Page 1

This information is subject to the controls of the Export Administration Regulations [EAR].

RETURN TO MAIN MENU

User's Manual

Spirit II 150

High Current Density Plasma Cutting System

with Manual Gas Console (MGC)

718114 Rev D

This information shall not be provided to non-U.S. persons or transferred by any means to

any location outside the United States contrary to the requirements of the EAR.

Page 2

Prologue Spirit II User’s Manual

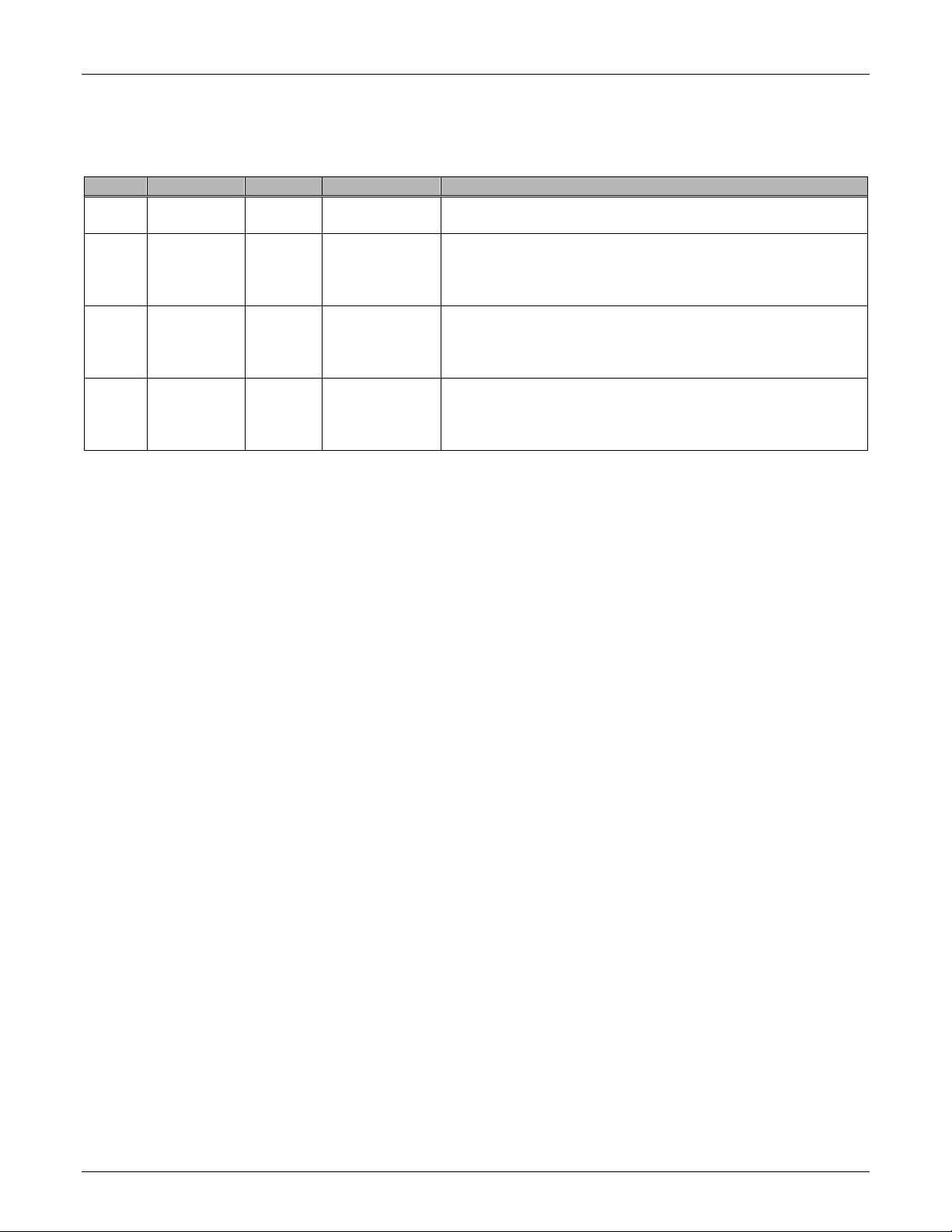

Rev

ECO#

Author

Date

Description of Change

Added 100A/150A silver electrodes, replaced RHF with

to inlet gas pressure.

Deionization filter cartridge (500510) replaced sediment

clarify cabling requirements for various configurations.

Corrected contact ratings on page 3-19.

ground in Parts List.

Revision History

A - CAD 02/04/2013 Initial Release

B LAD0202 CAD 06/07/2013

C LAD0217 CAD 08/06/2013

D

LAD0228

LAD0223

CAD 08/28/2013

This documentation may not be copied, photocopied, reproduced, translated,

or reduced to any electronic medium or machine-readable format without

explicit written permission from Kaliburn.

FASTON is a trademark of the TE Connectivity Ltd family of companies.

Other logos, products and company names mentioned herein

may be trademarks of their respective owners.

© Copyright 2013 Kaliburn Inc.

4130 Carolina Commerce Parkway

ISC, corrected system interconnect diagrams, changed

rated inlet gas pressure to 115 psi, added 100 psi minimum

filter (300152). Parts list updated.

Expanded notes on System Interconnection diagrams to

Added pinouts to CII, FII, JII cables in Parts List.

Corrected part numbers for coolant/power leads and work

a Lincoln Electric Company

Ladson, SC 29456 USA

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

ii

Page 3

Spirit II User’s Manual Prologue

Table of Contents

Section 1: Safety

General Precautions ......................................................................................... 1-1

Ultraviolet Radiation Protection ......................................................................... 1-1

Noise Protection ................................................................................................ 1-1

Toxic Fume Prevention ..................................................................................... 1-2

Electric Shock Prevention ................................................................................. 1-2

Fire Prevention .................................................................................................. 1-3

Explosion Prevention......................................................................................... 1-3

Health Support Equipment ................................................................................ 1-4

Safety Standards Booklet Index ........................................................................ 1-5

Section 2: Specifications

System Description ........................................................................................... 2-1

System Components ......................................................................................... 2-2

Power Supply Specifications ............................................................................. 2-3

Torch Coolant Specifications ............................................................................. 2-4

Manual Gas Console (MGC) Specifications ...................................................... 2-5

Gas Supply Requirements ................................................................................ 2-6

Impulse Start Console (ISC) Specifications ....................................................... 2-7

Torch and 2-Gang Manifold Specifications ........................................................ 2-8

5-Gang Manifold Specifications ......................................................................... 2-9

Airborne Noise Emissions ................................................................................. 2-10

Section 3: Installation

Initial Inspection ................................................................................................ 3-1

Component Placement ...................................................................................... 3-1

System Interconnection ..................................................................................... 3-2

Power Supply Primary Power Connections ....................................................... 3-5

Power Supply Output Connections ................................................................... 3-7

ISC Control Cable and ISC Ground Connections .............................................. 3-9

Cooling System Connections ............................................................................ 3-9

Torch Leads to Impulse Start Console Connections ......................................... 3-11

Torch Leads to Torch Base Connections .......................................................... 3-13

Torch Gas Connections ..................................................................................... 3-14

Gas Supply Connections ................................................................................... 3-17

CAN Communication Connections .................................................................... 3-18

CNC Machine Interface Connections ................................................................ 3-19

Filling the Cooling System ................................................................................. 3-20

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

iii

Page 4

Prologue Spirit II User’s Manual

Section 4: Operation

Operating the Manual Gas Console (MGC) ...................................................... 4-1

Setting up to Cut ............................................................................................... 4-2

Setting up to Mark (Overrides Cut) .................................................................... 4-3

Verifying Input Gas Pressures ........................................................................... 4-3

Making a Cut or Mark ........................................................................................ 4-4

Piercing Thick Materials .................................................................................... 4-5

Moving Pierces and Edge Starts ....................................................................... 4-5

Cut Quality ........................................................................................................ 4-6

Checking Errors ................................................................................................ 4-7

Checking the Version and Serial Number ......................................................... 4-7

Changing the Language .................................................................................... 4-8

Adjusting the Screen Contrast ........................................................................... 4-8

Section 5: Torch Consumables and Cut Charts

Installing / Removing the Torch Head ............................................................... 5-1

Installing / Replacing Consumables .................................................................. 5-2

Maximizing Consumable Life ............................................................................ 5-3

Inspecting for Damage ...................................................................................... 5-4

Selecting Consumables ..................................................................................... 5-5

Cutting Charts ................................................................................................... 5-12

Section 6: Maintenance and Troubleshooting

Routine Maintenance ........................................................................................ 6-1

Replacing the Torch Coolant and Filter ............................................................. 6-4

Microprocessor (DSP) Status Indicators ........................................................... 6-5

Microprocessor (DSP) Sequence of Operation ................................................. 6-5

Error Codes ....................................................................................................... 6-7

General Troubleshooting ................................................................................... 6-9

Chopper Test Procedure ................................................................................... 6-11

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

iv

Page 5

Spirit II User’s Manual Prologue

Section 7: Parts List

Power Supply (300211 - 300219) ...................................................................... 7-1

Manual Gas Console (300600) ......................................................................... 7-5

Impulse Start Console (300500) ........................................................................ 7-7

Torch and Manifold Assemblies ........................................................................ 7-8

Shielded Torch Leads ....................................................................................... 7-9

CAN Communication Cable and Termination Plug ........................................... 7-9

Manifold Control Cables .................................................................................... 7-9

Gas Hose Package with MGC ........................................................................... 7-10

Coolant and Power Leads ................................................................................. 7-11

Work Ground Lead ............................................................................................ 7-11

Oxygen Supply Gas Hose (Optional) ................................................................ 7-12

Nitrogen Supply Gas Hose (Optional) ............................................................... 7-12

Air Supply Gas Hose (Optional) ........................................................................ 7-12

H17 Supply Gas Hose (Optional) ...................................................................... 7-12

"CII" Cable (for Optional External Inova) ........................................................... 7-13

"FII" Cable (for Optional Internal Inova) ............................................................. 7-14

"JII" Cable (for Optional Internal Inova) ............................................................. 7-15

Section 8: Internal Inova Console Option

Overview ........................................................................................................... 8-1

Plug Identification .............................................................................................. 8-1

Unique Interconnect Cables .............................................................................. 8-1

Grounding ......................................................................................................... 8-2

Parts List ........................................................................................................... 8-3

Appendix A: Electromagnetic Compatibility (EMC)

Background ....................................................................................................... A-1

Installation and Use ........................................................................................... A-1

Assessment of Area .......................................................................................... A-2

Methods of Reducing Emissions ....................................................................... A-2

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

v

Page 6

Prologue Spirit II User’s Manual

Limited Warranty

KALIBURN expressly warrants that this product shall be free from defects in materials

and workmanship, under proper and normal use for the intended function of such

product, for a period of three (3) years for the Spirit II plasma power supply (includes the

cooling system and internally installed Inova option) and one (1) year for all other Spirit

II system component. This warranty does not apply to torch consumable parts.

The warranty period starts three (3) months after the product ships from the factory.

This product is intended for commercial use and is not intended for personal, family, or

household purposes. There are no warranties that extend beyond the express limited

warranty set forth immediately above. All other warranties, whether expressed, implied,

statutory or made herein or in any other communication, including any implied warranty

of merchantability, fitness for any particular purpose or non-infringement, are expressly

excluded.

This warranty will be considered void if the Spirit II system is operated with non-genuine

KALIBURN torch consumables, or if the equipment has been subjected to improper

installation, improper care or abnormal operation.

