PMV grease pump

Models V450120000 and V450400000, series “A”, 50:1 ratio,

(4.25 in. airmotor)

Installation and maintenance guide

Read manual prior to installation or use

of this product. Keep manual nearby for

future reference. Failure to follow

instructions and safety precautions may

result in death or serious injury.

DANGERDate of issue August 2014

Form number 404137E

Section A5

Page 85E

Explanation of signal

words for safety

Safety

Read and carefully observe these

instructions before installing, operating or

troubleshooting this equipment.

The equipment must be installed, maintained and repaired exclusively by persons

familiar with the instructions.

Install and/or operate the equipment only

after safety instructions and this guide have

been read and are completely understood.

Adequate personal protection must be

used to prevent splashing of material on the

skin or in the eyes.

Always disconnect power source (electricity, air or hydraulic) from the equipment

when it is not being used.

Any other use not in accordance with

instructions will result in loss of claim for

warranty or liability.

• Do not misuse, over-pressurize, modify

parts, use incompatible chemicals, fluids,

or use worn and/or damaged parts.

• Always read and follow the fluid manufac-

turer’s recommendations regarding fluid

compatibility, and the use of protective

clothing and equipment.

• Failure to comply may result in death or

serious injury.

• Adequate personal protection is recom-

mended to prevent splashing of material

on the skin or in the eyes.

• Always disconnect air coupler from pump

when the pump is not being used.

• Always wear eye protection.

Indicates a hazardous situation which,

if not avoided, could result in minor or

moderate injury.

CAUTION

Indicates a hazardous situation which,

if not avoided will result in death or

serious injury.

WARNING

Indicates a hazardous situation which,

if not avoided, will result in death or

serious injury.

DANGER

Safety instruction signs indicate specific

safety-related instructions or

procedures.

SAFETY INSTRUCTION

This is the safety alert symbol. It is used

to alert you to potential physical injury

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death.

Contents

Safety ............................2

Explanation of signal words for safety ...2

Owner/operator responsibility .........3

Description ........................3

Appropriate use ....................4

Initial pump priming .................4

Installation ........................5

Bung bushing installation ............5

System start-up ....................5

Pressure relief procedure .............5

Pump repair .......................5

Pump grounding ....................6

Sealant application instructions .......6

Basic pump operation. . . . . . . . . . . . . . . .6

Lincoln industrial

standard warranty .................15

2

Owner/operator

responsibility

It is the owner/operator responsibility to

properly use and maintain this equipment.

The instructions and warnings contained

in this manual shall be read and understood

by the owner/operator prior to operating

this equipment.

It is the owner/operator responsibility to

maintain the legibility of all warning and

instruction labels.

The owner/operator shall retain this

manual for future reference to important

warnings, operating and maintenance

instructions.

Description

Models V450120000 and V450400000 are

air operated double acting grease pumps for

dispensing automotive greases.

Models V450120000 and V450400000

are stub pumps with a 1 1/2 NPT threaded

inlet. It may be mounted in the bung

opening of a grease drum by using an

optional bung bushing and suction tube

(† fig. 1, page 5).

