Lincoln A, 275260, V350400HF, V450400HF Installation And Maintenance Manual

Pump and hoist assembly

Models 275260, V350400HF and V450400HF, series “A”

400 lb.

(181 kg)

drum size, air operated, manually controlled

Installation and maintenance guide

Date of issue October 2014

Form number 404478B

Page A31

Section 21B

Model V450400HF

4 in. (101 mm)

PMV pump with hoist

Model V350400HF

3 in. (72 mm)

PMV pump with hoist

Models V350400HF

and 275260

Description

Model 275260 is a pump hoist (without the

pump) for use with 120 lb. (54 kg) and

400 lb. (181 kg) refinery container drums,

400 lb. (181 kg) follower, and the necessary

hoses and fittings to perform a basic installation († Fig. 1, page 3).

Model V350400HF includes the 275260

pump hoist and follower and a 3 in. (76 mm)

PMV grease pump for use in 400 lb.

(181 kg) container drums.

Model V450400HF includes the 275260

pump hoist and follower and a 4 in.

(102 mm) PMV grease pump for use with

400 lb. (181 kg) container drums.

All models will place a pump and follower

in position for insertion into a standard

400 lb. (181 kg) refinery container. The prim-

ing action of these models is created by

gravity and the vacuum created when material is pumped from the drum. The weight of

the pump and follower, plus the effects of

atmospheric pressure, work with the shape

of the follower, to direct the material into the

pump inlet. The follower will remain on top

of the material until the container is emptied

by the pump. When the follower reaches the

bottom of the container, very little, if any,

material is left in the bottom of the drum.

The follower will work well with most drum

liners in good condition.

Specifications

Unit height, lowered position 60 1/4 in. (1,530 mm)

Unit height, raised position 97.00 in. (2,464 mm)

Hoist capacity 200 lbs. (91 Kg)

Operating pressure (hoist) 40 to 100 psi (3 to 7 bar)

Pump V350400000

Pump ratio 50:1

Pump maximum working pressure 5,000 psi (345 bar) (limited by hose working pressure)

Pump maximum air pressure 125 psi (9 bar)

Air inlet

3

/8 NPT male (3/8 in. ID hose)

Lube outlet

1

/4 NPT male x 84 in. (2,134 mm) (1/4 ID SAE 100R2) hose

Model V450400HF

Specifications

Unit height, lowered position 60 1/4 in. (1,530 mm)

Unit height, raised position 97 in. (2,464 mm)

Hoist capacity 200 lbs. (91 Kg)

Operating pressure (hoist) 40 to 100 psi (3 to 7 bar)

Pump V450400000

Pump ratio 50:1

Pump maximum working pressure 5,000 psi (345 bar) (limited by hose working pressure)

Pump max air pressure 100 psi (7 Bar)

Air inlet

3

/8 NPT male (3/8 in. ID hose)

