Page 1

Wire Feed Wire Size Range Dimensions

Product Product Input Rated Output Speed Range ipm (m/min) H x W x D Net Weight

Name Number Power Current / Duty Cycle ipm (m/min) Solid Cored Inches (mm) lbs (kg)

Power Feed 10M K2230-1 40 VDC 600A/60% High Speed: High Speed: 18.5 x 13.5 x 30.5 62 (28.1)

Bench Model 500A/100% 75-1200 (2.0-30.5) .025 - 1/16 .035 - 5/64 (470 x 343 x 775)

(0.6 - 1.6) (0.9 - 2.0)

20.0 x 20.0 x 30.7 90 (40.8)

Power Feed 10M K2234-1 Low Speed: Low Speed: (508 x 508 x 781)

Dual Bench Model 50-800 (1.27-20.3) .025 - 3/32 .035 -.120

(0.6 - 2.4) (0.9 - 3.0)

Description

Output Input

40

VDC

Power Feed

™

10M

SEMIAUTOMATIC WIRE FEEDERS

When you need a versatile, multi-process industrial wire feeder for welding virtually any

material, you need the Power Feed 10M. Choose the Power Feed 10M for automotive

manufacturing, shipbuilding, pressure vessels/heavy plate, oil, gas and pipeline

construction, particularly when code-quality work is required. The new MSP4 user

interface panel features the Infrared Port with a Palm® OS-based interface, allowing

wireless communication between a handheld device and the welding system, for fast,

easy and accurate process control.

Publication E8.266 8/04

www.lincolnelectric.com

Processes

Advantage Lincoln

Recommended General Options

Order

TECHNICAL SPECIFICATIONS

Recommended Power Source Options

• World-class arc performance on steel, stainless steel, aluminum

and other materials.

• Waveform Control Technology™ featuring patented processes like

Pulse-On-Pulse™, for a TIG-like bead appearance, and Power

Mode™, for a stable arc at low current levels.

• Utilizes ArcLink™ — the leading digital communication protocol

for welding, making it the best choice for seamless, time critical

integration with the power source.

• Synergic CV MIG welding with ideal voltage presets for many

applications. Adjust as needed based on personal preference.

• Pulsed MIG process — great for low spatter, low heat input and

out-of-position applications — makes virtually any operator a better

welder!

• Weld processes and settings at the feeder add efficiency by placing

controls close to the operator.

• Easy-to-understand user interface panel with large numeric displays

make it easy to set weld parameters.

• Features push-pull capability for great performance on aluminum.

• Three year warranty on parts and labor.

MIG Pulsed STT® Flux-Cored Stick TIG Gouging

ArcLink/LincNet Control Extension Cables, Weld Power Cables, Coaxial

Weld Power Cables, Feed Plate Gun Receiver Bushings, Drive Roll and

Wire Guide Kits, Magnum Gun and Cable Assemblies, Push-Pull Guns,

Push-Pull Gun Connection Kit, Dual Procedure Switch, ArcLink “T”

Connector Kit, Foot Amptrol Connector Kit, Wire Straightener, Spindle

Adapters, Readi-Reel Adapters, Coil Adapter, Wire Covers, Incoming

Bushing for Lincoln Conduit, Gas Guard Regulator, Water Connection Kit,

Magnum Flow Sensor, Caster Kit - Light Duty, 6000 Series Welding Arm

Power Wave® 355M, Power Wave 455M, Power Wave 455M/STT,

Power Wave 655 Robotic, Power Wave 355

(1)

, Power Wave 455

(1)

,

Power Wave 455/STT

(1)

.

Additional Options For Single Bench Model

Dual Procedure/Memory Panel, Swivel Platform, Insulated Lift Bail

K2230-1 Power Feed 10M Bench Model

K2234-1 Power Feed 10M Dual Bench Model

Single and Dual Bench Wire Feeders

Single and Dual Bench Models Include:

Wire reel stand, MSP4 Panel, 8 ft. input cable assembly with

ArcLink/Linc-Net control and weld power cable, high speed pinion gear,

gun trigger cable.

