Page 1

®

RETURN TO MAIN MENU

LN-10 / ZIPLINE BOOM PACKAGE

IM596-2A

March, 2001

For use with “K” Sales Spec Numbers:

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thoughtful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT READING THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

K1564-2

K1564-3

K1564-5

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

OPERATOR’S MANUAL

Copyright © 2001 Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Page 2

i

SAFETY

WARNING

READ AND FOLLOW ALL WARNING INFORMATION IN THIS AND ALL OTHER MANUALS

WARNING

SPRING UNDER PRESSURE

Release of spring pressure can cause serious personal injury and equipment

damage.

• Do not remove spring rod shipping support until boom is completely assembled

and all components are installed.

• Do not service or adjust spring pressure on boom without the spring rod shipping

support securely installed.

WARNING

MOVING BOOM PARTS CAN CAUSE SERIOUS PERSONAL INJURY.

i

• Keep hands away from spring rod clevis and swivel plates.

WARNING

FALLING BOOM CAN CAUSE SERIOUS PERSONAL INJURY AND EQUIPMENT

DAMAGE.

• Securely attach pallet base or pedestal to floor before operating boom arm.

WARNING

UNBALANCED BOOM CAN CAUSE SERIOUS PERSONAL INJURY AND

EQUIPMENT DAMAGE.

• Do not remove wire drive unit without the spring rod shipping support securely

installed.

CAUTION

ONLY QUALIFIED PERSONNEL SHOULD INSTALL, USE OR SERVICE THIS

EQUIPMENT.

READ AND FOLLOW THE MANUFACTURER’S INSTRUCTIONS AND YOUR

EMPLOYER’S SAFETY PRACTICES.

Page 3

for selecting a QUALITY product by Lincoln Electric. We want you

Thank You

to take pride in operating this Lincoln Electric Company product

••• as much pride as we have in bringing this product to you!

Please Examine Carton and Equipment For Damage Immediately

When this equipment is shipped, title passes to the purchaser upon receipt by the carrier. Consequently, Claims

for material damaged in shipment must be made by the purchaser against the transportation company at the

time the shipment is received.

Please record your equipment identification information below for future reference. This information can be

found on your sales information.

Model Name and Sales SpecNumber (K-xxx) _____________________________________

Date of Purchase __________________________________

Whenever you request replacement parts for or information on this equipment always supply the information

you have recorded above.

iiii

Read this Operators Manual completely before attempting to use this equipment. Save this manual and keep it

handy for quick reference. Pay particular attention to the safety instructions we have provided for your protection.

The level of seriousness to be applied to each is explained below:

WARNING

This statement appears where the information must be followed exactly to avoid serious personal injury or

loss of life.

CAUTION

This statement appears where the information must be followed to avoid minor personal injury or damage to

this equipment.

Page 4

iii

TABLE OF CONTENTS

Page

Installation.......................................................................................................................Section A

Product Description ..............................................................................................................A-1

Zipline Boom Models............................................................................................................A-1

Recommended Wire Feeder - Power Source Combinations ...............................................A-2

Product Specifications..........................................................................................................A-2

Unpacking and Checking Kit Contents.................................................................................A-3

Installation Procedure...........................................................................................................A-7

Tools Required..............................................................................................................A-7

Install the Wire Drive Assembly ....................................................................................A-7

Install the Control Box Assembly .................................................................................A-7

Install the Power Input Cable Assembly........................................................................A-7

Install the Electrode Weld Cable ...................................................................................A-7

Install the Control Cable Assembly ...............................................................................A-7

Install the Gas Hose......................................................................................................A-7

Install the Conduit Bushings and Electrode Conduit .....................................................A-8

Install the 2” Spindle Assembly .....................................................................................A-8

Install the Gun Control Plug Cable Assembly and the Gun and Cable Assembly ........A-8

Install the Welding Power Source .................................................................................A-8

Install the Wire Reel, Drive Rolls and Guides ...............................................................A-8

Dimension Prints ............................................................................................................Section B

12 Ft. Spring Balanced Zipline Boom Assembly ..................................................................B-1

12 Ft. Hydraulic Zipline Boom Assembly..............................................................................B-2

16 Ft. Spring Balanced Zipline Boom Assembly ..................................................................B-3

16 Ft. Hydraulic Zipline Boom Assembly..............................................................................B-4

Control Box Assembly ..........................................................................................................B-5

Wire Drive Assembly ............................................................................................................B-6

