Page 1

Copyright © 2018 The Shanghai Lincoln Electric Company

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation and thoughtful

operation on you part. DO NOT

INSTALL, OPERATE OR REPAIR

THIS EQUIPMENT WITHOUT

READING THIS MANUAL AND

THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT.

And, most importantly, think before

you act and be careful.

OPTIMARC

®

CV/CC500

For use with machine Part Number K60128-1, Code 76341

• World’s Leader in Welding and Cutting•

THE SHANGHAI LINCOLN ELECTRIC COMPANY

No. 195, Lane 5008, Hu Tai Rd. Baoshan, Shanghai, PRC 201907

www.lincolnelectric.com.cn

IM7025-1

Feb, 2018

Rev. 03

Rev. 03

Page 2

Thank you for selecting QUALITY Lincoln Electric products.

Please examine the packaging and equipment for damage. Claims for material damaged in shipment must be

notified immediately to the authorized dealer from whom you purchased the machine.

For future reference, please record your equipment identification information in the table below. Model Name,

Code & Serial Number can be found on the machine rating plate.

Model Name

□ OPTIMARC® CV/CC500

Code & Serial number

Date & Where Purchased

Authorized dealer’s shop

Declaration of conformity

THE SHANGHAI LINCOLN ELECTRIC COMPANY

Designed in conformance with the following norm:

GB/T 15579.1-2013

EN 60974-1

No. 195, Lane 5008, Hu Tai Rd. Baoshan, Shanghai, PRC 201907

THE SHANGHAI LINCOLN ELECTRIC COMPANY

Rev. 03

Page 3

i SAFETY i

OPTIMARC® CV/CC500

Rev. 03

Page 4

ii SAFETY ii

OPTIMARC® CV/CC500

Rev. 03

Page 5

iii SAFETY iii

OPTIMARC® CV/CC500

Rev. 03

Page 6

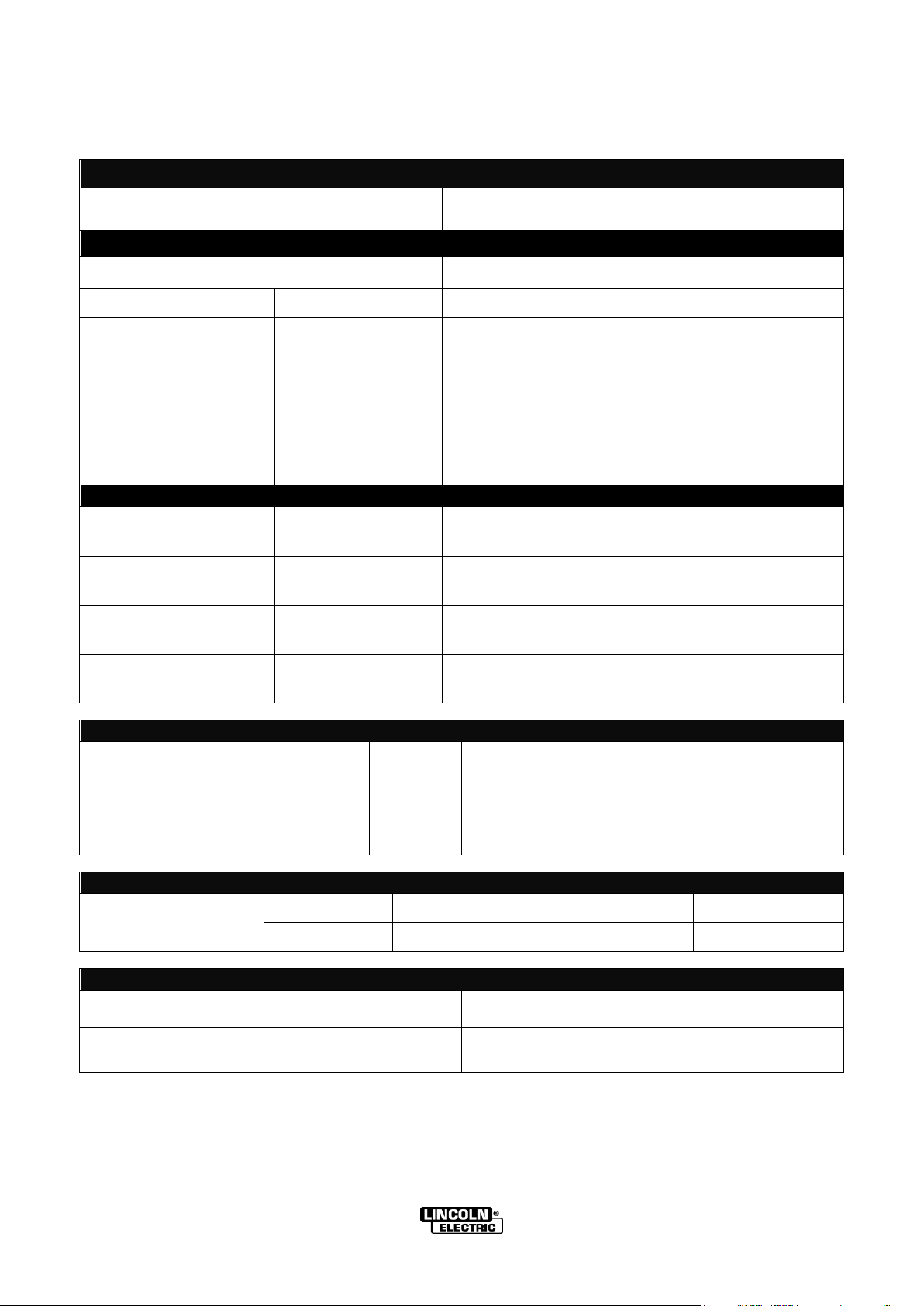

A-1 INSTALLATION A-1

INPUT – THREE PHASE ONLY

Standard Voltage / Phase / Frequency

380V ~ 415V (±10%) / 3 / 50 or 60 Hz

RATED OUTPUT – DC ONLY

Max Input Power at Rated Output ( SMAW )

23 kVA @ 60% Duty Cycle

Welding Mode

Duty Cycle

Amperes

Volts at Rated Amperes

GMAW

60%

100%

500A

390A

39V

33.5V

SMAW ( STICK )

60%

100%

500A

390A

40V

35.6V

GTAW ( TIG )

60%

100%

500A

390A

30V

25.6V

OUTPUT RANGE

Welding Mode

Welding Current Range

Open Circuit Voltage

Welding Voltage Range

GMAW

50A ~ 500A

60V

16 V ~ 39V

SMAW ( STICK )

15A ~ 500A

60V

20.6 V ~ 40V

GTAW ( TIG )

5A ~ 500A

60V

10.2 V ~ 30V

RECOMMENDED INPUT WIRE AND FUSE SIZES

OPTIMARC® CV/CC500

Input Voltage/

Frequency

(Hz)

380~415 V/

50Hz or 60Hz

Maximum

Input

Ampere

51A

Maximum

Effective

Supply

Current

40A

60°C Copper

Wire in

Conduct

Sizes

12mm2

Fuse or

Breaker Size

(Super Lag)

60A

Grounding

Conductor

Size

10mm2

PHYSICAL DIMENSIONS

OPTIMARC® CV/CC500

Height

Width

Depth

Weight

540mm

340mm

800mm

47Kg

TEMPERATURE RANGE

Operating Temperature Range

-10°C ~ +40°C

Storage Temperature Range

-25°C ~ +55°C

TECHNICAL SPECIFICATIONS – OPTIMARC® CV/CC500

For any maintenance or repair operation it is recommended to contact the nearest technical service center or directly

consult machine division of the Shanghai Lincoln Electric. Maintenance or repairs performed by unauthorized service

center or personnel will void the manufacturer’s warranty.

OPTIMARC® CV/CC500

Rev. 03

Page 7

A-2 INSTALLATION A-2

WARNING

CAUTION

WARNING

FIGURE A.1

SAFETY PRECAUTIONS

Read the entire installation section before starting

installation.

INPUT POWER AND GROUNDING

ELECTRIC SHOCK can kill.

Only qualified personnel

should perform this

installation.

Turn the input power OFF at

the main switch or fuse box

before working on this equipment. Turn off the

input power to any other equipment connected to

the welding system at the main switch or fuse

box before working on the equipment.

Do not touch electrically “Hot” parts.

Always connect the OPTIMARC® grounding lug

(located at the rear of the case) to a proper safety

(Earth) ground.

SELECT SUITABLE LOCATION

This power source should not be subjected to falling

water, nor should any parts of it be submerged in water.

Doing so may cause improper operation as well as

pose a safety hazard. The best practice is to keep the

machine in a dry, sheltered area.

CONNECTION

Only a qualified electrician should connect the

input leads to the OPTIMARC®. Connections

should be made in accordance with the connection

diagram. Failure to do so may result in bodily injury

or death.

Open the input box on the rear of the case. Use a

three-phase supply line, the three live wires should go

through the three holes of the input wire holder and be

securely clamped and fixed. Connect L1, L2, L3 and

ground according to the Input Supply Connection

Diagram decal, refer to Figure A.1 on this page.

Make sure the amount of power available from the input

connection is adequate for normal operation of the

machine. Refer to the Technical Specifications at the

beginning of this Installation section for recommended

fuse and wire sizes.

