Page 1

VRTEX™360

IM10046-A

July, 2010

For use with machines having Code Numbers:

Safety Depends on You

Lincoln equipment is designed

an d bu ilt with sa fety in min d.

However, your overall safety can

be increased by proper installation ... and thoughtful operation

on your part. DO NOT INSTALL,

OPERATE OR REPAIR THIS

EQUIPMENT WITHOUT READING THIS MANUAL AND THE

SAFETY PRECAUTIONS CONTAINED THROUGHOUT. And,

most importantly, t hink before

you act and be careful.

AD1332-1 Software Version 1.0.7.7

AD1332-2

NOTICE

The VRTEX

tual reality arc welding

training machine only

and NOT a real arc

welder. When welding

with arc welding equipment, be aware of all

standard safety practices

associated with arc welding. Some standard

warnings are included in

this manual.

TM

360 is a vir-

OPERATOR’S MANUAL

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 888.935.3878 FAX: 216.383.8823 WEB SITE: www.VRTEX360.com

Copyright © Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

Page 2

Page 3

i

SAFETY

i

WARNING

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer, birth defects, and other reproductive harm.

The Above For Diesel Engines

ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information, it is strongly recommended that you

purchase a copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American Welding Society, P.O. Box

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available

from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

The Above For Gasoline Engines

FOR ENGINE

powered equipment.

1.a. Turn the engine off before troubleshooting and maintenance

work unless the maintenance work requires it to be running.

____________________________________________________

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

____________________________________________________

1.c. Do not ad d the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from vaporizing on con tac t with hot engine parts and

igniting. Do not spill fuel when filling tank. If

fuel is spilled, wipe it up and do not start

engine until fumes have been eliminated.

____________________________________________________

1.d. Keep all equipment safety guards, covers and devices in

position and in good repair.Keep hands, hair, clothing and

tools away from V-belts, gears, fans and all other moving

parts when starting, operating or repairing equipment.

____________________________________________________

1.e. In so me ca se s it may be ne ce ss ar y to remove safety

gu a rds to p erf o rm r equ ire d ma i nt e nan ce. Rem ove

guards only when necessary and replace them when the

ma i nte nan ce re q uir ing th ei r remo val is co mpl ete .

Always use the greatest care when working near moving

parts.

___________________________________________________

1.f. Do not put your hands near the engine fan.

Do not attempt to override the governor or

idler by pushing on the throttle control rods

while the engine is running.

1.h. To avoid scalding, do not remove the

radiator pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS

may be dangerous

2.a. Electric current flo wing thr ough any conductor caus es

localized Electri c and Mag netic Field s (EMF). Welding

current cre ates EMF fields aro und welding ca bles and

welding machines

2.b. EMF fields may interfere wi th so me pa ce makers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1.

Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Nev er co il th e electr ode l ead around your body .

2.d.3. Do not place your body between the electrode and

work cables. If the electrode cable is on your right

side, the work cable should also be on your right side.

___________________________________________________

1.g. To prevent accidentally starting gasoline engines while

turning the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

2.d.4. Connect the work cable to the workpiece as close as

possible to the area being welded.

2.d.5. Do not work next to welding power source.

VRTEXTM360

Page 4

ii

SAFETY

ii

ELECTRIC SHOCK can

kill.

3.a. The electrode and work (or ground) circuits

are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare

skin or wet clothing. We ar dry, hole-free

gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

mu st be perform ed under electrically hazardous

conditions (in damp locations or while wearing wet

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel , welding head , nozzle or semiautomatic

welding gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection

should be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical

(earth) ground.

3.f.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously t ou ch el ec tr ic al ly “hot” pa rt s of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see Items 6.c. and 8.

ARC RAYS can burn.

4.a. Use a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. Headshield and filter lens

should conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

can be dangerous.

5.a. Weldi ng may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. Wh en welding , k eep

your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing zone. When

we lding with ele ctr odes wh ich req uir e sp eci al

ve nti lat ion such as sta inl ess or hard fac ing (see

instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure as

low as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or mechanical

ventilation. In confined spaces or in some circumst anc es, outdoors, a res pir ato r ma y be r equ ire d.

Additional precautions are also required when welding

on galvanized steel.

5. b. The operation of welding fume control equipment is affected

by various factors including proper use and positioning of

the equipment, maintenance of the equipment and the specific welding procedure and application involved. Worker

exposure level should be checked upon installation and

periodically thereafter to be certain it is within applicable

OSHA PEL and ACGIH TLV limits.

5.c.

Do not weld in locations near chlorinated hydrocarbon

coming from degreasing, cleaning or spraying operations.

The heat and rays of the arc can react with solvent vapors

form phosgene, a highly toxic gas, and other irritating products.

5.d. Shielding gases used for arc welding can displace air and

cause injury or deat h. Al wa ys use e nough ventil at ion,

especially in confined areas, to insure breathing air is safe.

vapors

to

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

ma t eri al safe ty da ta shee t ( MSD S) and fo llo w you r

employer’s safety practices. MSDS forms are available from

yo u r weld ing di str i but or or fro m th e manu fac tur er.

5.f. Also see item 1.b.

VRTEXTM360

Page 5

iii

SAFETY

iii

WELDING and CUTTING

SPARKS can

cause fire or explosion.

6.a.

Remove fire hazards from the welding area.

If this is not possible, cover them to prevent

Re m emb er t hat wel din g sp ark s an d hot

materials from welding can easily go through small cracks

an d open ings t o adj acent areas . Avo id w el ding n ear

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site,

special precautions should be used to prevent hazardous

situations. Refer to “Safety in Welding and Cutting” (ANSI

Stand ard Z49.1) and the operating information for the

equipment being used.

6.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact

can cause overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances

inside. They can cause an explosion even

been “cleaned”. For information, purchase “Recommended

Safe Practices for the

Co n tai ner s and Pip ing Th at Hav e Held Ha zar dou s

Substances”, AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

Sparks and spatter are thrown from the welding arc. Wear oil

6.f.

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a

welding area.

6.g. Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

increase th e possibili ty of the welding current pas sing

through lifting chains, crane cables or other alternate circuits. This can create fire hazards or overheat lifting chains

or cables until they fail.

6.h. Also see item 1.c.

the welding sparks from st arting a fire.

though

they have

Preparation

for Welding and Cutting of

CYLINDER may explode

if damaged.

7.a. Us e onl y com pre sse d gas c yli nde r s

containing the correct shielding gas for the

pr o ces s us ed a n d pr ope rly o per ati ng

re g ula tor s d esi gne d f or th e g as an d

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

7.b. Always keep cylinders in an upright position securely

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected to

physical damage.

• A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

7.g. Re ad and fo ll ow the in struction s on c om pressed ga s

cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in

Cylinders,” available from the Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202.

FOR ELECTRICALLY

powered equipment.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Ins tall equipment in ac cordance with the U.S. National

Electrical Co de, all local codes and the manufacturer’s

recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention

During Welding, Cutting and Other Hot Work”, available

from NFPA, 1 Batterymarch Park, PO box 9101, Quincy, Ma

022690-9101.

6.j. Do not use a welding power source for pipe thawing.

Refer to http://www.lincolnelectric.com/safety for additional safety information.

VRTEXTM360

Page 6

iv

SAFETY

iv

PRÉCAUTIONS DE SÛRETÉ

Pour votre propre protection lire et observer toutes les instructions

et les précautions de sûreté specifiques qui parraissent dans ce

manuel aussi bien que les précautions de sûreté générales suivantes:

Sûreté Pour Soudage A L’Arc

1. Protegez-vous contre la secousse électrique:

a. Les circuits à l’électrode et à la piéce sont sous tension

quand la machine à souder est en marche. Eviter toujours

tout contact entre les parties sous tension et la peau nue

ou les vétements mouillés. Porter des gants secs et sans

trous pour isoler les mains.

b. Faire trés attention de bien s’isoler de la masse quand on

soude dans des endroits humides, ou sur un plancher

metallique ou des grilles metalliques, principalement dans

les positions assis ou couché pour lesquelles une grande

partie du corps peut être en contact avec la masse.

c. Maintenir le porte-électrode, la pince de masse, le câble

de soudage et la machine à souder en bon et sûr état

defonctionnement.

d.Ne jamais plonger le porte-électrode dans l’eau pour le

refroidir.

e. Ne jamais toucher simultanément les parties sous tension

des porte-électrodes connectés à deux machines à souder

parce que la tension entre les deux pinces peut être le

total de la tension à vide des deux machines.

f. Si on utilise la machine à souder comme une source de

courant pour soudage semi-automatique, ces precautions

pour le porte-électrode s’applicuent aussi au pistolet de

soudage.

