Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Quicklub - Progressive Metering Devices

for Grease and Oil

Model SSV, SSV-E and SSV M

B-SSV-000a11

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 2 f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 3 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Table of Contents

Page

Introduction

Explanation of Symbols Used ........................................... 4

User’s Responsibility ........................................................ 4

Environmental Protection .................................................. 4

Service ............................................................................. 4

Safety instructions

Appropriate Use ............................................................... 5

General Safety Instructions ............................................... 5

Accident Prevention Regulations ...................................... 5

Operation, Maintenance, Repair ....................................... 5

Installation ........................................................................ 5

Installation

Tube Fittings, Screw-Type ................................................ 6

Main- and secondary Metering devices ........................ 6

Tube Fittings, Push-in Type .............................................. 6

Metering Devices ......................................................... 6

Check Valv es .............................................................. 6

Connection of the High-pressure Hose and

the Pressure Plastic Tube ........................................... 7

Pressure Plastic Tubes and High-pressure Hoses ............ 8

Description

Progressiv e Metering Dev ices Model SSV, SSV-E

and SSV M ....................................................................... 9

Progressive Plunger Metering Devices – General ........ 9

Features of a Progressive Metering Device ................. 9

Different of Features from SSV, SSV-E and SSV M ... 10

Page

Operation

Applications ................................................................... 10

Lubricant Distribution withi n the Metering Device ............ 12

Phase 1 + 2 .............................................................. 12

Phase 3 - 5 ............................................................... 13

Monitoring of the Operation ............................................ 14

System-dependent monitoring .................................. 14

Visual monitoring ...................................................... 14

Electrical monitoring (microprocessor control) ........... 15

Pressure relief valve ................................................. 15

Determining the Lubricant Output by Combining Outlets . 16

Tube Fittings, Screw-Type ........................................ 16

Tube Fittings, Push-in-Type (main metering device) .. 17

Tube Fittings, Push-in-Type

(secondary metering devices) ................................... 18

Troubleshooting ........................................................... 19

Technical Data

Metering Devices ........................................................... 21

Lines .............................................................................. 21

Push-in-Type Tube Fittings ............................................ 21

Tightening torques ......................................................... 21

Dimensions .................................................................... 22

Metering Devices Model SSV 6 to 22 &

SSV6-E to 22-E ........................................................ 22

Metering Devices SSV M 6 to 12 .............................. 22

EC Declaration of incorporation .................................. 23

Further Information can be found in the following manuals:

Technical Description Quicklub - Pump 203

Technical Description for “Electronic Control Units” of pump 203:

Printed-Circuit Board 236-13857-1 - Model H

1)

Printed-Circuit Board 236-10697-1 - Model V10 - V13

1)

Printed-Circuit Board 236-13870-3 - Model M 00 - M 15

1)

Printed-Circuit Board 236-13870-3 - Model M 16 - M 23

1)

Installation Instructions

Parts Catalogue

List of Lubricants

Planning and Layout of Quicklub Progressive Systems

1)

The model designation of the printed-circuit board is part of the pump model designation indicated on the pump nameplate,

e. g. : P 203 - 2XN - 1K6 - 24 - 1A1.10 - V10

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Introduction

Explanation of Symbols Used

The following description standards are used in this manual:

Safety Instructions

Structure of safety instructions:

Pictogram

Signal word

Danger text

- Danger note

- How to avoid danger

The following pictograms are used in this manual and are

combined with the corresponding signal words:

1013A94

4273a00

6001a02

- ATTENTION

- CAUTION

- WARNING

- ATTENTION

- CAUTION

- WARNING

- NOTE

- IMPORTANT

The signal words give the seriousness of danger if the following text is not observed:

ATTENTION refers to faults or damages on

machines.

CAUTION refers to bad damages and possi-

ble injuries.

WARNING refers to possible dangerous inju-

ries.

NOTE indicates improved operation of the

device.

IMPORTANT indicates special operating fea-

tures of the device.

Example:

1013A94

ATTENTION!

When making use of other than the tested

spare parts, serious damage may affect

your device.

Furthermore, you will find the following text symbols in this

manual:

Listing of applicable statements

- Subpoint of applicable statements

1. Determination of the number or sequence of contents

Procedural instruction

User's Responsibility

To ensure the safe operation of the unit, the user is responsible for the following:

1. The pump / system shall be operated only for the intended use (see next chapter "Safety Instructions") and its

design shall neither be modified nor transformed.

2. The pump / system shall be operated only if it is in a

proper functioning condition and if it is operated in accordance with the maintenance requirements.

3. The operating personnel must be familiar with this User

Manual and the safety instructions mentioned within and

observe these carefully.

7KHFRUUHFWLQVWDOODWLRQDQGFRQQHFWLRQRIWXEHVDQGKRVHVLI

QRWVSHFL ILHGE\6.)LVWKHXVH U V UHV SRQVL EL OLW \

/LQFROQ*PE+ZLOOJODGO\DVVLVW\RXZLWKDQ\TXHVWLRQVSHU

WDLQLQJWRWKHLQVWDOODWLRQ

Environmental Protection

Waste (e.g. used oil, detergents, lubricants) must be disposed of in accordance with relevant environmental regulations.

Service

7KHSHUVRQQHOUHVSRQVLEOHIRUWKHKDQGOLQJRIWKHSXPS

V\VWHPPXVWEHVXLWDEO\TXDOLILHG,IUHTXLUHG6.)

RIIHUV\RXIXOOVHUYLFHLQWKHIRUPRIDGYLFHRQVLWHLQVWDOODWLRQ

DVVLVWDQFHWUDLQLQJHWF:HZLOOEHSOHDVHGWRLQIRUP\RX

DERXWRXUSRVVLELOLWLHVWRVXSSRUW\RXSXUSRVHIXOO \

,QWKHHYHQWRILQTXL ULHVSHU WDLQLQJWRPDLQWHQDQFHUHSDLUV

DQGVSDUHSDUWVZHUHTXLUHPRGHOVSHFLILFGDWDWRHQDEOHXV

WRFOHDUO\LGHQWLI\WKHFRPSRQHQWVRI\RXUSXPSV\VWHP

7KHUHIRUHDOZD\VLQGLFDWHWKHSDUWPRGHODQGVHULHVQXPEHU

RI\RXUSXPSV\VWHP

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 5 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Regulations for Prevention of Accidents

To prevent accidents, observe all city, state and federal

safety regulations of the country in which the product will

be used.

Avoid the operation with

- unapproved parts.

- insufficient or contaminated lubricants.

Operation, Repair and Maintenance

Authorized and instructed personnel who are familiar with the

centralized lubrication systems should only perform repair.

Appropriate Use

Use the SSV, SSV-E and SSV M lubricant metering devices

only for dispensing lubricants in centralized lubrication systems.

Suitable Lub rica nts

The progressive metering devices model SSV can be used

for dispensing

- mineral oils of at least 40 mm

2

/s (cST) or

- greases up to the penetration class NLGI 2

6001a02

IMPORTANT

It must nevertheless be ensured that the

oils or greases used do not alter their consistency significantly in the course of time or

u

nder the influence of temperature or

pressure.