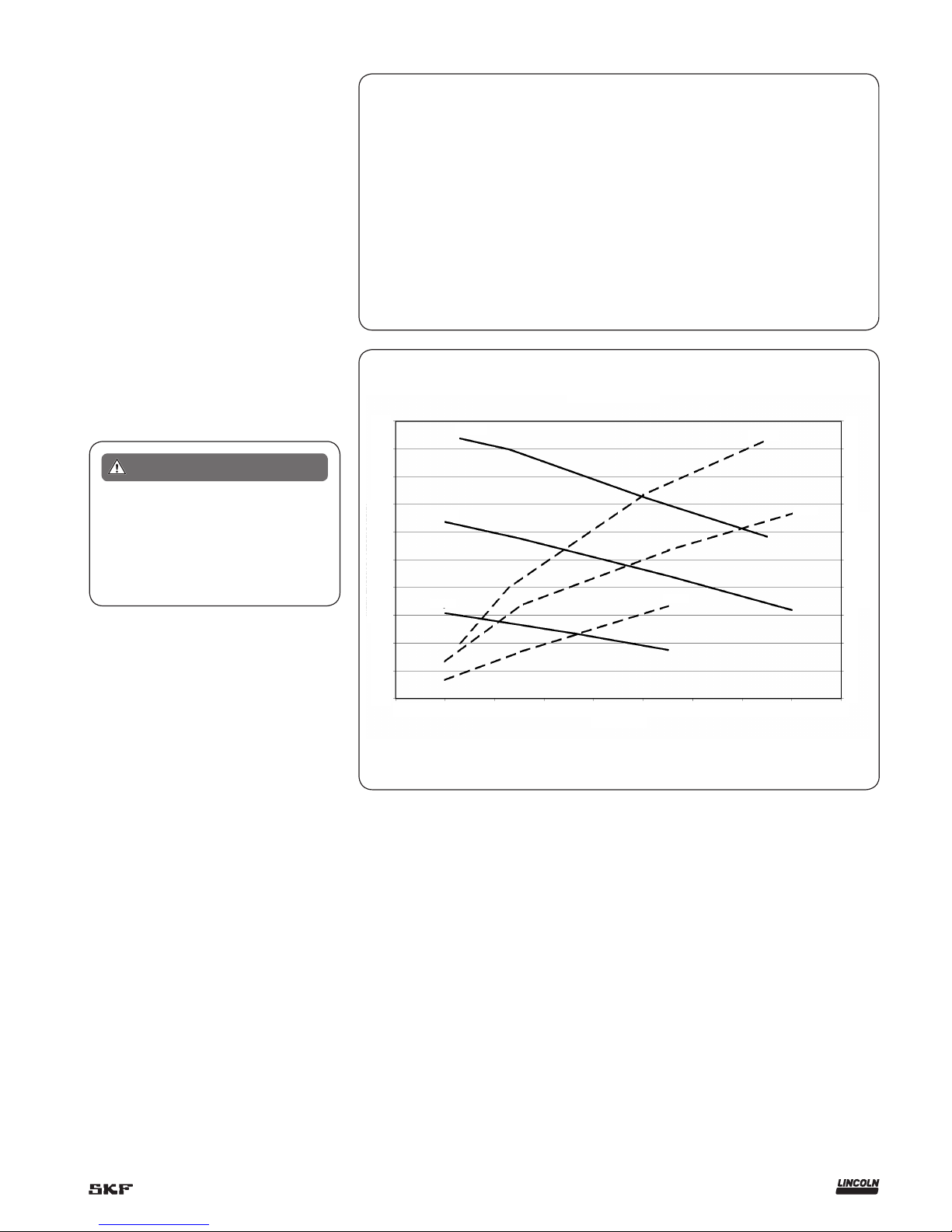

Mean effective pressure [psi (bar)]

5,000

(345)

4,500

(310)

4,000

(276)

3,500

(241)

3,000

(206)

2,500

(172)

2,000

(138)

1,500

(103)

1,000

(69)

500

(34)

0

Air consumption [scfm (m³/min.)]

30

(0.85)

27

(0.76)

24

(0.67)

21

(0.59)

18

(0.5)

15

(0.42)

12

(0.34)

9

(0.25)

6

(0.17)

3

(0.08)

0

Output [lbs/min.(kg/min.)]

0 0.5

(0.23)

1

(0.45)

1.5

(0.68)

2

(0.91)

2.5

(1.13)

3

(1.36)

3.5

(1.59)

4

(1.81)

4.5

(2.04)

100 psi

(6,9 bar)

100 psi

(6,9 bar)

70 psi

(4,8 bar)

70 psi

(4,8 bar)

40 psi

(2,8 bar)

40 psi

(2,8 bar)

If any fluid appears to penetrate the skin,

get emergency medical attention immediately. Do not treat injury as a simple

cut. Tell attending physician exactly what

fluid was injected.

WARNING

Pump specifications

Pumping ration 50:1

Air pressure 40 to 150 psi (2,7 to 10,3 bar)

Maximum operating pressure 7,500 psi (517 bar)

Operating temperature –40 to 150 °F (–40 to 65 °C)

Air inlet

3

/8 in. NPFT

Material outlet

1

/4 in NPTF

Airmotor bore diameter 4.25 in. (108 mm)

Stroke 3.25 in. (82,5 mm)

Output per cycle 1.47 in.³ (24,1 cm³)

Wetted parts Carbon steel, brass, zinc, polyurethane, nitrile

Performance chart

3

Failure to heed the following warnings

may result in personal injury and/or

property damage.