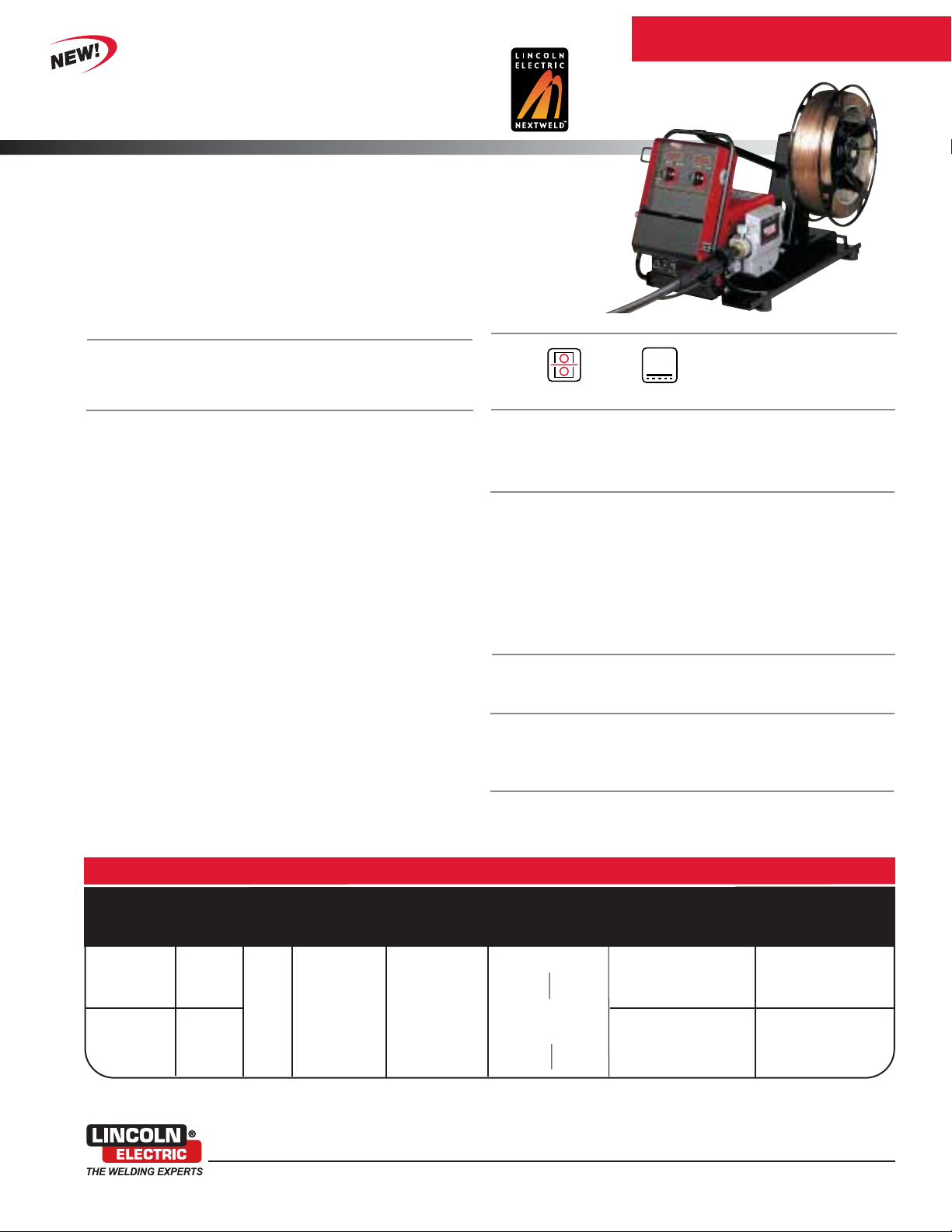

Power Feed 10M Single

Bench Model shown

with optional coil

adapter and wire.

(1) The LinkNet Power Waves will provide limited capabilities.

Page 2

Power Feed 10M

[2]

A CLOSER LOOK

FEATURES

MSP4 User Interface Panel

PATENTED DRIVE ROLL SYSTEM — FOUR DRIVE

• Split wire guide provides easy wire loading and maintenance.

•Variety of drive rolls for any application.

• New Twist-Lock™ design.

• High speed gear for most fine wire applications. Low speed gear for

higher torque with Innershield® wire.

• Wire feed speed calibrated to monitor and maintain constant speed.

•Tachometer feedback to monitor and maintain constant speed.

•Brass-to-brass connections and rugged aluminum cast housing provide

reliable performance.

