Page 1

Table of Contents

Table of Contents

Introduction

Table of Contents

Using this Catalog

Stick Welders

TIG Welders

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MIG: Wire Feeder/Welders

MIG: Industrial Welders

Multi-Process Welders

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advanced Process Welders

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

3

4

5-10

11-18

19-24

25-28

29-35

36-41

Multi-Operator

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Drives: Commercial/Small Contractors

Engine Drives: Industrial/Construction

Semiautomatic Wire Feeders

Automatic Wire Feeders

Plasma Cutting Systems

Environmental Systems

Automated Solutions

Consumables

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

42-44

45-53

54-62

63-76

77-81

82-84

85-90

91-98

99-148

Recommended Options

www.lincolnelectric.com

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

149-171

3

Page 2

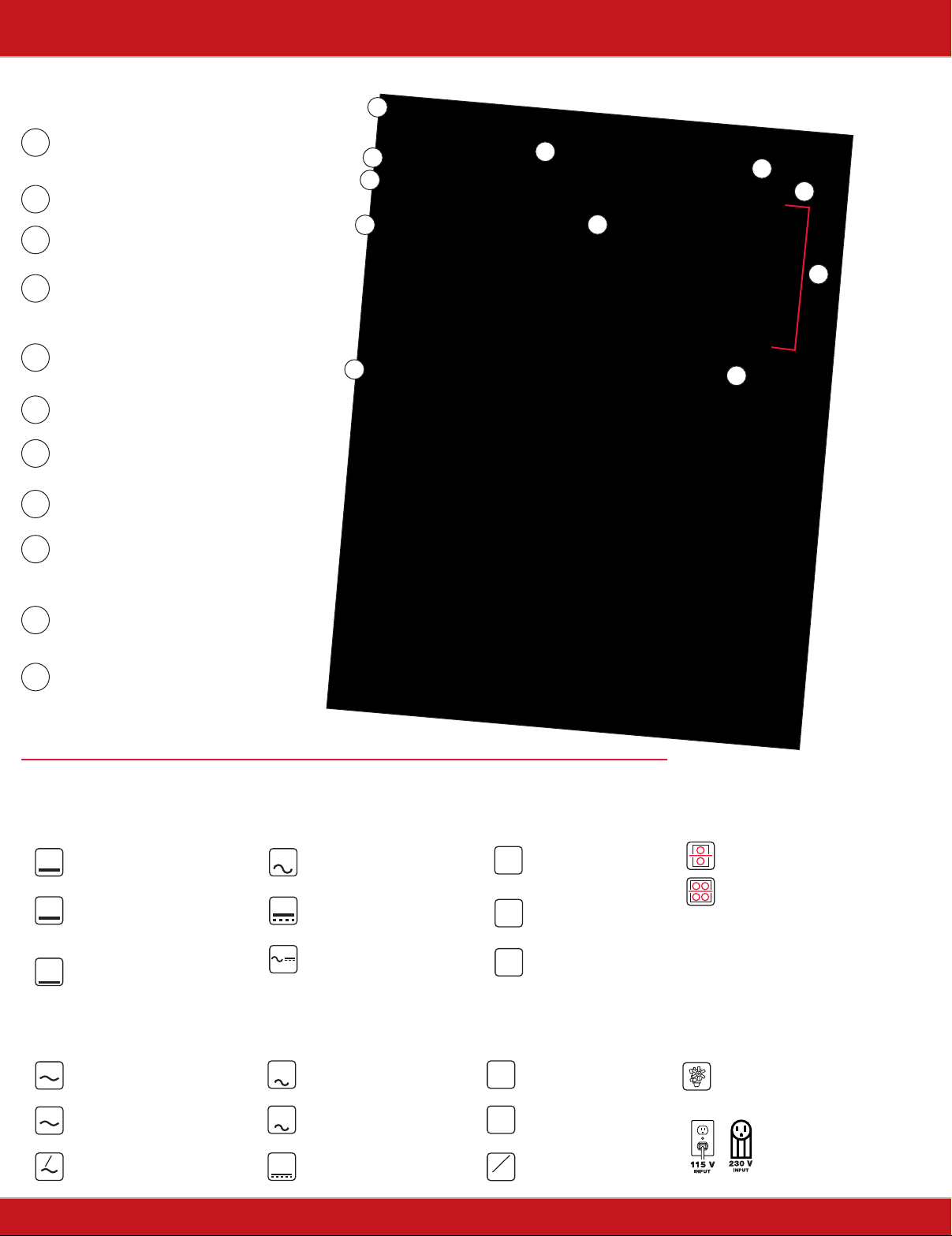

How To Use This Catalog

Content

Catalog Section

1

Identifies catalog section for easy-to-find

products.

Product Name

2

Official Lincoln product name.

Product Description

3

Brief description of the product.

Opening Paragraph

This is a general description of the

4

product. It may include features and

applications of the product.

Advantage Lincoln

5

This section highlights the key features

and benefits of the product.

Product Picture

6

Detailed photo of Lincoln product.

Processes

7

Recommended arc welding processes

for the product.

Input

8

9

10

11

& Output Icons

See below for descriptions.

Unit Includes/Key Options

These sections lists options that are

included or are the most popular

options requested for each product.

Literature Number

Order number to request more

information.

Technical Specifications

Common specifications, ratings,

dimensions and weight for the product.

11

1

3

4

5

2

7

8

6

9

10

Icons

Output Icons

For constant current stick

CC

and TIG processes

For constant voltage

CV

MIG, flux-cored and

subarc processes

For multiprocess constant

CC

CV

current or constant

voltage applications

Input Icons

Single phase input power

1

PHASE

Three phase input power

3

PHASE

Single or three phase

1

3

input power

PHASE

4

Alternating current

AC

welding output

Direct current

DC

welding output

Alternating or direct

AC

current welding output

DC

11 5

115 Volt AC

VAC

Wire feeder input power

42

42 Volt AC

VAC

Wire feeder input power

40 Volt DC

40

VDC

Wire feeder input power

Peak auxiliary power

P

5.11

kW

ouput

Surge auxiliary power

5.5

s

kW

output

Continuous auxiliary

10

power output

kW

50 Hertz input power

50

Hz

60 Hertz input power

60

Hz

50/60 Hertz input power

50

60

Hz

www.lincolnelectric.com

2-Roll Wire feeder

4-Roll Wire feeder

Engine Driven –

Gas, Diesel or LPG

Page 3

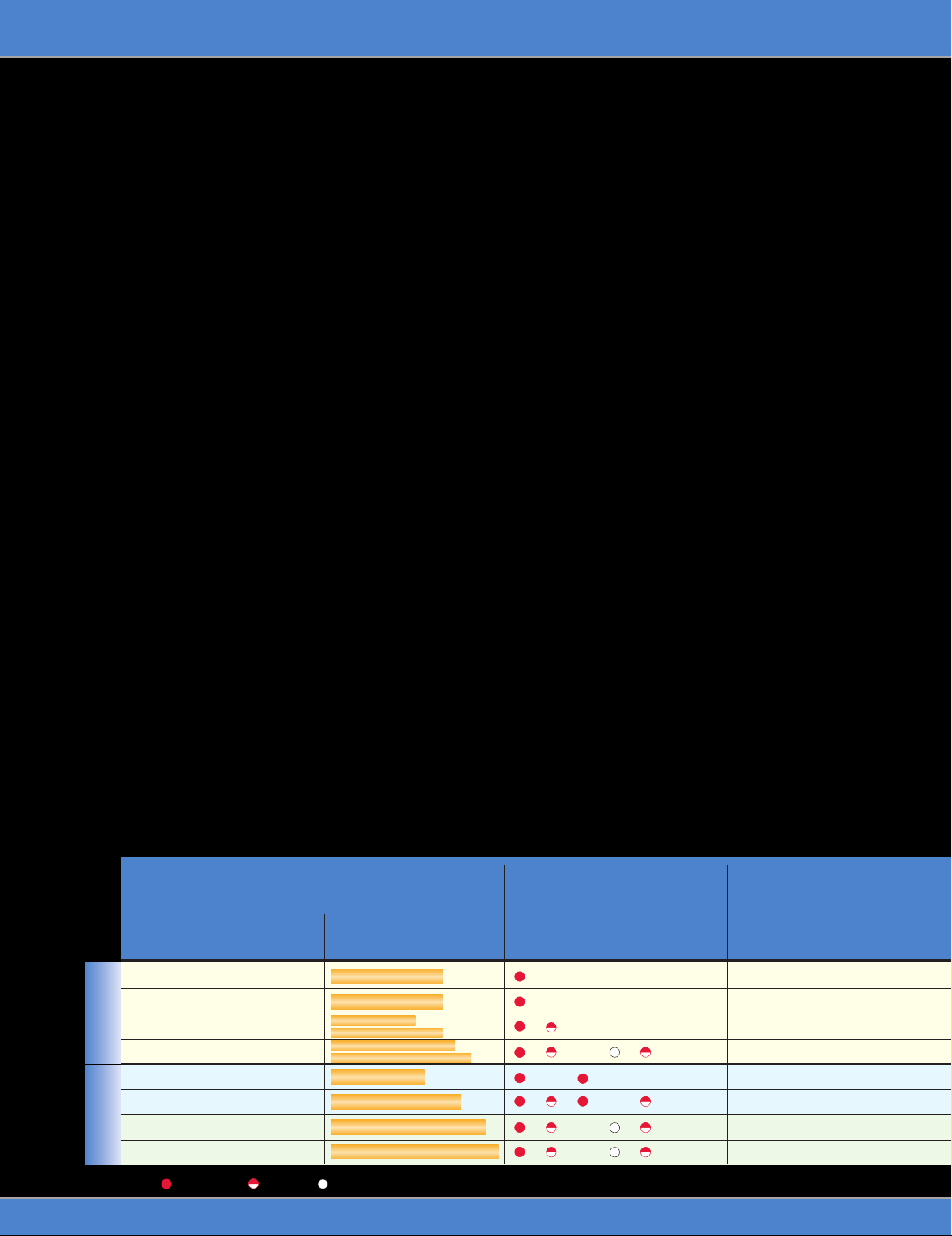

Versatile Stick Welders for Shop or Field

• Weld a Wide Range of Materials and

Thicknesses

• Conventional or Inverter Models

MODEL

Mode

Polarity

AC-225C

AC-225

1-Phase

AC/DC 225/125

Rectifier

Idealarc®250

Invertec®V155-S

Inverter

Invertec®V275-S

Idealarc®R3R-400

Idealarc

3-Phase

Rectifier

KEY: Excellent Good Optional

®

R3R-500

ACCC

ACCC

AC/DCCC

AC/DCCC

DCCC

DCCC

DCCC

DCCC

PROCESS

Current Range

(Amps)

40-225 AC

40-225 AC

30-125 DC

40-225 AC

40-250 DC

35-300 AC

5-155 DC

5-275 DC

60-500 DC

75-625 DC

www.lincolnelectric.com/stick-welders

Stick

TIG Scratch

TIG Touch-Start®TIG Hi-Freq™Arc Gouge

160

1 50,60

1 50,60

1 50,60

1 50,60

1/3 50/60

3

3

INPUTOUTPUT FEATURES

Phase

Hertz

Compact

115/230 Volt

Auto-Sensing

Hot Start

Arc Force

•

•

•

•

50/60

50/60

••

•

•

•

•

Meters

•

•

7-Yr. Warranty

•••••

(on Power Rectifier)

