Pump and hoist assembly

Models 275260, V350400HF and V450400HF, series “A”

400 lb.

(181 kg)

drum size, air operated, manually controlled

Installation and maintenance guide

Date of issue October 2014

Form number 404478B

Page A31

Section 21B

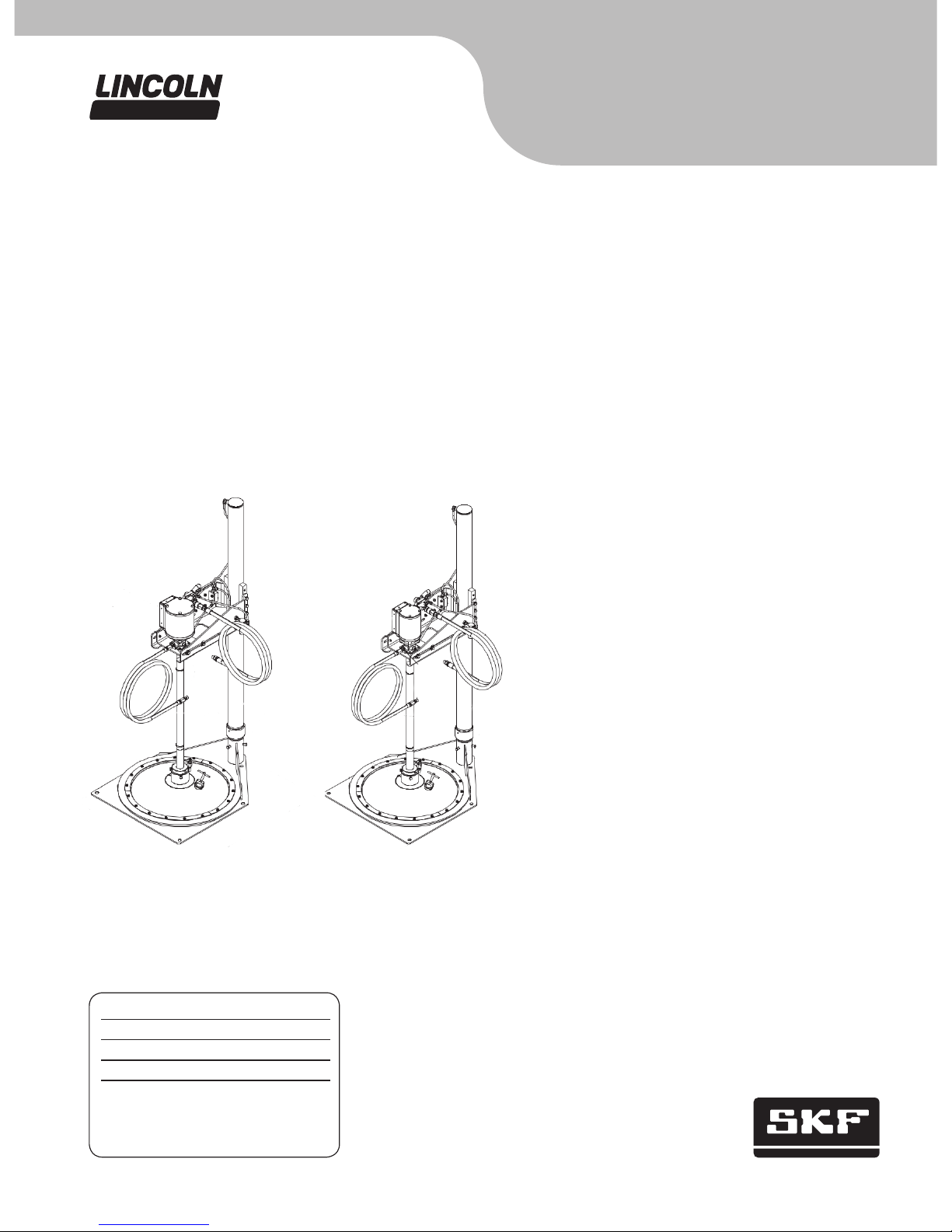

Model V450400HF

4 in. (101 mm)

PMV pump with hoist

Model V350400HF

3 in. (72 mm)

PMV pump with hoist

Models V350400HF

and 275260

Description

Model 275260 is a pump hoist (without the

pump) for use with 120 lb. (54 kg) and

400 lb. (181 kg) refinery container drums,

400 lb. (181 kg) follower, and the necessary

hoses and fittings to perform a basic installation († Fig. 1, page 3).

Model V350400HF includes the 275260

pump hoist and follower and a 3 in. (76 mm)

PMV grease pump for use in 400 lb.

(181 kg) container drums.

Model V450400HF includes the 275260

pump hoist and follower and a 4 in.