iii

Page 5

A-1

INSTALLATION

A-1

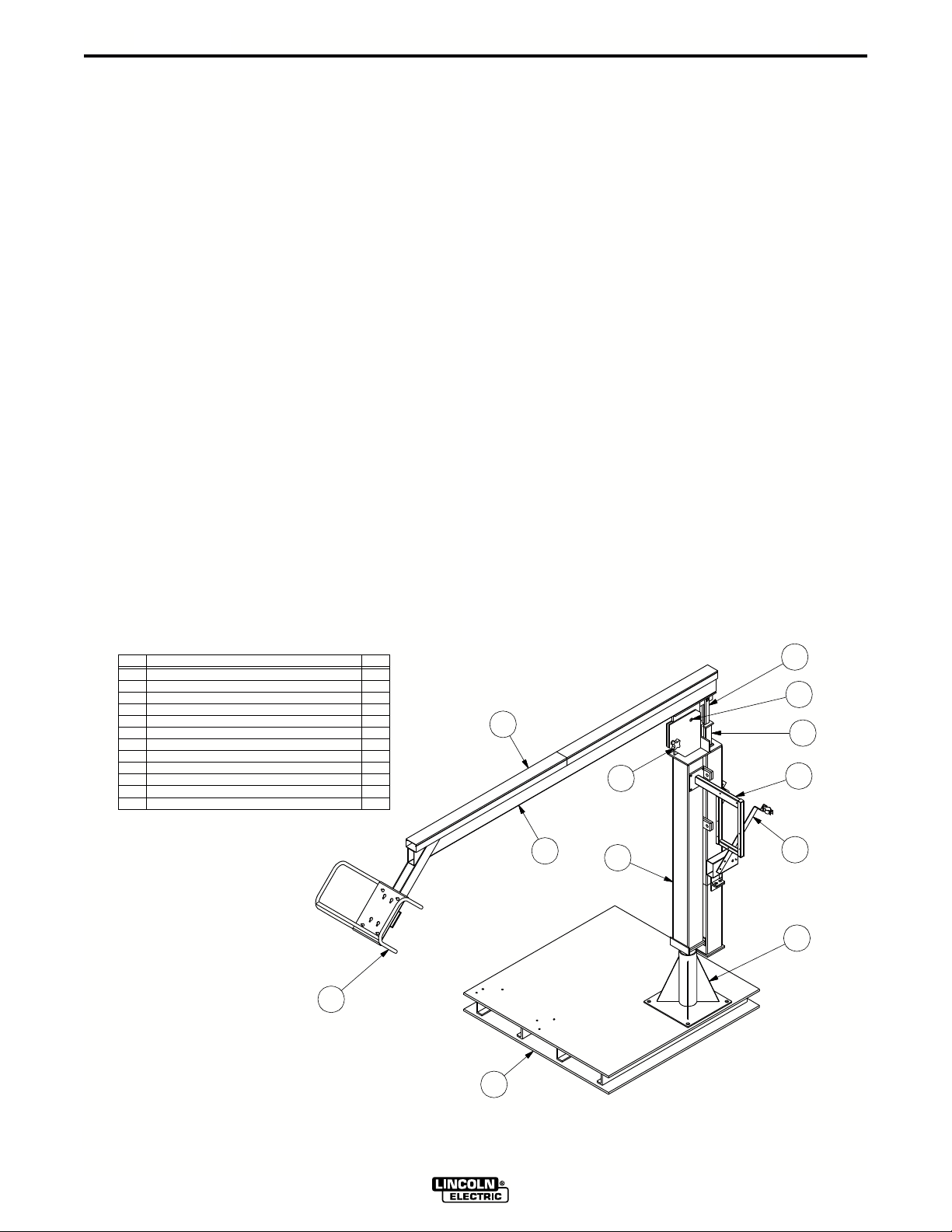

PRODUCT DESCRIPTION

This wire feeder boom package comprised of Lincoln

equipment will allow you to setup a boom welding system when used in conjunction with Zipline® boom

products. This boom package includes everything you

need from Lincoln to easily setup a standard 12 or 16

foot welding station using the Zipline boom product

line.

You will need to purchase the boom and related products from Bird Machine and Repair, Inc., 100 Station

St., Johnstown, PA. 15905, (814)288-3641, the manufacturer of the Zipline® boom product line.

The Lincoln boom package will include the following

items:

Wire Drive Assembly

Control Box Assembly

Electrode Weld Cables

Control or Linc-Net Cables

Gas Hoses

Electrode Conduits

2" Spindle Assemblies

Hardware Kit

Conduit Bushing Kit

Gun Control Plug Cable Assembly (1 per Head)

Wire Feeder Instruction Manual

Boom Package Instruction Manual

ZIPLINE BOOM MODELS

Both 12 and 16 foot boom length models are available

from Zipline. Two different boom balancing designs

are also available; a spring balanced boom model and

a hydraulic boom model. The standard Zipline boom

configurations are as follows:

12' Spring Balanced Zipline Boom

16' Spring Balanced Zipline Boom

12' Hydraulic Zipline Boom

16' Hydraulic Zipline Boom

The following items will be provided by Bird Machine and Repair

Inc., the manufacturer of the Zipline boom product line:

Pallet Base Assembly (optional)

Pedestal Base Assembly

Boom Mast

Spring Retainer Housing or Hydraulic Device

Boom Arm

Cable and Hose Trough

Conduit Bushing Bracket

Provisions to Mount 2" Spindle Assembly

Control Box Support Assembly (optional)

Feeder Mount Bracket and Cage Assembly (optional)

See Figure A.1 for illustration of the Zipline products.

See the following pages for illustrations of the Lincoln

Products.