Lube outlet

1

/4 NPT male x 84 in. (2,134 mm) (1/4 ID SAE 100R2) hose

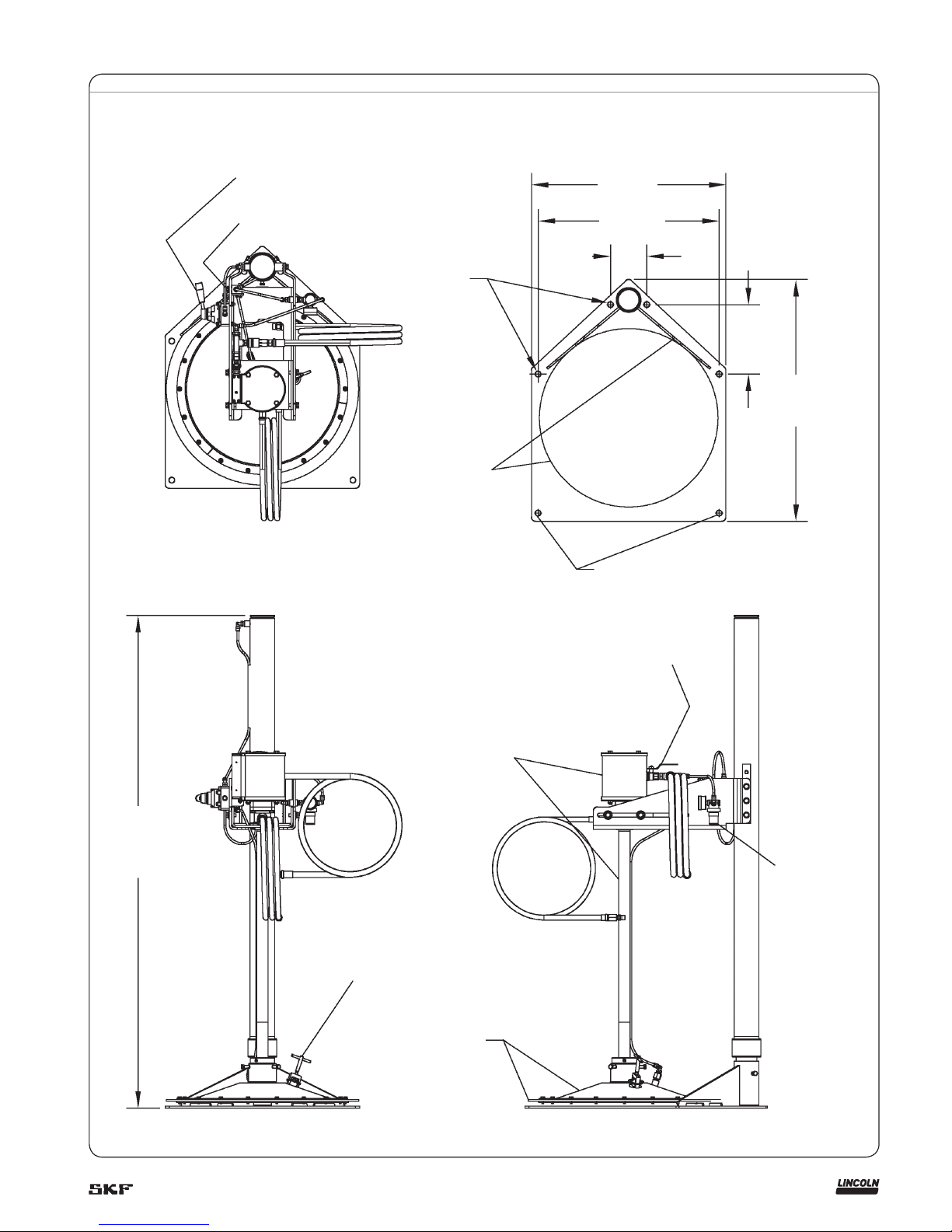

2

Fig. 1

(10) Hoist control valve

(17) Air assist push button

4 x Ø.69 in. (Ø17 mm)

Mounting holes

23.75 in.

(603 mm)

22.13 in.

(562 mm)

4.44 in.

(113 mm)

8.50 in.

(216 mm)

29.57 in.

(751 mm)

Shipping holes

For pump operating and service instructions, see the

appropriate owner’s manual for each pump.

Model V350400000 († section A5 page 82 series).

Model V450400000 († section A5 page 85 series).

60.25 [1530]

lowered

97.00 [2464]

raised

(21) Air vent

Base mounting detail

V350400000 3 in. (76 mm) pump assembly or

V450400000 4 in. (102 mm) pump assembly

(47) Follower

assembly

(34) Pump air supply valve

(44) Hoist

regulator

3

Fig. 2

Air assist push button.

Hoist control valve shown in

neutral position.

Pump air supply valve.

Remove six bolts, move mount down one set of holes

to position shown. Reinstall bolts, adjust mount to be

level with floor. Tighten bolts securely.

Position pump mount so that follower is aligned

with drum when drum is positioned against

stops at back side of mounting base. Tighten

bolts securely.

Connect length of 1/4 in . (6 mm) OD tubing

between air assist valve (17), and follower as

shown († fig. 3, page 6). Secure pump tube

with two nylon ties.

Left side view

Right side view

4

Installation

1 Select a location where there is adequate

clearance around the hoist to operate

and maneuver around the hoist and

pump assembly when installing and

removing drums.

2 The mounting base must be securely

fastened to the floor before use.

Mounting dimensions are provided on

base mounting detail in fig. 1, page 3 or

the base may be used as a template for

drilling and positioning anchors.