(102 mm) PMV grease pump for use with

400 lb. (181 kg) container drums.

All models will place a pump and follower

in position for insertion into a standard

400 lb. (181 kg) refinery container. The prim-

ing action of these models is created by

gravity and the vacuum created when material is pumped from the drum. The weight of

the pump and follower, plus the effects of

atmospheric pressure, work with the shape

of the follower, to direct the material into the

pump inlet. The follower will remain on top

of the material until the container is emptied

by the pump. When the follower reaches the

bottom of the container, very little, if any,

material is left in the bottom of the drum.

The follower will work well with most drum

liners in good condition.

Specifications

Unit height, lowered position 60 1/4 in. (1,530 mm)

Unit height, raised position 97.00 in. (2,464 mm)

Hoist capacity 200 lbs. (91 Kg)

Operating pressure (hoist) 40 to 100 psi (3 to 7 bar)

Pump V350400000

Pump ratio 50:1

Pump maximum working pressure 5,000 psi (345 bar) (limited by hose working pressure)

Pump maximum air pressure 125 psi (9 bar)

Air inlet

3

/8 NPT male (3/8 in. ID hose)

Lube outlet

1

/4 NPT male x 84 in. (2,134 mm) (1/4 ID SAE 100R2) hose

Model V450400HF

Specifications

Unit height, lowered position 60 1/4 in. (1,530 mm)

Unit height, raised position 97 in. (2,464 mm)

Hoist capacity 200 lbs. (91 Kg)

Operating pressure (hoist) 40 to 100 psi (3 to 7 bar)

Pump V450400000

Pump ratio 50:1

Pump maximum working pressure 5,000 psi (345 bar) (limited by hose working pressure)

Pump max air pressure 100 psi (7 Bar)

Air inlet

3

/8 NPT male (3/8 in. ID hose)

