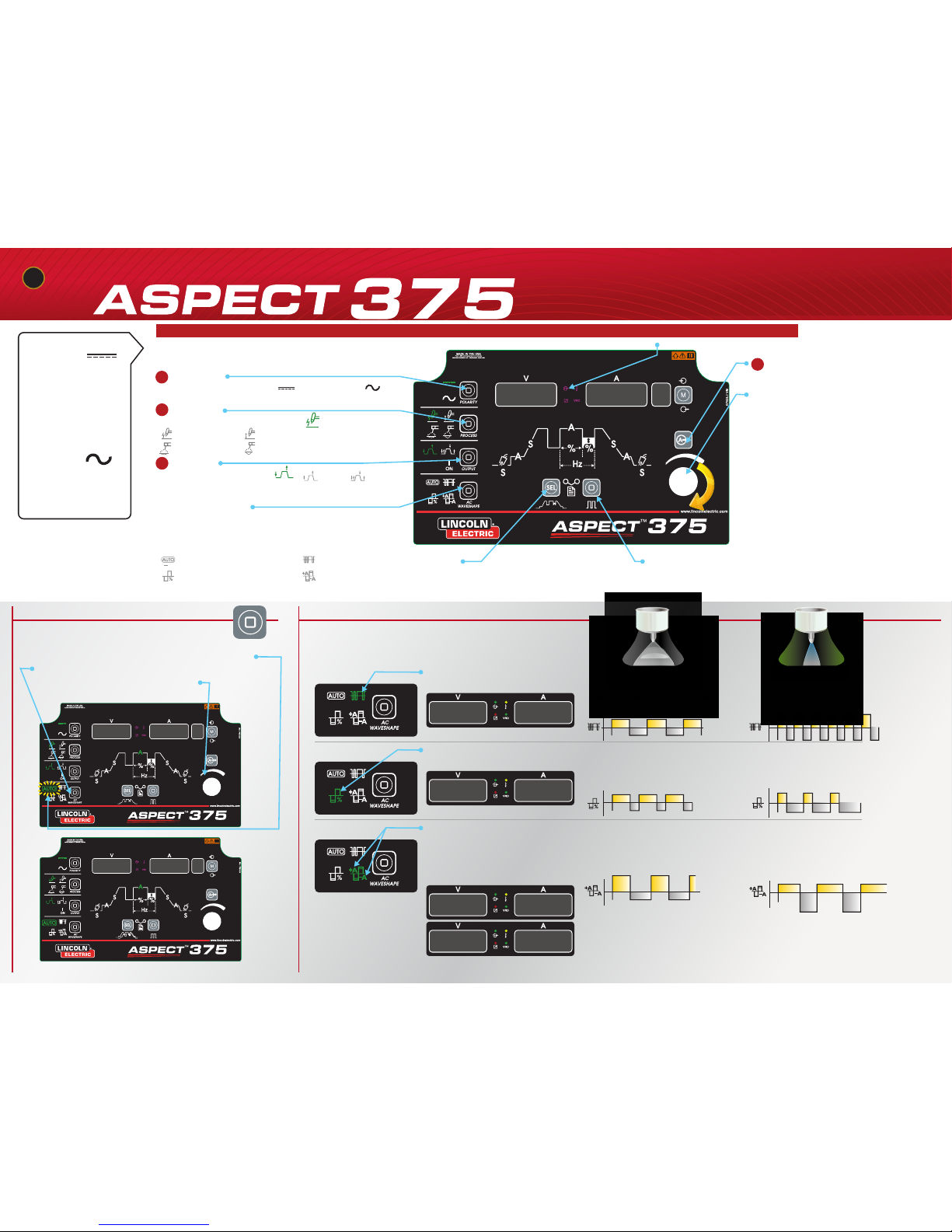

Lincoln Electric Aspect 375 Quick Reference Manual

OFFAUTO

ONAUTO

QUICK REFERENCE GUIDE

1 Polarity

Choose between DC polarity and AC polarity

2 Process

Select high-frequency arc starting

3 Output

Select 2-step functionality,

for use with standard foot pedal

AC Wave Shape

AC Balance and Electrode Positive (EP) / Electrode Negative (EN) Offset

are inaccessible with AC Auto Balance® on

AC Frequency is available with AC Auto Balance® on or off

DC

Steel Alloys

Stainless Steels

Nickel Alloys

Copper Alloys

Titanium

AC

Aluminum

Magnesium

Instructions to activate “AC Auto Balance®”

Select the AC Wave Shape button until the “Auto” icon

blinks, at which point “AC Auto Balance

®

” can be turned on

or off by rotating the main control knob.

™

Within each setting, make

adjustments with main control knob

4 Select to change main welding amperage

Note: Also push to exit from menus

AC Auto Balance

®

AC Wave Shape Controls

Sequencer

Machine is set with default settings;

- see Sequencer Functions for specialized settings

Pulse

Machine is set with pulse mode de-activated,

- see Pulse Functions for specialized settings

Hi-Frequency TIG Touch Start TIG

®

Stick- Soft Mode Stick - Crisp Mode

AC Frequency cycles per second

Electrode Positive (EP) /

Electrode Negative (EN)

current values

AC Balance - time as percentage that

polarity is electrode negative

2-Step 4-Step

Machine controls AC Balance, EP and EN

values based on output amperage

Upon machine startup, system is inoperable when green light is

blinking for 7 seconds during system startup sequence.

