Lincoln Electric POWER FEED 25M, POWER FEED 25M ALUMINIUM, POWER FEED 25M ALUMINUM Operator's Manual

Operator’s Manual

POWER FEED ®25M & 25M ALUMINUM

For use with machines having Code Numbers:

11743, 11744, 12375, 12617,

12618, 12624

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10077-C | Issue D ate Nov-16

© Lincoln Global, Inc. All Rights Reserved.

POWER FEED®25M & 25M ALUMINUM

G

A

M

O

R

T

C

E

L

E

T

I

L

I

B

I

T

A

P

M

O

C

E

C

N

A

M

R

O

F

N

O

C

o

f

n

o

c

n

i

e

r

a

k

r

a

m

E

C

e

h

t

g

n

i

y

a

l

p

s

i

d

s

t

c

u

d

o

r

P

9

8

9

1

y

a

M

3

f

o

e

v

i

t

c

e

r

i

D

l

i

c

n

u

o

C

y

t

i

n

u

m

m

o

C

o

r

t

c

e

l

e

o

t

g

n

i

t

a

l

e

r

s

e

t

a

t

S

r

e

b

m

e

M

e

h

t

f

o

s

w

a

l

r

o

f

n

o

c

n

i

d

e

r

u

t

c

a

f

u

n

a

m

s

a

w

t

I

.

)

C

E

E

/

6

3

3

/

9

8

(

n

a

t

s

d

e

z

i

n

o

m

r

a

h

a

s

t

n

e

m

e

l

p

m

i

t

a

h

t

d

r

a

d

n

a

t

s

c

u

d

o

r

P

)

C

M

E

(

y

t

i

l

i

b

i

t

a

p

m

o

C

c

i

t

e

n

g

a

m

o

r

t

c

e

l

E

l

E

n

l

o

c

n

i

L

r

e

h

t

o

h

t

i

w

e

s

u

r

o

f

s

i

t

I

.

t

n

e

m

p

i

u

q

E

.

e

s

u

l

a

n

o

i

s

s

e

f

o

r

p

d

n

a

l

a

i

r

t

s

u

d

n

i

r

o

f

d

e

n

g

i

s

e

d

N

O

I

T

C

U

D

O

R

T

N

I

o

m

a

l

l

a

m

s

s

e

t

a

r

e

n

e

g

t

n

e

m

p

i

u

q

e

l

a

c

i

r

t

c

e

l

e

l

l

A

m

s

n

a

r

t

e

b

y

a

m

n

o

i

s

s

i

m

e

l

a

c

i

r

t

c

e

l

E

.

n

o

i

s

s

i

m

e

a

r

t

o

i

d

a

r

a

o

t

r

a

l

i

m

i

s

,

e

c

a

p

s

h

g

u

o

r

h

t

d

e

t

a

i

d

a

r

i

l

a

c

i

r

t

c

e

l

e

,

t

n

e

m

p

i

u

q

e

r

e

h

t

o

y

b

d

e

v

i

e

c

e

r

e

r

a

o

s

d

n

i

k

y

n

a

m

t

c

e

f

f

a

y

a

m

s

n

o

i

s

s

i

m

e

l

a

c

i

r

t

c

e

l

E

T

d

n

a

o

i

d

a

r

,

t

n

e

m

p

i

u

q

e

g

n

i

d

l

e

w

y

b

r

a

e

n

r

e

h

t

o

o

c

,

s

m

e

t

s

y

s

e

n

o

h

p

e

l

e

t

,

s

e

n

i

h

c

a

m

d

e

l

l

o

r

t

n

o

c

n

o

i

t

u

a

c

e

r

p

a

r

t

x

e

d

n

a

t

l

u

s

e

r

y

a

m

e

c

n

e

r

e

f

r

e

t

n

i

c

i

t

s

e

m

o

d

a

n

i

d

e

s

u

s

i

e

c

r

u

o

s

r

e

w

o

p

g

n

i

d

l

e

w

E

S

U

D

N

A

N

O

I

T

A

L

L

A

T

S

N

I

u

d

n

a

g

n

i

l

l

a

t

s

n

i

r

o

f

e

l

b

i

s

n

o

p

s

e

r

s

i

r

e

s

u

e

h

T

n

o

i

t

c

u

r

t

s

n

i

s

’

r

e

r

u

t

c

a

f

u

n

a

m

e

h

t

o

t

g

n

i

d

r

o

c

c

a

t

e

b

l

l

a

h

s

t

i

n

e

h

t

d

e

t

c

e

t

e

d

e

r

a

s

e

c

n

a

b

r

u

t

s

i

d

h

t

e

v

l

o

s

e

r

o

t

t

n

e

m

p

i

u

q

e

g

n

i

d

l

e

w

e

h

t

f

o

r

e

s

u

I

.

r

e

r

u

t

c

a

f

u

n

a

m

e

h

t

f

o

e

c

n

a

t

s

i

s

s

a

l

a

c

i

n

h

c

e

t

n

u

o

r

g

(

g

n

i

h

t

r

a

e

s

a

e

l

p

m

i

s

s

a

e

b

y

a

m

n

o

i

t

c

a

o

c

e

v

l

o

v

n

i

d

l

u

o

c

t

i

s

e

s

a

c

r

e

h

t

o

n

I

.

e

t

o

N

e

e

s

r

u

o

s

r

e

w

o

p

e

h

t

g

n

i

s

o

l

c

n

e

n

e

e

r

c

s

c

i

t

e

n

g

a

m

l

e

s

e

s

a

c

l

l

a

n

I

.

s

r

e

t

l

i

f

t

u

p

n

i

d

e

t

a

i

c

o

s

s

a

h

t

i

w

a

y

e

h

t

e

r

e

h

w

t

n

i

o

p

e

h

t

o

t

d

e

c

u

d

e

r

e

b

t

s

u

m

e

f

a

s

r

o

f

d

e

h

t

r

a

e

e

b

t

o

n

y

a

m

r

o

y

a

m

t

i

u

c

r

i

c

g

n

i

d

l

e

w

e

h

T

:

e

t

o

N

a

h

C

a

o

t

g

n

i

E

S

S

A

e

r

o

f

e

B

s

s

e

s

s

a

T

.

a

e

r

a

o

.

a

a

a

r

.

b

c

.

c

s

.

d

h

t

.

e

h

e

.

f

h

t

.

g

e

c

h

t

.

h

a

e

e

h

t

g

n

i

g

n

h

t

e

h

w

s

s

e

c

c

r

u

t

e

r

t

n

e

r

r

u

c

N

E

M

S

S

g

n

i

l

l

a

t

s

n

i

f

o

t

n

e

m

w

o

l

l

o

f

e

h

p

p

u

s

r

e

h

t

l

e

b

,

e

v

o

b

t

d

n

a

o

i

d

a

r

e

t

u

p

m

o

i

t

i

r

c

y

t

e

f

a

h

t

l

a

e

h

e

d

i

a

g

n

i

r

a

e

t

n

e

m

p

i

u

q

n

u

m

m

i

e

a

h

t

e

r

u

s

n

e

l

b

i

t

a

p

m

o

f

o

e

m

i

t

e

g

n

a

r

r

a

g

n

i

h

t

r

g

n

a

h

c

e

h

t

r

e

c

i

h

w

s

h

t

a

p

n

A

F

O

T

g

n

i

d

l

e

w

l

a

i

t

n

e

t

o

p

l

l

a

h

s

g

n

i

,

s

e

l

b

a

c

y

l

d

a

d

n

a

w

o

n

o

i

s

i

v

e

l

e

r

e

h

t

o

d

n

m

p

i

u

q

e

l

a

c

o

e

p

e

h

t

f

o

;

s

r

o

f

d

e

s

u

e

h

t

o

f

o

y

t

i

q

e

r

e

h

t

o

t

a

m

s

i

h

T

.

t

a

h

t

y

a

d

u

o

h

s

s

t

n

e

m

e

a

e

r

c

n

i

l

l

i

w

s

e

a

m

a

d

y

a

m

h

A

E

R

e

m

p

i

u

q

e

m

o

r

t

c

e

l

e

n

e

k

a

t

e

b

a

c

l

o

r

t

n

o

c

o

t

t

n

e

c

a

j

e

t

t

i

m

s

n

a

r

t

q

e

l

o

r

t

n

o

c

.

g

.

e

,

t

n

e

n

u

o

r

a

e

l

p

n

o

i

t

a

r

b

i

l

a

c

m

p

i

u

q

e

r

b

t

n

e

m

p

i

u

e

r

i

u

q

e

r

y

o

g

n

i

d

l

e

w

u

a

e

b

y

l

n

o

d

l

f

o

k

s

i

r

e

h

t

e

s

c

h

t

r

a

e

e

h

t

e

g

s

u

e

h

t

t

n

p

c

i

t

e

n

g

a

c

c

a

o

t

n

i

n

g

i

s

,

s

e

l

b

i

d

l

e

w

e

h

t

e

r

d

n

a

s

r

;

t

n

e

m

p

i

u

g

n

i

d

r

a

u

g

,

h

t

,

.

g

.

e

,

d

s

a

e

m

r

o

e

h

t

n

i

t

n

e

d

e

s

u

g

n

i

e

l

a

n

o

i

t

i

d

d

a

c

a

r

e

h

t

o

r

n

m

s

e

r

o

n

c

t

e

n

c

r

t

t

u

Y

r

o

m

m

d

u

t

i

n

t

f

V

s

e

i

s

h

e

d

n

e

y

h

n

i

r

i

e

o

u

a

g

e

e

e

p

i

t

SAFETY

e

h

t

n

o

d

n

e

p

e

d

l

l

i

w

d

e

r

e

d

i

s

n

o

c

e

b

o

t

a

e

r

a

g

n

i

d

n

u

o

r

r

u

s

e

h

t

f

o

e

z

i

s

e

h

C

I

T

E

N

)

C

M

E

(

n

a

e

p

o

r

u

E

h

t

i

w

y

t

i

m

o

n

o

i

t

a

m

i

x

o

r

p

p

a

e

h

t

n

y

t

i

l

i

b

i

t

a

p

m

o

c

c

i

t

e

n

g

a

l

a

n

o

i

t

a

n

a

h

t

i

w

y

t

i

0

1

-

4

7

9

0

6

N

E

:

d

r

a

d

l

e

W

c

r

A

r

o

f

d

r

a

d

n

a

t

S

s

i

t

I

.

t

n

e

m

p

i

u

q

e

c

i

r

t

c

t

e

n

g

a

m

o

r

t

c

e

l

e

f

o

s

t

n

n

i

l

r

e

w

o

p

h

g

u

o

r

h

t

d

e

t

i

s

s

i

m

e

n

e

h

W

.

r

e

t

t

i

m

s

.

t

l

u

s

e

r

y

a

m

e

c

n

e

r

e

f

r

e

;

t

n

e

m

p

i

u

q

e

l

a

c

i

r

t

c

e

l

e

a

c

i

r

e

m

u

n

,

n

o

i

t

p

e

c

e

r

e

r

a

w

a

e

B

.

c

t

e

,

s

r

e

t

u

p

e

h

w

d

e

r

i

u

q

e

r

e

b

y

a

m

.

t

n

e

m

h

s

i

l

b

a

t

s

p

i

u

q

e

g

n

i

d

l

e

w

e

h

t

g

n

c

i

t

e

n

g

a

m

o

r

t

c

e

l

e

f

I

.

e

h

t

f

o

y

t

i

l

i

b

i

s

n

o

p

s

e

r

e

e

h

t

h

t

i

w

n

o

i

t

a

u

t

i

s

m

e

r

s

i

h

t

s

e

s

a

c

e

m

o

s

c

r

i

c

g

n

i

d

l

e

w

e

h

t

)

g

n

i

r

t

c

e

l

e

n

a

f

o

n

o

i

t

c

u

r

t

s

p

m

o

c

k

r

o

w

e

h

t

d

n

a

e

b

r

u

t

s

i

d

c

i

t

e

n

g

a

m

o

r

t

c

o

s

e

l

b

u

o

r

t

r

e

g

n

o

l

o

n

a

n

o

i

t

a

n

o

t

g

n

i

d

r

o

c

c

a

s

n

o

s

a

e

r

z

i

r

o

y

r

u

j

s

t

i

u

c

s

r

e

l

b

t

n

n

i

l

e

e

v

i

i

f

o

s

u

m

e

r

i

v

n

t

n

i

o

r

i

t

i

v

o

s

r

e

p

a

y

b

d

e

o

l

l

a

y

b

,

.

g

.

