Lincoln Electric IM596-2 User Manual

®

RETURN TO MAIN MENU

LN-10 / ZIPLINE BOOM PACKAGE

IM596-2A

March, 2001

For use with “K” Sales Spec Numbers:

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thoughtful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT READING THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

K1564-2

K1564-3

K1564-5

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

OPERATOR’S MANUAL

Copyright © 2001 Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

i

SAFETY

WARNING

READ AND FOLLOW ALL WARNING INFORMATION IN THIS AND ALL OTHER MANUALS

WARNING

SPRING UNDER PRESSURE

Release of spring pressure can cause serious personal injury and equipment

damage.

• Do not remove spring rod shipping support until boom is completely assembled

and all components are installed.

• Do not service or adjust spring pressure on boom without the spring rod shipping

support securely installed.

WARNING

MOVING BOOM PARTS CAN CAUSE SERIOUS PERSONAL INJURY.

i

• Keep hands away from spring rod clevis and swivel plates.

WARNING

FALLING BOOM CAN CAUSE SERIOUS PERSONAL INJURY AND EQUIPMENT

DAMAGE.

• Securely attach pallet base or pedestal to floor before operating boom arm.

WARNING

UNBALANCED BOOM CAN CAUSE SERIOUS PERSONAL INJURY AND

EQUIPMENT DAMAGE.

• Do not remove wire drive unit without the spring rod shipping support securely

installed.

CAUTION

ONLY QUALIFIED PERSONNEL SHOULD INSTALL, USE OR SERVICE THIS

EQUIPMENT.

READ AND FOLLOW THE MANUFACTURER’S INSTRUCTIONS AND YOUR

EMPLOYER’S SAFETY PRACTICES.

for selecting a QUALITY product by Lincoln Electric. We want you

Thank You

to take pride in operating this Lincoln Electric Company product

••• as much pride as we have in bringing this product to you!

Please Examine Carton and Equipment For Damage Immediately

When this equipment is shipped, title passes to the purchaser upon receipt by the carrier. Consequently, Claims

for material damaged in shipment must be made by the purchaser against the transportation company at the

time the shipment is received.

Please record your equipment identification information below for future reference. This information can be

found on your sales information.

Model Name and Sales SpecNumber (K-xxx) _____________________________________

Date of Purchase __________________________________

Whenever you request replacement parts for or information on this equipment always supply the information

you have recorded above.

iiii

Read this Operators Manual completely before attempting to use this equipment. Save this manual and keep it

handy for quick reference. Pay particular attention to the safety instructions we have provided for your protection.

The level of seriousness to be applied to each is explained below:

WARNING

This statement appears where the information must be followed exactly to avoid serious personal injury or

loss of life.

CAUTION

This statement appears where the information must be followed to avoid minor personal injury or damage to

this equipment.

iii

TABLE OF CONTENTS

Page

Installation.......................................................................................................................Section A

Product Description ..............................................................................................................A-1

Zipline Boom Models............................................................................................................A-1

Recommended Wire Feeder - Power Source Combinations ...............................................A-2

Product Specifications..........................................................................................................A-2

Unpacking and Checking Kit Contents.................................................................................A-3

Installation Procedure...........................................................................................................A-7

Tools Required..............................................................................................................A-7

Install the Wire Drive Assembly ....................................................................................A-7

Install the Control Box Assembly .................................................................................A-7

Install the Power Input Cable Assembly........................................................................A-7

Install the Electrode Weld Cable ...................................................................................A-7

Install the Control Cable Assembly ...............................................................................A-7

Install the Gas Hose......................................................................................................A-7

Install the Conduit Bushings and Electrode Conduit .....................................................A-8

Install the 2” Spindle Assembly .....................................................................................A-8

Install the Gun Control Plug Cable Assembly and the Gun and Cable Assembly ........A-8

Install the Welding Power Source .................................................................................A-8

Install the Wire Reel, Drive Rolls and Guides ...............................................................A-8

Dimension Prints ............................................................................................................Section B