If this product or any component thereof is determined to be defective in materials or

workmanship, KALIBURN will repair or replace the defective component or product.

The buyer’s remedies are limited to the return of the product for repair or replacement of

any defective product or part at the sole discretion of KALIBURN. No freight charges of

any kind are covered under this warranty. All returned goods shall be at the buyer’s risk

and expense. In no event will KALIBURN be responsible for any special, incidental or

consequential damages or injury to the person or property of anyone by reason of any

defect in any equipment sold hereunder.

Returned Goods Procedure

KALIBURN utilizes a returned goods procedure that must be followed before returning

any items for repair, replacement, or restocking. This means that a returned goods

authorization number must be obtained prior to shipment to KALIBURN. It will be

necessary for the customer to provide a description, along with the part number and

serial number, if applicable, of the item to be returned. In no case will KALIBURN

accept a returned shipment without the proper returned goods authorization number.

For shipments inside the U.S., parts must be returned to KALIBURN within 30 days of

the invoice date to be considered for credit. For shipments outside the U.S., parts must

be returned within 60 days of the invoice date to be considered for credit.

Electromagnetic Compatibility (EMC)

The 380V 50/60Hz and 415V 50/60Hz CE marked Spirit II plasma cutting systems are

manufactured to comply with the European standard EN 60974-10 (Electromagnetic

compatibility (EMC) – Product standard for arc welding equipment). Information about

the EMC standard EN 60974-10 can be found in Appendix A.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

vi

Page 7

Spirit II User’s Manual Section 1: Safety

Ultraviolet Radiation Protection

Noise Protection

Section 1: Safety

General Precautions

Whereas plasma cutting has been used safely for years, it does require certain

precautions to ensure the safety of the operator and other people around the

equipment. The following safety information must be provided to each person who will

operate, observe, perform maintenance, or work in close proximity to this piece of

equipment.

Installation, operation, and repairs made to the Spirit system should only be performed

by qualified personnel. The system makes use of both A.C. and D.C. circuitry for

operation. Fatal shock hazard does exist. Exercise extreme caution while working

on the system.

Plasma cutting produces ultraviolet radiation similar to a welding arc. This ultraviolet

radiation can cause skin and eye burns. For this reason, it is essential that proper

protection be worn. The eyes are best protected by using safety glasses or a welding

helmet with an AWS No. 12 shade or ISO 4850 No. 13 shade, which provides protection

up to 400 amperes. All exposed skin areas should be covered with flame-retardant

clothing. The cutting area should also be prepared in such a way that ultraviolet light

does not reflect. Walls and other surfaces should be painted with dark colors to reduce

reflected light. Protective screens or curtains should be installed to protect additional

workers in the area from ultraviolet radiation.

The system generates high noise levels while cutting. Depending on the size of the

cutting area, distance from the cutting torch, and arc current cutting level, acceptable

noise levels may be exceeded. Proper ear protection should be used as defined by

local or national codes. See Section 2 for noise emission levels.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

1-1

Page 8

Section 1: Safety Spirit II User’s Manual

Toxic Fume Prevention

Electric Shock Prevention

Care should be taken to ensure adequate ventilation in the cutting area. Some

materials give off toxic fumes that can be harmful or fatal to people in the vicinity of the

cutting area. Also, some solvents decompose and form harmful gases when exposed

to ultraviolet radiation. These solvents should be removed from the area prior to cutting.

Galvanized metal can produce harmful gases during the cutting process. Ensure proper

ventilation and use breathing equipment when cutting these materials.

Certain metals coated with or containing lead, cadmium, zinc, beryllium, and mercury

produce harmful toxins. Do not cut these metals unless all people subjected to the

fumes wear proper air breathing equipment.

The Spirit system uses high open circuit voltages that can be fatal. Extreme care

should be used when operating or performing maintenance on the system. Only

qualified personnel should service the system. Observe the following guidelines to

protect against electric shock:

• A wall-mounted disconnect switch should be installed and fused according to local

and national electrical codes. The disconnect switch should be located as close as

possible to the power supply so it can be turned off in case of an emergency.

• The primary power cord should have a 600 volt minimum rating in order to protect

the operator. In addition, it should be sized according to local and national electrical

codes. Inspect the primary power cord frequently. Never operate the system if the

power cord is damaged in any way.

• Make sure the primary power ground wire is connected to the input power ground

stud on the power supply. Make sure the connection is securely tightened.

• Make sure the positive output (work ground) of the power supply is connected to a

bare metal area on the cutting table. A driven ground rod should be placed no

further than five feet from this connection. Make sure this ground point on the

cutting table is used as the star ground point for all other ground connections.

• Inspect the torch leads frequently. Never use the system if the leads are damaged

in any way.

• Do not stand in wet, damp areas when operating or performing maintenance on the

system.

• Wear insulated gloves and shoes while operating or performing maintenance on the

system.

• Make sure the system is switched off at the wall disconnect before servicing the

power supply or torch.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

1-2

Page 9

Spirit II User’s Manual Section 1: Safety

Fire Prevention

Explosion Prevention

• Never change torch consumable parts unless the system is switched off at the wall

disconnect.

• Do not attempt to remove any parts from beneath the torch when cutting.

Remember that the workpiece forms the current path back to the power supply.

• Never bypass the safety interlock devices.

• Before removing any of the covers, switch the system off at the wall disconnect.

Wait at least five (5) minutes before removing any cover. This will give the

capacitors inside the unit time to discharge. See Section 6 for additional safety

precautions.

• Never operate the system without all of the covers in place. See Section 6 for

additional safety precautions.

• Preventive maintenance should be performed daily to avoid possible safety hazards.

When using the Spirit system, it is necessary to exercise good judgment. While cutting,

the arc produces sparks that could cause a fire if they fall on flammable materials.

Make sure that all flammable materials are a suitable distance away from the cutting

area. All flammable liquids should be at least 40 feet away from the cutting area,

preferably stored in a metal cabinet. Plasma cutting should never be attempted on

containers that contain flammable materials. Make sure that fire extinguishers are

readily accessible in the cutting area.

Make sure that the cutting area is properly ventilated when using oxygen as a cutting

gas.

The Spirit system uses compressed gases. Use proper techniques when handling

compressed gas cylinders and other compressed gas equipment. Observe the

following guidelines to protect against explosion:

• Never operate the system in the presence of explosive gases or other explosive

materials.

• Never cut pressurized cylinders or any closed container.

• When using a water table and cutting aluminum under water or with water touching

the underside of the aluminum plate, hydrogen gas is produced. This hydrogen gas

may collect under the plate and explode during the cutting process. Make sure the

water table is properly aerated to help prevent the accumulation of hydrogen gas.

• Handle all gas cylinders in accordance with safety standards published by the U.S.

Compressed Gas Association (CGA), American Welding Society (AWS), Canadian

Standards Association (CSA), or other local or national codes.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

1-3

Page 10

Section 1: Safety Spirit II User’s Manual

Health Support Equipment

• Compressed gas cylinders should be maintained properly. Never attempt to use a

cylinder that is leaking, cracked, or has other signs of physical damage.

• All gas cylinders should be secured to a wall or rack to prevent accidental knock

over.

• If a compressed gas cylinder is not being used, replace the protective valve cover.

• Never attempt to repair compressed gas cylinders.

• Keep compressed gas cylinders away from intense heat, sparks, or flames.

• Clear the compressed gas cylinder connection point by opening the valve

momentarily prior to installing a regulator.

• Never lubricate compressed gas cylinder valves or pressure regulators with any type

of oil or grease.

• Never use a compressed gas cylinder or pressure regulator for any purpose other

than which it is intended.

• Never use a pressure regulator for any gas other than which it is intended.

• Never use a pressure regulator that is leaking or has other signs of physical

damage.

• Never use oxygen hoses and pressure regulators for any gas other than oxygen.

• Never use any gas hose that is leaking or has other signs of physical damage.

The Spirit system creates electric and magnetic fields that may interfere with certain

types of health support equipment, such as pacemakers. Any person who uses a

pacemaker or similar item should consult a doctor before operating, observing,

maintaining, or servicing the system. Observe the following guidelines to minimize

exposure to these electric and magnetic fields:

• Stay as far away from the power supply, torch, torch leads, and impulse start

console as possible.

• Route the torch leads as close as possible to the work ground cable.

• Never place your body between the torch leads and work ground cable. Keep the

work ground cable and the torch leads on the same side of your body.

• Never stand in the center of a coiled up set of torch leads or work ground cable.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

1-4

Page 11

Spirit II User’s Manual Section 1: Safety

Safety Standards Booklet Index

For further information concerning safety practices to be exercised with plasma arc

cutting equipment, please refer to the following publications:

1. AWS Standard AWN, Arc Welding and Cutting Noise, obtainable from the American

Welding Society, 550 NW LeJeune Road, Miami, FL 33126.

2. AWS Standard C5.2, Recommended Practices for Plasma Arc Cutting, obtainable

from the American Welding Society, 550 NW LeJeune Road, Miami, FL 33126.

3. AWS Standard FSW, Fire Safety in Welding and Cutting, obtainable from the

American Welding Society, 550 NW LeJeune Road, Miami, FL 33126.

4. AWS Standard F4.1, Recommended Safe Practices for Preparation for Welding and

Cutting of Containers and Piping, obtainable from the American Welding Society,

550 NW LeJeune Road, Miami, FL 33126.

5. AWS Standard ULR, Ultraviolet Reflectance of Paint, obtainable from the American

Welding Society, 550 NW LeJeune Road, Miami, FL 33126.

6. AWS / ANSI Standard Z49.1, Safety in Welding, Cutting, and Allied Processes,

obtainable from the American Welding Society, 550 NW LeJeune Road, Miami, FL

33126.

7. ANSI Standard Z41.1, Standard For Men’s Safety-Toe Footwear, obtainable from

the American National Standards Institute, 11 West 42nd Street, New York, NY

10036.

8. ANSI Standard Z49.2, Fire Prevention in the Use of Cutting and Welding

Processes, obtainable from the American National Standards Institute, 11 West

42nd Street, New York, NY 10036.

9. ANSI Standard Z87.1, Safe Practices For Occupation and Educational Eye and

Face Protection, obtainable from the American National Standards Institute, 11

West 42nd Street, New York, NY 10036.

10. ANSI Standard Z88.2, Respiratory Protection, obtainable from the American

National Standards Institute, 11 West 42nd Street, New York, NY 10036.

11. OSHA Standard 29CFR 1910.252, Safety and Health Standards, obtainable from

the U.S. Government Printing Office, Washington, D.C. 20402.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

1-5

Page 12

Section 1: Safety Spirit II User’s Manual

12. NFPA Standard 51, Oxygen - Fuel Gas Systems for Welding, Cutting, and Allied

Processes, obtainable from the National Fire Protection Association, 1

Batterymarch Park, Quincy, MA 02269.

13. NFPA Standard 51B, Cutting and Welding Processes, obtainable from the National

Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02269.

14. NFPA Standard 70, National Electrical Code, obtainable from the National Fire

Protection Association, 1 Batterymarch Park, Quincy, MA 02269.

15. CGA booklet P-1, Safe Handling of Compressed Gases in Containers, obtainable

from the Compressed Gas Association, 1725 Jefferson Davis Highway, Suite 1004,

Arlington, VA 22202.

16. CGA booklet P-14, Accident Prevention in Oxygen-Rich and Oxygen-Deficient

Atmospheres, obtainable from the Compressed Gas Association, 1725 Jefferson

Davis Highway, Suite 1004, Arlington, VA 22202.