• Angled for ease of payoff and less stress on cables.

• Interchangeable gun bushings for use with a variety of guns.

4-Drive Roll System

Brass Connector

4-Drive Roll

Split Wire Guide

GENERAL STEEL STAINLESS

METAL CORE

ALUMINUM

CV

CC

4043 5356

GMAW

GMAW

GMAW

PULSE (CRISP)

PULSE (SOFT)

STT (NO TAILOUT)

STT II

GMAW

PULSE

PULSE-ON-PULSE

GMAW

PULSE

PULSE-ON-PULSE

GMAW

PULSE

GMAW

GMAW

PULSE

PULSE

PULSE

STT

STT II

CO

2

Ar (MIX)

Ar (MIX)

Ar (MIX)

CO

2, Ar/CO2

CO2, Ar/CO2

Ar

Ar

Ar

Ar

Ar

Ar

Ar/CO

2

Ar/CO2

Ar (Mix)

Ar/He/CO

2

Ar/CO2

Ar/O2

Ar/He/CO2

Ar/He/CO2

Ar/He/CO2

--94

95

---

109

110

148

149

98

151

152

101

81

82

61

63

66

62

--109

110

31

33

36

32

34

109

110

41

43

46

42

44

125

126

0.030

0.035 0.035

0.045

0.0300.035

3/64 3/64

0.052

M20240 VM

0.0350.045

1/16 1/16

1/16

0.0450.052

10

11

12

14

109

110

71

72

99

75

76

102

83

84

20

21

22

19

125

126

73

74

100

77

78

103

85

86

24

25

26

28

125

126

STD. CV 5

FCAW STD. CV 6

STICK SOFT (7018) 1

STICK CRISP (6010) 2

TIG TOUCH START 3

GOUGE - - -

9

GMAW POWER MODE 40

www.lincolnelectric.com

A welding waveform program chart, conveniently located on the Power Feed 10M

Control Box panel, makes standard program selection easy. Delivering an

unprecedented level of arc control, the Power Feed 10M includes a number of preset

welding waveform programs for applications on a variety of materials, including steel,

stainless steel, aluminum, nickel alloys and silicon bronze. Lincoln Electric can add or

design custom waveform programs for those customers requiring targeted solutions

for other materials, joint configurations, welding procedures, shielding gases or other

variables. In addition, Lincoln’s Wave Designer™ software, available upon request,

alllows you to build or customize waveform programs yourself.

Start Options —

preflow time, run-in

wire feed speed and

start time.

End Options —

crater time, burnback

time, and postflow time.

Weld Mode provides easy

access to the multiple

welding waveform programs

in the Power Wave power

sources.

Arc Control — Also known

as Inductance or Wave

Control. It allows the

operator to vary the arc

characteristics from “soft” to

“crisp” in most weld modes.

Infrared Port (IR)

Wireless machine configuration and diagnostics using a

Palm® OS-based hand-held PDA — no serial cable

needed for connection!

Our Palm® OS-based application configures and

troubleshoots Lincoln welding machines that are

equipped with the IR Port.

Custom set-up to “lock out” operator or limit access to

settings to secure systems, regulate activity and produce

reliable results time after time.

Large, easy-to-read

alpha numeric display.

The New MSP4 User Interface Panel

provides full control of mode selection, arc

control, weld sequence and — through the

IR Port — lockout control.

Page 3

Power Feed 10M

[3]

A CLOSER LOOK

Printed circuit boards are trayed, potted

and filled with epoxy to provide a robust

environmental shield.

Key Controls

Synergic Control CV Voltage Display

Synergic Control CV programs feature an ideal voltage best suited for most

procedures. Use this voltage as a starting point for the weld procedure and

adjust if needed based on personal preference. When the voltage knob is rotated,

the display will show an upper or lower bar indicating that the voltage is above or

below the ideal voltage.

• Above ideal voltage (upper bar display)

• At ideal voltage (no bar displayed)

• Below ideal voltage (lower bar display)

Front:

1. Bright, high intensity large digital display of voltage and wire feed speed.

2. Dual Procedure Memory Panel - retain settings in memory to switch back and forth between two

different weld procedures. Use any of six memories to store your favorite settings.

3. MSP4 Panel (see page 2).

4. 2-Step/4-Step Trigger Switch — change from simple ON/OFF in 2-step position to trigger interlock in

4-step position.