12 Ft. Spring Balanced Zipline Boom Assembly ..................................................................B-1

12 Ft. Hydraulic Zipline Boom Assembly..............................................................................B-2

16 Ft. Spring Balanced Zipline Boom Assembly ..................................................................B-3

16 Ft. Hydraulic Zipline Boom Assembly..............................................................................B-4

Control Box Assembly ..........................................................................................................B-5

Wire Drive Assembly ............................................................................................................B-6

iii

A-1

INSTALLATION

A-1

PRODUCT DESCRIPTION

This wire feeder boom package comprised of Lincoln

equipment will allow you to setup a boom welding system when used in conjunction with Zipline® boom

products. This boom package includes everything you

need from Lincoln to easily setup a standard 12 or 16

foot welding station using the Zipline boom product

line.

You will need to purchase the boom and related products from Bird Machine and Repair, Inc., 100 Station

St., Johnstown, PA. 15905, (814)288-3641, the manufacturer of the Zipline® boom product line.

The Lincoln boom package will include the following

items:

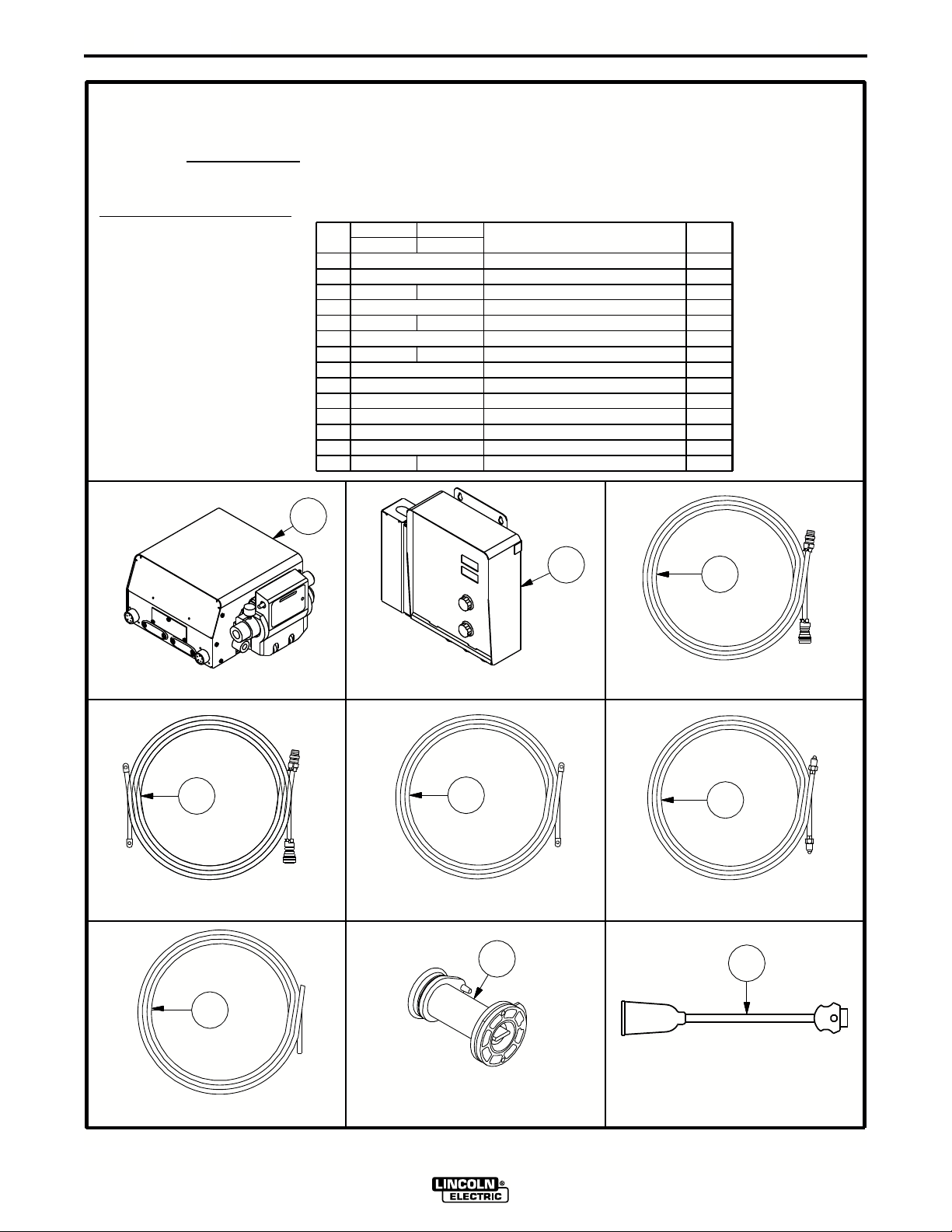

Wire Drive Assembly

Control Box Assembly

Electrode Weld Cables

Control or Linc-Net Cables

Gas Hoses

Electrode Conduits

2" Spindle Assemblies

Hardware Kit

Conduit Bushing Kit

Gun Control Plug Cable Assembly (1 per Head)

Wire Feeder Instruction Manual

Boom Package Instruction Manual

ZIPLINE BOOM MODELS

Both 12 and 16 foot boom length models are available

from Zipline. Two different boom balancing designs

are also available; a spring balanced boom model and

a hydraulic boom model. The standard Zipline boom

configurations are as follows:

12' Spring Balanced Zipline Boom

16' Spring Balanced Zipline Boom

12' Hydraulic Zipline Boom

16' Hydraulic Zipline Boom

The following items will be provided by Bird Machine and Repair

Inc., the manufacturer of the Zipline boom product line:

Pallet Base Assembly (optional)

Pedestal Base Assembly

Boom Mast

Spring Retainer Housing or Hydraulic Device

Boom Arm

Cable and Hose Trough

Conduit Bushing Bracket

Provisions to Mount 2" Spindle Assembly

Control Box Support Assembly (optional)

Feeder Mount Bracket and Cage Assembly (optional)

