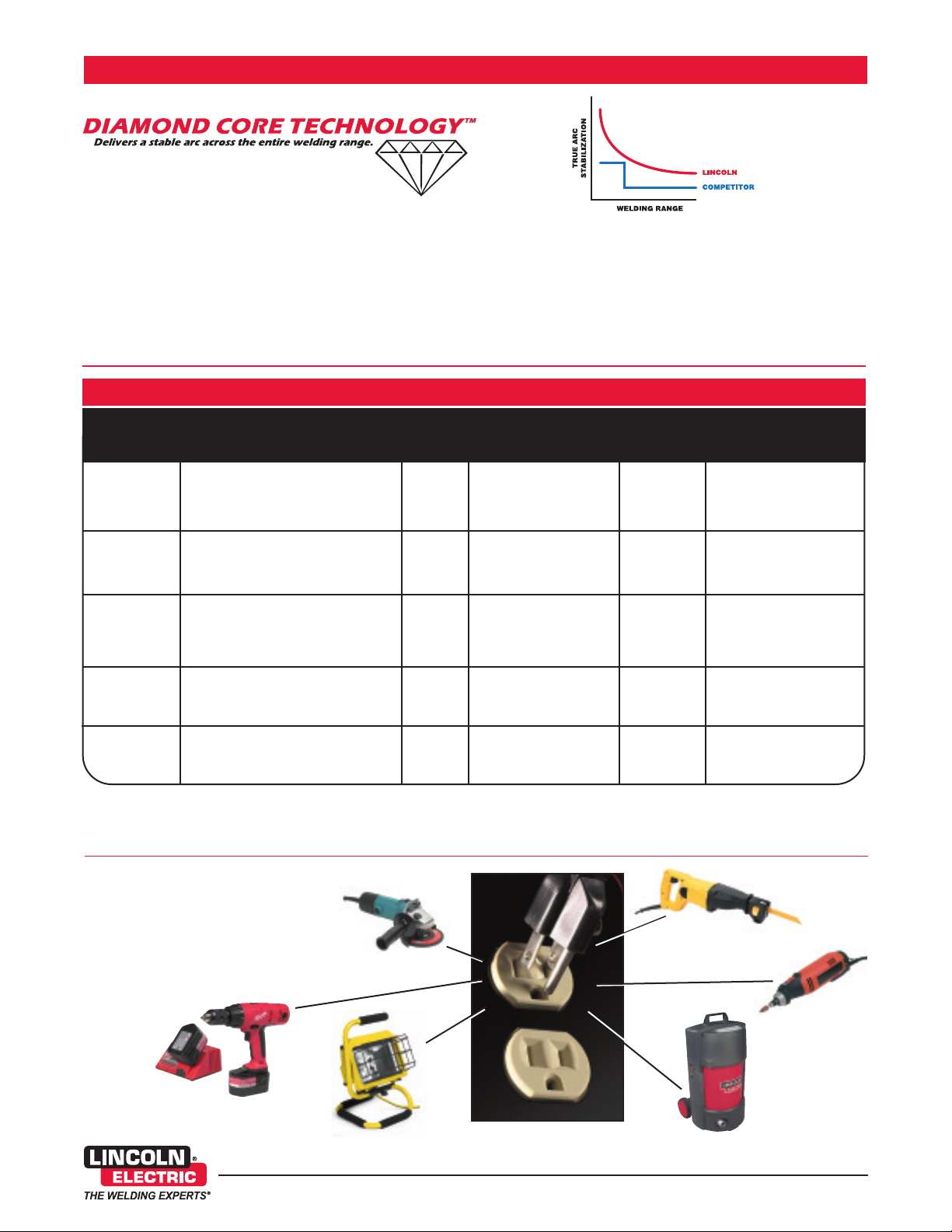

What Is It?

Diamond Core Technology™is a patented innovative

choke design that filters the welding arc. It provides

dynamic arc filtering across the entire welding amp

rage. Other arc stabilization methods are “fixed” –

Results:

• Great starts and low spatter.

• A wide sweet spot for optimal

arc performance.

Great For:

• Steel, stainless and aluminum.

• Out-of-position work.

• Long arc applications.

• Weaving techniques.

or only working at certain amperages – resulting in

harsh arc characteristic changes over the welding

range.

