Page 1

Multi-Weld

TM

350

Distribution Box, Welding Cable Connectors, Input Cables, Remote

Output Control, Undercarriage

K1735-1 Multi-Weld 350

SAE-400, Vantage 500, DC-655, DC-1000, DC-1500

• Independent arcs. Starting or stopping one Multi-Weld doesn’t

affect the welding of the others.

• The Multi-Weld 350 is capable of continuous operation at 350

amps in 122°F (50°C) air temperature.

• No control cables are needed. Single weld cable output from the

power source to one or several Multi-Weld 350s.

• Controls are located close to the operator for quick access.

• High efficiency design uses less than half the power of other

grid systems.

• Lincoln Chopper Technology™ for quality welds with

instant control of the arc for superior welding results.

• Constant voltage (CV) for MIG or flux-cored wire welding.

• Constant current (CC) for stick welding or arc gouging.

• Additional stick welding controls include hot start, arc force,

electrode type selection (E7018 and E6010).

•Arc gouging capability with a single Multi-Weld 350 and up to

5/16" (8.0mm) electrode, or with paralleled units for up to 700

amps of power using a 3/8" (9.5mm) electrode.

• Manufactured under a quality system certified to ISO 9001

requirements and ISO 14001 environmental standards.

• Three-year warranty on parts and labor.

MULTI-OPERATOR

Connect Several DC+ Welders to One Power Supply.

Stick MIG Flux-Cored Gouging

Processes (DC+ Processes Only)

Description

Output Input

80

VDC

Advantage Lincoln

Recommended General Options

Recommended Power Source Options

LN-15 Across-the-Arc, LN-25 Across-the-Arc

Recommended Wire Feeder Options

Order

The Multi-Weld 350 is a 350 amp, DC+, 100% duty cycle welder capable of

CV-wire, CC-stick or arc gouging. With its high efficiency, the Multi-Weld 350

offers an entirely new and better way to build large structures. This unique

system offers a cleaner, safer job site, and allows operators to have high

performance welding control right where they need it — at the arc.

Publication E5.302 3/05

Web Update 6/05

www.lincolnelectric.com

TECHNICAL SPECIFICATIONS

Input Current Dimensions Net

Product Product Input Rated DC+ Output at Rated DC Output H x W x D Weight

Name Number Volts Current/Voltage/Duty Cycle Output (80V DC) Range in. (mm) lbs. (kg)

80V DC 15 - 40 Volts

Multi-Weld K1735-1 (50 - 113 350A / 34V / 100% DC

+ 165A 30 - 350 Amps 11.6 x 10 x 21.5 59

350 Peak Range) Max. OCV: 78V (295 x 254 x 546) (27)

Page 2

[2][2]