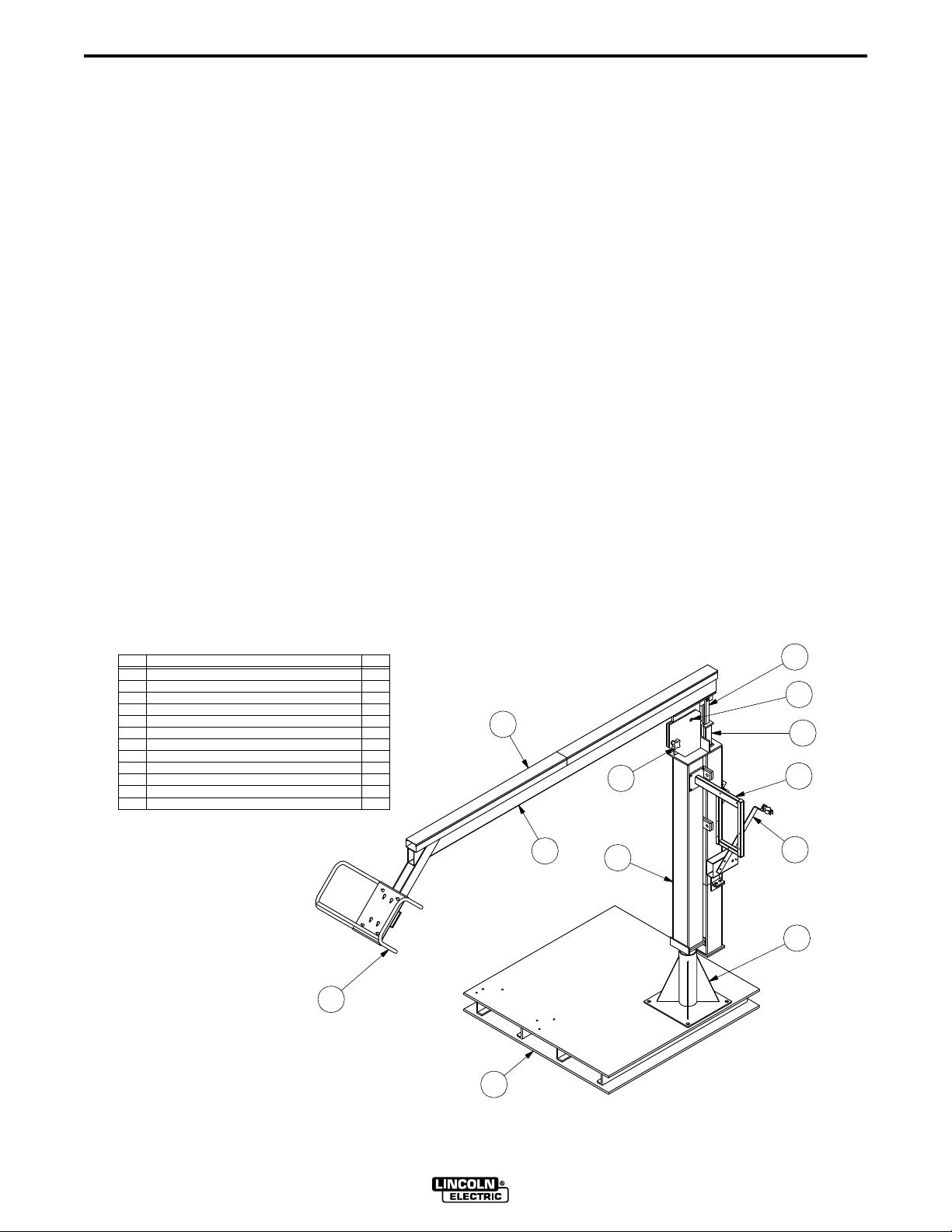

See Figure A.1 for illustration of the Zipline products.

See the following pages for illustrations of the Lincoln

Products.

DESCRIPTIONITEM

12PALLET BASE ASSEMBLY (OPTIONAL)

PEDESTAL ASSEMBLY

BOOM MAST & SPRING RETAINER HOUSING ASSY

3

4

SPRING ROD CLEVIS

5

MAIN SWIVEL PIN

6

FRICTION CONTROL KNOB

7

SPRING ROD SHIPPING SUPPORT

CONDUIT BUSHING BRACKET

8

9

CONTROL BOX SUPPORT ASSEMBLY (OPTIONAL)

10

BOOM ARM ASSEMBLY

11

CABLE & HOSE TROUGH

FEEDER MOUNT BRACKET & CAGE ASSEMBLY (OPTIONAL)

12

12

QTY.

4

1

1

1

1

1

1

1

2

1

1

2

1

11

6

10

1

3

ZIPLINE BOOM PACKAGES

8

S

5

7

9

2

24078

24078

A

FIGURE A.1

LN-10 / ZIPLINE BOOM PACKAGE

A-2

INSTALLATION

A-2

RECOMMENDED WIRE FEEDER POWER SOURCE COMBINATIONS

The Zipline booms have been designed to integrate

with newer wire feeders and power sources. The following is a list of wire feeders and power sources that

are compatible with the Zipline boom’s pallet base,

control box support and feeder mount bracket/cage

assembly.

Wire Feeders Power Sources

LN-10 CV-250

DH-10 CV-300-I

CV-300

CV-400-I

CV-400

CV-500-I

CV-655

** DC-250

DC-400

** PP-500

** DC-600

DC-655

** DC-1000

See the appropriate Dimension Print in Section B of

this manual for details on the physical size of the

equipment.

PF-10 PW-455

STT-10 STT-II

** A K1520-1 115V/42V Transformer Kit is required

with these power sources.

PRODUCT SPECIFICATIONS

Product Number Product Description Net Weight (lbs.)