5. ArcLink status Lighted Electronic Display.

6. Cold Inch/Gas Purge switch — feed wire through a gun, or purge gas line to set flow rate all with

welding output off for safety and gas savings.

7. Water Cooler Kit Connection (Optional).

8. 5-pin amphenol gun trigger connector.

Back:

1. Access Panel — remove to change DIP settings.

2. Shielding Gas Inlet — industry standard 5/8 - 18 CGA connection.

3. Spool Gun/Push-Pull Gun Connector — for connecting Python®, CobraMAX™ and Prince XL® guns.

4. Remote/Foot Amptrol Connector for TIG welding (Optional).

5. ArcLink Control Cable Connector.

6. Water Cooler Connector (Optional).

www.lincolnelectric.com

Press to select procedure.

Dual Procedure/Memory Panel Option shown

for Power Feed 10M Single Bench Model

The Dual Procedure/Memory Panel is standard equipment on

Power Feed 10M Dual Bench Models and optional on Single

Bench Models. This panel performs three functions: weld

procedure selection, feed head selection and memory

saving/recall. There are two procedure memories (A and B)

and six user memories (1- 6) for each feed head to store your

favorite settings.

QUALITY AND RELIABILITY

• Rugged steel case, sturdy controls and quality meter displays.

• Ambient temperature range for operation (-10° C to +40° C) and storage

(-40° C to +40° C).

• Designed to resist electrical noise.

• Conforms to cCSAUL/ CE Standards:

C22.2 No. 60, UL551, EN 60974-5, EN 50199.

• Meets IP21S rating.

• PC Boards are potted, trayed and filled with epoxy for ultimate protection in

harsh environments.

• Three-year Lincoln warranty on parts and labor.

• Manufactured under a quality system certified to ISO 9001 requirements and

ISO 14001 environmental standards.

Page 4

Waveform Control Technology®

Driving Superior Welding Performance

Lincoln’s Waveform Control Technology controls and shapes the output waveforms (or

weld modes) to adapt to virtually any application, material or weld position. In addition,

you can have our Application Engineering department add or customize standard

waveform programs or request Lincoln Wave Designer™ software to build or

customize waveform progams yourself.

For more information see Nextweld Document #NX-1.10

Lincoln Nextweld Innovations for Challenging Applications

Waveform Control Technology makes it possible to take advantage of Lincoln innovations like these patented processes using the

Power Feed 10M and a Power Wave® power source:

Pulse-On-Pulse on 3 mm Aluminum

Power Feed 10M

[4]

A CLOSER LOOK

www.lincolnelectric.com

WHAT IS NEXTWELD

®

?

Nextweld integrates Lincoln’s technologies,

processes and products to create a comprehensive,

flexible, user-friendly welding system that can

increase efficiency and reduce fabrication costs.

Waveform Control Technology™ and digital

communications provide the foundation for Nextweld innovations

like Pulse-On-Pulse™, Power Mode™, STT® and ArcLink®.

Look for Nextweld for ultimate arc control, high

efficiency/reliability and seamless system integration.

Power Mode reduces spatter and

improves bead appearance, even

for low voltage procedures

on stainless.

Power Mode aids bead wetting

and penetration on aluminum.

Power Mode™ uses high-speed regulation of output power

to deliver extremely fast response to changes in the arc, for

example, when using a whip technique. The result is improved

MIG welding performance, including low spatter, very uniform,

consistent bead wetting and controlled penetration. Power

Mode benefits are especially apparent on low voltage applications on thin steel and stainless steel material less than 20

gauge (0.7 mm). It also delivers excellent arc characteristics on

aluminum and other alloys such as silicon bronze and nickel

alloys.

For more information see Nextweld Document #NX-2.60

Pulse-On-Pulse

™

uses a sequence of varying pulse wave shapes

to produce a TIG-like bead appearance and excellent weld properties

when MIG welding aluminum. Pulse-On-Pulse controls arc length and

heat input together, making it easier to achieve good penetration.

For more information see Nextweld Document #NX-2.10

Page 5

Digital Communications

Fast, Reliable, System-Wide

ArcLink is the leading digital communications protocol for the arc welding industry. It integrates all welding

components for seamless, time-critical data transfer. The strength of ArcLink lies in the ability to communicate with each

system component in a pre-defined welding language. In addition, ArcLink is an open communications protocol, meaning

that Lincoln Electric publishes how it works and encourages other companies to adopt it.

