Lincoln Electric POWER MIG 180 DUAL Operator's Manual

OPERATOR’S MANUAL

MANUAL DE OPERACIÓN

MANUEL DE L’OPÉRATEUR

Operator’s Manual

POWER MIG®180 DUAL

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

IMT10106-A | Issue D ate Aug-16

© Lincoln Global, Inc. All Rights Reserved.

For use with machines having Code Numbers:

11828, 12631

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

THANK YOU FOR SELECTING

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser

upon receipt by the carrier. Consequently, claims for material

damaged in shipment must be made by the purchaser against the

transportation company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built

with safety in mind. However, your overall safety can be increased

by proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED THROUGHOUT. And, most importantly,

think before you act and be careful.

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

This statement appears where the information must be followed

to avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc.

Use corrective lenses if necessary

to stay a reasonable distance

away from the arc.

READ and obey the Safety Data

Sheet (SDS) and the warning label

that appears on all containers of

welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to

keep the fumes and gases from

your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away

from your face.

If you de velop unusual symptoms, see your supervisor.

Perhaps the welding atmosphere and ventilation system

should be checked.

WEAR CORRECT EYE, EAR &

BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare

with protective screens or barriers.

IN SOME AREAS, protection from noise may be appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area

AT ALL TIMES.

SPECIAL SITUATIONS

DO NOT WELD OR CUT containers or materials which previously

had been in contact with hazardous substances unless they are

properly cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release

highly toxic fumes or gases.

Additional precautionary measures

PROTECT compressed gas cylinders from excessive heat,

mechanical shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an

electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

WARNING

CAUTION

Safety 01 of 04 - 5/16/2018

SECTION A:

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

WARNING: Breathing diesel engine exhaust

exposes you to chemicals known to the State

of California to cause cancer and birth defects,

or other reproductive harm.

• Always start and operate the engine in a

well-ventilated area.

• If in an exposed area, vent the exhaust to the outside.

• Do not modify or tamper with the exhaust system.

• Do not idle the engine except as necessary.

For more information go to

www.P65 warnings.ca.gov/diesel

WARNING: This product, when used for welding or

cutting, produces fumes or gases which contain

chemicals known to the State of California to cause

birth defects and, in some cases, cancer. (California

Health & Safety Code § 25249.5 et seq.)

WARNING: Cancer and Reproductive Harm

www.P65warnings.ca.gov

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY.

PACEMAKER WEARERS SHOULD CONSULT WITH

THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For

additional safety information, it is strongly recommended

that you purchase a copy of “Safety in Welding & Cutting ANSI Standard Z49.1” from the American Welding Society,

P.O. Box 351040, Miami, Florida 33135 or CSA Standard

W117.2-1974. A Free copy of “Arc Welding Safety” booklet

E205 is available from the Lincoln Electric Company,

22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated areas or vent the engine

exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame welding

arc or when the engine is running. Stop the

engine and allow it to cool before refueling to

prevent spilled fuel from vaporizing on contact

with hot engine parts and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

1.d. Keep all equipment safety guards, covers

and devices in position and in good repair.

Keep hands, hair, clothing and tools away

from V-belts, gears, fans and all other

moving parts when starting, operating or

repairing equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete. Always use the greatest care when

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF).

Welding current creates EMF fields around welding cables

and welding machines

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

SAFETY

Safety 02 of 04 - 5/16/2018

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin or wet clothing.

Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

of physical contact with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

between the

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see It ems 6.c. and 8.

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep your head out of the fume.

Use enough ventilation and/or exhaust at the arc to keep fumes

and gases away from the breathing zone. When welding

hardfacing (see instructions on container or SDS)

or on lead or cadmium plated steel and other

metals or coatings which produce highly toxic

fumes, keep exposure as low as possible and

within applicable OSHA PEL and ACGIH TLV limits

using local exhaust or mechanical ventilation

unless exposure assessments indicate otherwise.

In confined spaces or in some circumstances,

outdoors, a respirator may also be required.

Additional precautions are also required when

welding

on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

5.d. Shielding gases used for arc welding can displace air and

cause

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

Safety Data Sheet (SDS) and follow your employer’s safety

practices. SDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

SAFETY

Safety 03 of 04 - 5/16/2018

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the welding sparks

from starting a fire. Remember that welding sparks and hot

materials from welding can easily go through small cracks and

openings to adjacent areas. Avoid welding near hydraulic lines.

Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

6.I. Read and follow NFPA 51B “Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, MA 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in Cylinders,” available from

the Compressed Gas Association, 14501 George Carter Way

Chantilly, VA 20151.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to

http://www.lincolnelectric.com/safety

for additional safety information.

SAFETY

Safety 04 of 04 - 5/16/2018

NOTES

OPERATOR’S MANUAL

3

TABLE OF CONTENTS

I

n

s

t

a

l

l

a

t

i

o

n

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

S

e

c

t

i

o

n

A

T

e

ch

n

ica

l

S

p

e

cif

ica

t

io

n

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A

-

1

S

a

f

e

t

y

P

r

e

ca

u

t

io

n

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A

-

1

L

o

ca

t

io

n

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A

-

1

S

t

a

ck

in

g

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A

-

1

T

ilt

in

g

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A

-

1

Id

e

n

t

if

y

a

n

d

L

o

ca

t

e

C

o

m

p

o

n

e

n

t

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

A

-

2

O

p

e

r

a

t

i

o

n

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

S

e

c

t

i

o

n

B

S

a

f

e

t

y

a

n

d

P

r

o

d

u

ct

D

e

scr

ip

t

io

n

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

B

-

1

C

o

n

t

r

o

ls

a

n

d

S

e

t

t

in

g

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

B

-

2

,

B

-

3

D

r

ive

R

o

ll

a

n

d

W

ir

e

G

u

id

e

s

T

a

b

le

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

B

-

4

S

e

t

t

in

g

U

p

a

n

d

M

a

k

in

g

a

F

lu

x-

C

o

r

e

d

W

e

ld

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

B

-

5

t

h

r

u

B

-

7

S

e

t

t

in

g

U

p

a

n

d

M

a

k

in

g

a

M

IG

W

e

ld

a

n

d

In

st

a

ll

S

h

ie

ld

in

g

G

a

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

B

-

8

t

h

r

u

B

-

1

1

S

e

t

t

in

g

U

p

a

n

d

M

a

k

in

g

a

A

lu

m

in

u

m

W

e

ld

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

B

-

1

2

A

c

c

e

s

s

o

r

i

e

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

S

e

c

t

i

o

n

C

O

p

t

io

n

a

l

A

cce

sso

r

ie

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

C

-

1

Ut

ilit

y

Ca

rt

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

C-

2,

C-

3

Ma

i

nte

na

nc

e

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Se

c

ti

on

D

Sa

f

e

t

y

Pre

ca

u

t

io

n

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

D-

1

Wire

F

e

e

d

Co

mp

a

rt

me

n

t

,

F

a

n

M

o

t

o

r,

Wire

Re

e

l

M

a

in

t

e

n

a

n

ce

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

D-

1

Gu

n

An

d

Ca

b

le

M

a

in

t

e

n

a

n

ce

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

D-

1

Ove

rlo

a

d

P

ro

t

e

ct

io

n

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

D-

2

Co

mp

o

n

e

n

t

Re

p

la

ce

me

n

t

P

ro

ce

d

u

re

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

D-

2

Troubl

e

s

hooti

ng.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Se

c

ti

on

E

Sa

f

e

t

y

P

re

ca

u

t

io

n

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

E

-

1

Ho

w

t

o

Use

T

ro

u

b

le

sh

o

o

t

in

g

Gu

id

e

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

E

-

1

T

ro

u

b

le

sh

o

o

t

in

g

Gu

id

e

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

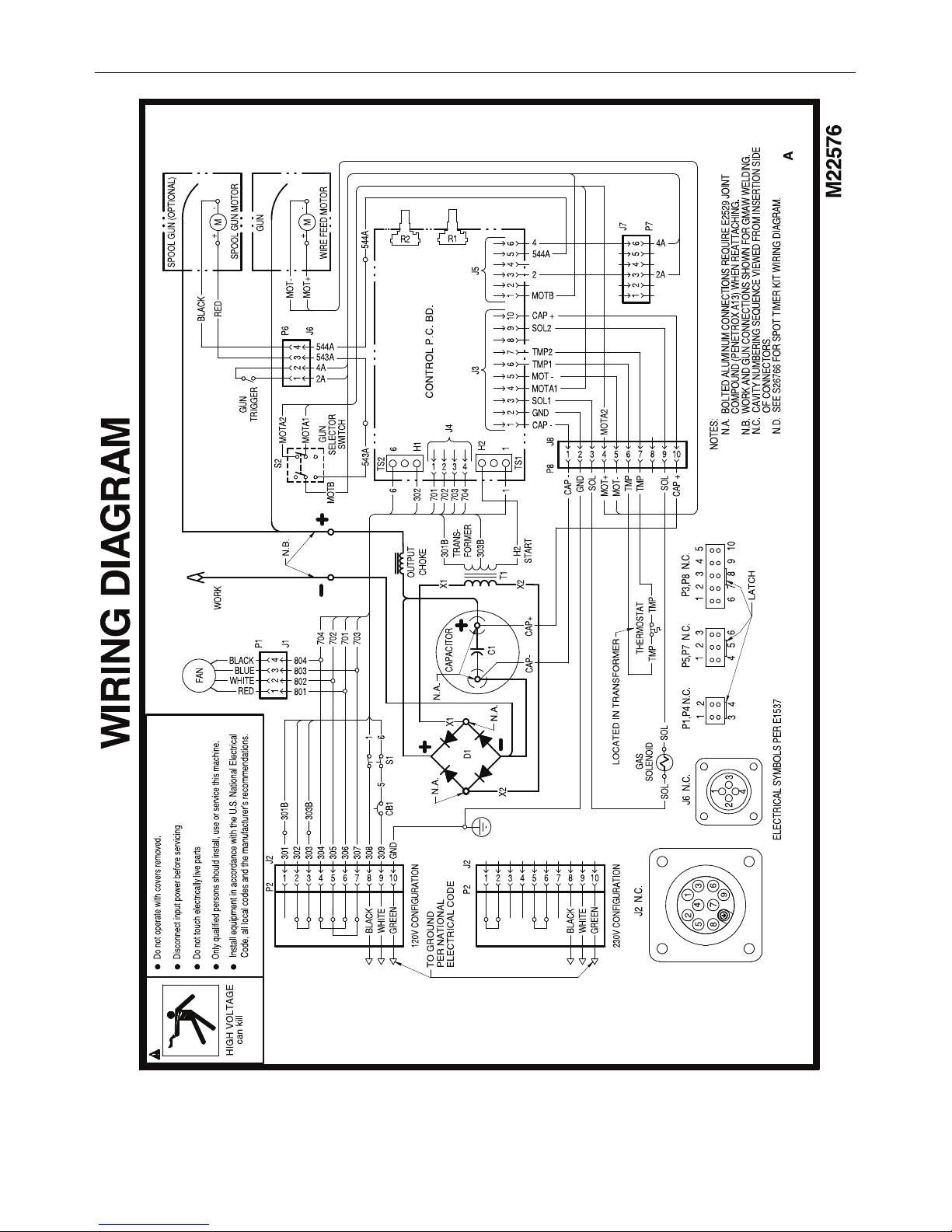

E

-

2

t

h

ru

E

-

3

Wi

ri

ng

D

i

agram

and

D

i

m

e

ns

i

on

Pri

nt

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. Se

c

ti

on

F

Parts

L

i

s

t

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

parts

.

l

i

nc

ol

ne

l

e

c

tri

c

.

c

om

Co

n

t

e

n

t

/

d

e

t

a

ils

ma

y

b

e

ch

a

n

g

e

d

o

r

u

p

d

a

t

e

d

wit

h

o

u

t

n

o

t

ice

.

