Page 1

IM3028

09/2010

Rev. 0b

LINC FEED 45

OPERATOR’S MANUAL

MANUALE OPERATIVO

BEDIENUNGSANLEITUNG

MANUAL DE INSTRUCCIONES

MANUEL D'UTILISATION

BRUKSANVISNING OG DELELISTE

GEBRUIKSAANWIJZING

INSTRUKCJA OBSŁUGI

KÄYTTÖOHJE

Lincoln Electric Bester Sp. z.o.o.

ul. Jana III Sobieskiego 19A, 58-260 Bielawa, Poland

www.lincolnelectric.eu

Page 2

English EnglishI

Declaration of conformity

Lincoln Electric Bester Sp. z.o.o.

Declares that the welding machine:

LINC FEED 45

conforms to the following directives:

2006/95/CEE, 2004/108/CEE

and has been designed in compliance with the

following standards:

EN 60974-1, EN60974-5, EN 60974-10

(2009)

Paweł Lipiński

Operations Director

Lincoln Electric Bester Sp. z.o.o., ul. Jana III Sobieskiego 19A, 58-260 Bielawa, Poland

12/05

Page 3

English EnglishII

12/05

THANKS! For having choosen the QUALITY of the Lincoln Electric products.

Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………... ……………………….…………………………………………..

ENGLISH INDEX

Safety ..............................................................................................................................................................................1

Installation and Operator Instructions..............................................................................................................................2

Electromagnetic Compatibility (EMC)............................................................................................................................11

Technical Specifications................................................................................................................................................ 11

WEEE............................................................................................................................................................................11

Spare Parts....................................................................................................................................................................12

Electrical Schematic ......................................................................................................................................................12

Accessories...................................................................................................................................................................12

Page 4

English English1

Safety

11/04

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual b efore operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not respons ible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating

this equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could

cause serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from

the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before o perating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding

area and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

Page 5

English English2

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the g as an d

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

Location and Environment

This machine will operate in harsh environments.

However, it is important that simple preventative

measures are followed to assure long life and reliable

operation:

Do not place or operate this machine on a surface

with an incline greater than 15° from horizontal.

Do not use this machine for pipe thawing.

This machine must be located where there is free

circulation of clean air without restrictions for air

movement to and from the air vents. Do not cover

the machine with paper, cloth or rags when

switched on.

Dirt and dust that can be drawn into the machine

should be kept to a minimum.

This machine has a protection rating of IP23. Keep

it dry when possible and do not place it on wet

ground or in puddles.

Locate the machine away from radio controlled

machinery. Normal operation may adversely affect

the operation of nearby radio controlled machinery,

which may result in injury or equipment damage.

Read the section on electromagnetic compatibility in

this manual.

Do not operate in areas with an ambient

temperature greater than 40°C.

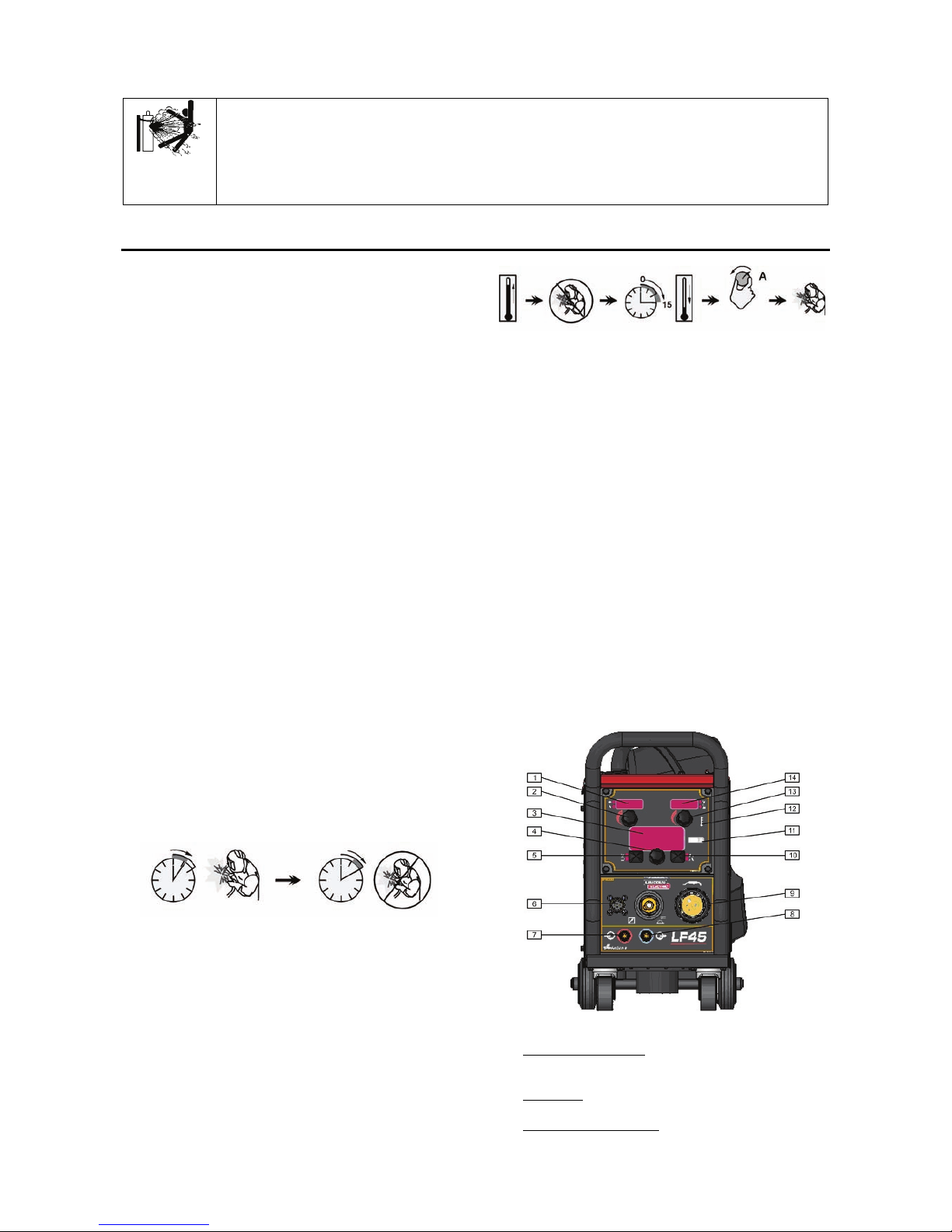

Duty cycle and Overheating

The duty cycle of a welding machine is the percentage of

time in a 10 minute cycle at which the welder can

operate the machine at rated welding current.

Example: 60% duty cycle:

Welding for 6 minutes. Break for 4 minutes.

Excessive extension of the duty cycle will cause the

thermal protection circuit to activate.

The machine is protected from overheating by a

thermostat. When the machine is overheated the output

of the machine will turn "OFF", and the Thermal Indicator

Light (on front panel of wire feeder) will turn "ON". When

the machine has cooled to a safe temperature the

Thermal Indicator light will go out and the machine may

resume normal operation. Note: For safety reasons the

machine will not come out of thermal shutdown if the

trigger on the welding gun has not been released.

