Lincoln Electric ARC TRACKER K3019-1 Operator's Manual

ARC TRACKER

OPERATOR’S MANUAL

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland Ohio 44117-1199 USA

www.lincolnelectric.eu

IM3047

06/2017

REV01

TM

ENGLISH

English English 1

THANKS! For having chosen the QUALITY of the Lincoln Electric products.

Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………... ……………………….…………………………………………..

ENGLISH INDEX

Technical Specification ....................................................................................................................................................... 3

Electromagnetic Compatibility (EMC) ................................................................................................................................. 5

Safety .................................................................................................................................................................................. 6

Installation and Operator Instructions ................................................................................................................................. 7

WEEE ................................................................................................................................................................................ 15

Spare Parts ....................................................................................................................................................................... 15

Authorized Service Shops Location .................................................................................................................................. 15

Suggested Accessories ..................................................................................................................................................... 15

Electrical Schematic .......................................................................................................................................................... 16

English English 2

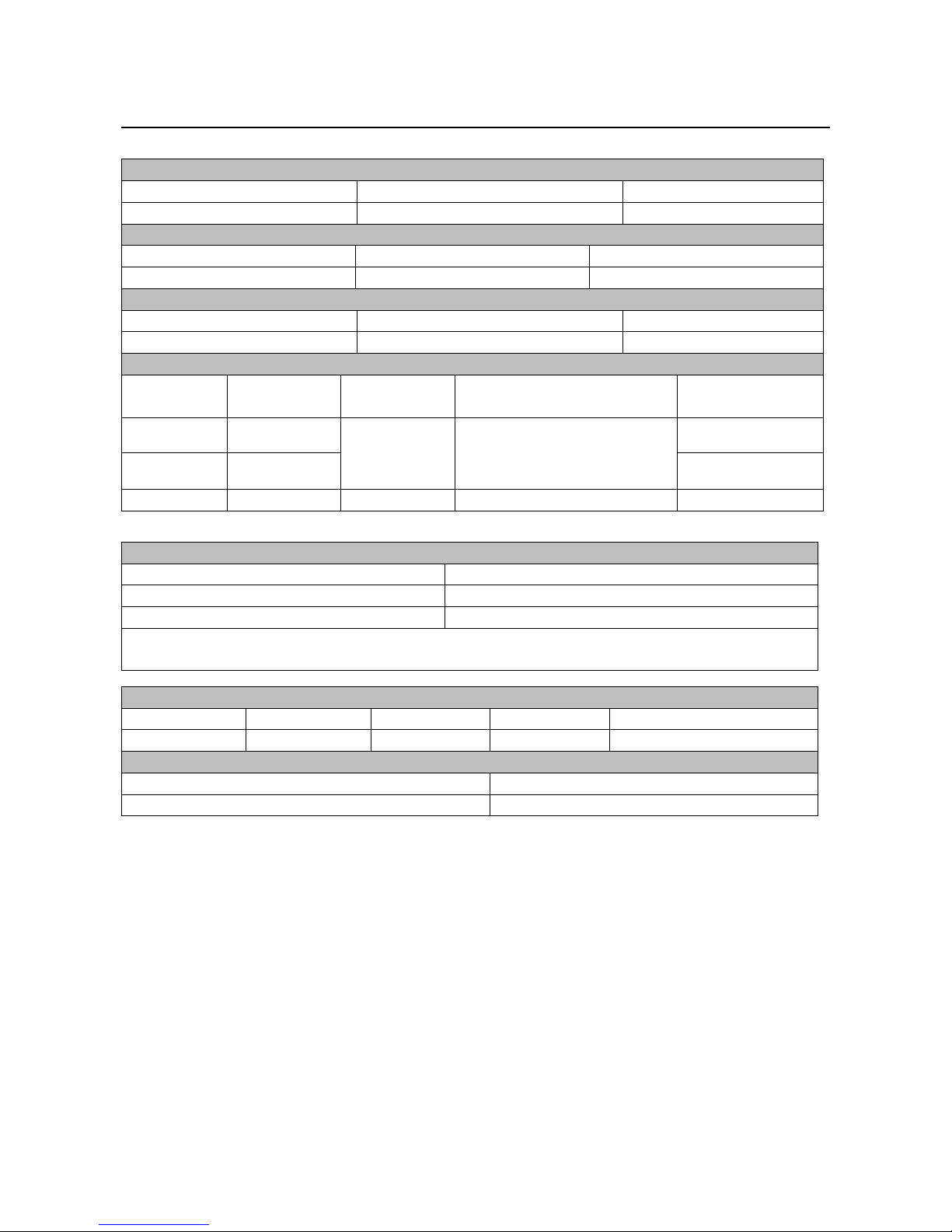

Technical Specification

ARC TRACKER™

INPUT VOLTAGE AND CURRENT

Model Input Voltage ± 10% Input Amperes

K3019-1 120-230 V AC, 50/60 Hz 0,8-0,5 A

RATED OPERATING RANGE NEMA EW1

Duty Cycle

100% 44 V DC 1000 A DC

RATED OPERATING RANGE IEC60974-1

Duty Cycle

100% 44 V DC 1000 A DC

RECOMMENDED INPUT WIRE

VOLTAGE

50/60 Hz

120 0.8A

230 0.5A

230 0,5A EUROPE 3 CONDUCTOR, 1.0 mm2 HAR CEE 7/7

* All attachment plugs must comply with the Standard for Attachment Plugs and Receptable, UL498.

MODEL HEIGHT WIDTH DEPTH WEIGHT

K3019-1 305 mm 220 mm 380 mm 9 kg

OPERATING TEMPERATURE RANGE -10°C TO 40°C

STORAGE TEMPERATURE RANGE -40°C TO 85°C

Input [A] REGION

3 CONDUCTOR, #18 AWG

NORTH

AMERICA

METER ACCURACY (AS SHIPPED)

VOLTMETER ± 2% + 0.1**

AMMETER ± 2% + 2**

ENERGY ± 5%

**Accuracy is expressed as +/- [Percentage of Reading + Digits].

For example: 10A = +/- 10A x 0.02 + 2 = 10A +/- 2.2, or 7.8A to 12.2A

PHYSICAL DIMENSIONS

TEMPERATURE RANGES

TYPE S, SO, SOO, ST, STO,

STOO OR EQUIVALENT

EXTRA HARD USAGE CORD

NEMA 5-15P

(INCLUDED)

ANY NEMA 250V