Polarity Switch

Voltmeter/Ammeter

•

5

Page 4

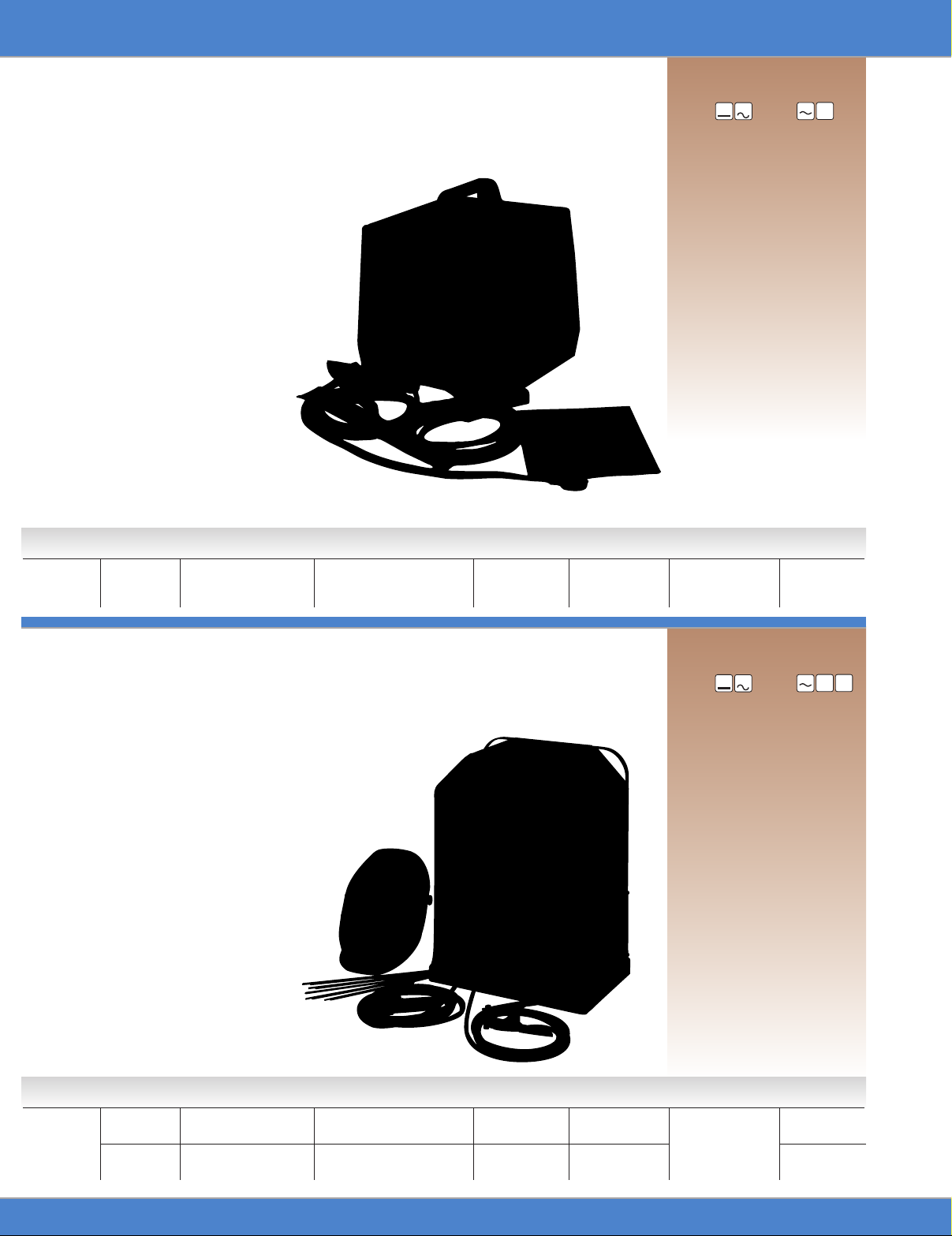

Stick Welders

AC-225C

Easy Set-Up for 16 Gauge and Up

This compact continuous control stick welder delivers

smooth AC output of 40-225 amps for basic hobby and

repair welding.

• 40-225 amps AC continuous output control is

enough current for 3/16" (4.8 mm) diameter mild

steel general purpose stick electrodes and select

5/32" (4.0 mm) diameter electrodes.

• Recommended for mild, low alloy and stainless

steels from 16 gauge sheet metal to heavy plate.

• Easy to set up and easy to operate with

handy application/procedure chart on

faceplate.

• Three-year warranty on parts and labor.

Processes

•Stick

AC

CC

Output Input

Unit Includes

• Insulated electrode holder and

cable

• Heavy duty work clamp and cable

• Sample pack of electrodes

• Helpful Welder’s Guide

• Input Cable with integrated plug

Key Options

• K520 Utility Cart

•

More options at end of section

Literature

E2.40

1

60

Hz

PHASE

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

AC-225C K1357 230/1/60 170A/25V/20% 45A 40-225 Amps 15.25 x 14 x 13.5 84

AC-225

Max. 50A Max OCV: 58V (387 x 356 x 343) (38)

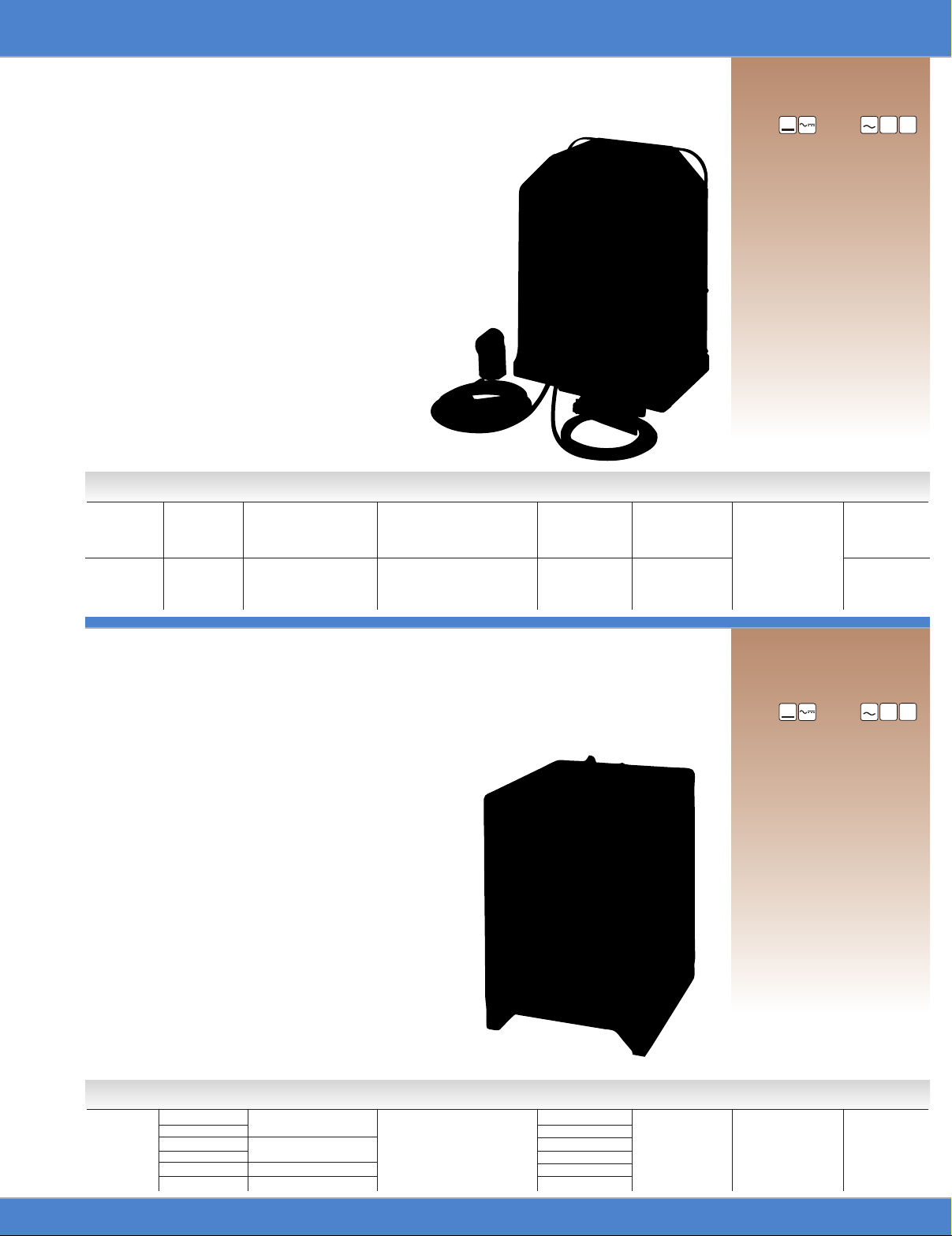

Processes

• Stick

AC

CC

Output Input

AC General Purpose Welding

Unit Includes

Use our popular AC-225 to stick weld mild steel, low alloy

and stainless steels as well as cast iron for common

repair and hobby projects.

• 40-225 amps AC stepped output control is

enough for 3/16" (4.8 mm) diameter mild steel

general purpose stick electrodes and select

5/32" (4.0 mm) diameter electrodes.

• Weld 16 gauge sheet metal to heavy plate

on mild steel, low alloy stainless, cast iron

and hardfacing applications.

• Included Helmet and Sample Electrodes

allow you to start welding right away.

• Three-year warranty on parts and labor.

• Insulated electrode holder and

cable

• Lightweight helmet with lenses

• Heavy duty work clamp and cable

• Sample pack of electrodes

• Helpful Welder’s Guide

• Input Cable with integrated plug

• K1170-4 also includes Wheel Kit

and Gloves

Key Options

• K761 Wheel Kit

•

More options at end of section

Literature

E2.30

1

60Hz50

Hz

PHASE

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

AC-225 K1170 230/1/60 225A/25V/20%

(1)

Except 75 amp setting which can be used continuously for 1 hour.

6

K1170-4 Max. OCV: 79V (610 x 438 x 305) (49.5)

K1290 220/1/50 225A/25V/15% 63A 50-250 Amps 108

www.lincolnelectric.com/stick-welders

(1)

50A 40-225 Amps 24 x 17.25 x 12 109

Max. OCV: 76V (49.0)

Page 5

Stick Welders

Processes

•Stick

AC/DC 225/125

Tackle More Tasks with AC/DC

Select DC polarity for extremely stable arc action or out-of-position

welding with Lincoln®Fleetweld®5P+. Choose AC polarity for

welding on heavier plate, greater deposition or faster travel

speeds with Lincoln®Fleetweld®35. Great choice for stick

welding on mild steel, low alloy and stainless steels as

well as cast iron and hardfacing for maintenance, repair

and light fabrication projects.

• 40-225 amps AC and 30-125 amps DC stepped output control is

enough for 3/16" (4.8 mm) mild steel general purpose electrode

diameters and select 5/32" (4.0 mm) diameter electrodes.

• Weld 16 gauge sheet metal to heavy plate on mild steel,

low alloy stainless, cast iron and hardfacing applications.

• Includes integrated input power cable with plug and

receptacle for wall-mounting.

• Three-year warranty on parts and labor.

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

AC/DC K1297 230/1/60 AC: 225A/25V/20% AC: 50A 40-225 Amps AC 124

225/125 DC: 125A/25V/20% DC: 36A Max. OCV: 79V 24 x 17.25 x 12 (56.3)

30-125 Amps DC (610 x 438 x 305)

Max. OCV: 73V

AC/DC K1299 220/1/50 AC: 225A/25V/15% AC: 55A 50-250 Amps AC 123

225/125 DC: 125A/25V/15% DC: 41A Max. OCV: 76V (55.8)

35-135 Amps DC

Max. OCV: 69V

• TIG

AC

CC

Output Input

Unit Includes

• Insulated electrode holder and

cable

• Heavy duty work clamp and cable

• Helpful Welder’s Guide

• Input Cable with integrated plug

and receptacle

Key Options

• K761 Wheel Kit

•

More options at end of section

Literature

E2.60

DC

1

60Hz50

Hz

PHASE

Processes

Idealarc®250

Basic Industrial Stick Welding

The Idealarc®250 delivers up to 300 amps AC (250 amps DC) for

stick welding in vocational education, industrial production,

maintenance and repair or farm shop environments.