2. Dans le cas de travail au dessus du niveau du sol, se protéger

contre les chutes dans le cas ou on recoit un choc. Ne jamais

enrouler le câble-électrode autour de n’importe quelle partie

du corps.

5. Toujours porter des lunettes de sécurité dans la zone de

soudage. Utiliser des lunettes avec écrans lateraux dans les

zones où l’on pique le laitier.

6. Eloigner les matériaux inflammables ou les recouvrir afin de

prévenir tout risque d’incendie dû aux étincelles.

7. Quand on ne soude pas, poser la pince à une endroit isolé de

la mas se. Un court-circ uit ac cidental peut pro voquer un

échauffement et un risque d’incendie.

8. S’assurer que la masse est connectée le plus prés possible

de la zone de travail qu’il est pratique de le faire. Si on place

la masse sur la charpente de la construction ou d’autres

endroits éloignés de la zone de travail, on augmente le risque

de voir passer le courant de soudage par les chaines de levage, câbles de grue, ou autres circuits. Cela peut provoquer

des risques d’incendie ou d’echauffement des chaines et des

câbles jusqu’à ce qu’ils se rompent.

9. Assurer une ventilation suffisante dans la zone de soudage.

Ceci est particuliérement important pour le soudage de tôles

galvanisées plombées, ou cadmiées ou tout autre métal qui

produit des fumeés toxiques.

10. Ne pas souder en présence de vapeurs de chlore provenant

d’o pérations de dégraissage, nettoyage ou pistolage. La

chaleur ou les rayons de l’arc peuvent réagir avec les vapeurs

du solvant pour produire du phosgéne (gas fortement toxique)

ou autres produits irritants.

11. Pour obtenir de plus amples renseignements sur la sûreté,

voir le code “Code for safety in welding and cutting” CSA

Standard W 117.2-1974.

PRÉCAUTIONS DE SÛRETÉ POUR

3. Un coup d’arc peut être plus sévère qu’un coup de soliel,

donc:

a. Utiliser un bon masque avec un verre filtrant approprié

ainsi qu’un verre blanc afin de se protéger les yeux du rayonnement de l’arc et des projections quand on soude ou

quand on regarde l’arc.

b. Porter des vêtements convenables afin de protéger la

peau de soudeur et des aides contre le rayonnement de

l‘arc.

c. Protége r l ’autre person nel travaillant à proximité au

soudage à l’aide d’écrans appropriés et non-inflammables.

4. Des gouttes de laitier en fu sion sont émise s de l’arc de

soudage. Se protéger avec des vêtements de protection libres

de l’huile, tels que les gants en cuir, chemise épaisse, pantalons sans revers, et chaussures montantes.

LES MACHINES À SOUDER À

TRANSFORMATEUR ET À

REDRESSEUR

1. Relier à la terre le chassis du poste conformement au code de

l’électricité et aux recommendations du fabricant. Le dispositif

de montage ou la piece à souder doit être branché à une

bonne mise à la terre.

2. Autant que possible, I’installation et l’entretien du poste seront

effectués par un électricien qualifié.

3. Avant de faires des travaux à l’interieur de poste, la debrancher à l’interrupteur à la boite de fusibles.

4. Garder tous les couvercles et dispositifs de sûreté à leur

place.

VRTEXTM360

Page 7

v

SAFETY

v

WARNINGS

Do not place objects on the VR Table, Arm

or Weld Machine.

Handle the Face Mounted Display (FMD)

integrated helmet with care. When not in

use, the Helmet should be placed on the

helmet hanger peg. If you will not be

using the system for longer than 4 hours,

shut down your VRTEX(TM) 360 System.

Handle t h e VR SMAW device and V R

GMAW/FCAW gun with care. When not in

use, these items should be placed on the

appropriate holders located on the sides

of the VR machine. These devices are

customized and cannot be used on normal welding machines.

Handle the VR Coupons with care. When

not in use, store them in the Coupon

Drawer at the b a c k o f the VR Weld

Machine.

During lightning storms, turn off the system and unplug it from the power outlet.

VRTEXTM360

Page 8

vi

SAFETY

vi

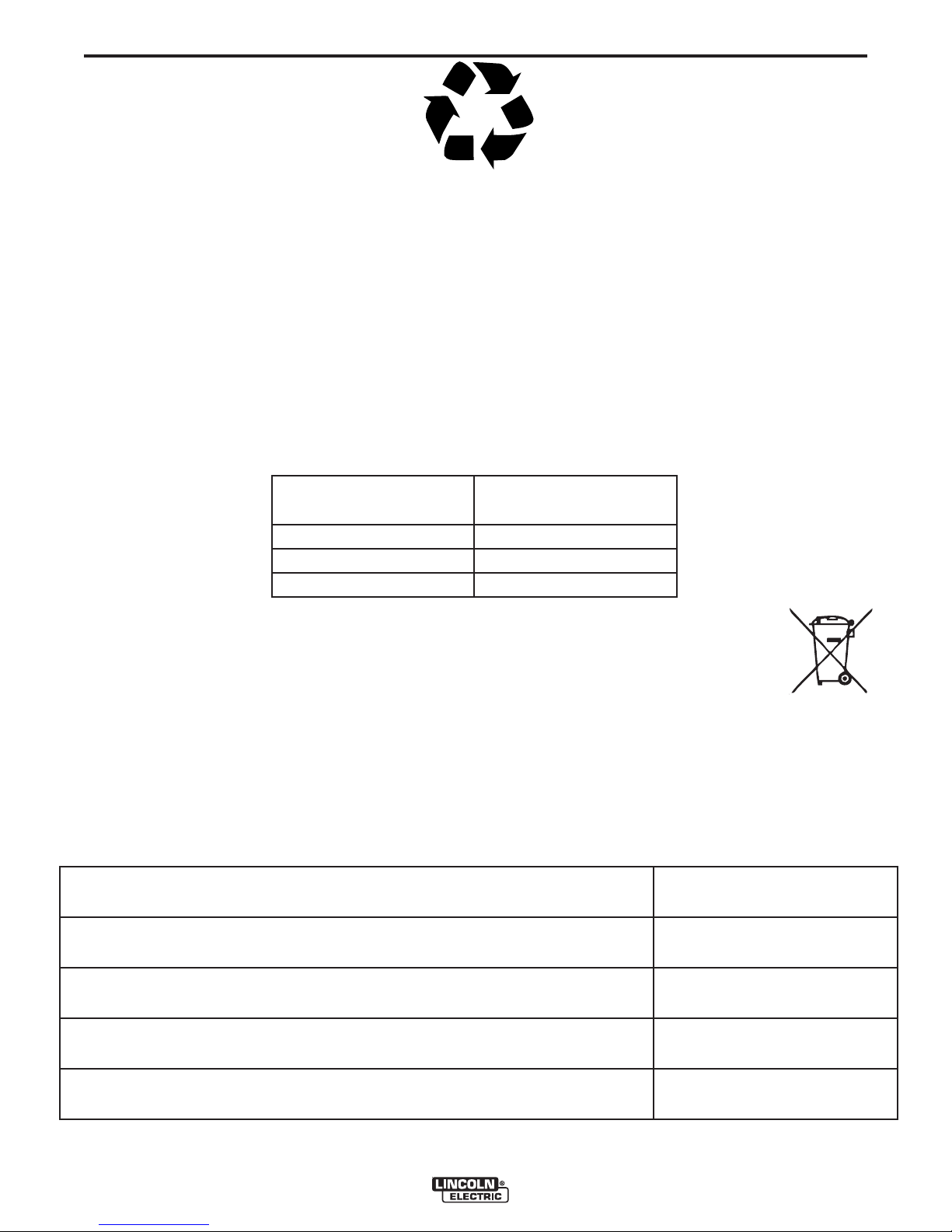

Recycling Welding Equipment at End of Life

Waste Electrical and Electronic Equipment (WEEE)

Recycling

Recycling and reclamation of used electrical and electronic equipment is important to many nations and localities. Lincoln

Electric provides information to assist in the recycling of welding equipment.