Lube outlet

1

/4 NPT male x 84 in. (2,134 mm) (1/4 ID SAE 100R2) hose

2

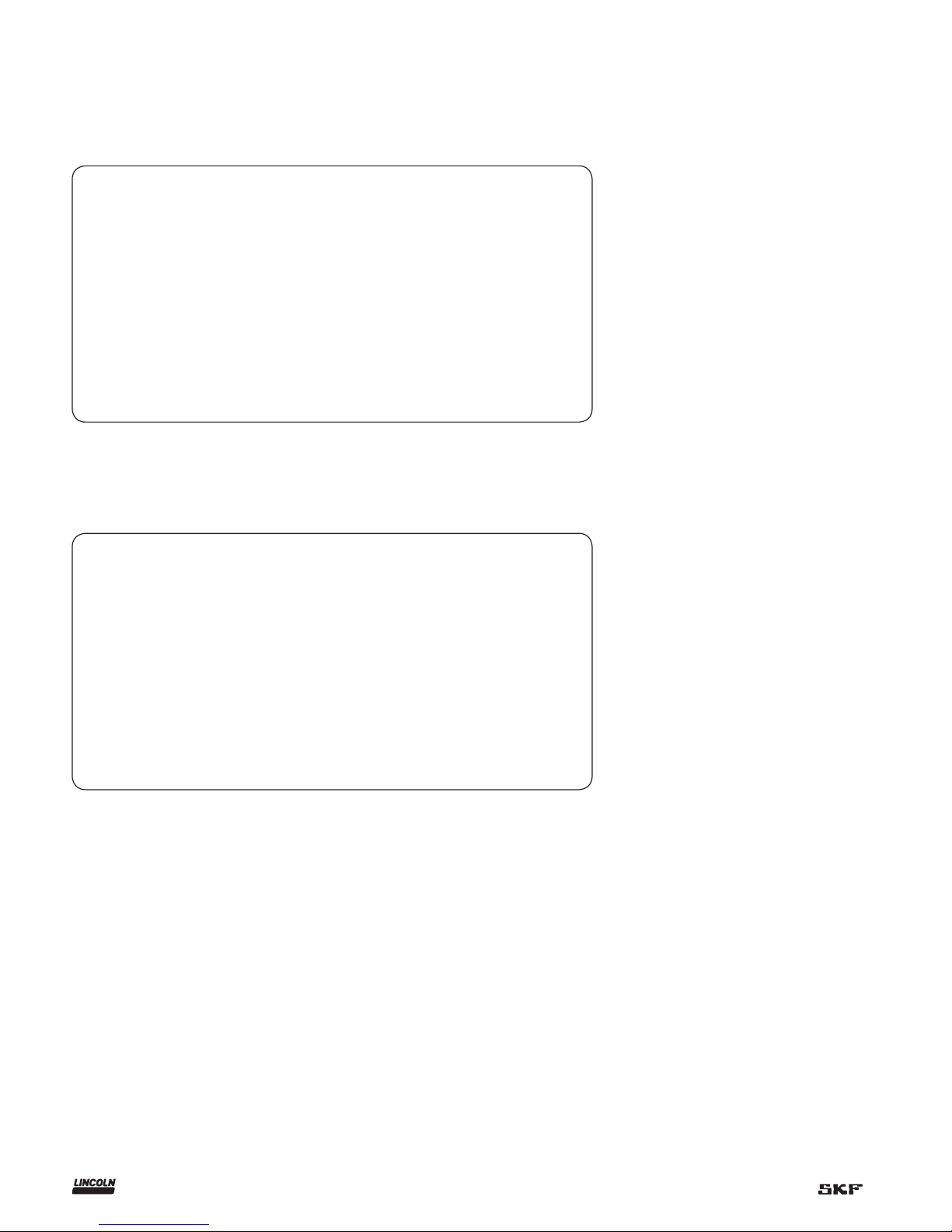

Fig. 1

(10) Hoist control valve

(17) Air assist push button

4 x Ø.69 in. (Ø17 mm)

Mounting holes

23.75 in.

(603 mm)

22.13 in.

(562 mm)

4.44 in.

(113 mm)

8.50 in.

(216 mm)

29.57 in.

(751 mm)

Shipping holes

For pump operating and service instructions, see the

appropriate owner’s manual for each pump.

Model V350400000 († section A5 page 82 series).

Model V450400000 († section A5 page 85 series).

60.25 [1530]

lowered

97.00 [2464]