• Always determine the correct air

pressure to operate the lubrication

pump. This pump can develop over

7,500 psi (517 bar). To determine the

air pressure to operate the lubrication

pump, simply divide the rated pressure of the lowest rated component

on the down stream side of the pump

by the lubricant to air pressure ratio of

the pump. Example: The lowest rated

component has a rating of 4,000 psi

(276 bar). If the lubrication pump is a

50:1 pump, divide 4,000 psi (276 bar)

by 50 to determine the correct air

pressure setting, (4,000 psi

(276 bar)/50 = 80 psi (5,5 bar)).

Set the air regulator that controls the

air to the pump to 80 psi (5,5 bar) or

less.

• Never point the control valve at any

part of the body or at another person.

• Never try to stop or deflect material

from the dispensing valve, leaking

connection or component with your

hand.

• Always relieve pressure from the

system before servicing.

• Avoid contact with the nozzle.

WARNING

Appropriate use

The pump is designed to dispense automotive greases directly from the refinery

container. It can be used in a system with

mutiple hose reels and control valves.

Pumps are to be operated with compressed air only. Operation with combustible gasses is prohibited.

Maximum air pressures should not be

exceeded. Failure to heed this warning

may result in serious personal injury,

property damage, and failure of the

pump.

WARNING

Do not use this equipment to pump any

fluids other than the fluids for which it is

designed. Types of fluids not to be

pumped with this equipment include:

• gasoline

• fuel oil

• diesel fuel

• windshield washer solvent

• antifreeze

• brake fluid

• water

Failure to comply may result in serious

personal injury, significant damage to

equipment, and fire or other types of

property damage.

Failure to comply will also result in

loss of claim for warranty or liability.

WARNING

Failure to comply with the warnings listed below may result in serious personal

injury, significant damage to equipment,

and fire or other types of property

damage.

Failure to comply will also result in

loss of claim for warranty or liability.

• Do not alter or modify any part of the

equipment.

Before each use:

• Read and follow fluid manufacturer’s

recommendations regarding fluid

compatibility and use of protective

clothing/equipment.

• Confirm equipment and safety devices

are in place and operating properly.

• Immediately repair or replace any

parts that are found to be worn or

damaged.

• Confirm all grease connections are

tightened securely.

Once system is pressurized:

• Do not attempt to repair, disassemble,

or replace any part of the equipment

without de-pressurizing system first.

• Do not exceed the stated maximum

working pressure of pump or the

lowest pressure-rated component of

the system.

• Do not point dispensing valve at any

part of the body or at another person.

• Do not attempt to block fluid coming

out of dispensing valve, leading

connection, or other component with

any part of the body.

WARNING

Initial pump priming

When the pump is operated for the first

time, the pump will have to be primed.

To prime the pump, remove the grease hose

from the pump lube outlet and set aside.

Connect the airline to the air inlet of the

pump with an air pressure of less than

40 psi (2,76 bar). Slowly increase the air

pressure to the pump until the pump begins

to operate very slowly. Allow the pump to

operate at the slow speed until lubricant

begins to flow out of the pump lube outlet.

After lubricant, free of air begins to flow

from outlet, stop the pump. Attach the high

pressure hose and control valve to the pump

lubricant outlet. Restart the pump and hold

the control valve nozzle in a suitable container while holding the control valve open

to prime the hose and control valve.

Increase the air pressure to the pump as

required, keeping it operating.

4

Installation

Pumps are tested in light oil before shipment. To avoid system contamination, flush

the pump with the lubricant to be dispensed

before installing the pump.

Flush all supply lines, hoses, reels and fittings used in the dispensing system with

mineral spirits or other petroleum based

solvent to remove dirt, chips and other foreign matter that may damage the pump or

other system components. The components

should be blown dry with air after flushing.

Placement of a low restriction shut-off

valve (such as a ball or gate valve) into the

system between the pump outlet and overhead delivery system is recommended.