The bottom of machine must always be placed on a

firm, secure, level surface. There is a danger of the

machine toppling over if this precaution is not

taken.

Place the welder where clean cooling air can freely

circulate in through the back louvers and out through

the case sides. Water,dirt, dust or any foreign material

that can be drawn into the welder should be kept to a

minimum. Failure to observe these precautions can

result in excessive operating temperatures and

nuisance shutdowns.

Locate the OPTIMARC® machine away from radio

controlled machinery. Normal operation of the welder

may adversely affect the operation of RF controlled

equipment, which may result in bodily injury or damage

to the equipment.

STACKING

The OPTIMARC® machine can not be stacked. Be

sure to locate the machines on a firm level surface.

LIFTING

The OPTIMARC® machine can be moved using the

handles .

OPTIMARC® CV/CC500

Rev. 03

Page 8

A-3 INSTALLATION A-3

Current (60% Duty Cycle)

Minimum Copper

Work Cable Size

200A

300A

400A

500A

Up To 30m Length

30 mm2

50 mm2

70 mm

2

95 mm

2

WARNING

PROCESS SELECTIONS AND

CONNECTIONS

ELECTRIC SHOCK can kill.

Only qualified personnel

should perform this

installation.

Turn the input power OFF at

the main switch or fuse box before working on

this equipment. Turn off the input power to any

other equipment connected to the welding

system at the main switch or fuse box before

working on the equipment.

Do not touch electrically “Hot” parts.

Always connect the OPTIMARC® grounding lug

(located at the rear of the case) to a proper safety

(Earth) ground.

WORK CONNECTION

Connect a work lead of sufficient size between the

proper output stud on the power source and the work.

Be sure the connection to the work makes tight metal to

metal electrical contact. Poor work lead connections

can result in poor welding performance.

To avoid interference problems with other equipment

and to achieve the best possible operation, route all

cables directly to the work and wire feeder. Avoid

excessive lengths and do not coil excess cable.

Cable sizes are increased for greater lengths primarily

for the purpose of minimizing cable drop.

Minimum work and electrode cable sizes are as follows:

TABLE A.1

Note: The recommended cable size may need to

change depending on its quality. When the rated

current flow goes through, the total voltage drop on

ground cable and electrode cable must not exceed 4

volts.

GMAW PROCESS ( CV MODE ) WIRE FEEDER CONNECTION

1. LWF WIRE FEEDER ( FIGURE A.2 )

Set the rotary switch to FCAW-GS mode or GMAW mode;

Set the control switch to Feeder

FIGURE A.2

OPTIMARC® CV/CC500

Rev. 03

Page 9

A-4 INSTALLATION A-4

Items

Modes

Controls

Wire feeders

Voltage control

WFS/Current

control

Remote

control box

Polarity

connections

1

OPTIONAL

(Default

FCAW-SS)

Local

LN-25 Pro

Front panel of

CV/CC500

LN-25 Pro

DCEN

2

Feeder

LN-25 Pro

Remote

control box

K60030-8M/15M/-30M

3

FCAW-GS

Local

LN-25 Pro

Front panel of

CV/CC500

DCEP

4

Feeder

LWF-22

LWF-24 PLUS

LWF-22 / LWF-24 PLUS

5

GMAW

Local

LN-25 Pro

Front panel of

CV/CC500

LN-25 Pro

6 Feeder

LWF-22

LWF-24 PLUS

LWF-22 / LWF-24 PLUS

2. LN-25 PRO FEEDER ( FIGURE A.3 )

Remote control methods

Set the rotary switch to OPTIONAL (Default FCAW-SS);

Set the control switch to Feeder;

The remote control box with order part numbers K60030-8M/-15M/-30M should be used to control the machine output

and set the voltage, Use the wire feed speed pot on LN-25 to set the current.

FIGURE A.3

Local control methods

Set the rotary switch to OPTIONAL / FCAW-GS or GMAW;

Set the control switch to Local;

A summary list for all of wire feeders connections and controls

OPTIMARC® CV/CC500

Rev. 03

Page 10

A-5 INSTALLATION A-5

The actual output current would be set by the remote device up to the maximum current set by local output pot.

Note: When the machine set to 4 step, turning the crater current and voltage, the crater value will be shown on the

display, then change back to the weld preser value.

TIG torch with handle switch can be used while the switch connect correctly to the remote connector.

3. GTAW PROCESS ( CC MODE ) CONNECTION ( FIGURE A.4 )

Set the rotary switch to GTAW mode;

Set the control switch to REMOTE

Recommended to use Foot Amptrol K870.