e

,

u

q

e

r

e

h

t

o

f

o

e

k

a

m

l

l

a

h

h

t

n

i

s

m

:

e

l

e

t

d

n

a

g

;

t

n

e

m

p

i

u

q

;

s

r

e

l

a

i

r

t

s

u

d

n

e

c

a

p

f

o

e

t

n

e

.

t

n

e

m

n

o

r

o

r

i

v

n

e

e

h

e

m

n

o

i

t

c

e

t

o

t

e

r

a

s

e

m

o

c

s

i

o

h

w

n

e

l

l

a

r

a

p

g

n

i

w

.

t

n

e

m

p

i

n

a

n

u

o

r

r

u

s

e

a

c

e

n

o

h

p

n

e

m

p

i

u

q

a

s

r

e

k

a

m

r

e

s

u

e

h

T

s

i

t

n

e

m

n

;

s

e

r

u

s

a

d

e

i

r

r

a

c

e

b

T

e

h

T

.

e

c

a

l

p

g

n

i

k

a

t

e

r

a

t

a

h

t

s

e

i

t

i

v

i

t

c

a

r

e

h

t

o

d

n

a

g

n

i

d

l

i

u

b

e

h

t

f

o

e

r

u

t

c

u

r

t

s

.

s

e

s

i

m

e

r

p

e

h

t

f

o

s

e

i

r

a

d

n

u

o

b

e

h

t

d

n

o

y

e

b

d

n

e

t

x

e

y

a

m

a

e

r

a

g

n

i

d

n

u

o

r

r

u

s

S

N

O

I

S

S

I

M

E

G

N

I

C

U

D

E

R

F

O

S

D

O

H

T

E

M

y

l

p

p

u

S

s

n

i

a

M

e

h

t

f

i

a

m

e

h

t

o

t

d

e

t

c

e

n

n

o

c

e

b

d

l

u

o

h

s

t

n

e

m

p

i

u

q

e

g

n

i

d

l

e

W

.

s

n

o

i

t

a

d

n

e

m

m

o

c

e

r

s

’

r

e

r

u

t

c

a

f

u

n

a

m

e

h

t

o

t

g

n

i

d

r

o

c

c

a

a

c

e

r

p

l

a

n

o

i

t

i

d

d

a

e

k

a

t

o

t

y

r

a

s

s

e

c

e

n

e

b

y

a

m

t

i

,

s

r

u

c

c

o

b

d

l

u

o

h

s

n

o

i

t

a

r

e

d

i

s

n

o

C

.

y

l

p

p

u

s

s

n

i

a

m

e

h

t

f

o

g

n

i

r

e

t

l

i

f

g

n

i

y

l

t

n

e

n

a

m

r

e

p

f

o

e

l

b

a

c

y

l

p

p

u

s

e

h

t

g

n

i

d

l

e

i

h

s

n

e

l

a

v

i

u

q

e

r

o

t

i

u

d

n

o

c

c

i

l

l

a

t

e

m

n

i

,

t

n

e

m

p

i

u

q

e

t

g

n

e

l

s

t

i

t

u

o

h

g

u

o

r

h

t

s

u

o

u

n

i

t

n

o

c

y

l

l

a

c

i

r

t

c

e

l

e

o

s

e

c

r

u

o

s

r

e

w

o

p

g

n

i

d

l

e

w

e

h

t

o

t

d

e

t

c

e

n

n

o

c

e

h

t

d

n

a

t

i

u

d

n

o

c

e

h

t

n

e

e

w

t

e

b

d

e

n

i

a

t

n

i

a

m

s

i

.

e

r

u

s

o

l

c

n

e

c

i

r

o

s

e

s

n

o

l

t

a

h

t

a

n

n

e

m

a

i

d

e

,

t

i

u

-

o

e

t

e

l

e

c

n

a

.

e

m

s

e

d

o

c

l

n

e

t

e

p

-

d

l

e

w

l

g

n

i

d

;

s

e

l

b

;

t

d

n

l

l

a

h

s

.

t

u

o

n

i

a

M

w

e

h

T

m

e

h

t

c

d

n

a

p

i

u

q

e

i

d

o

m

r

e

v

o

c

s

p

a

g

n

i

a

m

d

l

e

W

t

w

e

h

T

t

i

s

o

p

i

u

q

E

l

d

n

o

B

c

a

j

d

a

d

n

o

b

i

e

c

e

r

s

t

c

e

l

e

h

c

u

s

.

t

t

r

a

E

r

e

h

W

n

n

o

c

d

l

i

u

b

c

u

d

e

r

e

r

p

o

t

s

u

o

t

c

e

h

t

n

n

o

c

n

n

o

c

a

t

i

u

s

e

r

c

S

c

e

l

e

S

s

e

h

t

e

e

r

c

S

i

c

e

p

s

1

t

r

o

P

a

p

m

o

C

c

n

a

n

e

t

e

g

n

i

d

l

e

u

t

c

a

f

u

n

a

o

h

s

s

r

e

v

o

i

s

i

t

n

e

m

n

a

n

i

d

e

i

f

e

h

t

n

i

d

e

r

t

s

c

r

a

f

o

c

a

d

e

n

i

a

t

b

a

C

g

n

i

a

c

g

n

i

d

l

e

s

o

l

c

d

e

n

o

i

i

t

n

e

t

o

p

l

l

a

f

o

g

n

i

s

t

i

o

t

t

n

e

e

h

t

o

t

d

e

c

o

h

s

a

e

v

h

t

t

a

e

d

o

r

m

d

e

d

n

o

b

f

o

g

n

i

h

r

o

w

e

h

t

e

e

o

t

d

e

t

c

e

w

l

e

e

t

s

g

n

i

o

i

s

s

i

m

e

e

e

h

t

t

n

e

v

a

d

r

o

,

s

r

e

n

o

i

t

c

e

n

n

o

o

t

n

o

i

t

c

e

n

s

i

n

o

i

t

c

e

c

a

p

a

c

e

l

b

a

g

n

i

n

e

e

e

r

c

s

e

v

i

t

n

i

d

n

u

o

r

r

u

h

t

f

o

g

n

i

n

a

c

i

l

p

p

a

l

a

e

h

t

f

o

s

n

o

i

C

M

E

(

y

t

i

l

i

b

i

t

e

h

t

f

o

e

t

n

e

m

p

i

u

q

c

e

r

s

’

r

e

r

c

e

b

d

l

u

i

t

a

r

e

p

o

n

x

e

y

a

w

y

c

a

f

u

n

a

m

d

n

a

g

n

i

k

i

t

g

n

i

d

r

o

c

s

e

l

o

h

s

s

e

l

b

h

t

e

g

o

t

e

d

n

o

B

l

a

c

i

l

l

a

t

e

m

e

b

d

l

u

o

h

e

i

p

k

r

o

w

c

u

o

t

y

b

k

t

e

m

a

s

e

c

c

i

l

l

a

t

e

r

o

W

e

h

t

s

i

e

c

e

i

p

k

c

e

b

h

t

r

a

o

c

a

,

k

r

o

o

s

n

i

s

n

g

n

i

h

t

r

a

e

o

t

e

g

a

m

w

e

h

t

f

o

k

r

o

w

e

h

t

m

r

e

p

t

o

s

,

e

c

n

a

t

i

e

i

h

S

d

n

d

n

a

g

n

i

n

m

a

e

r

a

g

e

r

i

t

n

e

e

.

s

n

o

i

t

t

g

n

i

d

e

c

e

r

p

s

t

c

u

d

o

r

p

)

n

i

d

l

e

W

b

d

l

u

o

h

s

a

d

n

e

m

m

o

d

n

a

d

e

s

o

l

w

e

h

T

.

n

o

h

t

r

o

f

t

p

e

c

s

n

i

s

r

e

r

u

t

n

i

z

i

l

i

b

a

t

s

n

a

m

e

h

t

o

e

k

e

b

d

l

u

n

i

n

n

u

r

,

r

e

g

n

i

n

e

n

o

p

m

o

c

r

e

d

i

s

n

o

c

c

n

i

l

l

i

w

e

c

s

e

h

t

g

n

i

h

e

h

T

.

e

m

i

n

e

n

o

p

m

o

e

c

e

i

p

k

d

n

o

b

t

o

n

s

t

i

f

o

e

s

u

a

n

o

i

t

c

e

n

n

n

t

u

b

,

e

m

o

w

e

h

t

f

o

c

e

l

e

r

e

h

t

o

e

c

e

i

p

k

r

o

u

b

,

e

c

e

i

p

e

h

t

,

d

e

t

t

i

c

a

d

e

t

c

e

l

e

g

n

i

d

l

g

n

i

d

l

e

i

h

s

a

i

v

e

l

l

a

y

a

i

g

n

i

d

l

e

w

t

n

o

c

e

r

a

t

x

e

r

o

f

d

r

a

d

n

a

t

p

i

u

q

E

g

y

l

e

n

i

t

u

o

r

e

l

l

A

.

s

n

o

i

t

y

l

r

e

p

o

r

p

u

q

e

g

n

i

d

l

e

n

a

h

c

e

s

o

.

s

n

o

i

t

c

u

r

t

s

e

c

i

v

e

d

g

r

e

r

u

t

c

a

f

u

r

o

h

s

s

a

t

p

o

l

c

r

o

t

a

g

w

e

h

t

n

i

s

t

v

e

w

o

H

.

d

e

e

h

t

e

s

a

e

r

c

i

l

l

a

t

e

m

e

s

r

o

t

a

r

e

p

o

.

s

t

t

r

a

e

o

t

d

e

d

n

a

e

z

i

s

t

g

n

i

d

n

o

b

a

t

s

n

i

l

l

a

t

o

n

i

e

c

e

i

p

k

r

u

q

e

l

a

c

i

r

t

s

h

t

r

a

e

o

t

e

m

o

s

n

i

t

s

g

n

i

d

n

o

b

o

t

g

n

i

d

r

o

c

r

e

h

t

o

f

o

m

e

l

b

o

r

p

e

t

n

o

i

t

a

l

l

a

t

s

n

N

E

n

i

d

e

n

i

a

g

n

i

d

l

e

w

c

r

a

i

m

a

f

g

’

h

h

h

6

d

e

l

l

a

t

s

n

d

l

e

i

h

S

.

t

h

s

e

h

T

.

h

d

o

o

g

t

a

h

t

g

n

i

d

l

e

w

t

n

e

n

i

a

t

n

i

a

m

n

a

s

s

e

c

c

d

e

n

e

t

s

a

s

t

n

e

m

p

i

a

d

n

a

s

e

u

c

i

t

r

a

p

n

I

b

d

l

u

o

h

s

m

m

o

c

e

r

s

s

s

o

p

s

a

t

o

o

l

f

o

t

e

s

n

i

g

n

i

d

l

e

l

a

t

e

m

,

r

e

t

a

h

t

k

s

i

r

e

n

o

p

m

o

c

e

b

d

l

u

o

h

c

e

l

e

r

o

f

h

,

n

o

i

t

i

s

o

p

p

k

r

o

w

e

a

C

.

s

e

c

n

g

n

i

s

a

e

r

c

W

.

t

n

e

m

p

i

e

b

d

l

u

o

s

e

i

r

t

n

u

o

c

e

b

d

l

u

o

l

a

n

o

i

t

a

n

n

a

s

e

l

b

a

c

e

t

n

i

f

o

s

c

e

b

y

a

m

“

:

0

1

-

4

7

9

0

.

t

n

e

m

p

i

u

q

e

y

l

p

p

u

s

s

n

e

c

n

e

r

e

f

r

e

t

n

i

f

I

s

a

h

c

u

s

s

n

o

i

t

u

o

t

n

e

v

i

g

e

g

n

i

d

l

e

w

e

b

d

l

u

o

h

s

g

n

i

e

b

d

l

u

o

h

s

g

n

i

d

l

e

i

t

c

a

t

n

o

c

l

a

c

i

r

t

c

e

l

e

e

c

r

u

o

s

r

e

w

o

p

o

t

g

n

i

d

r

o

c

c

a

d

e

s

r

o

o

d

e

c

i

v

r

e

s

d

g

n

i

d

l

e

w

e

h

t

n

e

h

w

e

b

t

o

n

d

l

u

o

h

s

t

n

e

m

t

s

u

j

d

k

r

a

p

s

e

h

t

,

r

a

l

d

n

a

d

e

t

s

u

j

d

a

e

.

s

n

o

i

t

a

d

n

e

e

b

d

l

u

o

h

s

d

n

a

e

l

b

i

.

l

e

v

e

l

r

d

n

a

n

o

i

t

a

l

l

a

t

s

s

t

n

e

n

o

p

m

o

c

c

i

l

d

l

u

o

c

r

o

t

a

r

e

p

o

e

h

t

e

h

t

d

n

a

s

t

n

l

l

a

m

o

r

f

d

e

t

a

l

u

s

n

i

t

o

n

,

y

t

e

f

a

s

l

a

c

i

r

t

r

o

l

l

u

h

s

p

i

h

s

,

.