raised

(21) Air vent

Base mounting detail

V350400000 3 in. (76 mm) pump assembly or

V450400000 4 in. (102 mm) pump assembly

(47) Follower

assembly

(34) Pump air supply valve

(44) Hoist

regulator

3

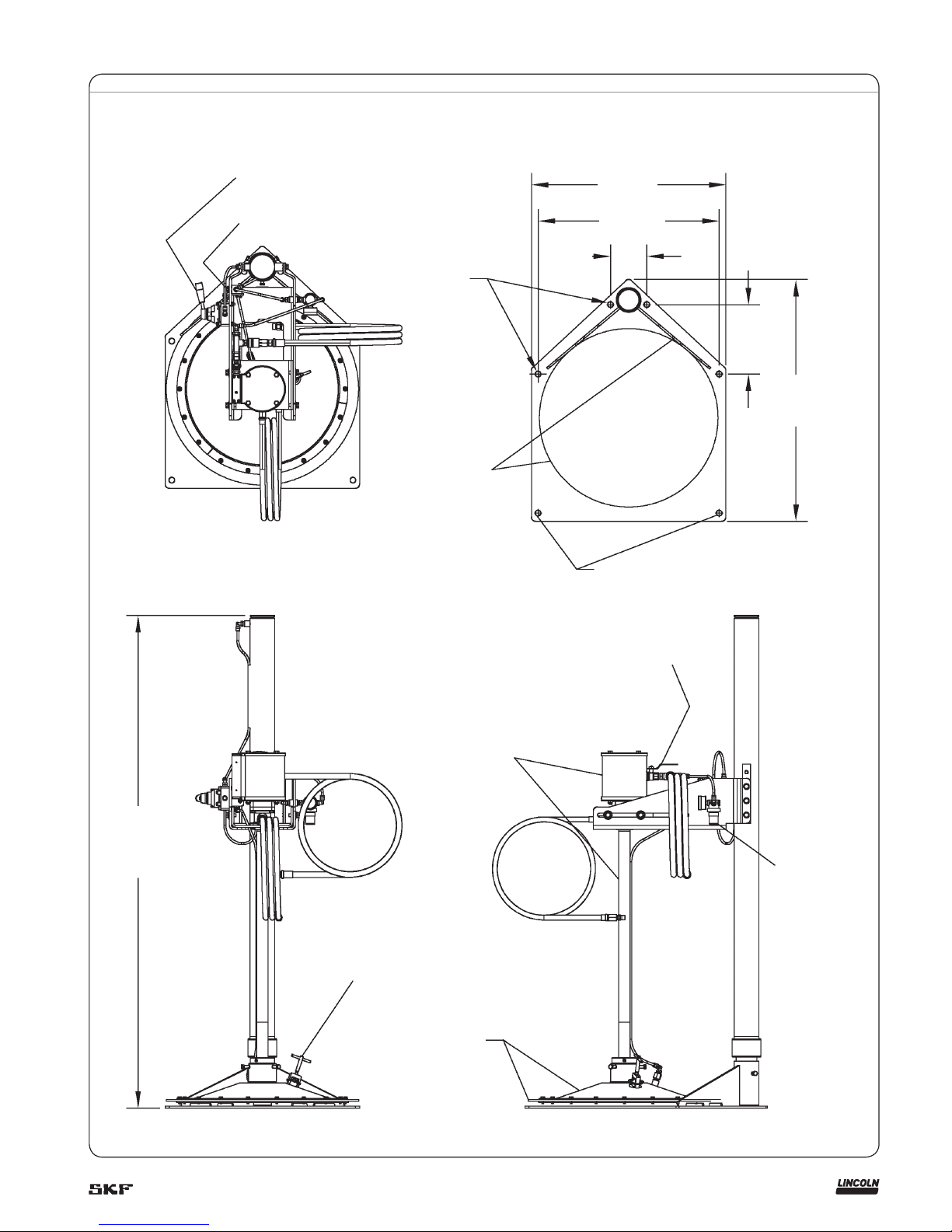

Fig. 2

Air assist push button.

Hoist control valve shown in

neutral position.

Pump air supply valve.

Remove six bolts, move mount down one set of holes

to position shown. Reinstall bolts, adjust mount to be

level with floor. Tighten bolts securely.

Position pump mount so that follower is aligned

with drum when drum is positioned against

stops at back side of mounting base. Tighten

bolts securely.

Connect length of 1/4 in . (6 mm) OD tubing

between air assist valve (17), and follower as

shown († fig. 3, page 6). Secure pump tube

with two nylon ties.

Left side view

Right side view

4

Installation

1 Select a location where there is adequate

clearance around the hoist to operate

and maneuver around the hoist and

pump assembly when installing and

removing drums.

2 The mounting base must be securely

fastened to the floor before use.

Mounting dimensions are provided on

base mounting detail in fig. 1, page 3 or

the base may be used as a template for

drilling and positioning anchors.

3 After hoist has been secured to the floor

reposition the pump support (46) by

moving it down on the support tube (15)

(† fig. 3, page 6). Adjust the pump sup-

port so that it is parallel to the floor and

secure by tightening the six mounting

bolts (4). This will keep the pump tube

parallel with the support tube.

4 Mount pump to pump mount (29).

The holes in the pump mount are off

center with the pump mount. When the

pump mount is placed in the pump support (46) the pump mount should be

placed with the holes closest to the open

end of the pump support († fig. 3,

page 6). When attaching the pump to

the mount (29) attach pump outlet body

to pump mount with four 1/4–20 x 9/16

hex screw and washer assemblies (39)

(† fig. 3, page 6).

5 Place pump and mount into pump sup-

port (46) and loosely install hex bolts,

lock washers, and flat washers (4, 5, and

6) through slots in support. Leave loose

until final adjustments are made.

6 Assemble air inlet fittings († fig. 3,

page 6). Assemble the air regulator (44)

to the air inlet of the hoist as shown in

the figure. Note that there is a 1/8 in. pipe

plug packaged with each regulator for

plugging the unused gage port in the

regulator. Install this plug into the unused port on the regulator (44) as

shown.

7 Measure and cut a length of the supplied

1

/4 in. OD black polyurethane tubing to

connect the air inlet to the regulator inlet

(† fig. 3, page 6). The tubing will simply

push fit into the 1/4 in. fittings included

with the model.

8 Assemble the air hose to the air coupler

(24). Make sure the ball valve (34) is

closed and the hoist control valve (10) is

in the down position. Attach air hose to

source of filtered, regulated air. The air

pressure should be set initially to about

40 psi (3 bar).

9 Adjust the hoist air regulator (44) for a

pressure of around 30 to 40 psi (2 to

3 bar). Check for air leaks in all connections. Slowly move the hoist control valve

(10) to the raised position and raise

pump so the end of the pump tube will

clear the primer assembly.

10 Attach the primer assembly to the end of

the pump tube. When assembling pump

to the follower, a reducing adapter is

used (38). Apply some grease to the

outside of the adapter and the o-rings

on the inside of the adapter and the

|inside of the follower. Push the adapter

into the follower assembly until it seats

against the shoulder. Tighten the three

hex bolts on the follower (14) securely.

Apply some grease to the end of the

pump tube and slide into the reducing

adapter (38) until the pump tube is flush

with the bottom of the follower. Tighten

the three set screws (32) securely.

Failure to securely fasten the base to the

floor may result in severe injury and or

property damage. Pump hoist may topple over if not securely fastened.

WARNING

11 Raise the follower high enough to clear

an open 400 lb. (181 kg) container.

Place the container under the follower

and slide the drum back on the mounting

base (8) until the bottom is against both

gusset plates on the base. Adjust the

position of the pump with respect to the

drum by sliding the pump mount (29) in

the pump support (46) until the follower

is centered over the open drum.