Set the control switch to LOCAL

Machine output the maximum current set by local output pot

FIGURE A.4

4. SMAW PROCESS ( CC MODE ) CONNECTION ( FIGURE A.5 )

Set the rotary switch to SMAW mode;

Set the control switch REMOTE;

Max. output will be limited by panel output set, display always shows remote setpoint.

Set the control switch LOCAL;

Max. output current can be setted by panel output pot, arc force can be setted by arc control.

FIGURE A.5

OPTIMARC® CV/CC500

Rev. 03

Page 11

A-6 INSTALLATION A-6

TABLE A.2

Power Source

Wire Feeder

Pin

Function

Lead #

Pin

Function

Lead #

1

“ + ” pulse signal for motor control.

91

1 Positive terminal of motor.

91

2

“ + ” pulse signal for gas solenoid.

92

2

Connected to one lead of gas

solenoid.

92

3

“ + ” control signal for gas purge, cold

inch and trigger.

93

3

Control signals output ( gas purge,

cold inch and trigger ).

93

4

+/- 10V control signal for arc current

and arc voltage.

94

4

Control signals output (arc current

and arc voltage ).

94

5

GND for arc current, arc voltage, gas

purge, cold inch and trigger control.

95

5

Common GND.

95

6

GND for gas solenoid and motor

control.

96

6

Negative terminal of motor; and

connected to another lead of gas

solenoid.

96

CAUTION

A

B

C

D

E

F

FIGURE A.6 FIGURE A.7

TABLE A.3

Power Source

Remote Controller

Pin

Function

Lead #

Pin

Function

Lead #

A

Output control power +

77

A

Pot foot 1

77

B

Output control signal

76

B

Pot foot 2

76 C Output control power -

75

C

Pot foot 3

75 D Output control switch +

2 D

Switch foot 1

2 E Output control switch -

4 E

Switch foot 2

4

F

Ground lead ( case )

G2

F

Case

G2

6-PIN AMPHENOL CONNECTOR INSTRUCTION

For secure electrical connection, the screws

connecting the output terminals and cables must

be tightened. Damage may occur to the output stud

or welding performance maybe compromised.

6-PIN LWF WIRE FEEDER CONNECTOR

INSTRUCTION

Please see FIGURE A.6 and TABLE A.2 for more

details.

Please see FIGURE A.7 and TABLE A.3 for more

details.

SAFETY PRECAUTIONS

Read this entire section of operating instructions before operating the machine.

OPTIMARC® CV/CC500

Rev. 03

Page 12

A-7 INSTALLATION A-7

Weld for 6 minutes

Break for 4 minutes

WARNING

ELECTRIC SHOCK can kill.

Do not touch electrically live

parts or electrode with skin or

wet clothing.

Insulate yourself from work

and ground.

Always wear dry insulating gloves.

FUMES AND GASES can be

dangerous.

Keep your head out of fumes.

Use ventilation or exhaust to

remove fumes from breathing

zone.

WELDING SPARKS can cause

fire or explosion.

Keep flammable material away.

Do not weld on closed

containers.

ARC RAYS can burn eyes and

skin.

Wear eye, ear and body

protection.

PLEASE SEE ADDITIONAL

WARNING INFORMATION AT THE FRONT OF

THIS OPERATOR’S MANUAL

DUTY CYCLE

The duty cycle of a welding machine is the percentage

of time in a 10 minute cycle at which the welder can

operate the machine at rated welding current.

60% duty cycle:

Excessive extension of the duty cycle will cause the

thermal protection circuit to activate.

THERMAL PROTECTION

The OPTIMARC® machine is equipped with a thermal

protection device. When the machine has gone into

thermal overload, the output will be turned off and the

thermal indicator light will be turned “ON“. When the

machine has cooled to a safe temperature, the Thermal

Indicator Light will go out and the machine may resume

normal operation.

Note: For safety reasons the machine’s welding output

will not come on after a thermal shutdown until the

output is disabled and re-enabled.

OPTIMARC® CV/CC500

Rev. 03

Page 13

B-3 OPERATION B-3

OPERATIONAL FEATURES AND

CONTROLS

FRONT PANEL (SEE FIGURE B.1)

1. GAS SELECTION

OPTIMARC® CV/CC500 is designed for CO2 and

Ar/CO2.

2. WELDING MODE SELECTION

OPTIMARC® CV/CC500 includes 5 following modes:

OPTIONAL.

A default procedure is for self-shielded flux

cored wire arc welding.

FCAW-GS.

It is for gas shielded flux cored wire arc welding.

Setting up the machine, please see the Figure

A.3

GMAW.

It is for gas shielded solid wire arc welding.

GTAW.

It is for TIG mode. OPTIMARC® CV/CC500

must apply “touch start” for arc start.