g

.

e

y

a

m

h

t

r

a

e

o

t

e

c

e

i

n

e

k

a

t

e

b

d

l

u

o

h

s

e

r

y

r

u

j

n

i

f

o

k

s

i

r

e

h

t

,

y

r

a

s

s

e

c

e

n

e

r

e

h

t

c

e

r

i

d

a

y

b

e

d

a

m

t

c

e

r

i

d

e

r

e

h

w

y

b

d

e

v

e

i

h

c

a

.

s

n

o

i

t

a

l

u

g

e

r

n

i

t

n

e

m

p

i

u

q

e

d

.

e

c

n

e

r

e

f

r

r

o

f

d

e

r

e

d

i

s

n

o

c

i

t

e

n

g

a

m

o

r

t

c

e

l

E

”

TABLE OF CONTENTS

Page

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––-–––––––––

Graphic Symbols that appear on this Machine or in this Manual........................................................................7

Definition of Welding Terms..............................................................................................................................7

General Description, Recommended Process, Equipment Limitations, Recommended Power Sources ..............8

Installation ................................................................................................................................................Section A

Technical Specifications................................................................................................................................A-1

Safety Precautions ........................................................................................................................................A-2

Location........................................................................................................................................................A-2

High Frequency Protection ............................................................................................................................A-2

Arclink Control Cable.....................................................................................................................................A-3

Cable Connections ........................................................................................................................................A-3

Weld cable Sizes...........................................................................................................................................A-4

Coaxial Weld Cable .......................................................................................................................................A-4

Shielding Gas Connection..............................................................................................................................A-5

Changing The Drive Motor Gears ...........................................................................................................A-5, A-6

Wire Drive Configuration ...............................................................................................................................A-7

Procedure to Install Drive Rolls and Wire Guides............................................................................................A-7

Remote Sense Lead Specification .................................................................................................................A-8

Loading Spools of Wire .................................................................................................................................A-9

Typical System Configurations ......................................................................................................................A-9

_________________________________________________________________________________________

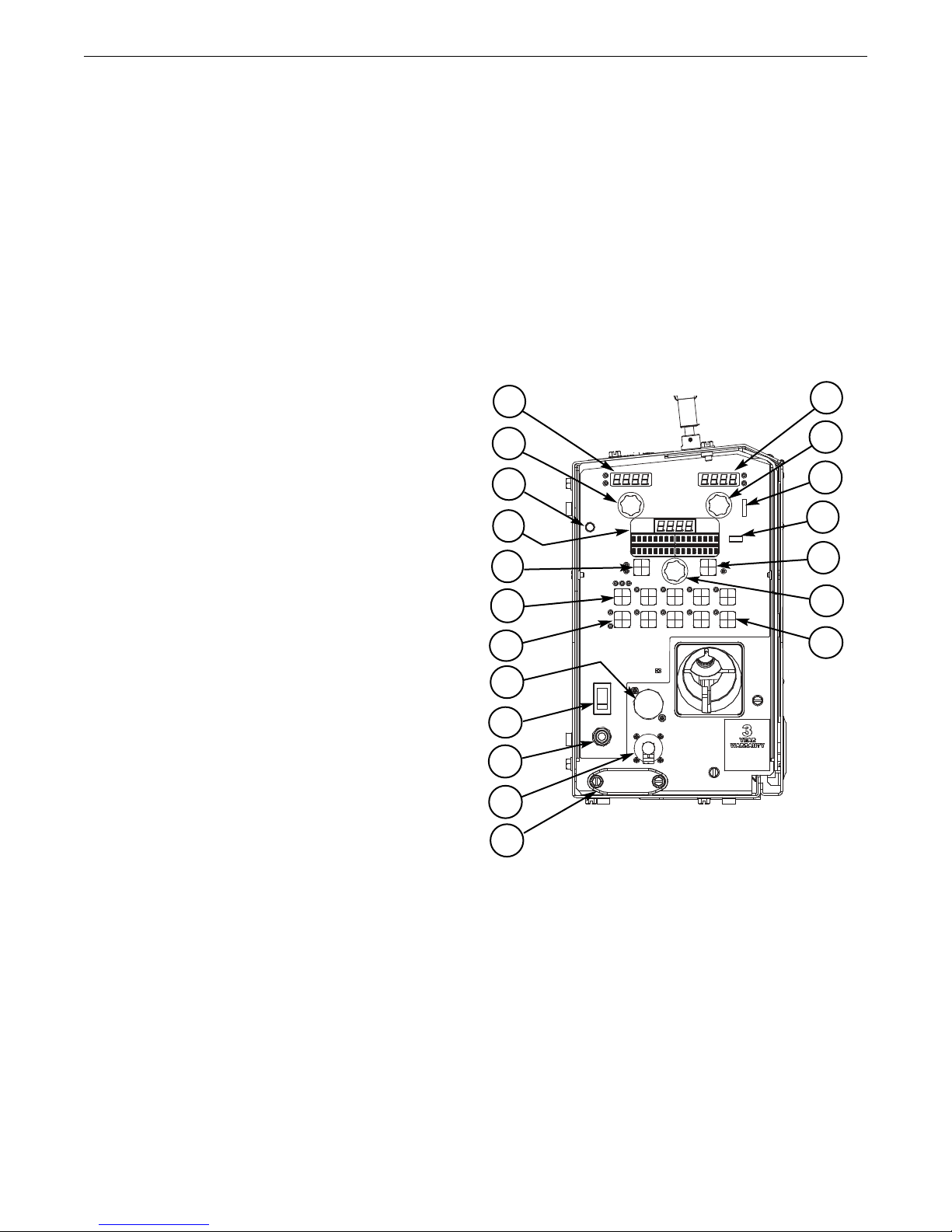

Operation ..................................................................................................................................................Section B

Safety Precautions ........................................................................................................................................B-1

Duty Cycle ....................................................................................................................................................B-1

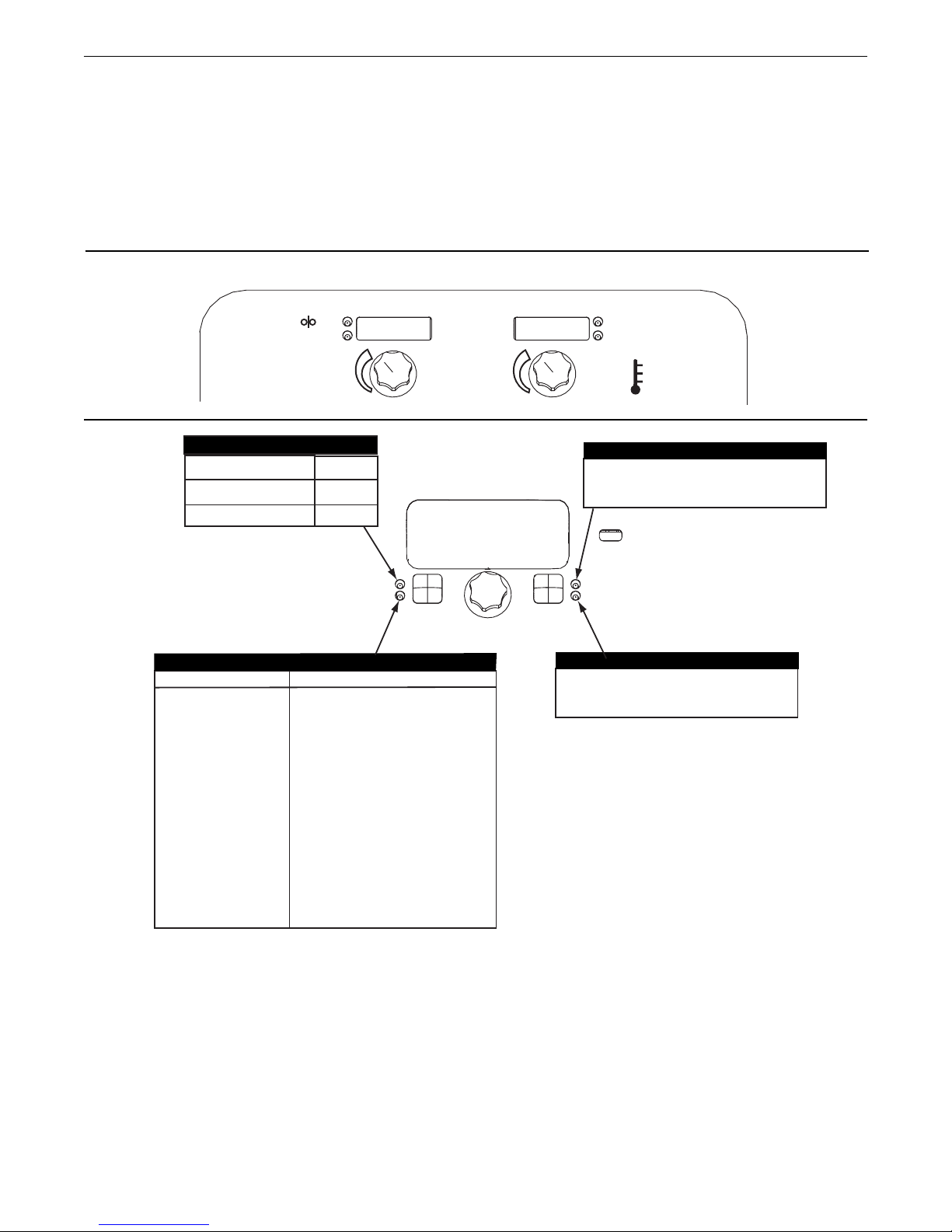

Case Front Controls.......................................................................................................................................B-2

On-Off Switch ...............................................................................................................................................B-3

Power Wave System Operation......................................................................................................B-4 thru B-20

Set-Up Feature Menu for Parameters and Definition ...................................................................B-21 thru B-29

Dual Procedure/Memory Buttons.................................................................................................B-30 thru B-32

Internal Controls .........................................................................................................................................B-33

Cold Feed / Gas Purge Switch, Light Switch, Heater Switch, Pressure Arm Adjustment ...............................B-34

2 Step - 4 Step Trigger Operation and Graphics...........................................................................B-35 thru B-40

Rear Controls..............................................................................................................................................B-41

Flow Meter..................................................................................................................................................B-42

_________________________________________________________________________________________

Accessories ...............................................................................................................................................Section C

Factory Installed Equipment ..........................................................................................................................C-1

Drive Roll Kits ..............................................................................................................................................C-1

Common Packages with Accessories Used......................................................................................C-2 thru C-3

Installation of Water Cooling Kit .............................................................................................................C-4, C-5

Water Cooled Guns .......................................................................................................................................C-6

_________________________________________________________________________________________

Maintenance..............................................................................................................................................Section D

Safety Precautions........................................................................................................................................D-1

Routine Maintenance ....................................................................................................................................D-1

Periodic Maintenance ...................................................................................................................................D-1

Calibration Specification ...............................................................................................................................D-1

________________________________________________________________________________________

Troubleshooting.........................................................................................................................................Section E

How to Use Troubleshooting Guide ................................................................................................................E-1

Error Fault Codes ..........................................................................................................................................E-2

Troubleshooting Guide.....................................................................................................................E-3 thru E-4

_________________________________________________________________________________________

Wiring Diagrams & Dimension Prints .......................................................................................................Section F

_________________________________________________________________________________________

Parts List .........................................................................................................................parts.lincolnelectric.com

Content/details may be changed or updated without notice. For most current Instruction Manuals, go to

parts.lincolnelectric.com.

_______________________________________________________________________

________________

POWER FEED®25M & 25M ALUMINUM

GENERAL DESCRIPTION

GRAPHIC SYMBOLS T HAT APPEAR ON THIS

MACHINE OR IN THIS MANUAL

INPUT POWER

ON

OFF

WIRE FEEDER

POSITIVE OUTPUT

NEGATIVE OUTPUT

INPUT POWER

DEFINITION OF WELDING TERMS

NON-SYNERGIC WELDING MODES

• A Non-synergic welding mode requires all welding process

variables to be set by the operator.

SYNERGIC WELDING MODES

• A Synergic welding mode offers the simplicity of single knob

control. The machine will select the correct voltage and

amperage based on the wire feed speed (WFS) set by the

operator.