Minutes or decrease

duty cycle

Input Supply Connection

Check the input voltage, phase, and frequency of the

power source that will be connected to this wire feeder.

The allowable input voltage of the power source is

indicated on the rating plate of the wire feeder. Verify

the connection of grounding wires from the power source

to the input source.

Gas Connection

A gas cylinder must be installed with a proper flow

regulator. Once a gas cylinder with a flow regulator has

been securely installed, connect the gas hose from the

regulator to the machine gas inlet connector. Refer to

point [1] of the image Figure 2. The wire feeder supports

all suitable shielding gases including carbon dio x ide,

argon and helium at a maximum pressure of 5,0 bar.

Output Connections

Refer to point [9] of the image Figure 1.

Controls and Operational Features

Figure 1.

1. Left Display Window: Shows Wire Feed Speed or

Amperage.

2. Left Knob: Adjusts values in left display.

3. MSP4 Display Window: Shows detailed welding

and diagnostic information.

Page 6

English English3

4. Set Knob: Changes the value on the MSP4 display.

5. Left Button: Changes the MSP4 display to show the

Weld Mode or Arc Control.

6. 12-pin Connector: Connector for a remote control

and a push-pull gun.

7. Water Cooling Line: Warm water from torch.

8. Water Cooling Line: Cool water to torch.

9. EURO Connector.

10. Right Button: Changes the MSP4 display to show

Start Options or End Options.

11. Set-Up: Lights when feeder is set-up.

12. Thermal: Lights when the drive overheats.

13. Right Knob: Adjusts values in the right display.

14. Right Display Window: Shows Voltage or Trim.

Figure 2.

1. Gas Connector: Connection for gas line.

2. 5-pin Connector: ArcLink connection to power

source.

3. Fast-Mate Adapter: Input power connection.

4 - 5. Quick Connect Couplings: If water cooled

torches are used, connect water lines from

water cooler here. Refer to torch and water

cooler guidelines for recommended cooling

liquid and flow rates.

Figure 3.

1. Wire Drive: 4-Roll wire drive compatible with 37mm

drive rolls.

2. Cold Inch / Gas Purge Switch: This switch enables

wire feeding or gas flow without turning on output

voltage.

3. Wire Spool Support: Maximum 15kg spools.

Accepts plastic, steel and fiber spools onto 51mm

spindle.

WARNING

The Linc Feed wire feeders must be used with the door

completely closed during welding.

Not use handle to move the Linc Feed during work.

Loading the Electrode Wire

Open the side cover of the machine.

Unscrew the fastening cap of the sleeve.

Load the spool with the wire on the sleeve such that the

spool turns clockwise when the wire is fed into the wire

feeder.

Make sure that the spool locating pin goes into the fitting

hole on the spool.

Screw in the fastening cap of the sleeve.

Put on the wire roll using the correct groove

corresponding to the wire diameter.

Free the end of the wire and cut off the bent end making

sure it has no burr.

WARNING

Sharp end of the wire can hurt.

Rotate the wire spool clockwise and thread the end of

the wire into the wire feeder as far as the Euro socket.

Adjust force of pressure roll of the wire feeder properly.

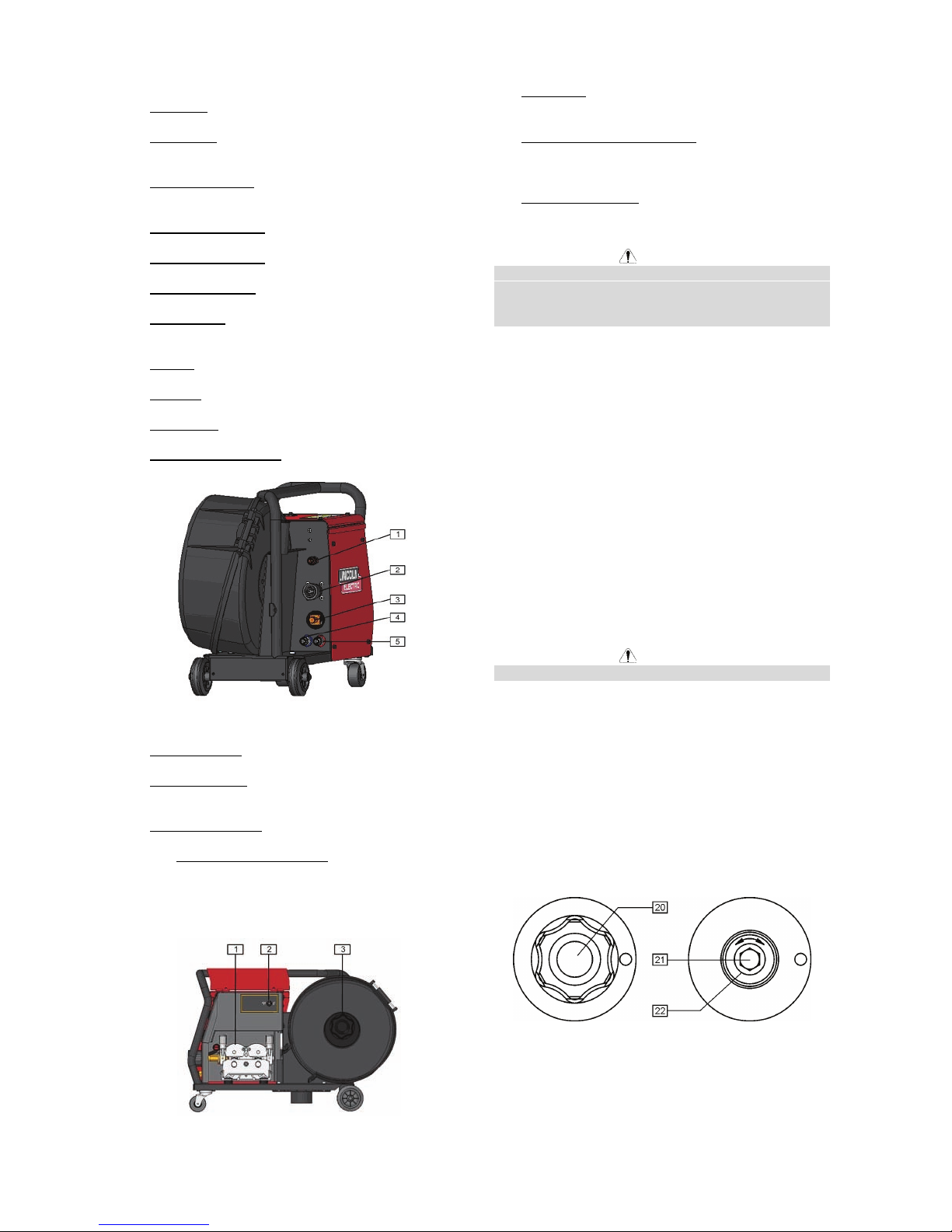

Adjustments of Brake Torque of Sleeve

To avoid spontaneous unrolling of the welding wire the

sleeve is fitted with a brake.

Adjustment is carried by rotation of its screw M10, which

is placed inside of the sleeve frame after unscrewing the

fastening cap of the sleeve.

Figure 4.