General Safety Instructions

The progressive centralized lubrication system connected

to the Quicklub pump model 203 must always be secured

with a pressure relief valve.

Lincoln SSV, SSV-E and SSV M lubricant metering devices

are state of the art.

Incorrect use may result in bearing damage caused by

poor or over-lubrication.

Each outlet which will be used must be equipped with a

check valve.

In the case of the metering devices model SSV 6 to 12 or

SSV6-E to 12-E and SSVM 6 to 12 the outlets 1 and/or 2

must never be closed.

Unauthorized modifications or changes to an installed

system are not admissible. Any modification must be

subject to prior consultation with the manufacturer of the

lubrication system.

Use only original Lincoln spare parts (see Parts Catalogue)

or the parts approved by

Installation

Install the metering devices at a suitable location in ac-

cordance with the lubrication diagram.

It is recommended that the metering devices be installed in

such a way that the outlets are not close to the chassis or

the attaching plate. This will facilitate troubleshooting in the

case the system is blocked.

The main metering devices with indicator pin must be

installed in such a way that the indicator pin is easily visible.

When the push-in ty pe fittings are used, note the following:

For the metering device inlet use only push-in type

fittings (R 1/8) with reinforced collar and sealing ring.

For the outlet tube fittings of the SSV divider valve

(M 10x1) depending on the design of the lubricant line, for

example

- high-pressure plastic hose (Ø 4.1 x 2.3) use valve bodies

with reinforced collar only, or,

- pressure plastic tube (Ø 6 x 1.5) use valve bodies with

knurled collar only

For the outlet fittings of the SSV M divider divider valve

(M 8x1) pressure plastic tube (Ø 4 x 1) use valve bodies

with knurled collar only.

6001a02

NOTE

In the case of construction machines or

agricultural machines use high pressure

plastic hoses for the lubric ant feet lines. I n

such cases the outlet fittings of the secondary metering devices and the connection fittings to the lubricant points must

have a reinforced collet.

8VHRQO\WKHPDLQDQGIHHGOLQHVVSHFLILHGE\6.)DQG

DGKHUHWRWKHVSHFLILHGV\VWHPSUHVVXUHV.

1013A94

CAUTION!

Danger of injury in the case of serious

corrosion of meter ing dev ice sur fac es:

An increasing corrosion of the surfaces will

cause the balls pressed in to lose their hold.

Under pressure, they may suddenly burst

out and cause injuries.

For applications in corrosive environments,

use metering devices in stainless steel

version only.

Safety Instructions

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 6 f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Installation