• Plenty of output—300 amps AC and 250 amps DC is enough

for up to 1/4" (6.4 mm) diameter of some stick electrode types.

• Run every type of stick electrode, including cellulosic and

low hydrogen, and those for stainless steel, hardfacing

and cast iron applications.

• Stick

•TIG

• Gouging

AC

CC

Output Input

Key Options

• K1894-1 Power Factor

Capacitor Kit (60 Hz)

• K866 Undercarriage

• K704 Accessory Kit, 400 Amp

• K930-2 TIG Module

•

More options at end of section

Literature

E2.70

DC

• Easy to use full range continous control provides precise

command of heat input in the weld.

• Stackable case design can be stacked up to three high

to save valuable floor space.

• Three-year warranty on parts and labor.

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current /Voltage/ Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

®

250 K1053-7 208/230/460/1/60 AC: 250A/30V/30% 95/86/43A 35-300 Amps AC 27 x 19 x 21.5 350

Idealarc

K1053-9 (w/PFC) DC: 250A/30V/30% 75/68/34A Max. OCV: 72V (686 x 483 x 546) (159)

K1053-8 230/460/575/1/60 86/43/34A 40-250 Amps DC

K1053-10 (w/PFC) 68/34/27A Max. OVC: 70V

K1054-3 380/415/500/1/50 50/46/38A

K1054-4 220/380/440/1/50 86/50/43A

1

60Hz50

Hz

PHASE

www.lincolnelectric.com/stick-welders

7

Page 6

Stick Welders

Processes

•Stick

Invertec®V155-S

Portable. Professional. Rugged. Affordable.

The NEW Invertec®V155-S offers much more than you would expect from a welder

this size. Weighing in at just under 15 lbs. (6.8 kg) the Invertec®V155-S is no

lightweight contender. It packs the full punch of a heavyweight professional that you can take to the most demanding job sites. It

features 120/230V auto reconnect operation and can operate

from a portable generator. It can also plug into a 200 ft. (61 m)

230V extension cord so you can weld just about anywhere.

• Two stick modes, SOFT and CRISP, provide the right arc

characteristics for different types of electrodes.

• Fan-As-Needed

inside the machine.

• Auto-Adaptive Arc Force

sticking in the puddle without compromising

arc stability or increased spatter.

• Automatic Hot-Start

starting to make striking an arc easier.

• Touch Start TIG

TIG welder for free!

• Three-year warranty on parts and labor.

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output

Invertec

V155-S and 100A/24.0V/30% Stick 33.8A Max. OCV: 75V (288 x 158 x 392) (6.7)

™

(F.A.N.™) reduces noise and dust

™

minimizes electrode

™

boosts the current during

®

mode – it’s like getting a

®

K2605-1 120V/1/50/60 75A/23.0V/100% Stick 24.0A 5-155 Amps DC 11.3 x 6.2 x 15.4 14.7

K2606-1 105A/14.2V/100% TIG 21.5A

130A/15.2V/30% TIG 28.8A

230V/1/50/60 100A/24.0V/100% Stick 21.0A

145A/25.8V/30% Stick 31.0A

100A/14.0V/100% TIG 14.1A

155A/16.2V/30% TIG 22.8A

Shown:

K2605-1 Base Unit

with Stick Accessories

(1)

Output Range inches (mm) lbs.(kg)

• DC TIG

DC

CC

Output Input

Base Unit Includes

• Invertec®V155-S (K2605-1).

• Stick electrode holder, cable and

Twist-Mate™plug.

• Work cable and clamp with

Twist-Mate™plug.

• Fully adjustable shoulder strap.

• 120/230V input cord, 6.6 ft. (2 m)

with a 120V 15 Amp plug.

• Extra 120V 20 Amp plug.

Key Options

• K2275-1 Welding Cart

• K852-25 Twist-Mate™Cable

Plug Kit

• TIG Ready-Pak

(

see TIG Section for details).

•

More options at end of section

®

(K2606-1)

Literature

E2.141

(1)

Input amps on 60 Hz input.

50

1

60

PHASE

Hz

8

www.lincolnelectric.com/stick-welders

Page 7

Stick Welders

Processes

• Stick

Invertec®V275-S

Weather-Resistant Stick and TIG Welder

The V275-S Stick and TIG power source is ideal for outdoor construction sites—it’s IP23S

rated and equipped with weather resistant features. Up to 275 amps of output gives you

access to a greater number of stick electrodes, including outstanding E6010 performance.

• Outstanding E6010 and E7018 performance using up

to 7/32" (5.6 mm) diameter electrode.

• Touch Start TIG

established without high frequency starting.

• Air Carbon Arc cutting and gouging with up to 3/16"

(4.8 mm) diameter carbon electrode.

• Selectable Hot Start—Turn it off for thin material or

flip it on for thick, rusty or dirty material.

• Variable Arc Force—Dial in the “soft” or “crisp” arc

you want.

• All-in-one machine—208/230/460/575 input volt

settings—no single phase de-rating.

• Three-year warranty on parts and labor.

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

Invertec

V275-S 575/3/60 250A/30V/60% 34/33/17/14A (345 x 229 x 514) (24.7)

or or 208/230/460/ 275A/29-31V/35% 68/67/38/31A

Invertec

V275-S 415/440/3/50 200A/28V/100% 25/15/15/14/13A

®

)

(Tweco

®

DC allows the welding arc to be

®

®

(1)

K2269-1 208/230/460/ 275A/31V/35% 38/37/19/16A 5-275A 13.6 x 9.0 x 20.25 54.5

200A/28V/100% 27/25/13/11A

575/1/60 250A/30V/60% 63/62/33/27A

K2269-3 220/380/400/ 250A/30V/35% 32/20/19/18/17A

220/380/440/ 63/42/40/38/36A

415/440/1/50 48/32/30/29/27A

200A/28V/100% 49/48/26/21A

•TIG

• Gouging

DC

CC

Output Input

Key Options

• K852-70 Twist-Mate™Cable Plug

for 1/0-2/0, 50-70 mm2cable

• K1759-70 Twist-Mate

Receptacle for 1/0-2/0, 50-70mm

cable

• K2394-1 Stick Electrode Holder,

Work Clamp, Cable and TwistMate™Set

• K857 Remote Output Control,

25 ft (7.6 m)

• K2265-1 TIG-Mate™17V TIG Torch

Starter Kit (air-cooled)

More options at end of section

•

Literature

E2.161

( Tweco®is a registered trademark of Thermadyne. )

1

3

60Hz50

Hz

PHASE

™

2

®

Idealarc

R3R-400 & R3R-500

Heavy Duty Stick Welding and Arc Gouging

Look to the R3R-400 and R3R-500 for your heavy-duty stick welding needs. Whether you are using

cellulosic, low hydrogen, stainless steel or hardfacing electrodes, the Idealarc

R3R-500 produce a smooth, quality arc for consistent results day-in and day-out.

• Substantial amperage ranges include the

R3R-400 at 60-500 amps and the R3R-500 at

72-625 amps.

• Easy to operate—Calibrated current control

knob makes procedure setting simple and easy.

• Polarity switch, voltmeter and ammeter are

standard.

• Arc gouge with the R3R-400 using up to 5/16"

(7.9 mm) diameter carbon electrode and the

R3R-500 using up to 3/8" (9.5 mm) diameter

carbon electrode.

• Three-year warranty on parts and labor.

• Seven-year warranty on the power rectifier.

®

R3R-400 and

Processes

• Stick

•TIG

• Gouging

DC

CC

Output Input

Key Options

• K841 Undercarriage – Hand

moving

• K2149-1 Work Lead Package

• K704 Accessory Kit, 400 Amp

• K857-1 Remote Output Control,

100 ft. (30 m)

•

More options at end of section

Literature

E2.100

3

60

Hz

PHASE

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

®

Idealarc

R3R-400 Max. OCV: 67V (699 x 566 x 813)

Idealarc

R3R-500 Max. OVC: 67V

NOTE: 50 Hertz models available.

K1285-16 230/460/3/60 400A/36V/60% 74/37A 60-500A 27.5 x 22.3 x 32 402 (183)

®

K1286-16 500A/40V/60% 88/44A 72-625A 446 (203)

www.lincolnelectric.com/stick-welders

9

Page 8

Stick Welders

Stick Options

See “Recommended General Options” pgs.149-171 for descriptions.

AC-225C

General Options

K520 Utility Cart (150 cu ft. bottle capacity)

— Fume Extraction System

AC-225

General Options

K761 Wheel Kit

— Fume Extraction System

AC/DC 225/125

General Options

K761 Wheel Kit

— Fume Extraction System

Idealarc

®

250

General Options

K1894-1 Power Factor Capacitor Kit (60 Hz)

K866 Undercarriage

— Fume Extraction System

Stick Options

K875 Accessory Kit, 150 Amp

K704 Accessory Kit, 400 Amp

TIG Options

K930-2 TIG Module

K938-1 Contactor Kit

K936-4 Control Cable (9-pin to 115V plug)

Invertec

®

V155-S

General Options

K2275-1 Welding Cart (80 cu ft bottle capacity)

K852-25 Twist-Mate™ Cable Plug Kit

— Fume Extraction System

TIG Options

K1781-7 PTA-9FV Flexible Head Gas Valve Torch (25 ft., 1 pc.)

K960-2 Small Twist-Mate

™

Torch Adapter (with separate gas)

KP507 Parts Kit for PTA-9 Series Torches

K1782-13 PTA-17FV Flex Head Gas Valve TIG Torch

w/Ultra-Flex

K960-2 Small Twist-Mate

™

Cable (12.5 ft., 1 pc.)

™

Torch Adapter (with separate gas)

KP508 Parts Kit for PTA-17 Series Torches

K586-1 Deluxe Adjustable Gas Regulator and Gas Hose Kit

®

Invertec

V275-S

General Options

K852-70 Twist-Mate™Cable Plug, for 1/0-2/0, 50-70 mm2cable

K852-95 Twist-Mate

K1759-70 Twist-Mate

K1759-95 Twist-Mate

™

Cable Plug, for 2/0-3/0, 70-95 mm2cable

™

Receptacle, for 1/0-2/0, 50-70 mm2cable

™

Receptacle, for 2/0-3/0, 70-95 mm2cable

— Fume Extraction System

Stick Options

K2394-1 Stick Electrode Holder, Work Clamp, Cable &

Twist-Mate

™

Set

K704 Accessory Kit, 400 Amp

K875 Accessory Kit, 150 Amp

K857 Remote Output Control, 25 ft. (7.6 m)

K857-1 Remote Output Control, 100 ft. (30 m)

TIG Options

K2265-1 TIG-Mate™17V TIG Torch Starter Kit (air-cooled)

K960-1 Twist-Mate

K870 Foot Amptrol

™

Torch Adapter (with separate gas)

®

K963-3 Hand Amptrol®(Rotary Track Style)

®

Idealarc

R3R-400 and R3R-500

General Options

K841 Undercarriage – Hand moving

K2149-1 Work Lead Package

— Fume Extraction System

Stick Options

K704 Accessory Kit, 400 Amp

K857 Remote Output Control, 25 ft. (7.6 m)

K857-1 Remote Output Control, 100 ft. (30 m)

TIG Options

K930-2 TIG Module

K939-1 Docking Kit

K963-3 Hand Amptrol

K870 Foot Amptrol

®

(Rotary Track Style)

®

K938-1 Contactor Kit

K936-3 Control Cable (9-pin to 6-pin and 115V plug)

K937-45 Control Cable Extension, 45 ft.

K586-1 Deluxe Adjustable Gas Regulator and Hose Kit

10

www.lincolnelectric.com/stick-welders

Page 9

Lincoln

®

TIG Welders Give You the Power to Perform!