For more information see Nextweld Document #NX-1.30

Power Feed 10M

www.lincolnelectric.com

[5]

A CLOSER LOOK

Conventional CV short circuit

transfer using CO2and .045”

solid wire.

STT using CO2and .045”

solid wire. Note reduced

spatter and fume.

Pulsed MIG varies weld current between peak (high heat) and

background (low heat) current to provide better control of heat

input, which reduces warping and burnthrough on thin materials.

Pulsed MIG also enables in-the-flat, horizontal, vertical up, or

overhead welding without a slag system. It can be used in hard

automation, robotic, and high production semiautomatic applications. Optimized GMAW-P waveforms are readily available to use on

aluminum, carbon steel, high strength low alloy steel, stainless steel,

and nickel alloys.

For more information see Nextweld Document #NX-2.70

STT® (Surface Tension Transfer®) is a

controlled GMAW short circuit transfer process

that uses current controls to adjust the heat

independent of wire feed speed, resulting in

superior arc performance, good penetration,

low heat input control, and reduced spatter

and fumes. STT is especially well-suited for

steel and stainless steel applications.

For more information see Nextweld

Document #NX-2.20

Synergic MIG

Synergic control of voltage and wire feed speed allows you to

set weld procedures with only one control for simplicity and ease

of use.

Set the wire feed speed and your voltage is automatically set.

Override the setting with the voltage control for personal preference.

1. Use one

knob to set

procedures.

2. Voltage is

automatically set.

f

PULSE CYCLE

Ramp Up

Background

WELDING CURRENT

TIME

Peak

Tail Out

Step Of

Low Heat

(Background)

High Heat

(Peak)

®

®

Page 6

Lug to Lug, 3/0, 600A, 60% duty cycle, 10 ft. K1842-10

Lug to Lug, 3/0, 600A, 60% duty cycle, 35 ft. K1842-35

Lug to Lug, 3/0, 600A, 60% duty cycle, 60 ft. K1842-60

Lug to Lug, 4/0, 600A, 60% duty cycle, 110 ft. K1842-110

Power Feed 10M

[6]

RECOMMENDED OPTIONS

456

DRIVE ROLL AND WIRE GUIDE KITS

Description Order Number

Solid Steel Wire, Smooth V Groove:

.023-.030” (0.6-0.8mm) KP1505-030S

.035” (0.9mm) solid KP1505-035S

.040-.045” (1.0-1.2mm) KP1505-045S

.052” (1.4mm) KP1505-052S

1/16” (1.6mm) KP1505-1/16S

Cored Steel Wire, Knurled V Groove:

.030-.035” (0.8-0.9mm) KP1505-035C

.040-.045” (1.0-1.2mm) KP1505-045C

.052” (1.4mm) KP1505-052C

1/16” (1.6mm) KP1505-1/16C

7/64” Hardfacing KP1505-7/64H

(Knurled V Groove with matching Smooth U Groove)

Cored or Solid Steel Wire, Knurled V Groove:

.068-.072” (1.8mm) KP1505-068

5/64” (2.0mm) KP1505-5/64

3/32” (2.4mm) KP1505-3/32

7/64” (2.8mm) Cored KP1505-7/64

.120” (3.2mm) Cored KP1505-120

Aluminum Wire, Smooth U Groove:

.035” (0.9mm) KP1507-035A

.040” (1.0mm) KP1507-040A

3/64” (1.2mm) KP1507-3/64A

1/16” (1.6mm) KP1507-1/16A

3/32” (2.4mm) KP1507-3/32A

456

ARCLINK®/LINC-NET CONTROL EXTENSION CABLES

Description Order Number

8 ft. (2.5m) Without weld cable K1543-8

16 ft. (4.8m) Without weld cable K1543-16

25 ft. (7.6m) Without weld cable K1543-25

50 ft. (15.2m) Without weld cable K1543-50

100 ft.(30.4m) Without weld cable K1543-100

COAXIAL WELD POWER CABLES (2)

Description Order Number

25 ft. (7.6m) 350 amps K1796-25

50 ft. (15.2m) 350 amps K1796-50

75 ft. (22.8m) 325 amps K1796-75

100 ft. (30.4m) 300 amps K1796-100

(2) Recommended for STT and pulse welding when using long distances between

feeder and power source.