13

4

5

6

7

8

9

10

11

12

2

Access Door Removed for Clarity

A CLOSER LOOK

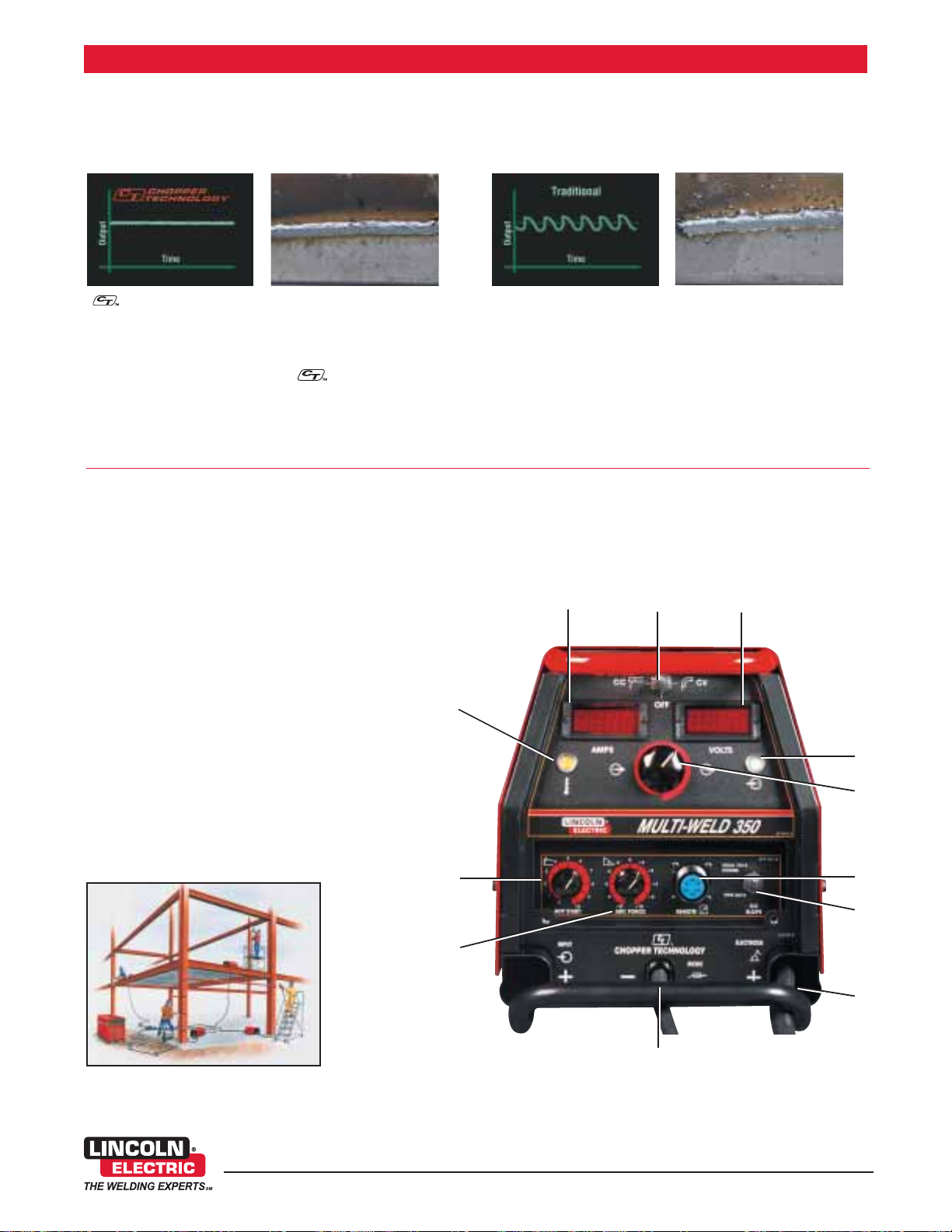

1) Large, Easy to Read, Presettable Digital Amp Meter

2) Off/CC/CV Switch

3) Large, Easy to Read, Presettable Digital Volt Meter

4) Input Voltage OK Light

5) Large Control Knob for Gloved Hands

6) Remote Control Connection

7) Optimized Arc Switch for E7018 or E6010 Type Electrodes

8) “Pig Tail” Cables for Custom Quick Connectors. Front

and rear routings.

9) 10 ft. (3m) Work Clamp Lead

10) Arc Force Control

11) Hot Start Control For Fast and Easy Starts

12) Thermal Protection Trip Indicator Light

Multi-Weld 350

www.lincolnelectric.com

Key Controls

A single weld cable output from the power source to a distribution

box connects several work stations equipped with Multi-Weld 350s.

SUPERIOR WELDING PERFORMANCE

• Superior starting compliments the soft, stable welding arc

yielding very low spatter levels. Chopper control has an

extremely fast response for tighter output control than

tradition weld control.

• High efficient design and low input current draw means

more welding.

Patented and award-winning Lincoln Chopper Technology delivers superior DC arc welding performance for general purpose stick,

Downhill Pipe, DC TIG, MIG, cored-wire and arc gouging.

Benefits of Chopper Technology include: - Easy arc starting

- Smooth arc action

- Low spatter levels

- Excellent bead appearance

Traditional weld control is

more variable around the

desired output.

Chopper Technology

for extremely fast response

for smoother output control.

Chopper Technology

CV-Wire Mode

Traditional Reactor

Technology

CV-Wire Mode

• Each Multi-Weld 350 has easy-to-use controls and a large control

knob designed for gloved hands.

• Digital meters show preset values before welding and actual

values while welding. Memory holds the values for 5 seconds

after welding stops.

• Convenient carrying handles and skids double as extra protection

from abuse in the field.