• Precision Arc Control

• Code Quality Results

• Convenient High Value Features

SM

Great Starting

MODEL

Mode

Precision TIG®225

Precision TIG®275

Rectifier

Conventional

Precision TIG®375

CC

CC

CC

Invertec®155-S

Invertec®V160-T

Invertec®V205-T DC

Inverter

Invertec®V205-T AC/DC

CC

CC

Invertec®V310-T AC/DC

KEY: Excellent Good Optional

Premium Focused Arc Precise Crater Fill

Current Range

Polarity

AC/DC

AC/DC

AC/DC

DC

DC

AC/DCCC

AC/DCCC

(Amps)

5-230

2-340

2-420

5-155

5-160

6-200

6-200

5-310

www.lincolnelectric.com/tig-welders

PROCESS INPUTOUTPUT FEATURES

™

®

II

™

Stick

TIG Touch-Start®TIG Hi-Freq™TIG Pulse

1

1

1

1

1

Phase

Hertz

50,60

50,60

50,60

50,60DCCC 1

50,60

50,60

50,601

50,601/3

Auto-Balance

Micro-Start

Auto-Reconnect

•• •

•••

•

•

•

•

•

••••

Variable AC

Frequency

•

®

Ready-Pak®One-Pak

•

•

•

•

11

Page 10

TIG Welders

Processes

Precision TIG®225

Great for Motorsports and Other Custom Fabricators

The Precision TIG®225 gives you the “Power to PerformSM”, for general

fabrication, automotive/ motorsports, vocational schools or serious

hobby work. Micro-Start™II Technology delivers precision arc

performance to improve arc starting, welding and weld cratering.

• 5-230 amps is the widest welding range in its class.

• Patented Micro-Start

stable low amperage starting, welding and cratering

for AC and DC welding.

• AC Auto-Balance

cleaning vs. penetration levels for great looking

aluminum welds.

• FREE! Built-in TIG pulser helps control heat

input in the weld.

• 115 volt auxiliary power receptacles with

20 amp service reliably powers water

coolers or other tools.

• Base Unit Includes: Torch Parts

Storage Compartment, Torch

Hanger, 10 ft. Work Cable and

Clamp, Removable Lift Eye, 9 ft.

Input Power Cord, TIG Procedure

Guide, and GTAW (TIG) Handbook.

NEMA 6-50P Plug and NEMA 6-50R

Receptacle included with 208/230 models

only. Shielding gas sold separately.

• Three-year warranty on parts and labor.

Product Product Input Power Rated Output

Name Number Voltage/Phase/Hertz Current/ Voltage/Duty Cycle Rated Output

Precision TIG®225 K2535-1 208/230/1/60 90A/23.4V/100% 42/39A 5-230 Amps AC 20.7 x 14.5 x 25.6 212

Precision TIG®225 K2535-2

Ready-Pak

Precision TIG®225 K2533-1 208/230/1/60 42/39A 20.7 x 14.5 x 25.6 192

(1)

Tested at 104°F (40°C).

®

Ready-Pak

Pkg. 5-230 Amps DC (526 x 368 x 650) (96)

®

w/Cart Pkg. (794 x 503 x 966) (117)

Base Model K2533-2 460/575/1/60 18/15A (526 x 368 x 650) (87)

™

II Technology delivers extremely

®

automatically sets the optimal

(1)

K2534-1 380/400-415/1/50/60 21/20A

(2)

All inputs reported include 20 amp output on 115 volt auxiliary.

Shown:

®

K2535-2 Ready-Pak

Input Current @ H x W x D Net Weight

(2)

w/Cart Pkg.

Output Range inches (mm) lbs.(kg)

Max. OCV: 75V

• Stick

• TIG

Output Input

DC

AC

CC

Ready-Pak®Pkg. (K2535-1)

Includes

• Precision TIG®225 (K2533-1)

• Removable Lift Eye

• 10 ft. (3.0 m) Work Cable & Clamp

• NEMA 6-50R Receptacle

(208/230V models only)

• TIG Procedure Guide

• GTAW (TIG) Handbook

• PTA-17 One-Piece TIG Torch

• Gas Regulator/Hose

• Foot Amptrol

®

Ready-Pak®w/Cart Pkg. (K2535-2)

Includes

• Everything Listed Above (K2535-1)

• Understorage Cart

One-Pak®w/Power MIG 140

(K2680-1)

• See below for what’s included

Key Options

• K2266-1 TIG-Mate™17 Air-Cooled

TIG Torch Starter Pack

• K870 Foot Amptrol

®

• K963-3 Hand Amptrol

• K2348-1 Understorage Cart

• Fume Extraction System

•

More options at end of section

Literature

E3.37

31.2 x 19.8 x 38 258

1

60Hz50

Hz

PHASE

®

COMPLETE PACKAGE Includes:

Precision TIG®225 (208/230/1/60) (K2535-1)

• 10 ft. (3.0 m) Work Cable & Clamp

• 9 ft. (2.7 m) Input Power Cord with Plug

• NEMA 6-50R Receptacle

• GTAW (TIG) Handbook

• PTA-17 12 ft.Ultra-Flex

• Gas Regulator with Hose

• Foot Amptrol

Wire Feed Welder Mounting Bracket (K2616-1)

Dual Cylinder Cart (K2617-1)

Stick Electrode Holder

12

®

(K870)

™

TIG Torch Package

& Cable (K2374-1)

Power MIG 140C (K2471-1)

®

• Magnum

• Contact Tips

• Gasless & Gas Nozzle

• .025"-.035" Wire Guide

• .025" & .035 Smooth Drive Rolls

• .030"-.045" Knurled Drive Roll

• Gas Regulator and Hose

• Spool of .025" SuperArc

• Spool of .035" Innershield

• Spindle Adapter for 8" Diameter Spools

• Work Clamp and Cable

• How to Use DVD

100L gun

Solid MIG wire

NR®-211-MP®wire

®

L-56

®

®

www.lincolnelectric.com/tig-welders

Page 11

TIG Welders

Processes

• Stick

Precision TIG®275

NEW

NEW

&

IMPROVED

IMPROVED

&

Serious TIG Welding Performance

The Precision TIG®275 gives you the “Power to PerformSM”, for fabrication,

areospace, production, motorsports or vocational education.

• Patented Micro-Start™II Technology delivers extremely stable low

amperage starting, welding and cratering for AC and DC welding.

• AC Auto-Balance

vs. penetration levels for great looking aluminum welds.

• Widest Output Range – 2-340 amps.

• Highest duty cycle – 275 amps @ 40%.

• Optional TIG pulser helps control heat input in the weld to reduce

distortion and burnthrough on thin materials.

• Neat/organized cable management with integrated torch holster.

• Built-in storage compartment for torch consumables.

• Fan-As-Needed

™

(F.A.N.™) prevents overheating. F.A.N.™reduces

power consumption, noise, motor wear and dust in the machine.

• New set-up menu gives more features.

• Three-year warranty on parts and labor.

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/ Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

Precision TIG®275 K2618-1 208/230/460/1/60 275A/31V/40% 80/72/36A with PFC DC: 2-340A 49.7 x 28 x 41 641

®

Ready-Pak

w/Cart Pkg. (rated @ 104˚F (40˚C)) 104/94/47A w/o PFC AC: 2-340A (1262 x 711 x 1041) (291)

®

Precision TIG

275 K2619-2 460/575/1/60 35/28A with PFC (787 x 559 x 660) (180)

®

automatically sets the optimal cleaning

Shown:

K2618-1 Ready-Pak®w/Cart Pkg.

K2619-1 208/230/460/1/60 80/72/36A with PFC

K2620-1 220-230/380-400/ 80/46/43A with PFC

415/1/50/60 95/55/50A w/o PFC

104/94/47A w/o PFC 31 x 22 x 26 397

47/38A w/o PFC

Max. OCV: 75V

• TIG

AC

CC

Output Input

Water-Cooled Ready-Pak

w/Cart Includes

• K2619-1 Precision TIG®275

• Under-Cooler Cart

• Foot Amptrol

• Gas Regulator/Flowmeter/Hose

• PTW-20 Pro-Torch™TIG Torch

• Zippered Torch Cover

• Parts Kit

• Water Hose (2 included)

• 15 ft. (4.5 m) 2/0 Work Cable/Clamp

Key Options

• K2621-1 Advanced Control Panel

• K963-3 Hand Amptrol

• K704 Stick Welding Accessory Kit

•

More options at end of section

Literature

E3.42

DC

®

1

60Hz50

Hz

PHASE

®

®

Processes

Precision TIG®375

NEW

NEW

&

IMPROVED

IMPROVED

&

Precision Arc—Maximum Control

The Precision TIG®375 delivers full featured welding sequencing, pulsing

controls and power factor correction for serious code-level TIG welders.

• Patented Micro-Start™II Technology delivers extremely stable low amperage

starting, welding and cratering for AC and DC welding.

• AC Auto-Balance

penetration levels for great looking aluminum welds.

• Widest Output Range in its class – 2-340 amps.

• Highest duty cycle – 375 amps @ 40%.

• FREE! Built-in TIG pulser helps control heat input in the weld to reduce

distortion and burnthrough on thin materials.

• Neat/organized cable management with integrated torch holster.

• Built-in storage compartment with removable tray for torch consumables.

• Fan-As-Needed

™

(F.A.N.™) prevents overheating. F.A.N.™reduces

power consumption, noise, motor wear and dust in the machine.

• New set-up menu gives more features.

• Three-year warranty on parts and labor.

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current /Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

Precision TIG®375 K2624-1 208/230/460/1/60 375A/35V/40% 102/92/46A with PFC 49.7 x 28 x 41 751

®

Ready-Pak

w/Cart Pkg. (rated @ 104˚F (40˚C)) (1262 x 711 x 1041) (340)

®

Precision TIG

375 K2622-2 230/460/575/1/60 102/51/41A with PFC Max. OCV: 80V (787 x 559 x 660) (230)

®

automatically sets the optimal cleaning vs.

K2624-1 Water-Cooled Ready-Pak

K2622-1 208/230/460/1/60 DC: 2-420A

K2623-1 220-230/380-400/ 119/69/63A with PFC

415/1/50/60

Shown:

w/Cart Pkg.

®

AC: 2-420A 31 x 22 x 26 507

•Stick

• TIG

AC

CC

Output Input

Water-Cooled Ready-Pak

w/Cart Includes

• K2622-1 Precision TIG®375

• Under-Cooler Cart

• Foot Amptrol

• Gas Regulator/Flowmeter/Hose

• PTW-20 Pro-Torch™TIG Torch

• Zippered Torch Cover

• Parts Kit

• Water Hose (2 included)

• 15 ft., (4.5m) 2/0 Work Cable/Clamp

• PTA-9 or -17 Torch Adapter

Key Options

• K963-1 Hand Amptrol

• K704 Stick Welding Accessory Kit

•

More options at end of section

Literature

E3.51

DC

®

www.lincolnelectric.com/tig-welders

1

50Hz60

Hz

PHASE

®

®

13

Page 12

TIG Welders

Processes

Invertec®V155-S

Portable. Professional. Rugged. Affordable.

The NEW Invertec®V155-S offers much more than you would expect from a welder this size. It

packs the full punch of a heavyweight professional that you can take to the most demanding job

sites. It features 120/230V auto reconnect operation and can operate from a portable generator.

It can also plug into a 200 ft. (61 m) 230V extension cord so you can weld

just about anywhere. The Invertec

a base unit with stick accessories or a complete Stick/TIG ready to

weld package in an Easy-Store/Easy-Carry Suitcase.

• Touch Start TIG®DC operation allows you to strike the arc

easily without high frequency or tungsten contamination.

• Dent resistant case is IP23 rated for outdoor use.

• Fan-As-Needed

the machine.

• Two stick modes, SOFT and CRISP, provide the right

arc characteristics for different types of electrodes.

• Auto-Adaptive Arc Force

sticking in the puddle without compromising

arc stability or increased spatter.

• Automatic Hot-Start

during starting to make striking an arc easier.

• Three-year warranty on parts and labor.