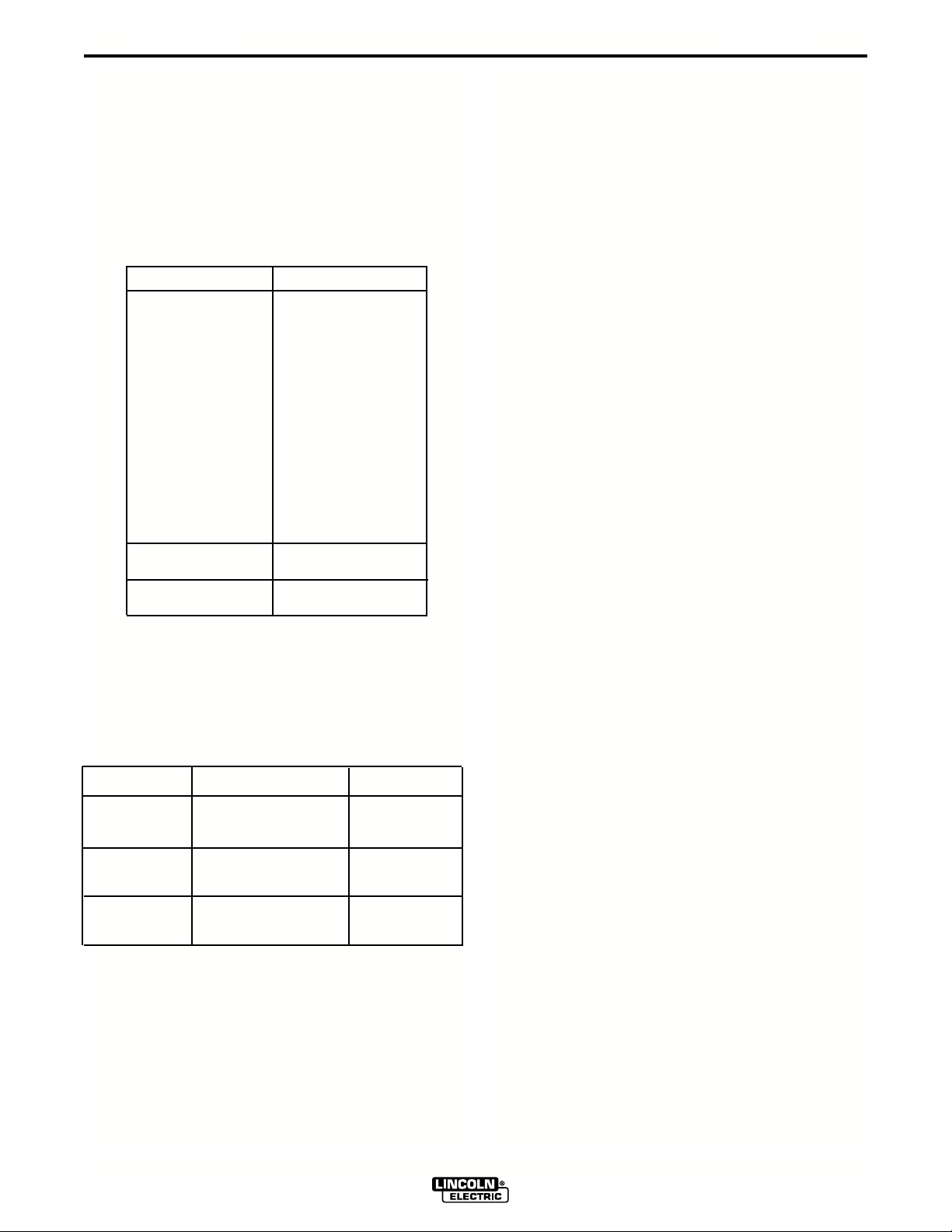

DESCRIPTIONITEM

12PALLET BASE ASSEMBLY (OPTIONAL)

PEDESTAL ASSEMBLY

BOOM MAST & SPRING RETAINER HOUSING ASSY

3

4

SPRING ROD CLEVIS

5

MAIN SWIVEL PIN

6

FRICTION CONTROL KNOB

7

SPRING ROD SHIPPING SUPPORT

CONDUIT BUSHING BRACKET

8

9

CONTROL BOX SUPPORT ASSEMBLY (OPTIONAL)

10

BOOM ARM ASSEMBLY

11

CABLE & HOSE TROUGH

FEEDER MOUNT BRACKET & CAGE ASSEMBLY (OPTIONAL)

12

12

QTY.

4

1

1

1

1

1

1

1

2

1

1

2

1

11

6

10

1

3

ZIPLINE BOOM PACKAGES

8

S

5

7

9

2

24078

24078

A

FIGURE A.1

LN-10 / ZIPLINE BOOM PACKAGE

Page 6

A-2

INSTALLATION

A-2

RECOMMENDED WIRE FEEDER POWER SOURCE COMBINATIONS

The Zipline booms have been designed to integrate

with newer wire feeders and power sources. The following is a list of wire feeders and power sources that

are compatible with the Zipline boom’s pallet base,

control box support and feeder mount bracket/cage

assembly.

Wire Feeders Power Sources

LN-10 CV-250

DH-10 CV-300-I

CV-300

CV-400-I

CV-400

CV-500-I

CV-655

** DC-250

DC-400

** PP-500

** DC-600

DC-655

** DC-1000

See the appropriate Dimension Print in Section B of

this manual for details on the physical size of the

equipment.

PF-10 PW-455

STT-10 STT-II

** A K1520-1 115V/42V Transformer Kit is required

with these power sources.

PRODUCT SPECIFICATIONS

Product Number Product Description Net Weight (lbs.)