Tighten the hex bolts (4) through the

slots in the pump support to secure the

pump mount. Do not insert the follow-

er into the drum at this time.

12 Using the remaining polyurethane tub-

ing, attach to the open fitting on the

2-way air valve (17) mounted on the

pump support (46) by pushing one end

of the tube into the fitting until secure.

(† fig. 3, page 6). Thread the tubing

down along the pump tube to the fitting

(1) in the top of the follower assembly.

Secure the tubing to the pump tube with

two nylon wire ties, supplied with the

assembly († fig. 2, page 4).

13 Check for proper air flow by pressing

button on 2-way air valve (17) making

sure that air flows through check valve

(30) and out under follower assembly.

14 Connect fluid hoses to pump outlet.

These models are supplied with a 1/4 in.

(6 mm) ID high pressure hose (40) with

33

/64 in. (13 mm) female thread on both

ends. Two male adapters (45) are supplied to adapt the hose to 1/4 NPT male

for the pump outlet, and working end of

the hose. Insert the hose adapters (45)

into each end of the high pressure hose

and tighten securely for leak proof seal.

Thread one end of the hose into the pump

outlet and tighten securely. Attach the

other end as required for the application.

5

Fig. 3

48*

45

9

2

7

1

44

42

4

5

6

39

40

43

46

41

2

1

36

35

37

33

34

33

24

Reposition pump support (46)

by moving down one hole on

support tube (15) as

shown. Top holes sould be

visible above the pump support.

Plug (packed with 44)

Right rear detail

Attach tubing from follower to open

tube fitting on bottom of air assist valve

(17) as shown.

Position pump mount (29) with edge

closest to holes facing to the front

.

Right front detail

Not shown

Hoist regulator

29

*Indicates change.

6

Operating controls

Refer to fig. 1, page 3.

Hoist control valve (10)

Three position air valve used to raise and

lower the pump into and out of the drum.

When the handle is moved up, the hoist will

raise. When placed in the neutral position,

with handle level with floor, hoist will stop

and hold position. When the handle is placed

in down position, the hoist will lower the

pump into the drum.

Air assist push button (17)

Two-way air valve used to force air under

the follower assembly to assist in lifting the

pump and follower from the drum. The air

assist is used in conjunction with the hoist

control valve when removing the pump and

follower from the drum.

Air vent (21)

Used to vent air trapped under the follower

plate when the follower and pump is lowered into the drum. This valve should be

open when the pump and follower are lowered into the drum. Air will escape from the

valve as the follower is lowered into the

drum. After the follower rests on top of the

lubricant, the valve is closed by turning

clockwise to seal the ball against the seat.

Hoist regulator (44)

Used to control the air pressure to the hoist

only. The air pressure should be set to the

necessary pressure required to raise the

pump and follower. Too much pressure will

cause the hoist to rise very quickly and may

damage the hoist.

Pump air supply valve (34)

Used to control air to the air motor and

pump assembly. When the pump is in

operation this valve must be open to allow

air to flow to the air motor. When servicing,

relieving pressure or operating the hoist,

this valve must be closed to stop air motor

and pump operation when the pump is

removed from the drum.

Operation

Before operating, ensure that the hoist is

securely fastened to the floor. All connecting

bolts must be tightened securely. Air connections and tube fittings are all tight and

leak proof. Fluid connections are tight and

leak proof.

All fluid and air hoses are to be connected

as required.

Installing a material drum

1 Adjust the hoist regulator (44) to about

30 psi (2 bar). Move the hoist control

valve (10) to the raise position to lift the

pump clear of the rim of the drum. Adjust

the hoist regulator as required to a pressure high enough to raise the pump clear

of the drum with out rapid uncontrolled

rising of the pump. Move the hoist control valve to the neutral position to hold

the pump in position.

2 Position the drum of lubricant on the

mounting base (8) so that the drum rests

against both gussets on the back side of

the base.

3 Adjust, if necessary, the location of the

pump support (29) to center the follower

assembly over the top of the drum.

Tighten the bolts (4) if an adjustment

was made.

4 Open the air vent (21) to allow air to vent

from below the follower as the follower is

lowered into the drum.

5 Move the hoist control valve (10) to the

down position and guide the follower into

the drum of lubricant. As the follower is

lowered into the drum, air will vent from

the vent valve. Continue to lower the

pump and follower into the drum until it

stops. Some lubricant may appear at the

vent valve as it is lowered into the drum.

This is normal. Close the air vent (21)

after the follower stops moving.