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output

Invertec

V155-S and 100A/24.0V/30% Stick 33.8A Max. OCV: 75V (288 x 158 x 392) (6.7)

™

(F.A.N.™) reduces noise and dust inside

™

minimizes electrode

™

boosts the current

®

K2606-1 120V/1/50/60 75A/23.0V/100% Stick 24.0A 5-155 Amps DC 11.3 x 6.2 x 15.4 14.7

K2605-1 105A/14.2V/100% TIG 21.5A

®

V155-S is available in two models:

130A/15.2V/30% TIG 28.8A

230V/1/50/60 75A/23.0V/100% Stick 21.0A

100A/24.0V/30% Stick 31.0A

105A/14.2V/100% TIG 14.1A

130A/15.2V/30% TIG 22.8A

Shown: K2606-1

Ready-Pak

(1)

Output Range inches (mm) lbs.(kg)

• Stick • DC TIG

DC

CC

Output Input

TIG Ready-Pak®Welding

Package (K2606-1) Includes

• Invertec®V155-S (K2605-1)

• Stick electrode holder & cable,

10 ft. (3.0 m) with Twist-Mate™plug

• Work clamp and cable, 10 ft.

(3.0 m) with Twist-Mate™plug

• Fully adjustable shoulder strap

• 120/230V input cord [6.6 ft. (2 m)]

with a 120V 15 Amp plug

• Extra 120V 20 Amp plug

• Gas Regulator

• PTA-17V TIG torch with Ultra-Flex

cable and Twist-Mate™dapter

• PTA-17 TIG Accessory Kit (KP508)

• Easy-Store/Easy-Carry Suitcase

Key Options

• K2275-1 Welding Cart

• K852-25 Twist-Mate™Cable

Plug Kit

®

• K1782-13 PTA-17FV Flex Head

Pkg.

Gas Valve Torch

• K1781-7 PTA-9FV Flex Head

Gas Valve Torch

•

More options at end of section

Literature: E2.141

(1)

Input amps on 60 Hz input.

50

1

60

PHASE

Hz

™

Processes

• Stick

Invertec®V160-T

Serious DC TIG Arc—Extremely Small Package

The Invertec®V160-T is a full function DC TIG inverter intended

for alloy fabrication or critical maintenance work.

• Advanced inverter technology delivers superior TIG performance.

• Selectable Touch Start TIG®starting or high frequency starting

makes it easy to establish an arc under a variety of conditions.

• Built-in pulsing functions give you greater control

over thin materials.

• Auto-reconnect between 115/230V 50/60Hz input

power eliminates operator error.

• Auto restore fuse protects the machine from

high input currents.

• Integral gas and power connector for simple

torch connections and quick changes

between TIG and stick welding.

• TIG

DC

CC

Output Input

Unit Includes

• 115V Input Cord (10 ft.) & Plug

(NEMA 5-15P).

• 20 Amp Plug (NEMA 5-20P).

• Twist-Mate™Torch Adapter for

PTA-9 or -17 one-piece torch.

• Adjustable Shoulder Strap.

• Work Clamp & Cable.

Key Options

• TIG-Mate™17 Air-Cooled TIG

Torch Starter Pack (K2266-1)

• Foot Amptrol®(K870)

• Hand Amptrol®(K963-3)

• Fume Extraction System

•

More options at end of section

Literature

E3.105

• Three-year warranty on parts and labor.

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output

®

Invertec

V160-T 20A Branch Circuit 60A/22.4V/100% Stick Max OCV: 48V (330 x 203 x 432) (10.8)

14

K1845-1 115/1/50/60 90A/13.6V/100% TIG 20A 5-160 Amps DC 13 x 8 x 17

115/1/50/60 110A/14.4V/100% TIG 25A

30A Branch Circuit 80A/23.2V/100% Stick

230/1/50/60 130A/15.2V/100% TIG 25A

30A Branch Circuit 130A/25.2V/100% Stick

www.lincolnelectric.com/tig-welders

(1)

Output Range inches (mm) lbs.(kg)

(1)

Input amps on 60 Hz input.

50

1

60

Hz

PHASE

Page 13

TIG Welders

Processes

NEW

NEW

&

Invertec®V205-T AC/DC

IMPROVED

IMPROVED

&

Code Quality AC/DC TIG Welding

The Invertec®V205-T AC/DC is a compact, TIG power source intended for critical AC or

DC TIG welding. The

• Added Stick Crisp Mode for exceptional Fleetweld®5P & 5P+ (E6010) Performance.

• Improved TIG starting. Now starts DC (-) to maintain a sharp tungsten

• Adjustable DC strike mode – Allows adjustment of a hotter or colder

start depending on the tungsten diameter.

• Voltage Reduction Device

in STICK mode for use in electrically hazardous conditions or when

the use of a VRD is required.

• 200 amps @ 40% duty cycle is the highest output rating in this

machine class

• Fan-As-Needed

to reduce power consumption, noise and dust in machine

• Three-year Lincoln Warranty on parts and labor

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current /Voltage/Duty Cycle Rated Output

®

Invertec

V205-T AC/DC 120A/14.8V/60% TIG 25.0A Max OCV: 53V (381 x 216 x 483) (17.3)

(1)

Input current on 60 hertz input.

NEW AND IMPROVED

™

(VRD™) – Reduces the open circuit voltage

™

(F.A.N.™) – Fan only operates when needed

K1855-4 115/1/50/60 150A/16.0V/40% TIG 34.0A 6-200A AC/DC 15.0 x 8.5 x 19.0 38

230/1/50/60 200A/18.0V/40% TIG 30.0A

115/1/50/60 110A/24.4V/35% Stick 34.0A

230/1/50/60 180A/27.2V/35% Stick 30.0A

V205-T AC/DC has many new features!

100A/14.0V/100% TIG 20.0A

170A/16.0V/60% TIG 18.0A

140A/15.6V/100% TIG 15.0A

90A/23.6V/60% Stick 28.0A

70A/22.8V/100% Stick 20.0A

150A/26.0V/60% Stick 23.0A

130A/25.2V/100% Stick 19.0A

(1)

Output Range inches (mm) lbs.(kg)

•Stick

• TIG

Output Input

DC

AC

CC

One-Pak®Pkg. (K2350-2) Includes

• K1855-4 V205-T AC/DC

• 230V Input Cord & Plug

• Adjustable Shoulder Strap

• K870 Foot Amptrol

®

• K2266-1 TIG Mate™17 TIG Torch

Starter Kit

Key Options

• K2266-1 TIG Mate™17 Air-Cooled

TIG Torch Starter Pack

• K870 Foot Amptrol

• K963-3 Hand Amprtol

®

®

• Fume Extraction System

•

More options at end of section

Literature

E3.110

50

1

60

Hz

PHASE

Processes

•Stick

Invertec®V205-T DC

Code Quality DC TIG Welding

The Invertec®V205-T DC is a compact, TIG power source intended for critical DC TIG welding.

From maintenance to production fabrication, to motorsports, aerospace, nuclear piping, and

shipbuilding, this feature-packed inverter is flexible enough for almost any job!

• Added Stick Crisp Mode for exceptional Fleetweld®5P & 5P+ (E6010) Performance.

• Improved TIG starting – Starts DC(-) to maintain a sharp tungsten

• Adjustable DC strike mode – Allows adjustment of a hotter or colder

start depending on the tungsten diameter.

• Voltage Reduction Device

in STICK mode for use in electrically hazardous conditions or when

the use of a VRD

™

• 200 amps @ 40% duty cycle – highest output rating in this machine class.

• Fan-As-Needed

™

(F.A.N.™) – Fan only operates when needed to reduce

™

is required.

(VRD™) – Reduces the open circuit voltage

• TIG

DC

CC

Output Input

One-Pak®Pkg. (K2671-1) Includes

• K2629-1 Invertec®V205-T DC

• K2266-1 TIG-Mate™17 air-cooled

TIG Torch Starter Pack

• K870 Foot Amptrol

®

Key Options

• K2413-1 TIG Mate™9 Air-Cooled

TIG Torch Starter Pack

• K870 Foot Amptrol

®

• K963-3 Hand Amprtol

•

More options at end of section

Literature

E3.110.1

power consumption, noise and dust in machine

• Three-year Lincoln Warranty on parts and labor

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current /Voltage/Duty Cycle Rated Output

®

Invertec

V205-T DC 120A/14.8V/60% TIG 25.0A Max OCV: 53.7V (381 x 216 x 483) (17.3)

(1)

Input current on 60 hertz input.

K2629-1 115/1/50/60 150A/16.0V/40% TIG 34.0A 6-200A DC 15.0 x 8.5 x 19.0 38

100A/14.0V/100% TIG 20.0A

230/1/50/60 200A/18.0V/40% TIG 30.0A

170A/16.0V/60% TIG 18.0A

140A/15.6V/100% TIG 15.0A

115/1/50/60 110A/24.4V/35% Stick 34.0A

90A/23.6V/60% Stick 28.0A

70A/22.8V/100% Stick 20.0A

230/1/50/60 180A/27.2V/35% Stick 30.0A

150A/26.0V/60% Stick 23.0A

130A/25.2V/100% Stick 19.0A

(1)

Output Range inches (mm) lbs.(kg)

www.lincolnelectric.com/tig-welders

50

1

60

Hz

PHASE

®

15

Page 14

TIG Welders

Invertec®V310-T AC/DC

Customize the Arc with Dynamic Display

The Invertec®V310-T AC/DC is the most technologically advanced

AC/DC TIG welder in its class. It fits the bill for serious fabrication,

maintenance, and production work, yet its compact, lightweight

size makes it ideal for field applications like advanced

motorsports, aerospace, shipbuilding, and construction.

• Dynamic LCD Display (patent pending) – Shows the effect

of adjusting the various welding parameters making

setup simple.

• Adjustable AC Frequency and Selectable Waveshapes –

Allows you to customize the arc.

• Soft, Crisp and AC Stick Modes – Excellent welding

performance for all electrode, even E6010!

• Optional Cool-Arc

controls the speed of the water cooler’s 3-phase pump

motor based on coolant temperature for quiet operation

and long dependable life.

• 208-460 1/3 phase auto-reconnect – Weld just about

anywhere with minimal set up.

• High efficiency inverter – Yields extremely low input

currents.

®

35 “Smart” water cooler – Digitally

™

Shown:

K2228-1 Invertec

with K2630-1 Cool-Arc

®

V3005-T AC/DC

®

35 Water Cooler

Processes

• Stick

• TIG

Output Input

DC

AC

CC

50

1

60

Hz

PHASE

One-Pak®Pkg. (K2695-1) Includes

• K2228-1 Invertec™V310-T AC/DC

• K2630-1 Coolarc™35 Water Cooler

• K2694-1 Inverter Cart

• K2267-1 TIG Mate™20 Torch Kit

• K870 Foot Amptrol

®

Key Options

• K2630-1 Coolarc™35 Water Cooler

• K2694-1 Inverter Cart

• K2666-1 TIG Mate™17 Air Cooled

TIG Torch Starter Pack

• K870 Foot Amptrol

• K963-3 Hand Amptrol

•

More options at end of section

®

®

Literature

E3.115

Product Product Input Power Input Current @ H x W x D Net Weight

Name Number Phase Voltage/Hertz Rated Output Rated Output Output Range inches (mm) lbs.(kg)

®

Invertec

V305-T AC/DC 230A/19.2V/60% 8.3 Max. OCV: (34)

(1)

Input current on 60 hertz input.

K2228-1 3-Phase 460/50/60 210A/18.4V/100% 7.3 5-310A 17.3 x 10.6 x 24 75

310A/22.4V/40% 12.3 80V

230/50/60 210A/18.4V/100% 13.9

230A/19.2V/60% 15.8

310A/22.4V/30% 24.6

1-Phase 460/50/60 200A/18.0V/100% 13.6

220A/18.8V/60% 14.9

310A/22.4V/35% 23.1

230/50/60 200A/18.0V/100% 21.9

220A/18.8V/60% 24.6

310A/22.4V/25% 41.5

208/50/60 200A/18.0V/100% 24.2

220A/18.8V/60% 27.7

310A/22.4V/25% 47.3

I Choose Lincoln Electric!