This parts list contains a “WEEE” column. The WEEE column describes potential recyclable materials. Materials that

require selective treatment, according to national regulations, are also identified in the WEEE column.

The following table describes substances that are potentially recyclable. Components with high substance content are

identified within the parts list. Easily identified and common components such as steel screws, steel nuts, steel washers

and copper wire are not identified on the list, but are also recyclable. Some components may contain mixed substances.

Substance

Steel, Iron Fe

Aluminum

Copper

Recyclable Material

Identification

Al

Cu

WEEE in Europe

This instruction is mandatory for equipment in Europe that displays this symbol:

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE) and its implementation in accordance with national law, electrical equipment that has reached the end of its life must be collected separately and returned to an environmentally compatible recycling facility. As the owner of the equipment, you should get

information on approved collection systems from your local Lincoln representative. By applying this European Directive

you will protect the environment and human health!

The following components must be removed from the welding equipment and shall be selectively treated. They shall be

disposed of or recovered in compliance with Council Directive 75/442/EEC. They are identified within the parts pages:

Component

Selective Treatment

Identification

Printed circuit boards with surface greater than 10 square centimeters ST

Liquid crystal displays with surface greater than 100 square centimeters ST

External electric cables (not all external cables are shown on parts pages) ST

Electrolyte capacitors with height >25 mm and diameter >25 mm or proportionately

similar in volume

ST

VRTEXTM360

Page 9

Thank You

viivii

for selecting a QUALITY product by Lincoln Electric. We want you

to take pride in operating this Lincoln Electric Company product

••• as much pride as we have in bringing this product to you!

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln

Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose,

with respect to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or

correcting any such information or advice once it has been given, nor does the provision of information or advice create, expand or alter any

warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control

of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in

applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com

for any updated information.

CUSTOMER ASSISTANCE POLICY

Please Examine Carton and Equipment For Damage Immediately

When this equipment is shipped, title passes to the purchaser upon receipt by the carrier. Consequently, Claims

for material damaged in shipment must be made by the purchaser against the transportation company at the

time the shipment is received.

Please record your equipment identification information below for future reference. This information can be

found on your machine nameplate.

Product _________________________________________________________________________________

Model Number ___________________________________________________________________________

Code Number or Date Code_________________________________________________________________

Serial Number____________________________________________________________________________

Date Purchased___________________________________________________________________________

Where Purchased_________________________________________________________________________

Whenever you request replacement parts or information on this equipment, always supply the information you

have recorded above. The code number is especially important when identifying the correct replacement parts.

On-Line Product Registration

- Register your machine with Lincoln Electric either via fax or over the Internet.

• For faxing: Complete the form on the back of the warranty statement included in the literature packet

accompanying this machine and fax the form per the instructions printed on it.

• For On-Line Registration: Go to our

“Product Registration”. Please complete the form and submit your registration.

Read this Operators Manual Completely before attempting to use this equipment. Save this manual

and keep it handy for quick reference. Pay particular attention to the safety instructions we have provided for your protection. The level of seriousness to be applied to each is explained below:

WEB SITE at www.lincolnelectric.com. Choose “Quick Links” and then

WARNING

This statement appears where the information must be followed exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to avoid minor personal injury or damage to this equipment.

VRTEXTM360

Page 10

viii

TABLE OF CONTENTS

Page

Installation .......................................................................................................Section A

Graphic Symbols ..................................................................................................................A-1

Technical Specifications.......................................................................................................A-2

Safety ...................................................................................................................................A-3

Location................................................................................................................................A-3

Environmental Area..............................................................................................................A-3

Stacking/Tilting/Lifting ..........................................................................................................A-3

High Frequency Interference Protection...............................................................................A-3

General Description..............................................................................................................A-4

Design Features ...................................................................................................................A-4

Hardware Uncrating & Set-up........................................................................................A-4/A-7

________________________________________________________________________________

Operation .........................................................................................................Section B

Product Description ..............................................................................................................B-1

User Interface Overview.......................................................................................................B-2

Hardware Specifications ................................................................................................B-3/B-5

Powering Up.........................................................................................................................B-6

Login Screen ........................................................................................................................B-7

Joint Configuration ...............................................................................................................B-8

Process Selection.................................................................................................................B-9

Stand Set-up ........................................................................................................................B-9

VR Coupons .........................................................................................................................B-9

Table/Arm Rotation ............................................................................................................B-10

Environment .......................................................................................................................B-11

VR Gas Set-up ...................................................................................................................B-11

Weld Machine Settings.......................................................................................................B-12

Push Buttons ......................................................................................................................B-13

Travel / Work Angle............................................................................................................B-14

Welders View .....................................................................................................................B-15

Instructors View..................................................................................................................B-15

LASER (Live Action Student Evaluation Report)................................................................B-15

Technique Parameters .......................................................................................................B-16

Position...............................................................................................................................B-17

Work/Travel Angle..............................................................................................................B-17

Pass Number, Travel Direction, Discontinuities .................................................................B-18

Instructor Mode ..................................................................................................................B-19

Updates ..............................................................................................................................B-19

Weldometer

Tolerance Editor .................................................................................................................B-21

Choosing Tolerance Set-up................................................................................................B-22

Choosing Tolerance To Load .............................................................................................B-22

Tolerances Screen(s) ................................................................................................B-22/B-25

Tolerances Whip & Travel Speed.......................................................................................B-26

Default Weld Processes Settings .......................................................................................B-27

________________________________________________________________________________

TM

.....................................................................................................................B-20

viii

Maintenance ....................................................................................................Section D

Cleaning & Maintenance .......................................................................................D-1

________________________________________________________________________

Troubleshooting..............................................................................................Section E

How to Use Troubleshooting Guide.......................................................................E-1

Troubleshooting Guide....................................................................................E-2/E-3

________________________________________________________________________

Wiring Diagrams..............................................................................................Section F

________________________________________________________________________

Parts Pages..............................................................................................................P638

VRTEXTM360

Page 11

A-1

INSTALLATION

GRAPHIC SYMBOLS THAT APPEAR ON

THIS MACHINE OR IN THIS MANUAL

A-1

1

INPUT POWER

ON

OFF

CIRCUIT BREAKER

INPUT POWER

SINGLE PHASE

ALTERNATING CURRENT

READ THIS OPERATORS

MANUAL COMPLETELY

U

1

I

1

INPUT VOLTAGE

INPUT CURRENT

PROTECTIVE

GROUND

WARNING or CAUTION

Documentation must be consulted in all cases where this

symbol is displayed.

Explosion

Dangerous Voltage

USB

Shock Hazard

Shock Hazard

VRTEXTM360

Page 12

A-2

INSTALLATION

TECHNICAL SPECIFICATIONS: AD1332-1 (STD. FREQ.) / AD1332-2 (ALT. FREQ.)

VRTEX™360 - VIRTUAL REALITY WELDING TRAINER

INPUT

MAKE/MODEL DESCRIPTION INPUT VOLTAGE INPUT CURRENT

+/- 10% (MAX.)

A-2

AD1332-1

AD1332-2

Standard Frequency 115-230 VAC (50-60 HZ) 4A-2A Single Phase

Alternate Frequency 115-230 VAC (50-60 HZ) 4A-2A Single Phase

WARNING

THIS PRODUCT INCORPORATES A PROTECTIVE EARTH IN THE AC POWER CORD. THE AC PLUG

SHOULD ONLY BE INSERTED INTO A SOCKET OUTLET PROVIDED WITH A

PROTECTIVE EARTH CONTACT.

TRACKING SYSTEM FREQUENCY

MAKE/MODEL DESCRIPTION OPERATING FREQUENCY

AD1332-1

AD1332-2

PHYSICAL DIMENSIONS (MACHINE W/MONITOR)

HEIGHT WIDTH DEPTH WEIGHT

71.0 in. 30.0 in. 50.0 in. 360 lbs.

1803 mm 762 mm 1270 mm 163 kg.

Standard Frequency HIGH

Alternate Frequency LOW

1

C

PHYSICAL DIMENSIONS (STAND)

HEIGHT WIDTH DEPTH WEIGHT

78.0 in. 39.0 in. 47.0 in. 102 lbs.