Tube Fittings, Screw type

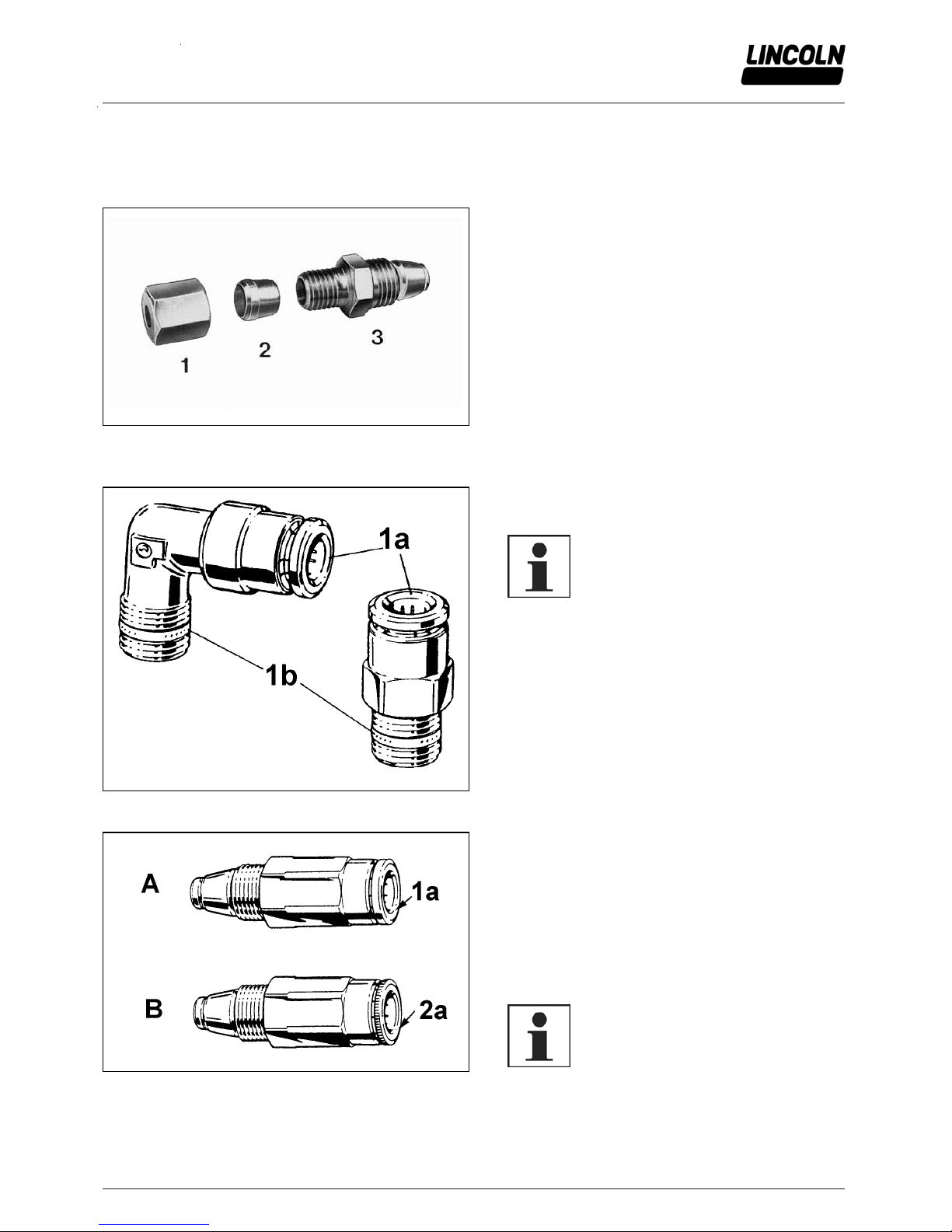

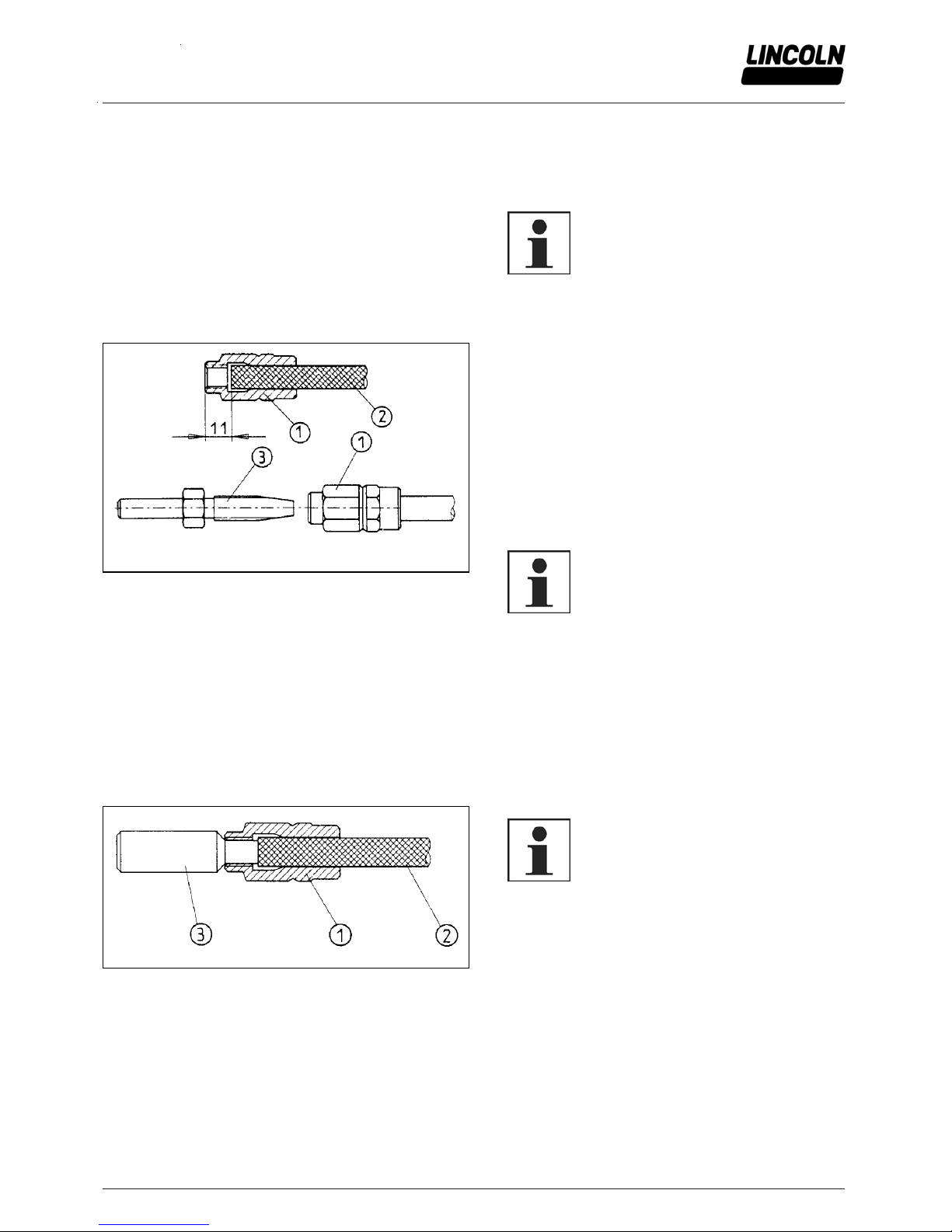

4239a99

Fig. 1 Single parts of the check va lve

Main- and secondary metering devices

Inlet tube fittings, straight and 90°

As inlet fitting use only tube fittings R1/8” thread.

Check valves

Install one complete check valve in each outlet bore that will

be used, see fig. 1.

Install one closure plug in e ach outlet borehole that will not be

used. Exception: outlet bore 1 & 2 on sizes6 to22. Check

valves must be installed in both bores.

1 coupling nut 3 valve body with seal and

clamp ring 2 ferrule

Tube Fittings, Push-in type

1008a98

Fig. 2 Inlet fittings

Metering devices

Inlet tube fittings, straight and 90 °

6001a02

IMPORTANT

For the inlet fitti ngs use only tube fittings

with reinforced collet 1a (fig. 2) and

sealing ring 1b at the thread.

1a Collet

1b Sealing ring

1009a98

Fig. 3 The different type s of check va lve

Check valves

A check valve must be mounted to the corresponding

metering device outlet of each feed line in order to be able

to precisely meter the predefined amount of lubricant.

Main metering device

Use check valves type A, Fig.3 with reinforced collet 1a

and smooth flange (Part no. 226-14091-4).

Secondary metering device

Use check valves type B, Fig. 3 with standard collet 2a

and knurled flange (Part no. 226-14091-2).

6001a02

NOTE

On construction machines or agricultural

machines use high-pressure plastic hoses.

In such cases the check valves of the

secondary metering devices must have a

reinforced collet and smooth flange.

A Check valve with reinforced collet

B Check valve with knurled collet

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 7 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Installation, continuation