WFS

• Wire Feed Speed

CC

• Constant Current

CV

• Constant Voltage

GMAW

• Gas Metal Arc Welding

GMAW-P

• Gas Metal Arc Welding-(Pulse Arc)

DIRECT CURRENT

GMAW-STT

U

0

U

1

U

2

I

1

I

2

OPEN CIRCUIT

VOLTAGE

INPUT VOLTAGE

OUTPUT VOLTAGE

INPUT CURRENT

OUTPUT CURRENT

• Gas Metal Arc Welding-(Surface Tension Transfer)

SMAW

• Shielded Metal Arc Welding

FCAW

• Flux Core Arc Welding

CAG

• Carbon Arc Gouging

PROTECTIVE GROUND

WARNING OR

CAUTION

4

POWER FEED®25M & 25M ALUMINUM

GENERAL DESCRIPTION

GENERAL DESCRIPTION

General Physical Description

The POWER FEED®25M is a premium portable wire feeder for

use with the Power Wave products. The wire feeder features a 2

roll MAXtrac®drive coupled to a powerful motor for driving wire

through difficult situations. The easy-to-use, user interface

rovides ready access to all welding modes in the Power Wave.

p

Built in memories are included with the POWER FEED

allows quick recall of favorite weld procedures. Two cases are

available: an engineered aluminum case with replaceable skids,

or an impact resistant polycarbonate plastic case.

The heart of the POWER FEED®25M is the MAXtrac®drive. The

patented features on the wire drive offer tool-less changing of

the drive rolls and the wire guides for quick spool changes.

Plus, the drive can be configured for extra torque when feeding

large diameter flux cored electrodes.

The POWER FEED®25M continues Lincoln’s lead role of

environmental protection for electronics. P.C. boards are potted

in epoxy and electrical connections are protected with dielectric

grease. Noise suppression components protect the POWER

FEED®25M from stray signals and keep the feeder from

interfering with other digital equipment.

®

25M and

RECOMMENDED PROCESSES

GMAW (CV, Synergic CV, Pulse, STT

•

®

Power, Pulse on Pulse

,

Push-Pull)

• FCAW

• SMAW

GTAW (Lift Start only)

•

Solid wires .025" to 1/16"

•

• Cored wires .035" to 5/64"

• Cored wires .035" to 3/32" when configured for "extra torque"

®

EQUIPMENT LIMITATIONS

• Works only on ArcLink®Power Wave power sources.

• Maximum gun length is 25ft.(7.6m) for push-only systems.

• Maximum gun length is 50ft.(15.2m) for push-pull systems.

• A remote control/foot amptrol and a push-pull gun may not be

connected to the POWER FEED®25M simultaneously.

• Maximum spool size is 12 in. (305 mm) diameter

• Maximum spool weight is 44 lb (20 kg).

• Maximum control cable length is 200 ft (61 m).

• Other gun bushings are required for welding guns that do not

have a Magnum®(Tweco #2-#4 compatible) back end.

• No more than 2 wire feeders may be connected to one ArcLink

power source at a time.

,

General Functional Description

The POWER FEED®25M is best suited for applications were quality

welds are expected. Combined with a Power Wave power source,

the POWER FEED®25M is great for aluminum, nickel, alloy and

other difficult to weld materials. Easy to use controls make it a

great feeder for consistent results with mild steel applications too.

DUTY CYCLE

The POWER FEED®25M is rated for 500 amps, 60% duty cycle.

The duty cycle is based on a 10 minute cycle.

For example, when welding at 500 amps, the POWER FEED

25M may run continuously for 6 minutes and then must sit idle

for 4 minutes.

®

RECOMMENDED POWER SOURCES

• Power Wave®355M

• Power Wave®455M

• Power Wave®455M/STT

• Power Wave®655/R

• Power Wave®S350

• Power Wave®R350

• Power Wave®i400

5

POWER FEED®25M & 25M ALUMINUM

INSTALLATION

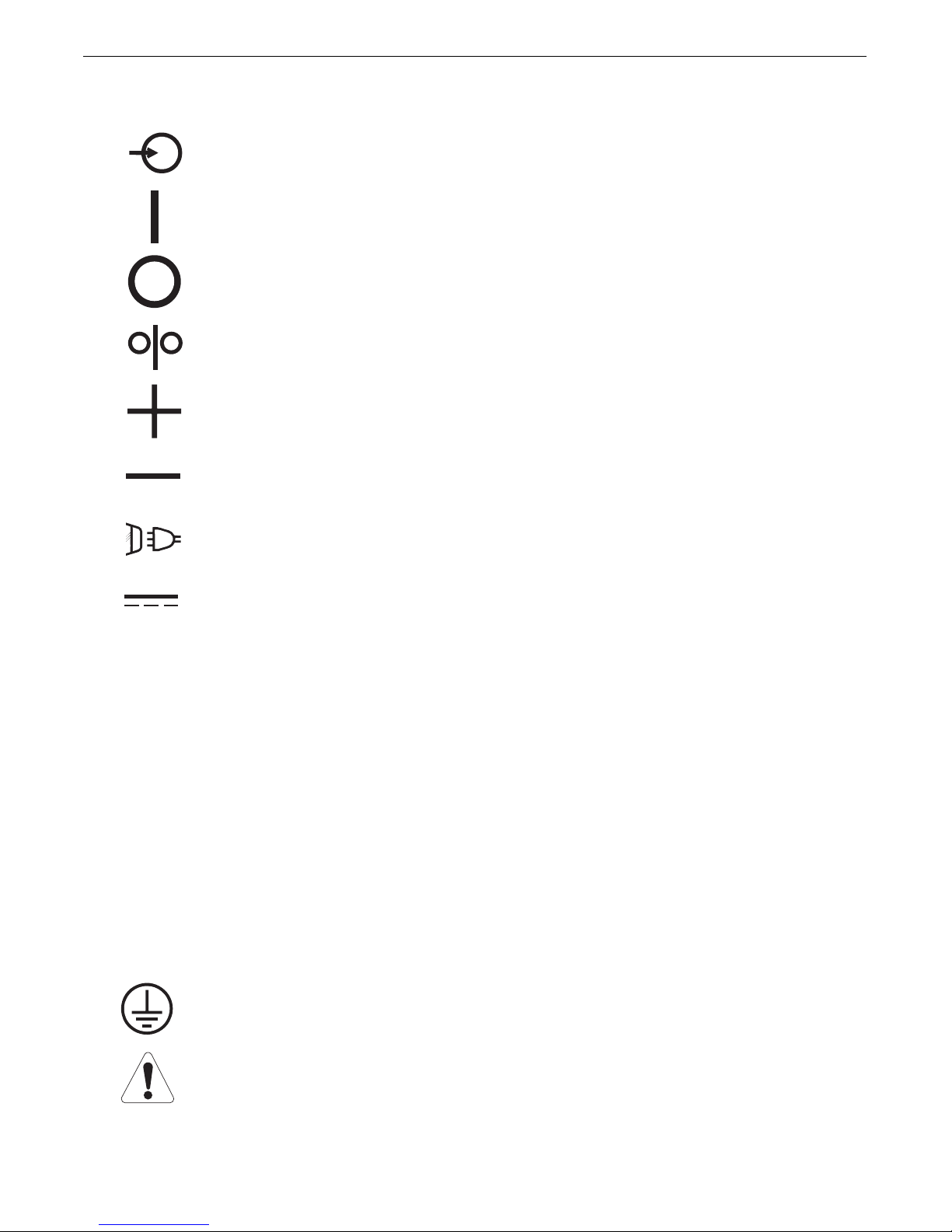

TECHNICAL SPECIFICATIONS –

INPUT VOLTAGE and CURRENT

NPUT AMPERES

NPUT VOLTAGE ± 10%

I

40 VDC

I

RATED OUTPUT @ 104°F (40°C)

DUTY CYCLE

60% rating

INPUT AMPERES

GEARING - WIRE FEED SPEED RANGE-WIRE SIZE

GMAW

GEARING

Normal Speed

(factory setting)

Extra torque

WFS RANGE

50 – 800 ipm

(2.5 – 20.3m/min)

30 – 400 ipm

(1.3 – 10.4m/min)

POWER FEED®25M K2536-4, -5, 25M ALUMINUM K4191-1

4A

500

FCAW

WIRE SIZES

.023 – 1/16"

(0.6 – 1.6mm)

.023 – 1/16"

(0.6 – 1.6mm)

WFS RANGE

50 – 800 ipm

(2.5 – 20.3m/min)

30 – 400 ipm

(1.3 – 10.4m/min)

WIRE SIZES

.030 – 5/64"

(0.8 – 2.0mm)

.030 – 3/32"

(0.8 – 2.4mm)

PHYSICAL DIMENSIONS

HEIGHT WIDTH DEPTH WEIGHT

14.5 Inches 8.5 Inches 23.5 Inches 35 lbs

(368 mm) ( 216 mm) (597 mm) (15.9 kg)

Handle folded down

TEMPERATURE RANGE

OPERATION: -40°F to 122°F (-40°C to 50°C)

STORAGE: -40°F to 185°F (-40°C to 85°C)

IP23

A-1

POWER FEED®25M & 25M ALUMINUM

INSTALLATION

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn the input power OFF at the welding

power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger,

electrode and drive mechanism are "hot"

to work and ground and could remain

energized several seconds after the gun

trigger is released.

• Welding power source must be connected to system

ground per the National Electrical Code or any applicable

local codes.

• Only qualified personnel should perform maintenance

work.

--------------------------------------------------------------------

LOCATION

For best wire feeding performance, place the POWER FEED®25M

on a stable and dry surface. Keep the wire feeder in a vertical

position. Do not operate the wire feeder on an angled surface of

more than 15 degrees.

HIGH FREQUENCY PROTECTION

CAUTION

Locate the POWER FEED®25M away from radio controlled

machinery. The normal operation of the POWER FEED®25M

ma y adversely affect the opera tion of RF co ntrolled

quipment, which may result in bodily injury or damage to the

e

equipment.

--------------------------------------------------------------------

Do not submerge the POWER FEED®25M.

The POWER FEED®25M is rated IP23 and is suitable for outdoor

use.

The handle of the POWER FEED®25M is intended for moving the

wire feeder about the work place only.

When suspending a wire feeder, insulate the hanging device from

the wire feeder enclosure.