1981 mm 990 mm 1194 mm 46 kg.

TEMPERATURE RANGES

OPERATING TEMPERATURE RANGE STORAGE TEMPERATURE RANGE

0

- 950F5

41

0

- 350C 320 - 1490F 00 - 650C

RELATIVE HUMIDITY OPERATING ALTITUDES

80% For Temperatures Up To 880F / 310C

50% @ 1040F / 400C 6562 Feet (2000 Meters)

ENVIRONMENT

This Product is Pollution Degree 1.

THIS PRODUCT HAS BEEN TESTED TO THE REQUIREMENTS OF CAN/CSA-C22.2 NO. 61010-1,

2ND EDITION, INCLUDING AMENDMENT 1, OR A LATER VERSION OF THE SAME STANDARD

INCORPORATING THE SAME LEVEL OF TESTING REQUIREMENTS.

VRTEXTM360

Page 13

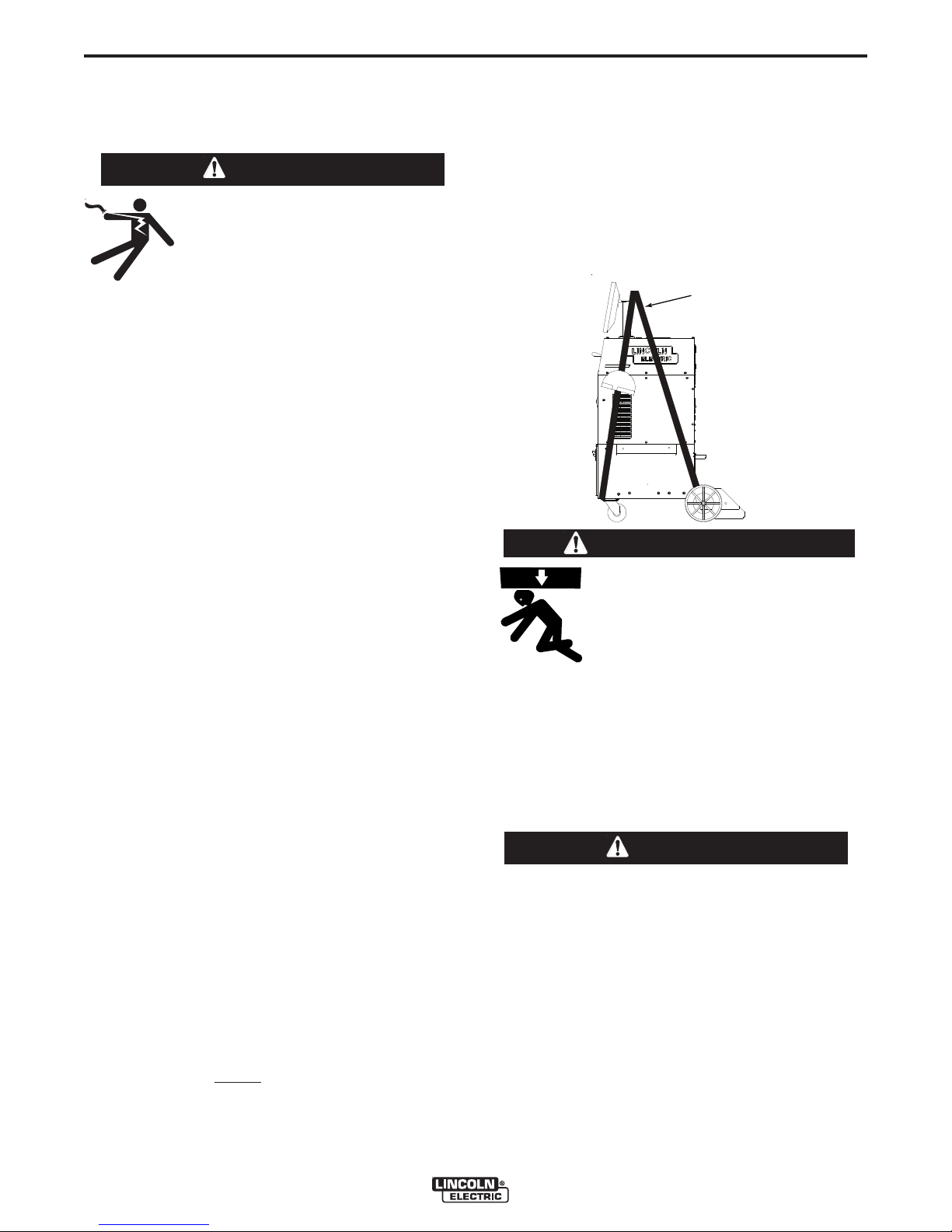

A-3

STRAPS

STRAPS

READ ENTIRE INSTALLATION SECTION BEFORE

STARTING INSTALLATION.

INSTALLATION

Safety Precautions

A-3

TILTING

Place the VRTEXTM360 directly on a secure, level surface.

WARNING

ELECTRIC SHOCK can kill.

• Only qualified personnel should perform this installation.

• Tur n the input p ower OFF and

unplug the machine from the receptacle before working on this equipment.

•

• Always connect the

ply grounded according to the National Electrical

Code and local codes.

------------------------------------------------------------

SELECT SUITABLE LOCATION

The machine will not operate in harsh environments.

It is important that simple preventative measures are

followed in order to assure long life and reliable operation. This product is for INDOOR USE ONLY.

• Dirt and dust that can be drawn into the machine

should be kept to a minimum. Failure to observe

these precautions can result in excessive operating

temperatures and nuisance shutdown.

• Do not locate where monitor is exposed to direct

sunlight.

VRTEXTM360

to a power sup-

If lifting the

rated for 500 pounds (226.8 kg) or more. Do not attempt to

lift the

VRTEXTM360

VRTEXTM360

is required, use two straps, each

with accessories attached to it.

• Lift only with equipment of adequate lifting capacity.

• Be sure machine is stable when

lifting.

• Do not operate machine while

suspended or when lifting.

• Do not place equipment near radiant heat sources.

• Do not place in a confined space. Allow a minimum

of 3 feet of clearance around machine and stand at

all times. Adequate ventilation is necessary.

• The circuit breaker switch on the rear panel is the

input power disconnect device. Do not position the

equipment so that it is difficult to operate the circuit

breaker.

• Route and protect power cable to minimize exposure

to damage.

ENVIRONMENTAL AREA

Keep the machine inside and dry at all times. Do not

place it on wet ground or in puddles. Never place liquids on top of the machine.

STACKING

The VRTEXTM360 cannot be stacked.

FALLING EQUIPMENT can cause injury.

------------------------------------------------------------------------

HIGH FREQUENCY INTERFERENCE PROTECTION

CAUTION

USE CAUTION WHEN OPERATING THIS MACHINE

AROUND OTHER EQUIPMENT.

• Large equipment, such as cranes, may interfere

with the operation of this machine.

• This machine may interfere with the operation of

other equipment in work/training area.