Tube Fittings, Push-in Type, continuation

Connection of High-pressure Hose and Pressure Plastic Tube

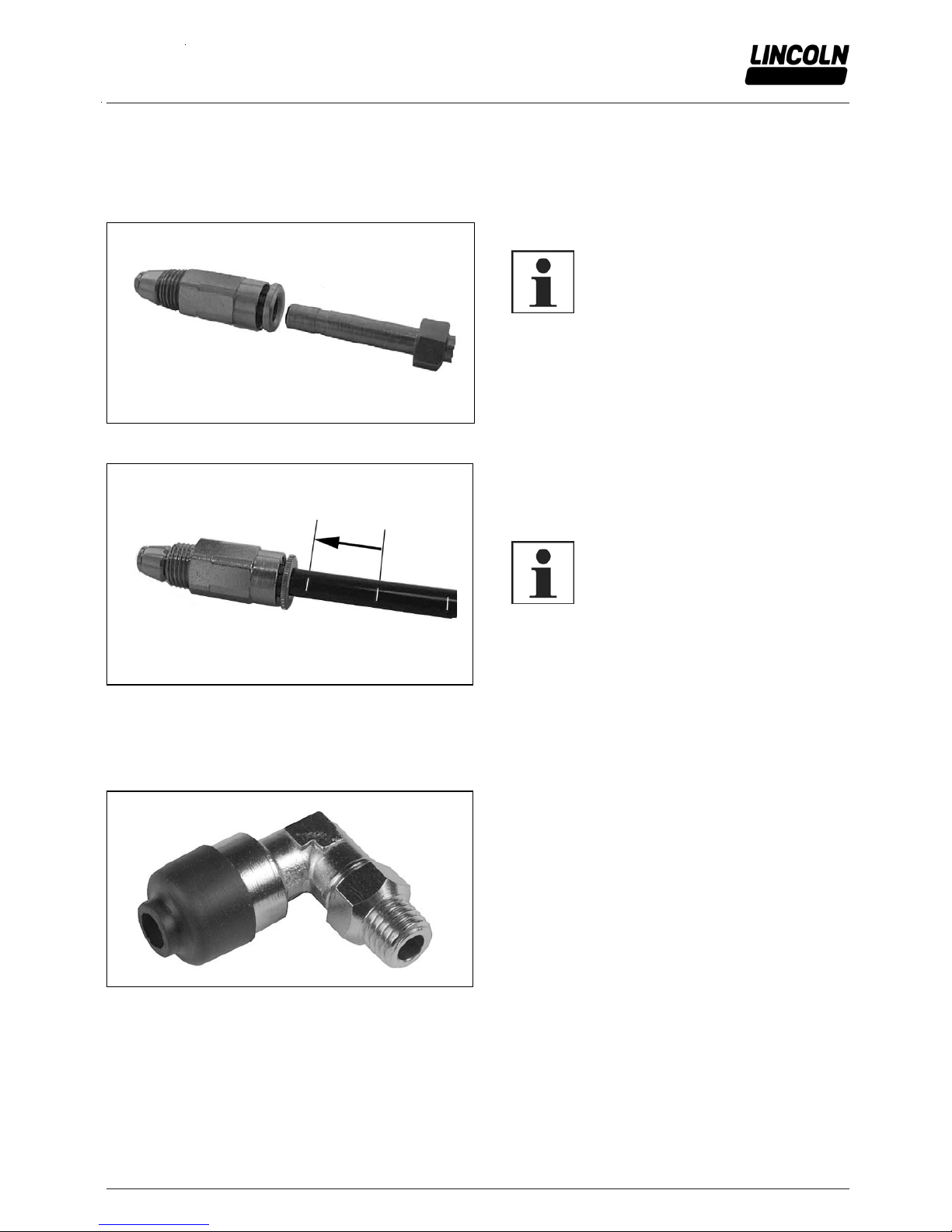

4156a98

Fig. 4 Check valve with reinforced collet and hose stud

High-pressure range (main metering device)

60 01a0 2

IMPORTANT

Only main lines (NW 4.1 x 2.3 mm) with

threaded sleeve and hose stud may be

connected to the inlet fitting and the check

valves with reinforced collar.

4157a98

Fig. 5 Check valve with knurled collet and pressure plastic tube

Low-pressure range (secondary metering device)

Connect the pressure plastic tube (Ø6x1.5 mm) to the check

valve with standard collet (knurled collet) and to the inlet

fittings towards the lubrication point (knurled coll et).

60 01a0 2

NOTE

Special cases, such as applications for

construction machines or agricultural machines, require the use of check valves

and inlet fittings (towards the lube point)

with reinforced collet also for the lowpressure range. Refer to Parts Catalog.

The pressure plastic tubes are marked with white lines

(Fig. 5) as an installation aid.

Cut the pressure plastic tube off at one of the white lines

before it is mounted. Then insert the pressure plasti c tube

into the fitting up to the next white mark.

This will ensure a correct installation of the pressure plastic

tube in the tube fitting.

00002632

Fig. 6 Push in type fitting with protective cap

Protective cap for push-in type fittings

Push-in type fittings, check valv es and pressure relief v alv es

can be closed with a protective cap in order to av oid contamination.

Designation .......................................................... Part No.

Protective cap ................................................. 432-24313-1

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 8 f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Installation, continuation

Pressure Plastic Tubes and High-pressure Hoses

Pressure plastic tubes Ø6 x 1.5 mm

Use the pressure plastic tubes only in the low-pressure

area, i.e. between secondary metering device and lubrication point.

6001a02

NOTE

Adhere to the pressures and bending radiuses mentioned in the chapter ”Technical

Data” when installing the parts and operating the device.

High-pressure hose NW 4.1 x 2.3 mm

1028a96

Fig. 7 Preassembly of threaded sleeves and hose studs on the

high pressure hose

1 Threaded slee ve

2 High pre ssure hose NW 4.1 x 2.3 mm

3 Hose stud

Use the high-pressure hose in the high-pressure area, i.e.

between the pump, main metering device and secondary

metering devices.

Adhere to the pressures and bending radiuses mentioned

in the chapter ”Technical Data” when installing the parts

and operating the device.

Installing the threaded sleeves and hose studs on the

high-pressure hose

Screw threaded sleeve, item 1 Fig. 7, counterclockwise

onto high-pressure plastic hose 2 until illustrated dimension of 11 mm is reached. Then screw hose stud 3 into

threaded sleeve 1.

6001a02

IMPORT ANT

Before screwing the parts 1, 2 (inside and

outside) and 3, rub them with oil.

NOTE

The outside diameter of the high-pressure

hose may show variations in dimension. In

such a case, press the threaded sleeve 1

at the end where it will be screwed onto

the high-pressure hose so that it becomes

oval in shape (1 to 2 mm). This will prevent

the high-pressure plastic hose from being

pushed out of the sleeve when the hose

stud is screwed.

1029a96

Fig. 8 Preassembly of threaded sleeve by means of adjusting

gauge

1 Threaded slee ve

2 High pre ssure hose NW 4.1 x 2.3 mm

3 Adjusting gauge 432 23077 1

6001a02

NOTE

When using the special adjusting gauge

432-23007-1 (see Parts Catalog) screw

threaded sleeve counterclockwise onto

high-pressure plastic hose until the gauge

inserted in the sleeve begins to rise.

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 9 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Progressive Metering Devices Model SSV, SSV-E and SSV M

10002709

Fig. 9 Metering device type SSV 8

Progressive plunger metering devices - general

The progressive meteri ng devi ces

- are piston-operated metering devices;

- automatically (progressively) dispense the lubricant fed

by the pump to the connected lubrication points;

- model SSV or SSV-E have a lubricant output of 0.2

ccm per outlet and piston stroke;

- model SSV M have a lubricant output of 0.07 ccm

per outlet and piston stroke;

- when one or more outlets are closed (see ”Combining

outlets”) they can dispense a double or multiple lubricant quantity;

- are available with 6 to 12 outlets or up to 22 outlets;

- offer the option of combining several lubricati on points

into one centralized lubrication point.

- meter the supplied lubricant into predetermined single

quantities.

- can be monitored visuall y (SSV, SSV-E and SSV M) or

electronically (SSV and SSV-E).

- in the SSV-E versi on include an emergency lubrication

fitting.

Any blockage in a lubrication circuit is indicated by grease

leaking from the respective pressure relief val ve.

10002710

Fig. 10 SSV 8 with p iston de tector

Features of a Progressive Metering Device

The term ”progressive” refers to the special features of

the lubricant distribution within the metering devices,

e.g.

- the successive movements of the i ndividual pistons

within the metering device due to the supplied lubricant

being under pressure;

- the pistons move in a predetermined order and the cycles are repeated constantly;

- each piston must have completed its movement fully

before the next piston can be moved, no matter whether

the lubricant is dispensed continuously or intermittently;

- the pistons operate interdependently of one another;

- no lubrication point, which is connected to the system,

is omitted.