This will allow the pump to be isolated from

the system and be removed for service.

Lincoln recommends using a filter/regulator (3/8 in. NPT port size) such as a Lincoln

#602136 in the air supply line to the pump

to regulate the air pressure to the pump.

Lincoln does not recommend using Teflon

tape pipe sealant when making connections

to this pump.

Do not use Teflon tape as sealant for

pump connections.

WARNING

Bung bushing

installation

Thread bung bushing into 2 in. NPT bung on

top of reservoir drum or tank.

(† fig. 1) Tighten bung bushing securely

into bung thread. (fig. 1 illustrates a

55-gallon drum; other containers will be

installed in a similar manner.)

!

Notice

Lincoln recommends using a

filter/regulator (3/8 in. NPT port size)

such as a Lincoln #602136 in the air

supply line to regulate the air pressure

to the pump.

System start-up

When operating the pump in a system for

the first time, purge all air from the system

in order for the pump to prime and operate

reliably. Before connecting the pump to a

system, make sure the pump is placed into a

container of the grease that is to be dispensed. Connect a short length of hose to

the pump outlet and direct the open end of

the hose into a container to catch the

grease. Operate the pump at low air pressure, 40 psi (2,7 bar), until the pump

primes, and grease flows smoothly from the

end of the hose.

The system can now be connected to the

pump outlet. Purge the entire system in a

similar manner, slowly pumping grease

through all reels and control valves until

grease, free of air, flows smoothly from each

outlet.

Pressure relief

procedure

The following procedure should be followed

when it becomes necessary to shut the

system down for service or container

changes.

1 Disconnect the air supply from the inlet of

the pump.

2 Bleed the lubricant pressure off the

system by opening a dispensing valve into

a container. Hold the valve open until all

flow from the system stops.

3 Close the shut-off valve between the

pump and reservoir on standpipe

installations (if present).

4 Close the shut-off valve between the

pump outlet and supply lines (if present).

5 Slowly loosen the lubricant supply line at

the pump outlet. A very small volume of

grease will leak from the threads. If

pressure is present, stop the loosening

procedure and repeat steps 1 through 4.

Pump repair

Repair is limited to the service parts listed

on following pages. In most cases, service is

going to be the replacement of soft seals in

the pump († fig. 5 and 6 for internal

components of the pump, and fig. 7 for

internal components if its an air valve

Contact your nearest authorized Lincoln

service dealer or Lincoln technical services

for assistance.

When ordering replacement parts, order

by part number and description. The model

number and series letter may also be

required.

!

Notice

New outlet body and gasket

New outlet body is designed for a

copper gasket. This gasket replaced the

o-ring that was installed on PMV pumps

manufactured prior to December 2013.

Replace o-ring with copper gasket.

5

Grounding wire

(user supplied)

Grounding screw

(inclided with pump)

!

Notice

After the pump and hose have

been primed and are free of are, the air

pressure may be increased to the desired operating pressure. Check for leaks

at all connections.

!

Notice

After the pump and hose have

been primed and are free of air, the air

pressure may be increased to the desired operating pressure. Check for leaks

at all connections.

Pump grounding

The pump should be grounded to reduce

static discharge. To ground the pump,

remove the grounding screw from the pump

outlet body and insert the screw through a

ring terminal that has been attached to a

grounding wire.

Securely tighten the screw into the outlet

body. The other end of the ground wire

should be securely connected to a true earth

ground.

Sealant application

instructions

1 Clean and dry all surfaces where sealant

will be applied.

2 Apply small bead of Dow Corning 1437

RTV sealant (or an equivalent sealant)

around end of exhaust cavities where part

(6) is displayed in Figure 4.

3 Reassemble pump.

!

Notice

Allow sealant to dry for 1-2 hours

before applying any air pressure to the

pump.

Basic pump operation

The air pressure should be adjusted so that

the pump can overcome the back pressure

in the lube system. Too much air pressure

can cause the pump to deliver grease very

rapidly, which can damage the equipment

being lubricated.

When the pump is not in operation,

disconnect the air supply to the pump and

relieve all pressure on the control valve and

grease hose († Pressure relief

procedure, below).

Followers are recommended with

lubricants that do not readily seek their own

level, or in cold temperature conditions.

