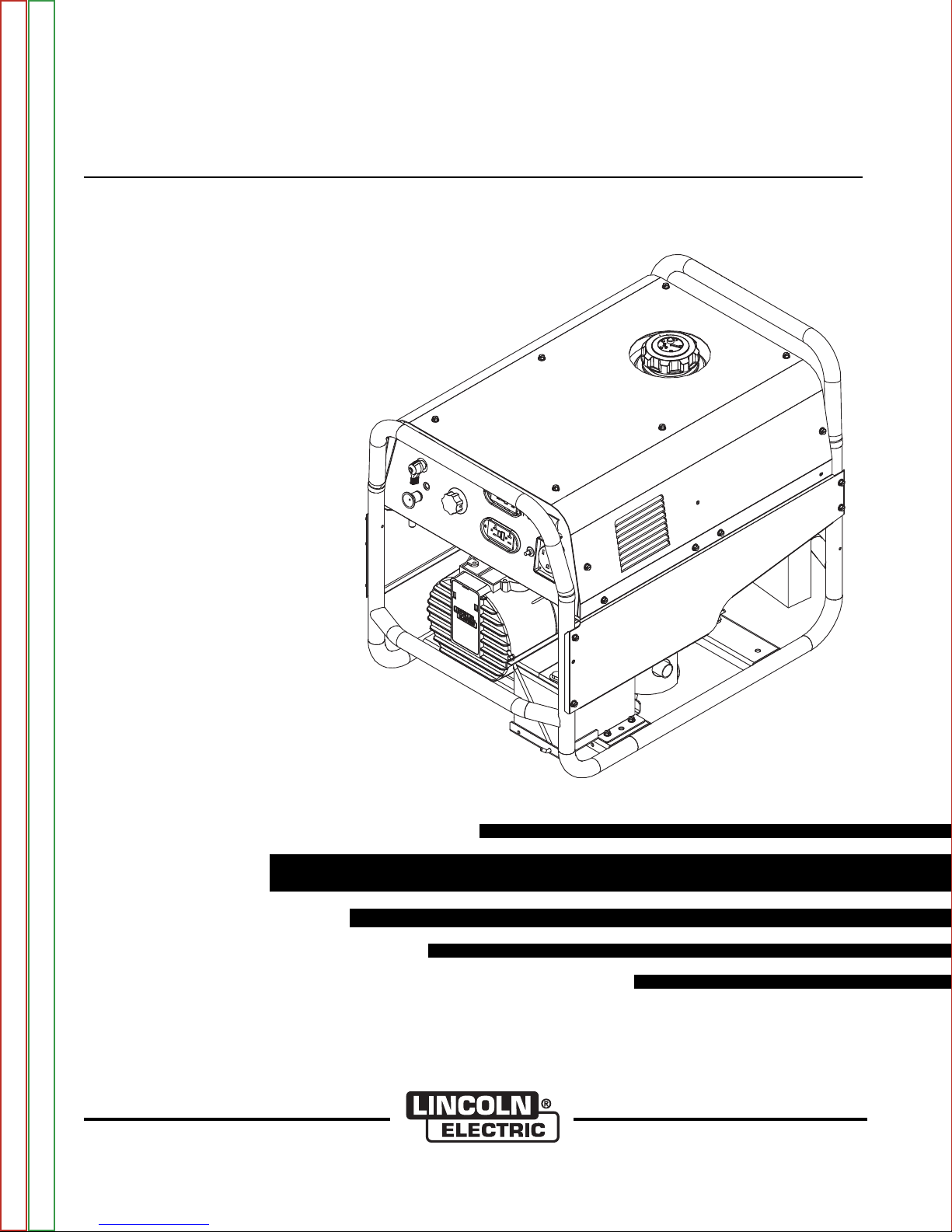

Page 1

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However,

your overall safety can be

increased by proper installation

. . . and thoughtful operation on

your part. DO NOT INSTALL,

OPERATE OR REPAIR THIS

EQUIPMENT WITHOUT READING THIS MANUAL AND THE

SAFETY PRECAUTIONS CONTAINED THROUGHOUT. And,

most importantly, think before you

act and be careful.

SVM204-A

October, 2010

OUTBACK®185

For use with machine code number: 11516

SERVICE MANUAL

View Safety Info View Safety Info View Safety Info View Safety Info

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 1.888.935.3877 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

• World's Leader in Welding and Cutting Products •

Copyright © Lincoln Global Inc.

Page 2

i i

SAFETY

WARNING

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer, birth defects, and other reproductive harm.

The Above For Diesel Engines

ARC WELDING can be hazardous. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information, it is strongly recommended that you

purchase a copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American Welding Society, P.O. Box 351040,

Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the

Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

The Above For Gasoline Engines

FOR ENGINE

powered equipment.

1.a. Turn the engine off before troubleshooting and maintenance

work unless the maintenance work requires it to be running.

____________________________________________________

1.b.Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

____________________________________________________

1.c. Do not add the fuel near an open flame welding arc or when the engine is running. Stop

the engine and allow it to cool before refueling to prevent spilled fuel from vaporizing on

contact with hot engine parts and igniting. Do

not spill fuel when filling tank. If fuel is spilled,

wipe it up and do not start engine until fumes

have been eliminated.

____________________________________________________

1.d. Keep all equipment safety guards, covers and devices in position and in good repair.Keep hands, hair, clothing and tools

away from V-belts, gears, fans and all other moving parts

when starting, operating or repairing equipment.

____________________________________________________

1.e. In some cases it may be necessary to remove safety

guards to perform required maintenance. Remove

guards only when necessary and replace them when the

maintenance requiring their removal is complete.

Always use the greatest care when working near moving

parts.

___________________________________________________

1.h. To avoid scalding, do not remove the

radiator pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS

may be dangerous

2.a. Electric current flowing through any conductor causes

localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and

welding machines

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1.

Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

1.f. Do not put your hands near the engine fan.

Do not attempt to override the governor or

idler by pushing on the throttle control rods

while the engine is running.

___________________________________________________

1.g. To prevent accidentally starting gasoline engines while

turning the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

2.d.3. Do not place your body between the electrode and

work cables. If the electrode cable is on your right

side, the work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as

possible to the area being welded.

2.d.5. Do not work next to welding power source.

OUTBACK® 185

Page 3

ii ii

SAFETY

ELECTRIC SHOCK can kill.

3.a. The electrode and work (or ground) circuits

are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare

skin or wet clothing. Wear dry, hole-free

gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

must be performed under electrically hazardous

conditions (in damp locations or while wearing wet

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic

welding gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection

should be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical

(earth) ground.

3.f.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see Items 6.c. and 8.

ARC RAYS can burn.

4.a. Use a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. Headshield and filter lens

should conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

can be dangerous.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases.When welding, keep

your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing zone. When

welding with electrodes which require special

ventilation such as stainless or hard facing (see

instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure as

low as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or mechanical ventilation. In confined spaces or in some circumstances,

outdoors, a respirator may be required. Additional precautions are also required when welding on galvanized

steel.

5. b. The operation of welding fume control equipment is affected

by various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure level should be checked upon installation and periodically thereafter to be certain it is within applicable OSHA PEL

and ACGIH TLV limits.

5.c.

Do not weld in locations near chlorinated hydrocarbon

coming from degreasing, cleaning or spraying operations.

The heat and rays of the arc can react with solvent vapors

form phosgene, a highly toxic gas, and other irritating products.

vapors

to

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

5.d. Shielding gases used for arc welding can displace air and

cause injury or death. Always use enough ventilation,

especially in confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your

employer’s safety practices. MSDS forms are available from

your welding distributor or from the manufacturer.

5.f. Also see item 1.b.

OUTBACK® 185

Page 4

iii iii

SAFETY

WELDING and CUTTING

SPARKS can cause fire or

explosion.

6.a.

this is not possible, cover them to prevent the welding sparks

from starting a fire. Remember that welding sparks and hot

materials from welding can easily go through small cracks

and openings to adjcent areas. Avoid welding near hydraulic

lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site,

special precautions should be used to prevent hazardous

situations. Refer to “Safety in Welding and Cutting” (ANSI

Standard Z49.1) and the operating information for the

equipment being used.

6.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact can

cause overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances

inside. They can cause an explosion even

been “cleaned”. For information, purchase “Recommended

Safe Practices for the

Containers and Piping That Have Held Hazardous

Substances”, AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

Sparks and spatter are thrown from the welding arc. Wear oil

6.f.

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a

welding area.

6.g. Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

increase the possibility of the welding current passing through

lifting chains, crane cables or other alternate circuits. This can

create fire hazards or overheat lifting chains or cables until

they fail.

6.h. Also see item 1.c.

Remove fire hazards from the welding area.

though

they have

Preparation

for Welding and Cutting of

CYLINDER may explode

if damaged.

7.a. Use only compressed gas cylinders

If

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

7.b. Always keep cylinders in an upright position securely

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected to

physical damage.

• A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

7.g. Read and follow the instructions on compressed gas

cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in

Cylinders,” available from the Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202.

containing the correct shielding gas for the

process used and properly operating

regulators designed for the gas and

FOR ELECTRICALLY

powered equipment.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accordance with the U.S. National

Electrical Code, all local codes and the manufacturer’s

recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention

During Welding, Cutting and Other Hot Work”, available from

NFPA, 1 Batterymarch Park,PO box 9101, Quincy, Ma

022690-9101.

6.j. Do not use a welding power source for pipe thawing.

Refer to http://www.lincolnelectric.com/safety for additional safety information.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OUTBACK® 185

Page 5

iv iv

SAFETY

PRÉCAUTIONS DE SÛRETÉ

Pour votre propre protection lire et observer toutes les instructions

et les précautions de sûreté specifiques qui parraissent dans ce

manuel aussi bien que les précautions de sûreté générales suivantes:

Sûreté Pour Soudage A L’Arc

1. Protegez-vous contre la secousse électrique:

a. Les circuits à l’électrode et à la piéce sont sous tension

quand la machine à souder est en marche. Eviter toujours

tout contact entre les parties sous tension et la peau nue

ou les vétements mouillés. Porter des gants secs et sans

trous pour isoler les mains.

b. Faire trés attention de bien s’isoler de la masse quand on

soude dans des endroits humides, ou sur un plancher metallique ou des grilles metalliques, principalement dans

les positions assis ou couché pour lesquelles une grande

partie du corps peut être en contact avec la masse.

c. Maintenir le porte-électrode, la pince de masse, le câble de

soudage et la machine à souder en bon et sûr état defonctionnement.

d.Ne jamais plonger le porte-électrode dans l’eau pour le

refroidir.

e. Ne jamais toucher simultanément les parties sous tension

des porte-électrodes connectés à deux machines à souder

parce que la tension entre les deux pinces peut être le total

de la tension à vide des deux machines.

f. Si on utilise la machine à souder comme une source de

courant pour soudage semi-automatique, ces precautions

pour le porte-électrode s’applicuent aussi au pistolet de

soudage.