Foose, Chip Foose and Foose Design are registered trademarks

of Foose Design, Inc. and used with permission.

16

Chip Foose at the Lincoln Booth (2007 AWS/Fabtech Show)

www.lincolnelectric.com/tig-welders

Page 15

TIG Options

See “Recommended General Options” pgs.149-171 for descriptions.

TIG Welders

Precision TIG®225

General Options

K2348-1 Understorage Cart

K2617-1 Dual Cylinder Cart

K2616-1 Small Wire Feeder Welder Mounting Bracket

K2378-1 Medium Canvas Cover

— Fume Extraction System

Stick Options

K2374-1 Stick Electrode Holder and Cable

TIG Options

K2266-1 TIG-Mate™17 TIG Torch Starter Kit (air-cooled)

K2267-1 TIG-Mate

K2413-1 TIG-Mate

K1781-9 PTA-9F Flexible Head w/Ultra-Flex

Package (12.5 ft., 1pc)

K1783-12 PTA-26 TIG Torch Package w/Ultra-Flex

™

20 TIG Torch Starter Kit (water-cooled)

™

9 TIG Torch Starter Kit (air-cooled)

™

Cable Torch

™

Cable (12.5 ft., 1pc)

KP2414-1 PTA-9/PTW-20 Gas Lens Parts Kit

KP508 Parts Kit For PTA-17 Series Torches

KP509 Parts Kit For PTW-18 and PTA-26 Series Torches

K870 Foot Amptrol

K963-3 Hand Amptrol®(Rotary Track Style)

K814 Arc Start

K1813-1 Cool-Arc

®

™

Switch

®

40 Water Cooler 115/1/50/60

— Cut Length Consumables

Precision TIG

®

275

General Options

K2621-1 Advanced Control Panel

K1869-1 Undercarriage

K2150-1 Work Clamp and Cable Assembly

K1831-1 Power Factor Capacitor Kit

— Fume Extraction System

Stick Options

K875 Accessory Kit, 150 Amp

K704 Accessory Kit, 400 Amp

K857 Remote Output Control, 25 ft. (7.6 m)

K857-1 Remote Output Control, 100 ft. (30 m)

TIG Options

— Pro-Torch™Air and Water-Cooled TIG Torches

K2166-3 PTA-9, -17 One Cable Torch Adapter

K2166-2 PTA-9, -17, -26 Two Cable Torch Adapter

K2166-1 PTA-26 One Cable Torch Adapter

K1828-1 Under-Cooler Cart Water Cooler

3100211 Harris

K870 Foot Amptrol

®

Argon Flowmeter Regulator and Hose Kit

®

K963-3 Hand Amptrol®(Rotary Track Style)

K814 Arc Start Switch

— Cut Length Consumables

Precision TIG

®

375

General Options

K1869-1 Undercarriage

K2150-1 Work Clamp and Cable Assembly

— Fume Extraction System

Stick Options

K704 Accessory Kit, 400 Amp

K857 Remote Output Control, 25 ft. (7.6 m)

K857-1 Remote Output Control, 100 ft. (30 m)

TIG Options

— Pro-Torch™Air and Water-Cooled TIG Torches

K2166-3 PTA-9, -17 One Cable Torch Adapter

K2166-2 PTA-9, -17, -26 Two Cable Torch Adapter

K2166-1 PTA-26 One Cable Torch Adapter

K1828-1 Under-Cooler Cart Water Cooler

3100211 Harris

K870 Foot Amptrol

®

Argon Flowmeter Regulator and Hose Kit

®

K963-3 Hand Amptrol®(Rotary Track Style)

K814 Arc Start Switch

— Cut Length Consumables

Invertec

®

V155-S

General Options

K2275-1 Welding Cart (80 cu ft bottle capacity)

K852-25 Twist-Mate™ Cable Plug Kit

— Fume Extraction System

TIG Options

K1781-7 PTA-9FV Flexible Head Gas Valve Torch (25 ft., 1 pc.)

K960-2 Small Twist-Mate

™

Torch Adapter (with separate gas)

KP507 Parts Kit for PTA-9 Series Torches

K1782-13 PTA-17FV Flex Head Gas Valve TIG Torch

w/Ultra-Flex

K960-2 Small Twist-Mate

™

Cable (12.5 ft., 1 pc.)

™

Torch Adapter (with separate gas)

KP508 Parts Kit for PTA-17 Series Torches

K586-1 Deluxe Adjustable Gas Regulator and Gas Hose Kit

Invertec

®

V160-T

General Options

K2275-1 Welding Cart (80 cu ft. bottle capacity)

K520 Utility Cart (150 cu ft. bottle capacity)

K2377-1 Small Canvas Cover

— Fume Extraction System

Stick Options

K2394-1 Stick Electrode Holder, Work Clamp, Cable

& Twist-Mate

™

Set

TIG Options

K2413-1 TIG-Mate™9 TIG Torch Starter Kit (air-cooled)

K2266-1 TIG-Mate

K2267-1 TIG-Mate

3100211 Harris

K870 Foot Amptrol

™

17 TIG Torch Starter Kit (air-cooled)

™

20 TIG Torch Starter Kit (water-cooled)

®

Argon Flowmeter Regulator and Hose Kit

®

K963-3 Hand Amptrol®(Rotary Track Style)

K814 Arc Start Switch

K1813-1 Cool-Arc

®

40 Water Cooler 115/1/50/60

— Cut Length Consumables

www.lincolnelectric.com/tig-welders

17

Page 16

TIG Welders

TIG Options, con’t.

See “Recommended General Options” pgs.149-171 for descriptions.

Invertec®V205-T AC/DC

General Options

K2275-1 Welding Cart (80 cu ft. bottle capacity)

K520 Utility Cart (150 cu ft. bottle capacity)

K2377-1 Small Canvas Cover

— Fume Extraction System

Stick Options

K2394-1 Stick Electrode Holder, Work Clamp, Cable

& Twist-Mate

™

Set

TIG Options

K2413-1 TIG-Mate™9 TIG Torch Starter Kit (air-cooled)

K2266-1 TIG-Mate

K2267-1 TIG-Mate

3100211 Harris

K870 Foot Amptrol

K963-3 Hand Amptrol®(Rotary Track Style)

K814 Arc Start

K1813-1 Cool-Arc

K1781-1 PTA-9 TIG Torch (12.5 ft., 1 pc.)

K1622-1 Twist-Mate

K1783-1 PTA-26 TIG Torch (12.5 ft., 1 pc.)

K1622-3 Twist-Mate

K1784-3 Magnum

K1622-4 Twist-Mate

™

17 TIG Torch Starter Kit (air-cooled)

™

20 TIG Torch Starter Kit (water-cooled)

®

Argon Flowmeter Regulator and Hose Kit

®

™

Switch

®

40 Water Cooler 115/1/50/60

™

Torch Adapter, PTA-9, -17

™

Torch Adapter, PTA-26

®

PTW-20 Braided TIG Torch (12.5 ft., 3 pc.)

™

Torch Adapter, Water-Cooled

K1859-2 Water Hose Kit, 25 ft. (5/8 LH CGA to 5/8 LH CGA)

— Cut Length Consumables

Invertec

®

V205-T DC

General Options

K2275-1 Welding Cart (80 cu ft. bottle capacity)

K520 Utility Cart (150 cu ft. bottle capacity)

K2377-1 Small Canvas Cover

— Fume Extraction System

Stick Options

K2394-1 Stick Electrode Holder, Work Clamp, Cable

& Twist-Mate

™

Set

TIG Options

K2413-1 TIG-Mate™9 TIG Torch Starter Kit (air-cooled)

K2266-1 TIG-Mate

K2267-1 TIG-Mate

3100211 Harris

K870 Foot Amptrol

K963-3 Hand Amptrol®(Rotary Track Style)

K814 Arc Start

K1813-1 Cool-Arc

™

17 TIG Torch Starter Kit (air-cooled)

™

20 TIG Torch Starter Kit (water-cooled)

®

Argon Flowmeter Regulator and Hose Kit

®

™

Switch

®

40 Water Cooler 115/1/50/60

K1859-2 Water Hose Kit - 25 ft (5/8 LH CGA to 5/8 LH CGA)

K1781-1 PTA-9 TIG Torch (12.5ft 1pc)

K1622-1 Twist-Mate

K1782-1 PTA-17 TIG Torch (12.5ft 1pc)

K1622-1 Twist-Mate

K1783-1 PTA-26 TIG Torch (12.5ft 1pc)

K1622-3 Twist-Mate

K1784-3 Magnum

K1622-4 Twist-Mate

™

Torch Adapter - PTA-9, -17

™

Torch Adapter - PTA-9, -17

™

Torch Adapter - PTA-26

®

PTW-20 Braided TIG Torch (12.5ft 3pc)

™

Torch Adapter - Water-Cooled

— Cut Length Consumables

®

Invertec

V310-T AC/DC

General Options

K2694-1 Inverter Cart

— Fume Extraction System

Stick Options

K2394-1 Stick Electrode Holder, Work Clamp, Cable

& Twist-Mate

™

Set

TIG Options

K2413-1 TIG-Mate™9 TIG Torch Starter Kit (air-cooled)

K2266-1 TIG-Mate

K2267-1 TIG-Mate

3100211 Harris

K870 Foot Amptrol

K963-3 Hand Amptrol®(Rotary Track Style)

K814 Arc Start

K2630-1 Cool-Arc

K1781-1 PTA-9 TIG Torch (12.5 ft., 1 pc.)

K1622-1 Twist-Mate

K1783-1 PTA-26 TIG Torch (12.5 ft., 1 pc.)

K1622-3 Twist-Mate

K1784-3 Magnum

K1622-4 Twist-Mate

™

17 TIG Torch Starter Kit (air-cooled)

™

20 TIG Torch Starter Kit (water-cooled)

®

Argon Flowmeter Regulator and Hose Kit

®

™

Switch

®

35 Water Cooler

™

Torch Adapter, PTA-9, -17

™

Torch Adapter, PTA-26

®

PTW-20 Braided TIG Torch (12.5 ft., 3 pc.)