They help by keeping the grease on an even

level and reduce the air pockets that can

form in the grease by the removal of grease

by the pump from the bottom of the

container.

6

4 x / -20 UNC

1

4

2 / in.

(57,2 mm)

1

4

1 / in.

(35 mm)

3

8

/ in. NPTF

Material outlet

1

4

3

4

/ in.

(18 mm)

A

B

2 / in.

(54 mm)

1

8

/ in. NPTF

air inlet

3

8

6 / in.

(166 mm)

1

2

3 / in.

(94 mm)

11

16

3 / in.

(81 mm)

3

16

5 / in.

(143 mm)

5

8

6 in.

(152 mm)

/ in.

(14 mm)

9

16

Exhaust ports

Mounting holes

Material inlet

Pump dimensions

Model numbers Drum size Dimensions A Dimension B

V450120000 120 lbs. (54 kg) 36 7/16 in. (926 mm) 27 3/8 in. (695 mm)

V450400000 400 lbs. (181 kg) 42 15/16 in. (1 091 mm) 33 7/8 in. (860 mm)

7

1

2

Torque to

24 to 30 in.lbf.

(2,7to 3,3 Nm)

4

3

5

Torque to 4 to 5 ft.lbf.

(5,4 to 6,8 Nm)

6

11

7

Apply Loctite 243* (blue)

to threadsTorque to

20 to 22 ft.lbf.

(27,1 to 29,7 Nm)

8

9

10

5

12

13

14

Apply a small bead of Dow Corning 737

RTV sealant or equivalent to top

mating surface of cylinder as shown

by dotted line.

8

16

17

18

19

20

21

22

23

24

25

26

27

28

27

29

30

31

32

33

Apply Loctite 243 (blue).

Torque to 5 to 6 ft.lbs.

(6,8 to 8,1 Nm)

Torque to

150 to 160 ft.lbf.

(203 to 216,9 Nm)

34

Torque to 40 to 44 ft.lbf.

(54 to 59,6 Nm)

35

36

37

38

39

40

41 Apply Loctite 243* (blue).

Torque to 5 to 6 ft.lbs.

(6,8 to 8,1 Nm)

42

Torque to 190 to 200 ft.lbf.

(257 to 271 Nm)*

Torque to 190 to 200 ft.lbf.

(257 to 271 Nm)*

9

Parts list

Item no. Description Qt y. Part no.

1 Socket head screw (M5 x 0.8 x 30 mm) 4 275045

2 Valve bar assembly 1 275408

3 Hex head screw (M8 x 1.25 x 160 mm) 4 275040

4 Cylinder head 1 275050

5 O-ring (nitrile) 2 275038

1)

6 Air cylinder 1 275049

7 Hex head screw (M10 x 1.5 x 30 mm) 1 275035

8 Seal (nitrile) 1 275036

1)

9 O-ring (nitrile) 1 34657

1)

10 Piston 1 275055

11 Muffler element 1 275180

1)

12 Cylinder base 1 275052

13 Hex nut (M8 x 1.25) 4 275032

14 O-ring (nitrile) 1 34309

1)

15 Adapter 1 275127

16 O-ring (nitrile) 1 34314

1)

17 O-ring (nitrile) 1 275096

1)

18 Gland nut 1 275074

19 O-ring (polyurethane) 1 275095

1)

20 U-cup (polyurethane/nitrile) 1 275098

1)

*21 Outlet body and gasket kit 1 278902

22 Hex head screw (M8 x 1.25 x 20 mm) 4 275066

23 Grounding screw (#10-32 x 3/8 in.) 1 275129

24 Gasket, copper 1 278701

1)*

25 Pump tube 1 See tube/rod list

26 Plunger rod 1 275070

27 Spring pin 2 275126

1)

28 Connecting rod 1 See tube/rod list

29 Piston adapter 1 275117

30 Check ball 1 275125

31 U-cup (polyurethane/nitrile) 1 275102

1)

32 Piston body 1 275116

33 O-ring (polyurethane) 1 275122

1)

34 Bushing tube 1 275100

35 Check stop 1 275113

36 U-cup (polyurethane/nitrile) 1 275104

1)*

37 Check 1 275111

38 O-ring (polyurethane) 1 275121

1)