Description

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 0 f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Progressive Metering Devices Model SSV, SSV-E and SSV M, continuation

B-SSV-020a11

Fig. 11 Differe nces be tween SSV M a nd SSV/SSV E

E Emergency lubrication fitting

Different features of SSV, SSV-E and SSV M

The SSV-E progressive metering device consists of an

SSV progressive metering device and an emergency lubrication fitting E (fig. 11). Time for troubleshooting can be

reduced significantly by using e. g. a hand-lever gun in

combination with the emergency lubrication fitting.

The SSV, SSV-E and SSV M progressive metering devic-

es operate similarly. Apart from their outer dimensions

they also differ in the following data:

SSV and SSV-E

Lubricant output per outlet and stroke ......................... 0.2ccm

Maximum operating pressure ..................................... 350 bar

Minimum operating pressure ........................................ 20 bar

Maximum differential pressure between 2 outlets ....... 100 bar

Outlet connection for tube ................................ Ø 4 and 6 mm

SSV M

Lubricant output per outlet and stroke ....................... 0.07ccm

Maximum operating pressure ..................................... 200 bar

Minimum operating pressure ........................................ 20 bar

Maximum differential pressure between 2 outlets ......... 40 bar

Outlet connection for tube .......................................... Ø 4 mm

Applications

1205a95

Fig. 12 Central lubrication po int

Quicklub progressive metering devices offer the option of

combining several lubrication points on a machine to one

or more central lubrication points, as shown in Fig. 12,

which illustrates this basic feature.

4024b95

Fig. 13 Possible pump conne ctio ns

1 Hand opera ted p ump

2 Pneuma tica lly o pera ted pump

3 Electrically ope rate d pump

4 Lubrication fitting block

5 Hand operated filling pump

When they are used in connection with hand-operated

pumps, pneumatic or electric pumps the progressive metering devices are a simple and low-cost centrali zed lubrication system (see Fig. 13).

Mode of Operation

Description, continuation

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 11 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Applications, continuation

4025a95

Fig. 14 Multi line pump e xpande d by a progressive metering device

1207a95

Fig. 15 Two line system expanded by a pro gressiv e me tering

device

Progressive metering devices can be used in two-line or

single-line centralized lubrication systems in order to increase the number of outlets of multiline pumps or to subdivide the single metering devices and measuring valves

(Fig. 12 to 16) also as secondary metering devices in

large and small oil circulating systems.

1206a95

Fig. 16 Sing le line system e xpa nded by a p rogressive me terin g

device

Mode of Operation, continuation

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 2 f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Lubricant distribution inside the metering device

The 5 following illustrations show the piston movements and

the depending lubricant distribution to the indiv idual outlets .

6001a02

NOTE

Illustrations fig. 17 to 21 show the sequence of delivery only of outlets 2, 7, 5, 3

and 1. Delivery of the residual outlets 8, 6

and 4 is derived from the logical pumping

until the com pl ete meter ing devi ce cycle

has finished. The functional principle of

SSV is identical with SSV M metering

devices.

When the lubricant supply is interrupted

- The pistons come to a halt;

- Lubricant is no longer dispensed to the lubrication point.

When the lubricant is supplied to the metering device again,

the cycle begins from the point where it had been interrupted.

2007a99

Fig. 17 Phase 1

Phase 1

The lubricant enters the metering device from above

(white arrow) and flows to the right-hand end of piston A.

Piston A (black arrow) moves to the left under the pres-

sure of the lubricant, causing the lubricant ahead of the

left-hand end of piston A to be dispensed to outlet 2

(dashed arrow).

Lubricant under pump pressure

Lubricant under deli ve ry pre ssure of the piston

Lubricant, without pre ssuress

2008a95

Fig. 18 Phase 2

Phase 2

Once piston A has reached its left-hand final position, the

junction channel to the right-hand end of piston B is

opened.

The lubricant, which arriv es from above (white arrow),

also moves piston B (black arrow) to the left and causes

the lubricant quantity ahead of the left-hand end of piston

B to be dispensed to outlet 7 (dashed arrow).

Lubricant under pump pressure

Lubricant under deli ve ry pre ssure of the piston

Lubricant, without pre ssuress

Mode of Operation, continuation

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 13 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Lubricant Distribution within the Metering Device, continuation

2009a95

Fig. 19 Phase 3

Phase 3

Once piston B has reached its left-hand final position, the

junction channel to the right-hand end of piston C is

opened.

The lubricant, which flows from above (white arrow)

moves piston C (black arrow) to the left, causing the lubricant quantity ahead of the left-hand end of piston C to be

dispensed to outle t 5 (dashed arrow ).

Lubricant under pump pre ssure

Lubricant under del ive ry pressure of the piston

Lubricant, pre ssurele ss

2010a95

Fig. 20 Phase 4

Phase 4

The channel of piston C to the right-hand end of piston D

is now open (black arrow).

The lubricant which is fe d from above (white arrow)

moves piston D to the left, causing the lubricant quantity

ahead of the left-hand end of piston D to be dispensed out

of the metering device via outlet 3 (dashed arrow).

Lubricant under pump pre ssure

Lubricant under del ive ry pressure of the piston

Lubricant, pre ssurele ss

2011a95

Fig. 21 Phase 5

Phase 5

In phase 4, piston D had opened the junction channel to

the left-hand end of piston A.

The lubricant flowing in (white arrow) moves piston A to

the right (black arrow), causing the lubricant quantity to be

dispensed to outlet 1(dashed arrow).

In the subsequent distribution sequence, pistons B - D are

moved from the left to the right one after the other.

A complete distribution sequence is finished and a new

cycle can begin.

Lubricant under pump pre ssure

Lubricant under del ive ry pressure of the piston

Lubricant, pre ssurele ss

Mode of Operation, continuation

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Monitoring of the Operation

1064b95

Fig. 22 Example of a lubrica tion system

System-dependent monitoring

The main metering device B (fig. 22) and the secondary

metering devices are connected by a high-pressure

hose G. This feature automatically causes the linkage of

the progressive system connected downstream of the

pump.

If only one piston does not move in any metering device

or if the metering device can no longer dispense any lubricant via its outlets, this metering device will block itself.

If one of the secondary metering devices is blocked, the

main metering device is also blocked. The whole progressive system installed downstream of the pump stops operating.

The fundamental internal structure of the progressive

metering device guarantees the self-monitoring of the sequence within the metering device.

The linkage makes it possible to monitor the operation of

the whole system.

A

pressure relief valve E Pressure plastic tube

B Main mete ring dev ice SSV 6 F Se condary m ete ring

device SSV 12 C Secondary met ering dev ice SSV 8

D Secondary metering device SSV 6 G High pressure plastic hose

Fig. 23 Indicator pin instal led o n metering de vice

1011b96

Visual monitoring

The metering devices can be equipped with an indicator

pin which is connected to the piston and moves back and

forth during lubricant distribution.

If there is a blockage in the system, the indicator pin stops

moving.

6001a02

NOTE

It is also possible to electrically check the

movements of the indicator pin or any

blockage in the system by means of a

control switch (KS) or a proximity switch

(KN).