20. Fastening cap.

21. Adjusting screw M10.

22. Pressing spring.

Turning the screw M10 clockwise increases the spring

tension and you can increase the brake torque.

Page 7

English English4

Turning the screw M10 counterclockwise decreases the

spring tension and you can decrease the brake torque.

After finishing of adjustment, you should screw in the

fastening cap again.

Adjusting of Pressure Roll Force

WARNING

ELECTRIC SHOCK can kill.

Turn the input power OFF at the welding power

source before installation or changing drive rolls

and/or guides.

Do not touch electrically live parts.

When inching with the gun trigger, electrode and

drive mechanism are "hot" to work and ground and

could remain energized several seconds after the

gun trigger is released.

Do not operate with covers, panels or guards

removed or open.

Only qualified personnel should perform

maintenance work.

Pressure force is adjusted by turning the adjustment nut

clockwise to increase force, counterclockwise to

decrease force.

The pressure arm controls the amount of force the drive

rolls exert on the wire. Proper adjustment of pressure

arm gives the best welding performance. Set the

pressure arm as follows:

Aluminum wires: between 1 and 3

Cored wires: between 3 and 4

Steel, Stainless wires: between 4 and 6

WARNING

If the roll pressure is too low the roll will slide on the wire.

If the roll pressure is set too high the wire may be

deformed, which will cause feeding problems in the

welding gun. The pressure force should be set properly.

Decrease the pressure force slowly until the wire just

begins to slide on the drive roll and then increase the

force slightly by turning of the adjustment nut by one

turn.

Inserting Electrode Wire into Welding

Torch

Connect the proper welding torch to the Euro socket, the

rated parameters of the torch and of the welding source

shall match.

Remove the gas diffuser and contact tip from the

welding torch.

Switch the Cold Inch / Gas Purge switch [2] (see Figure

3.) in the position "Cold Inch" and keep in this position

until the electrode wire leaves the contact tip of the

welding torch.

Set the wire feeding speed in the position of about

10m/min by the Left Knob [2] (see Figure 1.).

WARNING

Take precaution to keep eyes and hands away from the

end of the torch while feeding wire.

WARNING

Once the wire has finished feeding through the welding

gun turn the machine “OFF“ before replacing to contact

tip and gas diffuser.

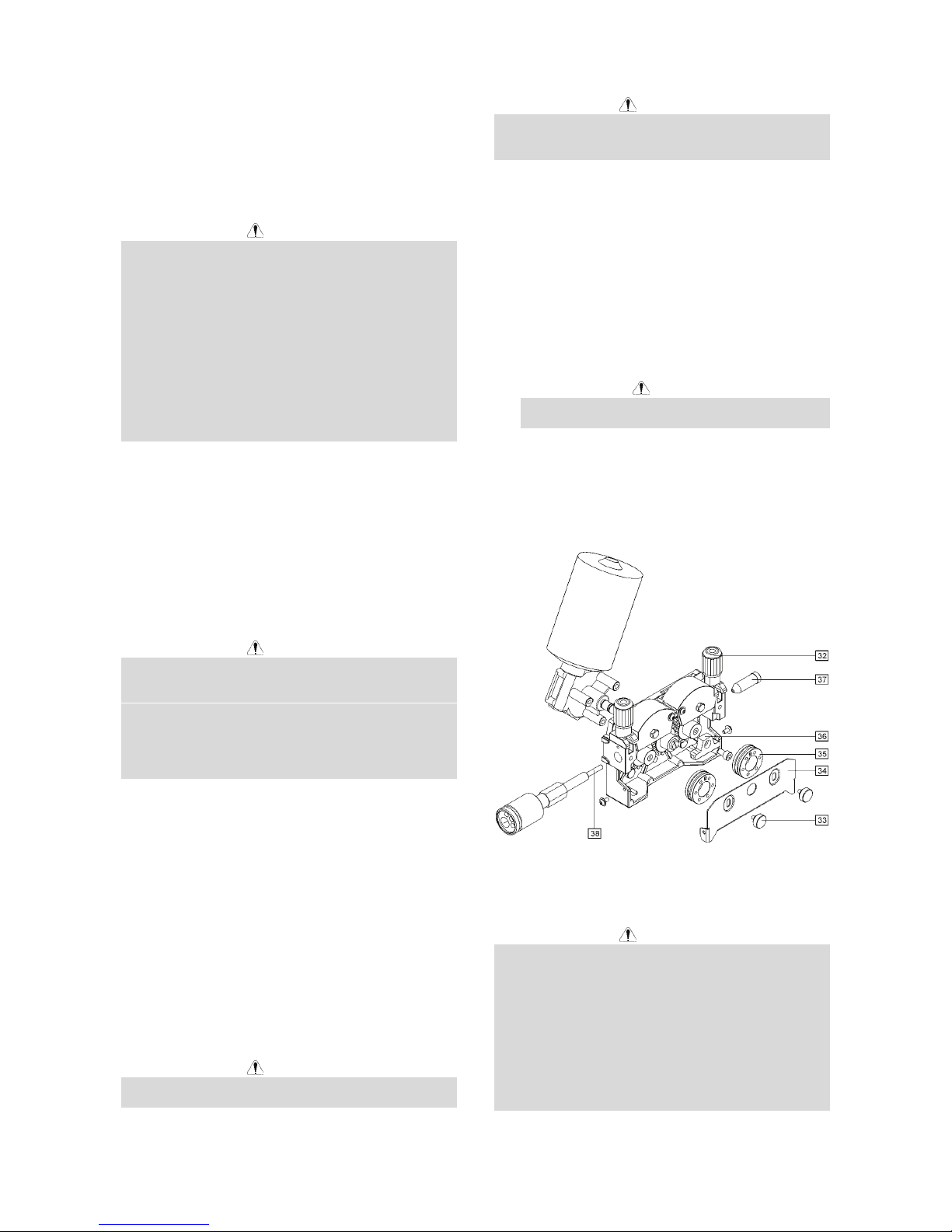

Changing Driving Rolls

The machine is equipped with drive rolls for the wire of

1.0 and 1.2mm (factory default). For others wire sizes,

is available the proper drive rolls kit (see chapter

Accessories for ordering the desired kit). Below is the

drive rolls replacement procedure:

Switch off the machine.

Release the pressure roll lever [32].

Unscrew the fastening cap [33].

Open the protection cover [34].

Change the drive rolls [35] with the compatible ones

corresponding to the used wire.

WARNING

For wires with the diameter greater than 1.6mm, the

following parts are to be changed:

The guide tube of the feeding console [36] and

[37].

The guide tube of the Euro socket [38].

Replace and tighten the protection cover [34] to the

drive rolls.

Screw the protection cover by fastening screws [33].

Figure 5.

Making A Weld With Waveform

Technology Power Sources

WARNING

The serviceability of a product or structure utilizing the

welding programs is and must be the sole responsibility

of the builder/user. Many variables beyond the control of

The Lincoln Electric Company affect the results obtained

in applying these programs. These variables include,

but are not limited to welding procedure, plate chemistr y

and temperature, weldment design, fabrication methods

and service requirements. The available range of a

welding program may not be suitable for all applications,

and the build/user is and must be solely responsible for

welding program selection.

