Page 1

S UCCESS

WAVEFORM CONTROL TECHNOLOGY

Pulsed GMAW

Automation

Valley Industries, of Lodi,

California, has produced trailer

hitches and towing accessories

for 57 years.

-CHALLENGE-

Valley Industries was looking to

increase welding productivity and

improve product quality.

-SOLUTION-

• A pulsed GMAW (MIG) process using

Lincoln Power Wave® 455M power

sources embedded with Nextweld®

technologies with FANUC® 120iLB

six-axis robot cells.

Valley Industries

®

• A Lincoln System 40 robotic workcell

with a FANUC® 100iB six-axis robot.

• Lincoln SuperArc® L-50 MIG wire

supplied on 1000 lb. Accu-Trak®

drums.

-RESULTS-

Valley experienced a 60 percent

increase in productivity, improved

process control and higher quality parts

resulting from the move to automation

with a Pulsed GMAW process.

Valley also improved manufacturing

delivery times and reduced inventories.

s the manufacturer and

distributor of 400 different

A

accompanying towing accessory

components, Valley Industries, LLC

of Lodi, California, was looking for a

way to increase welding productivity

and improve product quality. To do

this, the company made the switch

from a semiautomatic GMAW (MIG)

welding process to robotic GMAW-P

(Pulsed MIG) welding systems from

The Lincoln Electric Company. The

move to automation has resulted in

a 60 percent increase in productivity,

improved process control and higher

quality parts – adding up to a

competitive advantage for Valley

Industries among its OEM and

aftermarket customers.

In addition, the robotic systems,

which combine Lincoln’s Power

Wave® 455M power sources with

FANUC® robots, allowed Valley

Industries to improve order delivery

time on popular products like

receiver style, fifth wheel, and

gooseneck hitches. This, in turn,

trailer hitches and

reduced inventories for work-inprocess and finished goods.

Brad Ownbey, Manager of

Manufacturing, Maintenance and

Special Projects for Valley Industries,

indicated that half of the company’s

products involve some type of

welding. Therefore, efficient welding

practices are extremely critical to the

57-year-old company’s success.

“Welding, and especially automated

welding, have been key elements in

addressing sales, operating cost,

new products, quality, and

efficiency,” said Ownbey. “Valley is

also very much about people. You

cannot be successful without them.

Sustained business growth, year over

year, has afforded us the ability to

maintain employment levels while

integrating automation into the

operation.”