™

Torch Adapter, Water-Cooled

— Cut Length Consumables

18

www.lincolnelectric.com/tig-welders

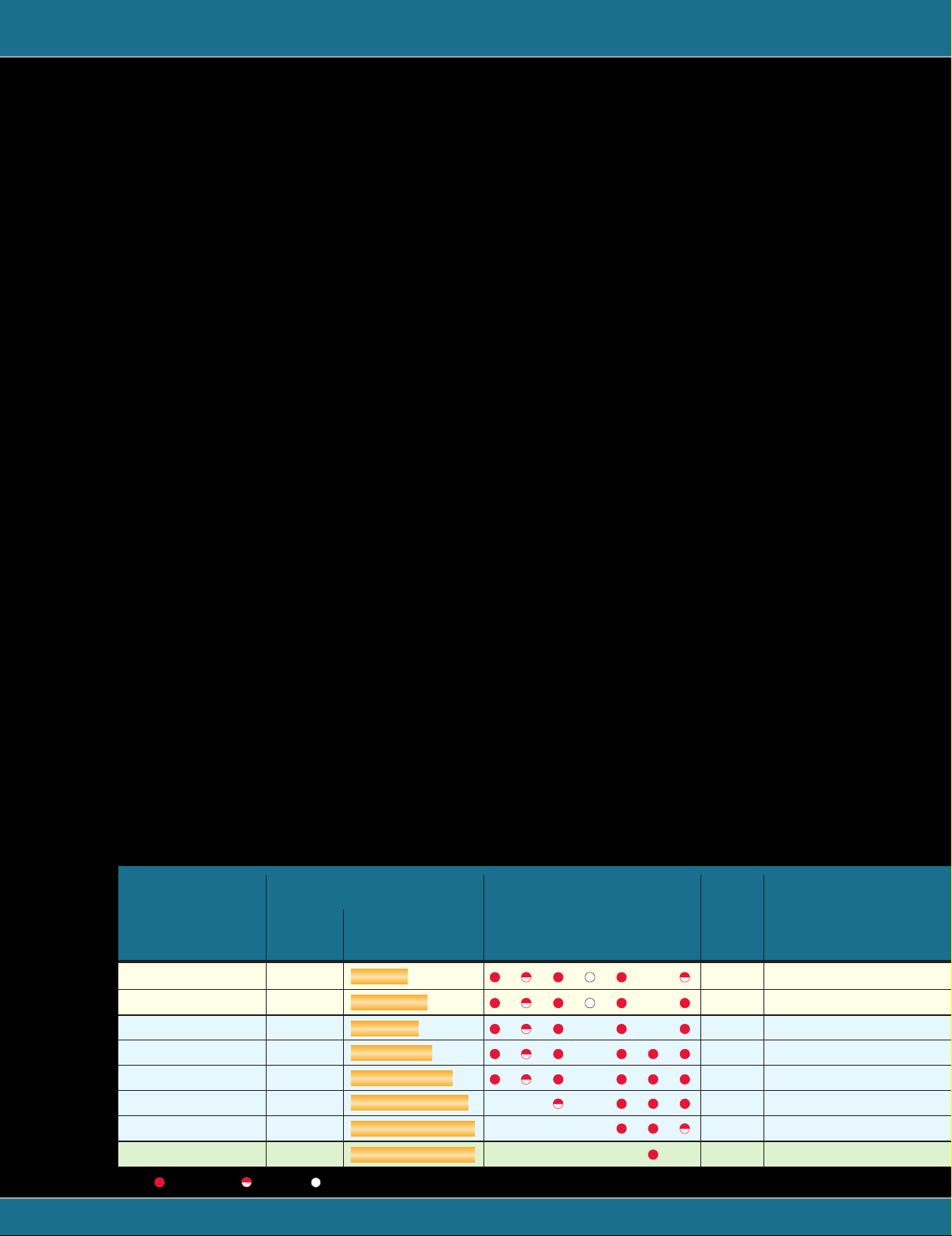

Page 17

Power MIG

®

– The Professional’s Choice!

SM

• For home, farm, autobody, maintenance or fabrication.

™

• Diamond Core

Technology delivers a superior arc.

• Professional Drive System.

• Spool Gun Ready— New low cost Magnum

®

• Great Arc Starts

• Low Spatter

• Excellent Out-of-Position Arc Action

• Enhanced Stainless

&

Aluminum Performance

100SG.

MODEL

Current Range

(Amps)

SP-140T

Input

120 Volt

Power MIG®140C

SP-180T

Power MIG®180C

Power MIG®215

Input

208-230 Volt

Power MIG®255C

Power MIG®350MP

KEY: Excellent Good Optional

30-140

30-140

30-180

30-180

30-250

30-300

5-350

Thin Sheet Metal Autobody Work

OUTPUT

Wire Feed

Speed Range

ipm (m/min)

50-500

(1.3-12.7)

50-500

(1.3-12.7)

50-500

(1.3-12.7)

50-500

(1.3-12.7)

50-700

(1.3-17.7)

50-700

(1.3-17.7)

50-700

(1.3-17.7)

Solid Wire

Size Range

in. (mm)

.023-.035

(0.6-0.9)

.023-.035

(0.6-0.9)

.023-.035

(0.6-0.9)

.023-.035

(0.6-0.9)

.023-.045

(0.6-1.2)

.023-.035

(0.6-0.9)

.023-.045

(0.6-1.2)

www.lincolnelectric.com/mig-welders

Cored Wire

Size Range

in. (mm)

.035

(0.9)

.035

(0.9)

.035-.045

(0.9-1.2)

.035-.045

(0.9-1.2)

.035-.045

(0.9-1.2)

.035-.045

(0.9-1.2)

.035-.045

(0.9-1.2)

>>

PROCESS

MIG

MIG Pulsed

Flux-Cored

Stick

INPUT

TIG Touch-Start®Phase

160

160

160

160

1 50/60

160

1 50/60

FEATURES

Hertz

Compact

Spool Gun Capable

Locking Tool Storage

Meters

Synergic Control

Push-Pull Model

••

•• •

••

•• •

•• •

••• •

••••• • •

®

Diamond Core

Technology™Chopper Technology®Waveform Control

Technology

19

Page 18

MIG: Wire Feeder/Welders

Processes

• MIG

SP-140T

120 Volt AC Input Compact Wire Welder

Here’s a great little welder for project and repair welding with MIG on mild steel or stainless

and flux-cored on mild steel.

• Ready to Weld! Includes mild steel MIG AND flux-

cored wire spools, regulator and basic handshield.

Just add shielding gas (Sold separately).

• Easy to Set – 5 position tap voltage control and

continuous full-range wire feed speed control

help you dial in your application.

• Wide 30-140 amp welding output range.

• MIG weld 24 gauge up to 10 gauge (.135")

sheet metal in a single pass. Weld up to

5/16" steel using self-shielded Lincoln

Innershield

• Spool Gun Ready – add the optional

Magnum

aluminum wire feeding.

• Three-year warranty on parts and labor.

(Tapped Voltage 50-500 ipm WFS (357 x 258 x 472) (26.3)

®

wire (FCAW-S).

®

100SG spool gun for reliable

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

SP-140T K2688-1 120/1/60 90A/19.5V/20% 20A 30-140 Amps DC 14 x 10.15 x 18.6 58

Control) (1.3-12.7 m/min)

Max. OCV: 33

• Flux-Cored

DC

CV

Output Input

Unit Includes

• Magnum®100L gun 10 ft. (3.0 m)

• .025" (0.6 mm) Contact Tips (Qty. 3)

• .035" (0.9 mm) Contact Tips (Qty. 3)

• Gasless Nozzle for Innershield

• Gas Nozzle for MIG

• Spindle Adapter, 8" (203 mm)

Dia. Spools

• .025"-.030" (0.6-0.7 mm) MIG

Drive Roll

• .035" (0.9 mm) MIG Drive Roll

• .030"-.045" (0.7-1.1 mm) Knurled

Drive Roll

• Adjustable Gas Regulator & Hose

• 2 lb. (0.90 kg) Spool of SuperArc

L-56®MIG wire

• 1 lb. (0.45 kg) Spool NR®-211-MP

• Work Clamp & 10 ft. (3.0 m) Cable

• Handshield

• How to Use DVD

Key Options

•

More options at end of section

Literature

E7.41

1

60

Hz

PHASE

®

®

SP-180T

More Power for Thicker Material

Just plug this compact wire welder into a 208 or 230V outlet in your garage, barn or shop

and start welding– up to 3/16”with MIG welding and 1/2” with gas-less flux-cored welding.

• Ready to Weld! Includes both mild steel MIG AND flux-

cored wire as well as an adjustable gas regulator.

Just add shielding gas (sold separately).

• Easy to Set – 5 position tap voltage control and

continuous full-range wire feed speed control

help you dial in your application.

• Wide 30-180 amp welding output range –

use .025" wire on the thinnest sheet metal

up to .045" flux-cored wire on thick plate.

• MIG weld 24 gauge up to 3/16" sheet

metal in a single pass. Weld up to 1/2"

steel using self-shielded Lincoln

Innershield

• Spool Gun Ready – add the optional

Magnum

aluminum wire feeding.

• Three-year warranty on parts and labor.

®

wire (FCAW-S).

®

100SG spool gun for reliable

Processes

• MIG

• Flux-Cored

DC

CV

Output Input

Unit Includes

• Magnum®100L gun 10 ft. (3.0 m)

• .025" (0.6 mm) Contact Tips (Qty. 3)

• .035" (0.9 mm) Contact Tips (Qty. 3)

• Gasless Nozzle for Innershield

• Gas Nozzle for MIG

• Spindle Adapter, 8" (203 mm)

Dia. Spools

• .025"-.030" (0.6-0.7 mm) MIG

Drive Roll

• .035" (0.9 mm) MIG Drive Roll

• .030"-.045" (0.7-1.1 mm) Knurled

Drive Roll

• Adjustable Gas Regulator & Hose

• 2 lb. (0.90 kg) Spool of SuperArc

L-56®MIG wire

• 1 lb. (0.45 kg) Spool NR®-211-MP

• Work Clamp & 10 ft. (3.0 m) Cable

• Handshield

• How to Use DVD

Key Options

•

More options at end of section

Literature

E7.42

1

60

Hz

PHASE

®

®

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

SP-180T K2689-1 208/230/1/60 208: 130A/17V/30% 20A 30-180 Amps DC 14 x 10.15 x 18.6 66

20

230: 130A/20V/30% 50-500 ipm WFS (357 x 258 x 472) (30)

(1.3-12.7 m/min)

Max. OCV: 33V

www.lincolnelectric.com/mig-welders

Page 19

MIG: Wire Feeder/Welders

Power MIG®140C

Premium 120 Volt Input Wire Welder

Home projects and repair, sheet metal and autobody work, farm and small shop welding—the

Power MIG®140C designed for 120 volt household power does it all!

• Exclusive Diamond Core™Technology delivers

an outstanding arc you’ll notice immediately:

– Great arc starts make getting started easy.

– Wide voltage “sweet spot” gives you a very

forgiving arc.

– Extremely low spatter reduces clean-up.

– Outstanding aluminum

performance.

• Wide 30-140 amp welding output range is

the highest output in the 120 volt input

power welder class.

• MIG weld 24 gauge up to 10 gauge (.135")

sheet metal in a single pass. Weld up to

5/16” steel using self-shielded Lincoln

Innershield

®

wires (FCAW-S).

• Three-year warranty on parts and labor.

& stainless

Shown:

K2471-1 Power MIG®140C

Processes

• MIG

• Flux-Cored

DC

CV

Output Input

Unit Includes

• Magnum®100L Gun, 10 ft. (3.0 m)

• Gas and Gasless Nozzles

• Cable Liner

• Contact Tips

• Work Cable and Clamp

• Adjustable Gas Regulator & Hose

• Spindle Adapter

• 2 lb. (0.90 kg) Spool of SuperArc

L-56 Mild Steel MIG Wire

• 1 lb. (0.45 kg) Spool NR®-211-MP

Flux-Cored Wire

• Learn-To-Use DVD

Key Options

• K520 Utility Cart, 150 cu ft. bottle

capacity

• K2377-1 Small Canvas Cover

• K2525-1 Spot Timer Kit

• K2532-1 Magnum®100SG

Spool Gun

•

More options at end of section

Literature

E7.23

1

60

Hz

PHASE

®

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

Power MIG

(Continuous Voltage Control) 50-500 ipm WFS (357 x 258 x 472) (26.3)

Power MIG®180C

Premium 230 Volt Compact Wire Welder

Whether you’re a farmer or a fabricator, an autobody shop or a backyard mechanic, the Power

MIG®180C helps you get the job done! It’s a portable wire welder designed for use with industrial

230 volt input power, so you can weld on thicker material—up to 3/16"

with MIG welding and 1/2" with gas-less flux-cored welding.

• Exclusive Diamond Core™Technology delivers

an outstanding arc you‘ll notice immediately:

– Great arc starts make getting started easy.

– Wide voltage “sweet spot” gives you a very

forgiving arc.

– Extremely low spatter reduces clean-up.

– Outstanding aluminum

performance.

• Wide 30-180 amp welding output

range is the highest output in this

welder class.

• MIG weld 24 gauge up to 3/16" sheet

metal in a single pass. Weld up to 1/2"

steel using self-shielded Lincoln

Innershield

• Three-year warranty on parts and labor.