39 Check seat 1 275110

40 Priming plunger 1 275105

41 Priming shovel 1 275106

42 Priming tube 1 275112

1)

Denotes parts supplied in 275403 seal kit

* Indicates change

Tube/rod list

Model number Drum Size Item 24 Item 27

V450120000 120 lbs. (54 kg) 275108 275119

V450400000 400 lbs. (181 kg) 275107 275118

10

Declaration of

conformity as defined

by Machinery Directive

98/37/EG Annex II A

This is to declare that the design of the PMV

50:1 grease pumps (models V450120000

and V450400000) complies with the provisions of Directive 98/37/EG

Applied Standards:

EN 292-1 Safety of Machinery - Basic Concepts, General Principles and Design - Part

1: Basic Terminology, Methodology

EN 292-2 Safety of Machinery - Basic

Concepts, General Principles and Design Part 2: Technical Principles and Specifications - Incorporates amendments 1 (1995)

and 2 (1997)

EN 809 Pumps and Pump Units for Liquids - Common Safety Requirements

EN 349 Safety of Machinery - Minimum

Gaps to Avoid Crushing of Parts of the

Human Body

Troubleshooting

Condition Possible cause Corrective action

Pump does not operate. No air or low air to pump. Make sure air pressure to pump is adequate to

operate pump.

Muffler element (11) clogged. Remove muffler element and clean or replace.

Damaged air valve bar assembly (2). Replace air valve bar assembly.

Erratic operation or short stroking. Pump is not primed. Prime pump († Initial pump priming, page 5.

Insufficient material supply. Refill material supply.

Damaged air valve bar assembly (2). Replace air valve bar assembly.

Pump operates but dispenses material

on only one stroke.

Worn or damaged piston u-cup (31) or piston check

(30 and 32).

Inspect and replace if needed.

Worn or damaged inlet check (37 and 39). Inspect and replace if needed.

Insufficient material supply. Pump is not intaking

enough material to dispense on both strokes.

Check inlet for restrictions. Decrease air

pressure to reduce pump speed.

Pump is operating but not dispensing

material.

Inlet check (37 and 39) is not seating or is damaged. Inspect and replace if needed.

St. Louis, MO 08/14,

Bob Hoefler, Director Product Development and Product Engineering

11

This page intentionally left blank.

12

This page left intentionally blank

13

This page left intentionally blank

14

Lincoln industrial

standard warranty

Standard limited warranty

Lincoln warrants the equipment manufactured and supplied by Lincoln to be free

from defects in material and workmanship

for a period of one (1) year following the

date of purchase, excluding there from any

special, extended, or limited warranty published by Lincoln. If equipment is determined to be defective during this warranty

period, it will be repaired or replaced, within

Lincoln’s sole discretion, without charge.

This warranty is conditioned upon the

determination of a Lincoln authorized representative that the equipment is defective.

To obtain repair or replacement, you must

ship the equipment, transportation charges

prepaid, with proof of purchase to a Lincoln

Authorized Warranty and Service Center

within the warranty period.

This warranty is extended to the original

retail purchaser only. This warranty does not

apply to equipment damaged from accident,

overload, abuse, misuse, negligence, faulty

installation or abrasive or corrosive material,

equipment that has been altered, or equipment repaired by anyone not authorized by

Lincoln. This warranty applies only to equipment installed, operated and maintained in

strict accordance with the written specifications and recommendations provided by

Lincoln or its authorized field personnel.

This warranty is exclusive and is in lieu

of any other warranties, express or

implied, including, but not limited to, the

warranty of merchantability or warranty

of fitness for a particular purpose. War-

ranty on items sold by Lincoln, but not

manufactured by Lincoln are subject to

the warranty consideration, if any, of

their manufacturer (such as hoses,

hydraulic and electric motors, electrical

controllers, etc.) Assistance in making

such warranty claims can be offered as

required.

In no event shall Lincoln be liable for incidental or consequential damages. Lincoln’s

liability for any claim for loss or damages

arising out of the sale, resale or use of any

Lincoln equipment shall in no event exceed

the purchase price. Some jurisdictions do

not allow the exclusion or limitation of incidental or consequential damages, therefore

the above limitation or exclusion may not

apply to you.