F

o

r

mo

st

cu

rre

n

t

In

st

ru

ct

io

n

M

a

n

u

a

ls,

g

o

t

o

Pa

rt

s.

lin

co

ln

e

le

ct

ric.

co

m.

A-1

INSTALLATIONPOWER MIG®180 DUAL

1 If connected to a circuit protected by fuses use Time Delay Fuse

marked “D”.

2 Requirements for maximum output: In order to utilize the maximum output

capability of the machine, a branch circuit capable of 30 amps @ 120

volts, 60Hz is required.

Read this entire installation section before you

s

tart installation.

INSTALLATION

ELECTRIC SHOCK CAN KILL.

• Only qualified personnel should perform

this installation.

• Only personnel that have read and

understood the POWER MIG

®

180 DUAL

O

perator’s Manual should install and

operate this equipment.

• Machine must be plugged into a receptacle which is

grounded per any national, local or other applicable

electrical codes.

• The POWER MIG

®

180 DUAL power switch is to be in the

OFF (“O”) position when installing work cable and gun and

when connecting power cord to input power.

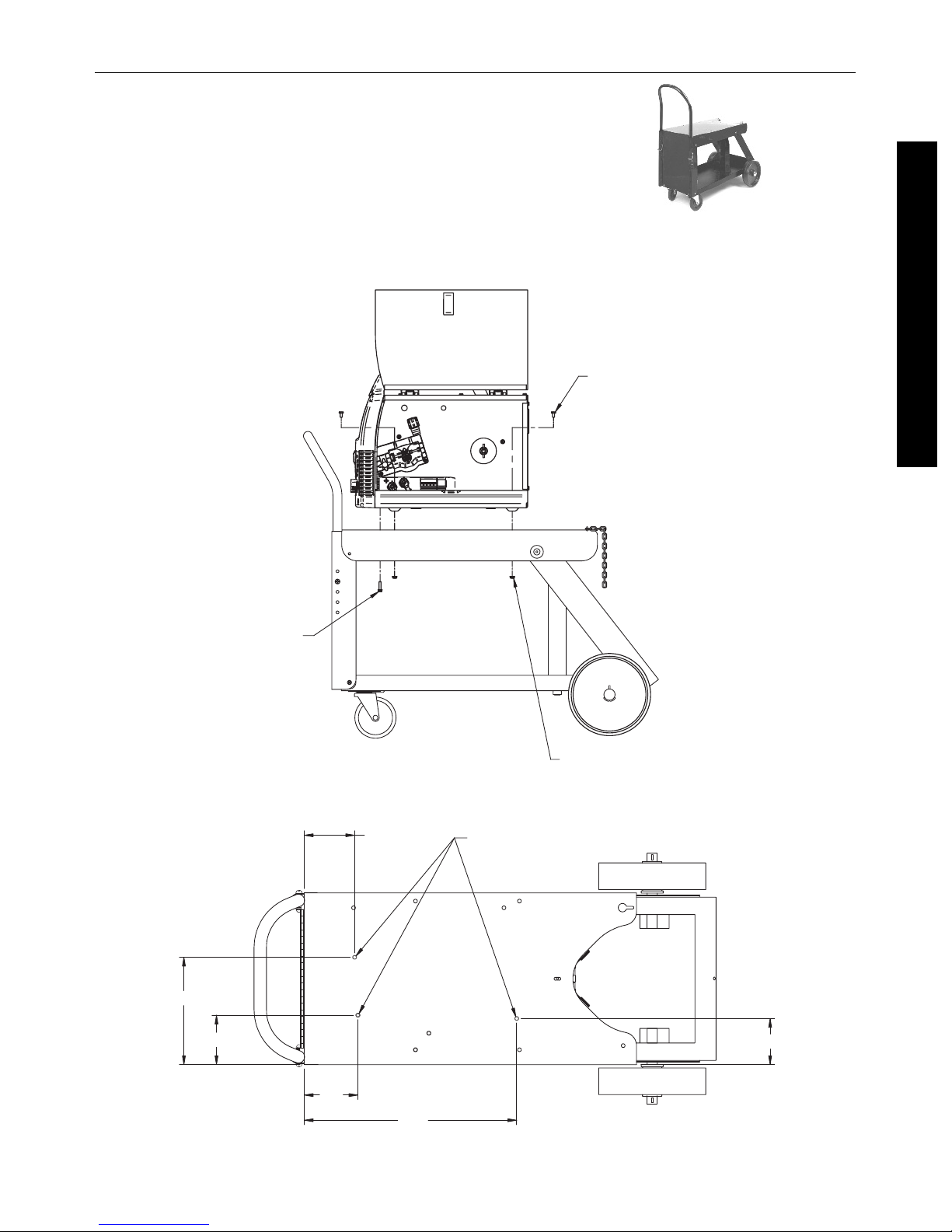

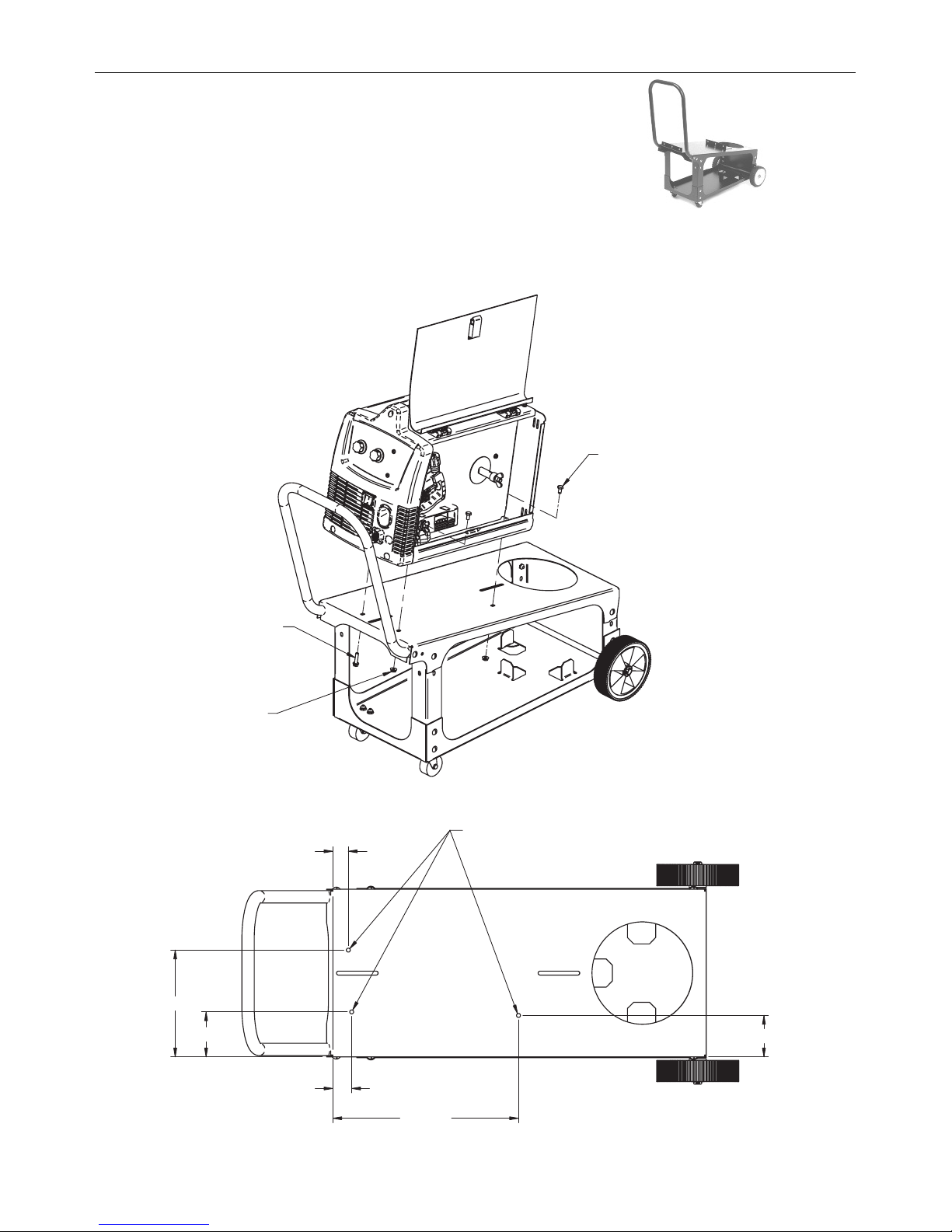

Locate the POWER MIG®180 Dual in a dry location where there is

free circulation of clean air into the louvers in the back and out the

front of the unit. A location that minimizes the amount of smoke

and dirt drawn into the rear louvers reduces the chance of dirt

accumulation that can block air passages and cause overheating.

POWER MIG®180 DUAL cannot be stacked.

Each machine must be placed on a secure, level surface, directly

or on recommended cart. The machine may topple over if this

procedure is not followed.