Components of the control pin tube fitting

Closure plug M 11x1x5 MS, assy. (pos. 1) ..........519-32123-1

Mode of Operation, continuation

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 15 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Monitoring of the Operation, continuation

00002634

Fig. 24 Pisto n dete ctor installed o n the me tering de vice

Electrical monitoring (microprocessor control)

A piston detector (initiator), which has been installed on

a metering device instead of a piston closure plug

(M 11 x 1), monitors the pump operating time and brings

it to a close after all the pistons of this metering device

have dispensed their lubricant quantity.

If there is a blockage in the system or if the pump reser-

voir is empty, the piston detector can no longer record the

piston movements. The switching off signal is not transmitted to the control unit. A fault signal occurs.

6001a02

NOTE

For the system monitoring it is recommended that one SSV-N metering device

with pre-assembled piston detector be

used per lubrication circuit. These special

metering devices must be ordered separately for each lubrication system. Refer to

the Parts Catal ogue.

The pre-assembled metering devices have the designa-

tion SSV ... - N (they are available for SSV 6, 8, 10

and 12). They must be installed in the system instead of a

normal metering device.

Applications:

6001a02

Metering device -

piston detector

Control unit / pump

SSV -NE

M08-23 / P203

MF01,02 / P223

MDF01,02,03 / P233

SSV -N

SSV -NP

PLC external

control unit

Mode of Operation, continuation

4092a97

Fig. 25 Pre ssure re lief valve

Pressure relief valve

The whole system can be monitored visual ly via the pres-

sure relief valve. If lubricant is leaking at the pressure relief valve during the distribution sequence, this indicates

that there is a blockage in the system.

6001a02

IMPORTANT

In the case of the progressive metering

devices models SSV6 to 22 and SSV6-E

to 22-E outlets 1 and/or 2 must never be

closed, otherwise the system will block

owing to the structure of the metering

device.

NOT E

Pressure relief valves to be ordered separately (see parts catalogue).

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 6 f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Operation, continuation

Determining the Lubricant Output by Combining Outlets

Tube Fittings, Screw-Type

1012c96

Fig. 26 Install the outle t fitting s and closure plugs in accordance with the dosage

1 Inle t fitting 4 Closure plug (M 11 x 1), piston

(with chamfered)

7 Cutting ring

2 Delivery hole of the piston 5 Outlet fitting assembly 8 Coupling nut

3 Closure plug (M 10x1) with with hex.

socket head, installed

6 Valve body w ith clamp ing ring (bra ss) 9 Junctio n channel

The output quantities can be raised by closing outlet

boreholes.

6001a02

IMPORTANT

The structure of the progressive metering

devices would be blocked if outlet 1

and/or 2 is closed (with SSV 6-22).

Never close outlet 1 and/or 2 !

Install an outlet fitting assembly 5 (M 10x1) in each outlet

borehole which will be used. Refer to Fig. 26, 27, 28.

Never remove closure plug 4 (M 11x1 chamfered) on

the piston side or remove it only for installing a piston detector.

6001a02

NOTE

Never use closure plug 3 (M 10 x 1,

Fig. 20, 21) as a piston closure plug 4 (G

1/8) on older models of metering devices.

Clamping ring 6 closes the junction channels 9 to the

other outlet channels.

6001a02

IMPORTANT

Always use valve body 6 in conjunction

with clamping ring.

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 17 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Operation, continuation

Determining the Lubricant Output by Combining Outlets, continuation

Tube Fittings, Push-in-Type (main metering device)

B-SSV-030b11

Fig. 27 Install the push in type outlet fittings and the closure plugs in accordance with the dosage

1 Inlet fitting (optio na lly with protective

cap

1)

)

3 Closure plug (M 10x1) with with hex.

socket head, installed

5 Valve body a ssembly

(with reinforced collar)

2 Delivery borehole of the piston 4 Closure plug (M11x1),

piston, (chamfered)

6 Junctio n cha nnels

1)

on de ma nd

6001a02

NOTE

In the case of construction machines or

agricultural machi nes use hi gh-pressure

hoses for the lubricant feed lines. In this

case, secondary metering devices (see

fig. 26) must also be equipped with check

valves with reinforced collet (standard

flange, see fig. 3).

6001a02

NOTE

In the case of push-in type fittings the

clamping ring is always a firm component

of the valve body 5.

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 8 f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Operation, continuation

Determining the Lubricant Output by Combining Outlets, continuation

Tube Fittings, Push-in Type (secondary metering devices)

B-SSV-030a11

Fig. 28 Install the push in type o utle ts fittings and clo sure plugs in accorda nce with the dosage

1 Inlet fitting 3 Closure plug (M 10x1) wit h hex . socket

head, in stalle d

5 Valve body assembly

(with knurled collar)

2 Delivery borehole of the piston 4 Closure plug (M11x1),

piston (cham fere d)

6 Junctio n channels

1014b96

Fig. 29 Single, double and trip le lubr icant output

... x Outlet quantity (1x: single, 2x: double, etc.)

1 .. 10 Outlet numbers

A Clam ping r ing (bra ss)

Single lubricant output

- The simple lubricant output is the lubricant quantity dispensed by a piston per stroke and per outlet borehole to

one lubrication point. It amounts to 0.2 cm³ on SSV

and 0.07 cm³ on SSV M.

Double or multiple lubrica nt output

If one or more lubrication points require a double or a

multiple lubricant amount, this can be performed by closing one or more outlets.

As shown in fig. 29, outlet borehole 10 has been closed.

The lubricant quantity supplied by this outlet flows out of

the metering device via outlet 8.

Total quantity at outlet 8:

- is the quantity of outlet 8

- plus the lubricant quantity of outlet 10.

If a triple quantity is needed (at outlet 1), close the outlet

borehole located above the discharge borehole. Refer to

outlets 3 and 5 on fig. 29.

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 19 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Fault: Blockage in the downstream progressive system

Cause: Correction:

Bearing, lines or metering device clogged. Find out which is the cause of the blockage and rectify it in

accordance with he following example:

In the case of the metering devices SSV 6 to 22 and

SSV6-E to 22-E the outlet boreholes 1 and/or 2 are closed.

The fault can be identified by:

a) grease leaking at the pressure relief valve;

b) the fact that the indicator pins installed on the metering

devices (if any) no longer move;

c) the fault signal of the signal lamp (if any) or LED display

A

llow pump to run (see ”To trigger an additional lubrication

cycle”).

Loosen all high press ure hose connections G one after the

other from the main metering device B (fig. 30) leading to

the secondary metering devices. If f. ex. grease or oil

emerges under pressure from outlet 1 of main metering

device B, the blockage will be found in the lubrication circuit of the secondary metering dev ice D.

6001a02

NOTE

If there is a blockage in the downstream

system, the main lines are under pressure.

In such a case, it is difficult to detach the

push-in type connecting parts of the main

line. Relieve the system by removing the

closure plug on the push-in type pressure

relief valve or, if any, by removing the fillin

g

nipple.

1064b95

Let the pump run.