This warranty gives you specific legal

rights. You may also have other rights that

vary by jurisdiction.

Customers not located in the Western

Hemisphere or East Asia: Please contact

Lincoln GmbH and Co. Kg, Walldorf,

Germany, for your warranty rights.

Special limited warranties

Special limited 2 year warranty

SL-V series, single injectors – 85772,

85782, and replacement injectors –

85771, 85781

Lincoln warrants the SL-V Injector series to

be free from defects in material and workmanship for two (2) years following the date

of purchase. If an injector model (single or

replacement) is determined to be defective

by Lincoln, in its sole discretion, during this

warranty period, it will be repaired or

replaced, at Lincoln’s discretion, without

charge.

Special limited 5 year warranty

series 20, 25, 40 bare pumps, pmv bare

pumps, heavy duty and 94000 series bare

reels

Lincoln warrants series 20, 25, 40 bare

pumps, PMV bare pumps, heavy duty

(82206), mini bench (81133, 81323), and

all 94000 LFR series (single arm and dual

arm) bare reels to be free from defects in

material and workmanship for five (5) years

following the date of purchase. If equipment

is determined by Lincoln, in its sole discretion, to be defective during the first year of

the warranty period, it will be repaired or

replaced at Lincoln’s discretion, without

charge. In years two (2) and three (3), the

warranty on this equipment is limited to repair with Lincoln paying parts and labor

only. In years four (4) and five (5), the warranty on this equipment is limited to repair

with Lincoln paying for parts only.

Special limited 5 year warranty

limited oil meters, limited fluid control

valves, aod (air-operated diaphragm

pumps)

Lincoln warrants the 712 series control

valves, 912 series lube meters, electronic

lube meters (980, 981, 982 series), our

universal inline digital meters (812/813

series), and our AOD pump offering to be

free from defects in material and workmanship for five (5) years following the date of

purchase. If either is determined to be

defective by Lincoln, in its sole discretion,

during the warranty period, they will be

repaired or replaced, at Lincoln’s discretion,

without charge.

Special DEF (diesel exhaust fluid) limited

warranty

DEF products are warranted to be free from

defects in material and workmanship for a

period of one (1) year following the date of

purchase. The following exceptions to the

standard warranty period are in effect:

• 85700-30/85700-50 DEF hose reels

(bare reel only),

277251/277252 AC DEF pumps, and

277256 and 277257 DEF meters are

warranted for two (2) years from date of

purchase.

• 85623 DEF AOD

(air operated diaphragm) pumps

are covered under the standard five (5)

year AOD pump warranty.

If either is determined to be defective by

Lincoln, in its sole discretion, during the

warranty period, they will be repaired or

replaced, at Lincoln’s discretion, without

charge.

Lincoln Industrial contact information

To find Lincoln Industrial’s nearest service

center call the following number;

customer service 314-679-4200

(international number 01-314-679-4200)

or you may also use our website

www.lincolnindustrial.com

15

® SKF is a registered trademark of the SKF Group.

® Lincoln is a registered trademark of Lincoln Industrial Corp.

Teflon is a registered trademark of DuPont Corporation.

© SKF Group 2014

The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be

accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein.

SKF PUB LS/I1 14331 EN/R1.US · August 2014 · Form 404137E

Seals

Bearings and

housings

Lubrication

systems

Mechatronics Services

The Power of Knowledge Engineering

Combining products, people, and applicationspecific knowledge, SKF delivers innovative

solutions to equipment manufacturers and production facilities in every major industry worldwide. Having expert ise in multiple competence

areas supports SKF Life Cycle Management, a

proven approach to improv ing equipment reliability, optimizing operational and energy efficiency

and reducing total cost of ownership.

These competence areas include bearings and

units, seals, lubrication systems, mecha tronics,

and awide range of services, from 3-D computer

modelling to cloud-based condition monitoring

and asset management services.

SKF’s global footprint provides SKF customers

with uniform quality standards and worldwide

product availability. Our local presence provides

direct access to the experience, knowledge and

ingenuity of SKF people.

lincolnindustrial.com skf.com/lubrication

Loading...

Loading...