WARNING

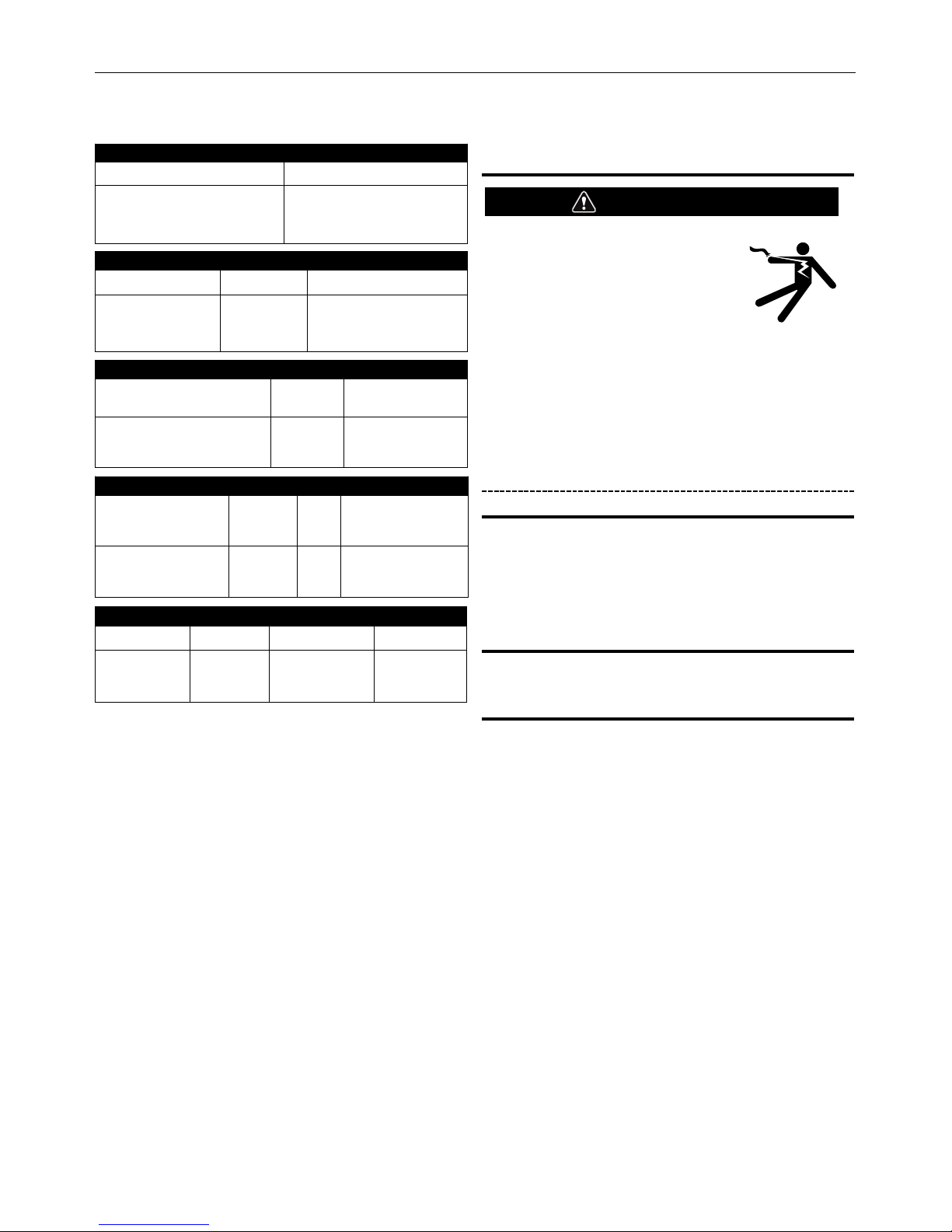

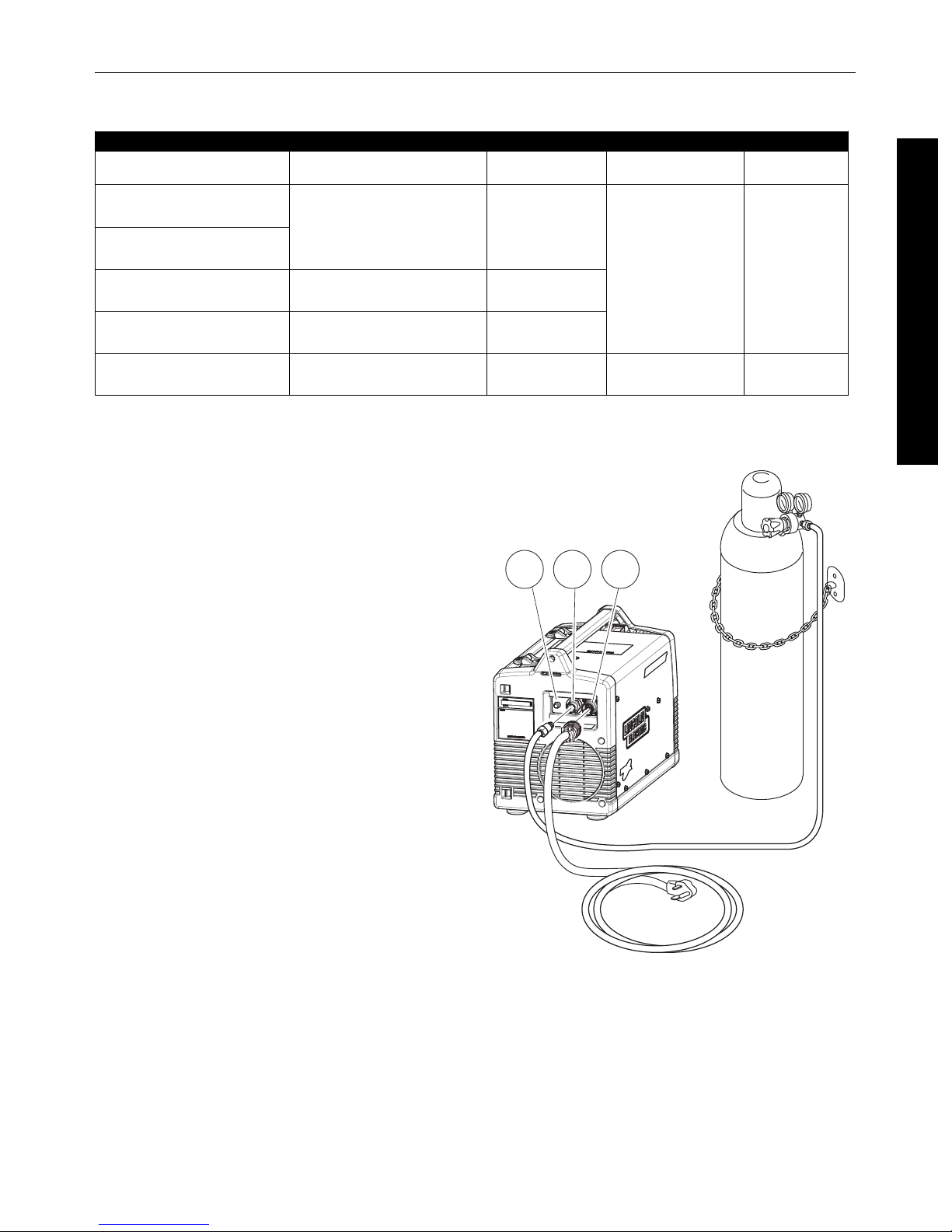

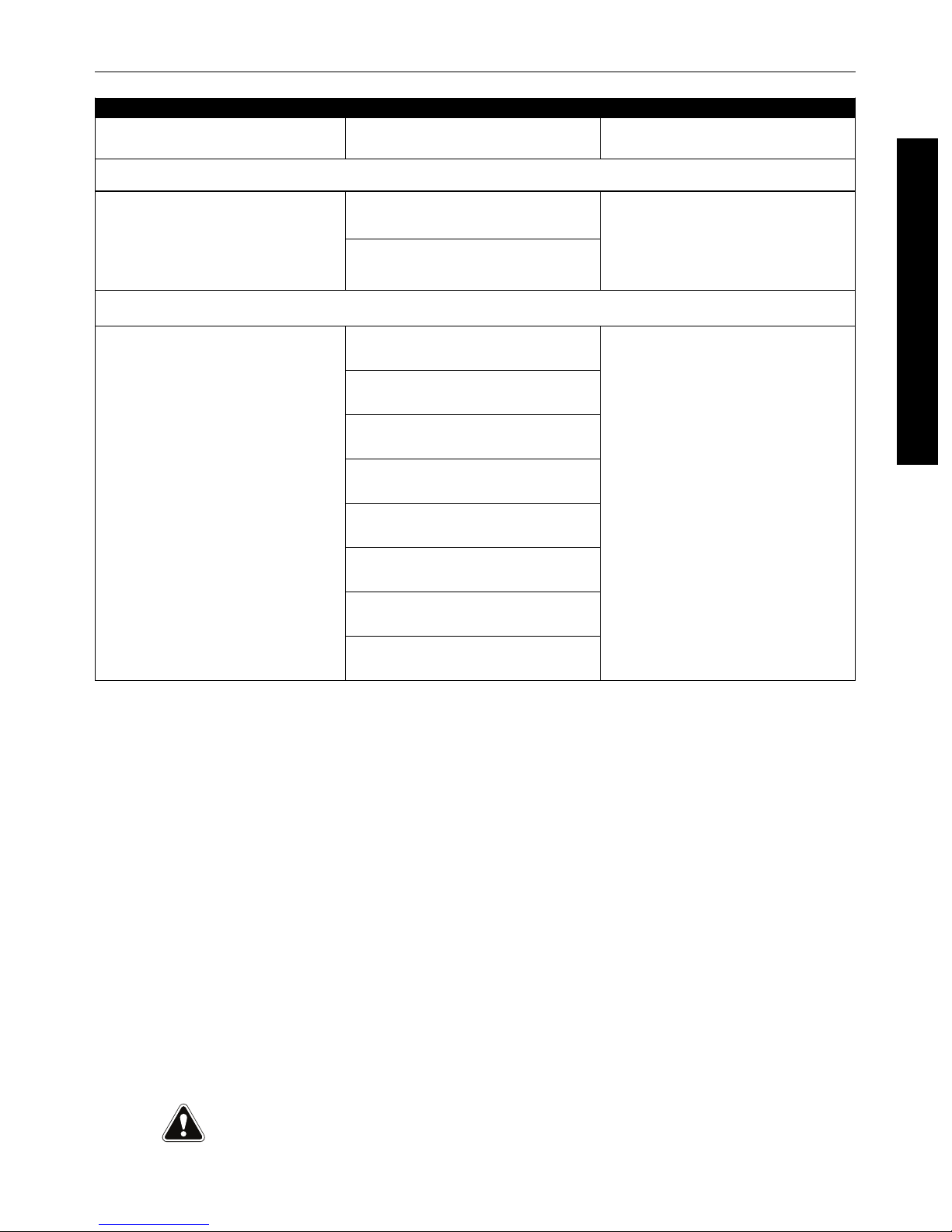

INPUT – SINGLE PHASE ONLY

Standard Voltage/Frequency Input Current

230 V 60 Hz

208 V 60 Hz

1

20 V 60 Hz

20 Amps @ rated output

RATED OUTPUT

Voltage/Duty Cycle Current Voltage at Rated Amperes

230 V 30%

208 V 30%

120 V 20%

130 Amps

130 Amps

90 Amps

20

17.6

19.5

OUTPUT

Welding Current Range

Open Circuit

Voltage

Wire Speed Range

(208 V / 230 V) 30-180 Amps

(120 V) 30-140 Amps

34 V

33 V

50 - 500 in/min.

(1.3 - 12.7 m/min.)

PHYSICAL DIMENSIONS

Height Width Depth Weight

14.08 in.

(357.6 mm)

10.37 in.

(263.4 mm)

18.78 in.

(477.6 mm)

66 lbs.

(30 kg.)

