Lincoln Speedtec 180C, Speedtec 200C Operator's Manual

IM3039

8/2015

REV05

SPEEDTEC 180C & 200C

OPERATOR’S MANUAL

ENGLISH

Lincoln Electric Bester Sp. z o.o.

ul. Jana III Sobieskiego 19A, 58-263 Bielawa, Poland

www.lincolnelectric.eu

English I English

Declaration of conformity

12

Lincoln Electric Bester Sp. z o.o.

Declares that the welding machine:

K14098

-1

SPEEDTEC 180C

K14099

-1

SPEEDTEC 200C

conforms to the following directives:

2006/95/CEE, 2004/108/CEE

and has been designed in compliance with the

following standards:

EN 60974-1, EN 60974-5, EN 60974-10:2007

26.07.2012

Paweł Lipiński

Operations Director

Lincoln Electric Bester Sp. z o.o., ul. Jana III Sobieskiego 19A, 58-263 Bielawa, Poland

12/05

English II English

12/05

THANKS! For having chosen the QUALITY of Lincoln Electric products.

• Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

• For future reference record in the table below your equipment identification information. Model Name, Code & Serial

Number can be found on the machine rating plate.

Model Name:

………………………………………………………………………………………………………………………………………….

Code & Serial Number:

………………………………………………………………….. …………………………………………………………………..

Date & Where Purchased

…………………………………………………………………. …………………………………………………………………..

ENGLISH INDEX

Safety .................................................................................................................................................................................. 1

Introduction ......................................................................................................................................................................... 2

Installation and Operator Instructions .................................................................................................................................. 2

Electromagnetic Compatibility (EMC) ................................................................................................................................ 12

Technical Specifications .................................................................................................................................................... 13

WEEE................................................................................................................................................................................ 14

Spare Parts ....................................................................................................................................................................... 14

Electrical Schematic .......................................................................................................................................................... 14

Accessories ....................................................................................................................................................................... 15

English 1 English

Safety

11/04

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating this

equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could cause

serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from the

electrode, work clamp and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode holder

directly on the welding table or any other surface in contact with the work clamp to avoid the risk of

accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some pacemakers

and welders having a pacemaker shall consult their physician before operating this equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

ARTIFICIAL OPTICAL RADIATION: According with the requirements in 2006/25/EC Directive and EN

12198 Standard, the equipment is a category 2. It makes mandatory the adoption of Personal Protective

Equipment (PPE) having filter with a protection degree up to a maximum of 15, as required by EN169

Standard.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use enough

ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel with

suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to the

arc.

English 2 English

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding area

and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any tanks,

drums, containers, or material until the proper steps have been taken to insure that no flammable or

toxic vapors will be present. Never operate this equipment when flammable gases, vapors or liquid

combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the correct

shielding gas for the process used and properly operating regulators designed for the gas and pressure

used. Always keep cylinders in an upright position securely chained to a fixed support. Do not move or

transport gas cylinders with the protection cap removed. Do not allow the electrode, electrode holder,

work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders must be located

away from areas where they may be subjected to physical damage or the welding process including

sparks and heat sources.

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in an

environment with increased hazard of electric shock.

The manufacturer reserves the right to make changes and/or improvements in design without upgrade at the same time

the operator’s manual.

Introduction

The welding machines SPEEDTEC 180C enables

welding:

• GMAW (MIG/MAG)

• FCAW-SS

• SMAW (MMA)

The welding machines SPEEDTEC 200C enables

welding:

• GMAW (MIG/MAG)

• FCAW-SS

• SMAW (MMA)

• GTAW (arc ignition using lift TIG)

The following equipment has been added to SPEEDTEC

180C and SPEEDTEC 200C:

• Work lead – 3m

• Gas hose – 2m

• Driving roll V0.8/V1.0 for solid wire (mounted in the

wire feeder).

For GMAW and FCAW-SS process, the technical

specification describes:

• Type of welding wire

• Wire diameter

Recommended equipment, which can be bought by

user, was mentioned in the chapter "Accessories".

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

Location and Environment

This machine will operate in harsh environments.

However, it is important that simple preventative

measures are followed to assure long life and reliable

operation:

• Do not place or operate this machine on a surface

with an incline greater than 15° from horizontal.

• Do not use this machine for pipe thawing.

• This machine must be located where there is free

circulation of clean air without restrictions for air

movement to and from the air vents. Do not cover

the machine with paper, cloth or rags when switched

on.

• Dirt and dust that can be drawn into the machine

should be kept to a minimum.

• This machine has a protection rating of IP23. Keep it

dry when possible and do not place it on wet ground

or in puddles.

• Locate the machine away from radio controlled

machinery. Normal operation may adversely affect

the operation of nearby radio controlled machinery,

which may result in injury or equipment damage.

Read the section on electromagnetic compatibility in

this manual.

• Do not operate in areas with an ambient temperature

greater than 40°C.