K1564-2 LN-10 Boom Package - 90

12' Zipline Boom

K1564-3 LN-10 Boom Package - 103

16' Zipline Boom

K1564-5 LN-10 Boom Package - 90

12' Zipline Boom

LN-10 / ZIPLINE BOOM PACKAGE

Page 7

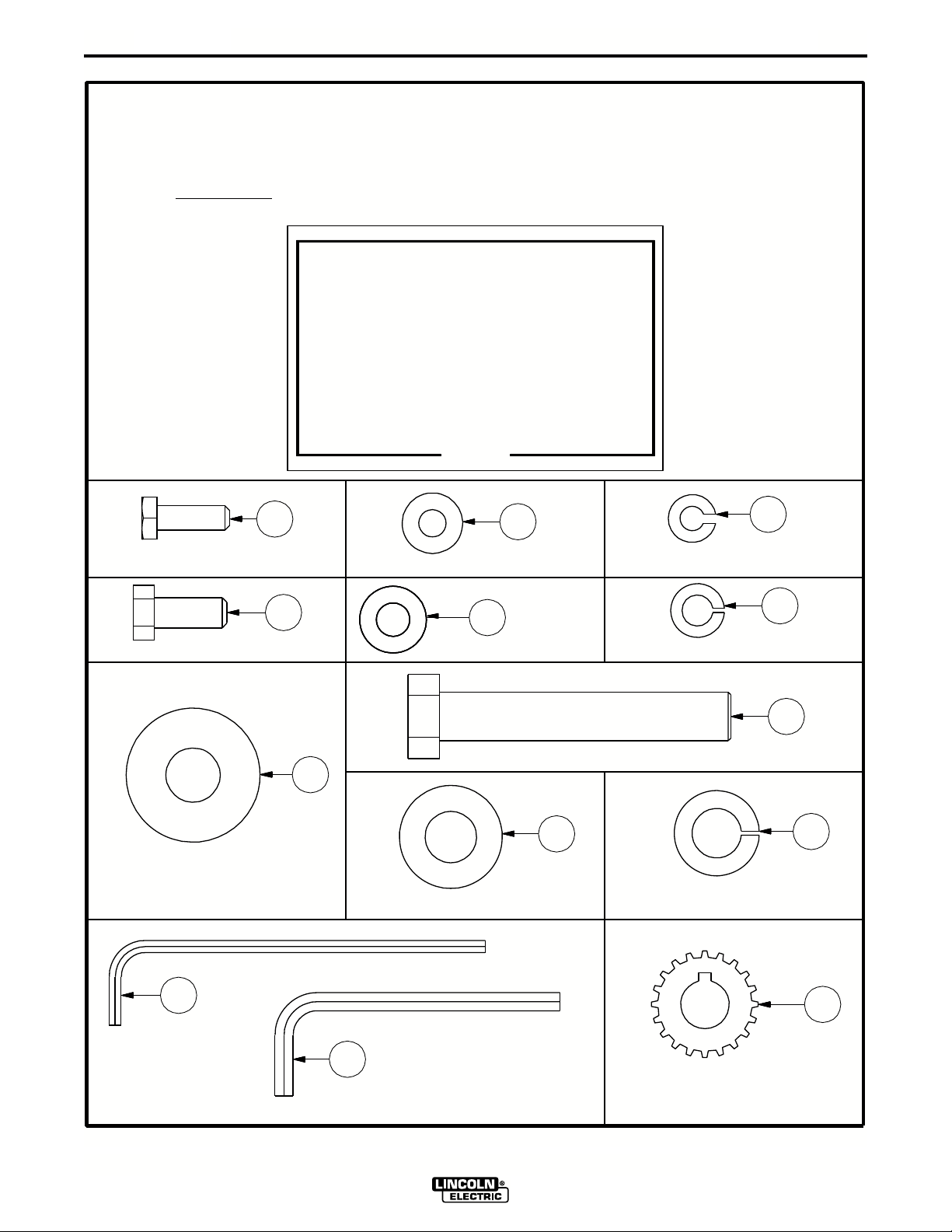

A-3

REQUIRED TOOLS

UNPACK THE BOOM PACKAGE

CHECK YOUR BOOM PACKAGE

FOR THE FOLLOWING:

INSTALLATION

K1564-2 LN-10 B00M PACKAGE - 12' ZIPLINE BOOM

K1564-3 LN-10 B00M PACKAGE - 16' ZIPLINE BOOM

ITEM

1

2

L9776-C-18 L9776-C-22

3

4

5

6

7

8

9

10

11

12

13

INSTRUCTION MANUAL

11/16" WRENCH7/16" WRENCH 3/4" WRENCH

1/2" WRENCH

K1564-3K1564-2

PART NO.PART NO.

M18899-1

M17869-5

M18298-2-10

CL012325

CL012326

S18453-3

S20023-A-21S20023-A-17

M14935-1

S23858-2

S23859

M15608

L3326-169

L2213-528

FLAT HEAD SCREWDRIVERPHILLIPS HEAD SCREWDRIVER

DESCRIPTION

WIRE DRIVE ASSEMBLY

CONTROL BOX ASSEMBLY

CONTROL CABLE ASSEMBLY

POWER INPUT CABLE ASSEMBLY

ELECTRODE WELD CABLE

GAS HOSE

ELECTRODE CONDUIT

2" SPINDLE ASSEMBLY

HARDWARE KIT

CONDUIT BUSHING KIT

GUN CONTROL ASSEMBLY

BOOM PACKAGE INSTRUCTION MANUAL

WIRE FEEDER INSTRUCTION MANUAL

A-3

REQ'D

1

1

1

1

1

1

1

1

1

1

1

1

1

1

(1) WIRE DRIVE ASSEMBLY

4

(1) POWER INPUT CABLE ASSEMBLY

2

(1) CONTROL BOX ASSEMBLY

5

(1) ELECTRODE WELD CABLE

8

3

(1) CONTROL CABLE ASSEMBLY

6

(1) GAS HOSE

11

7

(1) ELECTRODE CONDUIT

(1) 2" SPINDLE ASSEMBLY

LN-10 / ZIPLINE BOOM PACKAGE

(1) GUN CONTROL ASSEMBLY

Page 8

A-4

ITEM 9 S23858-2

INSTALLATION

K1564-2 LN-10 B00M PACKAGE - 12' ZIPLINE BOOM

K1564-3 LN-10 B00M PACKAGE - 16' ZIPLINE BOOM

INSTRUCTION MANUAL

A-4

1

(3) 1/4-20X.75 HHCS-GR2

4

(4) 5/16-18X.75 HHCS-GR2

ITEM

PART No.