RECOMMENDED INPUT CABLE AND FUSE SIZES

Input Voltage /

Frequence

Fuse or

Breaker

Size

1

Input

Amps

(Power Cord) Lincoln

Electric Part Number

230 V / 208 V 60 Hz

120 V 60 Hz

40 Amp

20 Amp

2

20

20

M22590

M22589

A-2

INSTALLATIONPOWER MIG®180 DUAL

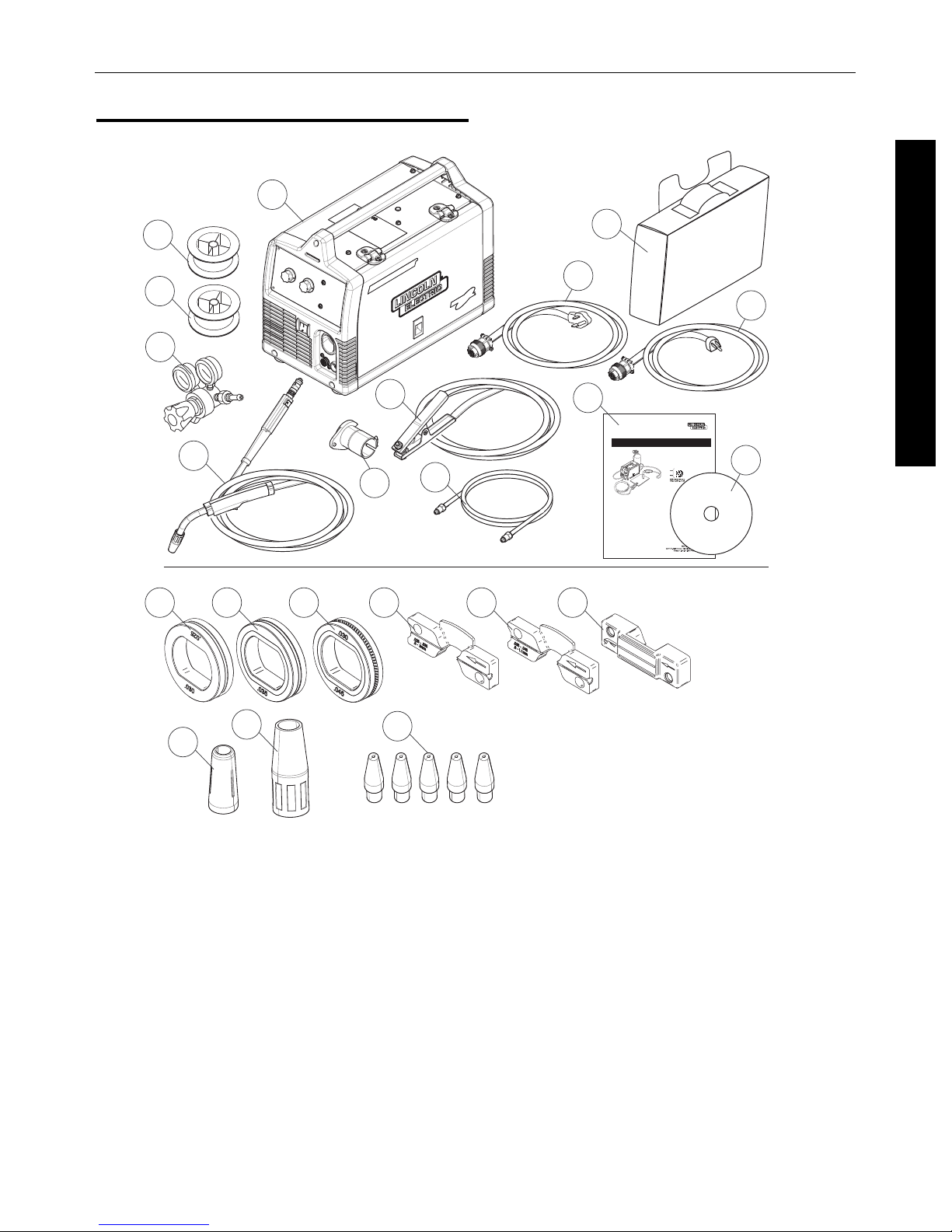

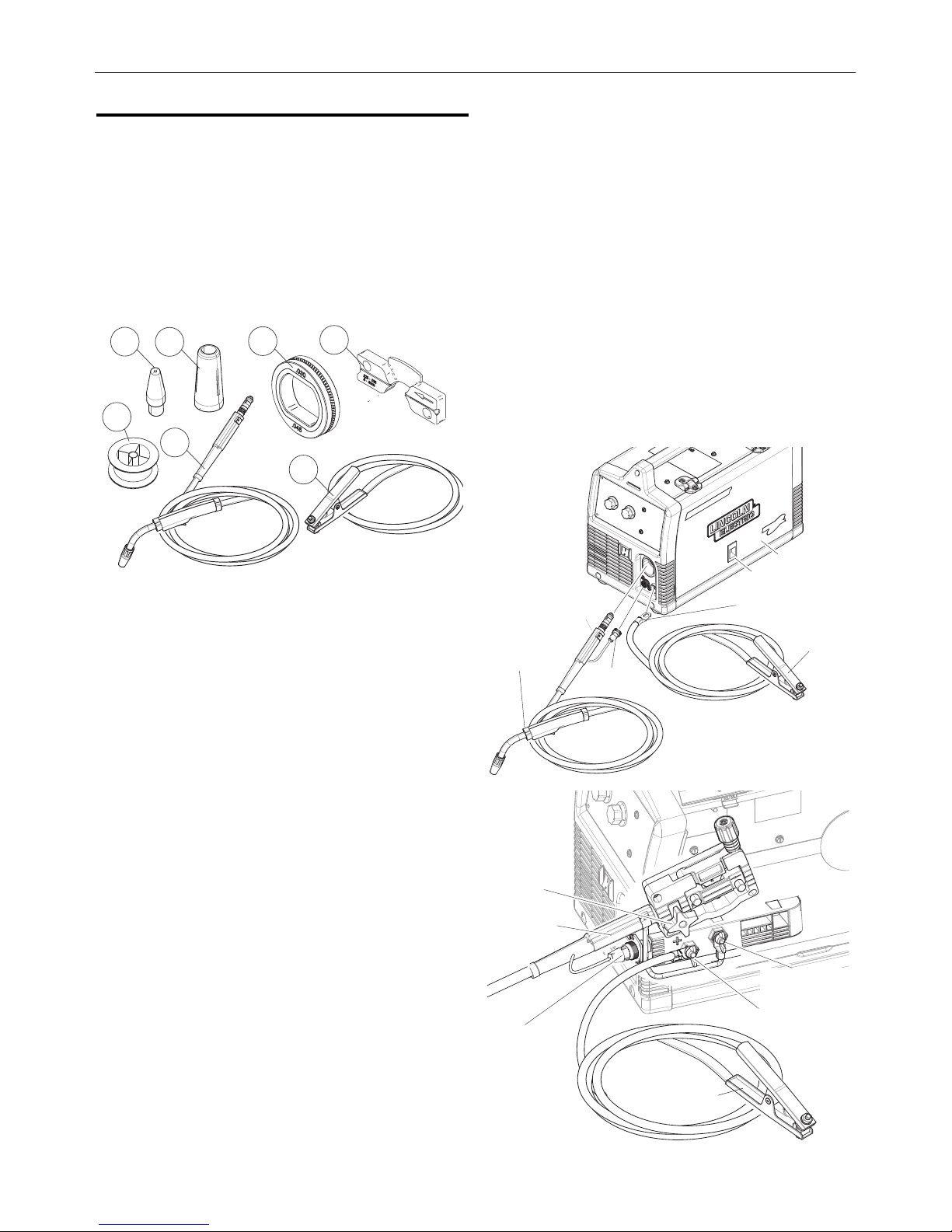

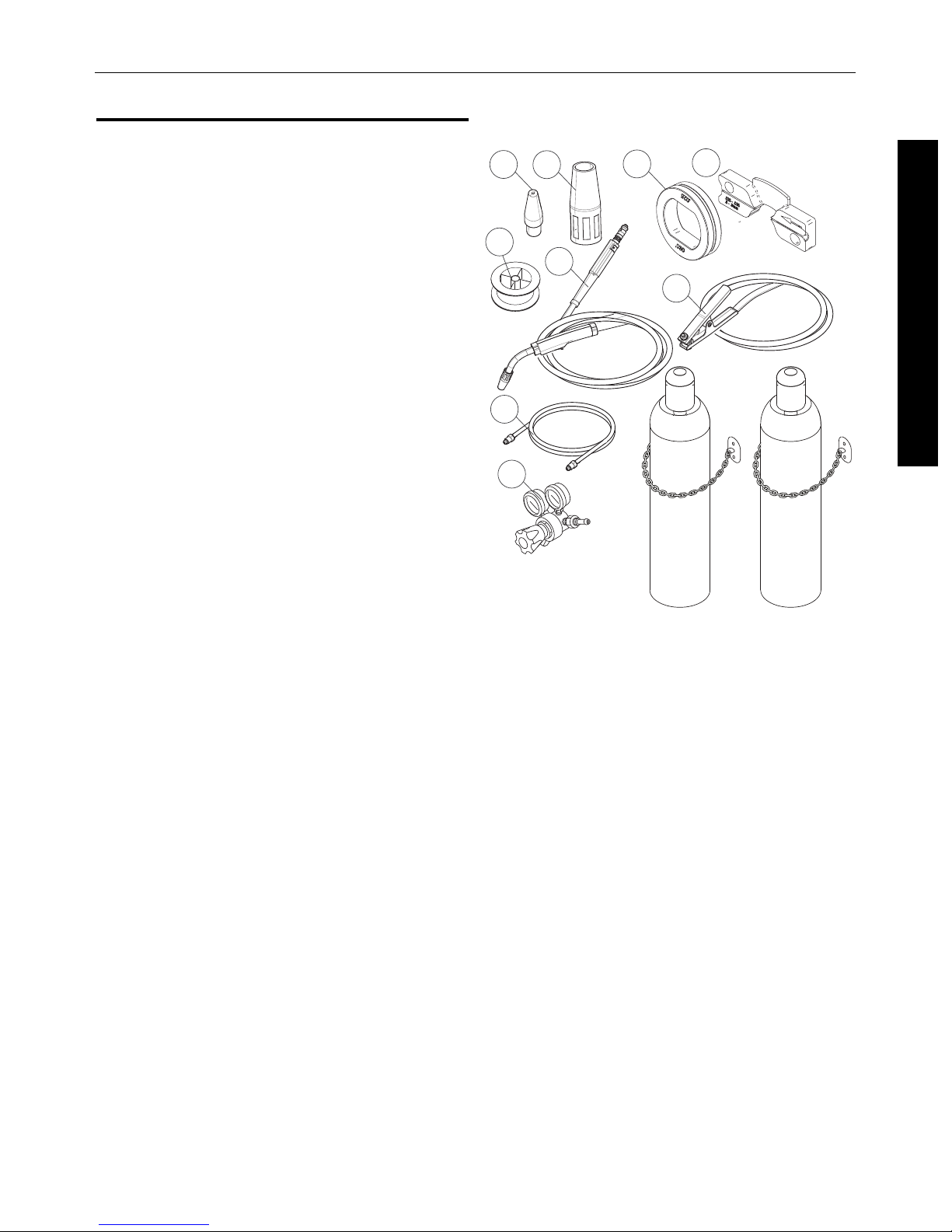

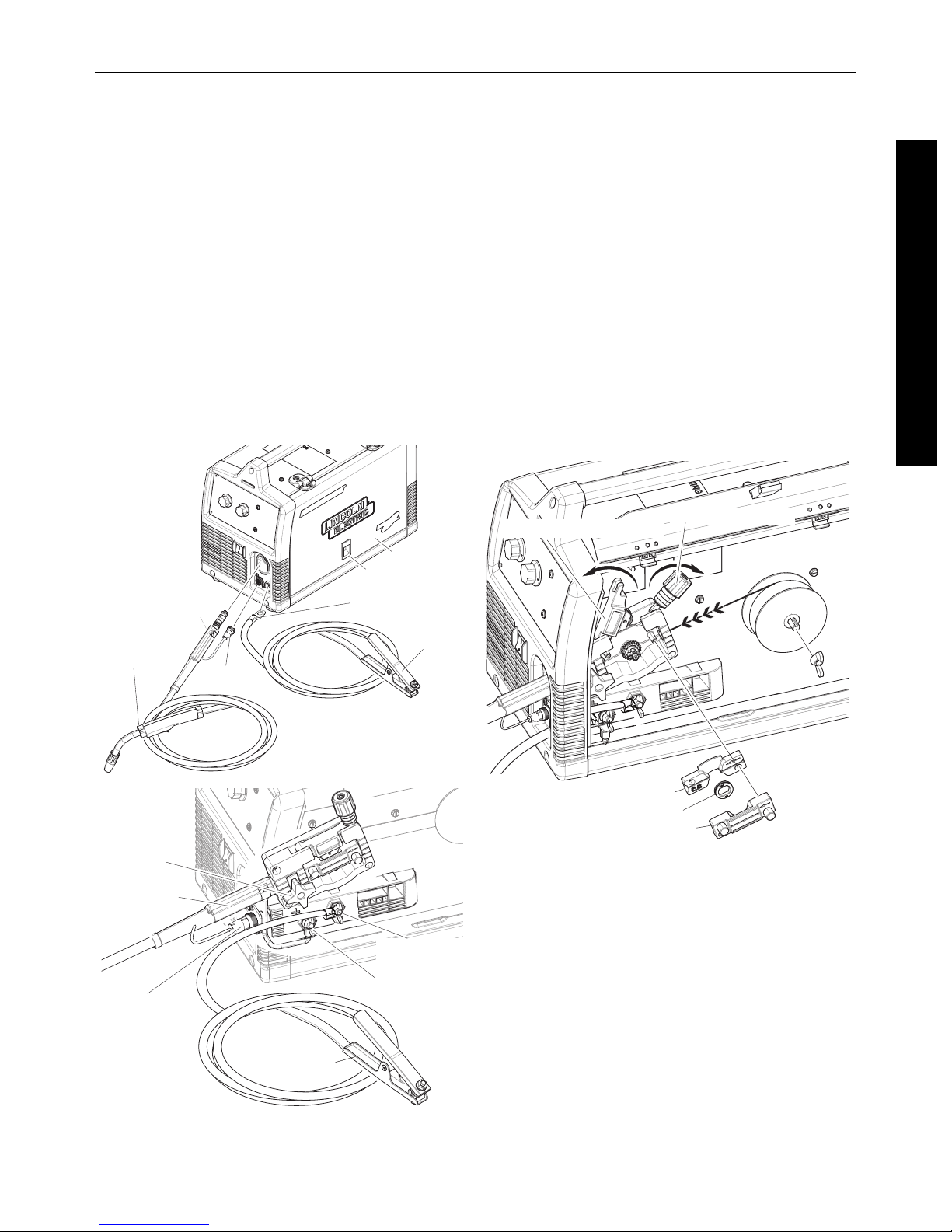

1. Wire Feeder Welder.

2. Work Cable & Clamp.

3. Magnum PRO 100L Welding Gun.

4. 3 (qty) .035(0.9mm) Contact Tips (1 installed on the

welding gun) & 3 (qty) .025(0.6mm) Contact Tips.