K1564-2 LN-10 Boom Package - 90

12' Zipline Boom

K1564-3 LN-10 Boom Package - 103

16' Zipline Boom

K1564-5 LN-10 Boom Package - 90

12' Zipline Boom

LN-10 / ZIPLINE BOOM PACKAGE

A-3

REQUIRED TOOLS

UNPACK THE BOOM PACKAGE

CHECK YOUR BOOM PACKAGE

FOR THE FOLLOWING:

INSTALLATION

K1564-2 LN-10 B00M PACKAGE - 12' ZIPLINE BOOM

K1564-3 LN-10 B00M PACKAGE - 16' ZIPLINE BOOM

ITEM

1

2

L9776-C-18 L9776-C-22

3

4

5

6

7

8

9

10

11

12

13

INSTRUCTION MANUAL

11/16" WRENCH7/16" WRENCH 3/4" WRENCH

1/2" WRENCH

K1564-3K1564-2

PART NO.PART NO.

M18899-1

M17869-5

M18298-2-10

CL012325

CL012326

S18453-3

S20023-A-21S20023-A-17

M14935-1

S23858-2

S23859

M15608

L3326-169

L2213-528

FLAT HEAD SCREWDRIVERPHILLIPS HEAD SCREWDRIVER

DESCRIPTION

WIRE DRIVE ASSEMBLY

CONTROL BOX ASSEMBLY

CONTROL CABLE ASSEMBLY

POWER INPUT CABLE ASSEMBLY

ELECTRODE WELD CABLE

GAS HOSE

ELECTRODE CONDUIT

2" SPINDLE ASSEMBLY

HARDWARE KIT

CONDUIT BUSHING KIT

GUN CONTROL ASSEMBLY

BOOM PACKAGE INSTRUCTION MANUAL

WIRE FEEDER INSTRUCTION MANUAL

A-3

REQ'D

1

1

1

1

1

1

1

1

1

1

1

1

1

1

(1) WIRE DRIVE ASSEMBLY

4

(1) POWER INPUT CABLE ASSEMBLY

2

(1) CONTROL BOX ASSEMBLY

5

(1) ELECTRODE WELD CABLE