17. CGA booklet TB-3, Hose Line Flashback Arrestors, obtainable from the

Compressed Gas Association, 1725 Jefferson Davis Highway, Suite 1004,

Arlington, VA 22202.

18. CSA Standard W117.2, Safety in Welding, Cutting, and Allied Processes,

obtainable from Canadian Standards Association, 178 Rexdale Boulevard, Toronto,

Ontario M9W lR3, Canada.

19. Canadian Electrical Code Part 1, Safety Standard for Electrical Installations,

obtainable from the Canadian Standards Association, 178 Rexdale Boulevard,

Toronto, Ontario M9W 1R3, Canada.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

1-6

Page 13

Spirit II User’s Manual Section 2: Specifications

Section 2: Specifications

System Description

The Spirit II 150 is a 150 amp microprocessor controlled, 100% duty cycle high current

density plasma cutting and marking system. It utilizes a precision, dual gas torch that is

capable of cutting mild steel up to 1-1/2" thick and stainless steel up to 1” thick.

The system contains a manually controlled gas console, which also provides the

primary interface to the entire Spirit system.

For cutting mild steel, the system uses oxygen for the plasma gas and either oxygen or

air for the shielding gas. When cutting stainless steel or other non-ferrous materials, air

or H17 (17.5% hydrogen, 32.5% argon, 50% nitrogen) is used for the plasma gas and

either air or nitrogen is used for the shielding gas. Oxygen and nitrogen are used for

the preflow and postflow gases.

The torch is water-cooled and consumables are machined to exacting dimensions and

checked with the latest computerized measuring systems. Five nozzle sizes (30, 50,

70, 100, and 150 amps) are available to produce excellent cut quality throughout the

cutting range.

Each enclosure in the system is rated for IP21S sealing, which is intended for

indoor use only. The system is not suitable for use in rain or snow.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-1

Page 14

Section 2: Specifications Spirit II User’s Manual

System Components

The Spirit II 150 System consists of the following components:

Standard Components

• Power Supply

• Manual Gas Console

• CAN Cable

• CAN Termination Plug

• Impulse Start Console (ISC)

• ISC Control Cable

• ISC Ground Cable

• Torch and Handle Assembly

• Torch Lead Set

• 5-gang Manifold Assembly

• 5-gang Manifold Control Cable

• 2-gang Manifold Assembly

• 2-gang Manifold Control Cable

• 17 Inch Plasma Hose

• Coolant and Power Leads

• Gas Hose Package

• Work Ground Lead

• Spirit II User’s Manual

Optional Components

• Supply Gas Hoses

• Internal Inova Console

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-2

Page 15

Spirit II User’s Manual Section 2: Specifications

Input Current at

Maximum Output

208 VAC, 3Ø, 60Hz

300211

99 amps

220 VAC, 3Ø, 60Hz

300212

94 amps

240 VAC, 3Ø, 60Hz

300213

86 amps

380 VAC, 3Ø, 50/60Hz

300214

54 amps

400 VAC, 3Ø, 50/60Hz

300215

52 amps

415 VAC, 3Ø, 50/60Hz

300216

50 amps

440 VAC, 3Ø, 50/60Hz

300217

47 amps

480 VAC, 3Ø, 60Hz

300218

43 amps

600 VAC, 3Ø, 60Hz

300219

34 amps

29.0" [737]

43.2" [1097]

150

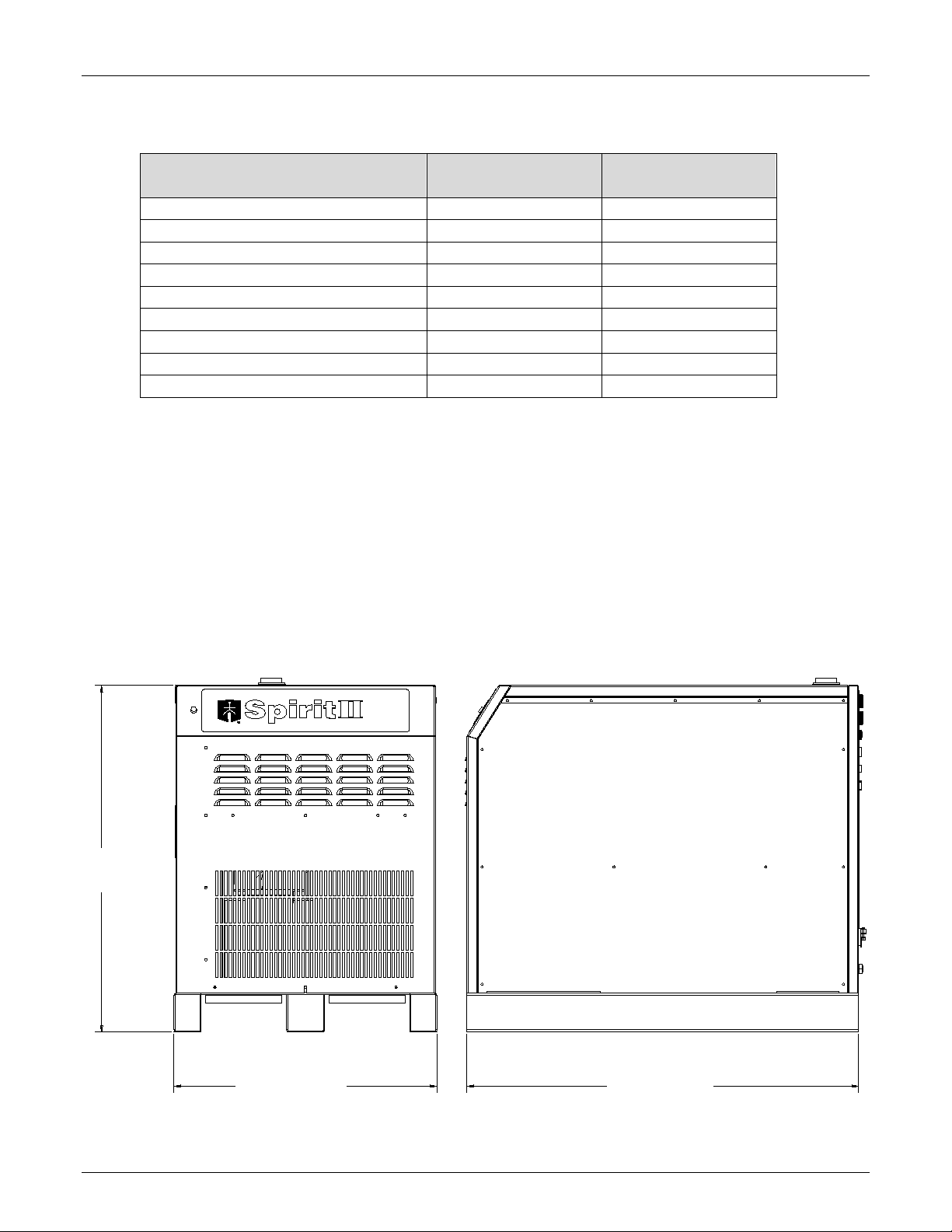

Power Supply Specifications

Power Supply Description Part Number

Open Circuit Voltage ......................................... 300 VDC

Output Current (drooping characteristic) ........... 10 - 150 amps

Maximum Output Voltage ................................. 170 VDC

Duty Cycle ........................................................ 100% @ 25.5 kW

Maximum Ambient Temperature ....................... 104° F (40° C)

Coolant Discharge Pressure ............................. 150 psi (10.2 bar)

Coolant Flow Rate ............................................ 1 gal/min (3.8 liters/min)

Coolant Fluid ..................................................... Propylene glycol solution

Coolant Tank Capacity ...................................... 3.2 gal (12 liters)

Weight (without coolant) ................................... 953 lb (432 kg)

38.4"

[975]

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-3

Page 16

Section 2: Specifications Spirit II User’s Manual

Torch Coolant Specifications

Note: Refer to the supplier’s most current Material Safety Data Sheet for

information regarding safety, handling, and storage of torch coolant.

The Spirit system is shipped without torch coolant in the reservoir. Coolant

must be added before applying power to the system. Only use Kaliburn

approved torch coolant solution for optimal system performance as commercially

available antifreeze contains corrosion inhibitors that will damage the cooling

system. The standard coolant solution consists of 25% industrial grade

propylene glycol and provides freezing protection down to -13º C (9º F). The

standard solution can be ordered in one-gallon containers, PN 500695. For

operating temperatures below -13º C, a 50% solution of industrial grade

propylene glycol can be ordered in one-gallon containers, PN 500895, providing

protection down to -36º C (-33º F).

Failure to use the proper propylene glycol solution may result in cooling

system and/or torch damage.

The torch coolant should be flushed out of the Spirit system every six months

and replaced with new coolant. The coolant filter / deionization cartridge should

also be changed at the same time. See Section 6 for details.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-4