6 Leave the hoist control valve in the

down position at all times except

when removing the follower from the

drum. This will allow the follower to drop

as the lubricant is depleted from the

drum.

7 Turn on the pump air supply valve (34)

and adjust the air pressure to the air

motor and pump tube assembly to prime

the pump as required. Refer to the owner’s manual for the air motor and pump

tube.

8 While in operation, as the pump removes

material from the drum, the pump will

continue to drop into the drum, following

the level of material down to the bottom

of the drum. Note that air pressure is not

used to exert force on the pump hoist to

force the follower into the drum.

Removing a material drum

When the pump follower reaches the bottom of the drum and drum replacement is

necessary the pump may be removed from

the drum as follows:

1 Close the pump air supply valve (34) to

stop the pump.

2 Move the hoist control valve (10) to the

raise position, and press the air assist

push button (17) at the same time.

3 Hold the base of the drum into the slots

formed in the gussets on the mounting

base with one foot while raising the

pump from the drum.

4 Modulate the hoist control valve and air

assist push button as necessary to work

the follower out of the drum. If the follower hangs up at the drum chimes, it

may help to allow the drum to rise off the

base slightly and allow the air assist to

force the drum off the follower while

guiding the drum by hand.

5 When the follower reaches the top of the

drum, release the air assist push button,

and place the hoist control valve in the

neutral position to hold the pump in

position while the drum is replaced.

6 After removing the drum, remove any

grease from the bottom side of the follower in the area of the air vent check

ball (22), so that air will flow freely

through the vent and grease is not forced

on top of the follower when placing the

follower back into the lubricant.

7

Air cylinder service

The pump must be removed from the hoist

to service the air cylinder assembly.

1 Disconnect all air lines between the pump

and hoist assembly.

2 Disconnect the air line to the follower as-

sembly. The pump and pump mount (29)

and the follower assembly, can be removed

as a unit from the pump support (46) by

removing the four attachment hex bolts,

and washers, (4, 5, and 6). Place the

pump and follower on large sheet of clean

paper or cardboard to keep follower clean.

3 Loosen set screw (12), and remove tube

cap (11) from upper support tube (15).

4 Slide the upper support tube off of the

lower support tube (18) and set aside.

5 The seal (20) is accessible and may be

replaced by removing from the piston (19)

and replacing with a new seal.

6 Carefully inspect the condition of the

upper support tube (15) before reassembly, checking for scratches or damage to

the inside surface. Before re-assembly,

apply a liberal coating of grease to the

inside surface of the upper support tube

(15), piston (19), and seal (20).

7 Reassemble in the reverse order of disas-

sembly. Check all tubing and connections

for leaks.

Service

When service is required see the appropriate

owner’s manual for the pump. Service on

the hoist is limited to the hoist air cylinder

assembly and the follower assembly. All other

hoist components are not serviceable items.

Before any service is attempted it is

important to disconnect the air supply to

the pump and hoist unit and bleed off all

material pressure from the pump outlet

and attached hoses.

WARNING

Follower service

The follower must be removed from the

bottom of the pump for service. The pump

does not need to be removed from the hoist.

1 To remove the follower, remove the

pump and follower from the material

drum.

2 Remove the drum from the base of the

hoist.

3 Lower the pump and follower to the base

on top of a piece of clean cardboard or

paper.

4 Place hoist control valve in neutral

position.

5 Disconnect the air line from the follower.

6 Loosen the three screws (14 or 32) and

slide the follower off the end of the pump

tube. The follower may be tight due to

the O-ring seals (25 or 31) around the

pump tube.

7 Place follower on clean flat surface with

air vent and pump tube bushing facing

the top side.

8 Remove the 18 hex screws (26), three

segment rings (27) and follower wiper

ring (28).

9 Inspect all components for wear or dam-

age, replacing any damaged or worn

components.

10 Re-assembly is the reverse of the disas-

sembly process. When installing the hex

screws (26) take care not to tighten too

tight. The screws only need to be tight

enough to seal the wiper to the follower.

There should be no deflection to the segment rings (27) when the screws are

tightened.

11 Check for leaks and test after

re-assembly.

Air vent service

The air vent (21, 22, and 23) may be

serviced without removing the pump or the

follower from the pump. The pump and

follower must be removed from the drum.

1 Lower the pump and follower to the base

on top of a piece of clean cardboard or

paper.

2 Place hoist control valve in neutral

position.

3 Remove the valve screw assembly (21)

by turning counterclockwise.

4 Remove the retaining ring (23).

5 The ball can now be removed through the

slots on the sides of the valve body.

6 Inspect the ball for any signs of wear or

damage. Replace as necessary. Clean and

inspect the valve body and follower surfaces where the ball is seated. Repair or

replace as necessary.