5. Spool of .035(0.9mm) diameter NR-211MP Innershield

Flux-cored Wire.

6. Spool of .025(0.6mm) diameter L-56 MIG Wire.

7. .025-.030(0.6-0.9mm) Smooth Drive Roll.

8. .035(0.9mm) Smooth Drive Roll.

9. .030 -.045(0.8-1.1mm) Knurled Drive Roll

(Installed on Machine).

10. .025” -.035” (0.6 - 0.9mm) Inner Wire guide.

11. .035” -.045” (0.9 - 1.1mm) Inner Wire Guide.

(Installed on Machine).

12. Outer Wire Guide (Installed on Machine).

13. Black Flux-cored Gasless Gun Nozzle.

14. Copper MIG Gas Gun Nozzle.

(Installed on welding gun).

15. Regulator

16. Gas Hose

17. 230V Input Cord

18. 120V Input Cord

19. Learn to Weld (LTW1 Manual)

20. How to Weld DVD

21. 2” Spindle Adapter (For 8” Reel of wire)

22. Accessory Bag

OPERATOR’S MANUAL

Welding Guide

LEARNING TO WELD

L

TW1

31/70 eta D eussI |

© Lincoln Global, Inc. All Rights Reserved.

Welding Safety

Interactive Web Guide

f

or mobile devices

OUTER WIRE GUIDE

INNER WIRE GUIDE

.025-.035 (.6-.9mm)

INNER WIRE GUIDE

.035-.045 (.9-1.1mm)

1

5

7 8 9 10 11 12

13

14

15

19

18

17

21

20

22

16

6

2

3

4

.035 .035 .025 .025 .025

B-1

OPERATION

OPERATION

SAFETY PRECAUTIONS

Read entire operation section before operating

the WIRE FEEDER WELDER.

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or

e

lectrode with skin or wet clothing.

•

Insulate yourself from work and ground.

• Always wear dry insulating gloves.

FUMES AND GASES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to remove

fumes from breathing zone.

WELDING SPARKS can cause fire or

explosion.

• Keep flammable material away.

• Do not weld on closed containers.

ARC RAYS can burn eyes and skin.

• Wear eye, ear and body protection.

Observe all safety information

throughout this manual.

This small portable wire feed welder is capable of MIG welding on

s

teel, stainless steel, and aluminum. The wire feed welder is also

capable of flux-cored welding on mild steel.

MIG welding stands for Metal Inert Gas welding and requires a

shielding gas to protect the weld until it cools. Appropriate

shielding gas based on the type of material you are welding can

be purchased separately from your local welding gas distributor.

MIG welding is ideal for welding on thinner and clean materials

when a very clean excellent cosmetic looking weld is required. An

example would be automotive body panels.

Self Shielding Flux-cored Welding does not require a separate

shielding gas to protect the weld since the welding wire has

special additives known as flux to protect the weld until it cools.

Flux-cored welding is ideal for medium to thicker material and if

welding on painted or rusty steel. Flux-cored welding is also ideal

in outdoor applications where windy conditions might blow the

MIG shielding gas away from the weld. Flux-cored welding

produces a good looking weld but does not produce an excellent

weld appearance as MIG welding does.

Your machine includes the necessary items to weld with either the

MIG or the flux-cored welding process on steel. To weld on

stainless steel optional stainless steel welding wire can be

purchased separately. This machine can weld aluminum using

.035”(0.9mm) diameter 4043 aluminum welding wire. Since

aluminum welding wire is soft an optional aluminum spool gun is

recommended for best results. A welding Procedure Decal is

located inside machine door to help provide suggested settings for

welding.

GMAW (MIG)

• Gas Metal Arc Welding

FCAW (INNERSHIELD OR OUTERSHIELD)

• Flux Core Arc Welding

WARNING

POWER MIG®180 DUAL

B-2

OPERATION

This machine has the following controls:

(See Figure B.1)

1. POWER SWITCH – Turns power on and off to the machine.

2. ARC VOLTAGE CONTROL – This knob sets the output voltage

o

f the machine. Along with wire feed speed (WFS) this

control sets a weld procedure. Refer to the procedure decal

on the inside wire drive compartment door to set a correct

welding procedure based on type of material and thickness

being welded.

3. WIRE FEED SPEED CONTROL (WFS) – The knob sets the

speed that the machine feeds wire. Along with arc voltage

this control sets a weld procedure. Refer to the procedure

decal on the inside wire drive compartment door to set a

correct welding procedure based on type of material and

thickness being welded.

FIGURE B.1

(

See Figure B.2)

4

. GUN TRIGGER – Pressing the trigger activates the wire drive

to feed wire and energizes the output of the machine. Press

the trigger to weld and release the trigger to stop welding.

5. WELDING GUN – Delivers wire and welding current to the

weld.

a. Gun Liner – wire travels through the liner from the wire drive.

The gun liner will feed .025” to .035” (0.6mm to 0.9mm)

wire. The 180A machine can weld with .045”(1.1mm) wire if

an optional .045”(1.1mm) liner is installed in the gun.

b. Contact Tip – provides electrical contact to the wire.

c. Nozzle – When flux-cored welding the black nozzle protects

the mounting threads on the gun. When MIG welding the

copper nozzle funnels the shielding gas to the weld.

6. WORK CLAMP & CABLE – Clamps to the work piece being

welded and completes the electrical welding circuit.

7. GUN TRIGGER CONNECTOR RECEPTACLE – Plug the 4 pin

gun trigger connector into this receptacle.

FIGURE B.2

2

1

3

5C 5B

5A

4

5

7

6

POWER MIG®180 DUAL

OPERATOR’S MANUAL

B-3

OPERATION

(See Figure B.3)