2. Dans le cas de travail au dessus du niveau du sol, se protéger

contre les chutes dans le cas ou on recoit un choc. Ne jamais

enrouler le câble-électrode autour de n’importe quelle partie du

corps.

3. Un coup d’arc peut être plus sévère qu’un coup de soliel, donc:

6. Eloigner les matériaux inflammables ou les recouvrir afin de

prévenir tout risque d’incendie dû aux étincelles.

7. Quand on ne soude pas, poser la pince à une endroit isolé de

la masse. Un court-circuit accidental peut provoquer un

échauffement et un risque d’incendie.

8. S’assurer que la masse est connectée le plus prés possible de

la zone de travail qu’il est pratique de le faire. Si on place la

masse sur la charpente de la construction ou d’autres endroits

éloignés de la zone de travail, on augmente le risque de voir

passer le courant de soudage par les chaines de levage,

câbles de grue, ou autres circuits. Cela peut provoquer des

risques d’incendie ou d’echauffement des chaines et des

câbles jusqu’à ce qu’ils se rompent.

9. Assurer une ventilation suffisante dans la zone de soudage.

Ceci est particuliérement important pour le soudage de tôles

galvanisées plombées, ou cadmiées ou tout autre métal qui

produit des fumeés toxiques.

10. Ne pas souder en présence de vapeurs de chlore provenant

d’opérations de dégraissage, nettoyage ou pistolage. La

chaleur ou les rayons de l’arc peuvent réagir avec les vapeurs

du solvant pour produire du phosgéne (gas fortement toxique)

ou autres produits irritants.

11. Pour obtenir de plus amples renseignements sur la sûreté, voir

le code “Code for safety in welding and cutting” CSA Standard

W 117.2-1974.

PRÉCAUTIONS DE SÛRETÉ POUR

LES MACHINES À SOUDER À

TRANSFORMATEUR ET À

REDRESSEUR

a. Utiliser un bon masque avec un verre filtrant approprié ainsi

qu’un verre blanc afin de se protéger les yeux du rayonnement de l’arc et des projections quand on soude ou

quand on regarde l’arc.

b. Porter des vêtements convenables afin de protéger la peau

de soudeur et des aides contre le rayonnement de l‘arc.

c. Protéger l’autre personnel travaillant à proximité au

soudage à l’aide d’écrans appropriés et non-inflammables.

4. Des gouttes de laitier en fusion sont émises de l’arc de

soudage. Se protéger avec des vêtements de protection libres

de l’huile, tels que les gants en cuir, chemise épaisse, pantalons sans revers, et chaussures montantes.

5. Toujours porter des lunettes de sécurité dans la zone de

soudage. Utiliser des lunettes avec écrans lateraux dans les

zones où l’on pique le laitier.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

1. Relier à la terre le chassis du poste conformement au code de

l’électricité et aux recommendations du fabricant. Le dispositif

de montage ou la piece à souder doit être branché à une

bonne mise à la terre.

2. Autant que possible, I’installation et l’entretien du poste seront

effectués par un électricien qualifié.

3. Avant de faires des travaux à l’interieur de poste, la debrancher à l’interrupteur à la boite de fusibles.

4. Garder tous les couvercles et dispositifs de sûreté à leur place.

OUTBACK® 185

Page 6

v v

SAFETY

Electromagnetic Compatibility (EMC)

Conformance

Products displaying the CE mark are in conformity with European Community Council Directive of 15 Dec

2004 on the approximation of the laws of the Member States relating to electromagnetic compatibility,

2004/108/EC. It was manufactured in conformity with a national standard that implements a harmonized

standard: EN 60974-10 Electromagnetic Compatibility (EMC) Product Standard for Arc Welding Equipment.

It is for use with other Lincoln Electric equipment. It is designed for industrial and professional use.

Introduction

All electrical equipment generates small amounts of electromagnetic emission. Electrical emission may be

transmitted through power lines or radiated through space, similar to a radio transmitter. When emissions

are received by other equipment, electrical interference may result. Electrical emissions may affect many

kinds of electrical equipment; other nearby welding equipment, radio and TV reception, numerical controlled

machines, telephone systems, computers, etc. Be aware that interference may result and extra precautions

may be required when a welding power source is used in a domestic establishment.

Installation and Use

The user is responsible for installing and using the welding equipment according to the manufacturer’s

instructions. If electromagnetic disturbances are detected then it shall be the responsibility of the user of the

welding equipment to resolve the situation with the technical assistance of the manufacturer. In some cases

this remedial action may be as simple as earthing (grounding) the welding circuit, see Note. In other cases

it could involve construction of an electromagnetic screen enclosing the power source and the work complete with associated input filters. In all cases electromagnetic disturbances must be reduced to the point

where they are no longer troublesome.

Note: The welding circuit may or may not be earthed for safety reasons according to national

codes. Changing the earthing arrangements should only be authorized by a person who is

competent to access whether the changes will increase the risk of injury, e.g., by allowing

parallel welding current return paths which may damage the earth circuits of other equipment.

Assessment of Area

Before installing welding equipment the user shall make an assessment of potential electromagnetic problems in the surrounding area. The following shall be taken into account:

a) other supply cables, control cables, signaling and telephone cables; above, below and adjacent to the

welding equipment;

b) radio and television transmitters and receivers;

c) computer and other control equipment;

d) safety critical equipment, e.g., guarding of industrial equipment;

e) the health of the people around, e.g., the use of pacemakers and hearing aids;

f) equipment used for calibration or measurement

g) the immunity of other equipment in the environment. The user shall ensure that other equipment being

used in the environment is compatible. This may require additional protection measures;

h) the time of day that welding or other activities are to be carried out.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OUTBACK® 185

Page 7

vi vi

SAFETY

Electromagnetic Compatibility (EMC)

The size of the surrounding area to be considered will depend on the structure of the building and other

activities that are taking place. The surrounding area may extend beyond the boundaries of the premises.

Methods of Reducing Emissions

Mains Supply

Welding equipment should be connected to the mains supply according to the manufacturer’s recommendations. If interference occurs, it may be necessary to take additional precautions such as filtering of the mains

supply. Consideration should be given to shielding the supply cable of permanently installed welding equipment, in metallic conduit or equivalent. Shielding should be electrically continuous throughout its length. The

shielding should be connected to the welding power source so that good electrical contact is maintained

between the conduit and the welding power source enclosure.

Maintenance of the Welding Equipment

The welding equipment should be routinely maintained according to the manufacturer’s recommendations.

All access and service doors and covers should be closed and properly fastened when the welding equipment is in operation. The welding equipment should not be modified in any way except for those changes

and adjustments covered in the manufacturers instructions. In particular, the spark gaps of arc striking and

stabilizing devices should be adjusted and maintained according to the manufacturer’s recommendations.

Welding Cables

The welding cables should be kept as short as possible and should be positioned close together, running at

or close to floor level.

Equipotential Bonding

Bonding of all metallic components in the welding installation and adjacent to it should be considered.

However, metallic components bonded to the work piece will increase the risk that the operator could

receive a shock by touching these metallic components and the electrode at the same time. The operator

should be insulated from all such bonded metallic components.

Earthing of the Workpiece

Where the workpiece is not bonded to earth for electrical safety, not connected to earth because of its size

and position, e.g., ships hull or building steelwork, a connection bonding the workpiece to earth may reduce

emissions in some, but not all instances. Care should be taken to prevent the earthing of the workpiece

increasing the risk of injury to users, or damage to other electrical equipment. Where necessary, the connection of the workpiece to earth should be made by a direct connection to the workpiece, but in some

countries where direct connection is not permitted, the bonding should be achieved by suitable capacitance,

selected according to national regulations.

Screening and Shielding

Selective screening and shielding of other cables and equipment in the surrounding area may alleviate

problems of interference. Screening of the entire welding installation may be considered for special applica-

1

tions.

_________________________

1

Portions of the preceding text are contained in EN 60974-10: “Electromagnetic Compatibility (EMC) product standard for arc welding equipment.”