CF000014

1

2

S9262-98

3

E106A-2

CF000040

4

5

S9262-30

6

E106A-14

S9262-14

7

8 T8833-64

9

S9262-1

10 E106A-15

11 T11563-2

12 T11563-3

M18223-113

HARDWARE KIT

DESCRIPTION

1/4-20X.75 HHCS-GR2

PLAIN WASHER

LOCKWASHER

5/16-18X.75HHCS-GR2

PLAIN WASHER

LOCKWASHER

PLAIN WASHER

1/2-13X3.00HHCS-GR8

PLAIN WASHER

LOCKWASHER

1/8 ALLEN WRENCH

3/16 ALLEN WRENCH

LOW SPEED PINION

2

(3) PLAIN WASHER

5

(4) PLAIN WASHER

QTY.

3

3

3

4

4

4

1

1

1

1

1

1

1

B-RW

S23858-2

(3) LOCK WASHER

(4) LOCK WASHER

3

6

(1) PLAIN WASHER

(1) SOCKET KEY-1/8 ALLEN WRENCH

11

(1) 1/2-13X3.0 HHCS-GR8

7

9

(1) PLAIN WASHER

(1) SOCKET KEY-3/16 ALLEN WRENCH

12

LN-10 / ZIPLINE BOOM PACKAGE

8

10

(1) LOCK WASHER

13

(1) LOW SPEED PINION

Page 9

A-5

ITEM 10 S23859

INSTALLATION

K1564-2 LN-10 B00M PACKAGE - 12' ZIPLINE BOOM

K1564-3 LN-10 B00M PACKAGE - 16' ZIPLINE BOOM

INSTRUCTION MANUAL

A-5

PART No.

ITEM

1

S23750-1

S23750-2

2

3

S22933

CONDUIT BUSHING KIT

DESCRIPTION

CONDUIT BUSHING (.025-.063)

CONDUIT BUSHING (.063-.125)

KNURLED KNOB ASSEMBLY

QTY.

2

2

2

B-RW

S23859

1

CONDUIT BUSHING (.025-.063)

2

CONDUIT BUSHING (.063-.125)

3

KNURLED KNOB ASSEMBLY

LN-10 / ZIPLINE BOOM PACKAGE

Page 10

A-6

REINSTALL

COVER AFTER

CONNECTIONS

ARE MADE

CONNECT

ELECTRODE

WELD CABLE

TO WIRE FEEDER

HERE

INSTALLATION

MOUNTING SLOTS

A-6

CONNECT

ELECTRODE

WELD CABLE

FROM POWER

SOURCE HERE

MOUNTING SLOT

CONNECT

CONTROL CABLE

ASSEMBLY TO WIRE

FEEDER HERE

LN-10 CONTROL BOX ASSEMBLY

FRONT VIEW

CONNECT

POWER INPUT

CONTROL CABLE

FROM POWER

SOURCE HERE

LN-10 / ZIPLINE BOOM PACKAGE

Page 11

A-7

INSTALLATION

A-7

INSTALLATION PROCEDURE

Assemble the Zipline boom according to the installation instructions provided with the boom. Next, install

and assemble the wire feeder boom package as follows:

TOOLS REQUIRED

• 7/16" wrench

• 1/2" wrench

• 11/16" wrench

• 3/4" wrench

• Phillips head screwdriver

• Flat head screwdriver

INSTALL THE WIRE DRIVE ASSEMBLY

With a 1/2" wrench, install the wire drive assembly

using the (4) 5/16-18 X .75 bolts and washers provided. Screw the bolts and washers partially into the bottom of the wire drive assembly before placing the wire

drive assembly onto the feeder mount bracket & cage

assembly. After the wire drive assembly is in place,

completely tighten the bolts.

INSTALL THE CONTROL BOX ASSEMBLY

With a 7/16" wrench, install the control box assembly

using the (3) 1/4-20 X.75 bolts and washers provided.

Screw the bolts and washers partially into the control

box support before placing the control box assembly

onto the control box support. After the control box

assembly is in place, completely tighten the bolts.

INSTALL THE POWER INPUT CABLE

ASSEMBLY

INSTALL THE ELECTRODE WELD CABLE

With a 3/4” wrench, install the single 3/0 electrode

weld cable between the wire drive assembly and the

control box assembly. The cable MUST

through the center of the boom arm steel tube.

Tighten all connections completely to ensure a good

electrical connection.

NOTE: The electrode weld cables provided with the

wire feeder boom package is rated for 600 amps @

60 % duty cycle. If operating above this rating, an

additional cable should be used in parallel with the

cable provided.

be routed

INSTALL THE CONTROL CABLE ASSEMBLY

Remove the trough cover on the top of the boom arm

assembly. Install the cable assembly between the wire

drive assembly and the control box assembly. The

pin end of the cable assembly connects to the control

box assembly. The socket end of the cable assembly

connects to the wire drive assembly. Neatly place the

cable in the trough and attach the cable to the control

box support using the supplied cable hangers.

Tighten all connections completely to ensure a good

electrical connection.

INSTALL THE GAS HOSE

With an 11/16” wrench, install the 25’ gas hose

between the wire drive assembly and a gas supply

connection. Neatly place the hose in the trough.

Tighten connections completely to ensure a good gas

connection.