Page 17

Spirit II User’s Manual Section 2: Specifications

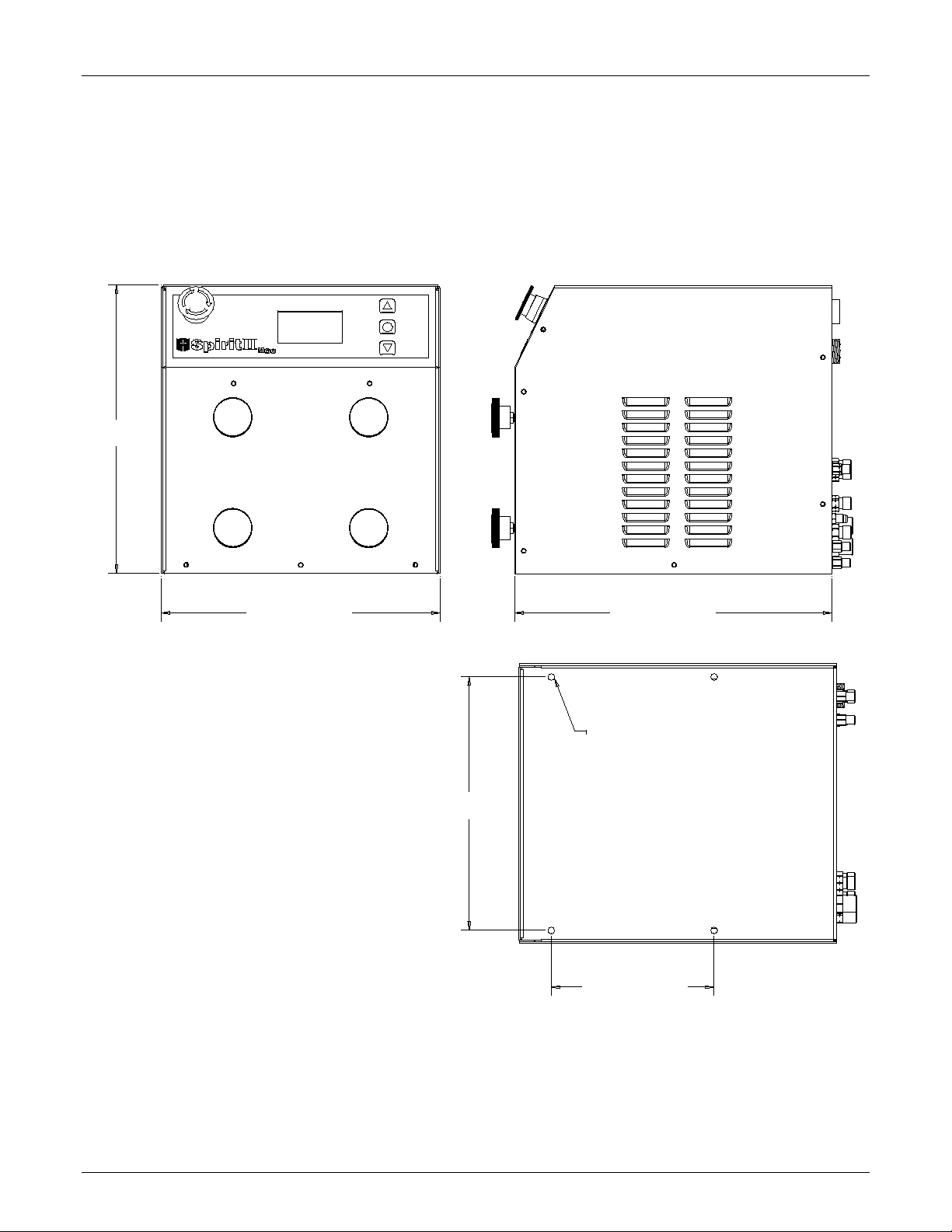

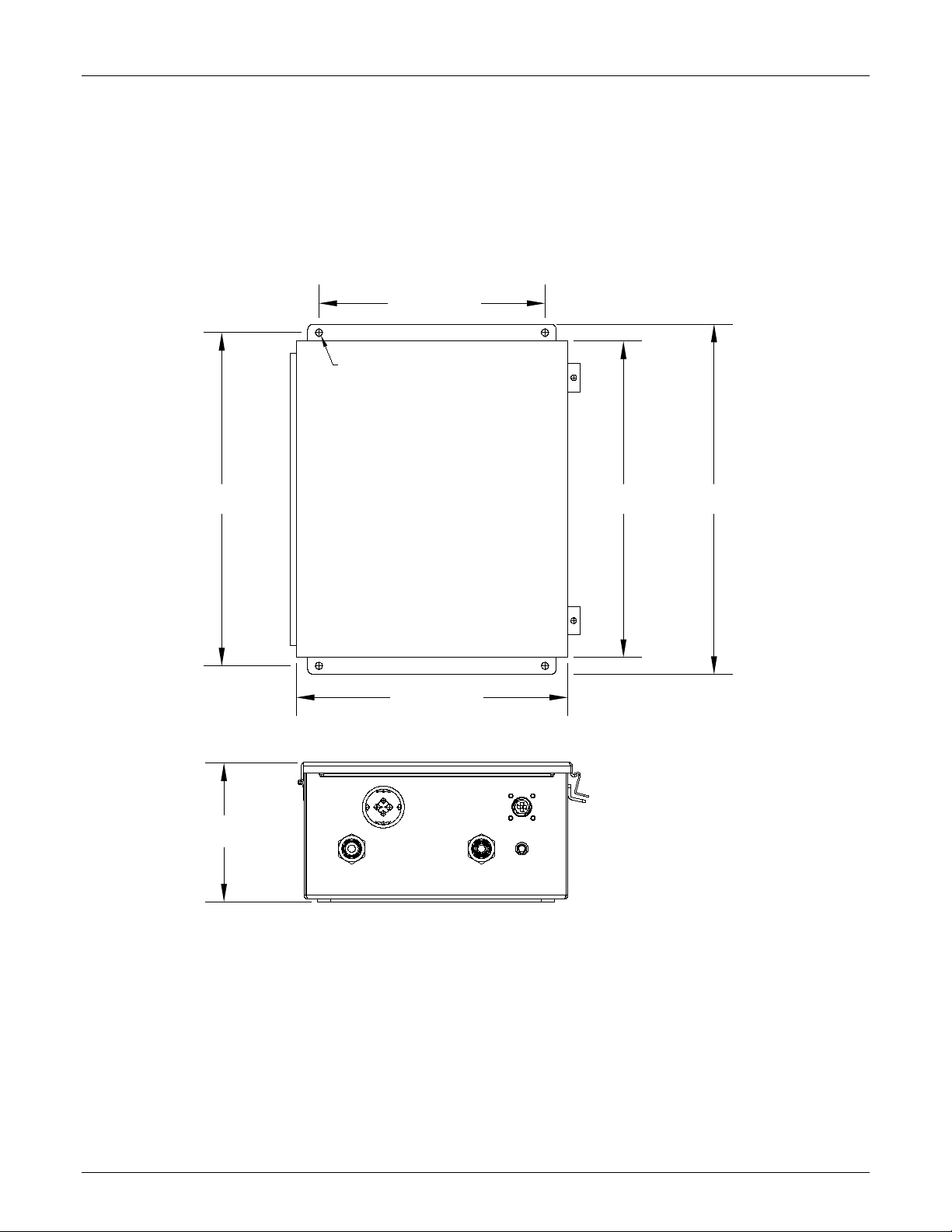

12.4" [315]

12.0" [305]

13.7" [348]

10.9" [277]

7.0" [178]

(4) Ø .300 [7.6]

Manual Gas Console (MGC) Specifications

Part Number .................................................... 300600

Weight .............................................................. 50 lb (23 kg)

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-5

Page 18

Section 2: Specifications Spirit II User’s Manual

Gas Supply Requirements

Plasma gas types:

Mild Steel ..................................................... Oxygen

Stainless Steel ............................................ Air or H17

Aluminum .................................................... Air

Shield gas types:

Mild Steel ..................................................... Oxygen or Air

Stainless Steel ............................................. Air or Nitrogen

Aluminum .................................................... Nitrogen

Preflow gas type ............................................... Oxygen and Nitrogen

Marking gas type............................................... Nitrogen

Plasma gas flow rate (maximum):

Oxygen or Air ............................................... 67 scfh (1897 liters/hour)

H17 .............................................................. 75 scfh (2124 liters/hour)

Shield gas flow rate (maximum):

Oxygen ........................................................ 19 scfh (538 liters/hour)

Air or Nitrogen ............................................. 225 scfh (6371 liters/hour)

Preflow gas flow rate (maximum) ...................... 60 scfh (1699 liters/hour)

Marking gas flow rate (maximum) ..................... 67 scfh (1897 liters/hour)

Rated Inlet gas pressure ................................... 115 psi (7.9 bar)

Minimum Inlet gas pressure .............................. 110 psi (7.6 bar)

Maximum Inlet gas pressure ............................. 145 psi (10.0 bar)

Oxygen and nitrogen should be supplied with a purity of at least 99.5%.

H17 should be supplied with a purity of at least 99.995%.

A potential fire hazard exists when cutting with oxygen. KALIBURN recommends

that an exhaust ventilation system be used when cutting with oxygen. Flashback

arrestors must be supplied (unless they are not available for the chosen gases

and pressures) to prevent a possible fire from propagating back to the gas

supplies.

Ensure that oxygen lines remain free from contaminants such as oil and grease. The

mixture of such contaminants with oxygen presents an additional fire hazard.

Compressed air must be clean, dry, and oil-free and may be supplied from compressed

cylinders or from an air compressor. Be aware that shop air systems are prone to oil

and moisture contamination. If shop air is used, it must be cleaned to ISO 8573.1:

Class 1.4.1. Specify dry air when using compressed cylinders. Breathing quality air

contains moisture and must not be used.

3/8” (inside diameter) hoses are required for all inlet gas connections. Mating

connectors are supplied with the unit. Quick-connect fittings must not be used.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-6

Page 19

Spirit II User’s Manual Section 2: Specifications

12.75" [324]

8.00" [203]

12.00" [305]

13.50" [343]

10.00" [254]

5.35" [136]

(4) Ø.312 [8]

Impulse Start Console (ISC) Specifications

Part Number ..................................................... 300500

Weight .............................................................. 22 lb (10 kg)

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-7

Page 20

Section 2: Specifications Spirit II User’s Manual

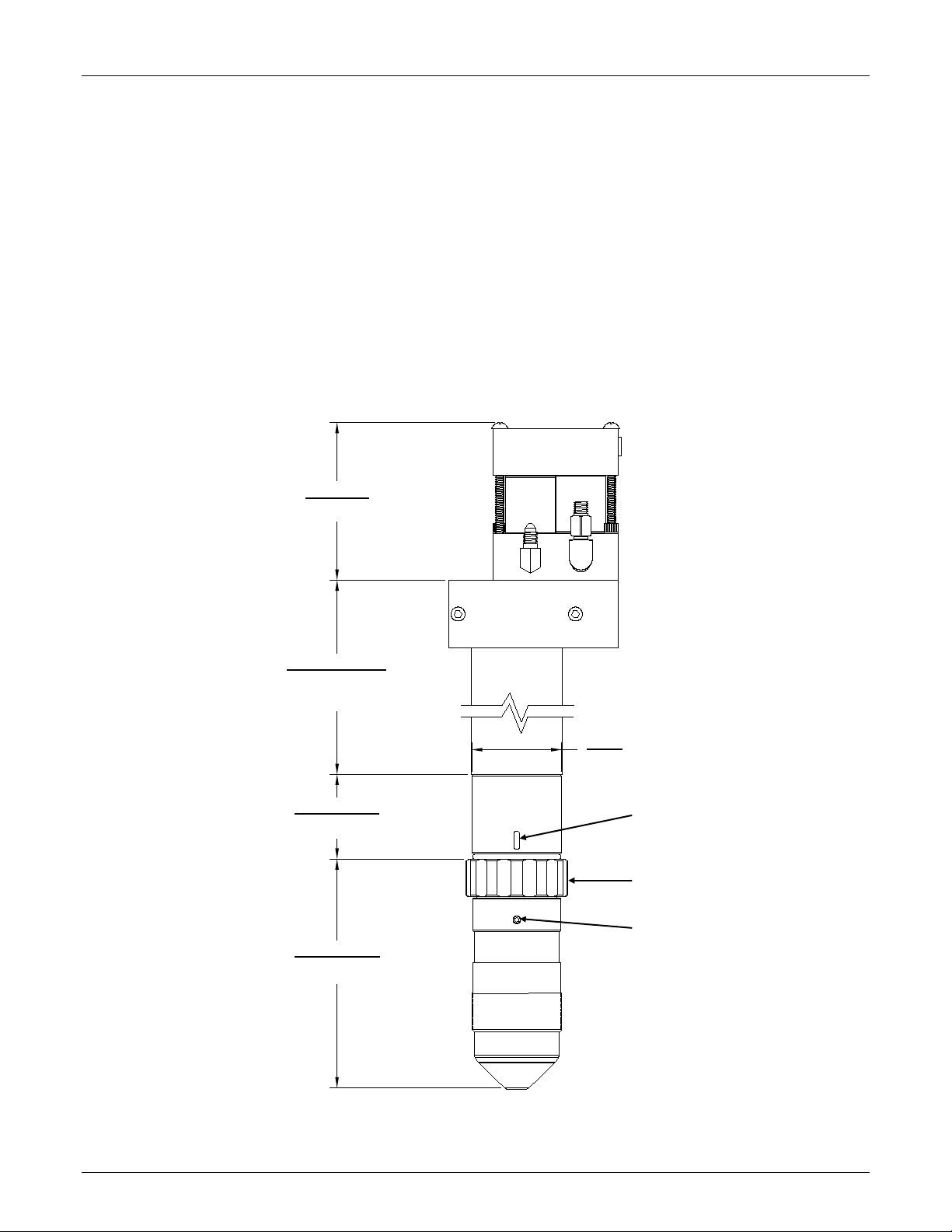

Torch Head

Torch Base

Torch Handle

1.99"

Alignment Indicator

Attachment Ring

Manifold

Torch and 2-Gang Manifold Specifications

Part Number:

2-Gang Manifold Assembly .................................................. 284214

Torch Handle (standard) ...................................................... 278001

Torch Handle (short) ............................................................ 278018