8

3

(1) CONTROL CABLE ASSEMBLY

6

(1) GAS HOSE

11

7

(1) ELECTRODE CONDUIT

(1) 2" SPINDLE ASSEMBLY

LN-10 / ZIPLINE BOOM PACKAGE

(1) GUN CONTROL ASSEMBLY

A-4

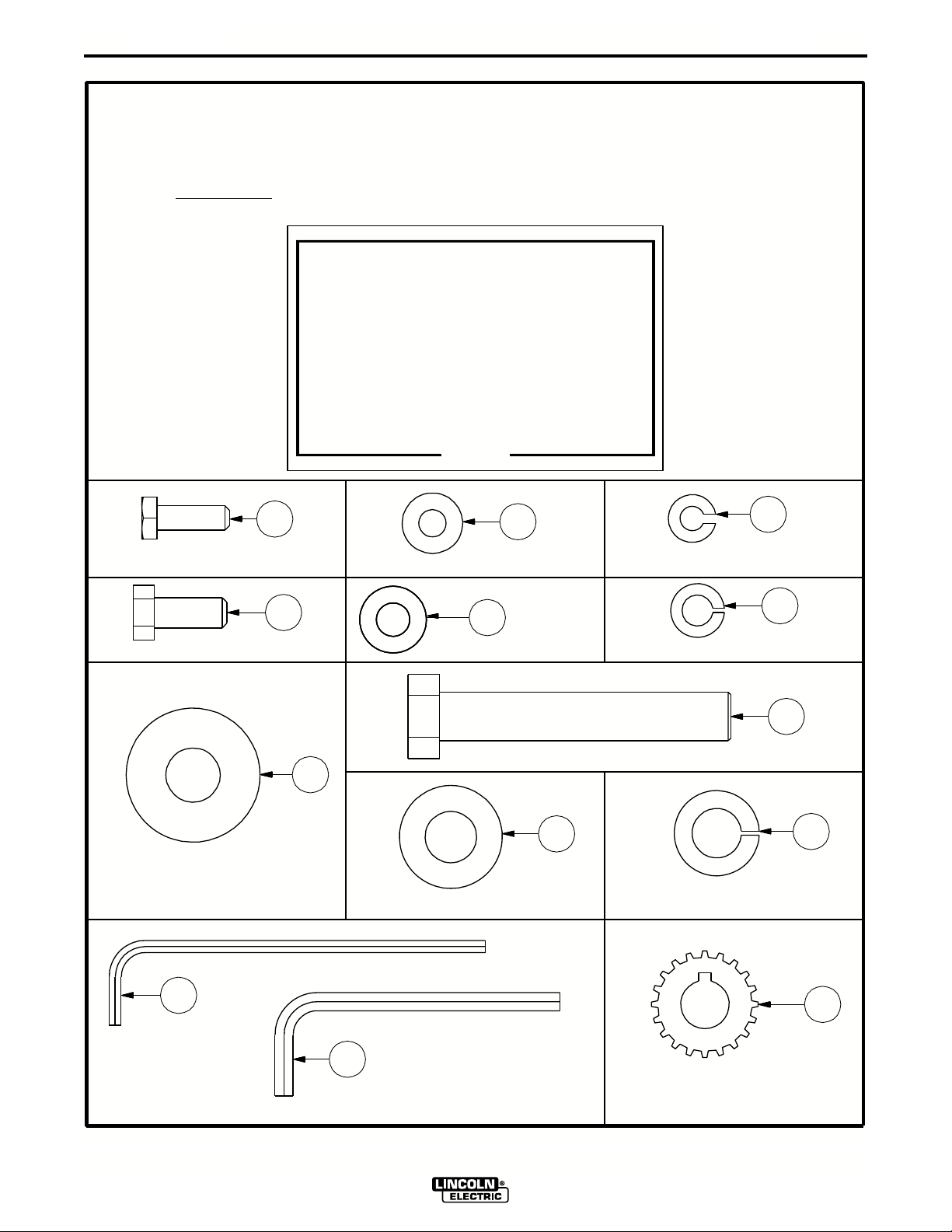

ITEM 9 S23858-2

INSTALLATION

K1564-2 LN-10 B00M PACKAGE - 12' ZIPLINE BOOM

K1564-3 LN-10 B00M PACKAGE - 16' ZIPLINE BOOM

INSTRUCTION MANUAL

A-4

1

(3) 1/4-20X.75 HHCS-GR2

4

(4) 5/16-18X.75 HHCS-GR2

ITEM

PART No.

CF000014

1

2

S9262-98

3

E106A-2

CF000040

4

5

S9262-30

6

E106A-14

S9262-14

7

8 T8833-64

9

S9262-1

10 E106A-15

11 T11563-2

12 T11563-3

M18223-113

HARDWARE KIT

DESCRIPTION

1/4-20X.75 HHCS-GR2

PLAIN WASHER

LOCKWASHER

5/16-18X.75HHCS-GR2

PLAIN WASHER

LOCKWASHER

PLAIN WASHER

1/2-13X3.00HHCS-GR8

PLAIN WASHER

LOCKWASHER

1/8 ALLEN WRENCH

3/16 ALLEN WRENCH

LOW SPEED PINION

2

(3) PLAIN WASHER

5

(4) PLAIN WASHER

QTY.

3

3

3

4

4

4

1

1

1

1

1

1

1

B-RW

S23858-2

(3) LOCK WASHER

(4) LOCK WASHER

3

6

(1) PLAIN WASHER

(1) SOCKET KEY-1/8 ALLEN WRENCH

11

(1) 1/2-13X3.0 HHCS-GR8

7

9

(1) PLAIN WASHER

(1) SOCKET KEY-3/16 ALLEN WRENCH

12

LN-10 / ZIPLINE BOOM PACKAGE

8

10

(1) LOCK WASHER

13

(1) LOW SPEED PINION

Loading...

Loading...