Page 8

English English5

The steps for operating the Power Source will vary

depending upon the user interface of the welding

system. The flexibility of the Power Source lets the user

customize operation for the best performance.

First, consider the desired welding process and the

part to be welded. Choose an electrode material,

diameter, shielding gas and process (GMAW,

SMAW, etc.)

Second, find the program in the welding software

that best matches the desired welding process. The

standard software shipped with the Power Source

encompasses a wide range of common processes

and will meet most needs. All adjustments are

made on the user interface. Because of the

different configuration options your system may not

have all of the following adjustments.

Regardless of availability, all controls are described

below.

SMAW (Stick) Welding

SMAW is most often used for outdoor construction, pipe

welding and general repairs. The wire feeder speed

controls Amperage, Output Control and Arc Force.

During SMAW welding, the wire feeder sets the weld

parameters and the wire drive remains idle. The “Volts””Trim” control is used to turn the power Source Output

ON or OFF (See Figure below)

O F F

5

S t i c k

C C S t i c k

Figure 6. SMAW (Stick) Welding Display

GTAW (TIG) Welding

The SpeedTec is excellent for Touch Start TIG welding.

The wire feeder speed controls Amperage. During

SMAW welding, the wire feeder sets the weld

parameters and the wire drive remains idle. The “Volts””Trim” control is used to turn the power Source Output

ON or OFF (See Figure below)

O F F

5

TIG

3

Figure 7. GTAW (TIG) Welding Display

GMAW (MIG) Synergic Welding Display

Synergic CV programs feature an ideal voltage best

suited for most procedures. Use this voltage as a

starting point and adjust if needed for personal

preferences.

1 7. 5

1. 2 7

S t e e l 1. 0 mm

C V C O 2

1 0

Figure 8. GMAW (MIG) Synergic Welding Display

Synergic CV Voltage Display

When the voltage knob is rotated, the display will show

an upper or lower bar indicating if the voltage is above or

below the ideal voltage.

Preset voltage above ideal voltage

(upper bar displayed)

Preset voltage at ideal voltage

(no bar displayed)

Preset voltage below ideal voltage

(lower bar displayed)

MSP4 Operation

Left Button:

Weld Mode

Wire Size

Electrode Gas

0.8 1.0 1.2 1.6

Steel CO2 93 10 20 24

Steel Ar(mix) 94 11 21 25

Stainless Ar(mix) 61 31 41 ---

Stainless Ar/He/CO2 63 33 43

Alu 4043 Ar --- 148 71 --Alu 5356 Ar --- 151 75 77

FluxCore Gas Shld 155

Arc Con t rol

Effect Range Description

Pinch Effect

(-10.0 to +10.0)

Pinch controls the arc characteristics

when short-arc welding.

Page 9

English English6

Memory

Effect Range Description

Job1..Job8 Allows memorizing the selected weld

mode.

Right Button:

Start Options

Effect/Range Description

Preflow Time

0-25.0 seconds

Adjusts the time that shielding gas

flows after the trigger is pulled and prior

to feeding.

Run-in WFS

Off, 1 to 12 m/min

Run-in sets the wire feed speed from

the time the trigger is pulled until an arc

is established.

Start Procedure The Start Procedure controls the WFS,

Volts at a specified time at the

beginning of the weld. During the start

time, the machine will ramp up or down

from the Start Procedure to the preset

Welding Procedure.

End options

Effect/Range Description

Spot Timer

0 to 120.0 seconds

Adjust the time welding will continue even

if the trigger is still pulled. This option has

no effect in 4-Step Trigger Mode.

Postflow Time

0 to 25.0 seconds

Adjusts the time that shielding gas flows

after the welding output turns off.

Burnback The burnback time is the amount of time

that the weld output continues after the

wire stops feeding. It prevents the wire

from sticking in the puddle and prepares

the end of the wire for the next arc start.

Crater Procedure Crater Procedure controls the WFS and

volts for a specified time at the end of the

weld after the trigger is released. During

the Crater time, the machine will ramp up

or down from the Weld Procedure to the

Crater Procedure.

2/4 Step Mode

Effect Range Description

2-Step, 4-Step Selects between 2-Step and 4-Step mode

of weld.

2- STEP 4- STEP- Trigger Operation

The 2-Step - 4-Step switch changes the function of the

gun trigger. 2-Step trigger operation switches the

welding output ON-OFF in direct response to the trigger.

4-Step trigger operation provides 'trigger interlock'

capability and gives the ability to control the amount of

time spent in the arc start and arc crater steps. Press

the push button on the case front to toggle between 2Step and 4-Step operation. The 2-Step, 4-Step trigger

has no effect when welding with SMAW or CAG

procedures.

2-Step Trigger

2-Step trigger operation is the most common. When the

gun trigger is pulled, the welding system (power source

and wire feeder) cycles through the arc starting

sequence and into the main welding parameters. The

welding system will continue to weld as long as the gun

trigger is activated. Once the trigger is released, the

welding system cycles through the arc ending steps.

4-Step Trigger

4-Step trigger operation gives the welder additional

control in the welding sequence. 4-Step trigger allows

the welder to choose the arc start, weld and arc end

time. It may also be set-up to work as a trigger interlock.

Example 1:

2 Step Trigger: Simple operation

The simplest trigger operation occurs with a 2 Step

trigger and the Start, Crater and Burnback functions all

set to OFF (See Figure Below). For this sequence:

PREFLOW: Shielding gas begins to flow

immediately when the gun trigger is pulled.

RUN-IN: After preflow time expires, the power

source regulates to the welding output and wire is

advanced towards the work piece at the Run-In

WFS. If an arc is not established within 1.5

seconds, the wire feed speed will jump to the

welding wire feed speed.

WELD: The power source output and the wire feed

speed continue at the weld settings for as long as

the trigger is pulled.

POSTFLOW: As soon as the trigger is released,

the power source output and the wire feed speed

are turned OFF. Shielding gas continues until the

post flow timer expires.

On

Off

Off

Off

Weld

Weld

Run-in

Shielding

Gas

Power

Source

Output

WFS

Idle Preflow Run-in Weld Postflow Idle

Trigger Pull led

Arc Establi shed

Trigger Released

2 Step Trigger

Start = Off

Crater = Off

Burnback = Off

1.5s max

Example 2:

2 Step Trigger: Improved Arc Start and Arc End.

Tailoring the arc start and arc end is a common method

for reducing spatter and improving weld quality. This

can be accomplished with the Start and Burnback

functions set to a desired values and Crater set to OFF

(See Figure Below). For this sequence:

PREFLOW: Shielding gas begins to flow

immediately when the gun trigger is pulled.

RUN-IN: After preflow time expires, the power

source regulates to the start output and wire is

advanced towards the work piece at the Run-In

WFS. If an arc is not established within 1.5

seconds, the power source output and wire feed

speed skips to the weld settings.

START & UPSLOPE: Once the wire touches the

work and an arc is established, both the machine

output and the wire feed speed ramp to the weld

settings throughout the start time. The time period

of ramping from the start settings to the weld

settings is called UPSLOPE.

WELD: After upslope, the power source output and

the wire feed speed continue at the weld settings.