Torch Base........................................................................... 279000

Torch Head (Copper Electrode) ........................................... 279100

Torch Head (Silver Electrode) .............................................. 279060

Max Weight:

Manifold/Bracket, Handle (278001), Base and Head ........... 8.3 lbs (3.8 kg)

3.38" [86]

278001 = 9.46" [240]

278018 = 7.06" [179]

[51]

1.87" [47]

5.08" [129]

(Slot)

Alignment Indicator

(Circle)

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-8

Page 21

Spirit II User’s Manual Section 2: Specifications

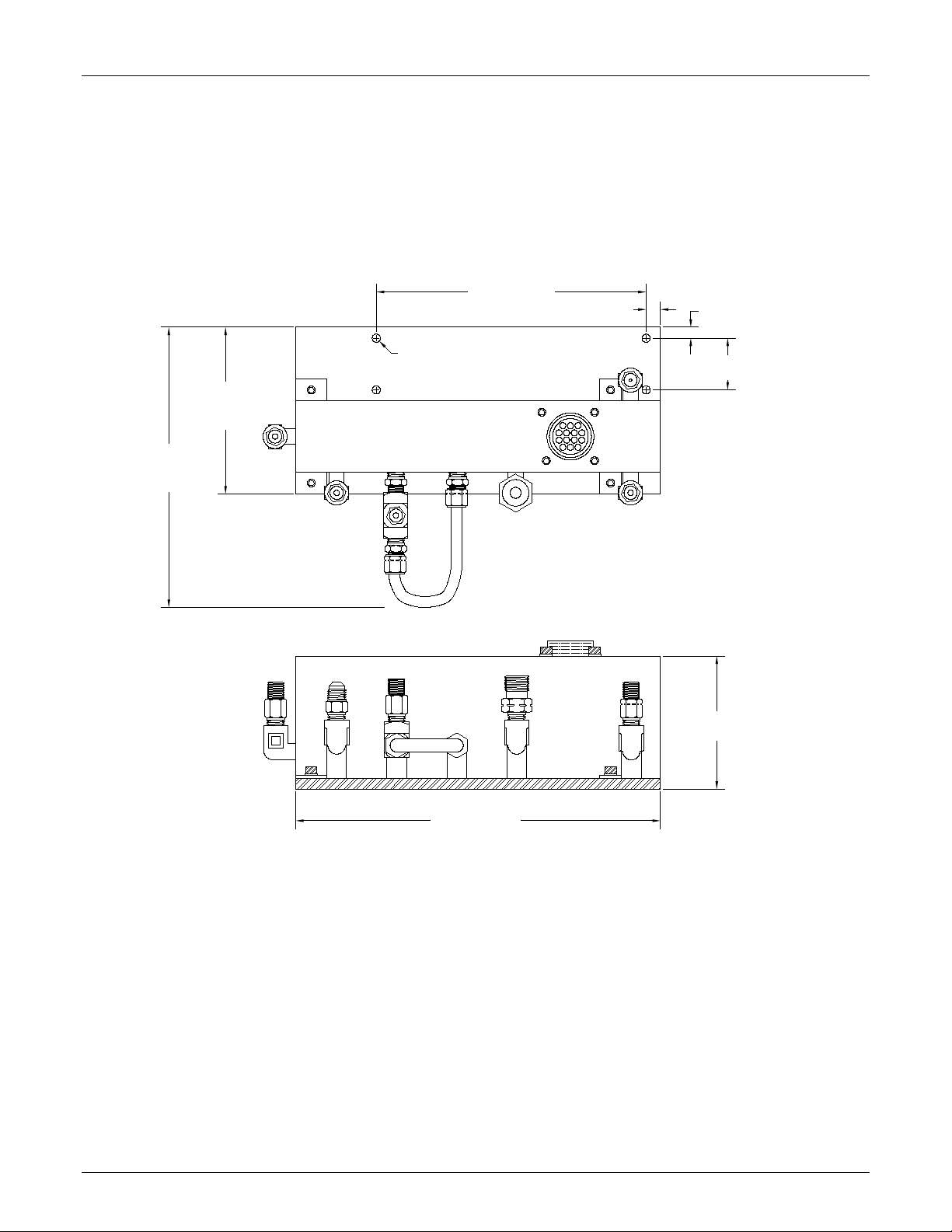

4.20"

6.18" [157]

0.327" [8.3]

0.25" [6.4]

1.18" [30]

3.035" [77]

(4) 0.187" [4.8] Mounting Holes

5-Gang Manifold Specifications

Part Number .................................................... 280022

Weight .............................................................. 6 lb (2.7 kg)

3.80"

[97]

[107]

8.35" [212]

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-9

Page 22

Section 2: Specifications Spirit II User’s Manual

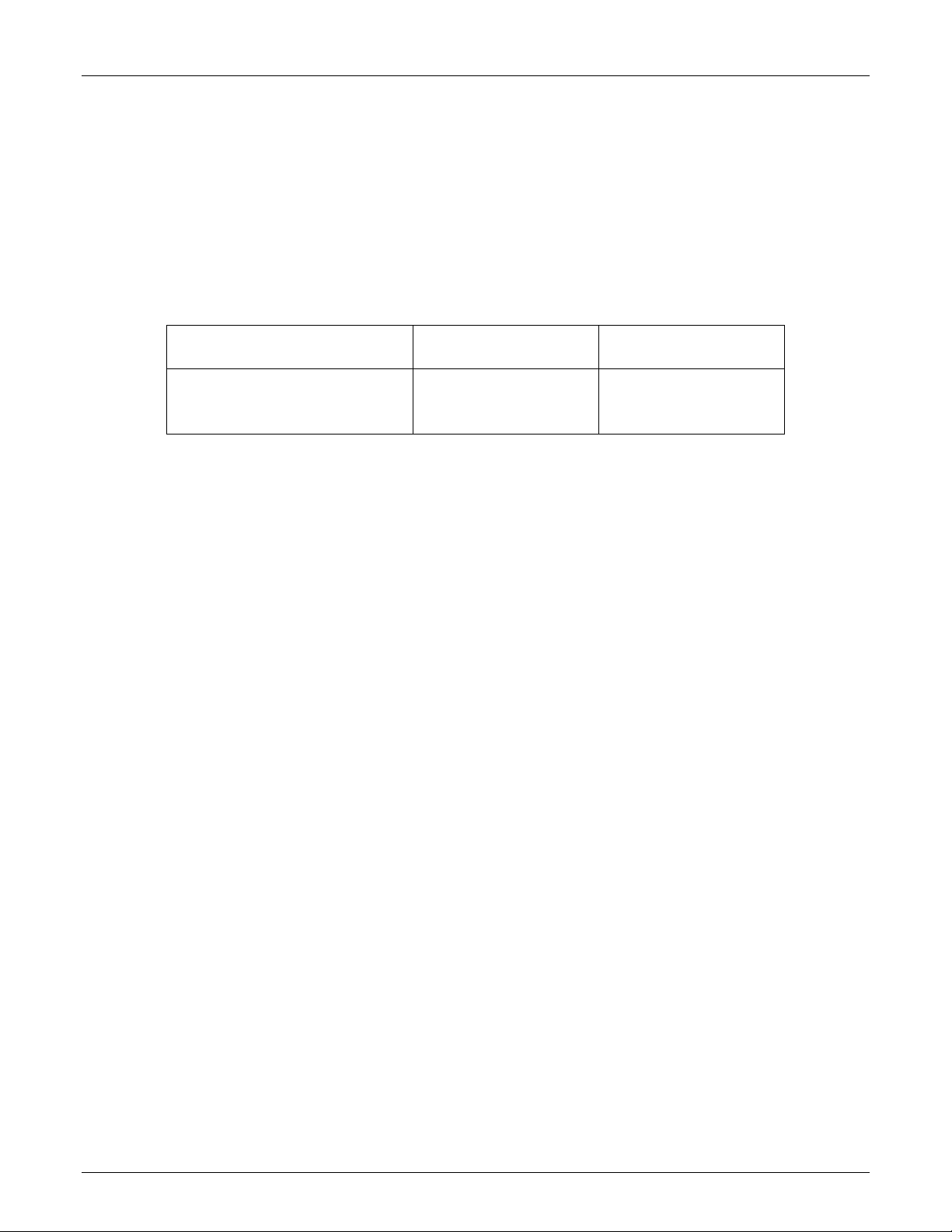

A-Weighted Sound

Pressure Level

C-Weighted Sound

Pressure Level

1 meter horizontal / 1.6

workpiece

Airborne Noise Emissions

The system generates high noise levels while cutting. Depending on the size of the

cutting area, distance from the cutting torch, and arc current cutting level, acceptable

noise levels may be exceeded. Proper ear protection should be used as defined by

local or national codes. The following chart gives the noise levels generated by the

system when operating at 150 amps, 130 arc volts. The measurements were made

with a sound level meter.

Distance From Torch

meters above the

97 dB 94 dB

The maximum noise level is 121 dB at a distance of 3 inches (76.2 mm) from the torch

while cutting at 150 amps, 130 arc volts.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

2-10

Page 23

Spirit II User’s Manual Section 3: Installation

Section 3: Installation

Initial Inspection

All systems undergo full testing before being shipped from Kaliburn. In the unlikely

event that one of the components is defective or missing, please contact Kaliburn so a

replacement item can be sent. Also, Kaliburn has taken special care in packaging the

system. If the system was damaged during shipment, file a claim with the shipping

company, and then contact Kaliburn to order replacement parts.

Component Placement

Plasma Power Supply

The power supply should be lifted by a forklift or pallet jack. In order to prevent

damaging the power supply, the forks should be of adequate length to protrude on the

far side of the power supply. The proper location of the power supply will provide

dependable service and reduce periodic maintenance time. Choose a location that will

provide unrestricted air movement into and out of the power supply. Maintain at least

24 inches of space on all sides of the unit. The location should subject the power

supply to the least amount of dust, dirt, moisture, and corrosive vapors. The surface on

which the power supply is located should have a grade of no greater than 10º to

eliminate the risk of toppling over. The power supply must be cleaned as often as

necessary to prevent the accumulation of metallic dust inside the unit. See Section 2

for unit dimensions.

Manual Gas Console (MGC)

The MGC should be mounted near the CNC controller so that it is easy accessible by

the operator. See Section 2 for mounting dimensions.

Impulse Start Console (ISC)

The ISC should be mounted in a convenient location that is away from other electronic

control devices. The ISC offers significantly reduced emissions compared to traditional

high frequency, however, the high voltage pulse generated inside the unit may interfere

with the operation of sensitive control electronics. The ISC is usually mounted on the

gantry of the cutting machine or on the cutting table. See Section 2 for mounting

dimensions.

5-Gang Manifold

The 5-gang manifold assembly must be mounted within 6 feet (1.8 m) of the torch. See

Section 2 for mounting dimensions.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-1

Page 24

Section 3: Installation Spirit II User’s Manual

2-Gang Manifold

The 2-gang manifold assembly must be mounted to the torch. See Section 2 for

mounting dimensions.

Torch

The torch must be installed on the positioner of an arc voltage control (height control)

capable of maintaining the cutting arc voltage within 1 arc volt. The arc voltage must be

adjustable in 1 arc volt increments. The positioner must be rigid to ensure cut quality

and a torch collision sensor is highly recommended. See Section 2 for mounting

dimensions.