AC Frequency control

Range 40 - 400Hz

+

–

+

–

+

–

+

–

+

–

+

–

A lower frequency results in a wider bead.

A lower AC Balance (EN%) results in an arc

with increased cleaning action.

A higher Electrode Positive (EP) current value

results in increased cleaning action.

A higher frequency results in a more

focused bead.

A higher AC Balance (EN%) results in

an arc with higher penetration.

A higher Electrode Negative (EN) current

value results in deeper penetration.

AC Balance control

Range 5 - 99% Electrode Negative

120FREQ

75%BAL

125EN

50EP

Electrode Positive and Negative Offset

Independently adjust the amplitude of the

positive and negative portions of the

AC Wave Shape

Range 2 - 375 amps

For Easy TIG Setup Follow Steps 1, 2, 3, & 4 - For AC polarity turn on AC Auto Balance® see instructions below

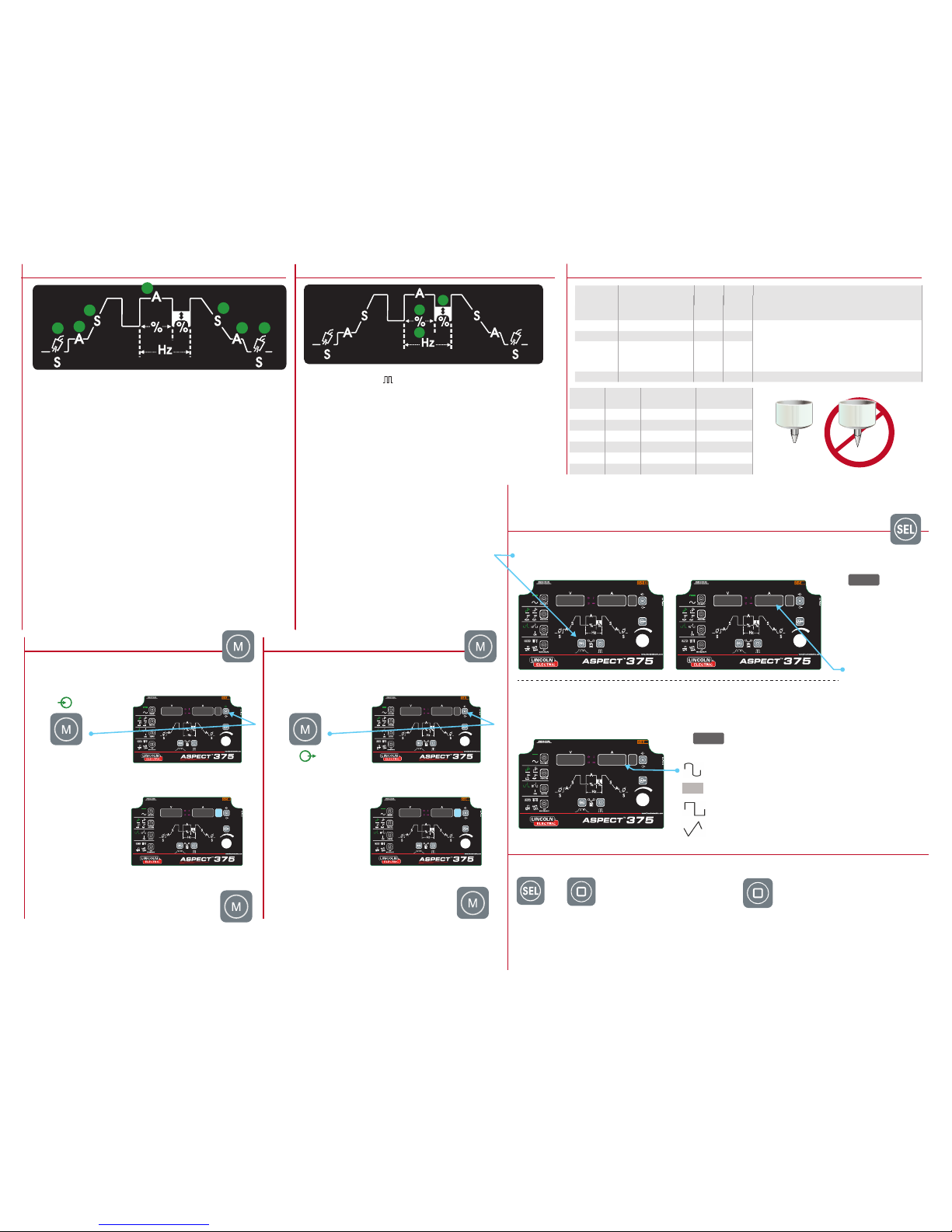

Save

1.) Press Memory button to save a Memory location.

2.) Turn control knob to select Memory location.