BURNBACK: As soon as the trigger is released,

the wire feed speed is turned OFF and the machine

output continues for the burnback time.

POSTFLOW: Next, the machine output is turned

OFF and shielding gas continues until the post flow

timer expires.

Page 10

English English7

On

Off

Off

Off

Weld

Weld

Run-in

Shielding

Gas

Power

Source

Output

WFS

Idle Preflow Strike Weld Postflow Idle

Trigger Pullled

Arc Establi shed

Trigger Released

2 Step Trigger

Start = On

Crater = Off

Burnback = On

1.5s max

Upslope Burnback

Start

Burnback T.

Start T.

Example 3:

2 Step Trigger: Customized Arc Start, Crater and Arc

End.

Sometimes it is advantageous to set specific arc start,

crater and arc ending parameters for the ideal weld.

Many times when welding aluminum crater control is

necessary to make a good weld. This is done by setting

Start, Crater and Burnback functions to desired values

(See Figure Below). For this sequence:

PREFLOW: Shielding gas begins to flow

immediately when the gun trigger is pulled.

RUN-IN: After preflow time expires, the power

source regulates to the start output and wire is

advanced towards the work piece at the Run-In

WFS. If an arc is not established within 1.5

seconds, the power source output and wire feed

speed skips to the weld settings.

START & UPSLOPE: Once the wire touches the

work and an arc is established, both the machine

output and the wire feed speed ramp to the weld

settings throughout the start time. The time period

of ramping from the start settings to the weld

settings is called UPSLOPE.

WELD: After upslope, the power source output and

the wire feed speed continue at the weld settings.

CRATER & DOWNSLOPE: As soon as the trigger

is released, the wire feed speed and power source

output ramp to the crater settings throughout the

crater time. The time period of ramping from the

weld settings to the crater settings is called

DOWNSLOPE.

BURNBACK: After the crater time expires, the wire

feed speed is turned OFF and the machine output

continues for the burnback time.

POSTFLOW: Next, the machine output is turned

OFF and shielding gas continues until the post flow

timer expires.

On

Off

Off

Off

Weld

Weld

Run-in

Shielding

Gas

Power

Source

Output

WFS

Idle Preflow Strike Weld Postflow Idle

Trigger Pullled

Arc Established

Trigger Released

2 Step Trigger

Start = On

Crater =On

Burnback = On

1.5s max

Upslope Burnback

Start

Burnback T.

Start T.

Down

slope

Crater

Crater T.

Crater

Example 4:

4 Step Trigger: Trigger Interlock

The 4 step trigger can be configured as a trigger

interlock. Trigger interlock adds to the welder’s comfort

when making long welds by allowing the trigger to be

released after an initial trigger pull. Welding stops when

the trigger is pulled a second time and then released, or

if the arc is interrupted (See Figure Below). For this

sequence:

PREFLOW: Shielding gas begins to flow

immediately when the gun trigger is pulled.

RUN-IN: After preflow time expires, the power

source regulates to the welding output and wire is

advanced towards the work piece at the Run-In

WFS. If an arc is not established within 1.5

seconds, the wire feed speed will jump to the

welding wire feed speed.

WELD: The power source output and the wire feed

speed continue at the weld settings. Welding

continues when the trigger is pulled a second time.

POSTFLOW: As soon as the trigger is released for

the second time, the power source output and the

wire feed speed are turned OFF. Shielding gas

flows until the post flow timer expires.

On

Off

Off

Off

Weld

Weld

Run-in

Shielding

Gas

Power

Source

Output

WFS

Idle Preflow Strike Weld Postflow Idle

Trigger Pullled

Arc Established

Trigger Released

4 Step Trigger

Start = Off

Crater =Off

Burnback = Off

1.5s max

Burnback

Start

Crater

Crater

Trigger Pullled

Trigger Released

Page 11

English English8

Example 5:

4 Step Trigger: Manual control of Start and Crater

times with Burnback ON

The 4 step trigger sequence gives the most flexibility

when the Start, Crater and Burnback functions are

active. This is a popular choice when welding aluminum

because extra heat may be needed during Start and less

heat desired during crater. With 4 step trigger, the

welder chooses the amount of time to weld at the Start,

Weld and Crater settings by using the gun trigger.

Burnback reduces the occurrence of wire to sticking into

the weld pool at the end of a weld and conditions the

end of the wire for the next arc start ( See Figure Below).

For this sequence:

PREFLOW: Shielding gas begins to flow

immediately when the gun trigger is pulled.

RUN-IN: After preflow time expires, the power

source regulates to the start output and wire is

advanced towards the work piece at the run-in

WFS. If an arc is not established within 1.5

seconds, the power source output and wire feed

speed skips to the weld settings.

START: The power source welds at the start WFS

and voltage until the trigger is released.

UPSLOPE: During upslope, the power source

output and the wire feed speed ramp to the weld

settings throughout the start time. The time period

of ramping from the start settings to the weld

settings is called UPSLOPE.

WELD: After upslope, the power source output and

the wire feed speed continue at the weld settings.

DOWNSLOPE: As soon as the trigger is released,

the wire feed speed and power source output ramp

to the crater settings throughout the crater time.

The time period of ramping from the weld settings to

the crater settings is called DOWNSLOPE.

CRATER: During CRATER, the power source

continues to supply output at the crater WFS and

voltage.

BURNBACK: When the trigger is released, the

wire feed speed is turned OFF and the machine

output continues for the burnback time.

POSTFLOW: Next, the machine output is turned

OFF and shielding gas continues until the post flow

timer expires.

On

Off

Off

Off

Weld

Weld

Run-in

Shielding

Gas

Power

Source

Output

WFS

Idle PreflowStri ke Weld

Postflow

Idle

Trigger Pullled

Arc Establi shed

Trigger Released

4 Step Trigger

Start = On

Crater =On

Burnback = On

1.5s max

Burnback

Start

Burnback T.

Start T.

Crater

Crater T.

Crater

Trigger Pullled

Trigger Rel eased

Start Upslope Downslope Crater

Start

SET-UP FEATURES MENU

The Setup Menu gives access to the set-up

configuration. Stored in the set-up configuration are

user parameters that generally need to be set only at

installation. The parameters are grouped as follows:

P.1 through P.99 Unsecured Parameters (always

adjustable).

P.101 through P.199 Diagnostic Parameters

(always read only).

P.501 through P.599 Secured Parameters

(accessible only though a p.c. or palm application).

To access the set-up menu, press the right and left

buttons of the MSP4 panel simultaneously. Note that

the set-up menu cannot be accessed if the system is

welding, or if there is a fault (The status LED is not solid

green). Change the value of the blinking parameter by

rotating the SET knob.

After changing a parameter it is necessary to press the

right hand button to save the new setting. Pressing the

left button will cancel the change. To exit the set-up

menu at any time, press the right and left buttons of the

MSP4 panel simultaneously. Alternately, 1 minute of

inactivity will also exit the setup menu.

Unsecured Parameters.

P.0 Press the left button to exit the set-up menu.

P.1 WFS units

Metric = m/min wire feed speed units

English = in/min wire feed speed units (default)

P.2 Arc Display Mode

Amps = The left display shows Amperage while

welding. (default)

WFS = The left display shows Wire Feed Speed

while welding.