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OUTBACK® 185

Page 8

I I

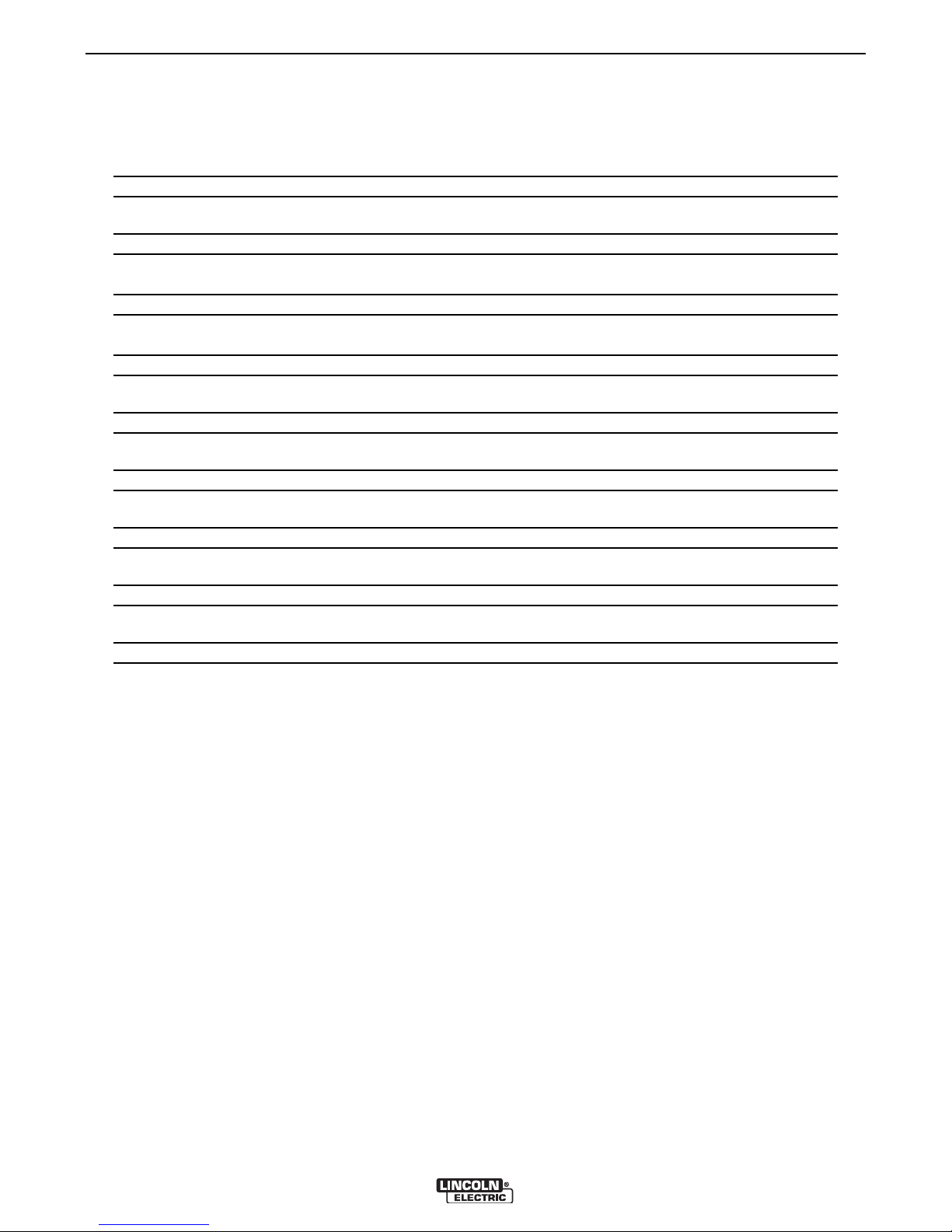

- MASTER TABLE OF CONTENTS FOR ALL SECTIONS -

Page

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i-vi

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section A

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section B

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section C

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section D

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section E

Troubleshooting and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section F

Electrical Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section G

Parts Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-591

OUTBACK® 185

Page 9

A-1 A-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Pre-Operation Engine Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

TABLE OF CONTENTS - INSTALLATION SECTION

Location and Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Stacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Tilting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Spark Arrester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Electrical and Welding Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Machine Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Plugs and Hand-Held Equipment, Auxiliary Power Receptacles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Premises Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Electrical Devices used with the OUTBACK® 185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OUTBACK® 185

Page 10

A-2 A-2

INSTALLATION

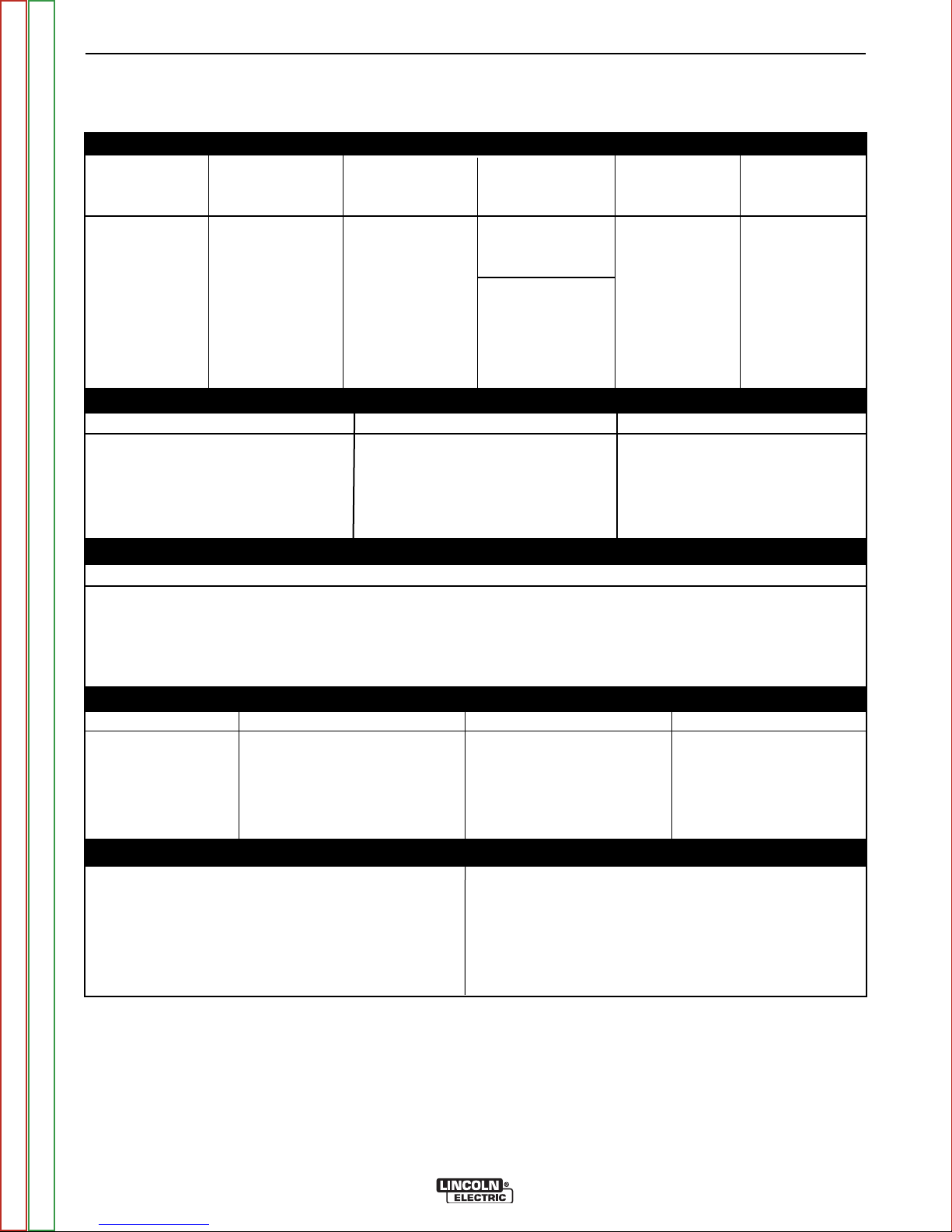

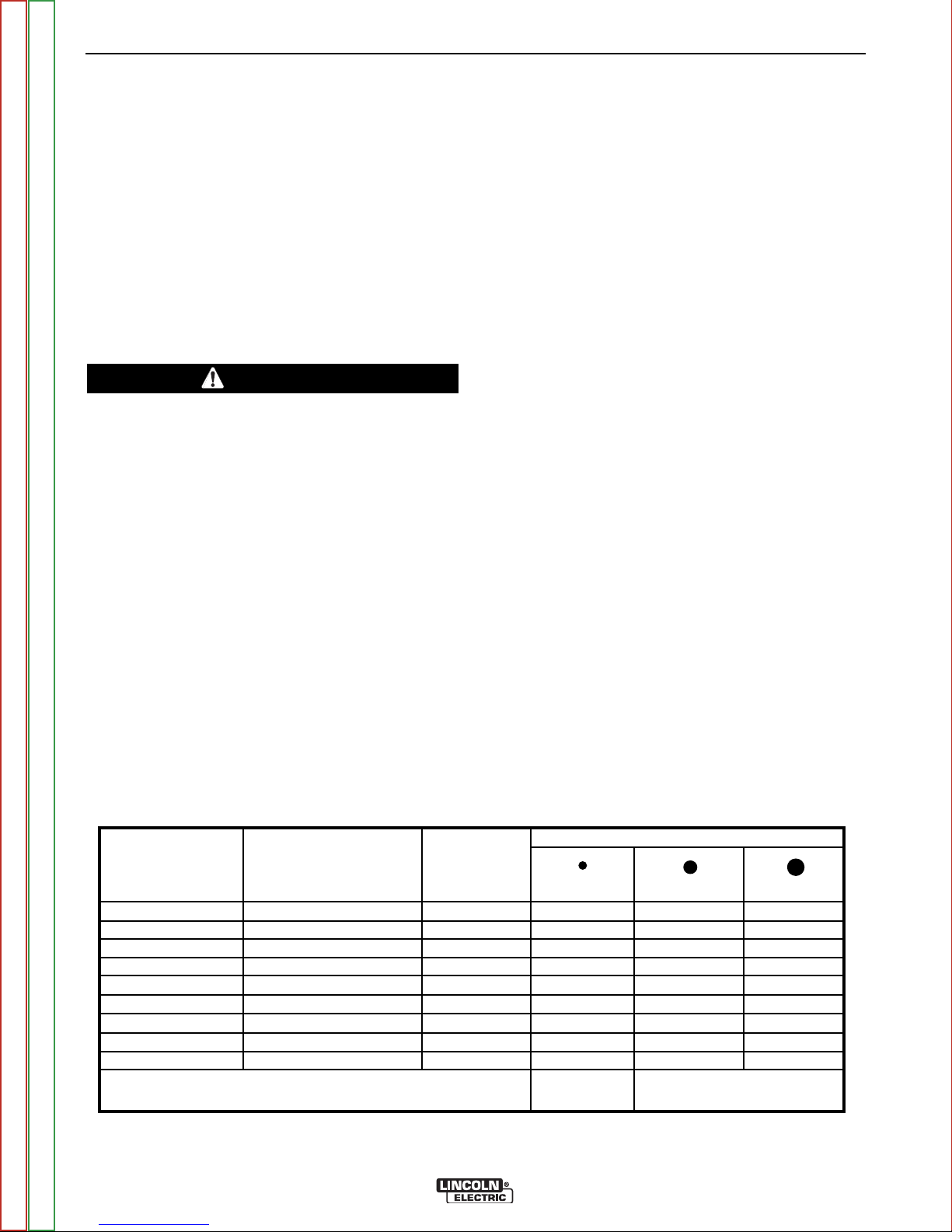

TECHNICAL SPECIFICATIONS -

OUTBACK® 185 (K2706-1)

INPUT - GASOLINE ENGINE

Make/Model Description Speed (RPM) Displacement Ignition Capacities

System

KOHLER 1 cylinder

CS 12.75 4 cycle 1825RPM Low Idle (360 cc) Start; (24.9L)

air-cooled 3400RPM Full Load

OHV gasoline Bore x Stroke

12.75 HP @ Choke (1.1L)

3600 RPM 3.35” x 2.48”

Aluminum Block

w/ Cast Iron Sleeve

3750RPM High Idle 21.96 cu. in

(85 mm x 63mm)

Electric & Recoil

Manual

Fuel: 6.86 gal.

Oil: 1.2 Qts.