FEATURES

Page 3

Description Diameter in. (mm) Process Kilowatts Used

(1),

Flux-Cored Wire .035 (0.9) 300 ipm WFS, 130A, 24V 3.4

Gas-Shielded .035 (0.9) 600 ipm WFS, 195A, 30V 6.4

.045 (1.2) 300 ipm WFS, 185A, 28V 5.7

500 ipm WFS, 255A, 29V 8.1

.052 (1.3) 250 ipm WFS, 210A, 26V 6.0

450 ipm WFS, 315A, 29V 10.4

1/16 (1.6) 200 ipm WFS, 255A, 26V 7.3

350 ipm WFS, 350A

(2)

, 29V 11.2

Flux Cored Wire 5/64 (2.0) 200 ipm WFS, 280A, 30V 10.1

Self-Shielded 300 ipm WFS, 350A

(2)

, 32V 13.7

MIG Wire .035 (0.9) 150 ipm WFS, 120A, 19V 2.5

250 ipm WFS, 175A, 22V 4.2

.045 (1.2) 125 ipm WFS, 145A, 19V 3.0

200 ipm WFS, 200A, 21V 4.6

Stick (7018) 1/8 (3.2) 130A, 27V 3.9

3/16 (4.8) 225A, 28V 6.9

Stick (7024) 3/16 (4.8) 260A, 27V 7.7

Stick (6010) 1/8 (3.2) 120A, 36V 4.7

NOTE: E6010 stick electrodes require higher

voltage to “whip” properly. Higher voltage power

sources are recommended.

Air Carbon 1/4 (6.4) 350A

(2),

, 34V 13.1

Arc Gouging 3/8 (9.5) 700A

(2),

, 34V Requires two Multi-Weld 350s in parallel. 26.2

System Selection is determined by kilowatts available on the power

source.

Note: For maximum output, set power source on Constant Current

and select maximum output. Constant Voltage power sources are not

recommended.

(1) Air Vantage and Vantage 500 output is 12 kW @ 58 volts.

(2) Vantage 300 output is 7 kW @ 58 volts.

Multi-Weld 350

www.lincolnelectric.com

[3]

A CLOSER LOOK

HOW MANY KILOWATTS DOES YOUR PROCESS REQUIRE?

SYSTEM SELECTION

4

POWER SOURCE/KILOWATTS AVAILABLE

(1)

Power Source KW = = KW input to Multi-Weld 350

(2)

Maximum rated output of Multi-Weld 350.

(KW)arc1 + (KW)arc2 + (KW)arcN(simultaneous)

.91 eff.

Kilowatts Available

Power Source

@60V Output

R3R-400 12

R3R-500 12

DC-600 15

DC-655 36

DC-1000 30

DC-1500 94

Classic 300D 12

SAE-400 22

Vantage 300

(2)

4.8

Vantage 500

(1)

5

Air Vantage 500

(1)

5

• Printed circuit boards are environmentally-shielded using Lincoln's

engineered potting and protective frame trays.

• Thermostat and voltage overload protection.

• Fan-As-Needed – solid state controlled fan operates cooling fan

only when needed. Minimizes power consumption, operating noise

and dust intake.

QUALITY AND RELIABILITY

Page 4

Process Electrode Wire/Stick Electrode Polarity Shielding Gas

Mild Steel FCAW .045" (1.2mm) UltraCore Positive

CO2 or Blended

Gas-Shielded Wire 71A75 Dual (DC+)

Mild Steel .045" (1.2mm) Metalshield MC-6 Positive

Blended

Composite MIG (DC+)

Mild Steel FCAW 5/64" (2.0mm) Innershield

®

Positive None Required

Self-Shielded Wire NS-3M Only (DC+) (Self-Shielded)

Hardfacing

.045 - 5/64" (1.2-2.0mm) Lincore

®

Positive

As Required

Self and Gas-Shielded (DC+)

Steel or Stainless 3/32" - 1/4" (2.4-6.4mm) Excalibur

®

7018 Positive None Required

SMAW, Stick and Fleetweld

®

6010 (DC+) (Stick Electrode)

Mild Steel or .025" - .052" (0.6-1.3mm) Super Arc

TM

Positive CO2 or CO2Ar Blended

Stainless MIG L-50 and L-56 and Blue Max

TM

(DC+) or Tri Mix

Aluminum 3/64" - 1/16" (1.2-1.6mm) SuperGlaze

TM

Positive

100% Argon

MIG 4043 and 5356 (DC+)

Air Carbon

5/32" - 5/16" (4.0-8.0mm)

Positive

Compressed Air

Arc Gouging (DC+)