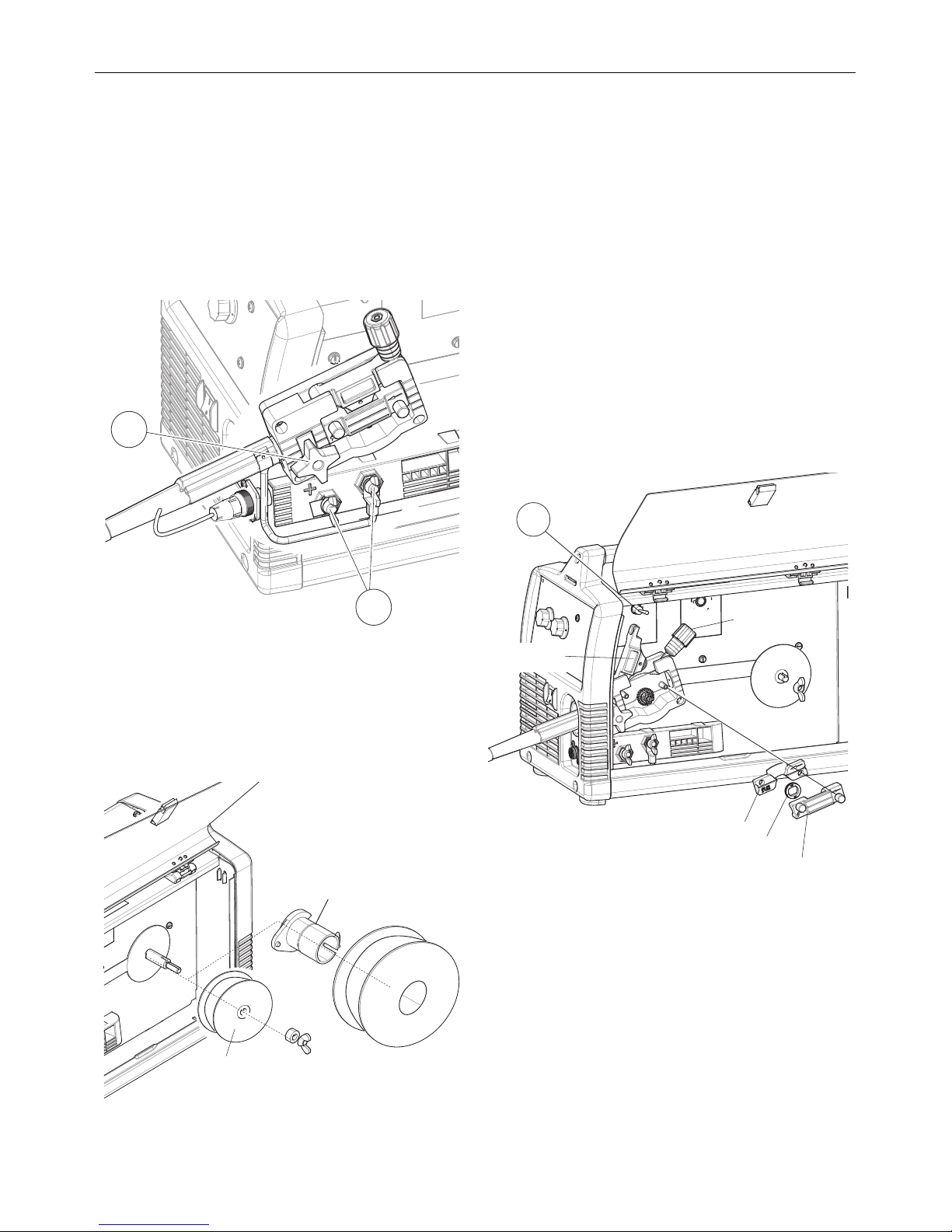

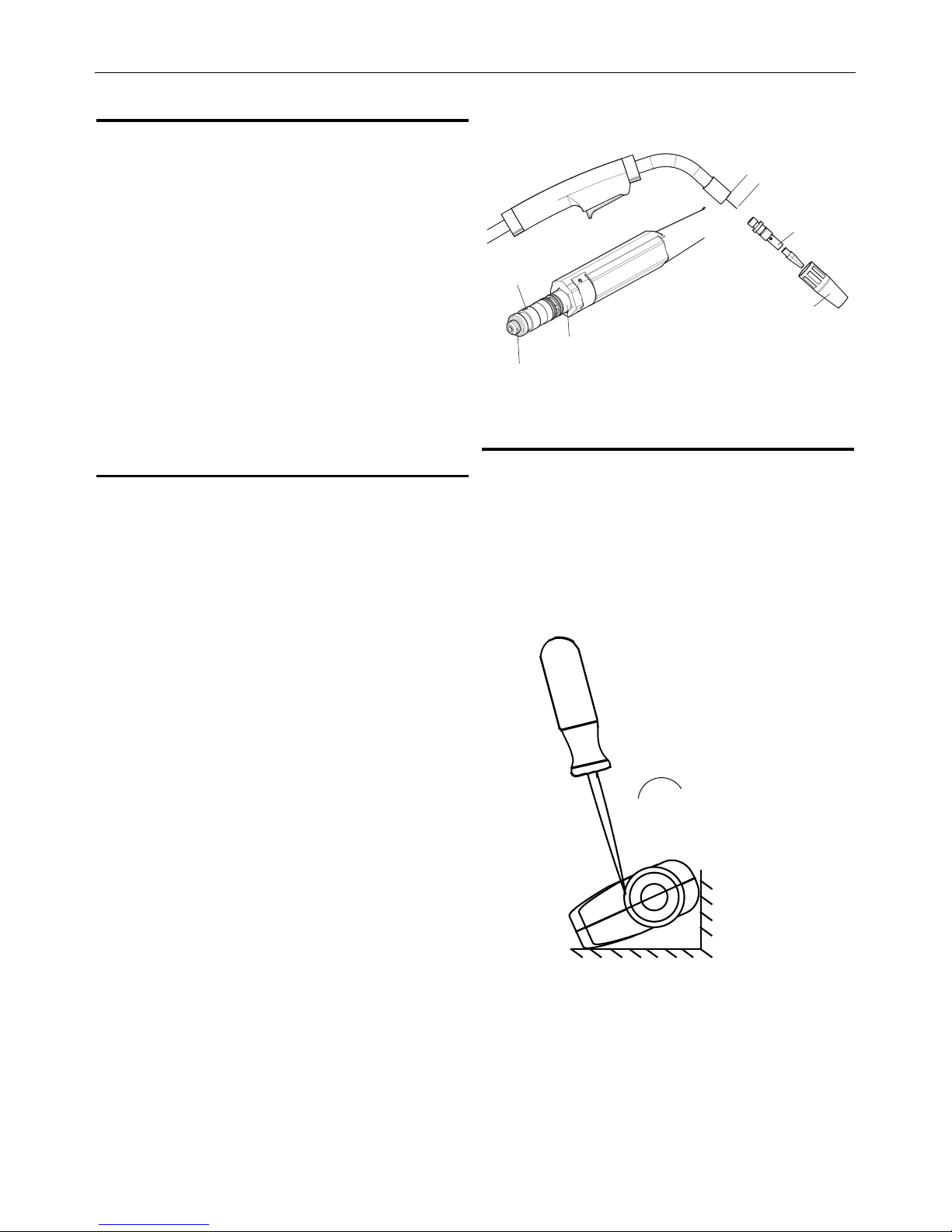

8. WELDING GUN CONNECTOR BUSHING & THUMBSCREW –

Provides electrical power to the welding gun. The

thumbscrew holds the welding gun into the connector block.

(Front of Machine, Side Door and Wire Drive Cover have been

removed for clarity of Items 8 and 9).

9. OUTPUT TERMINALS –These connections allow for changing

t

he welding polarity of the machine depending on whether

you are MIG welding or flux-cored welding.

FIGURE B.3

(See Figure B.4)

10. WIRE SPOOL SPINDLE AND BRAKE – Holds a 4 inch

diameter spool. Use the 2 inch I.D. spindle adapter included

with the machine to use 8 inch diameter spools. The Wing

Nut sets the brake friction to prevent the spool from over

rotating when the trigger is released.

FIGURE B.4

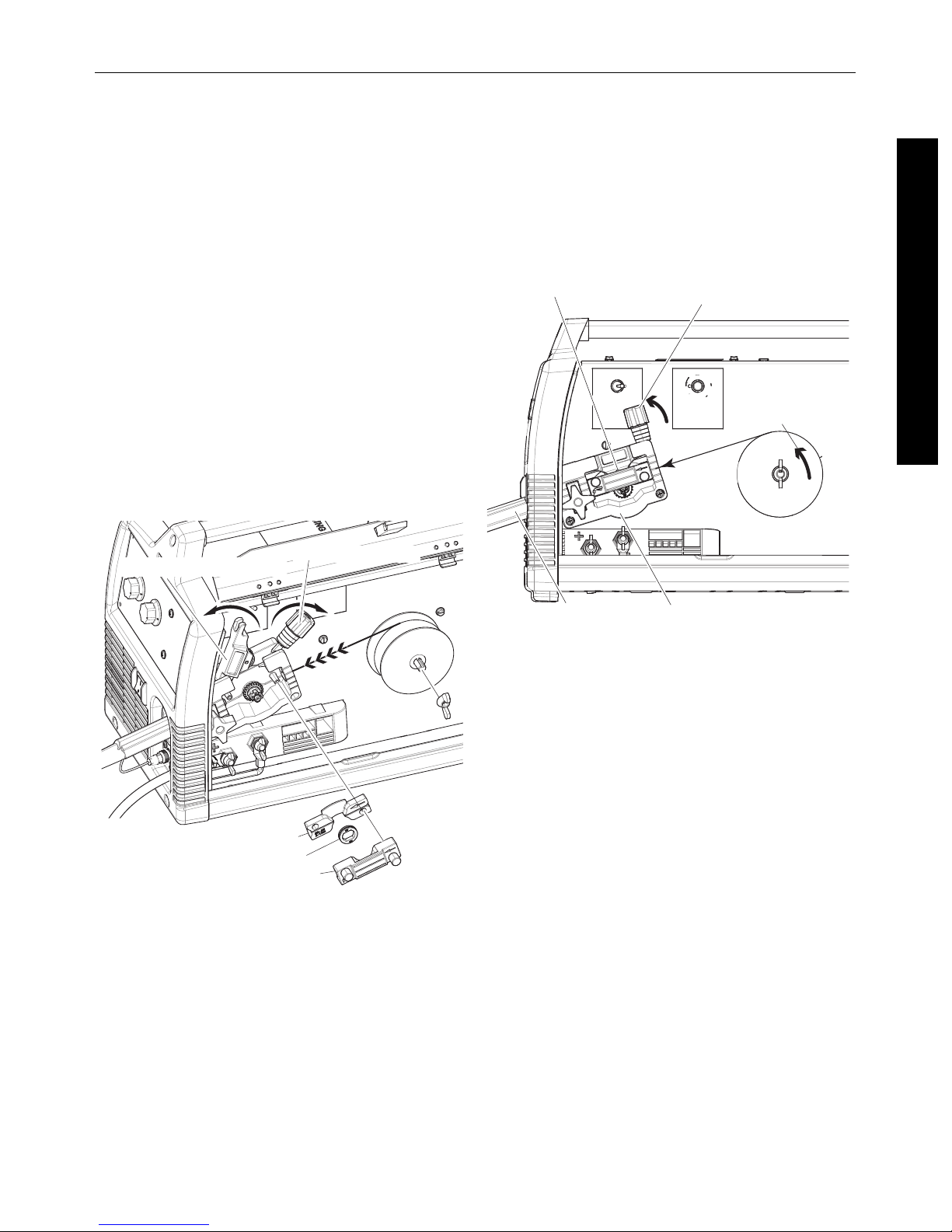

(See Figure B.5)

11. WIRE DRIVE & COMPONENTS – Feeds wire from the wire

spool through the drive and through the welding gun to the

weld.

a. Top and Bottom Drive Roll – Drives the wire through the

drive system. The drive roll has a groove to match the

specific wire type and diameter. Refer to Table B.1 for

a

vailable drive rolls.

b. Inner & Outer Wire Guide – Guides the wire between the Top

and Bottom Drive Roll and through the wire drive. The inner

guide has a groove to match a particular wire diameter.

Refer to Table B.1 for available wire guides.

c. Drive Roll Tension Thumbscrew – Turning clockwise

increases the force on the drive rolls and turning counterclockwise decreases the force.

12. SPOOL GUN SWITCH - Pre-Installed switch permits either

spool gun welding with the Magnum 100SG or standard

welding with the Magnum PRO 100L.

FIGURE B.5

8

9

2” Spindle Adaptor

(For 8” Reel of Wire)

4” Reel of Wire

12

INNER WIRE GUIDE REMOVED

LOWER DRIVE ROLL REMOVED

OUTER WIRE GUIDE REMOVED

TOP DRIVE ROLL

PRESSURE ARM

TENSION

ADJUSTOR DOWN

POWER MIG®180 DUAL

B-4

OPERATION

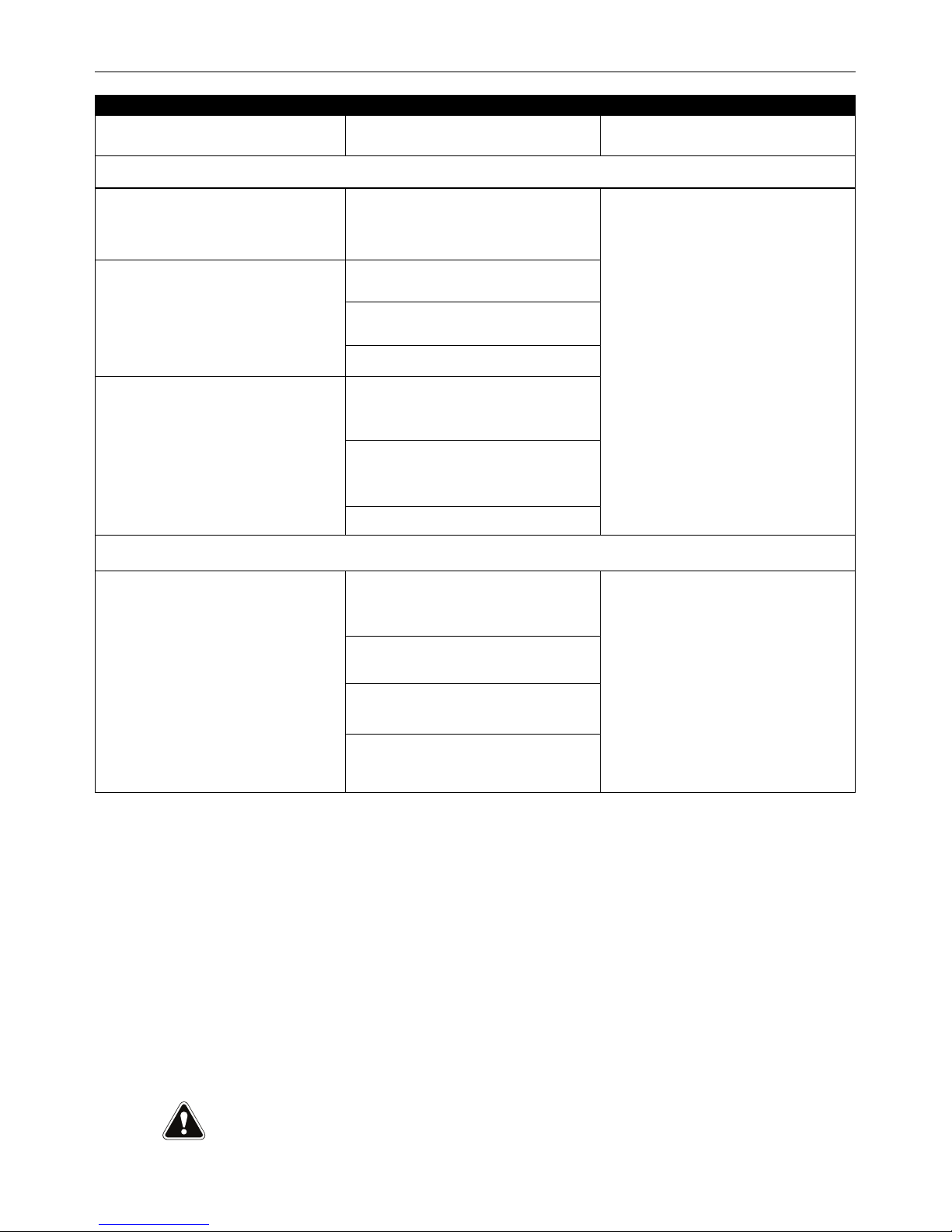

TABLE B.1

(See Figure B.6 for the following Items.)

13. CIRCUIT BREAKER – If the rated input current of the machine

is exceeded this circuit breaker will trip. Press to reset.