RATED OUTPUT - WELDER

AMPS @ DC CONSTANT CURRENT DUTY CYCLE VOLTS @ RATED AMPERES

100 100% 25

130 60% 25

150 20% 25

185 MAX OUTPUT ---

OUTPUT -WELDER AND GENERATOR

Welding Ranges Welding Open Circuit Voltage AC Auxiliary Power

4600 Watts 115V 1PH

100% Duty Cycle

50 - 185 Amps DC 80 VDC Max. 5700 Peak Watts

5200 Continuous Watts

120 / 230 V 1PH

PHYSICAL DIMENSIONS

HEIGHT WIDTH DEPTH WEIGHT

25.47 in. 21.12 in. 31.48 in. 310.0 lbs.

646.94 mm 536.45 mm 799.59 mm 140.6 kg

OPERATING TEMPERATURE RANGE STORAGE TEMPERATURE RANGE

0° F TO 104° F (-18° C TO 40° C) -40° F TO 131° F (-40° C TO 55° C)

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 11

A-3 A-3

INSTALLATION

SAFETY PRECAUTIONS

Read this entire installation section before you

start installation.

WARNING

Do not attempt to use this equipment until you

have thoroughly read all operating and maintenance manuals supplied with your machine. They

include important safety precautions, detailed

engine starting, operating and maintenance

instructions, and parts lists.

Hazards of Electric Shock, Engine

Exhaust & Moving Parts

WARNING

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrode with skin or wet clothing.

• Insulate yourself from work and

ground.

• Always wear dry insulating gloves.

ENGINE EXHAUST can kill.

• Use in open, well ventilated areas

or vent exhaust outside.

• Do not stack anything on or near

the engine.

MOVING PARTS can injure.

• Do not operate with doors open or

guards off.

• Stop engine before servicing.

• Keep away from moving parts.

Only qualified personnel should install, use, or

service this equipment.

LOCATION AND VENTILATION

Whenever you use the

cooling air can flow around the machine’s gasoline engine

and the generator. Avoid dusty, dirty areas. Also, keep the

machine away from heat sources. Do not place the back end

of the generator anywhere near hot engine exhaust from

another machine. And of course, make sure that engine

exhaust is ventilated to an open, outside area.

OUTBACK® 185

The

the machine in puddles or otherwise submerge it in water.

Such practices pose safety hazards and cause improper

operation and corrosion of parts.

Always operate the

and all machine components completely assembled. This will

help to protect you from the dangers of moving parts, hot

metal surfaces, and live electrical devices.

OUTBACK® 185

must be used outdoors. Do not set

OUTBACK® 185

, be sure that clean

with the case roof on

STORING

1. Store the machine in a cool, dry place when it is not in

use. Protect it from dust and dirt. Keep it where it can not

be accidentally damaged from construction activities,

moving vehicles and other hazards.

2. If you will be storing the machine for over 30 days, you

should drain the fuel to protect fuel system and carburetor parts from gum deposits. Empty all fuel from the tank

and run the engine until it stops from lack of fuel.

3. You can store the machine for up to 24 months if you use

a stabilizing Additive in the fuel system. Mix the additive

with the fuel in the tank and run the engine for a short

time to circulate the additive through the carburetor.

4. While the engine is still warm, drain the oil and refill with

fresh 10W30 oil.

5. Remove the spark plug and pour approximately 1/2

ounce (15ml) of engine oil into the cylinder. Replace the

spark plug and crank the engine slowly to distribute the

oil.

6. Clean any dirt and debris from the cylinder and cylinder

head fins and housing, rotating screen, and muffler

areas.

7. Store in a clean, dry area.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 12

A-4 A-4

INSTALLATION

STACKING

OUTBACK® 185 machines CANNOT be stacked.

TILTING

Place the machine on a secure, level surface whenever you use it or store it. Any surfaces you place it on

other than the ground must be firm, non-skid, and

structurally sound.

The gasoline engine is designed to run in a level position for best performance. It can operate at an angle,

but this should never be more than 15 degrees in any

direction. If you do operate it at a slight angle, be sure

to check the oil regularly and keep the oil level full.

Also, fuel capacity will be a little less at an angle.

LIFTING

The OUTBACK® 185 should be lifted by two people.

(See Technical Specification page for weight). The

LowLift™ grab bars on both ends make lifting easier.

PRE-OPERATION ENGINE SERVICE

Read and understand the engine operating and

maintenance instructions supplied with this machine

before you operate the OUTBACK® 185.

OIL

The OUTBACK® 185 is shipped with the engine filled

with SAE 10W30 oil. CHECK THE OIL LEVEL

BEFORE YOU START THE ENGINE. This is an added

precaution. Do not screw in dipstick when checking oil

level. DO NOT OVERFILL. Be sure the fill plug is tight

after servicing.

FUEL

Fill the fuel tank with clean, fresh, regular grade (minimum 87 octane lead free gasoline. DO NOT MIX OIL

WITH GAS. The OUTBACK® 185 capacity is approximately 6.8 gallons (25.74 Liter). DO NOT OVERFILL,

allow room in the fuel tank for fuel expansion.

SPARK ARRESTER

Some federal, state or local laws may require gasoline

engines to be equipped with exhaust spark arresters

when they are operated in certain locations where

unarrested sparks may present a fire hazard. The

standard muffler included with this machine does not

qualify as a spark arrester. For areas requiring spark

arrestors, use K2793-1.

CAUTION

WARNING

• Keep hands away from muffler or HOT engine

parts.

• Stop the engine when fueling.

• Do not smoke when fueling.

• Remove fuel cap slowly to release pressure.

• Do not overfill tank.

• Wipe up spilled fuel and allow fumes to clear

before starting engine.

• Keep sparks and flame away from tank.

------------------------------------------------------------------------

An incorrect additional arrester may lead to damage to the engine or adversely affect performance.

------------------------------------------------------------------------

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 13

A-5 A-5

1

2

7

8

4

6

3

9

10

5

INSTALLATION

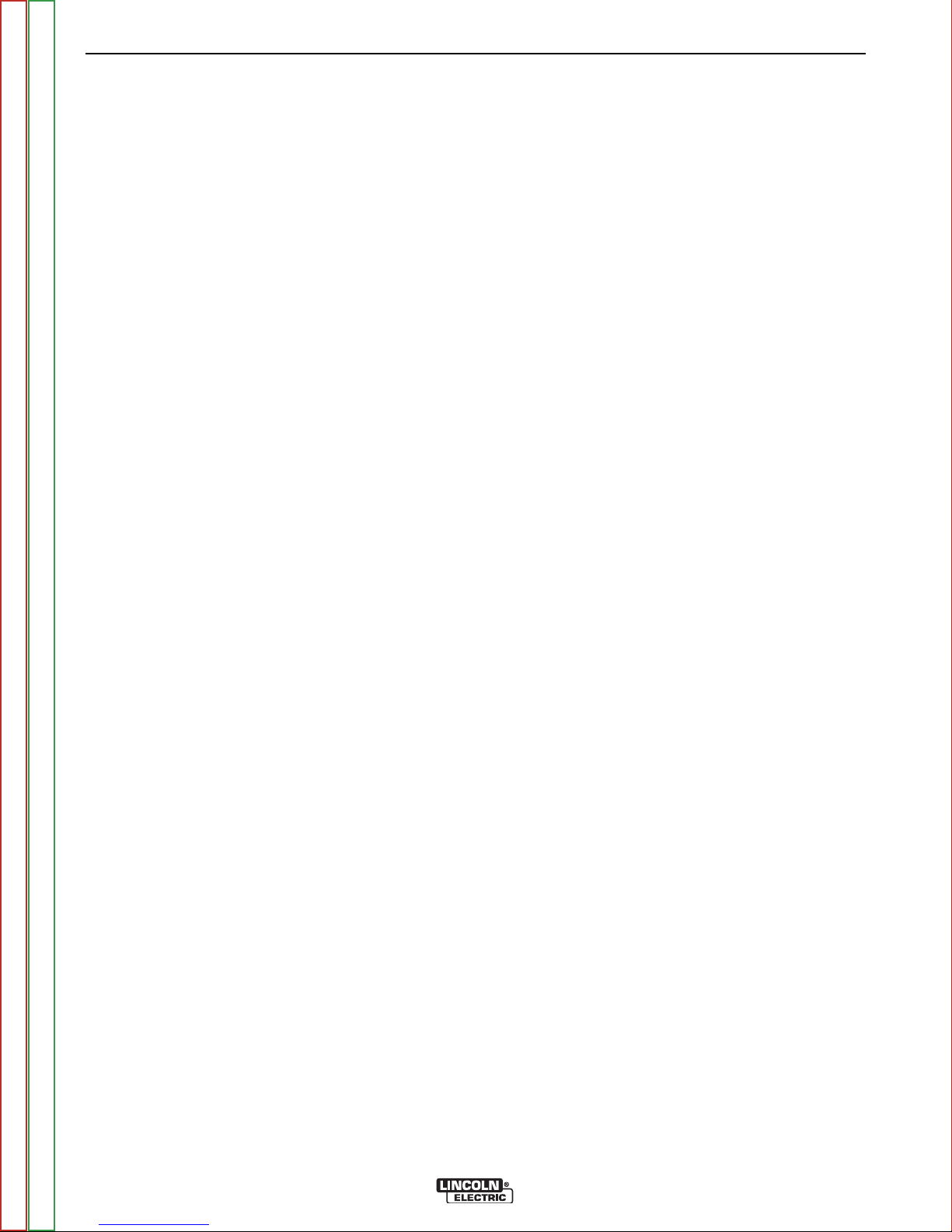

OUTBACK® 185 OUTPUT CONNECTIONS

1. CURRENT CONTROL DIAL

2. WELD OUTPUT TERMINALS (2)

3. GROUND STUD

4. CIRCUIT BREAKERS (2) - 20 AMP

5. CIRCUIT BREAKER 30 Amp

6. RECEPTACLE - 240 VOLT, 50 AMP

ELECTRICAL OUTPUT CONNECTIONS

See Figure A.1 for the location of the current control

dial, weld output terminals, ground stud, circuit breakers, 240 and 120 volt receptacles.

WELDING CABLE CONNECTIONS

Cable Size and Length

Be sure to use welding cables that are large enough.

The correct size and length becomes especially important when you are welding at a distance from the welder.

Table A.1 lists recommended cable sizes and lengths for

rated current and duty cycle. Length refers to the distance from the welder to the work and back to the

welder. Cable diameters are increased for long cable

lengths to reduce voltage drops.