TYPE*

English English 3

THE LINCOLN ELECTRIC COMPANY

EC DECLARATION OF CONFORMITY

Manufacturer and technical

documentation holder:

Address:

EC Company:

Address:

Hereby declare that welding equipment: Arc Tracker

Product number:

Is in conformity with Council Directives

and amendments:

Standards: EN 60974-1: 2012 Arc Welding Equipment – Part 1:

CE marking affixed in 11

SamirFarah,Manufacturer

ComplianceEngineeringManager

19May2017

MCD312c

The Lincoln Electric Company

22801 St. Clair Ave.

Cleveland Ohio 44117-1199 USA

Lincoln Electric Europe S.L.

c/o Balmes, 89 - 8

0 2a

08008 Barcelona SPAIN

K3019 (number may also contain prefixes and suffixes)

Electromagnetic Compatibility (EMC) Directive 2014/30/EU

Low Voltage Directive 2014/35/EU

Welding Power Sources

EN 60974-10: 2014 Arc Welding Equipment – Part 10:

Electromagnetic compatibility (EMC) requirements

DarioGatti,EuropeanCommunityRepresentative

EuropeanEngineeringDirectorMachines

22May2017

English English 4

Electromagnetic Compatibility (EMC)

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

with, if necessary, assistance from Lincoln Electric.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

machine.

Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

Safety and control equipment for industrial processes. Equipment for calibration and measurement.

Personal medical devices like pacemakers and hearing aids.

Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

that all equipment in the area is compatible. This may require additional protection measures.

The dimensions of the work area to consider will depend on the construction of the area and other activities that are

taking place.

Consider the following guidelines to reduce electromagnetic emissions from the machine.

Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

additional precautions such as filtering the input supply.

The output cables should be kept as short as possible and should be positioned together. If possible connect the

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting

the work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

applications.

EMC classification of this product is class A in accordance with electromagnetic compatibility standard EN 60974-10 and

therefore the product is designed to be used in an industrial environment only.

The Class A equipment is not intended for use in residential locations where the electrical power is provided by the public

low-voltage supply system. There can be potential difficulties in ensuring electromagnetic compatibility in those locations,

due to conducted as well as radio-frequency disturbances.

This machine has been designed to operate in an industrial area. To operate in a domestic area it is

necessary to observe particular precautions to eliminate possible electromagnetic disturbances. The

operator must install and operate this equipment as described in this manual. If any electromagnetic

disturbances are detected the operator must put in place corrective actions to eliminate these disturbances

WARNING

WARNING

01/11

English English 5

Loading...

Loading...