VRTEXTM360

Page 14

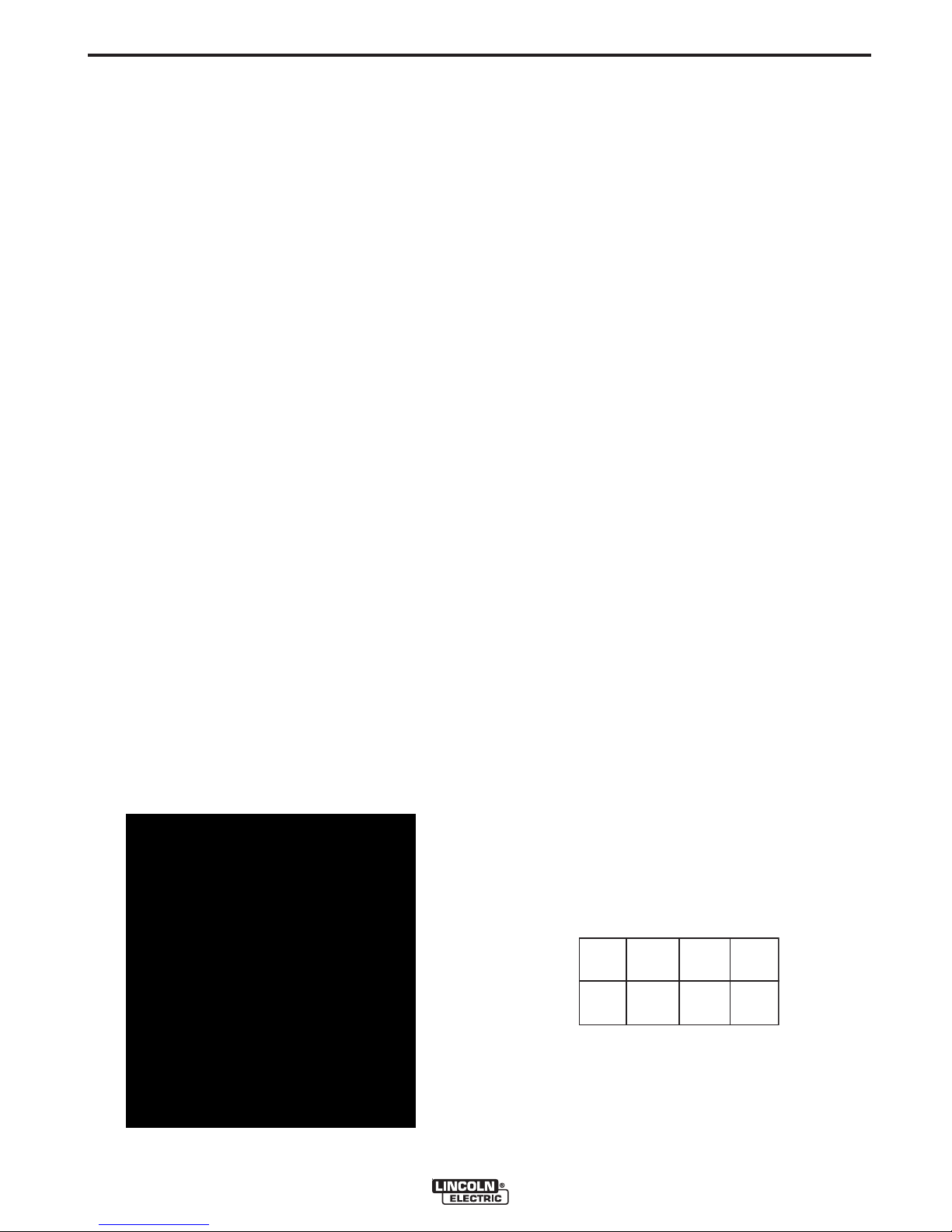

A-4

-1-2-1-2

-2-1-2-1

-1 -2 -1 -2

-2 -1 -2 -1

INSTALLATION

GENERAL DESCRIPTION

The VRTE XTM360 is a Virtual W elding Training

System and VRAW

Solution. This computer controlled interactive system

simulates arc welding through the use of realistic puddle graphics and sounds. This training system simulates multiple arc welding processes on a wide variety

of weld joint configurations. The VRTEX

sents the next generation of Virtual Reality (VR) welding training.

TM

(Virtual Reality Arc Welding)

TM

360 repre-

DESIGN FEATURES

HARDWARE OVERVIEW:

• Virtual Welding Machine, including:

o Monitor

o Coupon Drawer (back drawer)

o VR GMAW/FCAW Gun

o VR SMAW Device

o VR GMAW/FCAW Gun Holder

o VR SMAW Device Holder

o VR Helmet w/Face Mounted Display (FMD)

o Five VR Coupons - Flat Plate

Tee Joint

Groove Joint

2” Pipe XXS

6” Pipe Schedule 40

• Stand, including:

o Post

o Arm

o Table

o Pins

o Base

o Weights

A-4

HARDWARE UNCRATING:

TOOLS NEEDED

3/8” (9.5 mm) Wrench

3/16” (4.8 mm) Allen Wrench

Phillips Screwdriver

1. Decide on a location for your unit.

NOTE: The system requires approximately 8’ L x 8’

D x 8’ H (2.4 m L x 2.4 m D x 2.4 m H) of

space. Keep at least 3 feet in all directions

of both the stand and VR weld machine free

from obstruction. In addition, be conscious

of where you are placing the unit to avoid

magnetic fields, conductive, and high frequency ob jects and processes. H aving

these types of objects in the area can cause

interference and result in increased jitter

and/or distortion in the motion tracking.

TM

For best results, do not install VRTEX

machine in the welding lab. Electrical interference from power lines, though generally

small, can be present. Therefore all electrical power or lighting wiring within 50 feet of

the we lding area sha l l be e n closed in

grounded rigid metallic conduit. In the event

the VRTEX

TM

360 is affected by interference,

it is the user's responsibility to take steps to

isolate and/or eliminate the interference.

An uninterruptible power supply (UPS) may

be required for the protection of the system

from power irregularities or disruption.

MULTIPLE SYSTEM INSTALLATIONS

If multiple systems are required to operate together in

one location, a unique frequency transmitter can be

installed during the manufacturing process at Lincoln

Electric to reduce potential interference between systems. AD1332-1 systems have a standard frequency

source installed. AD1332-2 systems have an alternate

frequency source installed. For multiple system installations, alternate the -1 and -2 systems for best operation:

360

For Example: If 8 systems are to be installed in the VR

welding lab, the standard and alternate frequencies

should be positioned as seen below.

2. Using the 3/8” (9.5 mm) wrench, remove the screws

from the upper and lower front panels on the shipping crate.

NOTE: The rear of the crate is nailed on. Nail removal is

not required during the installation of this equipment.

VRTEXTM360

Page 15

A-5

INSTALLATION

FRONT

(upper)

FRONT

(lower)

BOLTS

3. Remove the six 3/8” (9.5 mm) bolts (three on each

side) from the bottom of the crate assembly.

A-5

6. Remove the monitor from the back of the machine.

7. Using the 3/8” (9.5 mm) wrench, remove the two

screws from the rear base securing the unit to the

wooden crate.

4. Car efull y s lide the cra te assem bly from the

VRTEXTM360 towards the rear of the machine. Be

careful to avoid damaging the welding device holders located on each side of the machine.

6. Carefu lly rem ove the po st (lo ng rectang ular

shaped cardboard box) from the crate.

5. Carefully cut and remove plastic wrapping from

the machine.

8. Remove the four screws from the wooden rear

cross brace.

9. Remove the wooden cross brace while ensuring

the unit is steady and secure.

10. Carefully roll the machine off the rear of the skid.

Ramping may be required.

11. Uncrate and unpack the table and table base.

VRTEXTM360

Page 16

A-6

Table

Weights

Stand

Screws

Table

Weights

Stand

Screws

INSTALLATION

5. Obtain the three post collar pins from the factory

packaging of the VRTEXTM360.

A-6

TABLE & SWING ARM SET-UP:

1. Place counter weights on base.

2. Using the 3/16” (4.8 mm) allen wrench, remove the

two ¼” x 20 Allen-head screws from the base

assembly.

NOTE: The longer screw is in the top.

Swing Arm

Table

Collar

Pins

6. Insert one of the collar pins into the post at the #6

location.

7. From the top, slide the table onto the post letting it

rest on the collar pin inserted in previous step.

8. Insert the second collar pin into the post at the #13

position.

9. Obtain the swing-arm from the rear of the VRTEX

360 by removing the cable ties from the swing arm

and cable. Grey cable should remain connected to

the VRTEX

TM

360 (DO NOT CUT!).

Post

T Pin

TM

3. Insert red post into base assembly aligning the flat

on the pole with the hole.

NOTE: The post will only insert one way.

4. Using the 3/16” (4.8 mm) allen wrench, secure the

post into position by replacing and tightening the

screws.

Cable Tie

Grey Cable

(DO NOT CUT)

VRTEXTM360

Page 17

A-7

SVGA Out

Audio Jack

Always i

n

the On posi

tion

Input Power

connection

SVGA Out

Audio Jack

Always i

n

the On posi

tion

Input Power

connection

INSTALLATION

A-7

9. Carefully slide swing-arm onto post with the letters

(on the collar) “ABC” up and the grey cable located

on the bottom of the swing arm assembly.

10. Insert a third collar pin at a convenient height for

holding the helmet.