3 After hoist has been secured to the floor

reposition the pump support (46) by

moving it down on the support tube (15)

(† fig. 3, page 6). Adjust the pump sup-

port so that it is parallel to the floor and

secure by tightening the six mounting

bolts (4). This will keep the pump tube

parallel with the support tube.

4 Mount pump to pump mount (29).

The holes in the pump mount are off

center with the pump mount. When the

pump mount is placed in the pump support (46) the pump mount should be

placed with the holes closest to the open

end of the pump support († fig. 3,

page 6). When attaching the pump to

the mount (29) attach pump outlet body

to pump mount with four 1/4–20 x 9/16

hex screw and washer assemblies (39)

(† fig. 3, page 6).

5 Place pump and mount into pump sup-

port (46) and loosely install hex bolts,

lock washers, and flat washers (4, 5, and

6) through slots in support. Leave loose

until final adjustments are made.

6 Assemble air inlet fittings († fig. 3,

page 6). Assemble the air regulator (44)

to the air inlet of the hoist as shown in

the figure. Note that there is a 1/8 in. pipe

plug packaged with each regulator for

plugging the unused gage port in the

regulator. Install this plug into the unused port on the regulator (44) as

shown.

7 Measure and cut a length of the supplied

1

/4 in. OD black polyurethane tubing to

connect the air inlet to the regulator inlet

(† fig. 3, page 6). The tubing will simply

push fit into the 1/4 in. fittings included

with the model.

8 Assemble the air hose to the air coupler

(24). Make sure the ball valve (34) is

closed and the hoist control valve (10) is

in the down position. Attach air hose to

source of filtered, regulated air. The air

pressure should be set initially to about

40 psi (3 bar).

9 Adjust the hoist air regulator (44) for a

pressure of around 30 to 40 psi (2 to

3 bar). Check for air leaks in all connections. Slowly move the hoist control valve

(10) to the raised position and raise

pump so the end of the pump tube will

clear the primer assembly.

10 Attach the primer assembly to the end of

the pump tube. When assembling pump

to the follower, a reducing adapter is

used (38). Apply some grease to the

outside of the adapter and the o-rings

on the inside of the adapter and the

|inside of the follower. Push the adapter

into the follower assembly until it seats

against the shoulder. Tighten the three

hex bolts on the follower (14) securely.

Apply some grease to the end of the

pump tube and slide into the reducing

adapter (38) until the pump tube is flush

with the bottom of the follower. Tighten

the three set screws (32) securely.

Failure to securely fasten the base to the

floor may result in severe injury and or

property damage. Pump hoist may topple over if not securely fastened.

WARNING

11 Raise the follower high enough to clear

an open 400 lb. (181 kg) container.

Place the container under the follower

and slide the drum back on the mounting

base (8) until the bottom is against both

gusset plates on the base. Adjust the

position of the pump with respect to the

drum by sliding the pump mount (29) in

the pump support (46) until the follower

is centered over the open drum.

Tighten the hex bolts (4) through the

slots in the pump support to secure the

pump mount. Do not insert the follow-

er into the drum at this time.

12 Using the remaining polyurethane tub-

ing, attach to the open fitting on the

2-way air valve (17) mounted on the

pump support (46) by pushing one end

of the tube into the fitting until secure.

(† fig. 3, page 6). Thread the tubing

down along the pump tube to the fitting

(1) in the top of the follower assembly.

Secure the tubing to the pump tube with

two nylon wire ties, supplied with the

assembly († fig. 2, page 4).

13 Check for proper air flow by pressing

button on 2-way air valve (17) making

sure that air flows through check valve

(30) and out under follower assembly.

14 Connect fluid hoses to pump outlet.

These models are supplied with a 1/4 in.

(6 mm) ID high pressure hose (40) with

33

/64 in. (13 mm) female thread on both

ends. Two male adapters (45) are supplied to adapt the hose to 1/4 NPT male

for the pump outlet, and working end of

the hose. Insert the hose adapters (45)

into each end of the high pressure hose

and tighten securely for leak proof seal.

Thread one end of the hose into the pump

outlet and tighten securely. Attach the

other end as required for the application.

5

Loading...

Loading...