With a 3/4" wrench, install the 10' power input cable

assembly between the control box and the power

source. This assembly includes a control cable fastened to a 3/0 weld cable. The pin end of the control

cable assembly connects to the power source. The

socket end of the control cable assembly connects to

the control box assembly. Install the user provided

electrode work cable between the power source and

work piece. Tighten all connections completely to

ensure a good electrical connection.

NOTE: The electrode weld cable provided with the

power input cable assembly is rated for 600 amps @

60 % duty cycle. If operating above this rating, an

additional cable should be used in parallel with the

cable provided.

LN-10 / ZIPLINE BOOM PACKAGE

Page 12

A-8

INSTALLATION

A-8

INSTALL THE CONDUIT BUSHINGS and

ELECTRODE CONDUIT

With the provided 1/8” allen wrench, remove the

incoming guide on the wire drive assembly. Two different size conduit bushings are provided in the conduit bushing kit, .025 to .063 and .063 to .125. Based

on the wire used for your application, find two appropriate wire size conduit bushings. Install one of the

conduit bushings where the incoming guide was.

Install the second conduit bushing in the clamp on the

conduit bushing bracket, located on the boom mast

above the spindle mounting bracket. Install the electrode conduit between the two conduit bushings.

Push the electrode conduit into the bushing until it

stops. Screw the knurled knob assembly into each

conduit bushing to securely hold the electrode conduit

in place. Neatly place the conduit in the trough. Reinstall the trough cover.

INSTALL THE 2” SPINDLE ASSEMBLY

With a 3/4” wrench, install the 2” spindle assembly

using the 1/2-13 x 3.00 bolt and washers provided.

Place the larger washer into the spindle assembly

before installation to the boom mast spindle bracket.

Line up the small hole on the spindle assembly with

the roll pin on the mast. After the 2” spindle assembly

is in place, completely tighten the bolt.

INSTALL THE GUN CONTROL PLUG

CABLE ASSEMBLY and

THE GUN AND CABLE ASSEMBLY

Install the provided gun control plug cable assembly to

the front of the wire drive assembly. Install the gun

and cable assembly per the instruction manual provided with the gun. Gun adapters may be required if

using a Non-Lincoln gun.

INSTALL THE WELDING POWER SOURCE

Install the welding power source per the instruction

manual provided with the power source.

INSTALL THE WIRE REEL, DRIVE ROLLS

AND GUIDES

Load the wire reel with a coil of wire so as to dereel off

the side of the coil closest to the conduit bushing.

Install the appropriate drive rolls and guides for your

specific wire size application per the instruction manual provided with the wire feeder. Thread the wire

through the entire length of conduit to the drive rolls to

feed through the gun cable. Repeat this step for the

opposite side of your wire feeder.

LN-10 / ZIPLINE BOOM PACKAGE

Page 13

B-1

DIMENSION PRINTS

12 FT. SPRING BALANCED ZIPLINE BOOM ASSEMBLY

B-1

60.00

48.00

60.00

46.00

R 144.0

(R 12'-0")

N.B.

165.6

(13'-10")

18.28

144.0

135.0

(12'-0")

(11'-3")

88.25

5.00

15.00

33.00

45.00

TYP.

.81

12.38

14.00

12.38

HOLE

.81

14.00

.81

TYP.

FOR 3/4" BOLTING

(4 PLACES)

MAST PEDESTAL DETAIL

N.A.

17.38

UPWARD 50 TO DOWNWARD 6.

46" X 48" OR 60" X 60".

N.B. PALLET BASE IS OPTIONAL. AVAILABLE SIZES ARE

N.A. BOOM ADJUSTS FROM THE HORIZONTAL POSTION

7.75

38.25

52.25

LN-10 / ZIPLINE BOOM PACKAGE

Page 14

B-2

DIMENSION PRINTS

12 FT. HYDRAULIC ZIPLINE BOOM ASSEMBLY

B-2

XA

60.00

48.00

60.00

R 144.0

46.00

(12'-0")

N.B.

163.6

(13'-8")

16.45

144.0

133.0

(12'-0")

(11'-1")

N.A.

83.13

5.00

15.00

33.00

45.00

TYP.

.81

12.38

14.00

12.38

HOLE

.81

14.00

.81

TYP.

FOR 3/4" BOLTING

(4 PLACES)

MAST PEDESTAL DETAIL

LN-10 / ZIPLINE BOOM PACKAGE

17.38

UPWARD 50 TO DOWNWARD 18.

46" X 48" OR 60" X 60".

N.B. PALLET BASE IS OPTIONAL. AVAILABLE SIZES ARE

N.A. BOOM ADJUSTS FROM THE HORIZONTAL POSTION

7.75

38.25

52.25

Page 15

B-3

DIMENSION PRINTS

16 FT. SPRING BALANCED ZIPLINE BOOM ASSEMBLY

XA

60.00

46.00

88.25

B-3

5.00

60.00

48.00

R 192.0

(R 16'-0")

N.B.

213.6

(17'-10")

18.28

192.0

183.0

(16'-0")

15.00

33.00

45.00

(15'-3")

TYP.

.81

12.38

14.00

12.38

HOLE

.81

14.00

.81

TYP.

FOR 3/4" BOLTING

(4 PLACES)

MAST PEDESTAL DETAIL

N.A.

17.38

UPWARD 50 TO DOWNWARD 6.

46" X 48" OR 60" X 60".