MONITOR:

Note: always use the factory supplied

monitor with the VRTEX(TM) 360

1. Remove monitor from cardboard box.

MONITOR (Mounting Screws)

Screws

BACK OF MACHINE

3. External speakers may be connected using the

audio jack located on the back of the machine.

TRACKING SYSTEM FUNDAMENTALS:

The magnetic tracking system is composed of the

following:

Input

VGA

Power

2. Remo v e the cable ties from monito r cabl e s

secured to the monitor mounting post.

3. Using a Phillips-head screwdriver to carefully

mount the monitor onto the mounting post bracket.

Tighten the four Phillips-head screws securely.

4. Connect input power cable and VGA cable into the

monitor.

APPLY SYSTEM POWER:

1. Insert the input supply power cord into the back

of the VRTEXTM360 and into a standard electrical

outlet capable of 115 to 230 VAC at 4 to 2 Amps.

ADDITIONAL FEATURES:

• Control Unit (Inside VR Machine)

o Contains the hardware and software neces-

sary to compute position and orientation.

• Source (part of the Swing Arm)

o The source contains electromagnetic coils

enclosed in a plastic shell that emit a magnetic

field. The source is the system’s reference

frame for sensor measurements.

• Sensor (in the VR GMAW/FCAW gun, VR SMAW

device, and helmet)

o The sensor contains electromagnetic coils

enclosed in a plastic shell that detect the magnetic fields emitted by the source. The sensor’s position and orientation are precisely

measured as it moves in reference to the

source. The sensor is completely passive,

having no active voltage applied to it.

1. The welding coupons are stored in the coupon

drawer in the rear of the machine.

2. The weld simulation can be displayed on an external monitor or projector by using the SVGA output

on the back of the machine. The external display

must support 1024x780 resolution.

VRTEXTM360

Page 18

B-1

1

2

3

6

7

8

10

11

9

6

5

4

12

14

13

1

2

3

6

7

8

10

11

9

6

5

4

12

14

13

PRODUCT DESCRIPTION

OPERATION

B-1

The VRTEXTM360 is a virtual reality arc welding training machin e only and NOT a real arc w elding

machine. Please be aware of all standard safety

practices associated with welding. Some standard

warnings are included in this manual.

If the equipment is used in a manner not specified by

the manufacturer, the protection provided to the

equipment and user may be impaired.

FRONT OF MACHINE

Access panels are not to be removed except by qualified service personnel due to risk of electric shock

from accessible live parts.

VRTEXTM360

Page 19

B-2

OPERATION

B-2

USER INTERFACE OVERVIEW

The VRTEXTM360 is a virtual reality arc welding trainer. This computer based training system is an educational tool designed to allow students to practice their

welding technique in a simulated environment. It promotes the efficient transfer of welding skills from the

classroom to the welding booth, while reducing material waste and energy consumption associated with traditional welding training.

See figure on page B-1 for locations of operator controls and indicators.

1. The monitor allows the student to view the setup

screens and provides an active view of the actual

welding process for teachers and students. The

monitor can be rotated for ease of viewing. Make

certain the power button on the monitor is ON and

the green LED is lit.

2. Th e joys tic k allo ws the op erator to nav igate

through various options by moving the red highlighted box and zoom / r o tate the coupon in the

Instructor View.

3. The colored buttons on the front of the machine

correlate to the colored rectangles at the bottom of

the monitor screen when the simulation software is

running. These buttons perform various functions

depending upon the command shown in the corresponding box on the screen.

10. The key switch is located on the lower right of the

control panel. When the system is in the login

screen the instructor may insert the key shipped

with the system into the key lock and then rotate it

90 degrees to the right. This allows the instructor

to access the instructor mode which includes the

Weldometer

Update screens.

11 Pressing and holding the green circular button

for 3 seconds powers up the VRTEX

Note: The green power button does not power

down the system. Select Log Out and Shutdown

from the red menu to turn off the system

12. The red select button accepts (enters) the data

displayed or highlighted on the monitor.

13. VR GMAW/FCAW gun holder should be used to

store the VR GMAW/FCAW gun when not in use.

14. VR SMAW devi ce hold er sho uld be used t o

store the VR SMAW device when not in use.

TM

, Tolerance Editor, Options and

TM

360 system.

4. The wire feed speed/amperage dial allows the

user to input wire feed speed or amperage depending on the VR welding process selected.

5. The voltage dial allows the user to input the weld-

ing voltage. This dial also allows input of trim values when pulse process is in use.

6. The left and right white screen select arrows

allow the operator to cycle through various screens.

7. The process selector switch is used to selected

the virtual welding process. (GMAW, FCAW, or

SMAW)

8. The polarity selector switch is used to indicate

the welding polarity for any given process. (DC+,

DC-, or AC).

9. The USB port is used to upload software and

download user data from the system.

VRTEXTM360

Page 20

B-3

OPERATION

B-3

HARDWARE SPECIFICS:

VR GMAW/FCAW GUN

The VR gun has a trigger that is used during the simulation of GMAW and FCAW processes to initiate and

main t ain the simul a ted weldin g a r c. T he V R

GMAW/FCAW gun should be placed on the round gun

holder on the right side when not in use.

VR GMAW/FCAW GUN

CAUTION

In order to strike an arc with the VR SMAW device,

strike or tap the tip of the rod (of the VR SMAW

device) on the coupon being welded. To break the

arc, move the VR SMAW device rod away from the

work piece.

CAUTION

Do not try to strike the arc with excessive force,

as the arc start is distance based. Excessive

force may result in da mage to the VR SM AW

device.

The angle of the rod can be changed by squeezing

the handle of the VR SMAW device. This allows the

rod to be moved into the 45 or 90 degree position.

Once the rod is at one of these angles, release the

handle. The rod should now be fixed in that position.

Do not change the rod angle while the rod is

extending or retracting.

VR SMAW DEVICE

Store gun as shown below to

avoid damage.

VR GMAW/FCAW GUN (Properly Stored)

VR SMAW DEVICE

The VR SMAW device has a rod that represents a

stick electrode. This rod retracts when a virtual arc is

struck to simulate the electrode burning off during the

virtual welding process. When the virtual electrode

burns down to a stub, the rod will stop retracting and

the user will no longer be able to weld. When the user

presses “new stick” in the orange actions menu button, the rod extends out, simulating that a new electrode was put into the VR SMAW device. When not in

use, the VR SMAW device should be placed in the VR

SMAW holder on the left side of the VR weld machine.

CAUTION

Store device as shown below to

avoid damage.

VR SMAW DEVICE (Properly Stored)

VRTEXTM360

Page 21

B-4

RATCHET KNOB

HEAD GEAR

FORE / AFT ADJUSTMENT

TILT ADJUSTMENT

CROWN

A

DJUSTMENT

PIN HOLES FOR

ADJUSTMENT

RATCHET KNOB

HEAD GEAR

FORE / AFT ADJUSTMENT

TILT ADJUSTMENT

CROWN

A

DJUSTMENT

PIN HOLES FOR

ADJUSTMENT

OPERATION

B-4

Helmet

Adjust the helmet so it fits comfortably. Adjustments

can be made by depressing and turning the knob at

the b ack of th e helm et unt il the de sired size i s

achieved. If necessary, the user may also have to

adjust the top crown adjustment to fit their head size.

HELMET FUNCTIONS

The helmet has an FMD (Face Mounted Display) on

the inside. These FMD lenses display the virtual environment to the user. Each lens can be shifted left or

right to align with the users eyes by applying gentle

pressure. In addition, the lenses can be lifted up and

down as well as shifted forward and back for the best

fit. The user should make sure the lenses are parallel

to their eyes. Keep the lenses clean at all times. See

Cleaning and Maintenance Section.

HELMET LENSES

Coupon Drawer

The coupon drawer houses the physical coupons.

When not in use, the coupons should be stored in the

drawer. To open the drawer, press the top indent

down, and slide the drawer out. Each coupon fits in

its own area defined by the foam locator in the drawer.

COUPON DRAWER

Coupons

The coupons represent the various workpieces on

which the user can virtually weld. During the virtual

welding process, they provide physical feedback to

the student.

There are five VR Coupons:

1. Flat Plate

2. Tee Joint

3. 3/8” Groove Joint w/Backing Bar

4. 2” Diameter XXS Pipe

5. 6” Diameter Schedule 40 Pipe

LENSES

When not in use, the helmet should be hung from the

stand or placed in the right front drawer to avoid being

damaged.