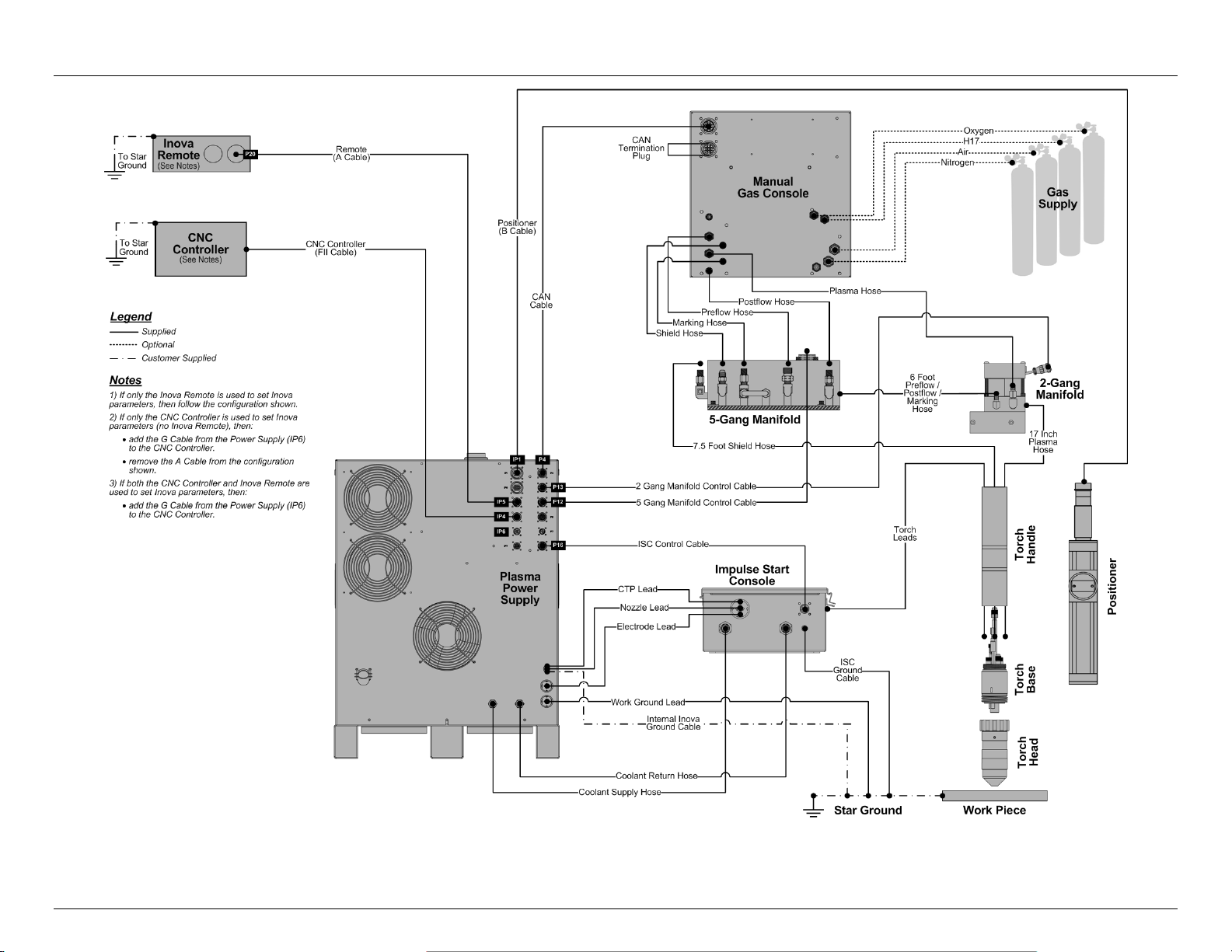

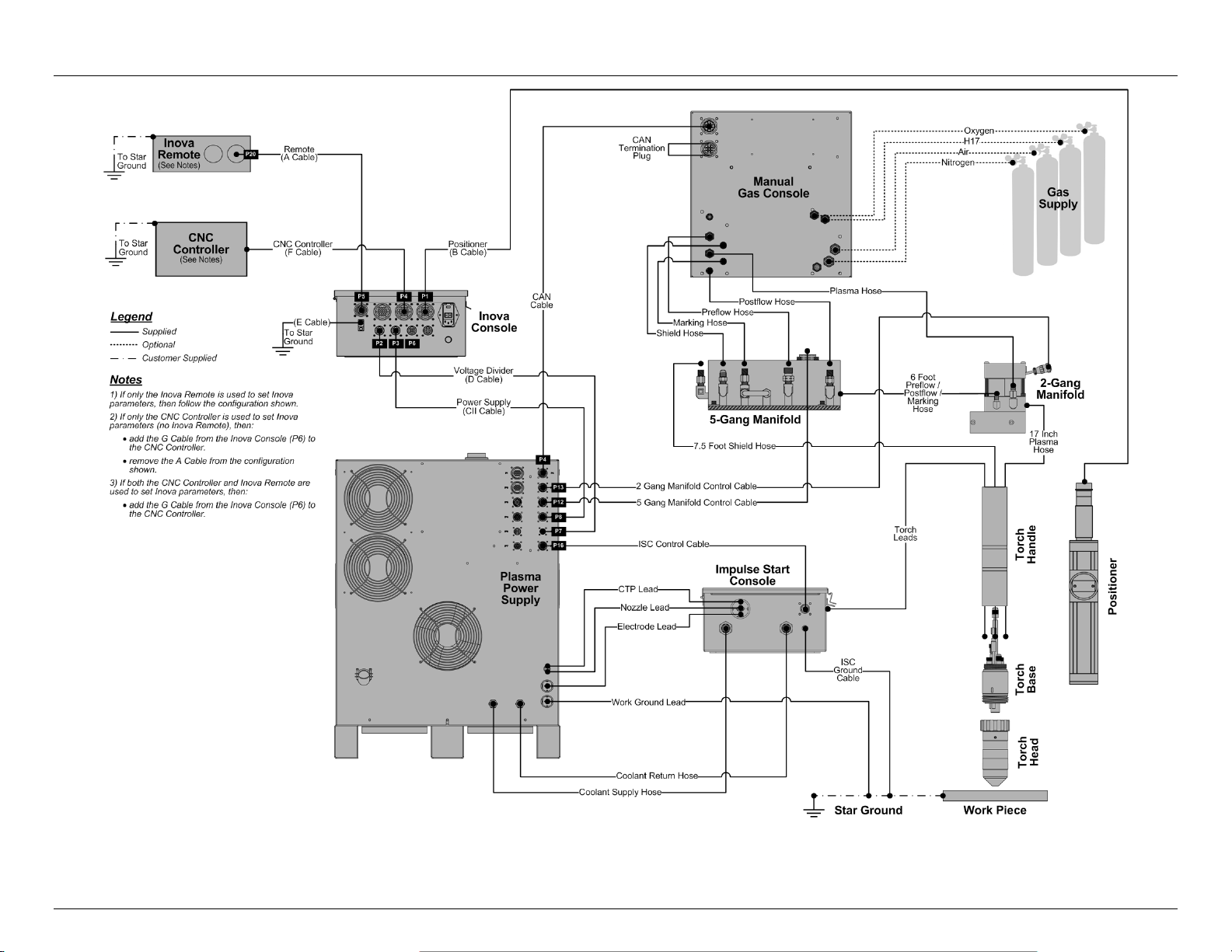

System Interconnection

The Spirit II system interconnection diagrams on the following pages will assist in the

planning and installation of the system as well as identifying cables and hoses upon

receipt.

The optional Inova torch height control is also shown to assist with its connections,

whether as an external console or internal to the plasma power supply.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-2

Page 25

Spirit II User’s Manual Section 3: Installation

Figure 1: Spirit II System with Manual Gas Console and Internal Inova System

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-3

Page 26

Section 3: Installation Spirit II User’s Manual

Figure 2: Spirit II System with Manual Gas Console and External Inova System

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-4

Page 27

Spirit II User’s Manual Section 3: Installation

Input Current at

Output (amps)

Recommended

Size (amps)

208 VAC, 60Hz

99

125

220 VAC, 60Hz

94

125

240 VAC, 60Hz

86

110

380 VAC, 50/60Hz

54

65

400 VAC, 50/60Hz

52

65

415 VAC, 50/60Hz

50

60

440 VAC, 50/60Hz

47

60

480 VAC, 60Hz

43

60

600 VAC, 60Hz

34

45

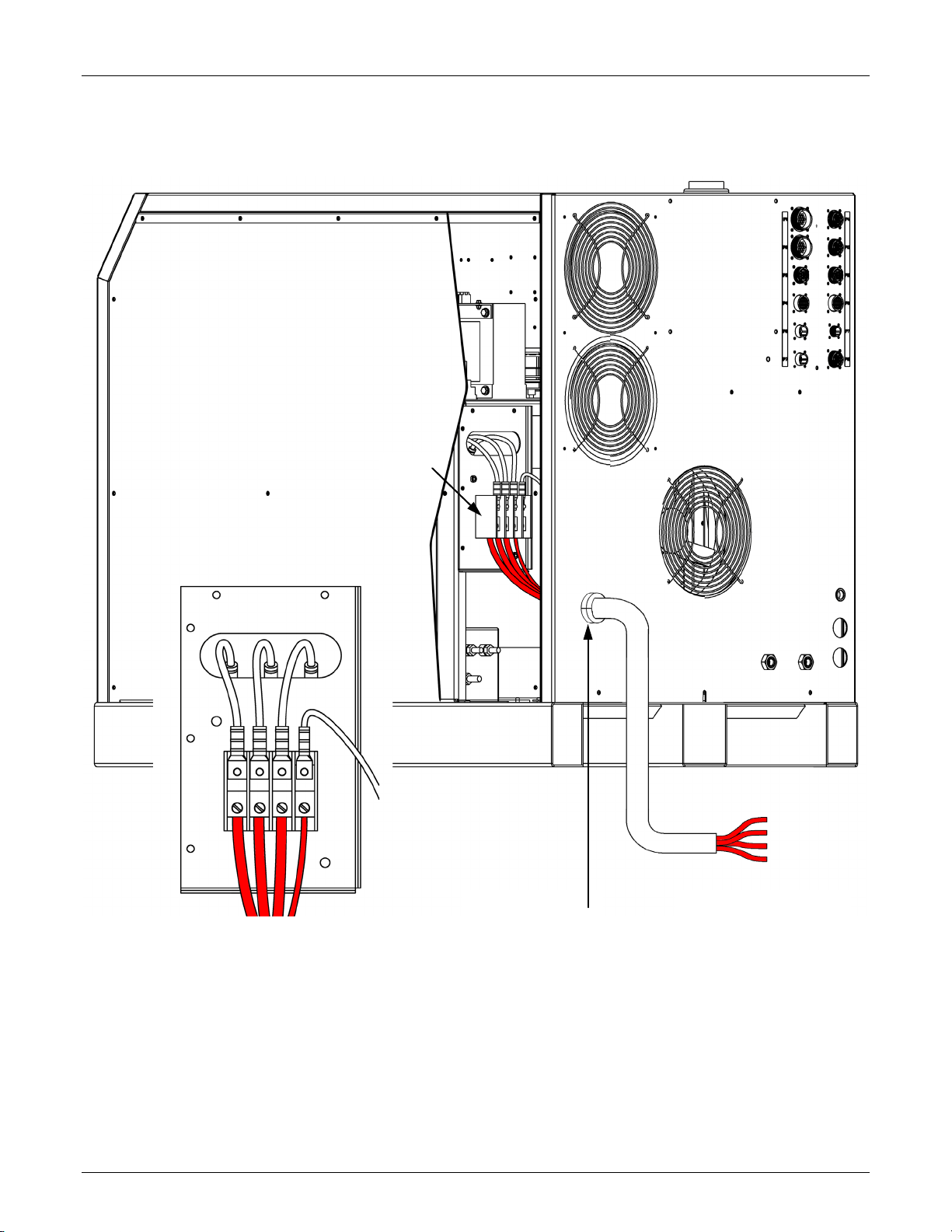

Power Supply Primary Power Connections

** Before connecting primary power, check the data plate

on the power supply to verify the voltage required **

A primary disconnect switch, switching all ungrounded supply conductors, should be

provided for each Spirit system. The disconnect switch should be located as close as

possible to the power supply so it can be turned off quickly in case of an emergency.