®

140C K2471-1 120/1/60 90A/19.5V/20% 20A 30-140 Amps DC 14 x 10.15 x 18.6 58

(1.3-12.7 m/min)

Max. OCV: 33V

Processes

• MIG

• Flux-Cored

1

PHASE

®

wires (FCAW-S).

& stainless

Shown:

K2473-1 Power MIG®180C

DC

CV

Output Input

Unit Includes

• Magnum®100L Gun, 10 ft. (3.0 m)

• Gas and Gasless Nozzles

• Cable Liner

• Contact Tips

• Work Cable and Clamp

• Adjustable Gas Regulator & Hose

• Spindle Adapter

• 2 lb. (0.90 kg) Spool of SuperArc

L-56 Mild Steel MIG Wire

• 1 lb. (0.45 kg) Spool NR®-211-MP

Flux-Cored Wire

• Learn-To-Use DVD

Key Options

• K520 Utility Cart, 150 cu ft. bottle

capacity

• K2377-1 Small Canvas Cover

• K2525-1 Spot Timer Kit

• K2532-1 Magnum®100SG

Spool Gun

•

More options at end of section

Literature

E7.24

60

Hz

®

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

Power MIG

(Continuous Voltage Control) 130A/17V/30% 50-500 ipm WFS (357 x 258 x 472) (30)

®

180C K2473-1 208/230/1/60 130A/17V/30% 20A 30-180 Amps DC 14 x 10.15 x 18.6 66

(1.3-12.7 m/min)

Max. OCV: 33V

www.lincolnelectric.com/mig-welders

21

Page 20

MIG: Wire Feeder/Welders

Processes

• MIG

Power MIG®215

Simple Control for Sheet Metal Welding

The Power MIG®215 offers the autobody and sheet metal

fabrication industries top welding performance and a host

of professional features not often found at this price.

• More Output—rated at 215 amps/22 volts @ 30% duty cycle,

with an amperage range of 30-250 amps DC – the highest

rating and widest amperage range in its class.

• Diamond Core Technology

out-of-position arc action, a wide voltage sweet spot at a given

wire feed speed and low spatter.

• Rugged cast aluminum industrial wire drive features dual

driven rolls, regulated wire feed speed control, easy-turn

numeric tension indicator, brass-to-brass connections and

Lincoln’s 100% wire supporting split wire guide system.

• Generous 15 ft. (4.5 m) gun and cable assembly makes

it easy to reach your work.

• Seven tapped voltage ranges make it easy to

select the right procedure for your application.

• 115 volt auxiliary power receptacle for grinders,

tool chargers.

• Three-year warranty on parts and labor. (90 days on gun.)

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

Power MIG

(1)

21V on 220V 50 Hz input.

®

215 K2326-1 208/230/1/50/60 215A/22V

™

delivers a forgiving arc, excellent

(1)

/30% 45/41A 30-250 Amps DC 31.8 x 18.9 x 38.8 198

190A/23V/40% 42/38A 50-700 ipm WFS (808 x 408 x 985) (90)

170A/24V/60% 39/35A (1.3 -17.7 m/min)

Max. OCV: 39V

• Flux-Cored

DC

CV

Output Input

Unit Includes

• Magnum®250L Gun, 15 ft. (4.5 m)

• Work Cable and Clamp

• Contact Tips

• Cable Liner

• Drive Rolls

• Adjustable Gas Regulator & Hose

Key Options

• K2378-1 Medium Canvas Cover

• K1809-1 Magnum®SG Spool

Gun/Adapter

•

More options at end of section

Literature

E7.51

50

1

60

PHASE

Hz

Processes

Power MIG®255C

The Professional’s Choice!SMfor Job Shop Fabrication

The Power MIG®255C sets the standard for MIG and

flux-cored welding in industrial production, job shop

fabrication, maintenance or repair work.

• Diamond Core Technology™delivers a wide voltage sweet spot across

• MIG

• Flux-Cored

DC

CV

Output Input

One-Pak®Spool Gun Pkg. Includes

• Power MIG 255C

• Magnum®SG Spool Gun

• Magnum®SG Cable Adapter Plug

• Spool Gun Holder

• Dual Cylinder Mounting Kit

the welding range, low spatter levels and a forgiving arc on steel,

stainless and aluminum—even for demanding out-of-position work.

• Rugged cast aluminum industrial wire drive features dual driven rolls,

easy-turn numeric tension indicator, brass-to-brass gun connections

and Lincoln’s

®

100% wire-supporting split wire guide system.

• Digital meters display, preset wire feed speed and voltage,

and actual amperage and voltage while welding.

• Spool Gun Ready—electronics and second gas solenoid

are built-in to drive either the Magnum

®

SG or Magnum

®

Key Options

• K1702-1 Dual Cylinder Kit

• K2378-1 Medium Canvas Cover

• K2490-1 Magnum®250LX™Spool

Gun

•

More options at end of section

Literature

E7.54

250LX™spool gun.

• 115V auxiliary receptacle (208/230V model only) powers

a grinder or other equipment.

• Base Unit Includes: Power MIG

®

255C; Magnum®250L Gun & 15 ft (4.5 m) “quick-connect“ cable assembly

eqipped with fixed gas nozzle assembly; Work Clamp & Cable, 10 ft. (3.0 m); 10 ft. (3.0 m) 230V Input Power

Cable w/Plug (208/230V model only); .035"/.045" (0.9/1.2 mm) Drive Rolls & Guide for Steel; Gas Regulator &

Hose Kit for CO

or Argon blend gases.

2

• Three-year warranty on parts and labor. (90 days on gun.)

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

Power MIG

One-Pak

Power MIG

22

®

255C K2417-1 208/230/1/60 250A/26V/40% 50/46A 30-300 Amps — —

®

w/Spool Gun 50-700 ipm WFS

®

255C K2416-1 208/230/1/60 50/46A (1.3 -17.7 m/min) 31.8 x 18.9 x 38.8 240 (109)

K2416-2 230/460/575/1/60 47/24/19A Max. OCV: 40V (808 x 480 x 985) (with gun)

www.lincolnelectric.com/mig-welders

1

60

Hz

PHASE

Page 21

MIG: Wire Feeder/Welders

Processes

•Stick

Power MIG®350MP

The Professional’s Choice!

When you want more than just a MIG machine, the Power MIG®350MPis the choice for you.

Lincoln’s

cored, and advanced processes such as Power Mode®and Pulse-On-Pulse®. With the simplicity

and sophistication of synergic control, no other wire feeder/welder offers so much!

• Pulse-on-Pulse®improves cleaning action when welding aluminum

and delivers a TIG-like appearance to the weld beads.

• Synergic control of voltage and wire feed speed allows

you to set weld procedures with one control.

• Push-Pull or Spool Gun Ready—A second gas solenoid

and other electronics are built-in to drive either a spool

gun or push-pull gun.

• 115V auxiliary receptacle powers a grinder or other equipment.

• Dual Procedure capable—select between either two

welding procedures or two welding modes.

• Rugged cast aluminum industrial wire drive features dual

driven rolls, regulated wire feed speed control, easy-turn

numeric tension indicator, brass-to-brass connections and

Lincoln’s

• Base Unit Includes: Power MIG

Magnum

.035"/.045" (0.9/1.2 mm) Drive Rolls

for Steel; Regulator

& Cable; 230V Input Cord & Plug.

• Three-year warranty on parts and labor.

(90 days on gun.)

(1)

®

Chopper Technology®delivers more welding processes: stick, TIG, MIG, flux-

®

100% wire supporting split wire guide system.

®

®

300 Gun & 15 ft. (4.5m) Cable;

350MP;

& Guide

& Hose; Work Clamp

Product Product Input Power Rated Output Input Current @ H x W x D Net Weight

Name Number Voltage/Phase/Hertz Current/Voltage/Duty Cycle Rated Output Output Range inches (mm) lbs.(kg)

Power MIG

Push-Pull One-Pak

Power MIG

40% on 208V input. Ratings based on 60 Hz operation.

®

350

MP

®

350

MP

K2451-2 208/230/460/575/1/50/60 300A/32V/60%

®

K2403-1 (1.3 -17.7 m/min) 31.8 x 18.9 x 38.8 255

SM

(1)

72/62/31/25A 5-350 Amps DC — —

50-700 ipm WFS

Max. OCV: 67 (808 x 408 x 985) (116)

•TIG

• MIG

• Pulsed

• Flux-Cored

CC

Output Input

DC

CV

Push-Pull One-Pak®Includes

• Power MIG®350MP (K2403-1)

• Python®-

Plus

Push-Pull Gun,

25 ft. (7.6 m)

• 3/64" Aluminum Drive Roll Kit

• Magnum®300 Gun, 15 ft. (4.5m)

• Cable Liner

• Contact Tips

• Work Clamp and Cable

• Adjustable Gas Regulator & Hose

Key Options

• K1702-1 Dual Cylinder Kit

• K2378-1 Medium Canvas Cover

• K2447-2 Python

Gun, 25 ft. (7.6 m)

• K2490-1 Magnum®250LX Spool

Gun

•

More options at end of section

Literature

E7.57

®

-

Plus

1

60

Hz

PHASE

Push-Pull

www.lincolnelectric.com/mig-welders

23

Page 22

MIG: Wire Feeder/Welders

MIG: Wire Feeder/Welders Options

See “Recommended General Options” pgs.149-171 for descriptions.

SP-140T and SP-180T

General Options

K2275-1 Welding Cart (80 cu. ft. bottle capacity)

K520 Utility Cart (150 cu. ft. bottle capacity)

K2377-1 Small Canvas Cover

K2525-1 Spot Timer Kit

— Fume Extraction System

Wire Feeder Options

K2532-1 Magnum®100SG Spool Gun

K2528-1 .045" Innershield

®

Welding Kit (Power MIG®180T only)

KP2529-1 Drive Roll, .025"-.030" Smooth

KP2529-2 Drive Roll, .035" Smooth

KP2529-3 Drive Roll, .030"-.045" Knurled

Power MIG

®

140C and Power MIG®180C

General Options

K2275-1 Welding Cart (80 cu. ft. bottle capacity)

K520 Utility Cart (150 cu. ft. bottle capacity)

K2377-1 Small Canvas Cover

K2525-1 Spot Timer Kit

— Fume Extraction System

Wire Feeder Options

K2532-1 Magnum®100SG Spool Gun

K2528-1 .045" Innershield

®

Welding Kit (Power MIG®180C only)

KP2529-1 Drive Roll, .025"-.030" Smooth

KP2529-2 Drive Roll, .035" Smooth

KP2529-3 Drive Roll, .030"-.045" Knurled

KP2531-1 Inner Wire Guide, .025"-.035" Steel

KP2531-2 Inner Wire Guide, .045" Steel

Power MIG

®

215

General Options

K2378-1 Medium Canvas Cover

K466-6 Connector Kit – Power MIG

®

/Wire-Matic

K1809-1 Magnum®SG Spool Gun and Adapter

(includes spool gun holder)

K1703-1 3/64" Aluminum Feeding Kit

K363P 22-30 lb. Readi-Reel

®

Adapter

K468 8" O.D. Spool Adapter

K1702-1 Dual Cylinder Mounting Kit

KP1696-030S Drive Roll Kit, .023"-.030" Solid Wire

KP1696-035S Drive Roll Kit, .035" Solid Wire

KP1696-1 Drive Roll Kit, .035" and .045" Solid Wire

KP1696-2 Drive Roll Kit, .040" Solid Wire

KP1696-045S Drive Roll Kit, .045" Solid Wire

KP1697-035C Drive Roll Kit, .030"-.035" Cored Wire

KP1697-045C Drive Roll Kit, .040"-.045" Cored Wire

KP1695-3/64A Drive Roll Kit, 3/64" Aluminum Wire

— Fume Extraction System

Power MIG

®

255C

General Options

K1701-1 Timer Kit