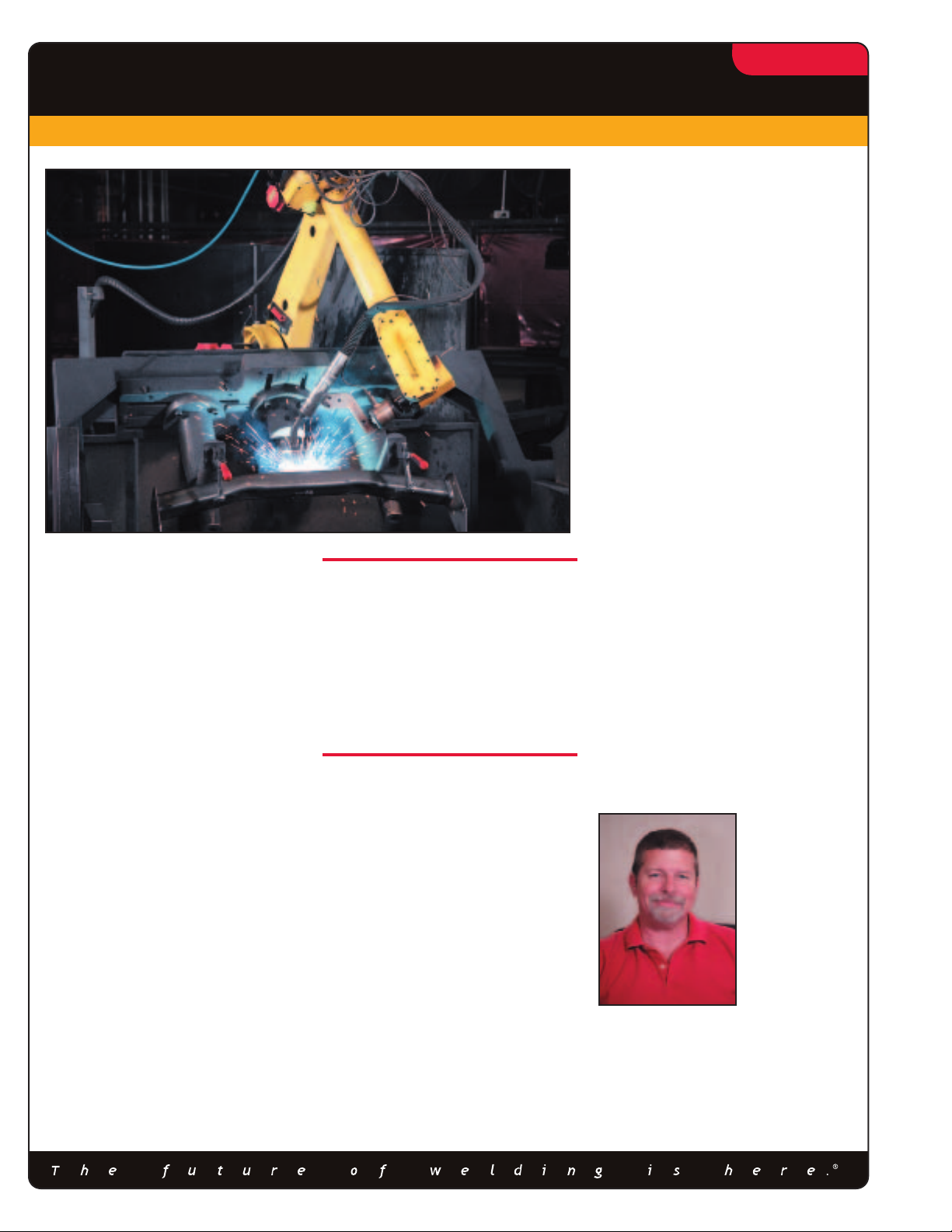

The Move To Robotics

When management decided that

automation was a viable option for

Valley Industries, the company set

out to evaluate several robotic

NX-4.310 2/06

Page 2

WAVEFORM CONTROL TECHNOLOGY

®

SUCCESS

Pulsed GMAW

Automation

2/4

Valley Industries

As indicated, each robotic cell is

equipped with a dual headstock/tailstock

fixture used to position and rotate the

production parts. Coordinated Motion

software is used to synchronize the

motions of the robot arm and the

rotation of the fixturing, allowing welding

and part rotation at the same time.

To maximize system uptime, the

operator unloads finished parts and reloads components into one side of the

cell while the robot welds on the other

side. Part program changeovers are

completed quickly and easily using

hand-held robot teach pendant controls.

According to Ownbey, the company’s

previous experience with CNC-type

machines (plasma/punch, tubing bender,

saws) helped to make an easy transition

to operate the Lincoln automation

systems.

welding systems. According to Ownbey,

Valley chose Lincoln’s system because it

was reliable, easy to use and had proven

success in numerous other manufacturing applications across the country.

“Another factor that helped make our

decision was our ongoing relationship

with Lincoln Electric. We trust their

people and enjoy good experiences with

the Lincoln semi-automatic products

already in our shop,” noted Ownbey.

Installation of the robot work cells was a

joint effort between Lincoln Electric and

Valley Industries personnel. “Since the

work cells are preassembled as three

major components at Lincoln’s

Automation Division, on-site installation

and set up goes quickly,” noted Ownbey.

“In our application, the robotic arm,

controller, and welding equipment make

up one component of the work cell. Two

headstock/tailstock fixture components

are then mounted in a symmetricallyopposed fashion in relation to the robot

arm to position our product for welding.

Electrical power, welding gas,

compressed air, and several digital

communication and power cables are

hooked up. The Lincoln technician then

ensures that the set up is correct and

programs the system operating functions

and welding programs.” He indicated

that installation and set up are

“Because these power

sources create such high

quality welds, we are able

to go directly to the paint

stage of our processing,

without having to do any

grinding or finish work on

the welds.”

accomplished in as little as four days

per cell.