The disconnect switch should be equipped with time delay fuses only. The

magnetic inrush current of the power supply will cause fast acting fuses to blow. The

disconnect switch should be sized according to local and national codes. The rating

must meet or exceed the continuous rating of the fuses used. See the following chart

for recommended fuse sizes:

3 Phase

Input Voltage (VAC)

Maximum

Time-Delay Fuse

Connection to the supply circuit can be by means of flexible supply cables or supply

cables through conduit to a permanent installation. The supply cables should have a

600 volt minimum rating and should be sized according to local and national codes.

Route flexible supply cables through the strain relief on the back of the power supply

and connect to the input terminal block TB5 as shown. For supply cables through

conduit, install the conduit in place of the strain relief and connect the associated supply

cables to the input terminal block TB5. See Figure 3 on the next page.

TB5 is located on the rear of the power supply and is accessible with the right-side

cover removed. Be sure to connect the primary ground cable to the ground stud

on the input terminal block.

Under no circumstances are the supply cables to be routed through the opening in the

power supply cabinet without conduit or an appropriate strain relief as per local and

national codes.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-5

Page 28

Section 3: Installation Spirit II User’s Manual

Strain Relief

Disconnect Box

TB5 Connections

L1 (U)

TB5

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

L1 L2 L3 Gnd

Figure 3: Power Supply Primary Connections

L2 (V)

L3 (W)

Ground

Connections

3-6

Page 29

Spirit II User’s Manual Section 3: Installation

2

1 3 4

Power Supply Output Connections

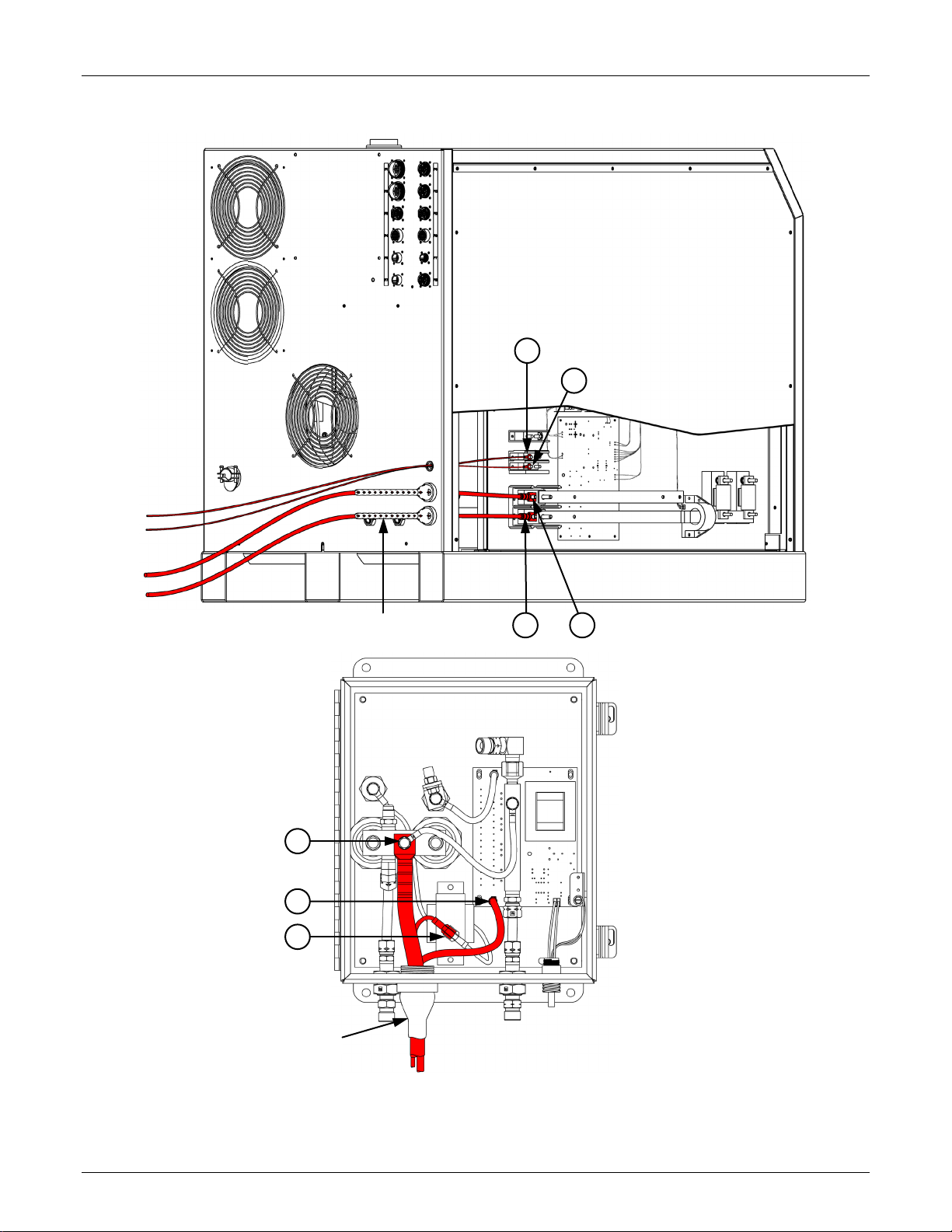

Perform the following steps to connect the output of the power supply to the impulse

start console and the work table. See Figure 4 on the next page.

Power Supply Electrode Lead

1. Route one end of the #1/0AWG power supply electrode lead through the upper

strain relief on the rear of the power supply and connect it to the electrode terminal.

2. Route the other end of the power supply electrode lead through the strain relief on

the impulse start console and connect it to the cathode manifold.

Power Supply Nozzle Lead

1. Route the larger ring terminal end of the #10AWG power supply nozzle lead through

the bushing on the rear of the power supply and connect it to the nozzle terminal.

2. Route the smaller ring terminal end of the power supply nozzle lead through the

strain relief on the impulse start console and connect it to the pilot terminal on the

printed circuit board.

Power Supply CTP Sensor Lead

1. Route the ring terminal end of the #14AWG power supply CTP sensor lead through

the bushing on the rear of the power supply and connect it to the CTP terminal.

2. Route the FASTON end of the power supply CTP sensor lead through the strain

relief on the impulse start console and connect it to the CTP sensor lead with

FASTON connector.

Work Ground Lead

1. Route one end of the #1/0AWG work ground lead through the bottom strain relief on

the rear of the power supply and connect it to the work terminal.

2. Connect the other end of the work ground lead to the star ground point on the cutting

table.

The star ground point is generally referred to as the common ground point on the

cutting table where all subsystems of the machine are grounded. This point is then

connected to a driven earth ground rod that should be as close as possible to the

star ground. The ground rod should have no other wires connected to it. The

ground rod should be at least 3/4 inches in diameter and should be driven into the

earth’s permanent moisture layer. The length of the ground rod varies from

installation to installation and should be installed according to local and national

codes. Refer to the National Electrical Code, Article 250, Section H, Ground

Electrode System for additional information.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-7

Page 30

Section 3: Installation Spirit II User’s Manual

4 1 3

2

Strain Relief

1

2

3

Strain Relief

Figure 4: Power Supply Output Connections

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-8

Page 31

Spirit II User’s Manual Section 3: Installation

5 6 7

8

ISC Control Cable and ISC Ground Connections

Perform the following steps to connect the ISC control cable and ISC ground. See

Figure 5 on the next page.

ISC Control Cable

1. Connect the ISC control cable plug labeled P16 to the connector labeled P16 on the

rear of the power supply.

2. Connect the ISC control cable plug labeled P1 to the connector labeled P1 on the

impulse start console.

ISC Ground Cable

1. Connect one end of the ISC ground cable to the ground stud on the impulse start

console.

2. Connect the other end of the ISC ground cable to the star ground on the cutting

table. Make sure that good metal-to-metal contact is made.

Cooling System Connections

Perform the following steps to connect the cooling system to the impulse start console.

See Figure 5 on the next page.

Coolant Supply Hose

1. Connect one end of the coolant supply hose to the coolant out fitting on the rear of

the power supply. Note that the coolant out fitting has right hand threads.

2. Connect the other end of the coolant supply hose to the coolant in fitting on the

impulse start console. Note that the coolant in fitting has right hand threads.

Coolant Return Hose

1. Connect one end of the coolant return hose to the coolant in fitting on the rear of the

power supply. Note that the coolant in fitting has left hand threads.

2. Connect the other end of the coolant return hose to the coolant out fitting on the

impulse start console. Note that the coolant out fitting has left hand threads.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-9

Page 32

Section 3: Installation Spirit II User’s Manual

Figure 5: Cooling System Connections

6 5 7 8 7

8

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-10

Page 33

Spirit II User’s Manual Section 3: Installation

11

12

13

14

15

Torch Leads to Impulse Start Console Connections

Perform the following steps to connect the torch leads to the impulse start console.

See Figure 6 on the next page.

Note: When making hose connections, only tighten the brass fittings enough to

make water or gas seals. The fittings are subject to damage if over tightened.

Braided Shield

1. Remove the threaded ring from the brass shield connector on the end of the braided

shield. Route the torch leads through the opening in the impulse start console and

push the shield connector through the hole until it is seated against the side of the

console.

2. Slide the threaded ring over the torch leads, thread it onto the brass shield

connector, and tighten firmly. The shield connector should ground the braided

shield to the case of the impulse start console in order to help reduce high frequency

noise emission. Using an ohmmeter, measure for zero ohms between the braided

shield and the ground stud located on the outside of the impulse start console.

Torch Electrode/Coolant Supply Lead

• Connect the torch electrode/coolant supply lead to the brass cathode manifold. Note

that the torch electrode/coolant supply lead has right hand threads.

Torch Coolant Return Lead

• Connect the torch coolant return lead to the brass cathode manifold. Note that the

torch coolant return lead has left hand threads.

Torch Nozzle Lead

• Connect the torch nozzle lead to the angled bracket on the red standoff. Note that

the torch nozzle lead has right hand threads.

Torch CTP Sensor Lead

• Connect the #18AWG torch CTP sensor lead to the red standoff as shown.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-11

Page 34

Section 3: Installation Spirit II User’s Manual

15

13

14

12

11

Figure 6: Torch Leads to Impulse Start Console Connections

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-12

Page 35

Spirit II User’s Manual Section 3: Installation

18

19

18

19

17

16

17

16

16

17

18

19

Torch Leads to Torch Base Connections

Perform the following steps to connect the torch leads to the torch base.

Note: When making hose connections, only tighten the brass fittings

enough to make water or gas seals. The fittings are subject to damage if

over tightened. Also, use two wrenches when tightening the torch fittings

to avoid damaging the torch base.

Torch Lead through Torch Handle Installation

1. Route the torch leads through the torch handle. Note that the threaded end of

the torch handle mates with the torch base.

Torch Electrode/Coolant Supply Lead

• Connect the torch electrode/coolant supply lead to the torch base as shown.