Disconnect all lubricant feed lines E from secondary me-

tering device D one after the other. If f. ex. grease or oil

emerges under pressure from outlet 3 of metering device

D, the blockage will be found in the line of outlet 3 or in the

connected bea ring.

Pump the blocked bearing or line through by means of a

manual pump.

6001a02

NOTE

When checking the individual outlets, keep

each outlet loosened for quite a while

because per each motor revolution there is

only one piston stroke. A complete cycle of

all metering devices requires several

strokes.

Fig. 30 Example of a lubrica tion system

Check pressure relief valve A. Replace it, if necessary.

A

pressure relief va lve B Main m ete ring de v ice

C Se conda ry m ete ring device

SSV 8

D Secondary me te ring de vice

SSV 6

E Pressure p lastic tubes F Secondary me te ring de vice

SSV 12

G High pre ssure plastic hose

Troubleshooting

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 20 f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Fault: Blockage in the downstream progressive system, continuation

Cause: Correction:

Metering device blocked Replace the metering device or clean it in accordance with

the following procedure:

Remove all tube fittings.

Unscrew the piston closure plugs.

If possible, try to eject the piston using a smooth drift

(Ø smaller than 6 mm).

6001a02

IMPORTANT

The pistons are precision-fitted into the

holes. Mark the pistons with regard to their

installation position and direction after they

have been removed. They must not be

exchanged.

Thoroughly clean the metering device bodies in fat-

dissolving washing agent, blow them through with compressed air.

Press free the slant ducts (Ø 1.5 mm) at the thread ends o

f

the piston holes using a pin.

Clean the metering devices again and blow them through.

Reassemble the metering devices.

Replace the copper washers.

Before the tube fittings are reassembled, the metering

devices should be pumped with oil several cycles by

means of a manual pump. Check that the pressure in the

metering device does not exceed 25 bar (362.8 psi).

If the pressure is higher, replace the metering device.

Fault: Differing lubricant amounts at the lubrication points

Cause: Correction:

Lubricant metering not correct Check the lubricant metering acc. to the lubrication chart

Respective valve body has been assembled without clamp-

ing ring

Remove the valve body and install a clamping ring.

Setting of the pause time or lubricating time incorrect Check the time setting. Refer to the corresponding setting

in the respective “Operating Instructions”.

Fault: Over- or underlubrication of the lubrication points

Cause: Correction:

Setting of the lubricating time or pause time incorrect Chec k the time setting at the printed circ uit boards. Re fer

to the corresponding setting in the respective “Operating

Instructions”.

Tab. 1 Trouble shooting, co ntinua tio n

Troubleshooting, continuation

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 21 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Technical Data

Metering Devices

Metering Device Model SSV and SSV-E

Lubricant output per outlet and per stroke ................. 0.2 ccm

Max. operating pressure ........................................... 350 bar

Min. operating pressure .............................................. 20 bar

Max.differential pressure

between two outlets .................................................. 100 bar

Outlet connection for tube ................................ Ø 4 and 6mm

Inlet connection ........................................................... G 1/8

Outlet connection ..................................................... M 10x1

Operating temperature ............................ – 40 °C to +200 °C

Metering Device Model SSV M

Lubricant output per outlet and per stroke ............... 0.07 ccm

Max. operating pressure ........................................... 200 bar

Min. operating pressure .............................................. 20 bar

Max.differential pressure

between two outlets .................................................... 40 bar

Outlet connection for tube ......................................... Ø 4mm

Inlet connection ........................................................... G 1/8

Outlet connection ....................................................... M 8x1

Operating temperature .............................. – 25 °C to +70 °C

Lines

High-pressure hose (∅ 4.1 x 2. 3 mm)

Min. bursting pressure

(in connection with hose clamp, screwed) ................. 600 bar

Min. bending radius ................................................... 35 mm

Min. temperature ...................................................... – 40 °C

Max. temperature ..................................................... + 60 °C

Pressure plastic hose (∅ 6 x 1.5 mm)

Min. bending radius ..................................................... 50 mm

Bursting pressure at 20° C ........................... approx. 210 bar

Min. temperature ...................................................... – 40 °C

Max. temperature ..................................................... + 60 °C

Screw-Type and Push-in Type Tube Fittings

High pressure range, p max. .................................... 350 bar

Inlet tube fittings of the metering devices

Outlet fittings, main metering device

Low-pressure range, p max. ..................................... 250 bar

Outlet fittings, secondary metering devices

Inlet fittings to the lubrication point

Tightening torques

Metering Device Model SSV and SSV-E

Closure plug (piston) in metering device ..................... 18 Nm

Closure plug (outlets) in metering device .................... 15 Nm

Inlet fitting in metering device

- screw-type ............................................................... 17 Nm

- plug-type .................................................................. 10 Nm

Outlet fitting in metering device

- screw-type ............................................................... 11 Nm

- plug-type .................................................................. 11 Nm

Compression nut onto outlet fitting, screw-type

- plastic tube ............................................................... 10 Nm

- steel tube ................................................................. 11 Nm

Control pin tube fitting in metering device .................... 18 Nm

Piston detecteur (N) in metering device ...................... 15 Nm

Proximity switch (KN) on metering device ................... 18 Nm

Install metering device

- dry ........................................................................... 10 Nm

- oiled ........................................................................ 7,5 Nm

Metering Device Model SSV M

Closure plug (piston) in metering device ....................... 6 Nm

Closure plug (outlets) in metering device ...................... 6 Nm

Inlet fitting in metering device

- screw-type ............................................................... 17 Nm

- plug-type .................................................................. 10 Nm

Outlet fitting in metering device

- screw-type ............................................................... 10 Nm

- plug-type .................................................................... 8 Nm

Compression nut onto outlet fitting, screw-type

- plastic tube ................................................................ 5 Nm

- steel tube ................................................................. 10 Nm

Control pin in metering device .................................... 10 Nm

Install metering device

- dry ............................................................................. 6 Nm

- oiled ........................................................................ 4,5 Nm

Metering device type SSV M flange

Install metering device .................................................. 6 Nm

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 22 f 2

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Dimensions

Metering Devices Model SSV6 to 22 & SSV6-E to 22-E

2012a95

Model SSV & SSV-E Dimensions A in

mm

6 60

8 75

10 90

12 105

14 120

16 135

18 150

20 165

22 180

Metering Devices Model SSV M 6 to SSV M 12

2012a99

Model SSV M Dimensions A in mm

6 48,5

8 60

10 71,5

12 83

Technical Data, continuation

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

P 23 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

D GB F E I

EG- Einbauerklärung

EC Declaration of

incorporation

Déclaration CE

d'incorporation

Declaración CE

de incorporación

Dichiarazione CE di

incorporazione

Hiermit erklären wir, dass die

Bauart von

Herewith we declare that the

model of

Par la présente, nous déclarons que le produit ci-dessous

Por la presente, declaramos

que el modelo suministrado

Si dichiara che il prodotto da

noi fornito

Walldorf, Nov 30, 2009, ppa. Dr.-Ing. Z. Paluncic

Director Research & Development

Original Language

Metering Devices SSV / SSV-E / SSV M

in der von uns gelieferten

Ausführung zum Einbau in

eine Maschine bestimmt ist

und dass ihre Inbetriebnahme

solange untersagt ist, bis

festgestellt wurde, dass die

Maschine, in die das o. g.