SMAW.

It is for stick mode.

3. WIRE DIAMETER SELECTION

OPTIMARC® CV/CC500 is designed for Φ1.0, Φ1.2

and Φ 1.6 wires.

4. ON/OFF POWER SWITCH

Switch up to power on; Switch down to power off.

5. CONTROL SWITCH

LOCAL

When switch to local,the output current or output

voltage can be setted by output control knob (See

item 15).

FEEDER

When switch to feeder,the welding current and

voltage can be setted by the feeder knob in GMAW

mode (See item 19).

REMOTE

When switch to remote,the welding current or

voltage can be setted by a remote control box,

choose the right connector according to the weld

mode (See item 18).

6. THERMAL INDICATOR

This status light illuminates when the power source has

been driven into thermal overload. The indicator light

also momentarily turns on during start up.

7. 2-STEP AND 4-STEP SELECTION

This toggle switch enables the selection of 2-STEP or

4-STEP operation mode without or with crater function.

2-STEP mode - no crater output after user release the

trigger. 4-STEP mode – crater function initiates when

uses “Clicks” trigger again after releasing it. Please

see FIGURE B.3 and B.4 to know the more details of

time sequence of OPTIMARC® CV/CC 500.

8. DIGITAL INDICATION VOLTAGE METER

This meter displays the preset voltage before a weld

and the actual voltage during a weld . The actual

voltage is displayed for 5 seconds after a weld ends.

During this time the display flash.

9. SYNERGIC

This status light illuminates when the power source is

set for synergic operation. Synergic operation is

controlled by DIP switch 5 on the control board. See

the DIP switch section for additional information.

10. DIGITAL INDICATION CURRENT METER

This meter displays the preset current before a weld

and theactual welding current during a weld. The

actual current is displayed for 5 seconds after a weld

ends. During this time the display falsh.

11. CRATER VOLTAGE

This knob sets the value of output voltage during the

crater time.

12. CRATER CURRENT

This knob sets the value of output current (wire

feeding speed) during the crater time.

13. HOT START

This knob can be used for setting the additional output

value at the start of weld in all of modes.

14. ARC CONTROL

This knob control the arc output characteristic. When

it is turned clockwise, the arc is crisper. When it

turned counter clockwise,the arc is softer.

15. LOCAL OUTPUT CONTROL

When item 9 is set to “LOCAL”, The output voltage

( CV mode ) or output current ( CC mode ) will be

controlled by this knob.

In TIG mode, it will control the maximum output

current.

In stick mode, it will limited the output current range.

16. NEGATIVE OUTPUT STUD

17. POSITIVE OUTPUT STUD

18. 6-PIN AMPHENOL CONNECTOR

Please see the FIGURE A.7 for the details of the

connection. Recommend the standard remote

controller for GTAW mode is K870 ( Foot amptrol );

and standard remote controller for SMAW is K857

( Pot control ).

19. 6-PIN LWF WIRE FEEDER CONNECTOR

Please see the FIGURE A.6 for the details of the

connection.

20. STATUS INDICATOR

The status light will be green for normal operation;

while the status light will flash in red with a serial of

error digital codes as power source gets in some

trouble. The status light will always have

synchronization with the LED3 on switchboard inside

machine.

OPTIMARC® CV/CC500

Rev. 03

Page 14

B-3 OPERATION B-3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

WARNING

CAUTION

REAR PANEL (PLEASE SEE FIGURE B.2).

21. INPUT CABLE HOLDING BRACKET

24. AUX. VOLTAGE RECEPTACLE

Export type machine: This is a 220V 200W max.

auxiliary power output socket, for plugging gas heater.

This bracket securely holds the three phase power cables

in place.

22. INPUT BOX

This insulation box is used to cover the input

connections.

This insulation box must be secure before turning on

the main power supply.

23. GROUND LEAD CONNECTION

Connect the ground lead to the paint-free location on

the case back by securing its lug-end with the screw

into the case hole.

Only Plug the correct gas heater into this receptacle.

DO NOT plug other electric devices into the

receptacle, otherwise damage may occur to the

OPTIMARC® machine.

25. FUSE AND FUSE HOLDER

Export type machine: 250V 2A fuse is used to protect

the auxiliary 220V power outlet

26. FUSE AND FUSE HOLDER

250V 8A fuse is used to protect the auxiliary power for

the wire feeder.