N.B. PALLET BASE IS OPTIONAL. AVAILABLE SIZES ARE

N.A. BOOM ADJUSTS FROM THE HORIZONTAL POSTION

7.75

38.25

52.25

LN-10 / ZIPLINE BOOM PACKAGE

Page 16

B-4

DIMENSION PRINTS

16 FT. HYDRAULIC ZIPLINE BOOM ASSEMBLY

B-4

XA

60.00

48.00

60.00

R 192.0

46.00

(16'-0")

N.B.

211.6

(17'-8")

16.45

192.0

181.0

(16'-0")

(15'-1")

N.A.

83.13

5.00

15.00

33.00

45.00

TYP.

.81

12.38

14.00

12.38

HOLE

.81

14.00

.81

TYP.

FOR 3/4" BOLTING

(4 PLACES)

MAST PEDESTAL DETAIL

LN-10 / ZIPLINE BOOM PACKAGE

17.38

UPWARD 50 TO DOWNWARD 18.

46" X 48" OR 60" X 60".

N.B. PALLET BASE IS OPTIONAL. AVAILABLE SIZES ARE

N.A. BOOM ADJUSTS FROM THE HORIZONTAL POSTION

7.75

38.25

52.25

Page 17

B-5

DIMENSION PRINTS

B-5

10.92

4.27

5.25 2.80

WARNING

2.63

13.75

3

YEAR

WARRANTY

4.58

5-2-97

18299

M

CONTROL BOX DIMENSION PRINT

R .141

(3 SLOTS)

GRAPHICS SHOWN REPRESENT M17869-1.

14.67

10.10

12.75

14.65

LN-10 / ZIPLINE BOOM PACKAGE

Page 18

B-6

6.55

7.81

DIMENSION PRINTS

12.74

B-6

4-24-98

18904

M

5.25

4.44

WIRE DRIVE DIMENSION PRINT

2.42

4.08

14.71

2.25

10.40

11.00

5/16-18UNC-2B

(4 PLACES)

LN-10 / ZIPLINE BOOM PACKAGE

3.00

6.00

Page 19

NOTES

LN-10 / ZIPLINE BOOM PACKAGE

Page 20

NOTES

LN-10 / ZIPLINE BOOM PACKAGE

Page 21

Now Available...12th Edition

VISA

®

Mas ter Car dMasterCard

®

The Procedure Handbook of Arc Welding

With over 500,000 copies of previous editions published

since 1933, the Procedure Handbook is considered by many to

be the “Bible” of the arc welding industry.

This printing will go fast so don’t delay. Place your

order now using the coupon below.

The hardbound book contains over 750 pages of welding

information, techniques and procedures. Much of this material

has never been included in any other book.

A must for all welders, supervisors, engineers and

designers. Many welding instructors will want to use the book

as a reference for all students by taking advantage of the low

quantity discount prices which include shipping by

4th class parcel post.

$15.00 postage paid U.S.A. Mainland

How To Read Shop Drawings

The book contains the latest information and application

data on the American Welding Society Standard Welding

Symbols. Detailed discussion tells how engineers and

draftsmen use the “short-cut” language of symbols to pass

on assembly and welding information to shop personnel.

New Lessons in Arc Welding

Lessons, simply written, cover manipulatory techniques;

machine and electrode characteristics; related subjects,

such as distortion; and supplemental information on arc

welding applications, speeds and costs. Practice materials,

exercises, questions and answers are suggested for each

lesson.

528 pages, well illustrated, 6” x 9” size, bound in simulated,

gold embossed leather.

$5.00 postage paid U.S.A.

Mainland

Need Welding T raining?

The Lincoln Electric Company operates the oldest and

most respected Arc Welding School in the United States at its

corporate

dents have graduated. Tuition is low and the training is

“hands on”

For details write: Lincoln Welding School

headquarters in Cleveland, Ohio. Over 100,000 stu-

22801 St. Clair Ave.

Cleveland, Ohio 44117-1199.

Practical exercises and examples develop the reader’s

to visualize mechanically drawn objects as they will appear

in their assembled form.

187 pages with more than 100 illustrations. Size 8-1/2” x

Durable, cloth-covered board binding.

$4.50 postage paid U.S.A.

ability

11”

Mainland

and ask for bulletin ED-80 or call 216-383-2259 and ask

for the

Welding School Registrar.

Lincoln Welding School

BASIC COURSE $700.00

5 weeks of fundamentals

There is a 10% discount on all orders of $50.00 or more for shipment at one time to one location.

Orders of $50 or less before discount or orders outside of North America must be prepaid with charge, check or money order in U.S. Funds Only.

Prices include shipment by 4 th Class Book Rate for U.S.A. Mainland Only. Please allow up to 4 weeks for delivery.

UPS Shipping for North America Only. All prepaid orders that request UPS shipment please add:

$5.00 For order value up to $49.99

$10.00 For order value between $50.00 & $99.99

$15.00 For order value between $100.00 & $149.00

For North America invoiced orders over $50.00 & credit card orders, if UPS is requested, it will be invoiced or charged to you at cost.

Outside U.S.A. Mainland order must be prepaid in U.S. Funds. Please add $2.00 per book for surface mail or $15.00 per book for air parcel post shipment.

METHOD OF PAYMENT: (Sorry, No C.O.D. Orders)

CHECK ONE:

Please Invoice (only if order is over $50.00)

Check or Money Order Enclosed, U.S. Funds only

Credit Card - Telephone: _______________________________________________

Account No.