7 Reassemble in the reverse order of disas-

sembly. Do not tighten the valve screw too

tightly. It should only be tight enough to

form a seal. If tightened too tightly, damage to the ball may occur.

8

Fig. 4

15

19

20

16

17

1

46

1

/4 in. (6mm) OD tubing as

required. Attach to follower.

18

11

12

14

7

1

2

8

9

10

13

Plug, install in bottom

port of 4-way valve.

4 and 5

3

1

2

1

9

Fig. 5

Primer assembly detail

14

32

31

25

38

22

21

23

26

27

28

1

1)

PowerMaster pump.

2)

PMV pump.

1)

1)

2)

2)

10

Parts list

Item Description Part no. Quantity. Item Description Part no. Quantity.

1

1

/4 in. (6 mm) OD x 1/4 in. NPT

(external) 90° ell

247761 7 25 O-ring (nitrile) 343371)2

2

1

/4 in. (6 mm) OD x 0.160 in.

(4 mm) ID polyurethane tubing

– As

required

26

1

/4–20 x 5/8 in. tapping screw 274648 18

3

1

/4–20 x 1 3/4 socket head cap screw 50779 4 27 Follower segment 274644 3

4

3

/8–16 x 1 hex head cap screw 50044 10 28 Wiper ring (nitrile) 34371 1

5

3

/8 in. split lock washer 66220 10 29 Pump mount 274734 1

6

3

/8 in. flat washer 48268 4 30 Check valve 274653 1

7

1

/4–20 hex nut 51010 6 31 O-ring 342622)2

8 Mounting base 274661 1 32

5

/16–18 x 1/2 in. cup point set screw 505252)3

9

1

/4 in. (6 mm) external run tee 274654 1 33

3

/8 in. (9 mm) hex nipple 10540 2

10 4-way air valve 237588 1 34

3

/8 in. (9 mm) ball valve, 1/4 turn 275291 1

11 Tube cap 274719 1 35

3

/8 in. (9 mm) tee 70159 1

12 #10–32 x 1/4 in. cup point set screw 50522 1 36

3

/8 NPT x 1/4 NPT bushing 275290 1

13

1

/4 NPT pipe plug 67359 1 37 Air nipple 640106 1

14

5

/16–18 x 3/4 in. hex head cap screw 500161)6 38 Follower adapter (includes 31 and 32) 275259 1

15 Upper support tube 274666 1 39

1

/4–20 x 9/16 hex screw

& washer assembly

50060 4

16

1

/4–20 x 1 1/2 socket head cap screw 50051 2 40

1

/4 x 84 in. (6 x 2,134 mm) high pressure

hose

75084 1

17 2-way air valve 274682 1 41

1

/4 NPT hex nipple 10462 1

18 Lower support tube 274664 1 42 Air pressure gage 247843 1

19 Piston 274663 1 43

3

/8 x 84 in. (9 x 2,134 mm) air hose 275289 1

20 Piston seal 34327 1 44 Mini air regulator 602003 1

21 Valve screw assembly 274651 1 45 Hose connector 10198 2

22 1 in. (25 mm) ball 274715 1 46 Pump support 274669 1

23 Retaining ring 274650 1 47 400 lb (181 kg) follower assembly 274655 1

24 Air coupler 242563 1 48 Check valve 1/4 NPT 245868* 1

1)

PowerMaster pump.

2)

PMV pump.

*Indicates change.

11

This page intentionally left blank.

12

This page intentionally left blank.

13

This page left intentionally blank.

14

15

Lincoln industrial

standard warranty

Standard limited warranty

Lincoln warrants the equipment manufactured and supplied by Lincoln to be free

from defects in material and workmanship

for a period of one (1) year following the

date of purchase, excluding there from any

special, extended, or limited warranty published by Lincoln. If equipment is determined to be defective during this warranty

period, it will be repaired or replaced, within

Lincoln’s sole discretion, without charge.

This warranty is conditioned upon the

determination of a Lincoln authorized representative that the equipment is defective.

To obtain repair or replacement, you must

ship the equipment, transportation charges

prepaid, with proof of purchase to a Lincoln

Authorized Warranty and Service Center

within the warranty period.

This warranty is extended to the original

retail purchaser only. This warranty does not

apply to equipment damaged from accident,

overload, abuse, misuse, negligence, faulty

installation or abrasive or corrosive material,

equipment that has been altered, or equipment repaired by anyone not authorized by

Lincoln. This warranty applies only to equipment installed, operated and maintained in

strict accordance with the written specifications and recommendations provided by

Lincoln or its authorized field personnel.