[4]

www.lincolnelectric.com

1. Power Source

2. Input Cable, 4/0 - 100 ft. .......................................... L-4/0-100

3. Distribution Box ........................................................ K1736-1

4. Input Cable, 1/0 - 25 ft............................................... L-1/0-25

5. Welding Cable Connectors

Twist-Mate Male Connector.................................... K852-70

Twist-Mate Female Connector................................ K1759-70

6. Multi-Weld 350s ........................................................ K1735-1

7. LN-25 ........................................................................ K449

Multi-Weld 350

[4]

PROCESS CAPABILITIES

A CLOSER LOOK

SYSTEM SELECTION

SYSTEM SELECTION

Product Product Number

POWER SOURCE WITH 72V

MINIMUM OCV

(OPEN CIRCUIT VOLTAGE)

ACROSS THE ARC

WIRE FEEDER

(DC+ ONLY)

4

5

5

4

3

700 AMP ARC GOUGING TORCH

Page 5

RECOMMENDED OPTIONS

GENERAL OPTIONS

Distribution Box

Makes connecting up to 10

Multi-Weld 350’s quick and easy.

Contains copper bus bar for

connecting multiple “pig-tails”.

Four “pig tails” included.

Order K1736-1

Twist-Mate Cable Plug

For connecting welding cable to

output terminal receptacles. For

1/0-2/0 (50-70mm

2

) cable.

Order K852-70

Twist-Mate Cable Plug

For connecting welding cable to

output terminal receptacles. For

2/0-3/0 (70-95mm2) cable.

Order K852-95

Twist-Mate Cable Receptacle

For connecting welding cable to

Twist-Mate cable plug. For

1/0-2/0 (50-70mm2) cable.

Order K1759-70

Twist-Mate Cable Receptacle

For connecting welding cable to

Twist-Mate cable plug. For

2/0-3/0 (70-95mm2) cable.

Order K1759-95

GENERAL OPTIONS CONT.

Remote Output Control

Provides 25 ft. or 100 ft. (7.6m or

30m) of remote output control.

Connects to 6-pin receptacle on

front of Multi-Weld 350.

Order K857 — 25 ft. cable.

Order K857-1 — 100 ft. cable.

Undercarriage

Valet style undercarriage with

unique pull-out handle. Provides

torch cable storage (up to 50 ft.

lengths), work cable storage and

input cord wrap for the ultimate in

portability.

Order K1838-1

WIRE FEEDER OPTIONS

LN-15 Across-The-Arc

Wire Feeder

Portable, lightweight, compact

CC/CV unit for flux-cored and MIG

welding. Includes gas solenoid,

adjustable flow meter and internal

contactor. For 10-15 lb.

(4.5 - 6.8 kg) spools. For more

information, see publication E8.60.

Order K1870-1

LN-25 Across-the-Arc

Wire Feeder

Designed to run “across-the-arc”

with no control cables. This portable

wire feeder offers constant wire feed

speed in a rugged case. For more

information, see publication E8.100.

Order K449

Multi-Weld 350

www.lincolnelectric.com

[5]

Page 6

MULTI-WELD SYSTEM ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

MULTI-WELD 350 K1735-1

Recommended General Options

Distribution Box K1736-1

Twist-Mate Cable Plug 1/0-2/0 (50-70mm2) K852-70

Twist-Mate Cable Plug 2/0-3/0 (70-95mm2) K852-95

Twist-Mate Cable Receptacle 1/0-2/0 (50-70mm2) K1759-70

Twist-Mate Cable Receptacle 2/0-3/0 (70-95mm2) K1759-95

Input Cable, 1/0 - 25 ft. (7.6m) L-1/0-25

Input Cable, 4/0 - 100 ft. (30m) L-4/0-100

Remote Output Control - 25 ft. (7.6m) K857

Remote Output Control - 100 ft. (30m) K857-1

Undercarriage K1838-1

Recommended Power Source Options

SAE-400 See publication E6.180

Vantage 500 See publication E6.216

DC-655 See publication E5.46

DC-1000 See publication E5.50

DC-1500 See publication E5.60

Recommended Wire Feeder Options

LN-15 Across-the-Arc K1870-1

LN-25 Across-the-Arc K449

TOTAL:

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the

needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond

to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability,

with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to

such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has

been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility

of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

Loading...

Loading...