P.4 Trigger Memory Recall

Enable = Selecting memories 2 through 6 with quick

trigger pulls is enabled when the optional dual

procedure/memory panel is installed. To recall a

memory with the gun trigger, quickly pull and

release the trigger the number of times that

correspond to the memory number. For example, to

recall memory 3, quickly pull and release the trigger

3 times. Trigger memory recall can only be

performed when the system is not welding.

Disable = Memory selection is performed only by

the buttons on the optional dual procedure/memory

panel (default).

P.5 Trigger Procedure Change

Quick Trigger = Allows switching between

Procedure A and procedure B while welding. The

optional dual procedure/memory panel is required.

To operate:

Select procedure “GUN” on the memory panel.

Start the weld by pulling the gun trigger. The

system will weld with procedure A settings.

While welding, quickly release and then pull the

gun trigger. The system will switch to

procedure B settings.

Release the trigger to stop welding. When the

next weld is made, the system will start again

with procedure A.

Integral TrigProc = Use Integral Trigger + Procedure

Page 12

English English9

Switch when using a Lincoln Dual Schedule gun.

When in 2-step, the system operates identical to the

External Switch selection. To operate in 4-step:

Select procedure “GUN” on the memory panel.

Start the weld by pulling the gun trigger. The

system will weld with procedure A settings.

While welding, quickly release and then pull the

gun trigger. The system will switch to

procedure B settings.

Release the trigger to stop welding. When the

next weld is made, the system will start again

with procedure A.

External Switch = Dual Procedure selection may

only be performed by the memory panel button or a

dual procedure gun (default).

P.6 Push Pull Gun, Stall Factor Adjustment

The stall factor controls the stall torque of the push

motor when using a push-pull gun. The wire feeder is

factory set to not stall unless there is a large resistance

to feeding wire. The stall factor can be reduced to stall

more easily and possibly prevent bird nesting. However,

low stall factors can cause motor stalling while welding

which results in the wire burning back to the tip. If you

are experiencing bird nests, check for other feeding

problems before adjusting the stall factor. Default value

for the stall factor is 75, with a range of 5 - 100. To

change the stall factor:

Use the VOLTS/TRIM knob to adjust the stall factor.

Increasing the stall factor raises the motor torque

and decreasing the stall factor lowers the motor

torque. Do not increase the stall factor more than

necessary. A high stall factor may increase the

occurrence of bird nesting and a low stall factor may

cause the wire to burn back to the tip.

Press the right hand button to save the new setting.

P.7 Push Pull Gun, Gun Offset Adjustment

The pushpull gun offset calibration adjusts the wire feed

speed calibration of the pull motor. The procedure

should only be performed when other possible

corrections do not solve the push-pull feeding problems.

A rpm meter is required to perform the pull gun motor

offset calibration. To perform the calibration procedure:

Release the pressure arm on both the pull and push

wire drives.

Set the wire feed speed to 200 rpm.

Remove wire from the pull wire drive.

Hold the rpm meter to the drive roll in the pull gun.

Pull the trigger on the push-pull gun.

Measure the rpm of the pull motor. The rpm should

be between 115 and 125 rpm. If necessary,

decrease the calibration setting to slow the pull

motor, or increase the calibration setting to speed

up the motor. The calibration range is -30 to +30,

with 0 as the default value.

Press the right hand button to save the new setting.

P.8 TIG Gas Control (Two Settings)

1. "Valve (manual)", the internal solenoid will not

actuate while TIG welding, gas flow is manually

controlled by an external valve.

2. "Solenoid (auto)", the internal gas solenoid will

turn on and off automatically while TIG welding as

follows:

Preflow time will not be accessible from the

MSP4.

Postflow time will be available in the MSP4

"End Options" and have a range of OFF to 10.0

seconds.

The postflow time value is maintained when

switching between MIG and TIG modes.

When machine output on/off is controlled via

the right encoder, gas flow will not start until the

tungsten touches, the work piece, gas flow will

stop after the postflow time when the arc is

broken.

When machine output on/off is controlled via an

arc start switch or foot Amptrol, gas will begin

flo

wing when the output is turned on and stop

flowing after the postflow period after the output

is turned off.

P.9 Crater Delay

Use the crater delay to skip the Crater sequence when

making short tack welds. If the trigger is released before

the Crater Delay Timer ends, then the Crater sequence

is skipped. If the trigger is released afterwards, the

Crater sequence functions normally.

Values = OFF to 10.0 seconds (OFF is default).

P.11 Set Timers

This menu is used to adjust timer values for Upslope,

Downslope and Restrike. Press the right button to enter

the Set Timer menu. Rotate the knob to select the timer

to adjust and then press the right button. Adjust the

value of the timer by rotating the knob. Press the left

MSP4 button to set the value and exit. Continue to

adjust other timers as necessary, and then press the left

button to exit the Set Timer menu.

P.12 Travel Options

This menu is used to change the travel options for a

travel carriage, including starting and ending functions.

The right MSP4 button to enter the Travel Options menu

and rotate the encoder to select either starting or ending

options. Press the right MSP4 button to select the

option. Press the left MSP4 button to set the value and

exit. Rotate the encoder to select other options, or press

the left MSP4 button to exit the menu.

P.13 Adjust Arc Force

Use this menu to adjust Arc Force values for Start, Weld

and Crater. Press the right MSP4 button to enter the

menu and rotate the knob to choose either Start, Weld or

Crater. Press the right MSP4 button and then rotate the

knob to the desired value. Press the left MSP4 button to

set the value and exit. Continue to adjust Arc Force for

other states, and then press the left MSP4 button to exit

the menu.

P.14 Reset Consumable Weight

This parameter only appears with systems using

Production Monitoring. Use this parameter to reset the

initial weight of the consumable package.

P.16 Push-Pull Gun Knob

Gun Pot Enabled = The wire feed speed is always

controlled by the potentiometer on the push-pull gun

(default).

Gun Pot Disabled = The wire feed speed is always

controlled by the left display knob on the feeder.

Gun Pot Proc A = When in procedure A, the wire

feed speed is set by the push-pull gun

potentiometer. When in procedure B, the wire feed

speed is set by the left display knob on the feeder.

P.25 Joystick Configuration

The new analog and digital gun controls have a joystick

Page 13

English English10

to allow the user to change various weld settings at the

gun rather than having to go to the user interface. P.25

can be used to change the behavior of the joystick. In all

configurations, the up and down joystick positions will

adjust the wire feed speed, while welding and while not

welding. P.25 is used to reconfigure the behavior of the

left and right joystick positions.

When P.25 is set to “Trim/Volts/etc.”, the left and

right joystick positions will adjust Arc Length Trim,

Arc Voltage, Power or STT Background Current

based on the selected weld mode. For example,

when a non-synergic STT weld mode is selected,

the left and right joystick positions will adjust

Background Current. When a Power mode is

selected, the left and right joystick positions will

adjust the Power (kW).

When P.25 is set to “Memory+Trim/etc.”, the left

and right joystick positions will select a user memory

while not welding and adjust

Trim/Voltage/Power/STT Background Current while

welding.