PROCESS CAPABILITIES

lectrode Electrode Shielding Minimum Maximum

Process Wire Polarity Gas Thickness Thickness

IG .025, .030, .035, .045"

M

ild Steel (0.6, 0.8, 0.9, 1.2 mm) DC+ 100% CO

M

MIG .030, .035, .045" DC+ Ar/CO

Stainless (0.8, 0.9, 1.2 mm) or (Tri-Mix) (0.9 mm) (6.4 mm)

Blue Max

MIG 3/64" 1/16" (.063") 1/4" (.250")

(3)

Aluminum

Flux-Cored, .035, .045" 100% CO

Gas-Shielded (0.9, 1.2 mm) DC+ (2.7 mm) (12.7 mm)

Mild Steel Outershield

E

r Ar/CO

o

®

SuperArc

SuperGlide

SuperGlaze

L50, L-56 (0.6 mm) (7.9 mm)

®

S-3, S-6

®

308LSi, 309LSi, 316LSi 90% He, 7-8% Ar/Balance C0

(0.2 mm) DC+ 100% Argon (1.6 mm) (6.4 mm)

®

4043 and 5356

®

71M and MC-710

2

or Ar/CO2Blend 12 ga. (.109") 1/2" (.500")

2

lend 24 ga. (.024") 5/16" (.312")

B

2

Blend 20 ga. (.036") 1/4" (.250")

2

2

(1)

Flux-Cored, .035, .045" 18 ga. (.050") 1/2" (.500")

Self-Shielded (0.9, 1.2 mm) DC- — (1.2 mm) (12.7 mm)

Mild Steel Innershield

(1)

Lincoln Electric recommends multiple pass welds on 1/2" (12.7 mm) material. Consult the appropriate application procedures and guidelines for selecting the correct wire size,

gas type and number of passes.

(2)

.035" and .045" (0.9 and 1.2 mm) NR®-211-MP is only recommended up to 5/16" (7.9 mm) thick material.

(3)

For .035" (0.9 mm) and 4043 aluminum wire, the spool gun is recommended for best feeding results.

®NR®

-211-MP

(2)

and NR®-212

FEATURES

Energize Your Shop

The POWER MIG®215XT is the only

machine in its class to feature a 115 volt

Saws

auxiliary power receptacle which allows

you to power grinders, lights, cordless

tool chargers or any other power tools.

Battery Chargers

for Cordless Tools

Grinders

Work Lights

Rotary Tools

Welding Fume

Extraction

POWER MIG®215XT

[2]

www.lincolnelectric.com

Page 3

A CLOSER LOOK

FEATURES CONʼT.

Compare These Innovations – Make the Professional’s ChoiceSM!

onvenient operating procedures for

C

MIG welding on mild steel, aluminum

nd stainless, located inside the

a

POWER MIG

®

215XT door.

Lockable storage compartment

with tool tray stows your welding

onsumables and valuable

c

personal tools.

Easy Load Wire Compartment

Professional Heavy Duty Wire Drive System

Internal feedback drive system

allows you to maintain

constant wire feed speed

for consistent welds.

Split guides support the wire

through the entire drive system

to minimize feeding problems.

Load Gas Cylinder Platform

Extra-Length 15 ft. (4.5 m) GunBuilt-in undercarriage with Easy

Easy turn numeric tension

indicator with optimized

ranges for different wire types.

Wide idler arm hinge provides

improved drive roll clamping

pressure.

Reliable brass-to-brass gun receiver

bushings provide connectivity to

®

Magnum

support and electrical current transfer.

or competitive guns. Easier

interchangeability, better mechanical

Angled gun cable connection

for improved feedability and

reduced gun liner wear.

[3]

Input bushing protects the

wire from damage.

Two gear driven rolls. No tools needed

to swap rolls on or off.

Separate drive gear reduces

pressure on motor shaft for

long life.

Removable outer wire guide

for easy access.

POWER MIG®215XT

www.lincolnelectric.com

Page 4

A CLOSER LOOK

Key Controls

A. Wide range wire feed speed (WFS) control up to 700 inches per

minute (17.7 m/min). Dial calibrated in true inches per minute for

easy procedure setting.