A-2

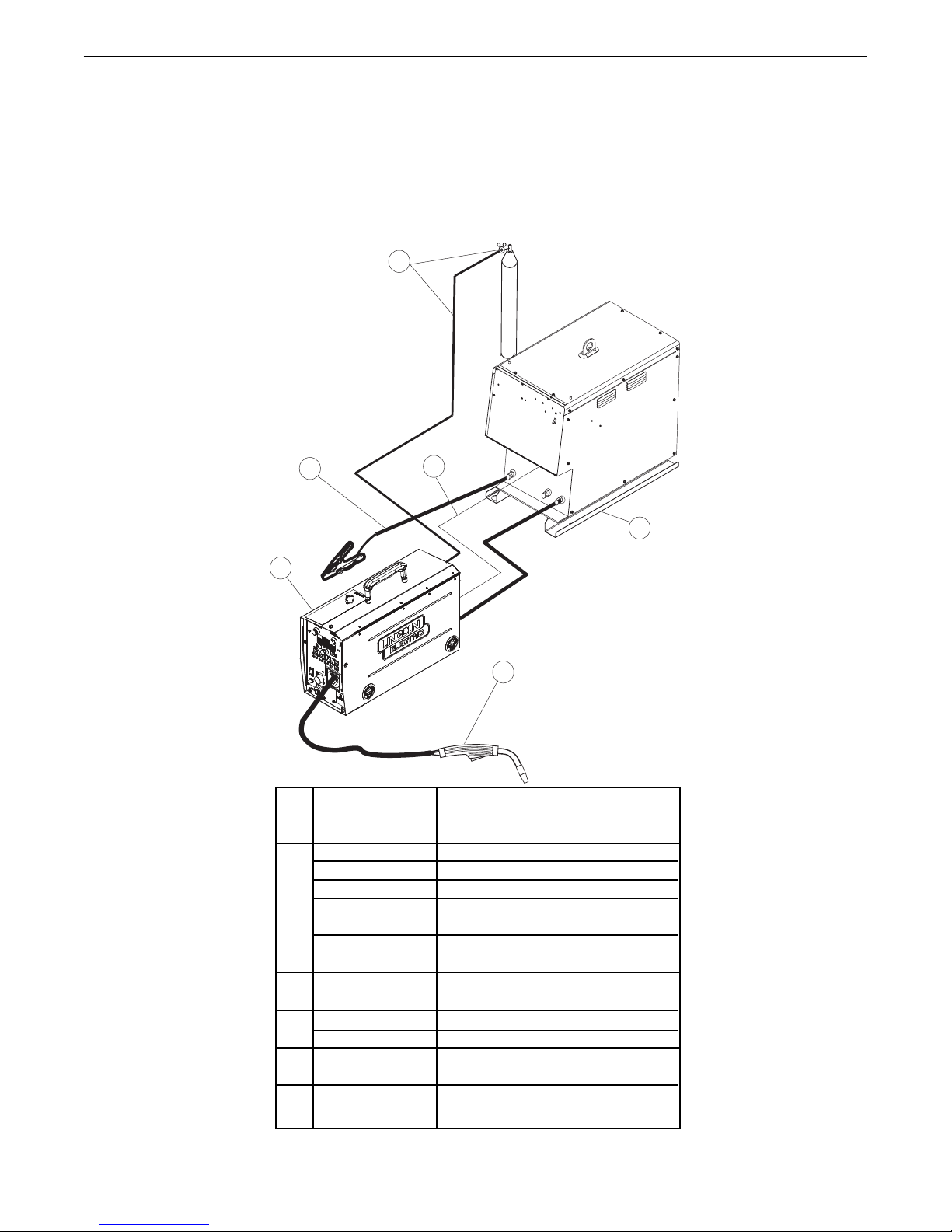

POWER FEED®25M & 25M ALUMINUM

AA

CC

BB

DD

EE

A

A

BB

CC

D

D

EE

POWER SOURCE

WIRE FEEDER

A

B

H

G

F

E

D

C

K

J

M

L

AA

BB

CC

DD

EE

INSTALLATION

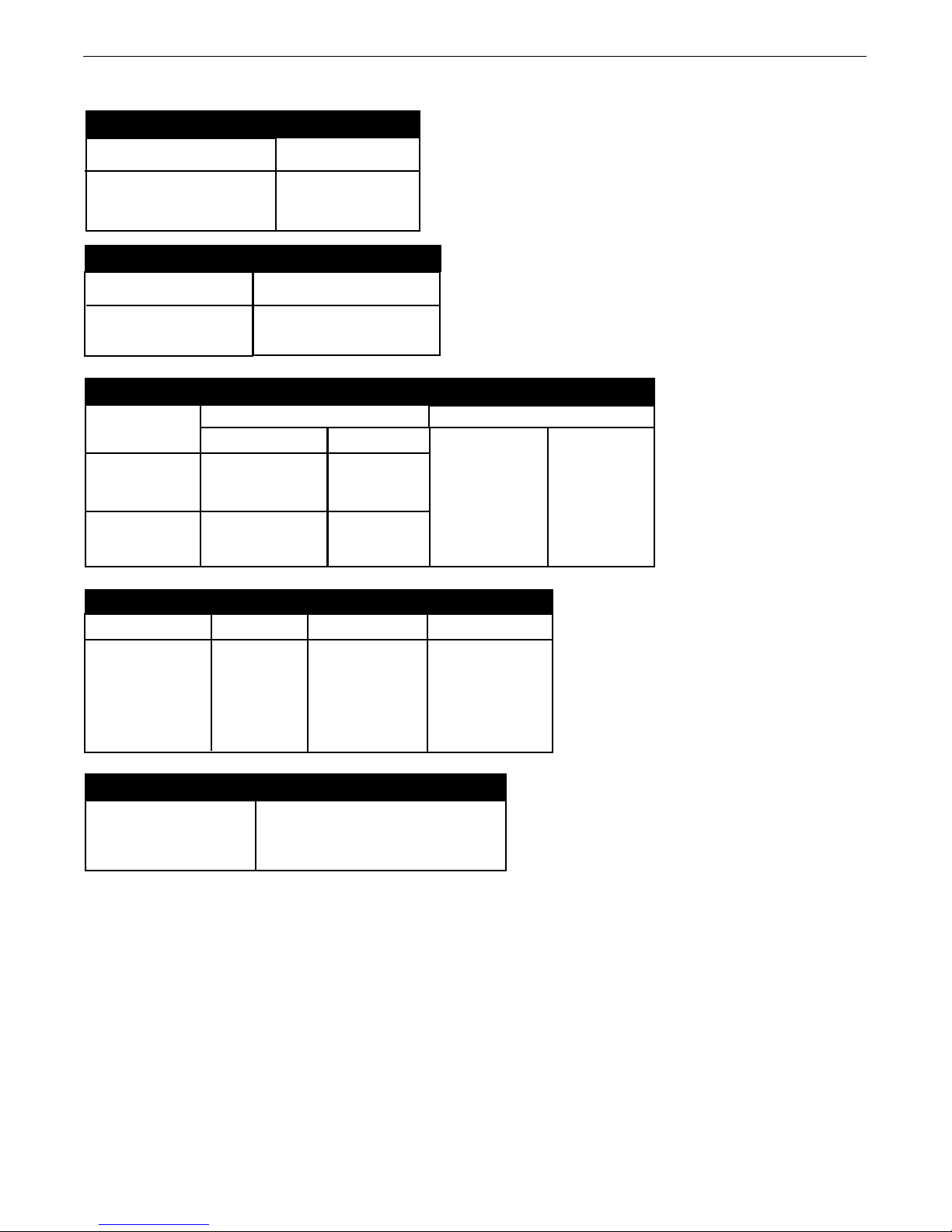

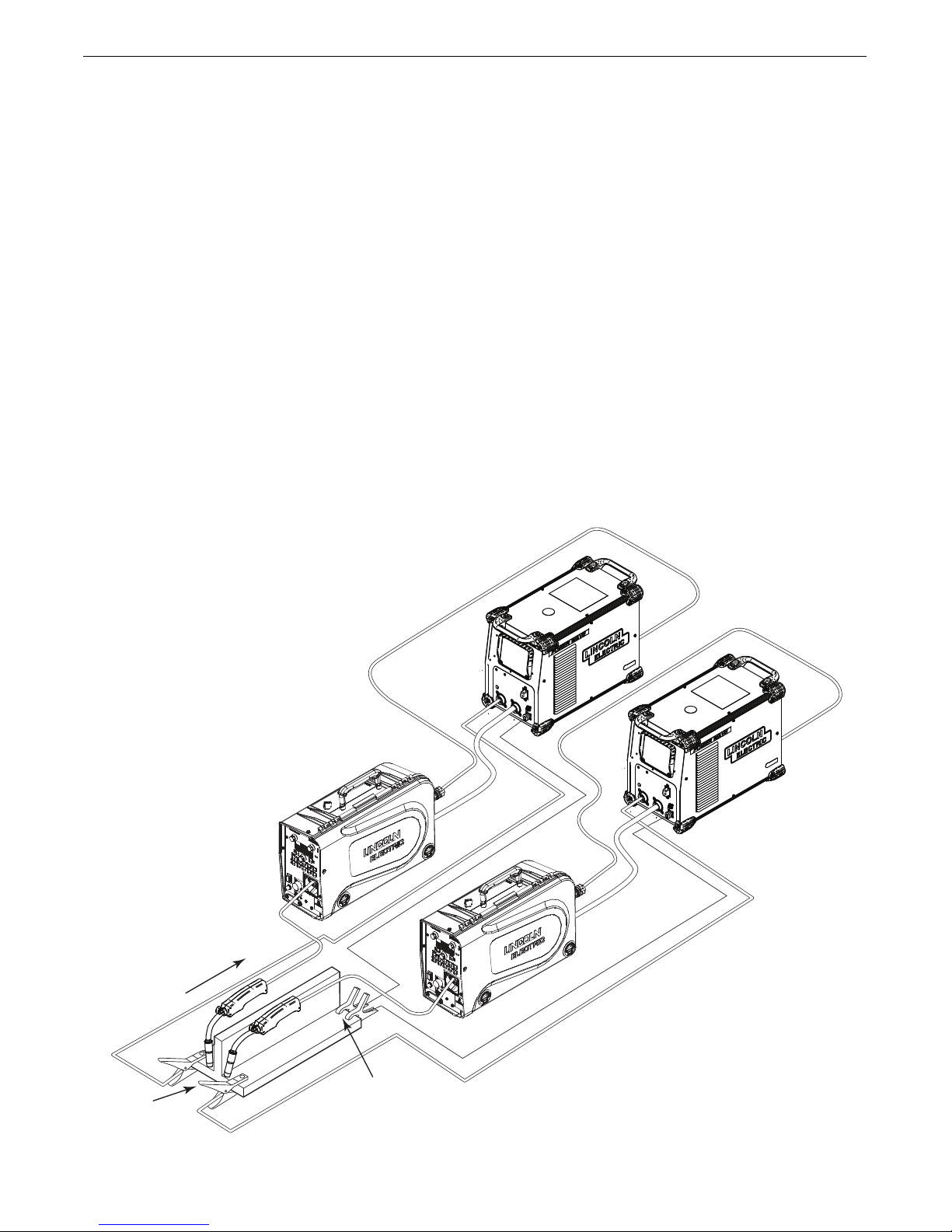

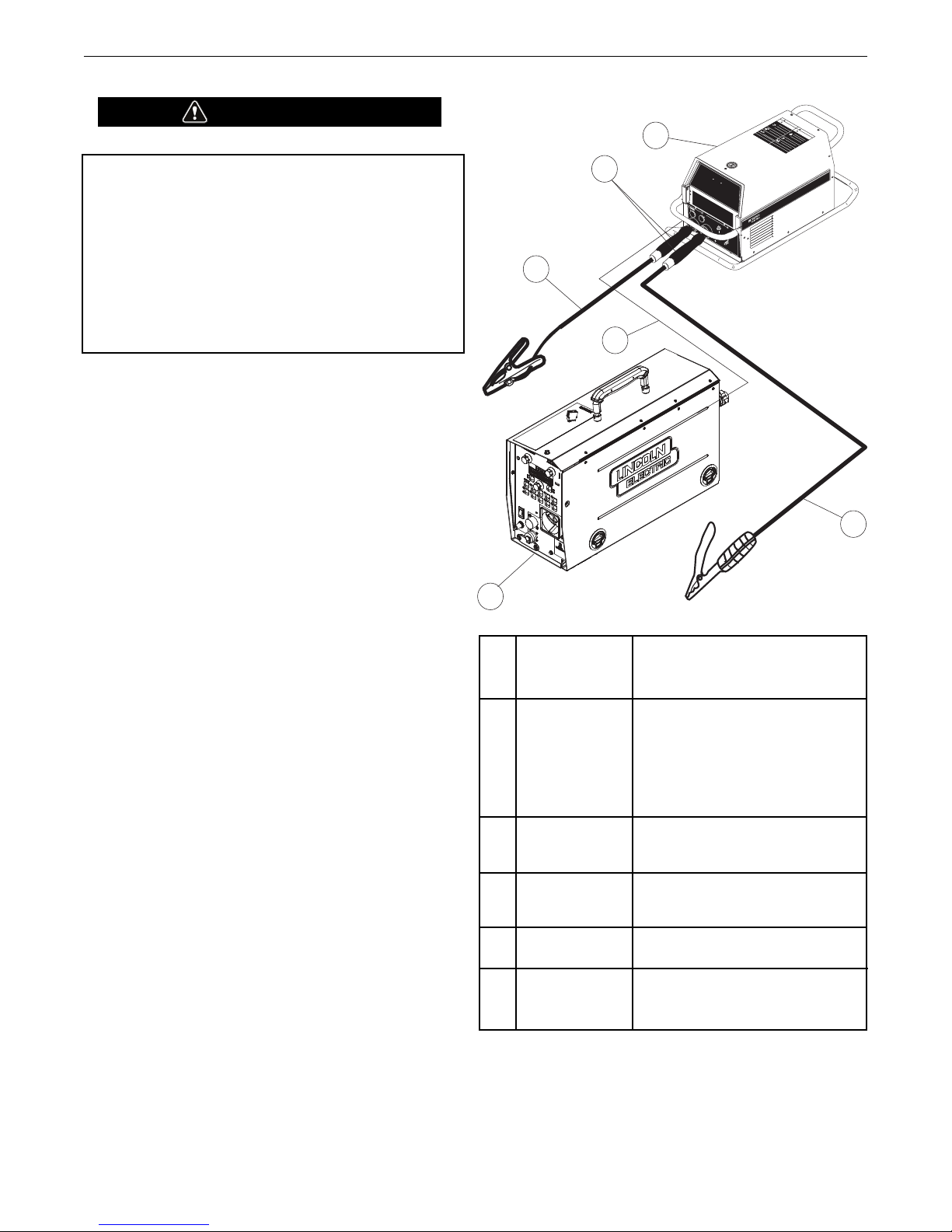

ARCLINK CONTROL CABLES

(See Figure A.3)

ArcLink Control Cables are available in two forms:

K1543-xx series for most indoor or factory installations.