WELD POWER CABLES

www.lincolnelectric.com

Description Order Number

FEED PLATE GUN RECEIVER BUSHINGS

• Magnum 200, 300

and 400 gun and

cable assemblies

with K466-1

connector kit.

• Lincoln Innershield

gun and cable

assembly.

• Magnum 550 gun

and cable assembly

with K613-1

connector kit.

•Magnum 200 and

400 fully assembled

guns (K497-2x and

K471-2x).

• Magnum 200, 300

and 400 gun and

cable assemblies with

K466-10 connector

kit.

• Guns with Tweco®

#2, #3, and #4

connectors.

• Magnum 550 gun

and cable assembly

with K613-7

connection.

• Guns with Tweco #5

connectors.

• Magnum 200, 300

and 400 gun and

cable assemblies

with K466-3

connector kit.

•To adapt to OXO

guns.

• Magnum gun and

cable assemblies

with Fast-Mate

TM

connections.

• Handles both single

and dual procedure

guns.

K1500-1 Gun

Receiver Bushing

(Optional)

K1500-2 Gun

Receiver Bushing

(Standard)

K1500-3 Gun

Receiver Bushing

(Optional)

K1500-4 Gun

Receiver Bushing

(Optional)

K1500-5 Gun

Receiver Bushing

(Optional)

K489-7 Fast-Mate

Gun Receiver

Bushing (Optional)

Page 7

Power Feed 10M

[7]

RECOMMENDED OPTIONS

GENERAL OPTIONS

Magnum® Gas-Shielded Gun & Cable

Assemblies

Available 200-550 amps, air-cooled, gasshielded welding guns. Dual procedure

capability with gun trigger lock available

on 400 amp gun.

See bulletin E12.10

Magnum® Self-Shielded Gun & Cable

Assemblies

Available 250-600 amps.

See bulletin E12.110

Push-Pull Guns

The Python®, CobraMAX™ and Prince®

XL provide optimum push-pull

performance at a variety of amperages.

Available in air-cooled or water-cooled

models.

Order K2297-X, K2212-X, and K2252-X

Push-Pull Gun Connection Kit

Required for aluminum welding with the

Prince XL, Python and CobraMax air or

water-cooled push-pull guns. Includes

power block, gun bushing, gas hose

adapter, torch gas bypass valve (required

for Prince XL Gun only), and wire reel

brake limiter. Requires aluminum drive

roll kit.

Order K2339-1

Dual Procedure Switch

Allows the use of two welding procedures

with each Lincoln Magnum gun

connected to an LN-10, DH-10 or Power

Feed 10M Bench or Boom model.

15 ft. (7.6m).

Order K683-3

ArcLink “T” Connector Kit

For connecting multiple feeders to a

single power source.

Order K2429-1

Foot Amptrol® Connector Kit

Provides 25 ft. (7.6m) of remote ouput

control for TIG welding. (6 pin plug

connection).

Order K2320-1

Wire Straightener

For Lincoln Electric 10 series wire feeders.

Straightens wire for better, smoother

feeding.

Order K1733-1

Spindle Adapter for 14 lb. (6 kg)

Innershield® Coils

Permits 14 lb. (6 kg) Innershield electrode

coils to be mounted on 2” (51 mm) O.D.

spindles.

Order K435

Spindle Adapter for 8” O.D. Spools

Permits 8” (200mm) O.D. spools to be

mounted on 2” (51mm) O.D. spindles.

Order K468

GENERAL OPTIONS

30 lb. (14 kg) Readi-Reel® Adapter

Adapts 22-30 lb. (10-14 kg) Lincoln

Readi-Reels of electrode to 2” (51mm)

spindle.

Order K363P

Wire Reel Cover Kit

Plastic enclosure for up to 44 lb.

(20 kg) wire packages.

Order K1634-1

50-60 lb. Readi-Reel® Adapter

Adapts 60 lb. (27.2 kg) coils of Lincoln

electrode to 2” (51mm) spindle.

Order K438

50-60 lb. Coil Adapter

Adapts 50-60 lb. (22.6-27.2 kg) coils of

Lincoln electrode to 2” (51mm) spindle.

Order K1504-1

Plastic Wire Cover

Plastic enclosure for up to 60 lb.