B. Seven voltage taps for wide range voltage control.

A

B

QUALITY AND RELIABILITY

• Thermostatic protection from current overload and excessive

temperatures.

• Clear reconnect door permits easy viewing of input voltage.

• Low input current draw for energy-efficient low cost operation.

• Fan-As-Needed™(F.A.N.™) provides cooling of transformer and

other components when welding, reducing power consumption,

noise and extending welder life.

• Manufactured under a quality system certified to ISO 9001

requirements and ISO 14001 environmental standards.

• Three-year warranty on parts and labor. 90 days warranty on gun

and cable.

Printed circuit boards are environmentally-shielded using

Lincolnʼs engineered potting and protective frame trays.

The POWER MIG®215XT is an excellent choice for sheet metal job

shop fabrication, autobody work and maintenance/repair welding.

[4]

POWER MIG®215XT

www.lincolnelectric.com

Page 5

SYSTEM SELECTION

WHATʼS INCLUDED

K2700-1 Includes:

• POWER MIG®215XT.

• Magnum®250L gun and 15 ft. (4.5 m) “quick-connect” cable assembly

equipped with fixed gas nozzle assembly.

• Lockable storage compartment with tool tray for keeping tools safe.

• Work clamp and 10 ft. (3.0 m) cable.

• 10 ft. (3.0 m) 230V input power cable with plug.

• Dual driven drive rolls and split wire guides to support the wire 100%.

• Drive roll and wire guide to feed both .035" & .045" (0.9 & 1.2 mm) wire.

• Gas regulator and hose kit for CO2or argon blend gases. (For use with

CO2shielding gas, order a Lincoln S19298 CO2shielding gas bottle

adapter.)

SPOOL GUN SOLUTIONS

Spool Guns offer an affordable way to reliably feed soft aluminum wire. Since spool guns feed small 4 inch spools of wire a short

distance it provides a reliable feeding solution that prevents wire jams and tangles. The POWER MIG®215XT provides three choices

of spool gun solutions form the cost effective light duty Magnum®100SG for occasional aluminum projects to the premium heavy

duty Magnum®250LX which is designed for day in day out aluminum welding applications.

LIGHT DUTY MEDIUM DUTY HEAVY DUTY

Magnum®100 SG Spool Gun

(K2532-1)

• 130 Amp 30% Duty Cycle

• 10 ft. cable length

• Feeds .030 - .035 in. diameter wire

• Wire Feed Speed is set at machine

• Fixed wire spool brake with friction

pads for 5356 wire

• Fixed drive roll tension

Magnum®SG Spool Gun

(K487-25)

• 250 Amp 60% Duty Cycle

• 25 ft. cable length

• Feeds .025 - 3/64 in. diameter wire

• Single Turn remote Wire feed speed

control at the gun

• Adjustable wire spool brake

• Adjustable drive roll tension

Magnum®250LX Spool Gun

(K2490-1)

• 300 Amp 60% Duty Cycle

• 25 ft. cable length

• Feeds .025 - 3/64 in. diameter wire

• Multi-Turn remote Wire feed speed

control at the gun

• Deluxe wire spool break requires

no adjustments

• Adjustable drive roll tension

• Ergonomic Sure Grip handle

• Contact tip storage built in spool

gun cover

• Easy open wire drive rolls for easy

wire loading

Factory Ready!

No Adapter Required! Requires K2703-1 Adapter Requires K2703-1 Adapter

POWER MIG®215XT

[5]

www.lincolnelectric.com

Page 6

A CLOSER LOOK

THE MAGNUM®250L GUN

• Magnum®250L gun and cable assembly, shipped with

the POWER MIG®215XT is equipped to feed .035"-.045"

(0.9-1.2 mm) solid steel wire.

• Extra reach 15 foot gun cable length.

• Lightweight and flexible for easy maneuverability.

• Fiberglass handle with non-slip grooves to maximize comfort

and control.

• Heavy duty gun trigger switch for positive electrical contact

and long life.

®

• Magnum

replacement parts are fully compatible with other

leading brands. Industry reference numbers are provided for

ease of interchangeability.

MAGNUM®REPLACEMENT PARTS

escription Order No. Reference No.