•

• K2683-xx series for outdoor use or when the equipment is

requently moved.

f

ArcLink/LincNet control cables are special high quality cables for

digital communication. The cables are copper 5 conductor cable

in a SO-type rubber jacket. There is one 20 gauge twisted pair

for network communications. This pair has an impedance of

approximately 120 ohms and a propagation delay per foot of less

than 2.1 nanoseconds. There are two 12 gauge conductors that

are used to supply 40VDC to the network. The fifth wire is 18

gauge and is used as an electrode sense lead.

Use of non-standard cables may lead to system shutdowns, poor

arc starting and wire feeding problems.

The control cables connect the power source to the wire feeder,

and the wire feeder to other wire feeders.

Control cables may be connected end to end to extend their

length. Use a maximum of 200 ft. (61.0m) of control cable

between components.

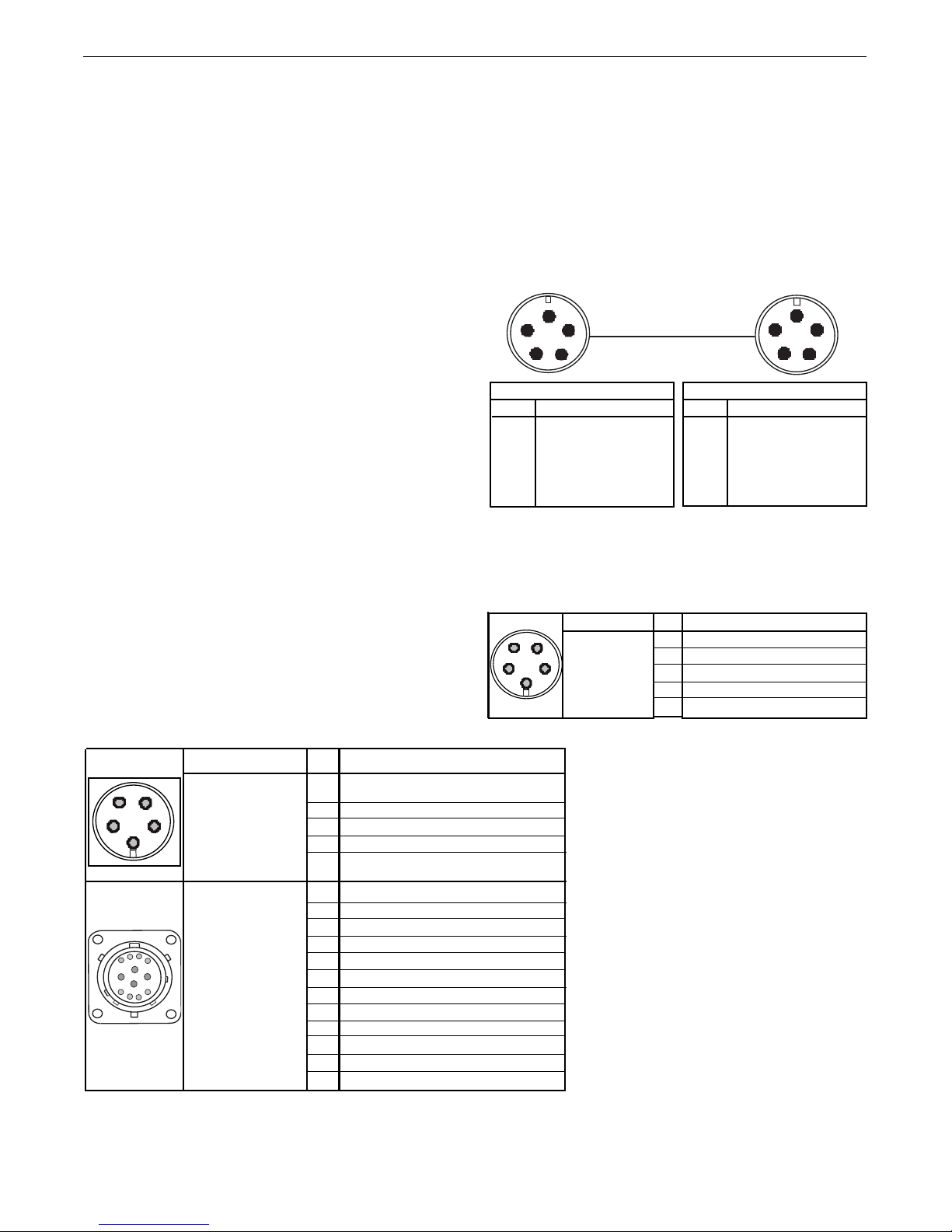

Figure A.3

Power Source

Pin Function

A ArcLink

B ArcLink

C "67" voltage sense

D 40 VDC

E Common

Pin Function

A ArcLink

B ArcLink

C "67" voltage sense

D 40 VDC

E Common

Wire Feeder

CABLE CONNECTIONS

There are two circular connectors on the front of the POWER

FEED®25M.

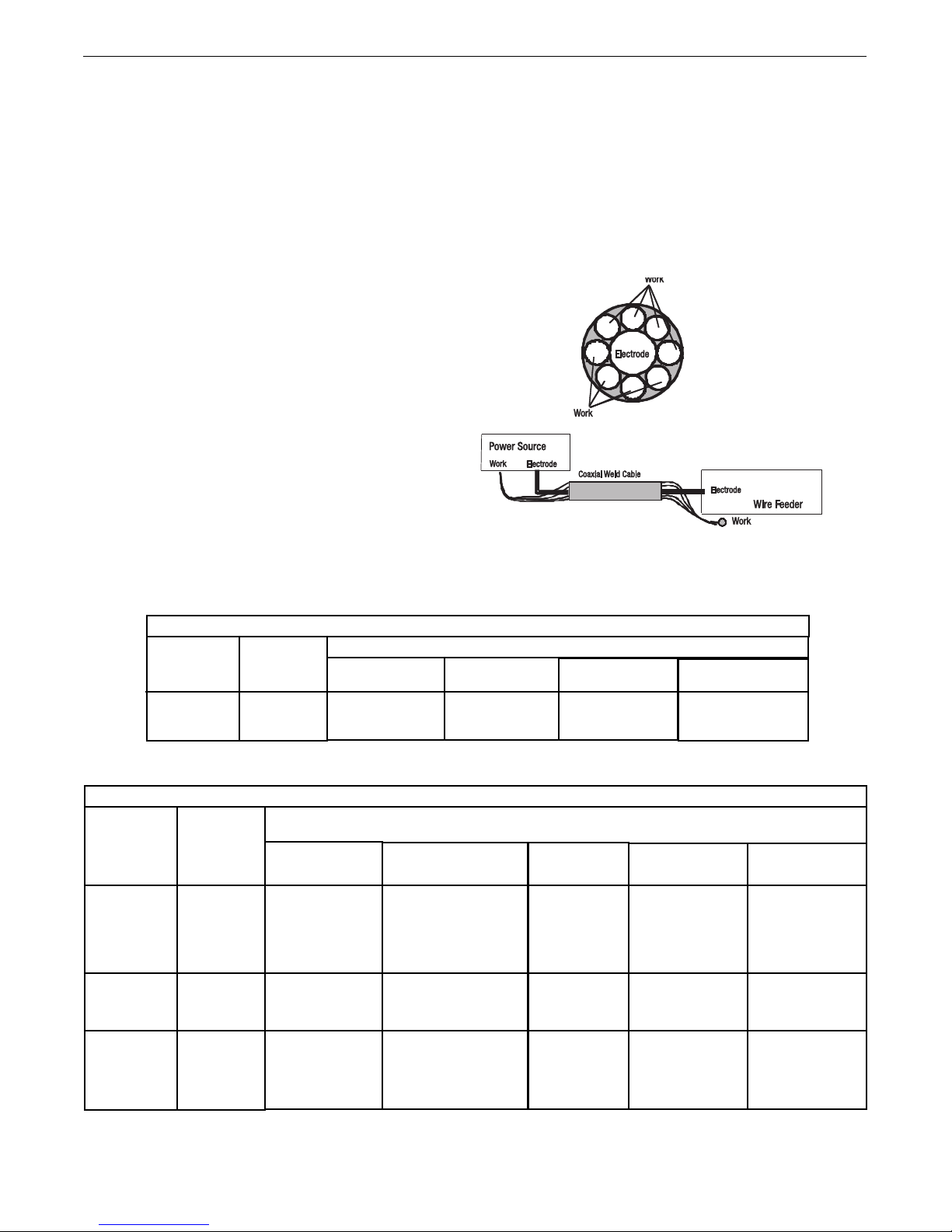

(See 5-pin and 12-pin Figure A.1)

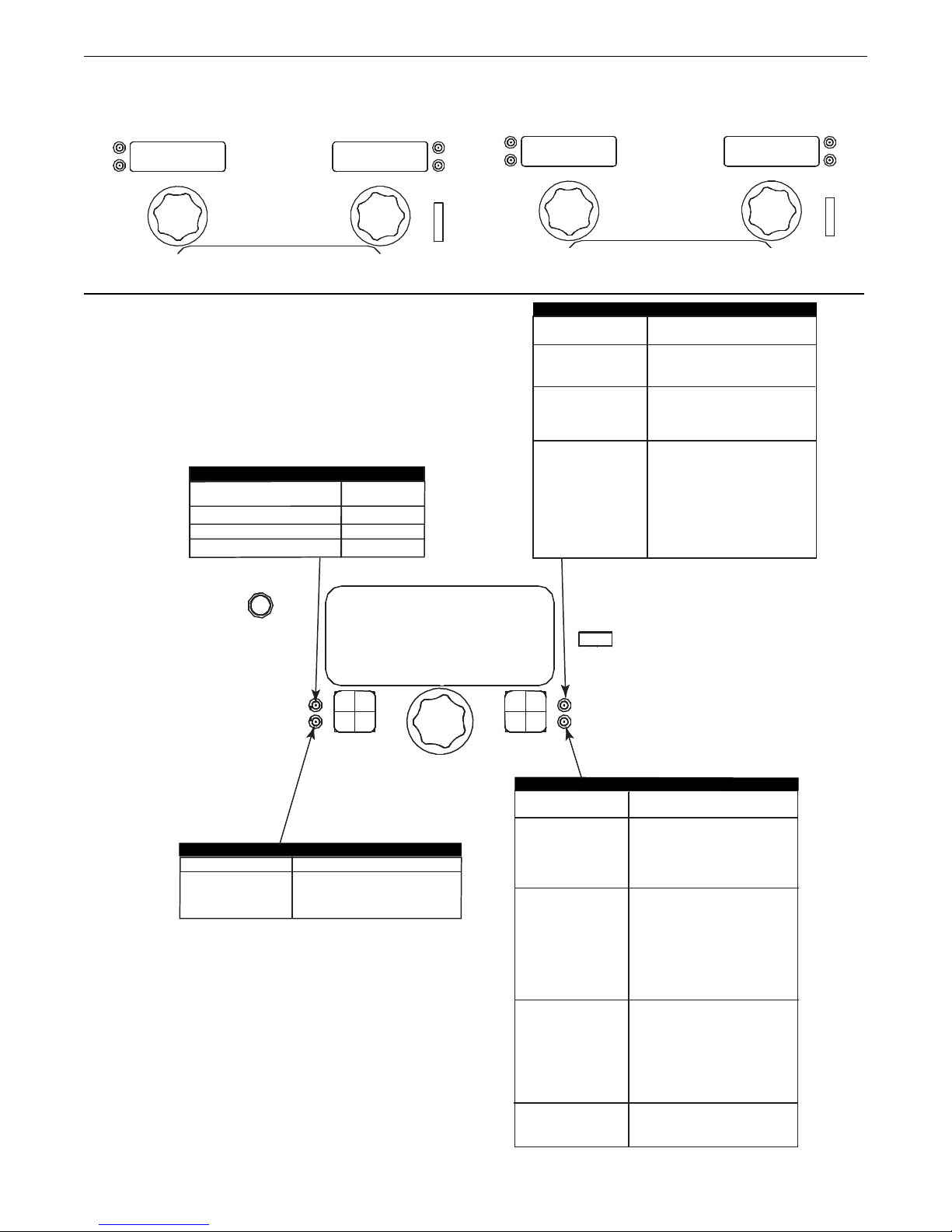

FIGURE A.1

Function

CC

DD

BB

5-pin trigger

connector for push-

AA

EE

only guns.