FIGURE A.1

7. DUPLEX RECEPTACLE (2)- 120 VOLT, 20 AMP

8. HOURMETER

9. ENGINE SWITCH

10. CHOKE

100-150 ft (30-46 m)

150-200 ft (46-61 m)

200-250 ft (61-76m)

TABLE A.1

RECOMMENDED WELDING CABLE

SIZE AND LENGTH

TOTAL COMBINED LENGTH OF

ELECTRODE AND WORK CABLES

Cable

Length

0-50 ft (0-15m)

50-100 ft (15-30 m)

125 Amps

30% Duty Cycle

6 AWG

5 AWG

3 AWG

2 AWG

1 AWG

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 14

A-6 A-6

Cable Installation

INSTALLATION

MACHINE GROUNDING

Install the welding cables to your OUTBACK® 185 as

follows. See Figure A.1 for the location of parts.

1. The gasoline engine must be OFF to install weld-

ing cables.

2. Remove the 1/2-13 flanged nuts from the output

terminals.

3. Connect the electrode holder and work cables to

the weld output terminals. Normally, the electrode

cable is connected to the positive (+) output stud.

4. Tighten the flanged nuts securely.

5. Be certain that the metal piece you are welding

(the “work”) is securely connected to the work

clamp and cable.

6. Check and tighten the connections periodically.

CAUTION

• Loose connections will cause the output studs to

overheat and the studs may eventually melt.

• Do not cross welding cables at output stud connec-

tion. Keep isolated and separate from one another.

------------------------------------------------------------------------

Lincoln Electric offers a welding accessory kit with #6

welding cables. See the ACCESSORIES section of

this manual for more information.

Because this portable engine driven welder or generator creates its own power, it is not necessary to connect

its frame to an earth ground, unless the machine is

connected to premises wiring (your home, shop, etc.).

To prevent dangerous electric shock, other equipment

to which this engine driven welder supplies power,

must:

a) be grounded to the frame of the welder using a

grounded type plug

or

b) be double insulated

When this welder is mounted on a truck or trailer, the

machine grounding stud must be securely connected to the metal frame of the vehicle.

In general if the machine is to be grounded, it should

be connected with a #8 or larger copper wire to a solid

earth ground such as a metal water pipe going into the

ground for at least ten feet and having no insulated

joints, or to the metal framework of a building which

has been effectively grounded. The U.S. National

Electrical Code lists a number of alternate means of

grounding electrical equipment. A machine grounding

stud marked with the symbol is provided on the

front of the welder.

WARNING

DO NOT GROUND MACHINE TO A PIPE WHICH CARRIES EXPLOSIVE OR COMBUSTIBLE MATERIAL.

------------------------------------------------------------------------

For more information on welding , see WELDING

OPERATION in the OPERATION section of this manual.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 15

A-7 A-7

INSTALLATION

PLUGS AND HAND HELD EQUIPMENT

For further protection against electric shock, any electrical equipment connected to the generator receptacles must use a three-blade, grounded type plug or an

Underwriter’s Laboratories (UL) approved double insulated tool with a two blade plug.

WARNING

Never operate this machine with damaged or

defective cords. All electrical equipment must be

in safe operating condition.

------------------------------------------------------------------------

AUXILIARY POWER RECEPTACLES

The control panel of the OUTBACK® 185 features

three auxiliary power receptacles:

• Two 20 amp,120 volt duplex (double outlet)

receptacle.

• A 50 amp, 240 volt single outlet receptacle.

See Figure A.1

PREMISES WIRING

The OUTBACK® 185 is not recommended for premises wiring. The OUTBACK® 185 does not have a combined 120/240 volt receptacle and cannot be connected to a premises as described in other Lincoln literature.

The OUTBACK® 185 is intended only for backup,

intermittent use power. Certain electrical devices cannot be powered by the OUTBACK® 185. Refer to

Table A.2 for these devices.

CIRCUIT BREAKERS

Auxiliary power is protected by circuit breakers. When

the machine is operated in high temperature environments, the breakers may tend to trip at lower loads

than normally.

CAUTION

NEVER BYPASS THE CIRCUIT BREAKERS. WITHOUT OVERLOAD PROTECTION, THE UNIT COULD

OVERHEAT AND/OR CAUSE DAMAGE TO THE

EQUIPMENT BEING USED.

Through these receptacles the machine can supply up

to 5700 watts surge or 5200 watts continuous of singlephase 60 Hertz AC power. The machine output voltages meet UL standards and fall within ± 10% of the

rated voltage.

------------------------------------------------------------------------

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 16

A-8 A-8

INSTALLATION

CAUTION

Certain Electrical devices cannot be powered by the OUTBACK® 185. See Table A.2

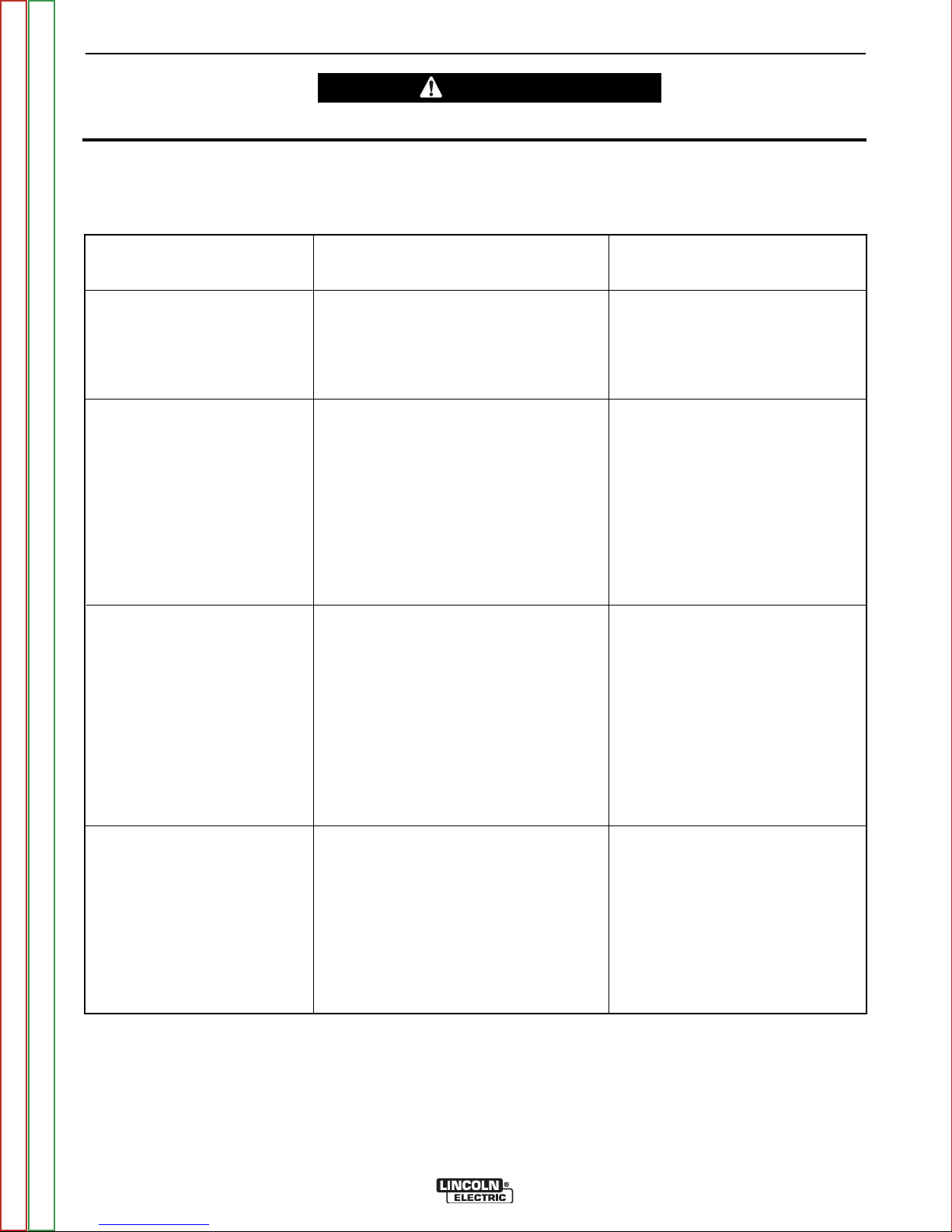

TABLE A.2

ELECTRICAL DEVICE USE WITH THE OUTBACK® 185

Type

Resistive

Capacitive

Inductive

Common Electrical Devices

Heaters, toasters, incandescent

light bulbs, electric range, hot

pan, skillet, coffee maker.

TV sets, radios, microwaves,

appliances with electrical control.

Single-phase induction motors,

drills, well pumps, grinders, small

refrigerators, weed and hedge

trimmers.

Possible Concerns

NONE

Voltage spikes or high voltage

regulation can cause the capacitative elements to fail. Surge

protection, transient protection,

and additional loading is recommended for 100% fail-safe operation. DO NOT RUN

THESE DEVICES WITHOUT

ADDITIONAL RESISTIVE TYPE

LOADS.

These devices require large

current inrush for starting. (See

Table B.3, AUXILIARY POWER

APPLICATIONS, in the OPERATION section of this manual for

required starting wattages.)

Some synchronous motors may

be frequency sensitive to attain

maximum output torque, but

they SHOULD BE SAFE from

any frequency induced failures.

Capacitive / Inductive

The Lincoln Electric Company is not responsible for any damage to electrical components

improperly connected to a OUTBACK® 185.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Computers, high resolution TV sets,

complicated electrical equipment.

OUTBACK® 185

An inductive type line conditioner along with transient and

surge protection is required,

and liabilities still exist.

DO NOT USE THESE DEVICES

WITH A OUTBACK® 185.

Page 17

B-1 B-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Recommended Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Operational Features and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Design Features and Advantages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Welding Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

TABLE OF CONTENTS - OPERATION SECTION

Controls and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Welder/Generator Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Engine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

Welding Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Auxiliary Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Electrode selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

Auxiliary Power Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-9

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OUTBACK® 185

Page 18

B-2 B-2

OPERATION

SAFETY INSTRUCTIONS

WARNING

ELECTRIC SHOCK

can kill.

• Do not touch electrically live parts

or electrode with skin or wet

clothing.

• Insulate yourself from work and

ground.

• Always wear dry insulating

gloves.

FUMES AND GASES

can be dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing

zone.

WARNING

ENGINE EXHAUST can kill.

• Use in open, well ventilated areas

or vent exhaust outside.

• Do not stack anything on or near

the engine.

MOVING PARTS can injure.

• Do not operate with doors open or

guards off.

• Stop engine before servicing.

• Keep away from moving parts.

Only qualified personnel should install, use, or

service this equipment.

Observe additional Safety Guidelines detailed

throughout this manual.

WELDING SPARKS

can cause fire or

explosion

• Keep flammable material away.

• Do not weld on containers that

have held combustibles.