(27.2 kg) wire packages.

Order K1634-2

Incoming Bushing for Lincoln

Conduit

Feed Plate Incoming Bushings connect

directly to wire conduit (not included),

for use in boom system, long

distances, or large payoff packages.

Bushings can be used with any wire

conduit (K515 or K565).

Order K1546-1 for .025-1/16” wire

Order K1546-2 for 1/16-1/8” wire

Gas Guard Regulator

For CO2and Argon blend gases.

Reduces surge caused by excess

pressure in supply hose. Includes

adjustable flow regulator with

removable adjustor key.

Order K659-1

Water Connection Kit

Includes fittings for use with watercooled guns and Magnum Coolers. Kit

provides for one gun.

Order K590-6

Magnum Flow Sensor

Rotary Flow Sensor with Leads

monitors water cooling flow and shuts

off power to gun if water stops.

Order K1536-1

Caster Kit — Light Duty

Mounts to the Universal Wire Reel

Stand. Allows for easy movement of

wire feeder.

Order K1556-1

6000 Series Welding Arm

Create a safe, uncluttered work

environment where floor space is

used effectively with a Lincoln Series

6000 Welding Arm. Glide the arm

effortlessly into position when in use

or swing it conveniently against a wall

or beam for safe, out-of-the-way

storage. An 18” x 18” (457 x 457mm)

footprint ties up very little floor space.

Order K1778-1

www.lincolnelectric.com

Page 8

POWER FEED 10M BENCH MODEL K2230-1

POWER FEED 10M DUAL BENCH MODEL K2234-1

RECOMMENDED GENERAL OPTIONS

ArcLink/Linc-Net Control Extension Cables See table on page 6

Weld Power Cables See table on page 6

Coaxial Weld Power Cables See table on page 6

Feed Plate Gun Receiver Bushings See table on page 6

Drive Roll and Wire Guide Kits See table on page 6

Magnum Gun and Cable Assemblies See publication E12.10

Magnum Self-Shielded Gun and Cable Assemblies See publication E12.110

Push-Pull Guns K2297-X, K2212-X, K2252-X

Push-Pull Gun Connection Kit K2339-1

Dual Procedure Switch K683-3

ArcLink “T” Connector Kit K2429-1

Foot Amptrol Connector Kit K2320-1

Wire Straightener K1733-1

Spindle Adapter for 14 lb. Innershield Coils K435

Spindle Adapter for 8” O.D. Spools K468

30 lb. Readi-Reel Adapter K363P

Wire Reel Cover Kit K1634-1

50-60 lb. Readi-Reel Adapter K438

50-60 lb. Coil Adapter K1504-1

Plastic Wire Cover K1634-2

Incoming Bushing for Lincoln Conduit:

- for .025-1/16” wire K1546-1

- for 1/16-1/8” wire K1546-2

Gas Guard Regulator K659-1

Water Connection Kit K590-6

Magnum Flow Sensor K1536-1

Caster Kit - Light Duty K1556-1

6000 Series Welding Arm K1778-1

ADDITIONAL OPTIONS FOR SINGLE BENCH MODEL

Dual Procedure/Memory Panel K2360-1

Swivel Platform K1557-1

Insulated Lift Bail K1555-1

RECOMMENDED POWER SOURCE OPTIONS

Power Wave 355M see publication E5.146

Power Wave 455M and 455M/STT see publication E5.161

Power Wave 655 Robotic see publication E10.95

TOTAL:

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

POWER FEED 10M ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and to exceed their

expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric

is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s

particular purpose, with respect to such information or advice. As a matter ofpractical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has been given, nor

does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many variables beyond the

control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change — This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

ADDITIONAL OPTIONS FOR SINGLE

BENCH MODEL

Dual Procedure/Memory Panel

Weld procedures are saved into memory for future

use. Option on Power Feed 10M Single Bench and

Boom.

Order K2360-1

Swivel Platform

Mounts to the lift bail on the power source and

bottom of the Universal Wire Reel Stand. Wire feeder

may be lifted off if needed. Compatible with Light Duty

Caster Kit. Includes “lazy susan” parts tray.

Order K1557-1

Insulated Lift Bail

Allows the entire wire feeder to be hung from a crane

or hook. Use with Universal Wire Reel Stand.

Order K1555-1

Loading...

Loading...