Figure B.1 Figure B.2

OPTIMARC® CV/CC500

Rev. 03

Page 15

B-3 OPERATION B-3

Trigger Open

Closed

Open

Closed

Shielding Gas

Preflow Time

Welding Voltage

OCV

Wire Feeder Speed

Run-in

Welding Current

Burn Back

Burn Back

FIGURE B.3

Trigger Open

Closed

Open

Closed

Shielding Gas

Preflow Time

Welding Voltage

OCV

Wire Feeder Speed

Run-in

Welding Current

Burn Back

Burn Back

Crater Voltage

Crater Current

Crater Status

Crater Status

FIGURE B.4

Trigger Open

Closed

Open

Closed

Shielded Gas

Preflow Time

Welding Voltage

OCV

Wire Feeder Speed

Run-in

Welding Current

Burn Back

Within 2 seconds

Crater Voltage

Crater Current

Crater Status

Crater Status

Crater

Current

Burn Back

Crater

Voltage

Open

Closed

Repeat Crater Status

FIGURE B.5

OPTIMARC® CV/CC500

Rev. 03

Page 16

B-4 OPERATION B-4

WARNING

DIP switch

continue output at crater voltage and current to fill this

DIP SWITCH DESCRIPTIONS

OPTIMARC® CV/CC machine offers a DIP switch on

the control board, which allows user to have additional

features. After disconnecting the machine from input

power remove the roof To set the DIP switch。

Disconnecting the machine,

before the roof removed.

See FIGURE B.7 for the right position.

There are 8 individual switches integrated into this

DIP switch .All the initial factory settings in the OFF

position. Please see FIGURE B.6.

1. PREFLOW ON/OFF SWITCH

This switch enables preflow before turning on output

voltage. Please see FIGURE B.3 for detail.

2. LONG CABLE WELD MODE SWITCH

OFF = welding with a cable length less than 20M.

ON = welding with a cable length more than 20M

(including 20M).

3. CRATER REPEAT MODE SWITCH

Should the operator find a visible crater appearing

after releasing the trigger, and within 2 seconds,

activating the trigger again the power source will

FIGURE B.6 FIGURE B.7

crater. For more details, please see FIGURE B.5.

4. SPECIAL FUNCTION TEST

It enables a test procedure to test the control knobs

and the toggle switches, when the DIP switch 4 is ON

and the other DIP switches are OFF. The DIP switch

should be OFF when user prepares to weld.

5. SYNERGIC

OFF = Amps and volts knobs on feeder are

independent

ON = Preset of volts knob is tied to the preset of the

amps knob.

Preset a current first , then set the voltage to match

the current, as 200A, 25V, then the voltage will follow

the current as machine programmed when the current

adjusted.

See operation feature item 8.

6. FAST RUN-IN

OFF = run-in is 35% of weld set wire feed speed

(limited by the absolute wire feed speed minimum set

in the parameter file)

ON = run-in is 75% of weld set wire feed speed

(limited by the absolute wire feed speed minimum set

in the parameter file)

7. FEEDER APPLICATION

OFF = 18.3V wire feeder application.

ON = 24V wire feeder application.

8. WIRE FEEDER SPEED CALIBRATION.

OPTIMARC® CV/CC500

Rev. 03

Page 17

C-1 TROUBLESHOOTING C-1

CAUTION

If for any reason you do not understand the test procedures or are unable to

perform the tests/repairs safely, contact your local authorized Lincoln Electric

Field Service Facility for technical assistance.

Observe all Safety Guidelines detailed in the beginning and throughout this manual.

Problems (Symptoms)

Possible Areas of Misadjustment(s)

Recommended Course of Action

Output Problems

Major physical or

electrical damage is

evident when the sheet

metal covers are

removed.

None

Contact your local

authorized Lincoln Electric

Field Service facility for

technical assistance.

Machine will not power up

(no lights, no fan, etc.)

1. Make certain that the power to the

OPTIMARC® CV/CC500 is energized and is

within the OPTIMARC® CV/CC500’s

operating range.

In a typical installation the

main power switch on the

controller is the power

switch.

Thermal LED is lit.

1. Check for proper fan operation. (Fan

should run whenever output power is on.)

Check for material blocking intake or

exhaust louvers, or for excessive dirt

clogging cooling channels in machine.

2. Machine may have been operated above

it’s duty cycle..

3.

Clear obstruction or repair

fan

After machine has cooled,

reduce load, duty cycle, or

both

Machine won’t weld, can’t

get any output.

1. Input voltage is too low or too high. Make

certain that input voltage is proper,

according to the Rating Plate.

2. If the Thermal LED is also lit, see Thermal

LED is Lit section.

3. If an error code is also present.

4. Make sure the terminal switch is ON.

Contact your local

authorized Lincoln Electric

Field Service facility for

technical assistance.

Machine won’t produce

full output.

1. Input voltage may be too low, limiting

output capability of the power source.

Make certain that the input voltage is

proper, according to the Rating Plate.