14. GAS INLET – Shielding gas connects to this inlet.

15. POWER CORD CONNECTION - Ensure power cord is

disconnected from input voltage supply prior to connecting or

removing the cord from the machine. Connect the circular

connector present on either input cord (120V or 230V) to the

receptacle on the back of the machine. The power cord

connector is secured to the receptacle by rotating the

connector’s coupling ring clockwise, until the coupling ring

latches on to the receptacle. Use only the appropriate (120V

or 230V) power cords supplied by the Lincoln Electric

Company.

FIGURE B.6

13 14 15

POWER MIG®180 DUAL

OPERATOR’S MANUAL

DRIVE ROLL AND WIRE GUIDES

Wire Diameter & Type Drive Roll

Drive Roll Part

Number

Inner Wire Guide

Inner Wire Guide

Part Number

.025”(0.6mm) MIG wire

.

025”/.030” (0.6mm/0.8mm)

Smooth Drive Roll

KP2529-1

.025”-.035”

(0.6mm-0.9mm)

Steel Wire Guide

KP2531-1

.030”(0.8mm) MIG wire

.035”(0.9mm) MIG wire

.035”(0.9mm)

Smooth Drive Roll

KP2529-2

.030”(0.8mm) flux-cored

.035”(0.9mm) flux-cored

.030”/.045” (0.8mm/1.1mm)

Knurled Drive Roll

KP2529-3

.045”(1.1mm) flux-cored

.030”/.045” (0.8mm/1.1mm)

Knurled Drive Roll

KP2529-3

.045” (1.1mm)

Steel Wire Guide

KP2531-2

B-5

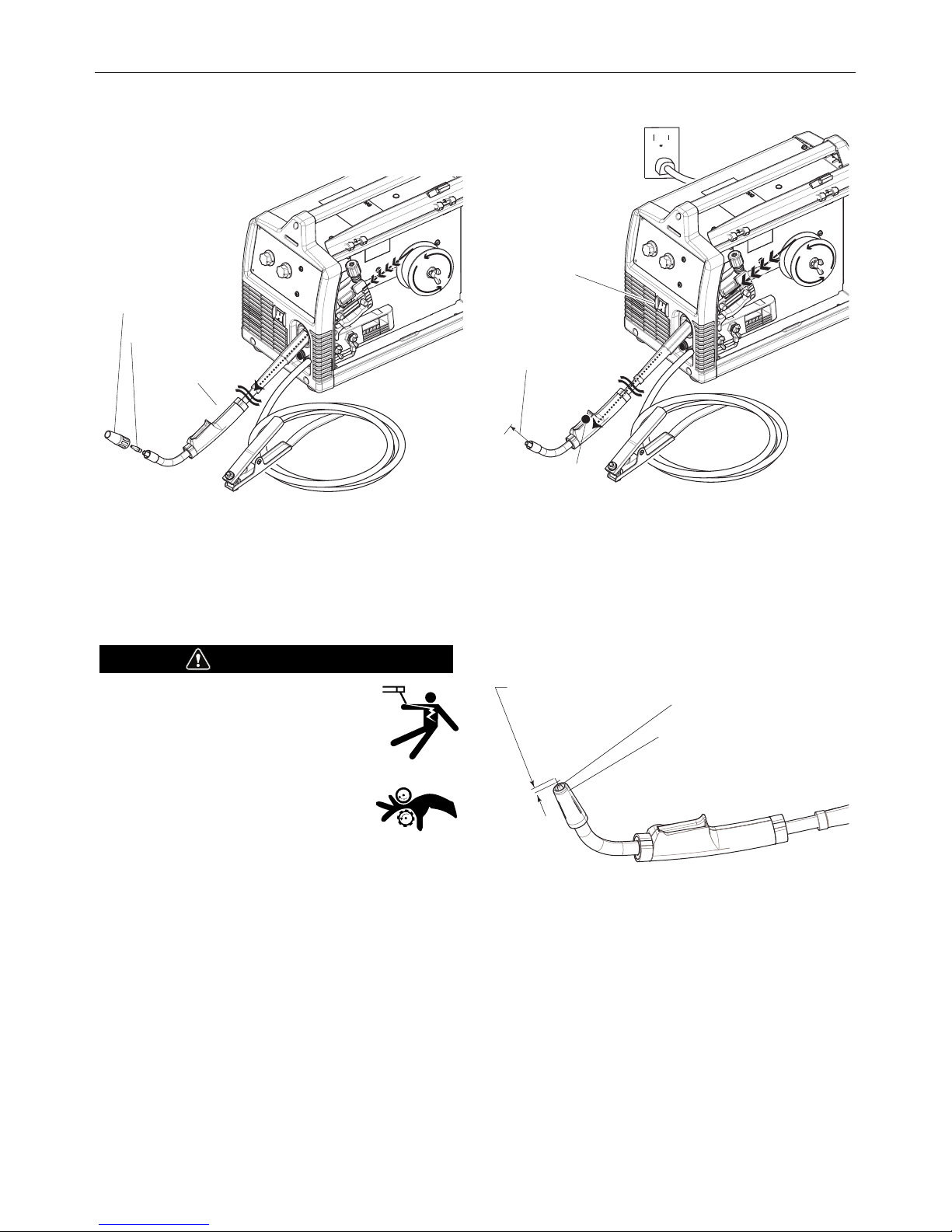

OPERATION

A

. Items needed for flux cored welding

1. 035”(0.9mm) Contact Tip

2.Black Flux Cored gun nozzle

3. Knurled Drive Roll

4. .025”-.035”(0.6mm-0.9mm) wire guide

5. .035”(0.9mm) NR-211MP Flux-Cored Wire

6. Welding Gun

7. Work Cable & Clamp

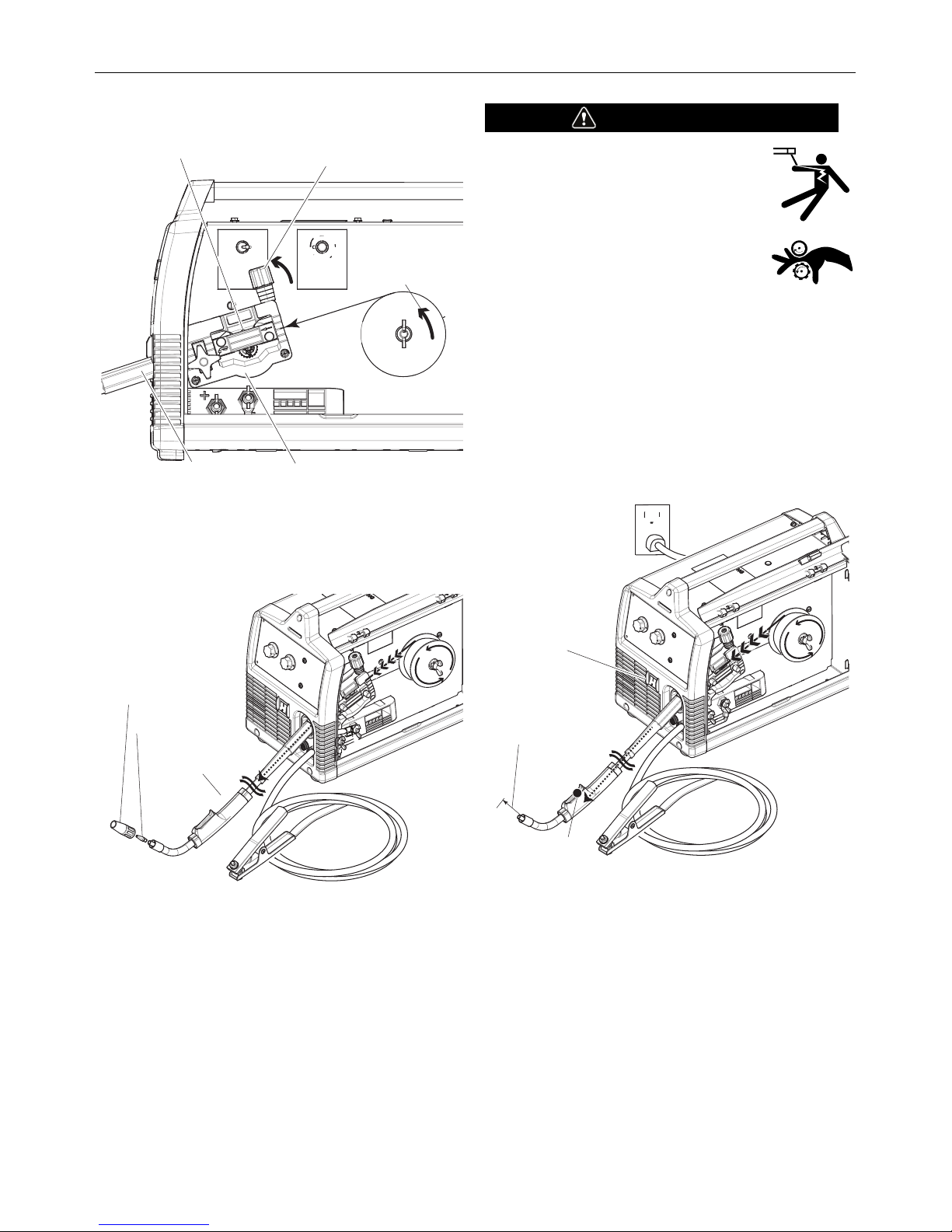

(See Figure B.7)

1. Open the case side door

2. Slide the connector end of the gun and cable through the hole

i

n the machine front and into the gun connector bushing on

the wire drive.

3. Make sure the gun connector end is seated fully into the wire

drive and tighten the thumbscrew to secure the gun

connector.

4. Plug the gun trigger lead connector into the 4 pin gun trigger

receptacle on the machine front.

5. Wire Drive Polarity. Flux cored welding requires negative (-)

polarity. Connect the short power cable from the wire drive to

the negative (-) output terminal and tighten the Wing Nut.

6. Work Lead Connection. Slide the lugged end of the work cable

through the hole in the machine front and place on the

positive (+) output terminal and tighten Wing Nut.

FIGURE B.7

G

U

N

A

N

D

C

A

B

L

E

W

O

R

K

C

L

A

M

P

(

4

P

I

N

)

L

EA

D

C

O

N

N

EC

TO

R

S

L

I

D

E

C

O

N

N

EC

TO

R

EN

D

H

ER

E

C

A

S

E

S

I

D

E

D

O

O

R

TER

M

I

N

A

L

E

N

D

(

FI

TS

O

N

S

TU

D

I

N

S

I

D

E

S

EE

FI

G

U

R

E

B

EL

O

W

)

O

P

E

N

L

A

T

CH

D

O

O

R

L

OCATE COMPONENTS

T

O CONNECT

TO THE

FRONT OF MACHINE

5

3

4

2

7

6

1

NR-211-MP

.035

(

4

P

I

N

)

BUSHING

W

O

R

K

C

L

A

M

P

T

R

I

G

G

E

R

R

E

C

E

P

T

A

C

L

E

P

L

U

G

G

E

D

I

N

C

O

N

N

E

C

T

O

R

E

N

D

A

T

T

A

C

H

WORK LEAD CONNECTION

POSITIVE "+" OUTPUT TERMINAL

THUMB SCREW TO

TIGHTEN CONNECTOR

SHORT POWER

CABLE NEGATIVE “–”

OUTPUT TERMINAL

POWER MIG®180 DUAL

B-6

OPERATION

(See Figure B.8)

1. Locate the 4"(102mm) diameter spool of .035”(0.9mm)

N

R-211MP flux-cored wire and place onto wire spool spindle.

Orient the spool so that the wire feeds off the top of the spool.

2. Secure spool in place by tightening the wing nut against the

against the spacer that holds the wire spool on the spindle.

3. Open the top drive roll pressure arm by rotating the tension

adjustor arm down and pivoting the drive roll pressure arm

up.

4. Remove the outer wire guide.

4a. Slide gun out of drive slightly.

5. Remove the lower drive roll and inner wire guide.

6. Install the .025”-.035”(0.6mm-0.9mm) inner wire guide.

7. Install the .030”/.045”(0.8mm/1.1mm) knurled lower drive

roll.