D

Industry

Magnum®250L Gun and Cable Assembly

Fixed Gas Nozzle Model

For .035-.045" (0.9-1.2 mm) wire sizes

12 ft. (3.6 m) cable K533-7

djustable Gas Nozzle Model

A

or .035-.045" (0.9-1.2 mm) wire sizes

F

10 ft. (3.0 m) cable K533-1

15 ft. (4.5 m) cable K533-3

Cable Liners

For All Gun Cable Lengths

.025-.030" (0.6-0.8 mm) KP1934-2 42-23-15

.030-.035" (0.8-0.9 mm) KP1934-3 42-3035-15

.035-.045" (0.9-1.2 mm) KP1934-1

3/64" (1.2 mm) Aluminum KP1955-1

Contact Tips

Standard Duty

.025" (0.6 mm) KP2020-6 14-23

.030" (0.8 mm) KP2020-7 14-30

.035" (0.9 mm) KP2020-1

.040" (1.0 mm) KP2020-8 14-40

.045" (1.2 mm) KP2020-2 14-45

Heavy Duty

.035" (0.9 mm) KP2021-1 14H-35

.040" (1.0 mm) KP2021-6 14H-40

.045" (1.2 mm) KP2021-2 14H-45

Tapered

.025" (0.6 mm) KP2022-5 14T-23

.030" (0.8 mm) KP2022-6 14T-30

.035" (0.9 mm) KP2022-1 14T-35

.040" (1.0 mm) KP2022-7 14T-40

.045" (1.2 mm) KP2022-2 14T-45

Aluminum

3/64" (1.2 mm) KP2010-5

(1)

(2)

(1)

(2)

42-4045-15

42N-3545-15

14-35

MAGNUM®REPLACEMENT PARTS

escription Order No. Reference No.

D

ixed Gas Nozzles/Diffuser Assembly

F

Fixed (flush)

/8" (9.5 mm) KP1931-1 23-37-F

3

1/2" (12.7 mm) KP1931-2

/8" (15.9 mm) KP1931-3 23-63-F

5

Fixed (recessed)

/8" (9.5 mm) KP1930-1 23-37

3

1/2" (12.7 mm) KP1930-2 23-50

5/8" (15.9 mm) KP1930-3 23-62

Requires: Gas Diffuser Assembly

.025-.045" (0.6 -1.2 mm) KP2026-3

Adjustable Gas Nozzle/Diffuser Assembly

Adjustable Slip-On

3/8" (9.5 mm) KP1935-3 22-37

1/2" (12.7 mm) KP1935-2 22-50

5/8" (15.9 mm) KP1935-1 22-62

Requires:

Nozzle Insulator Assembly KP2025-1 32

Gas Diffuser Assembly:

.023-.030" (0.6-0.8 mm) KP2026-2 52-23

.035-.045” (0.9-1.2 mm) KP2026-1 52

Gasless Nozzle/Diffuser Assembly

(Innershield

®

Nozzle) KP1947-1

Requires:

Gas Diffuser Assembly KP2026-1 52

Gun Tube Assembly

Standard (60°) KP2015-1

45° KP2041-1

(1)

Included with POWER MIG®215XT.

(2)

Included in the K1703-1 Aluminum Feeding Kit.

Industry

(1)

23-50-F

(1)

52FN

(1)

DRIVE ROLL KITS

Wire Size Order Number

Solid .035" (0.9 mm) KP1696-035S

Cored

Aluminum 3/64" (1.2 mm) KP1695-3/64A

(1)

Included with POWER MIG®215XT.

(2)

Included in the K1703-1 Aluminum Feeding Kit.

.023-.030” (0.6–0.8 mm) KP1696-030S

.035/.045" combination KP1696-1

.040" (1.0mm) KP1696-2

.045" (1.2 mm) KP1696-045S

.035" (0.9 mm) KP1697-035C

.045" (1.2 mm) KP1697-045C

[6]

(1)

(2)

POWER MIG®215XT

www.lincolnelectric.com

Page 7

RECOMMENDED OPTIONS

GENERAL OPTIONS

Magnum®Connection Kit

Permits use of Magnum®200, 300

and 400 gun and cable assemblies

on POWER MIG®215 XT.