When P.25 is set to “Procedure A/B”, the left and

right joystick positions will be used to select

procedure A and B, while welding and while not

welding. The left joystick position selects procedure

A, the right joystick position selects procedure B.

Diagnostic Parameters

P.80 Sense from Studs

Use this parameter for diagnostic purposes only. When

power is cycled, P.80 is automatically reset to False.

False = Sensing for the electrode (67) and work (21)

is determined by the DIP switches of the system.

True = Sensing for the electrode (67) and work (21)

is measured at the studs of the power source and

the DIP switch settings are overridden.

P.99 Show Test Modes

Many weld tables include special modes for testing and

servicing the welding system. Set this parameter to YES

to show all test modes. When the power source is

turned off, the Show Test Modes parameter

automatically reverts back to "NO".

P.100 View Diagnostics

Diagnostics are only used for servicing the Power Wave

system.

Yes = Shows P.101 through P.500 in the SETUP

menu.

No = Only P.0 through P.100 are shown in the

SETUP menu.

P.101 Event Logs

Press the right MSP4 button to view the Event Logs.

Rotate the encoder to select the object to read and then

press the right MSP4 button. Various software

information will appear about key system events. Press

the left MSP4 button to exit.

P.102 Fatal Logs

Press the right MSP4 button to view the Fatal Logs.

Rotate the encoder to select the module to read and

then press the right MSP4 button. Various software

information will appear about critical module actions.

Press the left MSP4 button to exit.

P.103 Software Version

Press the right MSP4 button to view the software loaded

into each module (p.c. board). Rotate the encoder to

select the module to read and then press the right MSP4

button. The panel will display the main software version

loaded into the module. Press the left MSP4 button to

exit.

P.104 Hardware Version

Press the right MSP4 button to view the hardware

version of each module (p.c. board). Rotate the encoder

to select the module to read and then press the right

MSP4 button. The panel will display the main hardware

version loaded into the module. Press the left MSP4

button to exit.

P.105 Welding Software

Press the right MSP4 button to view the welding

software version inside the power source. Press the left

MSP4 button to exit.

P.106 Ethernet IP Address

Press the right MSP4 button to view the IP address of

the Ethernet board. If no Ethernet Board is installed, the

display shows "No Enet Found". Press the left MSP4

button to exit.

P.107 Power Source

Press the right MSP4 button to view the type of power

source connected to the control box. Press the left

MSP4 button to exit.

Maintenance

WARNING

For any maintenance or repair operations it is

recommended to contact the nearest technical service

center or Lincoln Electric. Maintenance or repairs

performed by unauthorized service centers or personnel

will null and void the manufacturers warranty.

The frequency of the maintenance operations may vary

in accordance with the working environment where the

machine is placed.

Any noticeable damage should be reported immediately.

Routine maintenance

Check condition of insulation and connections of the

work cables and input power supply cable.

Remove the spatters from the welding gun nozzle.

Spatters could interfere with the shielding gas flow

to the arc.

Check the welding gun condition: replace it, if

necessary.

Check condition and operation of the cooling fan.

Keep clean its airflow slots.

Periodic maintenance

Perform the routine maintenance and, in addition:

Keep clean the machine. Using a dry ( and low

pressure) airflow, remove the dust from the external

case and from inside of the cabinet.

Check condition of all connections and change if

necessary.

Check and tighten all screws.

WARNING

Mains supply network must be disconnected from the

machine before each maintenance and service. After

each repair, perform proper tests to ensure safety.

Page 14

English English11

Electromagnetic Compatibility (EMC)

11/04

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

This machine has been designed to operate in an industrial area. To operate in a domestic area it is

necessary to observe particular precautions to eliminate possible electromagnetic disturbances. The

operator must install and operate this equipment as described in this manual. If any electromagnetic

disturbances are detected the operator must put in place corrective actions to eliminate these disturbances

with, if necessary, assistance from Lincoln Electric.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

machine.

Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

Safety and control equipment for industrial processes. Equipment for calibration and measurement.

Personal medical devices like pacemakers and hearing aids.

Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

that all equipment in the area is compatible. This may require additional protection measures.

The dimensions of the work area to consider will depend on the construction of the area and other activities that are

taking place.

Consider the following guidelines to reduce electromagnetic emissions from the machine.

Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

additional precautions such as filtering the input supply.

The output cables should be kept as short as possible and should be positioned together. If possible connect the

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting

the work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

applications.

Technical Specifications

INPUT VOLTAGE WIRE FEED SPEED

34-44 Vdc 0.75-22 m/min

RATED OUTPUT AT 40°C

Duty Cycle

(based on a 10 min. period)

100%

60%

Output Current

385 A

500 A

OUTPUT RANGE

Welding Current Range

5-500 A

Maximum Open Circuit Voltage

113 Vdc or Vac peak

WIRE SIZES (mm)

Solid wires

0.6 to 1.6

Cored wires

1.0 to 2.0

Aluminium wires

1.0 to 1.6

PHYSICAL DIMENSIONS

Height

440 mm

Width

270 mm

Length

636 mm

Weight

17 Kg

Operating Temperature

–10°C to +40°C

Storage Temperature

-25°C to +55°C

WEEE

07/06

English

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE)

and its implementation in accordance with national law, electrical equipment that has reached the end of its

life must be collected separately and returned to an environmentally compatible recycling facility. As the

owner of the equipment, you should get information on approved collection systems from our local

representative.

By applying this European Directive you will protect the environment and human health!

Page 15

English English12

Spare Parts

12/05

Part List reading instructions

Do not use this part list for a machine if its code number is not listed. Contact the Lincoln Electric Service

Department for any code number not listed.

Use the illustration of assembly page and the table below to determine where the part is located for your particular

code machine.

Use only the parts marked "X" in the column under the heading number called for in the assembly page (# indicate

a change in this printing).

First, read the Part List reading instructions above, then refer to the "Spare Part" manual supplied with the machine, that

contains a picture-descriptive part number cross-reference.

Electrical Schematic

Refer to the "Spare Part" manual supplied with the machine.

Accessories

K10349-PG-xM Source wire/feeder cable (gas). Available in 5, 10,15, 20, 25 or 30m.

K10349-PGW-xM Source wire/feeder cable (gas and water). Available in 5, 10,15, 20, 25 or 30m.

K10158 Plastic adaptor for 15-kg coils (delivered as standard).

K10343 Innershield torch adaptor.

Drive rolls and guide tubes 2 driven rolls

KP14017-0.8

KP14017-1.0

KP14017-1.2

KP14017-1.6

Solid wires:

0,6-0,8mm

0,8-1,0mm

1,0-1,2mm

1,2-1,6mm

KP14017-1.6R

KP14017-2.4R

Cored wires:

1.0-1.6mm

1.6-2.4mm

KP14017-1.2A

KP14017-1.6A

Aluminum wires:

1,0-1,2mm

1,2-1,6mm

Page 16

Italiano ItalianoI

Dichiarazione di conformità

Lincoln Electric Bester Sp. z.o.o.