8. Carefully unwind and straighten the first six inches of welding

wire from the spool. Do not let the end of the wire go to

prevent the wire from unspooling.

FIGURE B.8

(See Figure B.9)

9. Feed the wire through the wire drive inlet along the inner wire

guide groove and into the wire drive outlet on the gun side.

10. Close the top drive roll pressure arm and secure by pivoting

the tension adjustor back to the up position.

11. Re-install the outer wire guide.

FIGURE B.9

TENSION ADJUSTOR

LOCKED IN POSITION

LOWER DRIVE ROLL

BE SURE WIRE

IS IN GROOVE

W

IRE SPOOL

.

035" (0.9mm)

SLIDE WIRE

INTO GUN

CONNECTOR

SIDE

TOP DRIVE ROLL

PRESSED AGAINST

L

OWER DRIVE ROLL

DIRECTION

O

F WIRE

N

R-211-MP

WIRE SPOOL

.035" (0.9mm)

NR-211-MP

INNER WIRE GUIDE REMOVED

LOWER DRIVE ROLL REMOVED

OUTER WIRE GUIDE REMOVED

TENSION ADJUSTOR DOWN

TOP DRIVE ROLL PRESSURE ARM

POWER MIG®180 DUAL

OPERATOR’S MANUAL

B-7

OPERATION

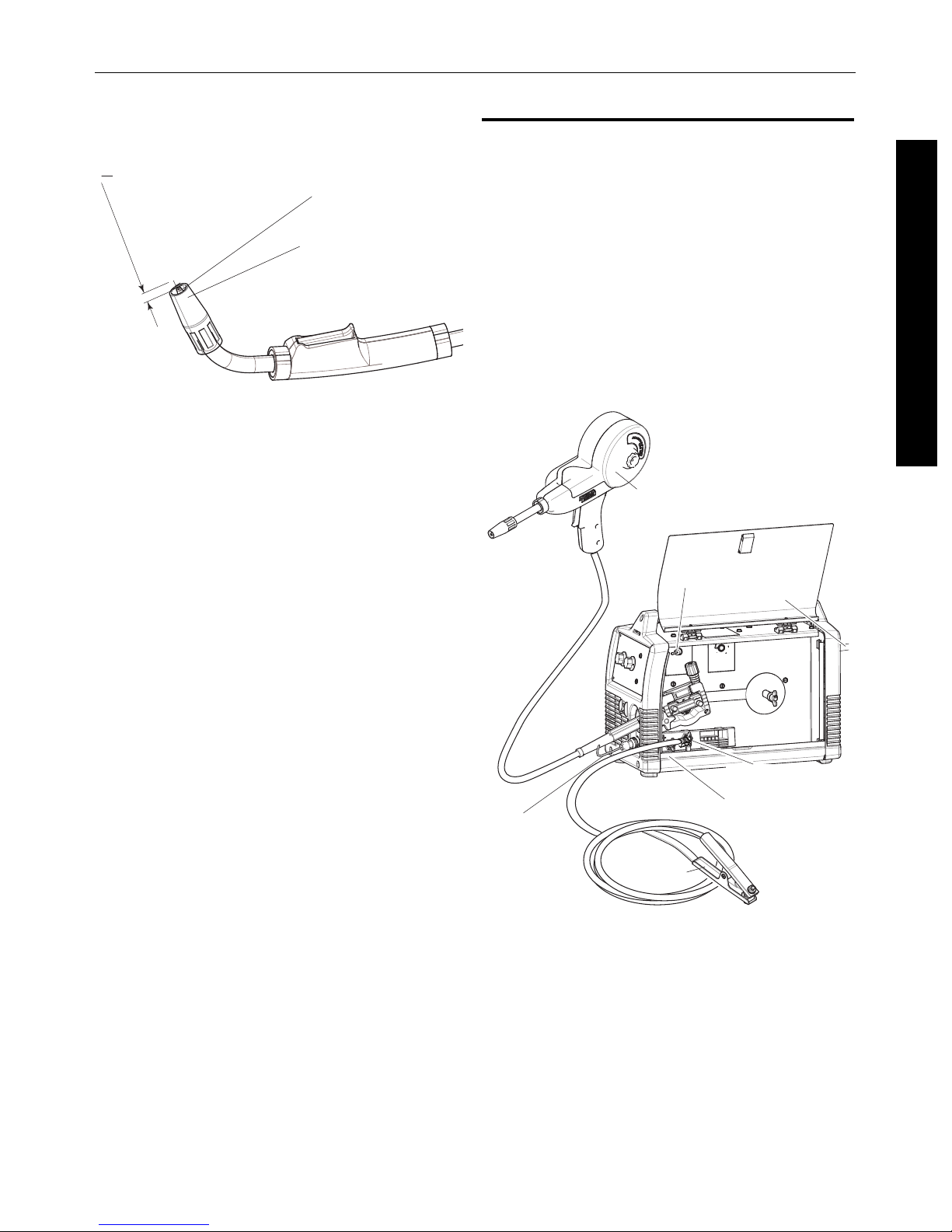

(See Figure B.10)

12. Remove the nozzle from the gun and contact tip and

straighten the gun out flat.

FIGURE B.10

(See Figure B.11)

13. Turn the machine power to on and depress the gun trigger to

feed the wire through the gun liner until the wire comes out

of the threaded end of the gun several inches.

14. When trigger is released spool of wire should not unwind.

Adjust wire spool brake accordingly.

MOVING PARTS AND ELECTRICAL

CONTACT CAN CAUSE INJURY OR

BE FATAL.

• When the gun trigger is depressed drive

rolls, spool of wire and electrode are

ELECTRICALLY LIVE (HOT).

• Keep away from moving parts and pinch

points.

• Keep all Doors, Covers, panels and

guards securely in place.

DO NOT REMOVE OR CONCEAL

WARNING LABELS.

------------------------------------------------------------------------

FIGURE B.11

15. Install the .035”(0.9mm) contact tip

16. Install the black flux cored welding nozzle to the gun.

17. Trim the wire stickout to 3/8”(9.5mm) from the contact tip.

(See Figure B.12)

FIGURE B.12

18. Close the case side door. The machine is now ready to weld.

19. Read "Learn to Weld" (LTW1) that is included with the

machine or watch the "How to Weld" DVD included with the

machine.

20. Based on the thickness of the material you are going to weld

and the type and diameter of the welding wire set the

voltage and the wire feed speed per the procedure decal

attached to the inside of the wire drive compartment door.

WARNING

NR-211-MP

REMOVED NOZZLE

REMOVED CONTACT TIP

L

AY CABLE AND GUN

S

TRAIGHTEN IN

THIS POSITION

NR-211-MP

DEPRESS TRIGGER

T

O ACTIVATE WIRE,

W

HICH FEEDS THE WIRE

THRU THE LINER

FEED WIRE

APPROXIMATELY 4.00”

FROM GUN TUBE END

PLUG IN POWER

I

NPUT CORD

ON/OFF

SWITCH

IN

S

T

A

L

L .0

3

5

C

O

N

T

A

C

T

T

IP

IN

S

T

A

L

L B

L

A

C

K

F

L

U

X

-C

O

R

E

D

N

O

Z

Z

L

E

T

R

IM

W

IR

E

S

T

IC

K

O

U

T

3

/8

"

(

9

.5

m

m

)

fr

o

m

th

e

C

o

n

ta

c

t

T

ip

POWER MIG®180 DUAL

OPERATOR’S MANUAL

B-8

OPERATION

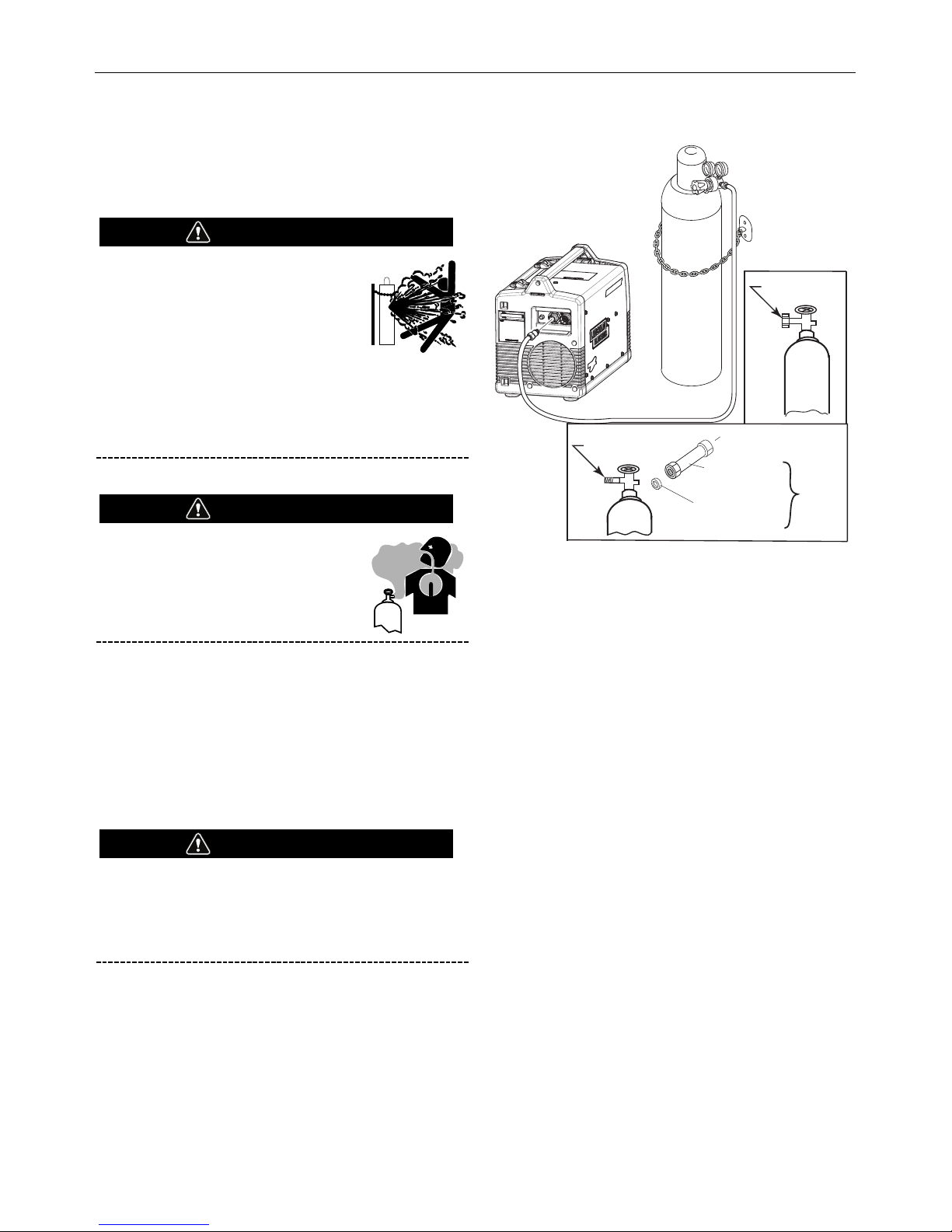

A. Items needed for MIG welding

1. 025”(0.6mm) Contact Tip

2. Copper gun nozzle

3. .025”(0.6mm) Drive Roll

4. 025”-035”(0.6mm-0.9mm) Inner wire guide

5. .025”(0.6mm) SuperArc L-56 Solid MIG Wire

6. Welding Gun

7. Work Cable & Clamp

8. Gas Line

9. Gas Regulator

Bottle of 75/25 Ar/CO2shielding gas (or 100% CO2shielding

gas) (note this requires a CO2regulator adapter which is sold

separately.

5

3

4

2

7

6

1

8

9

75/25

FEMALE

END

MIXES

MALE

END

.025