ARC RAYS

can burn.

• Wear eye, ear and body

protection.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 19

B-3 B-3

OPERATION

GRAPHIC SYMBOLS USED ON THIS EQUIPMENT OR IN THIS MANUAL

WARNING /

CAUTION

OIL

FUEL

WORK CLAMP

FAST

CHOKE

AIR CLEANER

CIRCUIT

BREAKER

GROUND

(AUXILIARY

POWER)

ELECTRODE

WELDING ARC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SLOW

AUTO IDLE

ENGINE OFF

ENGINE START

OUTBACK® 185

Page 20

B-4 B-4

OPERATION

GENERAL DESCRIPTION

The OUTBACK® 185 is designed for commercial use

welder/generator applications. As a welder it provides

185 amps of DC constant current for welding with DC

stick electrodes. A single dial lets you select a full

range of welding output from 50 to 185 amps.

As a generator it can supply up to surge watts or continuous watts of 120 / 240 volt, single-phase AC power.

The machine is portable.

A Kohler CS 12.75 HP air cooled, OHV gasoline

engine powers the welder / generator. It has an engine

warranty of 3 years.

RECOMMENDED APPLICATIONS

Welder

The OUTBACK® 185 provides excellent constant current DC welding output for stick (SMAW) welding.

Generator

The OUTBACK® 185 gives smooth AC generator output for continuous auxiliary power usage within the

engine manufacturer’s required maintenance recommendations.

OPERATIONAL FEATURES AND

CONTROLS

DESIGN FEATURES AND

ADVANTAGES

• 185 amp DC constant current welding for stick

electrodes.

• Lightweight / portable.

• Full range, continuous welding output control with

a single knob.

• Automatic shutdown under low oil level condition.

• Hour Meter Standard.

• Surge watts or Watts of continuous 120 / 240 volt

single phase AC auxiliary power.

• Kohler CS 12.75 HP overhead cam air-cooled

gasoline engine. Smooth running, long life.

WELDING CAPABILITY

The OUTBACK® 185 rated 185 amps, 20 VDC at 10%

duty cycle on a ten-minute basis. This means that you

can load the welder to 185 amps for one minute out of

every ten-minute period. The machine is capable of

higher duty cycles at lower output currents. For example, you can load the welder to 120 amps for ten minutes out of ten for a 100% duty cycle.

The current is continuously variable from 50 to 185

amps DC. The OUTBACK® 185 can, therefore, weld

with all 3/32”, 1/8” and most 5/32” diameter Lincoln DC

electrodes.

The OUTBACK® 185 was designed for simplicity.

Therefore, it has very few operating controls. A single

dial on the control panel lets you select either welder

or generator use. For welding, the same dial selects

continuous current output over the machine’s 50 to

185 amp range.

The gasoline engine controls include a recoil starter,

choke and stop switch. See ENGINE OPERATION in

the OPERATION section of this manual for details

about starting, running, stopping, and breaking in the

gasoline engine.

LIMITATIONS

• The OUTBACK® 185 is not recommended for any

processes besides those that are normally performed using stick welding (SMAW) procedures.

• The OUTBACK® 185 is not recommended for pipe

thawing.

• During welding, generator power is limited to 100

watts, and output voltages can drop from 120 to 80

volts and 240 to 160 volts. Therefore, DO NOT

OPERATE ANY SENSITIVE ELECTRICAL EQUIPMENT WHILE YOU ARE WELDING.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 21

B-5 B-5

1

2

7

8

3 or 4

6

9

10

12

11

5

OPERATION

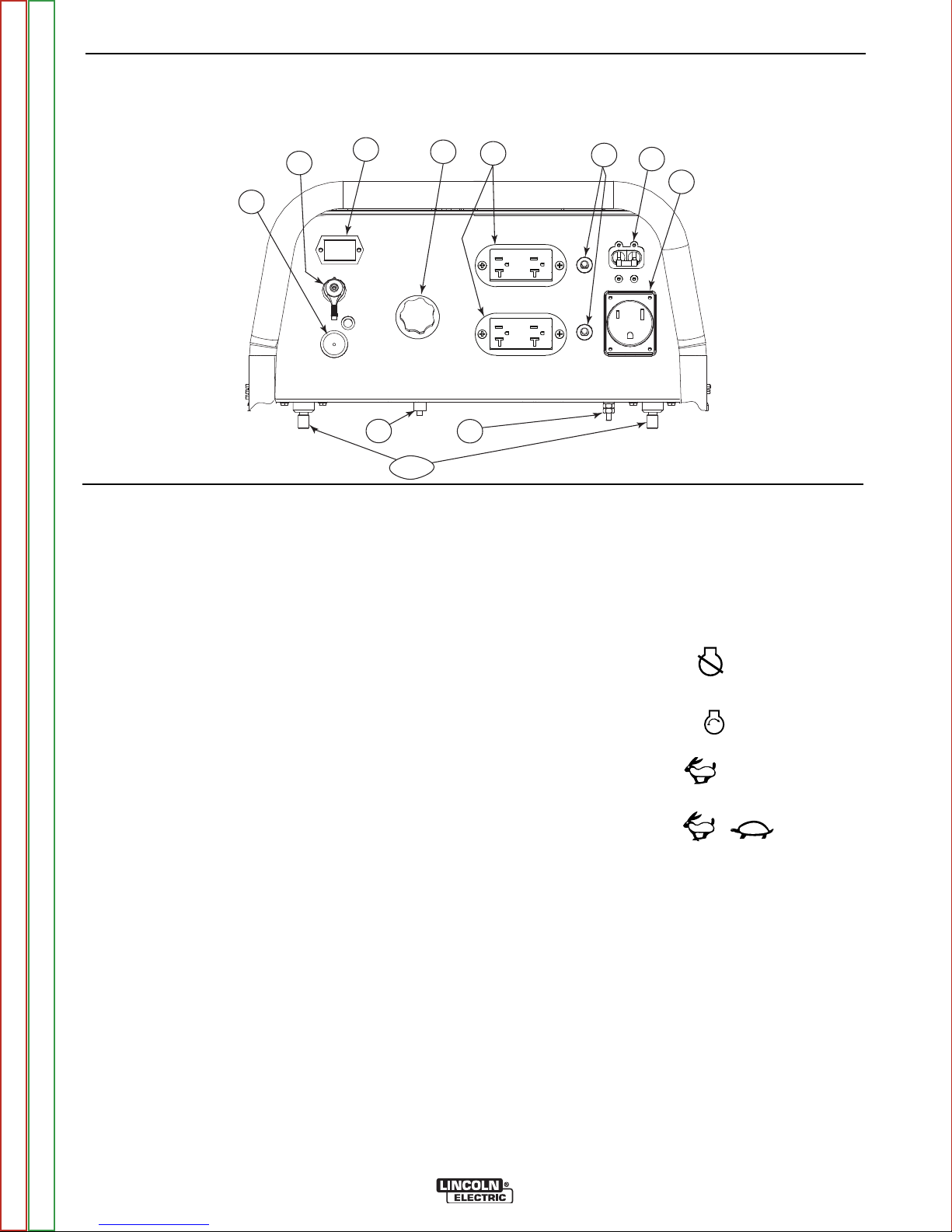

CONTROLS AND SETTINGS All welder/generator controls are located on the Output Control Panel. Gasoline

engine controls are mounted on the engine. See Figure B.1 and the figures in engine operation section.

OUTPUT PANEL CONTROLS

FIGURE B.1

WELDER/GENERATOR CONTROLS

See Figure B.1 for the location of the following features:

1. CURRENT CONTROL DIAL: Adjusts continuous current output. The amperages on the dial correspond to

10. HOUR METER: Records the time that the engine has

run for maintenance purposes.

11. ENGINE CHOKE: Engine starting aid.

the approximate amperages needed for specific

Lincoln welding electrodes.

2. 30 AMP CIRCUIT BREAKER: Provide separate overload current protection for the 120 Volt and 240 Volt

Receptacles

3. WELD POSITIVE OUTPUT TERMINAL: Pro vides the

12. ENGINE SWITCH:

Used to start the engine, Select High Idle or Auto Idle

while the engine is running and stops the engine.

When placed in the “OFF” position, the ignition

circuit is de-energized to shut down the engine.

connection point for either the electrode holder or the

work cable. (Because the OUTBACK® 185 is a DC

output machine, either output terminal can be used for

either cable.)

4. WELD NEGATIVE OUTPUT TERMINAL: Provides the

connection point for either the electrode holder or the

When held in the “START” position, the engine

starter motor is energized.

When in “HIGH IDLE” ( ) position, the engine

will run continuously at high idle.

work cable. (Because the OUTBACK®185 is a DC output machine, either output terminal can be used for

either cable.)

5. GROUND STUD: Provides a connection point for connecting the machine case to earth ground for the safest

grounding procedure.

6. CIRCUIT BREAKER: Provides overload protection for

weld output terminals.

7.

CIRCUIT BREAKERS (2): Provide separate overload current protection for the 120 volt and 240 volt receptacles

8. 240 VOLT RECEPTACLE: Connection point for supplying 250 volt power to operate one electrical device.

9. 120 VOLT DUPLEX RECEPTACLES (2): Connection

point for supplying 120 volt power to operate devices

needed for maintenance purposes.

When in “AUTO IDLE” ( / ) position, the

engine will run continuously and the idler operates as

follows:

• Welding

When the electrode touches the work, the welding

arc is initiated and the engine accelerates to full

speed. After welding ceases (and no auxiliary power

is being drawn), the engine will return to low idle after

approximately 10 to 14 seconds.

• Auxiliary Power

With the engine running at low idle and auxiliary

power for lights or tools is drawn (approximately 0150 watts or greater) from the receptacles, the

engine will accelerate to high speed. If no power is

being drawn from the receptacles (and not welding)

for 10-14 seconds, the idler reduces the engine

speed to low idle.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 22

B-6 B-6

OPERATION

ENGINE OPERATION

Starting/Shutdown Instructions

Be sure all Pre-Operation Engine Service has been

performed. Also, Read owners manual before starting

for the first time. (See INSTALLATION section)

Remove all loads connected to the AC power receptacles. Before starting, first open the fuel shutoff valve.

Always pull the choke control out when starting the

engine; cold, warm or hot.

Turn the engine switch to the “Start” position and

crank the engine until it starts, slowly return the choke

control to the full “in” position (choke open), and turn

the switch to the Auto Idle ( / ) position.

Do not turn the switch to the “start” position while the

engine is running because this will cause damage to

the ring gear and/or starter motor.