Dichiara che il generatore per saldatura tipo:

LINC FEED 45

è conforme alle seguenti direttive:

2006/95/CEE, 2004/108/CEE

ed è stato progettato in conformità alle seguenti

norme:

EN 60974-1, EN60974-5, EN 60974-10

(2009)

Paweł Lipiński

Operations Director

Lincoln Electric Bester Sp. z.o.o., ul. Jana III Sobieskiego 19A, 58-260 Bielawa, Poland

12/05

Page 17

Suomi Suomi12

Varusteet

K10349-PG-xM Välikaapeli (kaasu), saatavissa 5, 10, 15 ja 30 m:n pituisena.

K10349-PGW-xM Välikaapeli (kaasu, vesi), saatavissa 5, 10, 15, 20, 25 ja 30 m:n pituisena.

K10158 Muoviadapteri 15 kg:n keloille.

K10343 Innershield poltin adapteri.

Syöttöpyörät ja ohjausputket 2 - pyörävedolle

KP14017-0.8

KP14017-1.0

KP14017-1.2

KP14017-1.6

Umpilangat:

0,6-0,8mm

0,8-1,0mm

1,0-1,2mm

1,2-1,6mm

KP14017-1.6R

KP14017-2.4R

Täytelangat:

1.0-1.6mm

1.6-2.4mm

KP14017-1.2A

KP14017-1.6A

Alumiinilangat:

1,0-1,2mm

1,2-1,6mm

Page 18

Spare Parts - Electrical Schematic Spare Parts - Electrical Schematic1

Spare Parts

SP50194 Rev. 1

07/03

LINC FEED 45

ASSEMBLY

PAGE NAME

Machine Assembly

Wire Drive Assembly

CODE

NO.:

K NO.: FIGURE NO.: A-B C

50194 K14072-1 LINC FEED 45 1 1

Figure A

Figure B

Page 19

Spare Parts - Electrical Schematic Spare Parts - Electrical Schematic2

Figure A-B: Machine Assembly

Item Description Part Number QTY 1 2 3 4

1 LOCK 0654-610-004R 1 X

2 QUICK CONNECTOR MALE 0744-000-151R 1 X

3 QUICK CONNECTOR FEMALE 0744-000-152R 4 X

4 WIRE REEL SPINDLE 0744-000-192R 1 X

5 WIRE DRIVE 0744-000-241R 1 X

6 PLASTIC SHROUD ASSEMBLY 0749-901-003R 1 X

7 SOCKET MALE 1158-641-110R 1 X

8 GAS SOLENOID 0972-423-038R 1 X

9 FRONT WHEEL 1029-660-003R 2 X

10 REAR WHEEL 1029-660-081R 2 X

11 PROTECTION WASHER 0744-200-108R 1 X

12 SWITCH 1158-650-022R 1 X

13 PIVOT TOP PART 1361-598-180R 1 X

14 EURO SLEEVE 1361-599-708R 1 X

15 SLEEVE 1361-599-720R 4 X

16 RUBBER BUTTON 1373-182-005R 2 X

17 WARNING DECAL 2719-107-728R 1 X

18 BASE 2719-107-732R 1 X

19 PLASTIC CAP B11035-1 1 X

20 CONTROL PC BOARD R-6042-053-1R 1 X

21 UI PC BOARD R-6042-054-1R 1 X

22 KNOB 9ET13639-3R 3 X

23 WASHER C-1661-004-5R 2 X

24 DINSE SOCKET C-2986-001-3R 1 X

25 SLEEVE D-1869-033-3R 2 X

26 SOCKET D-2985-002-1R 1 X

27 HINGE D-3574-007-1R 2 X

28 LEFT PANEL R-1019-227-1R 1 X

29 STICKER R-0010-282-1R 1 X

30 NAME PLATE R-0010-284-1R 1 X

31 UI LABEL R-0010-285-1R 1 X

32 STICKER R-0010-290-1R 1 X

33 CONDUCTOR RAIL R-1010-039-1R 1 X

34 CONDUCTOR RAIL R-1010-040-1R 1 X

35 RIGHT PANEL R-1019-224-1R 1 X

36 DIVIDER R-1019-207-1/08R 1 X

37 AXLE R-2013-021-1R 1 X

38 ALU RING R-2013-032-1R 1 X

39 COUPLER R-2013-060-1R 1 X

40 FRAME R-3019-156-1/08R 1 X

41 COVER R-3019-162-1/02R 1 X

42 FRONT PANEL R-3019-168-1/08R 1 X

43 DIVIDER R-3019-169-1/08R 1 X

44 PLATE R-3019-170-1/08R 1 X

45 REMOTE SOCKET 1158-641-149R 1 X

46 HARNESS R-5041-171-1R 1 X

47 MOTOR R-8040-024-3R 1 X

48 EURO SOCKET R-8040-140-3R 1 X

49 MAGNETIC RING 0943-719-005R 1 X

50 TACHO CAP 0744-200-008R 1 X

51 HALL SENSOR 0943-719-008R 1 X

52 SUPPRESSION CHOKE R-5041-228-1R 1 X

Page 20

Spare Parts - Electrical Schematic Spare Parts - Electrical Schematic3

Figure C

Figure C: Wire Drive Assembly

Item Description Part Number QTY 1 2 3 4

1 FEED PLATE 0646-233-002R 1 X

2 FIXING ARM COMPL. 0646-233-015R 2 X

3 INLET GUIDE 0646-233-025R 1 X

4 AXIS PRESSURE ARM 0646-233-003R 2 X

5 SPRING PRESSURE ARM 0646-233-013R 2 X

6 PRESSURE ARM COMPL.L 0646-233-007R 1 X

7 INTERMEDIATE GUIDE 0646-233-023R 1 X

8 AXIS DRIVE ROLL 0646-233-020R 2 X

9 GEAR WHEEL ROLL 0646-231-090R 2 X

10 GEAR WHEEL MOTOR 0646-233-028R 1 X

11 FIXING CAP 0646-233-022R 2 X

12 METAL COVER 0646-233-027R 1 X

13 PRESSURE ARM COMPL.R 0646-233-005R 1 X

14 WIRE FEED MOTOR R-8040-024-3R 1 X

15 WOODRUFF KEY 0646-231-102R 1 X

Page 21

Spare Parts - Electrical Schematic Spare Parts - Electrical Schematic4

Electrical Schematic

LINC FEED 45

Page 22

Spare Parts - Electrical Schematic Spare Parts - Electrical Schematic5

WEEE

Recycle ST

Ref. Fe Al Cu Brass Boards Plastics

Liquid

Cristal

External

Electric

Cables Capacitors

Base Assembly 15 X

Bolt 22 X

Brake 25,26 X

Cover 2 X

Divider 17, 21 X

Euro Socket 12 X X

Front Panel 6 X

Knob 5 X

Left Side Panel 4 X

Motor 27 X X

P.C. Board 3 X

P.C. Board 11 X

Quick Coupling 9 X

Rail 1 X X

Control Socket 7, 31 X X

Right Side Panel 23 X

Rotary Bracket 14 X

Rubber Button 10 X

Gas Switch 30 X X X

Spool Cover 28 X

Switch 24 X X X

Top Panel 29 X

Washer 19, 20 X

Welding Socket 8 X X

Wheels 13,16 X X

Wire Feeder 18 X

Suppression choke 32 X

Loading...

Loading...