English 3 English

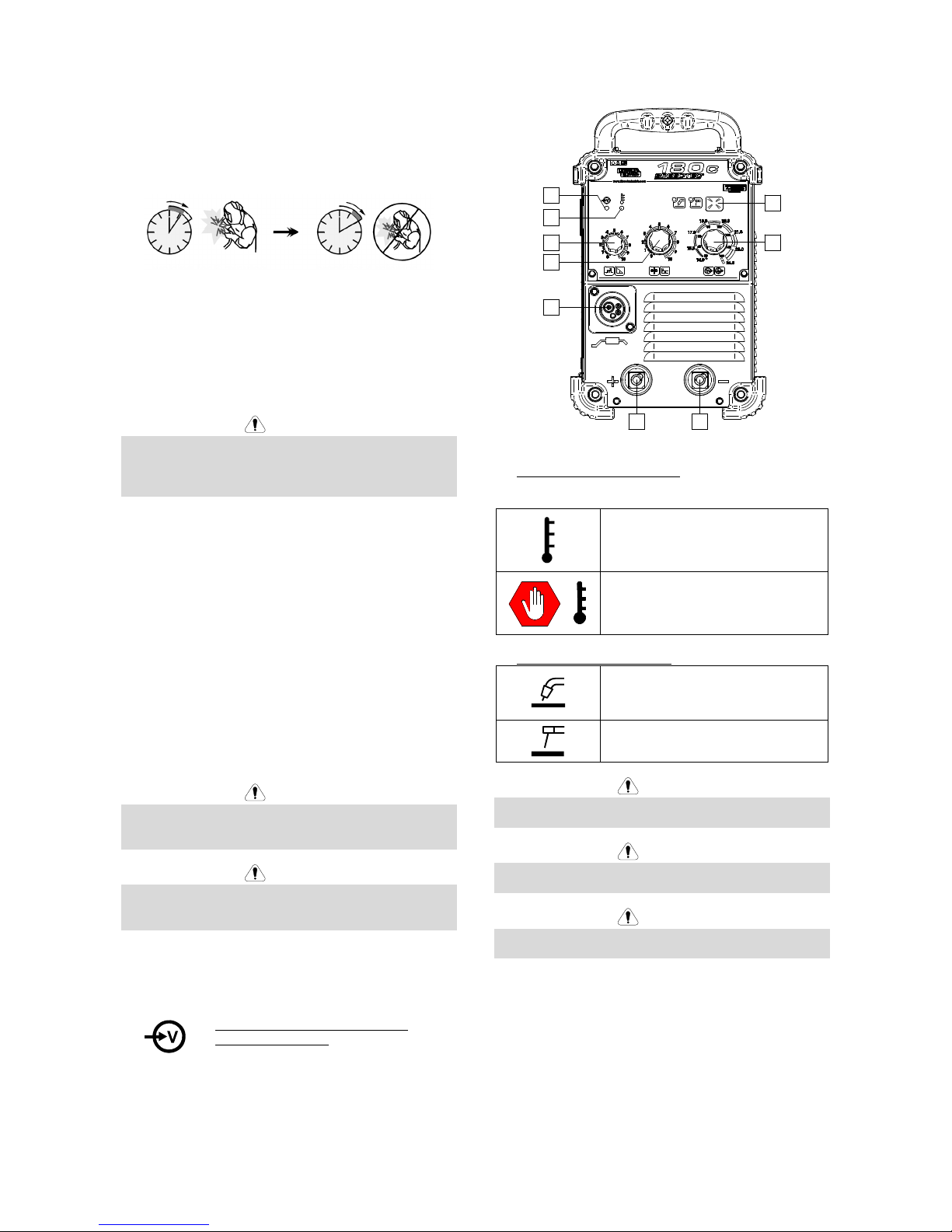

Duty cycle and Overheating

The duty cycle of a welding machine is the percentage of

time in a 10 minute cycle at which the welder can

operate the machine at rated welding current.

Example: 60% duty cycle

Welding for 6 minutes. Break for 4 minutes.

Excessive extension of the duty cycle will cause the

thermal protection circuit to activate.

The machine is protected from overheating by a

temperature sensor.

Input Supply Connection

WARNING

Only a qualified electrician can connect the welding

machine to the supply network. Installation had to be

made in accordance with the appropriate National

Electrical Code and local regulations.

Check the input voltage, phase and frequency supplied

to this machine before turning it on. Verify the

connection of ground wires from the machine to the input

source. The welding machine SPEEDTEC 180C,

SPEEDTEC 200C must be connected to a correctly

installed plug-in socket with an earth pin.

Input voltage is 230V, 50/60Hz. For more information

about input supply refer to the technical specification

section of this manual and to the rating plate of the

machine.

Make sure that the amount of mains power available

from the input supply is adequate for normal operation of

the machine. The necessary delayed fuse (or circuit

breaker with "B" characteristic) and cable sizes are

indicated in the technical specification section of this

manual.

WARNING

The welding machine can be supplied from a power

generator of output power at least 30% larger than input

power of the welding machine.

WARNING

When powering welder from a generator be sure to turn

off welder first, before generator is shut down, in order to

prevent damage to welder!

Output Connections

Refer to points [7], [8] and [9] of the Figures below.

Controls and Operational Features

1. LED Indicator Power switch (only

SPEEDTEC 180C): This LED lights up

when the welding machine is ON and is

ready to work

1

2

3

4

5

6

7

8 9

SPEEDTEC 180C

Figure 1.

2. Thermal Overload Indicator: It indicates that the

machine is overloaded or that the cooling is not

sufficient. Depending on:

SPEEDTEC 180C: Overload or

insufficient is shown by lighting LED

under the symbol.

SPEEDTEC 200C: The message as

image is shown by the display [13].

3. Process Welding’s Switch:

GMAW (MIG/MAG) process

Warning: Can be used to FCAWSS process.

SMAW (MMA) process

WARNING

When the machine is switched again on, last welding

process will be recalled.

WARNING

If the push-button is pushed in GMAW process in, the

output terminals will lived.

WARNING

During SMAW process, the output terminals are still

lived.

Loading...

Loading...