2. Secondary current or voltage is not

properly calibrated.

Correct input voltage level.

Contact your local

authorized Lincoln Electric

Field Service facility for

technical assistance.

Machine often “noodle”

welds (output is limited to

approximately 100 amps)

Secondary current limit has been exceeded,

and the machine has phased back to protect

itself.

Adjust procedure or reduce load

to lower current draw from the

machine.

General degradation of

the weld performance

1. Check for feeding problems, bad

connections, excessive loops in

cabling, etc.

2. Verify weld mode is correct for processes.

3. The power source may require calibration.

4.

If the machine need calibration,

contact an authorized Lincoln

Electric Service facility for

technical assistance.

The 4-step mode is not

available

1. Verify the CRATER ON/OFF toggle switch on

the front panel of machine is at ON position.

2. Verify the parameter of crater current and

voltage are set properly.

3. PC board in machine possibily at fault.

If PC board in machine is at

fault, contact an authorized

Lincoln Electric Service facility

for technical assistance.

The welding arc is not stable

and soft.

1. Verify the proper polarity is being used for the

weld procedure.

2. Check all electrode and work connections.

3. Verify the parameters of wire feeding speed,

output voltage and shielding gas are proper for

the welding procedure.

4. PC board in machine possibily at fault.

If PC board in machine is at

fault, contact an authorized

Lincoln Electric Service facility

for technical assistance.

OPTIMARC® CV/CC500

Rev. 03

Page 18

C-2 TROUBLESHOOTING C-2

CAUTION

If for any reason you do not understand the test procedures or are unable to

perform the tests/repairs safely, contact your local authorized Lincoln Electric

Field Service Facility for technical assistance.

Observe all Safety Guidelines detailed in the beginning and throughout this manual.

Problems (Symptoms)

Possible Areas of Misadjustment(s)

Recommended Course of Action

Starting arc is difficult.

1. Verify the proper polarity is being used for the

weld procedure.

2. Check all electrode and work connections.

3. Verify the parameters of wire feeding speed,

output voltage and shielding gas are proper for

the welding procedure.

4. PC board in machine possibily at fault.

If PC board in machine is at

fault, contact an authorized

Lincoln Electric Service facility

for technical assistance.

The meter displays ERR 031

Primary over current from switchboard.

Contact your local

authorized Lincoln Electric

Field Service facility for

technical assistance.

The meter displays ERR 032

Low input line voltage error from control board.

Contact your local

authorized Lincoln Electric

Field Service facility for

technical assistance.

The meter displays ERR 035

Input voltage out of range.

Make certain that input

voltage is proper, according

to the Rating Plate.

The meter displays ERR 036

Thermostat Trip.

Clear obstruction or repair

fan;

After machine has cooled,

reduce load, duty cycle, or

both.

The meter displays ERR 041

Secondary over current from switchboard

Contact your local

authorized Lincoln Electric

Field Service facility for

technical assistance.

The meter displays ERR 082

Motor overload.

Please reduce the welding duty

cycle of machine.

The meter displays ERR 124

Invalid weld mode.

Please check if all the welding

procedures are correct.

The meter displays ERR 213

CAN communication error.

Contact your local

authorized Lincoln Electric

Field Service facility for

technical assistance.