Stopping the Engine

Remove all welding and auxiliary power loads and

allow engine to run for a few minutes to cool the

engine.

Break-in Period

It is normal for any engine to use larger quantities of oil

until break-in is accomplished. Check the oil level

twice a day during the break-in period (about 50 running hours). Change the oil after the first 5 hours of

operation. See the Engine Instruction Manual for further details.

CAUTION

IN ORDER TO ACCOMPLISH THIS BREAK-IN, THE

UNIT SHOULD BE SUBJECTED TO MODERATE

LOADS, WITHIN THE RATING OF THE MACHINE.

AVOID LONG IDLE RUNNING PERIODS. REMOVE

LOADS AND ALLOW ENGINE TO COOL SEVERAL

MINUTES AT LOW IDLE BEFORE SHUTDOWN.

-----------------------------------------------------------------------

Low Oil Sensing

This engine has a built in sensor which responds to low

oil level (not pressure). When activated, the system

will shut the engine down. The engine will not restart

until sufficient oil is added. Check oil level frequently

and add oil as required to the full mark on the dipstick.

DO NOT OVERFILL.

Stop the engine by placing the engine switch in the

“Off” ( ) position.

WARNING

Close the fuel valve when the machine is

transported to prevent fuel leakage from

the carburetor.

------------------------------------------------------------------------

Typical Fuel Consumption

KOHLER CS 12.75 HP

NO LOAD

2250 R.P.M .75

NO LOAD .40 GALLONS/HOUR

3750 R.P.M. 1.51 ( LITERS/HOUR)

DC CC WELD OUTPUT .73 GALLONS/HOUR

100 AMPS, 25 VOLTS 2.77 ( LITERS/HOUR)

AUXILIARY POWER .99 GALLONS/HOUR

5200 KVA 3.74 ( LITERS/HOUR)

. .20 GALLONS/HOUR

( LITERS/HOUR)

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 23

B-7 B-7

WELDING OPERATION

WARNING

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrode with skin or wet clothing.

• Insulate yourself from work and

ground.

• Always wear dry insulating gloves.

ENGINE EXHAUST can kill.

• Use in open, well ventilated areas

or vent exhaust outside.

• Do not stack anything on or near

the engine.

MOVING PARTS can injure.

• Do not operate with doors open or

guards off.

• Stop engine before servicing.

• Keep away from moving parts.

Only qualified personnel should install, use, or

service this equipment.

The OUTBACK® 185 can deliver from 50 to 185

amps of welding output current . Output can be

adjusted by setting the current control dial on the output control panel.

You can get maximum welding output by setting the

dial to 185 AMPS. At high current settings like this,

some output may decrease as the machine is used.

If you are welding for a long time, you may need to

turn the dial slightly upward to maintain the same

results.

The numbers on the dial correspond to the approximate amps needed to weld using specific Lincoln

welding rods. Table B.2, WELDING APPLICATIONS,

give you the recommended dial settings based on the

thickness of the work and the size and type of rod

you’re using.

TO USE THE OUTBACK® 185 FOR WELDING:

1. Remove the flange nuts from the weld output terminals and place the work and electrode welding

cables over the terminals. See Figure B.1 and

B.1a. Replace and tighten the flange nuts

securely. Be sure the connections are tight.

2. Select the appropriate electrode. See Table B.2

3. Attach the work clamp securely to the work you are

welding.

OPERATION

4. Insert the electrode into the electrode hold

5. Set the current control dial to the desired output

current .

6. Start the gasoline engine.

See ENGINE OPERATION in this section of

the manual.

7. Strike an arc and begin welding.

AFTER YOU FINISH THE WELD:

1. Stop the gasoline engine. See ENGINE OPERATION in this section of the manual.

2. Allow the electrode and work to cool completely.

3. Remove the work clamp from the work.

4. Remove any remaining piece of electrode from the

electrode holder.

5. If you are finished using the OUTBACK® 185 for

welding, disconnect the welding cables from the weld

output terminals. Reattach the flange nuts and leave

them on the terminals.

For DC+ welding, the electrode cable is to be connected

to the “+” output stud and work cable to the “-” output

stud. (For DC- welding, reverse these connections.)

Semi-automatic Wire Welding with a Lincoln Wire

Feeder/Welder

The

OUTBACK® 185

supply up to 5,200 watts continuous input power to a

Lincoln Wire Feeder/Welder. The Wire Feeder/ Welder is

equipped with all the supplies needed for Flux-Cored Arc

Welding (FCAW). Also some Wire Feeder/Welders come

equipped with the essentials needed for Gas Metal Arc

Welding (GMAW) or MIG processes, while others require

the purchase of a conversion kit. These products are

available where Lincoln products are sold. Contact your

local authorized Lincoln representative for more details.

Plasma Cutting with Lincoln Pro-Cut 25.

OUTBACK® 185

The

supply up to 5,200 watts continuous input power to a ProCut 25. The Pro-Cut will work satisfactorily under the following conditions:

1. Set the Current Control on the

185 amp position. (Higher Settings may result in a

shutdown of the Pro-Cut 25.)

2. Leave the "ON/OFF" switch on the Pro-Cut "OFF"

until the OUTBACK® 185 has been started and is at

full operating speed.

er.

generator power can be used to

generator power can be used to

OUTBACK® 185

to the

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 24

B-8 B-8

120V Receptacle Operation:

• Set the Output Control on the Pro-Cut 25 no higher

than the 15 amp position.( Higher settings may cause

circuit breaker on the

• Maximum material thickness that can be cut is 1/4".

240V Receptacle Operation:

• The Pro-Cut 25 may be used for its full range of control.

• Maximum material thickness that can be cut is 3/8".

OUTBACK® 185

OPERATION

to trip.)

Electrical loads in watts are calculated by multiplying

the voltage rating of the load by the number of amps it

draws. (This information is given on the load device

nameplate.) For example, a device rated 120 volts, 2

amps will need 240 watts of power (120 x 2 = 240).

You can use Table B.3, AUXILIARY POWER APPLICATIONS, to determine the wattage requirements of

the most common types of loads you can power with

the OUTBACK® 185 Be sure to read the notes at the

bottom of the table.

TO USE THE OUTBACK® 185 AS AN AUXILIARY

POWER SUPPLY:

AUXILIARY POWER OPERATION

1. Start the gasoline engine. See ENGINE OPERA-

WARNING

Be sure that any electrical equipment plugged into the

generator AC power receptacles can withstand a ±10%

voltage and a ±5% frequency variation. Some electronic devices cannot be powered by the OUTBACK®

185 Refer to Table A.2, ELECTRICAL DEVICE USE

WITH THE OUTBACK® 185, in the INSTALLATION

section of this manual.

TION in this section of the manual.

2. Set the current control dial on the output control

panel to “MAX.” See Figure B.1.

3. Plug the load(s) into the appropriate 120 volt or

240 volt power receptacle.

NOTE: During welding, the maximum generator out-

put for auxiliary loads is 100 watts.

GENERAL INFORMATION

The OUTBACK® 185 is rated at 5700 Peak watts or

5200 continuous watts. It provides both 120 volt and

240 volt power. You can draw up to 20 amps from

either side of the 120 volt duplex receptacle, but not

more than 35.4 amps from both sides at once. Up to

17.7 amps can be drawn from the single 240 volt

receptacle.

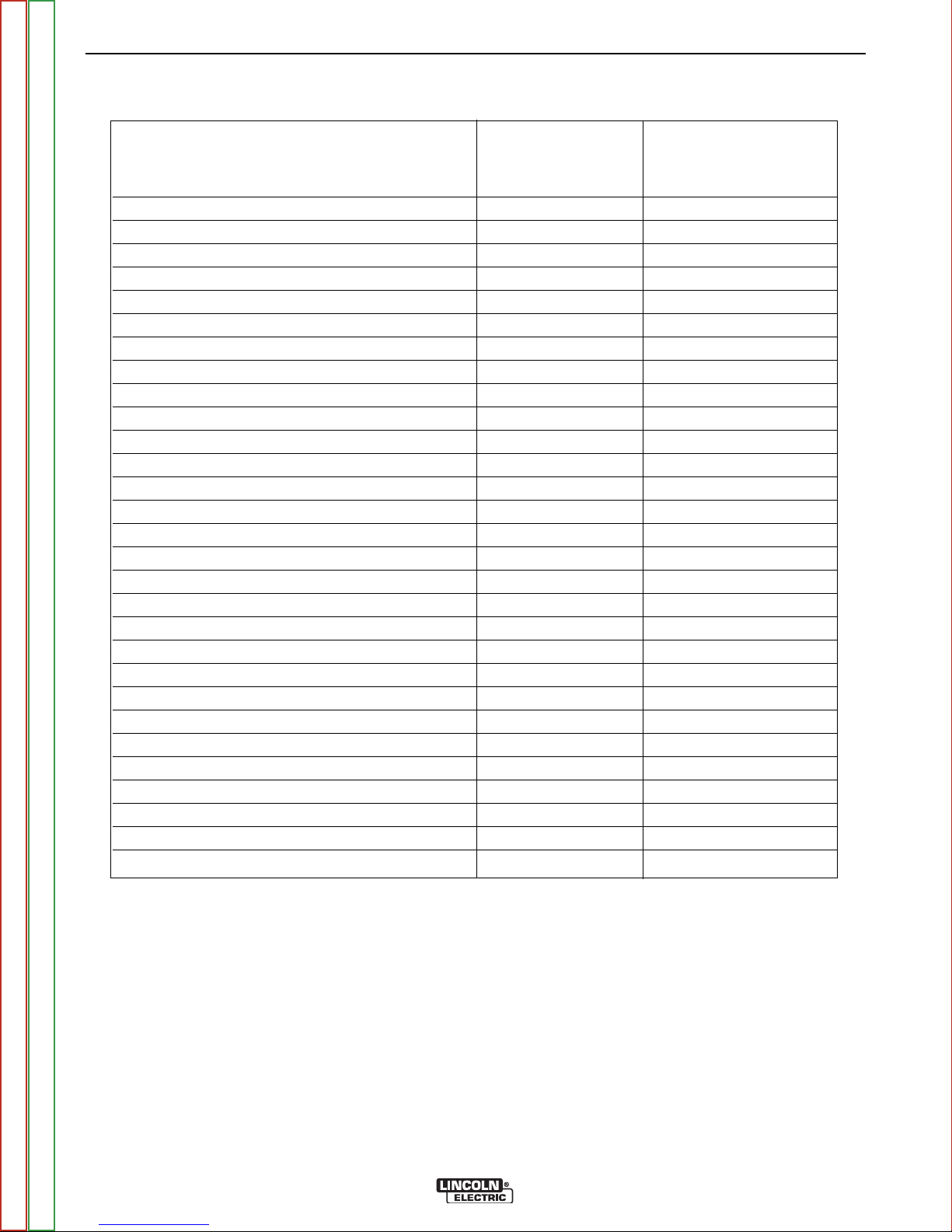

TABLE B.2

ELECTRODE SELECTION GUIDE

AWS ELECTRODE

CLASSIFICATION ELECTRODE TYPE POLARITY

E6010 FLEETWELD® 5P DC+ 50-75 75-135 90-175

E6011 FLEETWELD® 35 DC+ 50-75 70-110 80-145

E6011 FLEETWELD® 180 DC+ 50-80 55-110 105-135

E6013 FLEETWELD® 37 DC± 70-95 100-135 145-180

E7018 EXCALIBUR® 7018 DC+ 70-100 90-125 125-185

E7018 JETWELD® LH-73 DC+ 65-85 90-125 130-185

E708-17 & E308L-17

ENi-CI SOFTWELD® 99Ni DC+ 50-80 80-110 100-140

- WEARSHIELD® ABR DC+ - 50-150 50-185

BLUE MAX® 308/308L AC-DC

SHEET THICKNESS THINNER 1/8 AND THICKER

NOTE: You can supply multiple loads as long as the

total load does not exceed 5700 Peak watts or

5200 continuous watts. Be sure to start the

largest loads first.