12-pin connector for

remote control,

foot/hand amptrol,

push-pull guns and

ArcLink peripherals

PIN

A

B

C

D

E

A

B

C

D

E

F

G

H

J

K

L

M

Dual Procedure Selection

75 Remote potentiometer, common

76 Remote potentiometer, wiper

77 Remote potentiometer, 5K

ArcLink Peripheral Sense

40VDC Common

Pull Motor –

Pull Motor +

Wiring

Trigger

Not used

Common

Common

CANL

CANH

Trigger

Trigger

40VDC +

There is one circular connector on the rear of the POWER FEED

25M. Maximum control cable length is 200 ft (61 m). (See

Figure A.2)

FIGURE A.2

Function

5-pin ArcLink

connector.

PIN

A

B

C

67 Electrode Voltage Sense

D

E

Wiring

ArcLink

ArcLink

40VDC

Common

®

A-3

POWER FEED®25M & 25M ALUMINUM

WELD CABLE SIZE

able A.1 located below are copper cable sizes recommended for different

T

currents and duty cycles. Lengths stipulated are the distance from the welder to

work and back to the welder again. Cable sizes are increased for greater lengths

primarily for the purpose of minimizing cable drop.

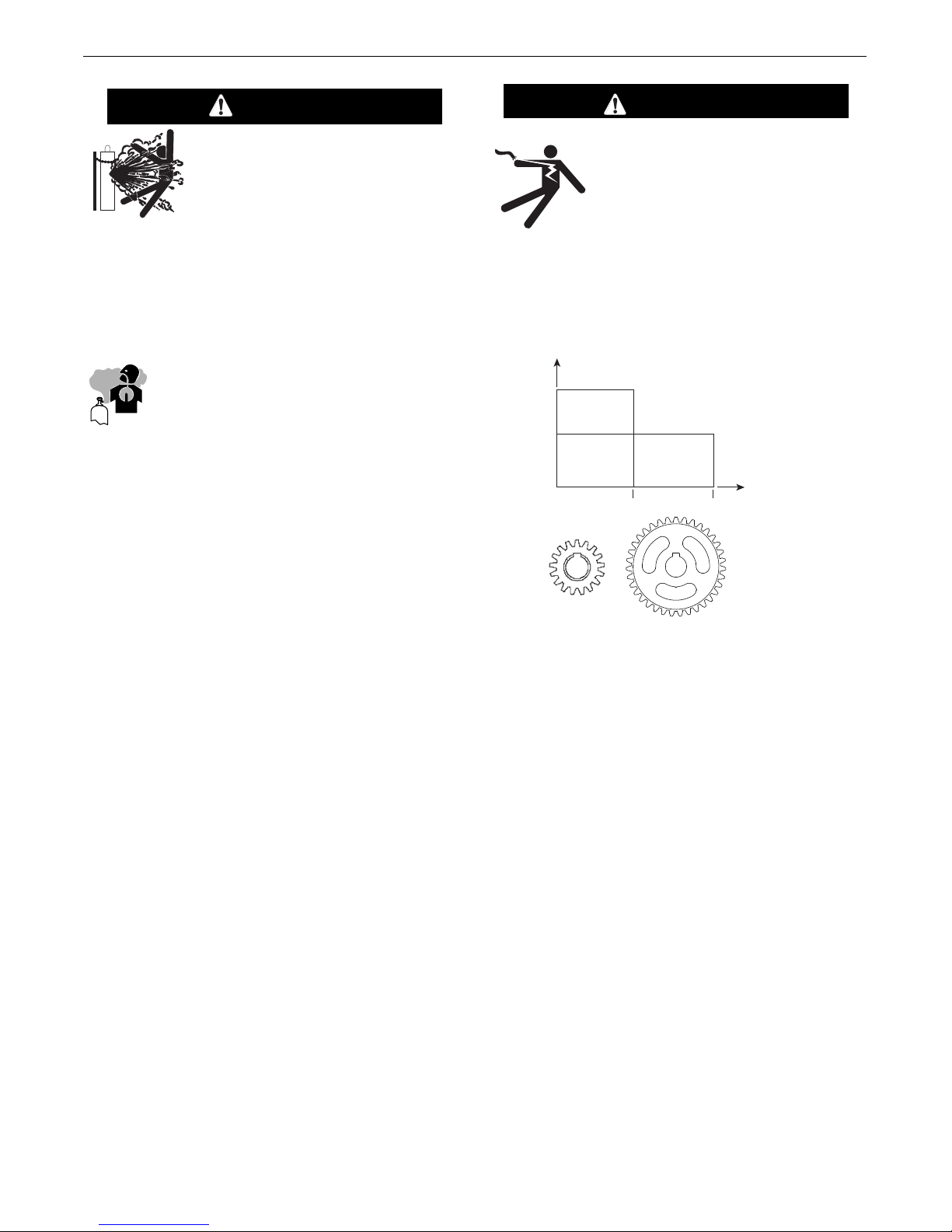

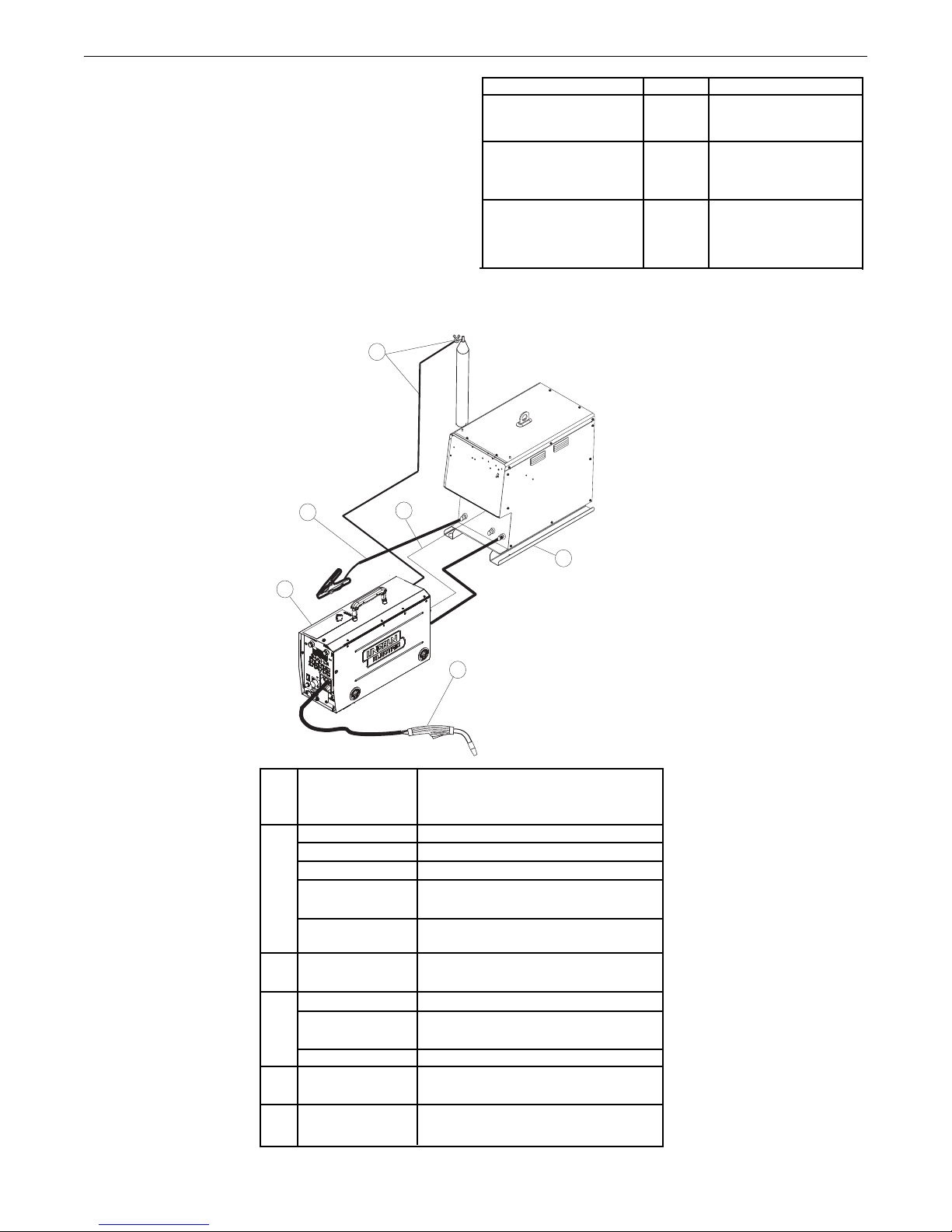

COAXIAL WELD CABLE

(See Table A.2)

Coaxial welding cables are specially designed welding cables for pulse welding

or STT®welding. Coaxial weld cables feature low inductance, allowing fast

changes in the weld current. Regular cables have a higher inductance which may

distort the pulse or STT®wave shape. Inductance becomes more severe as the

weld cables become longer.

Coaxial cables work best for high performance waveforms and when:

• long cables are present.

• the cables are housed in a metal tray.

A coaxial weld cable is constructed with multiple small leads wrapped around

one large lead. The large inner lead connects to the electrode stud on the power

source and the electrode connection on the wire feeder. The small leads combine

together to form the work lead, one end attached to the power source and the

other end to the work piece. See Figure A.5

INSTALLATION

o install:

T

1. Turn the input power off at the welding power source.

2. Connect one end of the center lead to the power source electrode

connection, and the other end to the wire feeder electrode

onnection.

c

3. Connect the outer lead bundle to the power source work connection,

and the other end to the work piece. Minimize the length of any

work lead extension for best results.

. Insulate all connections.

4

FIGURE A.5

TABLE A.2

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 75°C)**

COAXIAL CABLE LENGTH

AMPERES

250

300

350

DUTY

CYCLE

100%

60%

60%

0 to 25Ft.

(0 to 7.6M)

1

1

1/0

25 to 50Ft.

(7.6 to 15.2M)

1

1

1/0

50 to 75 Ft.

(15.2 to 22.9M)

1

1

--

75 to 100 Ft.

(22.9 to 30.5M)

1

1/0

--

TABLE A.1

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 167°F or 75°C)**

CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK CABLES

AMPERES

200

200

225

225

250

250

250

250

300

325

350

400

400

500

** Tabled values are for operation at ambient temperatures of 104°F(40°C) and below. Applications above 104°F(40°C) may require cables larger than recommended, or

cables rated higher than 167°F(75°C).

PERCENT

DUTY

CYCLE

60

100

20

40 & 30

30

40

60

100

60

100

60

60

100

60

0 to 50Ft.

(0 to 15M)

2

2

4 or 5

3

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

50 to 100Ft.

(15 to 30M)

2

2

3

3

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

100 to 150 Ft.

(30 to 46M)

2

2

2

2

2

1

1

1

1

2/0

2/0

2/0

3/0

3/0

150 to 200 Ft.

(46 to 61M)

1

1

1

1

1

1

1

1

1/0

2/0

2/0

3/0

3/0

3/0

200 to 250 Ft.

(61 to 76M)