OPTIMARC® CV/CC500

Rev. 03

Page 19

D-1 D I A G R A M D-1

STATUS

LED

R

G5964-43

A.02

_

26A

27 25A

+

OUTPUT CHOCK

L1

AC 220V

RECEPTACLE

SHUNT

600A 60mV

SWITCH

29

27 28

SWITCH

BOARD

-5

+

4

L3

L2

L1

223

221

RECTIFIER

26

+

-2683

82

4

220C

221C

30 OHM

200 W

220B

221B

21

20

19

21A

29A

207

209

223

221

33

34

283

284

J21-1

J21-4

201

204

2

1

209 207

220A

J21-6

J27-1

J27-2

207

209

J2

3-

1

J2

3-

2

19

20

21

X2

X4

1

~

2

~

3

~

+

-

+

-

H

L

FAN

U

N

B

G

INPUT

RECTIFIER

FUSE

2A/250V

U

V

W

CASE BACK

FRAME

W V

U

L3

L2

L1

G1

X1

MAIN

TRANSFORMER

X4

1

2

X2

X3

OUTPUT

RECTIFIER

220A

1

2

~380V

6

7

AUXILIARY

TRANSFORMER

4

5

~36V 3A

~220V 1A

20A

29

28

RECTIFIER

-

+

34

33

9

8

33

8

9

~36V 0.5A

258

265

91

92

93

J1-8

J5-1

J5-2

J5-3

J5-4

J5-5

J4-4

J4-3

J4-5

258

264

91

92

93

J2-8

J5-6

83

82

J6-3

J6-5

J6-2

J6-4

J6-1

283

284

265

264

WIRE SIZE

1.2

ARC CONTROL

J10-4

J10-5

J10-7

J10-6

J10-8

DISPLAY

BOARD

271

274

272

273

275

DATA

CLOCK

ENABLE

+15V

MOTOR

GAS SOLENOI

D

2.5K

10

K

GAS

PURGE

COLD

INCH

TRIGGER

91

92

94

93

96

95

<1<

<2<

<3<

<4<

<5<

<6<

WIRE FEEDER

CONNECTOR

GSA/MOTOR

POT/SWITCH

+/-10V

+15V

+24V

+50V

BLAKE

19.5KHZ

DRIVE

S1

1 2 3 4 5 6 7 8

ON

CONTROL BOARD

xx

xx

xx

x

ARC VOLTS

5K

ARC CURRENT

5K

4.7K

266

266

+15V

J2-7

CRATER VOLTAGE

HOT START

10 KOhm

10 KOhm

10 KOhm

J2-4

224

288

225

255

91

93

94

95

96

J7-4J7

-3

J7

-1

J7

-2

H

L

+50V

+15V

93B

93A

95A

95B

OPTIMARC CV/CC500 WIRING SCHEMATIC

20C

POSITIVE

NEGATIVE

1.0

1.6

5P ROTARY SWITCH

J3-1

OPTIONAL

J3-3

J3-2

GMAW

293

292

291

293

292

291

FCAW-GS

J3-7

296

296

J2-6

256

J2-9

259C

J20-13

J20-5

258258258258258268

267

CLOSED= 4 STEP

257

J4-1

257

J4-2

257

260

261

CLOSED = CO2/Ar

J1-9

221A

220A

221A

J21-3

21A

20A

B

B

21B

20B

288

254A

256

259A

254A

256

259A

258

257

258

257

257257257

260

261

260

261

258258258258258258258

268

267

258258258258258258258268

267

VIEW OF CONNECTOR ON PCB

ELECTRICAL SYMBOLS PER E1537

OHMS/WATTS

RESISTORS:

MFD/VO LTS

CAPACITORS:

8

LATCH

EXAMPLE: PIN 7 OF

CONNECTOR J5

32

LEAD COLORING CODE:

B-BLACK

21

8

G-GREEN

O-ORANGE

R-RED

CONNECTOR PIN

NUMBER:

7

14

U-BLUE

Y-YELLOW

W-WHITE

1

3

J5

N-BROWN

ALL COMPONENTS VIEWED FROM REAR.

FERRITE

BEAD

SPIKE

BLOCKER

G

1) ON = PREFLOW

2) ON = LONG CABLE WELD MODE

3) ON = CRATER REPLS MODE

4) ON = TEST MODE

5) ON = SYNERGIC

6) ON = FAST RUN-IN

7) ON = 24VWIRE FEEDER APPLICATION

8) ON = WIRE FEED SPEED CALIBRATION

THERMAL

LED

J20-12

J20-4

+15V

227

226

259B

254C

254B

xx

xx

xx

x

THER

MOSTAT

#2

228

225A

21A

20B

21B

COMPONENT

VALUE UNITE:

THER

MOSTAT

#1

FERRITE

BEAD

FERRITE

BEAD

SPIKE

BLOCKER

LOCAL OUTPUT

CONTROL

10 KOhm

J2-1

288

J2-2

256

J2-3

288

251

252

253

288

251

252

253

J2-5

CRATER CURRENT

10 KOhm

259D

255

255

254D

J4-7

J4-8

J4-6

262

269

FEEDER

263

LOCAL

REMOTE

262

269

263

J3-4GTAW

J3-5

295

294

295

294

SMAW

A

B

C

D

E

F 77

76

75

76

77

J1-3

J1-2

J1-1

2G24

FUSE

8A/250V

26

25

25

232

231

J20-6

J20-14

+15V

OUTPT

INPUT

NOTE: This diagram is for reference only. It may not be accurate for all machines coved by this manual. The specific diagram for a particular code is pasted inside the machine on one of the enclosure panels. If the diagram is illegible,

contact the Lincoln Electric Service Department for a replacement

OPTIMARC® CV/CC500

Rev. 03

Page 20

E-1 BOTTOM E-1

• World’s Leader in Welding and Cutting•

THE SHANGHAI LINCOLN ELECTRIC COMPANY

No. 195, Lane 5008, Hu Tai Rd. Baoshan, Shanghai, PRC 201907

www.lincolnelectric.com.cn

OPTIMARC® CV/CC500

Rev. 03

Loading...

Loading...