This warranty is exclusive and is in lieu

of any other warranties, express or

implied, including, but not limited to, the

warranty of merchantability or warranty

of fitness for a particular purpose. War-

ranty on items sold by Lincoln, but not

manufactured by Lincoln are subject to

the warranty consideration, if any, of

their manufacturer (such as hoses,

hydraulic and electric motors, electrical

controllers, etc.) Assistance in making

such warranty claims can be offered as

required.

In no event shall Lincoln be liable for inci-

dental or consequential damages. Lincoln’s

liability for any claim for loss or damages

arising out of the sale, resale or use of any

Lincoln equipment shall in no event exceed

the purchase price. Some jurisdictions do

not allow the exclusion or limitation of incidental or consequential damages, therefore

the above limitation or exclusion may not

apply to you.

This warranty gives you specific legal

rights. You may also have other rights that

vary by jurisdiction.

Customers not located in the Western

Hemisphere or East Asia: Please contact

Lincoln GmbH and Co. Kg, Walldorf,

Germany, for your warranty rights.

Special limited warranties

Special limited 2 year warranty

sl-v series, single injectors-85772,

85782, and replacement injectors-85771,

85781

Lincoln warrants the SL-V Injector series to

be free from defects in material and workmanship for two (2) years following the date

of purchase. If an injector model (single or

replacement) is determined to be defective

by Lincoln, in its sole discretion, during this

warranty period, it will be repaired or replaced, at Lincoln’s discretion, without

charge.

Special limited 5 year warranty

series 20, 25, 40 bare pumps, pmv bare

pumps, heavy duty and 94000 series bare

reels

Lincoln warrants series 20, 25, 40 bare

pumps, PMV bare pumps, heavy duty

(82206), mini bench (81133, 81323), and

all 94000 LFR series (single arm and dual

arm) bare reels to be free from defects in

material and workmanship for five (5) years

following the date of purchase. If equipment

is determined by Lincoln, in its sole discretion, to be defective during the first year of

the warranty period, it will be repaired or

replaced at Lincoln’s discretion, without

charge. In years two (2) and three (3), the

warranty on this equipment is limited to repair with Lincoln paying parts and labor

only. In years four (4) and five (5), the warranty on this equipment is limited to repair

with Lincoln paying for parts only.

Special limited 5 year warrantylimited oil meters, limited fluid control

valves, aod (air-operated diaphragm pumps)

Lincoln warrants the 712 series control

valves, 912 series lube meters, electronic

lube meters (980. 981, 982 series), our

universal inline digital meters (812/813

series), and our AOD pump offering to be

free from defects in material and workmanship for five (5) years following the date of

purchase. If either is determined to be

defective by Lincoln, in its sole discretion,

during the warranty period, they will be

repaired or replaced, at Lincoln’s discretion,

without charge.

Special DEF (diesel exhaust fluid) limited

warranty

DEF products are warranted to be free from

defects in material and workmanship for a

period of one (1) year following the date of

purchase. The following exceptions to the

standard warranty period are in effect:

• 85700-30/85700-50 DEF hose reels

(bare reel only),

277251/277252 AC DEF pumps, and

277256 and 277257 DEF meters are

warranted for two (2) years from date of

purchase.

• 85623 DEF AOD

(air operated diaphragm) pumps

are covered under the standard five (5)

year AOD pump warranty.

If either is determined to be defective by

Lincoln, in its sole discretion, during the

warranty period, they will be repaired or

replaced, at Lincoln’s discretion, without

charge.

Lincoln Industrial contact information

To find Lincoln Industrial’s nearest service

center call one of the following number;

customer service 314-679-4200

or you may also use our website

www.lincolnindustrial.com

® SKF is a registered trademark of the SKF Group.

® Lincoln is a registered trademark of Lincoln Industrial Corp.

© SKF Group 2014

The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be

accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein.

SKF PUB LS/I4 15242 EN.R1 · November 2014 · Form 404478B

Seals

Bearings and

housings

Lubrication

systems

Mechatronics Services

The Power of Knowledge Engineering

Combining products, people, and applicationspecific knowledge, SKF delivers innovative

solutions to equipment manufacturers and production facilities in every major industry worldwide. Having expert ise in multiple competence

areas supports SKF Life Cycle Management, a

proven approach to improv ing equipment reliability, optimizing operational and energy efficiency

and reducing total cost of ownership.

These competence areas include bearings and

units, seals, lubrication systems, mecha tronics,

and awide range of services, from 3-D computer

modelling to cloud-based condition monitoring

and asset management services.

SKF’s global footprint provides SKF customers

with uniform quality standards and worldwide

product availability. Our local presence provides

direct access to the experience, knowledge and

ingenuity of SKF people.

lincolnindustrial.com skf.com/lubrication

Loading...

Loading...