Produkt eingebaut werden

soll, den Bestimmungen aller

einschlägigen grundlegenden

Sicherheits- und Gesundheitsanforderungen entspricht, einschließlich deren

zum Zeitpunkt der Erklärung

geltenden Änderungen. Der

Hersteller verpflichtet sich,

technische Dokumente (gem.

Anhang VII Teil B) bei begründeter Anfrage zum o. g.

Produkt einzelstaatlichen

Stellen in gedruckter Form zur

Verfügung zu stellen.

Angewendete harmonisierte

Normen, insbesondere:

in the supplied version is

intended to be incorporated

into machinery and must not

be put into service until the

machinery into which it is to

be incorporated has been

declared in conformity with

the provisions of the relevant

fundam en tal requirem ent s on

health and safety, including all

modifications of this directive

valid at the time of the declaration. The manufacturer

undertakes to make available

any technical documents in

printed version (following

Annex VII Part B) to subnational authorities in the case

of reasonable request regarding the above mentioned

product.

Applied harmonized standards in particular

:

dans la version dans laquelle

nous le livrons, est destiné à

être installé sur une machine

et que sa mise en service est

interdite tant qu’il n’aura pas

été constaté que la machine

sur laquelle le produit mentionné ci-dessus doit être installé est conforme aux réglementations régissant toutes

les exigences fondamentales

de sécurité et celles relatives à

la santé, y compris les amendements en vigueur au moment de la présente déclaration. Le fabricant s’engage,

en cas de demande justifiée, à

fournir sous forme écrite aux

organismes nationaux respectifs les documents techniques

(suivant Annexe VII, Partie B)

relatifs au produit ci-dessus.

Normes harmonisées, notamment :

en la versión suministrada es

destinada a ser incorporada

en una máquina y que su

puesta en servicio está

prohibida antes de que la

máquina en la que vaya a ser

incorporada haya sido

declarada conforme a las

disposiciones de los

requisitos pertinentes y

fundam en tales de salud y

seguridad en su redacción

vigente en el momento de

instalación. El fabricante se

obliga a hacer disponible

documentos técnicos (según

anexo VII parte B) en versión

imprimida a entes

uniestatales a petición

fundada referente al producto

arriba mencionado.

Normas armonizadas

utilizadas, particularmente:

nella versione da noi fornita è

destinato all’installazione in

una macchina e che la relativa messa in esercizio resta

vietata fino all’avvenuto

accertamento della conformità

della macchina nella quale il

suddetto prodotto deve

essere installato con tutti i

requisiti basilari prescritti in

termini di sicurezza e di

salute, incluse le relative

modifiche vigenti al momento

della dichiarazione. Il costruttore si impegna a mettere a

disposizione la documentazione tecnica (ai sensi

dell’Allegato VII partel B) in

forma scritta relativa al summenzionato prodotto dietro

richiesta motivata presso le

singole sedi nazionali.

Norme ar monizzat e applicat e

in particolare

:

Maschinenrichtlinie

2006/42/EG

Machinery Directive

2006/42/EC

Directive machines

2006/42/CE

Directiva de máquinas

2006/42/CE

Direttiva Macchine

2006/42/CE

DIN EN ISO 12100 – Teil 1 & 2 – Part 1 & 2 – Parties 1 & 2 – Parte 1 & 2 – Parte 1 e 2

Sicherheit von Maschinen Safety of machinery Sécurité de machines

Seguridad de máquinas

Sicurezza delle macchine

Grundbegriffe, allgemeine

Gestaltungsleitsätze

Basic terms, general design

guidelines

Notions fondamentales, direc-

tives générales d’élaboration

Términos básicos, axiomas

generales de diseño

Concetti basilari, principi

guida generali

DIN EN 809

Pumpen und Pumpengeräte

für Flüssigkeiten

Pumps an d pum p un its

for liquids

Pompes et groupes

de pompes pour liquides

Bombas y equipos de

bombas para líquidos

Pompe e dispositivi

di pompagg io per liq uidi

Allgemeine sicherungs-

technische Anforderungen

General safety requirements

Exigences en matière

de sécurité technique

Prescripciones generales

referente a la seguridad

Requisiti generali di sicurezza

tecnica

EMV-Richtlinien

2009/19/EG

EMC directives

2009/19/EC

Réglementations CEM

2009/19/CE

Directivas CEM

2009/19/CE

Direttive EMC

2009/19/CE

Kraftfahrzeug Automotive véhicules automobile vehículo autoveicolo

2004/108/EG 2004/108/EC 2004/108/CE 2004/108/CE 2004/108/CE

DIN EN 61000-

Fachgrundnormen:

- Störaussendun

g

Generic emission standards:

- Emitted interference

Normes fondamentales :

- Emission de parasites

Normas especiales fundam.:

- Emisión de interferencias

Norme specifiche fondam.:

- Emissione di inter

f

e

renze

Teil 6-4

a

)

Part 6-4

a

)

Partie 6-4

a

)

Parte 6-4

a

)

Parte 6-4

a

)

Teil 6-3 b) Part 6-3 b) Partie 6-3 b) Parte 6-3 b) Parte 6-3 b)

- Störfestigkeit - Noise immunity - Résistance aux brouillages - Resistencia a interferencias - Resistenza alle interferenze

Teil 6-2

a

)

Part 6-2

a

)

Partie 6-2

a

)

Parte 6-2

a

)

Parte 6-2

a

)

Teil 6-1 b) Part 6-1 b) Partie 6-1 b) Parte 6-1 b) Parte 6-1 b)

a

)

für Industriebereiche

a

)

for industrial environment

a

)

pour domaine industriel

a

)

para áreas industriales

a

)

per settore industriale

b

)

für Wohnbereich, Geschäfts und Gewerbebereiche sowie

Kleinbetriebe

b

)

for residential, commercial

and light industry

b)

pour domaines de l’habitation,

des magasins et de l’artisanat

ainsi que des petites

entreprises

b

)

para áreas res i de nci ales,

comerciales e industriales

tanto como pequeñas

empresas

b)

per il settore residenziale,

commerciale, industriale e

per le piccole impr ese

Dokumentations-

bevollmächtigter

Documentation agent

Responsable du Service

de documentation

Encargado/a de la

documentación

Responsabile della

documentazione

Wolfgang Studer • Heinrich-Hertz-Str. 2-8 • 69190 Walldorf

SKF Lubrication Systems Germany GmbH ● Heinrich Hertz-Str. 2-8 D-69190 Walldorf Tel. +49(0) 6227 33-0 ● Fax: +49 (0) 6227 33-259

Loading...

Loading...