Torch Coolant Return Lead

• Connect the torch coolant return lead to the torch base as shown. Note that

the torch coolant return lead fitting has left hand threads.

Torch Nozzle Lead

• Connect the torch nozzle lead to the torch base as shown.

Torch CTP Sensor Lead

• Connect the torch CTP sensor lead to the torch base as shown.

Figure 7: Torch Leads to Torch Base Connections

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-13

Page 36

Section 3: Installation Spirit II User’s Manual

20

21

22

23

Torch Gas Connections

Perform the following steps to connect the torch gas hoses to the manual gas

console, torch base, and manifold assemblies. See figure 8.

Note: When making hose connections, only tighten the brass fittings

enough to make gas seals. The fittings are subject to damage if over

tightened.

7.5 Foot Shield Gas Hose

1. Route one end of the 7.5 foot (2.3 m) shield gas hose through the torch

handle and connect to the shield gas fitting on the torch base.

2. Connect the other end of the 7.5 foot (2.3 m) shield gas hose to the shield

gas outlet on the 5-gang manifold.

17 Inch Plasma Gas Hose

1. Route one end of the 17 inch (432 mm) plasma gas hose through the torch

handle and connect to the plasma gas fitting on the torch base.

2. Thread the torch handle onto the torch base, being careful not to twist the

torch leads and gas hoses when tightening the torch handle.

3. Tighten the base to the handle using a pin style adjustable spanner wrench

(fits 2" diameter with ¼" diameter pin).

4. Attach the 2-gang manifold assembly to the torch handle. The top of the

manifold bracket should be flush with the top of the torch handle.

5. Connect the other end of the 14 inch (432 mm) plasma gas hose to the

plasma gas outlet on the 2-gang manifold.

6. Mount the torch handle/base/manifold to the positioner. Note the alignment

indicators on the torch base (slot) and torch head (circle). These aid in

aligning the quick-disconnect torch base and head and should be oriented so

they are clearly visible when the operator is changing heads.

6 Foot Preflow/Postflow/Marking Gas Hose

1. Connect one end of the 6 foot (1.8 m) preflow/postflow/marking gas hose to

the preflow/postflow/marking outlet on the 5-gang manifold.

2. Connect the other end of the 6 foot (1.8 m) preflow/postflow/marking gas

hose to the preflow/postflow/marking inlet on the 2-gang manifold.

Marking Gas Hose

1. Connect one end of the marking shield gas hose to the marking shield outlet

on the rear of the MGC.

2. Connect the other end of the marking shield gas hose to the marking shield

inlet on the 5-gang manifold.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-14

Page 37

Spirit II User’s Manual Section 3: Installation

25

26

27

28

29

30

Postflow Gas Hose

1. Connect one end of the postflow hose to the postflow outlet on the rear of the

MGC. Note that the postflow hose fittings have left hand threads.

2. Connect the other end of the postflow hose to the postflow inlet on the 5-gang

manifold.

Plasma Gas Hose

1. Connect on end of the plasma hose to the plasma outlet on the rear of the

MGC.

2. Connect the other end of the plasma hose to the plasma inlet on the 2-gang

manifold.

Shield Gas Hose

1. Connect one end of the shield hose to the shield outlet on the rear of the

MGC.

2. Connect the other end of the shield hose to the shield inlet on the 5-gang

manifold.

Preflow Gas Hose

1. Connect one end of the preflow hose to the preflow outlet on the rear of the

MGC. Note that the preflow hose fittings have left hand threads.

2. Connect the other end of the preflow hose to the preflow inlet on the 5-gang

manifold.

5-Gang Manifold Control Cable

1. Connect the 5-gang manifold control cable plug marked P15 to the 5-gang

manifold as shown.

2. Connect the 5-gang manifold control cable plug labeled P12 to the connector

labeled P12 on the rear of the power supply.

2-Gang Manifold Control Cable

1. Connect the 2-gang manifold control cable plug marked P18 to the 2-gang

manifold as shown.

2. Connect the 2-gang manifold control cable plug labeled P13 to the connector

labeled P13 on the rear of the power supply.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-15

Page 38

Section 3: Installation Spirit II User’s Manual

Manual Gas

25

22

26

27

23

25

22

21

30

GREEN

REAR

REAR

BLUE

27

21

20

28

26

20

28

29

23

BLUE

GREEN

RED

Console

RED

Figure 8: Torch Gas Connections

PORT

PORT

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-16

Page 39

Spirit II User’s Manual Section 3: Installation

32

34

31

33

31

32

33

34

Gas Supply Connections

Perform the following steps to connect the gas supply lines to the MGC. See Section 2

for gas supply requirements. Mating hose barbs and connectors are supplied with the

system and are sized for 3/8 inch inside diameter hose. Do not change the inlet gas

supply fittings to quick-connect fittings. Using quick-connect fittings to connect

and disconnect pressurized hoses may cause damage to the system.

Note: When making hose connections, only tighten the brass fittings enough to

make gas seals. The fittings are subject to damage if over tightened.

Air Inlet (ISO 3821 hose color - black)

• Air must be supplied to the unit at all times, regardless of the cutting current or

material type.

Oxygen Inlet (ISO 3821 hose color - blue)

• Oxygen must be supplied to the unit at all times, unless stainless steel is being cut

with H17 plasma.

Nitrogen Inlet (ISO 3821 hose color - black)

• Nitrogen must be supplied to the unit at all times, regardless of the cutting current or

material type.

H17 Inlet (ISO 3821 hose color - red)

• H17 must be supplied to the unit when stainless steel is being cut with H17 as the

plasma gas. See cutting charts in Section 5 for more information.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-17

Page 40

Section 3: Installation Spirit II User’s Manual

35

36

35

35

36

CAN Communication Connections

Perform the following steps to connect the plasma power supply to the MGC.

CAN Cable

• Connect the male end of the CAN cable to the connector labeled P4 on the rear of

the plasma power supply.

• Connect the female end of the CAN cable to the top connector on the rear of the

MGC.

CAN Termination Plug

• If not already installed, connect the CAN termination plug to the bottom connector on

the rear of the MGC.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-18

Page 41

Spirit II User’s Manual Section 3: Installation

CNC Machine Interface Connections

Perform the following steps to properly interface the Spirit system with a CNC cutting

machine. See the system schematic for additional information.

Plasma Start Input

The power supply requires a contact closure between P8 pins 3 and 4 to commence the

cutting or marking sequence. The sequence is terminated when the contacts are

opened. The contacts should be rated for 24VDC - 7.3mA.

Plasma Cut/Mark Input

The power supply requires a contact closure between P8 pins 1 and 2 to put the system

in plasma marking mode. Opening the contacts puts the system in cutting mode. The

operating mode should be selected prior to applying a start signal. The contacts should

be rated for 24VDC - 7.3mA.

Arc Hold Input

The power supply requires a contact closure between P8 pins 10 and 11 to inhibit arc

starting even though a plasma start signal has been applied to the unit. When the

contacts are opened, the arc is initiated. This feature is used to decrease cycle time by

allowing pre-cut gas and contact sequencing to occur simultaneously with initial torch

height positioning. The contacts should be rated for 24VDC - 7.3mA.

Motion Output

The power supply provides a maintained contact closure output between P8 pins 12

and 14 as long as an arc is maintained between the torch and the workpiece. The

motion contacts are rated for 24VDC – 10mA.

Remote On/Off Input

The power supply requires a maintained contact closure between P8 pins 5 and 6 to

energize the system from a remote location, provided that the OFF Button on the

manual gas console is released. Opening the contacts deenergizes the system. If the

remote on/off feature is not used, install a jumper between terminal block TB1 positions

7 and 8. The contacts should be rated for 24VAC – 10mA.

Power Supply Ready Output

The power supply provides a maintained contact closure output between P8 pins 7 and

8 when the system is ready to cut or mark. The contacts are open during gas purge or

when an error occurs. The contacts are rated for 24VDC – 10mA.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-19

Page 42

Section 3: Installation Spirit II User’s Manual

Filling the Cooling System

WARNING: Do not touch the fans inside the power supply.

Important: Never turn on the system when the coolant reservoir is empty.

Important: When handling coolant, wear nitrile gloves and safety glasses.

Important: Only use Kaliburn approved coolant. Commercially available

antifreeze contains corrosion inhibitors that will damage the cooling

system. See Section 2 for more information.

1. Remove primary power from the Spirit system.

2. Ensure the torch base and torch head (with consumables) are properly installed.

3. Ensure the coolant supply (in and out) hoses are properly installed.

4. Remove the coolant reservoir cap/level gauge and then remove the top, left and

right covers from the power supply.

5. Ensure the coolant filter housing is tightened securely.

6. Ensure the drain petcock on the bottom of the reservoir is tightened securely.

7. Fill the reservoir with approximately 2 ½ gallons of approved coolant.

8. Apply primary power to the Spirit system and enable it by releasing (turn right) the

OFF Button on the MGC.

9. On the MGC main menu, move the pointer to On. Press SELECT to start the

coolant pump circulating coolant through the system. Note: The coolant pump will

turn off automatically if the coolant level drops below the minimum level inside the

reservoir. If this happens, add more coolant.

10. With the coolant pump running, locate the small red push-button on top of the

coolant filter housing (beneath the reservoir). Press and hold the red button until no

air or bubbles are seen inside the filter housing. Dry any coolant that leaks out.

11. Check for coolant leaks at all hose connections, the ISC, and at the torch.

12. Push the OFF Button on the MGC to stop the coolant pump.

13. Remove primary power from the Spirit system.

14. Fill the reservoir with coolant until the coolant gauge indicates full.

15. Replace the power supply covers and replace the coolant reservoir cap/level gauge.

16. End of procedure.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

3-20

Page 43

Spirit II User’s Manual Section 4: Operation with Manual Gas Console

OFF Button

Section 4: Operation

Operating the Manual Gas Console (MGC)

The Manual Gas Console (MGC) is the interface to the entire Spirit system when the

MGC is used instead of the Automatic Gas Console (AGC).

Push to disable the Spirit system.

Release (turn to the right) to enable

the system, which can then be

energized by choosing ON and then

SELECT.

Up/Down/Select Buttons

Press the up or down button to move

the pointer ( ) accordingly on the

display. These buttons are

represented as UP and DOWN

throughout this manual.

Press the select button to access

menu items or settings identified by

the pointer. This button is shown as

SELECT throughout this manual.

Display

The display turns on automatically

when AC power is applied to the

Spirit system. It displays the menu

tree, which is navigated using the

Up/Down/Select buttons and is used

to control the entire Spirit system.

Pressure Regulator Knobs

Turn to the left or right to adjust the

amount of output gas pressure for

PreFlow, PostFlow, Plasma and

Shield gases.

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

4-1

Page 44

Section 4: Operation with Manual Gas Console Spirit II User’s Manual

Push the OFF Button on the MGC to disable

Move the pointer to Current.

Move the pointer to Select Gas.

Move the pointer to Adjust Gas.

Move the pointer to a gas and then press

The system is now setup to cut.

Setting up to Cut

The following procedure uses the information from the cutting charts in Section 5 to

prepare the system to cut. Press the UP or DOWN button on the MGC to move the

pointer through the menu as described below.

the system. On the main menu, move the

pointer to Setup. Press SELECT.

Cutting is displayed.

Press SELECT to cycle through the list until

the desired amperage is displayed.

Press SELECT to cycle through the list until

Press SELECT.

Press SELECT to choose the Plasma gas.

Move the pointer to Shield and press SELECT

to choose the shield gas. Move the pointer to

Return and press SELECT.

Press SELECT.