Initially, Valley Industries purchased one

robot. However, over the last three

years, they added eight customdesigned robotic cells as the advantages

of automation became apparent.

Currently, 140 Valley products are

welded using automation.

It’s easy to see the efficiencies robots

brought to the production floor at Valley

Industries. Each of the seven FANUC

ArcMate 120 iLB six-axis robot cells on

the hitch line has two welding stations

that can be programmed to weld the

same part or entirely different parts,

adding tremendous production flexibility

to Valley’s operations.

In addition, with seven identical robotic

systems on the shop floor, Valley gains

more scheduling flexibility. At any time,

the production team can call up

previously set part welding programs to

quickly duplicate part production on any

number of robotic cells to meet changes

in demand.

For the company’s ball mount products,

Valley selected a Lincoln System 40

robotic work cell. This system features

a sizable 71 inch diameter turntable,

allowing four parts to be completed at

the same time

for optimum

overall

productivity. In

this cell, a

FANUC

ArcMate 100iB

six-axis robot

is used.

However,

robots and

fixturing are

Brad Ownbey

Industries. The heart of the welding

systems is the Power Wave 455M power

source with advanced Waveform Control

Technology® capabilities, an element of

Lincoln’s Nextweld® series of innova-

only part of the

story at Valley

Page 3

WAVEFORM CONTROL TECHNOLOGY

®

SUCCESS

Pulsed GMAW

Automation

tions. Waveform Control Technology® is

Lincoln’s proprietary welding software

platform that controls and shapes the

welding output waveform. Since the

waveform is shaped digitally using

software with an inverter-based Power

Wave® welder, optimized results are

delivered accounting for a specific

material type and thickness, electrode

wire type and diameter, shielding gas

mix and other variables.

In the case of Valley Industries, the

material is typically mild steel ranging

in thickness from 16

gauge to 1-inch. The

Power Wave welding

power source delivers

conventional MIG

welding procedures

as well as Pulsed MIG

welding procedures

for more difficult joint

configurations when

controlling heat input

to minimize distortion

is especially critical.

“The Power Waves

produce a very

consistent, stable arc

and deliver improved

deposition rates. With

automation, faster travel

speeds can be more

easily accomplished

than with manual or semiautomatic

welding,” said Ownbey. “We are able to

manipulate arc characteristics, resulting

in a weld bead that is more uniform in

appearance. We also experience far less

spatter. Because these power sources

create high quality welds, we are able

to go directly to the paint stage of our

processing, without having to do any

grinding or finish work on the welds.”

Valley Industries also uses the real-time

Production Monitoring™ capabilities of

the Lincoln Power Wave power sources

to monitor arc current, voltage and wire

feed speed. Technicians and operators

review the information to assist in

refining weld programs and to identify

and correct problems. As an added

bonus, Ownbey reports the Power

Wave 455M units are very durable in

Valley Industries

an inherently dirty environment for

electronics.

Hitch and Towing Components

Valley Industries’ trailer hitches require

an average of 16 welds per unit. Most of

the components are plate and round or

square tubing requiring single pass fillet

joint welds that range from 1/2-inch to

12-inches in length. On average, nine

component parts are loaded into the

work cell fixturing to complete a typical

hitch.

“The Power Waves produce

a very consistent, stable arc

and deliver improved

deposition rates.”

Demand and volume dictate which parts

are welded robotically versus those

completed by manual or semiautomatic

welding. The robots at Valley Industries

are currently running 24 hours a day, 6

days a week to keep up with the

demand. Automation allows the 250employee company to produce smaller

batches of parts with greater speed.

All new products are tested using the

transportation industry standard SAE J684 test (more commonly known as the

3/4

V-5 test) which simulates thousands of

miles of towing under extreme

conditions. “We take much care in the

design stage to ensure the safety of our

products, especially since most of them

will be used to tow recreational and

commercial trailers at highway speeds.

The consistent performance and weld

quality of automated welding are

naturally an enhancement in this area.”

said Ownbey.

According to Ownbey, because the

robotic weld sequence and weld joint

locations are

programmed, the same

exact process is repeated time after time.

This makes control of

distortion within the

welded assembly very

manageable compared

to hand welding.

Engineering tolerances

become less of a

challenge, manufacturing costs are

reduced, and more

options are realized

in product design.