EAR

BUDS

VRTEXTM360

VR COUPONS

5

2

4

1

The coupons along with the VR SMAW device and VR

GMAW/FCAW gun have been factory calibrated at

Lincoln Electric.

3

Page 22

B-5

OPERATION

B-5

Stand

The stand is comprised of the post, arm, table, collar

pins, base and two weights. Users should position

themselves at the stand during virtual welding.

Post

The arm and table slide up and down and rest on the

collar pins that are inserted into the post. Hole numbers 0 through 28 indicate position of welding for program accuracy. The position that the table or arm is

located is read by identifying the numbered hole that

the pin has been inserted into.

POST W/PIN INSERTED IN #18

SWING ARM ROTATION

POS. A

POS. B

POS. C

Table

The table can be used to gain stability and learn proper body positioning. The base supports the stand and

has weights on the back to maintain stability. The

table can be swung out of the way when not in use.

CAUTION

Do n ot us e the Stand/Table w ithou t the base

counter weights properly positioned.

___________________________________________

Coupon Positioning In Swing Arm

The coupons can be inserted into the arm to accommodate flat, horizontal, vertical or overhead welding

positions. The knob on the front of the swing arm can

be pulled out for coupons to be inserted or removed

and pushed in for coupons to be secured. The front of

the swing arm can be rotated down at a 45 or 90degree angle to allow 2G, 5G and 6G pipe welding

positions. The arm can also be rotated around the

post to comfortably accommodate left and right handed welders or simulate specific welding applications.

COUPON INSERTION / REMOVAL

TABLE ROTATION

Do not use excessive force when inserting and

removing coupons into the arm.

VRTEXTM360

Page 23

B-6

OPERATION

B-6

Powering Up Your System:

1. After you have set up the hardw are and have

become familiar with the user controls, you will be

ready to use your system.

2. Plug the power cord into a standard outlet.

3. Press and hold the green circular button on the

front panel until it lights up and you hear fans running inside the machine. (approx. 3 seconds)

GREEN CIRCULAR BUTTON LOCATION

4. Your system will start up.

However, users can set and use their own tolerances

for teaching beginner welders. The tolerances also

determine how the user is scored on such parameters

as work angle, travel angle, travel speed, position,

and contact tip to work distance or arc length. The

software will step the user through the following setup

screens:

• Login

• Joint configuration selection

• Process selection

• Stand set up

• Environment

• Gas set up

• Weld machine settings

• Instructor’s view

• Welder’s view

• LASER (Live Action Student Evaluation Report)

The key provided with the system allows the user to

access the Instructor Mode with additional information

and set-up pages.

• Weldometer

TM

• Tolerance Editor

• Options

• Update

5. Wait a few minutes until your system displays the

login screen on your monitor.

LOGIN SCREEN

System Setup Information

When setting up the virtual equipment, the user must

set the welding parameters (e.g. wire feed speed for

VR GMAW) within the ranges set in the tolerance editor. The system ships with Lincoln default tolerances.

Lincoln default tolerances can be reviewed in the tolerance editor, or refer to the Default Weld Process

Settings Chart (if using the default settings) located at

the end of this OPERATION SECTION. The WPS’s

are also available on www.VRTEX360.com.

VRTEXTM360

Page 24

B-7

OPERATION

B-7

Login Screen:

Overview

This page allows the user to:

• Enter Username

• Select Language Preference

• Select Imperial or Metric Units

• Shutdown System

• Continue to the next Setup Screen

1. On Screen Keyboard

The user enters their name by using the joystick and

red select button on the VR weld machine. The joystick allows the user to navigate the keyboard graphic

to highlight letters. Pressing the red select button

enters the letter highlighted into the enter name box

as indicated. The virtual keyboard starts with shift

enabled, so the first letter is automatically capitalized.

The user can select shift or lock (equivalent to caps

lock on a standard keyboard) at any time. If the user

makes a mistake, they can select the back arrow to

delete the last character entered.

LOGIN SCREEN

Press the red select button to accept.

Press the yellow button again to exit the language

menu. The system stores the language selection and

will automatically start up in the same language the

next time.

3. Measurement Units

The blue unit menu button brings up the measurement

system. Use the joystick to highlight the desired unit

of measurement. Press the red select button to

accept. Press the blue again to exit the measurement

unit menu. Selecting Metric or Imperial converts the

user interface into the corresponding measurement

system. The system stores the measurement selection, so it will automatically start up in the same unit of

measurement the next time. The system uses the

units shown in Table B.1.

4. Menu

The red menu button allows the student to shut down

the system. If the user selects shutdown, a submenu

appears asking the user if they are sure that they want

to shut down the system. This prompt prevents the

user from accidentally shutting down the system. If

the user selects “Yes”, the VRTEX

down.

TM

360 will shut

2. Language

Selecting the yellow language menu button brings up

the list of languages the software supports. Use the

joystick to highlight the desired language.

TABLE B.1

CAUTION

THIS METHOD SHOULD ALWAYS BE USED TO

SHUT DOWN THE VRTEX

could cause damage to the system.

5. Continue

After the user enters their name and all selections

outlines above have been made

panel button is pressed to continue to set up process.

TM

360. Failure to do this

, the green

VRTEXTM360

Page 25

B-8

OPERATION

B-8

Join t Confi gura tion Se lection

Screen:

Overview

The user selects which joint configuration they want to

virtually weld. First, the user selects the joint and

position. Using the joystick and the red select button,

the user highlights and selects the joint type and position in which to weld. A rotating view of the highlighted coupon shows in the upper area. For some configurations, the user will be given the choice of material

thicknesses to choose from. The user selects material thickness by using the joystick and red select button. See Table B.2 for supported joint configurations.

JOINT CONFIGURATION SELECTION SCREEN

Menu

Selecting Logout takes the user to the login screen,

with the user’s name removed.

Back

Selecting Back takes the user back to the previous

screen.

TABLE B.2

VRTEXTM360

Page 26

B-9

OPERATION

B-9

Process Selection Screen:

Overview

This screen allows the user to select the welding

processes. To change among VR GMAW, VR FCAW,

and VR SMAW, the user moves the process switch on

the front of the weld machine. See the joint configuration chart for available processes. If a process is not

supported for the selected material/thickness, it is

greyed out on this screen and cannot be selected. To

choose among different sub-processes, use the joystick and red select button or green continue button.

At the top of the screen, the user can see the coupon

position and thickness selected. As the user continues to set up the simulation, additional information will

be added to the right of this readout, so that the user

can reference what has previously been selected.

PROCESS SELECTION SCREEN

Stand Set-Up Screen:

Overview

The correct VR stand information must be put into

the software for the VRTEX

erly in all virtual welding applications.

STAND SET-UP SCREEN

Coupon Insertion

Insert one of the VR coupons into the desired position

in the physical VR stand. Make sure the coupon is

fully seated into the track and then lock the coupon in

place by pushing in the knob at the end of the arm.

To release, pull the knob into the unlocked position

and remove the coupon. When the system is in use,

the coupon should always be lock ed in place to

assure system accuracy.

TM

360 to operate prop-

Menu

Selecting Logout brings the user back to the login

screen, with the user’s name removed.

Change Coupon Type

Selecting Change Coupon Type goes back to the

configuration selection screen.

Back

Selecting Back takes the user to the previous screen.

VRTEXTM360

VR COUPON (UNLOCKED POSITION)

Page 27

B-10

OPERATION

B-10

Table/Arm Rotation

Move the physical VR table and arm to the desired

location for the position and joint configuration selected. To raise or lower the arm or table, hold the

arm/table in place and pull out the pin in the pole supporting it. Replace the pin in the hole that supports

th e arm/table at the proper height a nd res t the

arm/table on the pin. If the table is not needed,

swing the table to the left or right and out of the way.

The arm can also be rotated to the left (A), center (B)

or right (C) of the table.

SWING ARM ROTATION

POS. A

POS. B

POS. C

Pin Positions

When the physical stand is in the desired position,

proceed with the following: Use the joystick and red

select button to enter the numbers that appear next to

the pin positions for the table and arm height into the

stand setup screen. The image on the right side of

the stand setup screen moves to match the selections

entered on the left. If the table is in the “away” position, enter a table height value of 0. Next, enter the

arm rotation position A (left), B (center), or C (right).