CURRENT RANGE (AMPS)

3/32 SIZE 1/8 SIZE 5/32 SIZE

DC+ 50-80 75-110 95-150

1/8 AND

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 25

B-9 B-9

AUXILIARY POWER APPLICATIONS

Suggested Power Applications Running Watts *Start-up Watts

*Air Compressor - 1 HP 2,000 4,000 - 8,000

*Air Compressor - 3/4 HP 1,250 3,100 - 5,000

*Airless Sprayer - 1/3 HP 600 1,500 - 2,400

Chain Saw 1,200

Circular Saw 1,200

Coffee Maker 1,000

*Deep Freezer 500 750 - 2,000

*Electric Motor - 1 HP 1,000 2,500 - 4,000

Electric Range (1 element) 1,500

Electric Skillet 1,250

*Furnace Fan - 1/3 HP 1,200 3,000 - 4,800

Portable Grinder (4 1/2”) 600

Portable Grinder (7”) 2,000

Halogen Work Light 500

Hand Drill - 1/4” 500

Hand Drill - 3/8” 700

1500 Watt Heater 1,750

Hedge Trimmer 450

Light Bulb 100

Reciprocating Saw 900

Radial Arm Saw 2,600

Radio 50

*Refrigerator/Freezer (small) 600 1,500 - 2,400

Slow Cooker 200

*Submersible Pump - 1 HP 1,000 2,500 - 4,000

*Sump Pump 600 1,500 - 2,400

Toaster 1,100

Weed Trimmer 500

Lincoln Wire Feeder/Welder 4,000

OPERATION

TABLE B.3

(Continuous) (Peak)

NOTES:

Wattages listed are approximate. Check your equipment for actual wattage.

Equipment with unusually high *START-UP WATTS are listed. For start-up of other equipment that uses a

motor, listed in the table, multiply RUNNING WATTS by 2.

Multiple loads can be used as long as the total load does not exceed 5,700 Peak watts. Be sure to start

the largest loads first.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 26

B-10 B-10

NOTES

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 27

C-1 C-1

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Options / Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

TABLE OF CONTENTS - ACCESSORIES SECTION

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OUTBACK® 185

Page 28

C-2 C-2

ACCESSORIES

OPTIONS/ACCESSORIES

The following options/accessories are available for

your OUTBACK®185 from your local Lincoln

Distributor:

Accessory Kit (K875) – Includes the following:

• Twenty feet (6.1 meters) of #6 AWG electrode cable

with lug.

• Fifteen feet (4.6 meters) of #6 work cable with lugs.

• Work Clamp

• Headshield with No. 10 filter

• Insulated electrode holder and sample electrodes

150 amp capacity.

Undercarriage (K2722-1) - A two-wheeled, hand movable undercarriage is available for field installation.

Rotor Removal Kit (S20925) - A service kit with thru

bolt and impact bolt’s for removing the generator rotor

from tapered engine crank shaft.

Spark Arrestor Kit (K2793-1) - Attaches to muffler

exhaust tube. Virtually eliminates spark emissions.

Canvas Covers (K2804-1) - To protect the Outback®

185 when not in use. Made from attractive red canvas

which is flame retardant, mildew resistant and water

repellent.

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 29

D-1 D-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3

Routine and Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3

Engine Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

Slip Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

Engine Maintenance Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

Operational Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

Major Component Locationss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

TABLE OF CONTENTS - MAINTENANCE SECTION

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OUTBACK® 185

Page 30

D-2 D-2

MAINTENANCE

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

OUTBACK® 185

Page 31

D-3 D-3

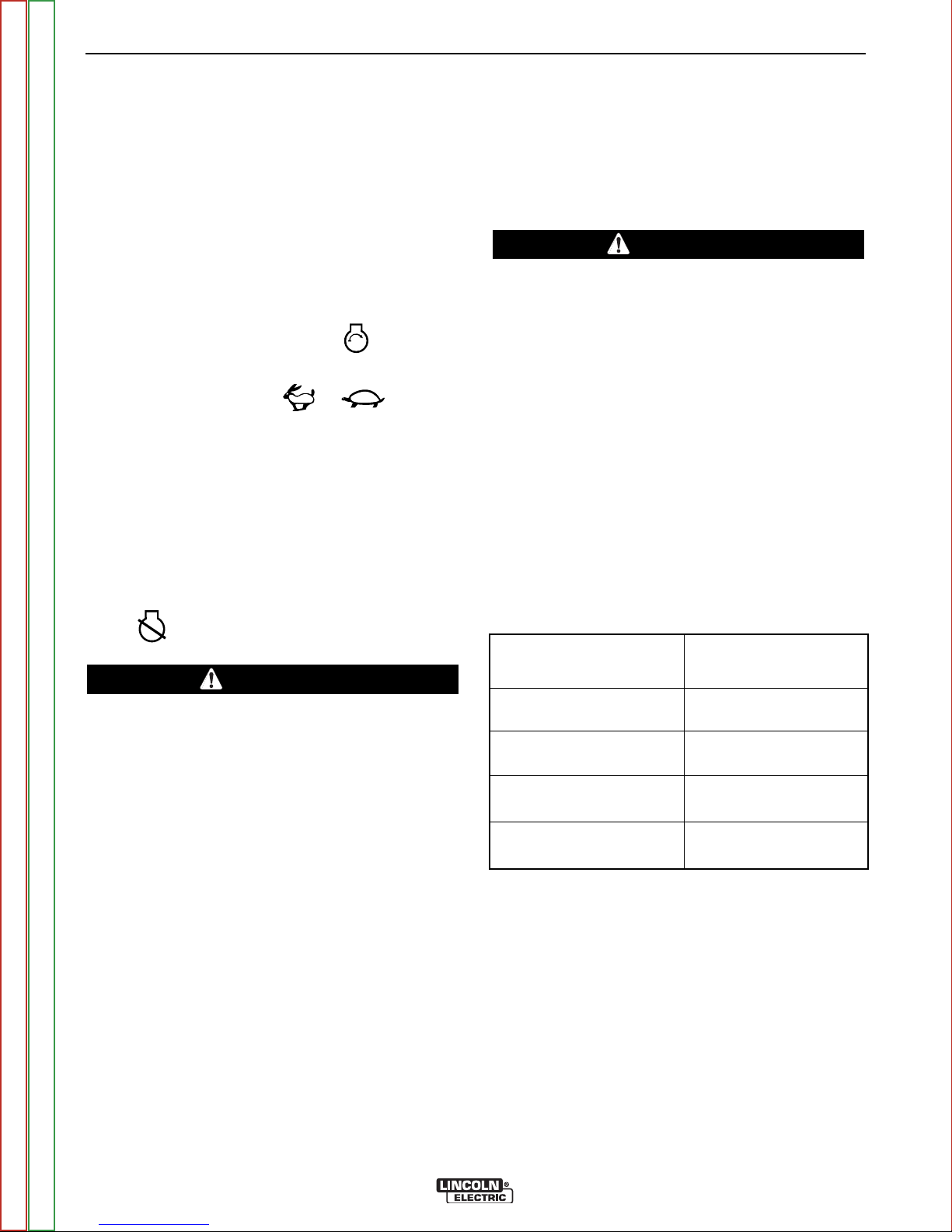

Do not screw in

dipstick to check oil

OIL

FILL to FULL mark on

dipstick - recheck

Tighten dipstick

firmly before starting

Drain

plug

Oil drain

OIL DRAIN

PLUG

12 mm

HEX

SAFETY PRECAUTIONS

WARNING

• Have qualified personnel do all maintenance and

troubleshooting work.

• Turn the engine off before working inside the

machine.

• Remove guards only when necessary to perform

maintenance and replace them when the maintenance requiring their removal is complete.

• If guards are missing from the machine, get replacements from a Lincoln Distributor. See the EXPLODED VIEW AND PARTS LIST at the back of this manual.

------------------------------------------------------------------------

Read the Safety Precautions in the front of this manual and in the Kohler Operating and Maintenance

Instructions manual before working on the OUT-

BACK®185 Keep all equipment safety guards, covers,

and devices in position and in good repair. Keep your

hands, hair, clothing, and tools away from the recoil

housing, fans, and all other moving parts when starting, operating, or repairing this machine.

MAINTENANCE

OIL: Check the oil level after every 5

hours of operation or daily. BE SURE

TO MAINTAIN THE OIL LEVEL.

Change the oil the first time after 20 hours of operation. Then, under normal operating conditions, change

the oil after every 100 hours or once a year, whichever occurs first. If the engine is operated under heavy

load or in high ambient temperatures, change the oil

every 50 hours.

Drain the oil from the drain plug located on either side

of the engine bottom, as shown in Figure D.1. Refill

through the oil fill plug until the oil reaches the full mark

on the dip stick. See Engine Owner’s manual for specific oil recommendations.

FIGURE D.1 - OIL DRAIN AND

REFILL LOCATION

ROUTINE AND PERIODIC

MAINTENANCE

ENGINE MAINTENANCE

CAUTION

To prevent the engine from accidentally starting, disconnect the spark plug lead before servicing the

engine.

------------------------------------------------------------------------

See the Kohler Owner’s manual for a summary of

maintenance intervals for the engine. Follow either the