In tandem with the

Lincoln Automation

system, Valley Industries

is utilizing .045-inch

diameter Lincoln

SuperArc® L-50 MIG wire with a 92%

Argon / 8% CO

The wire is supplied in 1,000-pound

Accu-Trak® drums, which according

to Ownbey, are delivering consistent

performance and are quick to set up.

“The L-50 is the highest quality welding

wire I have used in my 27 years in

manufacturing. Lincoln wire has a

distinct advantage in automation

applications, because it is clean and

very stiff. The copper coating doesn’t

flake, and it comes out of the container

straight. Arc starts are more consistent

and overall feeding problems are

minimal.”

Lincoln Service

“Our experience with Lincoln service has

been excellent. Technicians in Cleveland,

Ohio, are available by phone and often

shielding gas blend.

2

Page 4

SUCCESS

4/4

assist us remotely to solve problems,”

said Ownbey. “We also rely on our

local Lincoln representatives. All are

professional and quick to respond.

Recently, when we developed a

problem with a torch cooling unit, we

called Lincoln. By the next morning

we had a new unit in our shop.”

As far as training, ten of the company’s

robotic cell operators attended Lincoln

training in Cleveland for programming,

maintenance and service of the

systems.

Conclusion

According to Ownbey, the company

is currently pursuing automation in a

number of key areas within the plant.

As to the future of welding automation,

the company looks forward to performing their own off-line programming

soon.

In the future, look for Valley Industries

to introduce new products and enhance the size of current distribution

facilities to meet the growing demand

for their hitch products.

Valley Industries

Automation

Power Wave®455M

Superior Arc Performance.

Revolutionary Communication.

For welding thicker materials in

robotics, hard automation and semiautomatic applications, choose the

Power Wave

®

455M. This model

features Waveform Control Technology

®

for superior arc performance on a

variety of materials, including steel,

stainless steel, aluminum and nickel

alloys, and delivers custom control

of the arc for each wire type and size

for consistent welds time after time.

The Power Wave 455M is designed

to be part of a modular, multi-process

welding system in which power

sources can be added or removed

to create a series of highly integrated

and flexible welding cells.

SuperArc

®

L-50

Our most popular MIG wire, SuperArc

®

L-50, premium copper coated wire, is

an excellent choice for 50,000 psi (345

MPa) yield strength, carbon steel base

materials. SuperArc L-50 has moderate

levels of silicon and manganese for

deoxidation and cleaning action. Designed for use on clean, oil-free, and

rust-free base material. Will tolerate

light millscale. SuperArc L-50 also has

an excellent reputation for feedability

and trouble-free performance. Shielding

gases include argon/carbon dioxide

blends, argon/oxygen blends, straight

carbon dioxide, and three or four-part

gas mixes.

Pulsed GMAW

WAVEFORM CONTROL TECHNOLOGY

®

Featured Lincoln Products

WHAT IS NEXTWELD?

The challenges facing industrial

fabricators today are growing in number

and complexity. Rising labor, material and

energy costs, intense domestic and global

competition, a dwindling pool of skilled

workers, more stringent and specific

quality demands all contribute to a

more difficult welding environment

today.

Through our

commitment to

extensive

research

and

investments

in product

development,

Lincoln Electric

has established

an industry

benchmark for applying technology to

improve the quality, lower the cost and

enhance the performance of arc welding

processes. Advancements in power

electronics, digital communications and

Waveform Control Technology

TM

are the

foundation for many of the improvements.

NEXTWELD

®

brings you a series of

Process, Technology, Application and

Success Story documents like this one.

NEXTWELD explains how technologies,

products, processes and applications are

linked together to answer the important

questions that all businesses face:

• How can we work faster, smarter, more

efficiently?

• How can we get equipment and people

to perform in ways they’ve never had to

before?

• How do we stay competitive?

NEXTWELD is the future of welding but its

benefits are available to you today. Ask

your Lincoln Electric representative how

to improve the flexibility, efficiency and

quality of your welding operations to

reduce your cost of fabrication.

THE LINCOLN ELECTRIC COMPANY

www.lincolnelectric.com

1.216.481.8100

Loading...

Loading...