Order K466-6

POWER MIG®215XT Spool

Gun Adapter

This kit is designed to allow the

Magnum®SG or Magnum®250LX

spool gun to operate with the

POWER MIG®215XT. The kit

includes the solenoid, gas lines,

wiring harness and gun connection

panel. The gun connection panel

features a 6 pin MS-type

connector for the Magnum®SG

spool gun and a 7 pin MS-type

connector for the Magnum®250LX

spool gun and a selector switch to

choose which gun you are using.

Order K2703-1

Note the K2703-1 spool gun

adapter disables the Magnum

100SG capability.

Aluminum Feeding Kit

Conversion kit for welding with

3/64" (1.2 mm) 5356 aluminum

wire. Includes drive rolls,

contact tips (2), non-metallic wire

guides and cable liner.

Order K1703-1

®

Welding Fume Extractors

Lincoln offers a wide variety

of welding fume extraction

environmental system solutions,

ranging from portable systems

easily wheeled around the shop

to shop-wide central systems

servicing many dedicated welding

stations.

Request Publication E13.40

Magnum

®

100SG Spool Gun

130 Amp, 30% Duty Cycle with 10

ft of cable length. Feeds .030-.035

inch diameter wire. Wire Feed

Speed is set at the machine. Fixed

wire spool brake with friction pads

for 5356 wire. Fixed drive roll

tension.

Order K2532-1

Factory Ready!

No Adapter Required!

®

Magnum

SG Spool Gun

250 Amp, 60% Duty Cycle with

25 ft. of cable length. Feeds

.025 - 3/64 inch diameter wire.

Single Turn remote wire feed

speed control at the gun.

Adjustable wire spool brake and

adjustable drive roll tension.

Order K487-25

Requires K2703-1 Adapter

Spindle Adapter for 8" O.D.

Spools

Permits 8" (200 mm) O.D. spools

to be mounted on 2" (51 mm) O.D.

spindles.

Order K468

Dual Cylinder Mounting Kit

Permits side-by-side mounting of

two full size gas cylinders, with

easy loading. Attaches easily to

POWER MIG®215XT

undercarriage.

Order K1702-1

Canvas Cover

Protect your POWER MIG®when

not in use. Made from attractive

red canvas that is flame retardant,

mildew resistant and water

repellent. Fits any POWER MIG

®

machine with or without a gas

cylinder in the cylinder rack. Will

not fit if spool gun holder is

attached to the machine.

Order K2378-1

[7]

Magnum®250LX Spool Gun

300 Amp, 60% Duty Cycle with

25 ft. of cable length. Feeds

.025 - 3/64 inch diameter wire.

Multi-Turn remote wire feed

speed control at the gun.

Deluxe wire spool break requires

no adjustments. Adjustable drive

roll tension and easy open wire

drive rolls for easy wire loading.

Ergonomic Sure Grip handle.

Contact tip storage built in

spool gun cover.

Order K2490-1

Requires K2703-1 Adapter

POWER MIG®215XT

www.lincolnelectric.com

Page 8

POWER MIG®215XT ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

POWER MIG®215XT — 208/230V K2700-1

ECOMMENDED GENERAL OPTIONS

R

®

Magnum

POWER MIG

Aluminum Feeding Kit K1703-1

Spindle Adapter for 8" O.D. Spindles K468

Dual Cylinder Mounting Kit K1702-1

Canvas Cover K2378-1

Welding Fume Extractors See publication MC05-183

Magnum

Magnum

M

Connection Kit K466-6

®

215XT Spool Gun Adapter K2703-1

®

100SG Spool Gun K2532-1

®

SG Spool Gun K487-25

®

agnum

50LX Spool Gun K2490-1

2

TOTAL:

C U S T O M E R A S S I S TA N C E P O L I C Y

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the

needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric

to our customers based on the best information in our possession at that time. Lincoln Electric

with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to

such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has

been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric

of the customer. Many variables beyond the control of Lincoln Electric

Subject to Change — This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

®

is a responsible manufacturer, but the selection and use of specific products sold by Lincoln Electric®is solely within the control of, and remains the sole responsibility

®

affect the results obtained in applying these types of fabrication methods and service requirements.

®

is not in a position to warrant or guarantee such advice, and assumes no liability,

®

for advice or information about their use of our products. We respond

THE L INC OLN ELEC TR IC COM PA NY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

Loading...

Loading...