1/0

1/0

1/0

1/0

1/0

1/0

1/0

1/0

2/0

3/0

3/0

4/0

4/0

4/0

A-4

POWER FEED®25M & 25M ALUMINUM

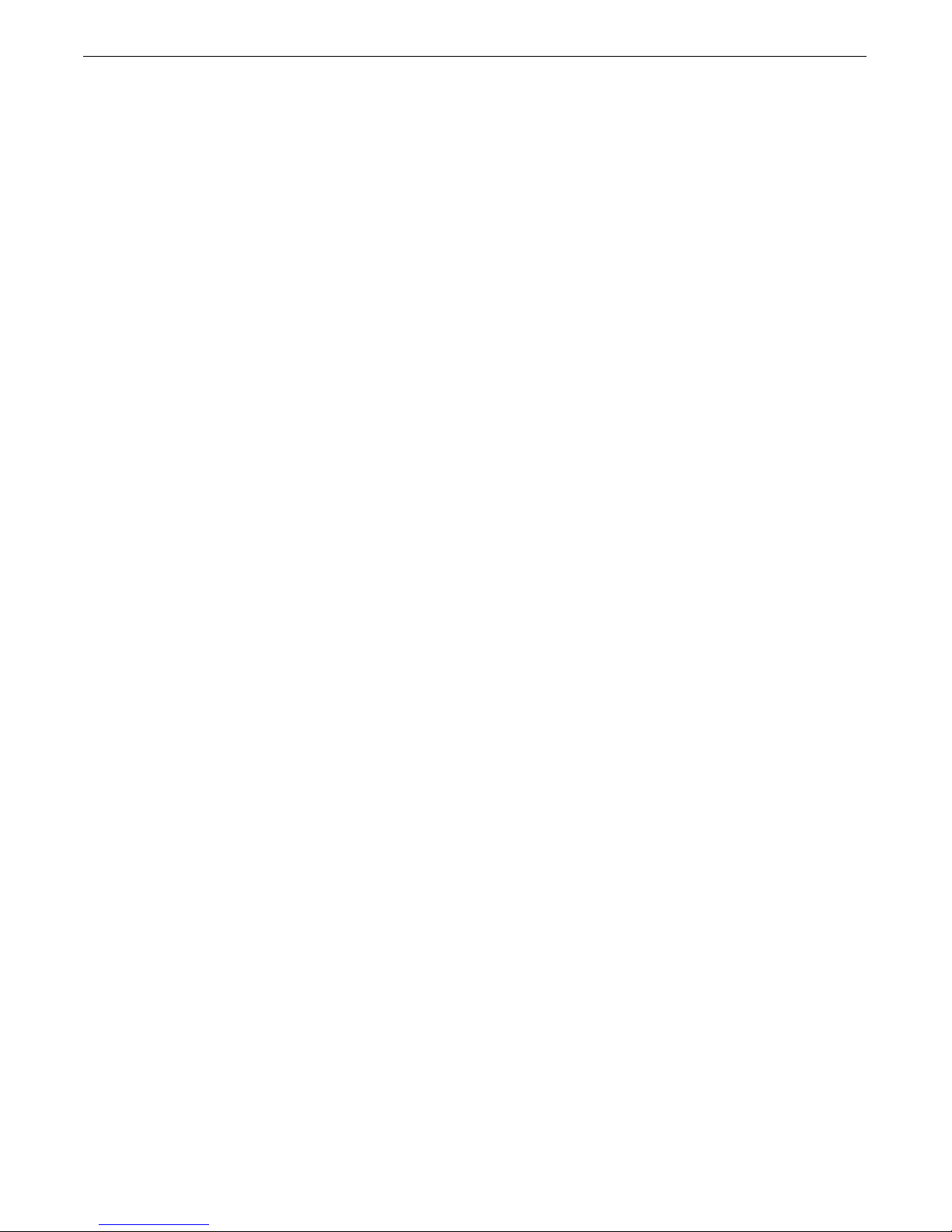

Extra Torque

Gearing

Normal Speed

Gearing

Extra

T

orque

Gearing

Normal

Speed

G

earing

4

00

800

WFS

Feed Force

INSTALLATION

SHIELDING GAS CONNECTION

WARNING

YLINDER may explode if

C

damaged.

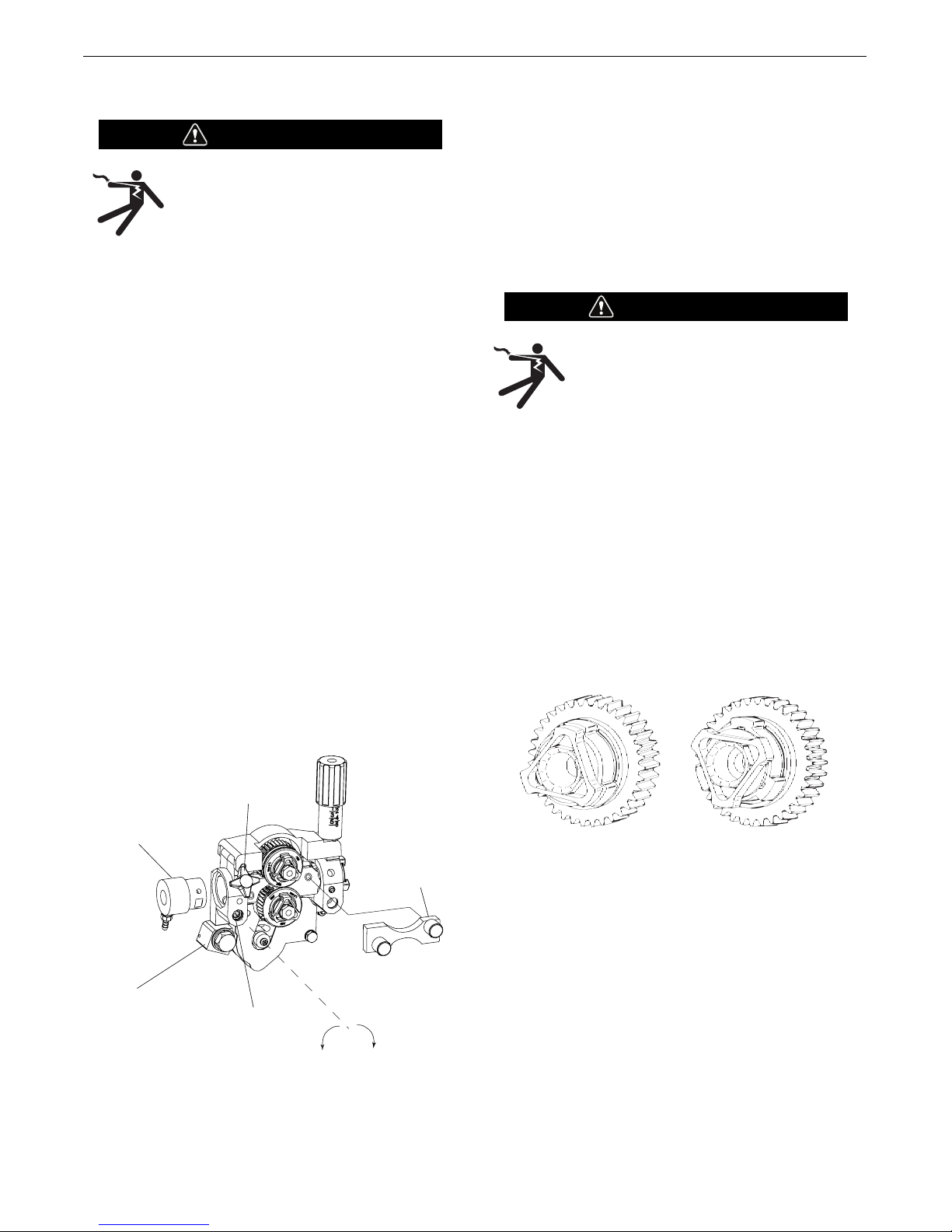

CHANGING THE DRIVE MOTOR GEAR RATIO

WARNING

• Turn off input power at the welding

power source before installation or

changing drive roll and/or wire guides.

•Keep cylinder upright and

chained to support.

Do not touch electrically live parts such

•

as the wire drive or internal wiring.

• When feeding with the gun trigger, the

• Keep cylinder away from areas where it may be damaged.

• Never lift welder with cylinder attached.

• Never allow welding electrode to touch cylinder.

• Keep cylinder away from welding or other live electrical

circuits.

• BUILD UP OF SHIELDING GAS MAY HARM HEALTH OR KILL.

• Only qualified personnel should perform this operation.

--------------------------------------------------------------------

electrode and wire drive mechanism are

"hot" to work and ground and could

remain energized several seconds after

the gun trigger is released.

• Shut off shielding gas supply when not in use.

• See American National Standard Z-49.1, "Safety

in Welding and Cutting” Published by the

American Welding Society.

--------------------------------------------------------------------

MAXIMUM INLET PRESSURE IS 100 PSI. (6.9 BAR.)

Install the shielding gas supply as follows:

1. Secure the cylinder to prevent it from falling.

2. Remove the cylinder cap. Inspect the cylinder valves and

regulator for damaged threads, dirt, dust, oil or grease. Remove

dust and dirt with a clean cloth. DO NOT ATTACH THE

REGULATOR IF OIL, GREASE OR DAMAGE IS PRESENT! Inform

your gas supplier of this condition. Oil or grease in the presence

of high pressure oxygen is explosive.

3. Stand to one side away from the outlet and open the cylinder

valve for an instant. This blows away any dust or dirt which may

have accumulated in the valve outlet.

4. Attach the flow regulator to the cylinder valve and tighten the

union nut(s) securely with a wrench. Note: if connecting to 100%

CO2cylinder, insert regulator adapter between regulator and

cylinder valve. If adapter is equipped with a plastic washer, be

sure it is seated for connection to the CO2cylinder.

5. Attach one end of the inlet hose to the outlet fitting of the flow

regulator. Attach the other end to the welding system shielding

gas inlet. Tighten the union nuts with a wrench.

6. Before opening the cylinder valve, turn the regulator adjusting

knob counterclockwise until the adjusting spring pressure is

released.

7. Standing to one side, open the cylinder valve slowly a fraction of

a turn. When the cylinder pressure gage stops moving, open the

valve fully.

8. The flow regulator is adjustable. Adjust it to the flow rate

recommended for the procedure and process being used before

making a weld.

Tools required:

• 1/4" hex key wrench

• 3/4" open end wrench

• 9/16" socket and ratchet wrench

• 7/16" nut driver

• 5/16" nut driver

• Phillips screw driver

1. Turn power off at the welding power source.

. Remove the spool of electrode from the wire feeder.

2

3. Loosen the thumb screw at the wire drive and remove the welding

gun.

4. Remove the outer wire guide, drive rolls and inner wire guide.

5. Use a 7/16" nut driver to remove the gear cover.

6. Use 9/16" socket and ratchet wrench to remove the lower drive roll

hub retainer. Remove the lower drive roll hub.

7. With a Phillips screwdriver, remove the screw, washer and collar

holding the pinion gear. Remove the pinion gear.

A-5

POWER FEED®25M & 25M ALUMINUM

8. Remove the busbar by unscrewing the bolt using a 3/4" open end

wrench.

. With a 1/4" hex key wrench, loosen the socket head cap screw

9

securing the gun bushing. Remove the gun bushing from the wire

drive.

10. With a 5/16" nut driver remove the five screws securing the wire

drive panel. Lift out the wire drive panel and disconnect the molex

connections.

11. Using a 5/16" nut driver, remove the four screws securing the

cover.

12. With a Phillips screwdriver, remove the three screws and lock

washers securing the motor. Remove the motor.

13. Place the motor in the new position.

14. Assemble the three screws and lock washer holding the wire drive

motor.

INSTALLATION

15. Assemble the molex connections and place the wire drive assembly

inside the wire feeder. Route the gas hose through the opening in

the wire drive panel.

16. Place the gun bushing in the wire drive and align the threaded hole

in the gun bushing with the hole in the feed plate. With a 1/4" hex

key, tighten the socket head cap screw to secure the bushing in the

wire drive.

17. Reassemble the busbar and tighten the mounting hardware with a

3/4" open end wrench.

18. Place the new gear on the motor shaft. Secure the gear to the

motor shaft with the collar, washer and screw.

19. Reassemble the lower drive roll hub and lower drive roll hub

retainer.

20. Reassemble the gear cover.

21. Reassemble the inner wire guide, drive rolls and outer wire guide.

22. Place the welding gun into the gun bushing and secure with the

thumb screw.

23. Restore power. Set the appropriate gear ratio using the set-up

menu.

A-6

POWER FEED®25M & 25M ALUMINUM

GUN RECEIVER BUSHING

LOOSEN TIGHTEN

THUMB SCREW

OUTER WIRE GUIDE

SOCKET HEAD

CAP SCREW

CONNECTOR BLOCK

UNLOCKED

POSITION

LOCKED

POSITION

INSTALLATION

WIRE DRIVE CONFIGURATION

See Figure A-6)

(

Changing the Gun Receiver Bushing

WARNING

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the welding

power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and drive

mechanism are "hot" to work and ground and could

remain energized several seconds after the gun trigger is

released.

• Only qualified personnel should perform maintenance

work.

-------------------------------------------------------------------Tools required:

• 1/4" hex key wrench.

Note: Some gun bushings do not require the use of the thumb

screw.

1. Turn power off at the welding power source.

2. Remove the welding wire from the wire drive.

3. Remove the thumb screw from the wire drive.

4. Remove the welding gun from the wire drive.

5. Loosen the socket head cap screw that holds the connector

bar against the gun bushing.

Important: Do not attempt to completely remove the

socket head cap screw.

6. Remove the outer wire guide, and push the gun bushing out

of the wire drive. Because of the precision fit, light tapping

may be required to remove the gun bushing.

7. Disconnect the shielding gas hose from the gun bushing, if

required.

. Connect the shielding gas hose to the new gun bushing, if

8

required.

9. Rotate the gun bushing until the thumb screw hole aligns

with the thumb screw hole in the feed plate. Slide the gun

receiver bushing into the wire drive and verify the thumb

screw holes are aligned.

0. Tighten the socket head cap screw.

1

11. Insert the welding gun into the gun bushing and tighten the

thumb screw.

PROCEDURE TO INSTALL DRIVE ROLLS AND WIRE

GUIDES

WARNING

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the welding

power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and drive

mechanism are "hot" to work and ground and could

remain energized several seconds after the gun trigger is

released.

• Only qualified personnel should perform maintenance

work.

--------------------------------------------------------------------

1. Turn power off at the welding power source.