3.) Press and hold Memory button for

5 seconds. Memory is now saved.

Memory Save Functions

3 sec.

MEM SET #

MEM SAV

Recall

1.) Press Memory button to recall a Memory location.

2.) Turn control knob to select Memory location.

3.) Press and hold Memory button for

5 seconds. Memory is now recalled.

Memory Recall Functions

3 sec.

MEM RECL

RECL MEM

Tungsten

Diameter

Cup Size DC Polarity

Amp Range

AC Polarity

Amp Range

0.020” 3, 4 or 5 2-20 2-20

0.040” 4 or 5 15-80 20-80

1/16” 4, 5 or 6 30-140 40-150

3/32” 6, 7 or 8 60-220 70-230

1/8” 7, 8 or 10 220-325 240-350

5/32” 8 or 10 300-375 350-375

Tungsten - Pure Tungsten is NOT Recommended

Tungsten should have a slightly blunted tip.

Tungsten Shaping

4 4

MENU G TAW

1

DIA 3/32

1

#

Intellistart, Tungsten Diameter,

and AC Wave Form Settings

5 sec.

5 sec.

5 sec.+

Tungsten Diameter

Selected desired tungsten

diameter for optimized arc

starting performance.

O.020”

0.040”

1/16”

3/32” default

1/8”

5/32”

AUTO = Intellistart™

ADV*

Press Sequencer button (SEL) for 5 seconds to access GTAW Setup Menu.

Press “SEL” button again until Diameter (DIA) setting appears

Rotate the main control knob to desired diameter or AUTO for Intellistart™

Press “SEL” button until Wave Form (WAVE) setting appears

Rotate Main Knob to desired Wave Form

SMAW Menu – Stick Welding

Press Pulse button

for 5 seconds to

access SMAW Setup Menu.

System Menu

Press Sequencer button (SEL) &

Pulse button together for 5 seconds

to access System Setup Menu.

DIA

NOTE * Tungsten ADV represents

Advanced Arc Starting settings.

Refer to Operator’s Manual

IM10152QS - © Lincoln Global Inc.

Press Sequencer (SEL) button to select through each of

the following settings (see 1-7 below). Within each

setting, make adjustments with main control knob.

1.) Pre-Flow: Sets the time in seconds that shielding gas will

ow prior to arc-start initiation.

2.) Starting Amperage: Sets the Starting Amperage for the

process.

3.) Initial Slope: Sets the time in seconds it takes the Starting

Amperage to reach user dened Operating Amperage.

Only functions in 4-Step operation.

4.) Operating Amperage: Sets the maximum Operating

Amperage.

5.) Final Slope: Sets the time in seconds it takes the Operating

Amperage to ramp down to the Finishing Amperage.

Only functions in 4-Step operation.

6.) Finishing Amperage: Sets the Finishing Amperage for the

process.

7.) Post Flow: Sets the time in seconds that shielding gas will

ow after the arc is extinguished. Default is set to Auto.

1

2

3

4

6

Sequencer Functions

Press Pulse button to activate Pulse functions.

Press Sequencer button (SEL) to select through each of the

following settings (see 8-10 below). Within each setting,

make adjustments with main control knob.

8.) Percent Peak Current: Sets the amount of time the pulse

waveform is set at the Peak Current setting. This function is set

as a percentage of total time for the pulse cycle.

9.) Pulses Per Second: Sets the total number of pulse cycles per

second of time.

10.) Background Current: Sets the Background

Current as a percentage of Peak Current.

Pulse Functions

8

9

10

Conventional TIG Pulsing

(< 10 pulses per second)

• Helps moderate filler metal deposition for consistent

bead appearance.

• Alternating the current between peak and background

reduces heat input and material distortion.

High Speed TIG Pulsing

(Up to 2,500 pulses per second)

• Increased puddle agitation for improved weld microstructure.

• Focused, stable arc.

• Increased travel speeds and reduced heat input.

5

7

AC Wave Forms

Soft Square default - Increased puddle control.

Sine - A soft sounding arc.

Square - Faster travel speeds.

Triangular - Reduced heat input on thinner

materials. Also provides for better cleaning

for anodized applications.

WAVE

Color Tungsten Types AC

Polarity

DC

Polarity

Applications

Color Tungsten Types AC

Polarity

DC

Polarity

Applications

Gold 1.5% Lanthanated

X

Blue 2% Lanthanted

X X

Good all around choice for both AC and DC, in welding

low alloyed & non-corroding steels, aluminum, magnesium, titanium, nickel, and copper.

Grey 2% Ceriated

X X

Chartreuse or

Purple

1.5% Lanthanum,

0.08% Zirconium,

0.08% Yttrium

X X

White 0.08% Zirconiated

X

A very good choice for aluminum or magnesium alloys.

Good choice for welding titanium, nickel,

copper, mild steel and stainless steel.

This menu contains system calibration controls and diagnostics - See

manual for additional information.

This menu contains stick welding Arc Force, Hot Start &

Stick Polarity controls - See manual for additional information.

™

1

WAVE SOFT

1

Loading...

Loading...