The arm position letter aligns with the vertical pin

number sticker. An arm height of 18 and and arm

rotation of A are shown in the picture below.

PIN POSITIONS 18 A

TABLE ROTATION

Note: If the table height indicator in the software

cannot be moved to the pin height indicated

on the post, move the arm height indicator

in the software to a higher position and try

again. See Troubleshooting Guide if necessary.

VRTEXTM360

Page 28

B-11

Indicate the coupon orientation used on the physical

stand in the coupon rotation area of the stand setup

screen. The red arrow indicates which side of the

coupon that the weld will be made. For pipe configurations, the coupon rotation is replaced with arm

angle. The arm angle can be adjusted by removing

the pin at the end of the arm, rotating the arm to 45 or

90 degrees from its original location, and reinserting

the pin. This is only used to accommodate 2G, 5G

and 6G pipe welding.

STAND SET-UP SCREEN (PIPE)

The physical stand should match the stand image

when these selections are completed. To continue,

press the green continue button. The stand setup verification screen will be displayed. This screen serves

as a reminder to make sure VR stand components

match the screen. When verified, press the green

continue button again.

STAND SET-UP SCREEN OVERLAY

OPERATION

B-11

ENVIRONMENT SCREEN

Menu

Selecting Logout takes the user back to the login

screen, with the user’s name removed.

Back

Selecting Back takes the user to the previous screen.

Gas Set-Up Screen:

Overview

On this screen, the user selects the gas mixture and

gas flow rate. The correct gas mixture and flow rate

must be entered according to the tolerance editor. If

acceptable values are not entered, this will be indicated on a later screen and the user may have to go

back and change the selection on this screen.

To select the gas mixture, use the joystick and the red

select button. The available gas mixtures are shown

on the gas set-up screen below.

To select the gas flow rate, use the joystick. Press

the red select button or green continue button to proceed.

GAS SET-UP SCREEN

Back

Selecting Back takes the user to the previous screen.

Environment Screen:

Overview

The VRTEXTM360 comes pre-configured with a number of different virtual welding environments. To

select an environment, the user moves the joystick left

or right and then presses the red select button or

green continue button to choose the environment.

Menu

Selecting Logout takes the user back to the login

screen, with the user’s name removed.

Back

Selecting Back takes the user to the previous screen.

VRTEXTM360

Page 29

B-12

OPERATION

B-12

Weld Machine Settings Screen:

Overview

The user must enter the proper welding procedure

and process settings, including wire feed speed,

amperage, voltage, polarity, and trim where applicable. As in the gas setup screen, the user must enter

values within the acceptable range as governed by

the tolerance editor. If not, they will be notified by the

incorrect weld setting screen when the green check

settings button is pressed.

The user changes the wire feed speed or amperage

by rotating the wire feed speed/amperage dial. The

display above the dial indicates the setting.

The user changes the voltage by rotating the voltage

dial. The display above the dial indicates the setting.

Some processes may not allow the user to pre-set

the voltage, in which case the display will be blank.

WELD MACHINE SETTINGS SCREEN

Once the user has set the welding parameters, they

should press the green check settings button. If the

user has entered any settings outside the acceptable

range specified by the settings in the tolerance editor,

the incorrect weld setting screen will appear. The

user will then have to change any settings that are not

correct. If the settings are correct and the green

check settings button is pressed, the welder’s view

screen will appear on the monitor and in the helmet’s

stereo visor. The user will then be able to start virtual

welding.

THE INCORRECT WELD SETTINGS SCREEN

Polarity Selector

Change the polarity by rotating the polarity selector

switch. The user can select the following:

• AC

• DC+

• DC-

If default tolerances are being used, refer to the

Default Weld Process Settings included in this

manual.

Menu

Selecting Logout brings the user back to the login

screen, with the user’s name removed.

Back

Pressing Back goes back to the previous screen.

Virtual Welding Overview

Wh ile a user is welding, observers can see t he

Welder’s view, LASER screen, or Instructor’s view

displayed on the monitor. The Welder’s view shows

what the user with the helmet on is seeing through the

FMD. The LASER screen displays a real time graph

of the weld being made and gives a score when the

user selects “end pass”. The Instructor’s view allows

another user to zoom in/out and rotate the coupon to

view the weldment from different angles in real time.

VRTEXTM360

Page 30

B-13

Distance)cue is only

Distance) cue is only

OPERATION

B-13

Upper Overlays

The welding technique set in the tolerance editor and

other process details are displayed on the upper right

portion of the screen.

Push Buttons

Menu

Selecting Logout brings the user back to the login

screen, with the user’s name removed.

Action Button

The orange action menu button has the following

options:

• Clean

• Trim

• Quench

• New Stick

These options are only available when applicable to

the welding process.

Clean removes the weld slag. Trim cuts back the VR

GMAW or VR FCAW wire. Quench simulates quickly

cooling the metal. New Stick extends the rod stick

out to a fixed length on the VR SMAW device to simulate replacing the consumed rod.

Generally, these cues are color coded as well as symbolic. When cues are red, they indicate being out of

tolerance. Yellow cues indicate close to tolerance, but

not optimal. Green cues indicate being within tolerance and close to optimal.

The “Cheater” Lens magnifies the image as seen by

the user in the helmet and in the welder’s view. The

user can toggle between Off, 1.25X, 1.5X, 1.75X, 2X

select their option with the red select button.

Travel Speed turns on the travel speed visual cue.

This cu e is lo cated on the si d e of th e VR

GMAW/FCAW Gun or VR SMAW device. This cue

uses the color coding position to indicate travel speed.

Note: The goal is to keep the arrow in the center of

the graph which will also keep it green.

TRAVEL SPEED VISUAL CUE

Visual Cues

The yellow visual cues menu button has the following

options:

• “Cheater” Lens – Off, 1.25X, 1.5X, 1.75X, 2X

• Travel Speed Visual Cue

• CTWD (Contact To Work Distance) Visual Cue

• Arc Length Visual Cue

• Travel/Work Angles Visual Cue

Visual cues are aids to help users learn faster. The

travel speed, CTWD, arc length, and travel/work angle

cues indicate whether the user is within the tolerances

set in the tolerances editor.

The CTWD (Contact To Work Distance) cue is only

available for VR GMAW and VR FCAW processes.

This cue uses color and position to indicate proper

CTWD. The goal is to get the tip of the green arrow

on the line of the “H” bar and keep the arrow color

green.

CTWD (Contact To Work Distance)

VRTEXTM360

Page 31

B-14

OPERATION

B-14

The Arc Length cue is similar to the CTWD cue but

represents arc length distance for the VR SMAW

process. The goal is to get the tip of the arrow on the

line and keep the arrow color Green.

The Travel/Work Angle cue can be used with the

SMAW, GMAW or FCAW processes. The goal of this

cue is to center the circle in the cross hair and keep

the color green.

TRAVEL/WORK ANGLE

The Whip cue can be used with the E6010 VR SMAW

process. This cue helps the student use correct spacing between whipping motions, puddle time and whip

time. Correct whipping technique is indicated by a

green outter ring (spacing) with a green center (puddle

and whip timing).

Whip

The Aim cue can be used with the VR SMAW, VR

GMAW or VR FCAW processes. The goal of this cue

is to position the VR GMAW/FCAW Gun or VR SMAW

device so the aim cue is a thin green line. This indicated that the weld is being made in the correct location

or position.

AIM

The Weave cue can be used with the VR SMAW, VR

GMAW or VR FCAW processes but is only available if

the technique identified in the Tolerance Editor is a

type of weave. The goal of this cue is to space the

weave so the outter ring is green (good weave spacing), set the width of the weave so line is green (good

weave width) and a green filled ring (good dwell time

on the toes of the previous weld).

Weave

VRTEXTM360

Page 32

B-15

OPERATION

B-15

New Coupon

Pressing the blue new coupon menu button instantly

replaces the current coupon with a fresh, unwelded

coupon. Note that this is a quick way to start over on

the same configuration and process but that it will

remove all passes from the coupon and the graphs on

the LASER screen.

White Screen Select Arrows

Pressing the white screen select arrows allow the user

to rotate through the LASER screen, instructor’s view

and welder’s view.

Welder’s View screen