USE THIS FORM TO ORDER:

BOOKS OR FREE INFORMATIVE CATALOGS Telephone: 216-383-2211 or, for fastest service, FAX this completed form to: 216-361-5901.

|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_|_| Exp Date |_|_| |_|_|

Order from: BOOK DIVISION, The Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199

Name: _______________________________________________

Address: _______________________________________________

_______________________________________________

Signature as it appears on Charge Card:

Month Year

______________________

Lincoln Welding School Titles: Price Code Quantity Cost

(ED-80)

Seminar Information Procedure Handbook “Twelfth Edition” $15.00 PH

(ED-45)

Educational Video Information Incentive Management $5.00 IM

(ED-93)

James F. Lincoln Arc Welding The American Century of John C. Lincoln $5.00 AC

Foundation Book Information Welding Preheat Calculator $3.00 WC-8

(JFLF-515)

New Lessons in Arc Welding $5.00 L

How to Read Shop Drawings $4.50 H

A New Approach to Industrial Economics $5.00 NA

Pipe Welding Charts $4.50 ED-89

SUB TOTAL

Additional Shipping Costs if any

TOTAL COST

Page 22

WARNING

Spanish

AVISO DE

PRECAUCION

● Do not touch electrically live parts or

electrode with skin or wet clothing.

● Insulate yourself from work and

ground.

● No toque las partes o los electrodos

bajo carga con la piel o ropa mojada.

● Aislese del trabajo y de la tierra.

● Keep flammable materials away.

● Mantenga el material combustible

fuera del área de trabajo.

● Wear eye, ear and body protection.

● Protéjase los ojos, los oídos y el

cuerpo.

French

ATTENTION

German

WARNUNG

Portuguese

ATENÇÃO

Japanese

Chinese

Korean

Arabic

● Ne laissez ni la peau ni des vête-

ments mouillés entrer en contact

avec des pièces sous tension.

● Isolez-vous du travail et de la terre.

● Berühren Sie keine stromführenden

Teile oder Elektroden mit Ihrem

Körper oder feuchter Kleidung!

● Isolieren Sie sich von den

Elektroden und dem Erdboden!

● Não toque partes elétricas e elec-

trodos com a pele ou roupa molhada.

● Isole-se da peça e terra.

● Gardez à l’écart de tout matériel

inflammable.

● Entfernen Sie brennbarres Material!

● Mantenha inflamáveis bem guarda-

dos.

● Protégez vos yeux, vos oreilles et

votre corps.

● Tragen Sie Augen-, Ohren- und Kör-

perschutz!

● Use proteção para a vista, ouvido e

corpo.

READ AND UNDERSTAND THE MANUFACTURER’S INSTRUCTION FOR THIS EQUIPMENT AND THE CONSUMABLES TO BE

USED AND FOLLOW YOUR EMPLOYER’S SAFETY PRACTICES.

SE RECOMIENDA LEER Y ENTENDER LAS INSTRUCCIONES DEL FABRICANTE PARA EL USO DE ESTE EQUIPO Y LOS

CONSUMIBLES QUE VA A UTILIZAR, SIGA LAS MEDIDAS DE SEGURIDAD DE SU SUPERVISOR.

LISEZ ET COMPRENEZ LES INSTRUCTIONS DU FABRICANT EN CE QUI REGARDE CET EQUIPMENT ET LES PRODUITS A

ETRE EMPLOYES ET SUIVEZ LES PROCEDURES DE SECURITE DE VOTRE EMPLOYEUR.

LESEN SIE UND BEFOLGEN SIE DIE BETRIEBSANLEITUNG DER ANLAGE UND DEN ELEKTRODENEINSATZ DES HERSTELLERS. DIE UNFALLVERHÜTUNGSVORSCHRIFTEN DES ARBEITGEBERS SIND EBENFALLS ZU BEACHTEN.

Page 23

● Keep your head out of fumes.

● Use ventilation or exhaust to

remove fumes from breathing zone.

● Turn power off before servicing.

● Do not operate with panel open or

guards off.

WARNING

● Los humos fuera de la zona de res-

piración.

● Mantenga la cabeza fuera de los

humos. Utilice ventilación o

aspiración para gases.

● Gardez la tête à l’écart des fumées.

● Utilisez un ventilateur ou un aspira-

teur pour ôter les fumées des zones

de travail.

● Vermeiden Sie das Einatmen von

Schweibrauch!

● Sorgen Sie für gute Be- und

Entlüftung des Arbeitsplatzes!

● Mantenha seu rosto da fumaça.

● Use ventilação e exhaustão para

remover fumo da zona respiratória.

● Desconectar el cable de ali-

mentación de poder de la máquina

antes de iniciar cualquier servicio.

● Débranchez le courant avant

l’entretien.

● Strom vor Wartungsarbeiten

abschalten! (Netzstrom völlig öffnen; Maschine anhalten!)

● Não opere com as tampas removidas.

● Desligue a corrente antes de fazer

serviço.

● Não toque as partes elétricas nuas.

● No operar con panel abierto o

guardas quitadas.

● N’opérez pas avec les panneaux

ouverts ou avec les dispositifs de

protection enlevés.

● Anlage nie ohne Schutzgehäuse

oder Innenschutzverkleidung in

Betrieb setzen!

● Mantenha-se afastado das partes

moventes.

● Não opere com os paineis abertos

ou guardas removidas.

Spanish

AVISO DE

PRECAUCION

French

ATTENTION

German

WARNUNG

Portuguese

ATENÇÃO

Japanese

Chinese

Korean

Arabic

LEIA E COMPREENDA AS INSTRUÇÕES DO FABRICANTE PARA ESTE EQUIPAMENTO E AS PARTES DE USO, E SIGA AS

PRÁTICAS DE SEGURANÇA DO EMPREGADOR.

Page 24

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

Loading...

Loading...