PARTS & SERVICE MANUAL

for

RT-2AR

“ADJUSTABLE RANGE” TOASTER

The information found in this manual will prove very helpful. Although the instructions are easy to follow,

all repair procedures should be carried out by a qualified Savory Certified Service Representative.

THIS MANUAL SHOULD BE RETAINED FOR FUTURE USE

P/N: 07155 REV: 11.10.09

BEFORE INSTALLATION

The RT-2AR should be placed in the most convenient location for ease of cleaning, maintenance, service and

general operation. Careful consideration should be given to avoid drafts, close proximity to grease or vaporproducing appliances or other high ambient heat equipment. A minimum of ½” clearance i s required for air

circulation. This is assured by the rounded “acorn” nuts protruding from the sides and rear of the unit. Overhead

clearance from the top of the toaster should be as much as possible and sufficient to allow heat dissipation.

REPLACEMENT PROCEDURES

A – CASE REMOVAL

1. Remove reflector tray, toast pan and delivery

chute.

2. Remove the 2 screws along the front trim

panel and remove.

3. Remove left front panel.

4. Remove the 4 screws holding control panel to

unit and carefully pull panel towards you with

all wires intact. Slide control panel towards

center of unit.

5. With hands on each side of case, pull forward

to remove.

B – CASE REPLACEMENT

1. Slide case over unit making sure tabs on the

sides and top of case fit into grooves on back

of unit.

2. Carefully replace control panel.

3. Replace left front panel and front trim panel.

4. Replace reflector tray, toast pan and delivery

chute.

C – ON/OFF (MAIN POWER) SWITCH

1. With control panel removed (Section A),

remove the 2 slotted screws holding the

ON/OFF switch to the control panel.

2. Disconnect wires and remove switch.

3. Install new switch from rear of panel and

reconnect wires. (Refer to appropriate wiring

diagram)

D – CONVEYOR ON/OFF SWITCH

1. With the control panel removed (Section A),

disconnect wires to switch noting proper

orientation.

2. Remove bezel from front of panel and push

switch through back of panel.

3. Insert new switch from back of panel. NOTE:

Be sure terminals are in correct position.

4. Attach bezel on front of panel and tighten.

5. Re-attach wires to switch. (Refer to

appropriate wiring diagram.)

E – INFINITE CONTROL SWITCH

1. With control panel removed (Section A),

remove the infinite control knob to gain access

to the 2 slotted screws that hold the control to

the unit. Remove these 2 screws.

2. Disconnect wires from infinite switch terminals.

3. Install new switch from back of panel and

reattach wires. (Refer to appropriate wiring

diagram).

NOTE: The two (2) infinite controls on the RT-2AR

model serve as on/off switches to the heating

elements. The upper infinite knob controls the

upper elements and the lower infinite knob controls

the lower heating elements.

F – SPEED CONTROL / P.C. BOARD ASSEMBLY

NOTE: The speed control and P.C. board are wired

together and must be replaced as an assembly.

1. With control panel removed (Section A), loosen

set screws on speed control knob and remove.

2. Remove retaining nut that holds speed control

in place and remove from back of panel.

3. Disconnect motor lead and on/off lead from

P.C. board terminals.

4. Remove the 2 screws and nuts holding P.C.

board terminals.

5. Reverse this procedure to install new assembly.

(Refer to appropriate wiring diagram.)

P.C. BOARD ADJUSTMENT

The P.C. board is factory set and should not require

adjustment. If speed control range appears faulty,

the following procedure should be carried out:

1. Turn speed control knob clockwise until it stops.

2. Connect to power source and turn unit on.

3. Turn trimmer adjustment to right to start

conveyor motor running. Now turn trimmer

adjustment screw to the left to slow conveyor

motor. Continue turning screw until motor just

stops. Adjustment is now completed. All

further adjustments can be made by operating

at the speed control knob.

SPECIAL NOTICE: The RT-2AR is no longer built with the P.C. board installed. To wire or convert units with

the old style assembly, which included a resistor and/or P.C. board, do the following: The gear motor, whi ch

has 2 black wires, one is plugged into the white side of the terminal block, and the other one is spliced together

with the black wire off the Conveyor Speed Control POT. Then the blue wire off the Conveyor Speed Control

POT is attached to the On/Off Switch.

RT-2AR Service Manual

2

G – GEAR MOTOR

1. With outer case removed (Section A),

disconnect motor leads from on/off switch and

conveyor speed control and cut wire ties at

floor panel.

2. Remove the 2 retaining bolts from the

underside of the unit.

3. Remove the drive chain and lift out the motor.

4. Separate motor from motor mounting bracket

by removing the 4 slotted screws on the

bracket.

5. Using a 1/16” Allen wrench, remove the drive

sprocket from the motor shaft.

6. Attach new gear motor to motor mounting

bracket.

7. Install drive sprocket on motor shaft making

sure the Allen screw rests on the flat of the

shaft. Do not tighten set screw.

8. Install new motor with bracket attached. DO

NOT tighten retaining bolts.

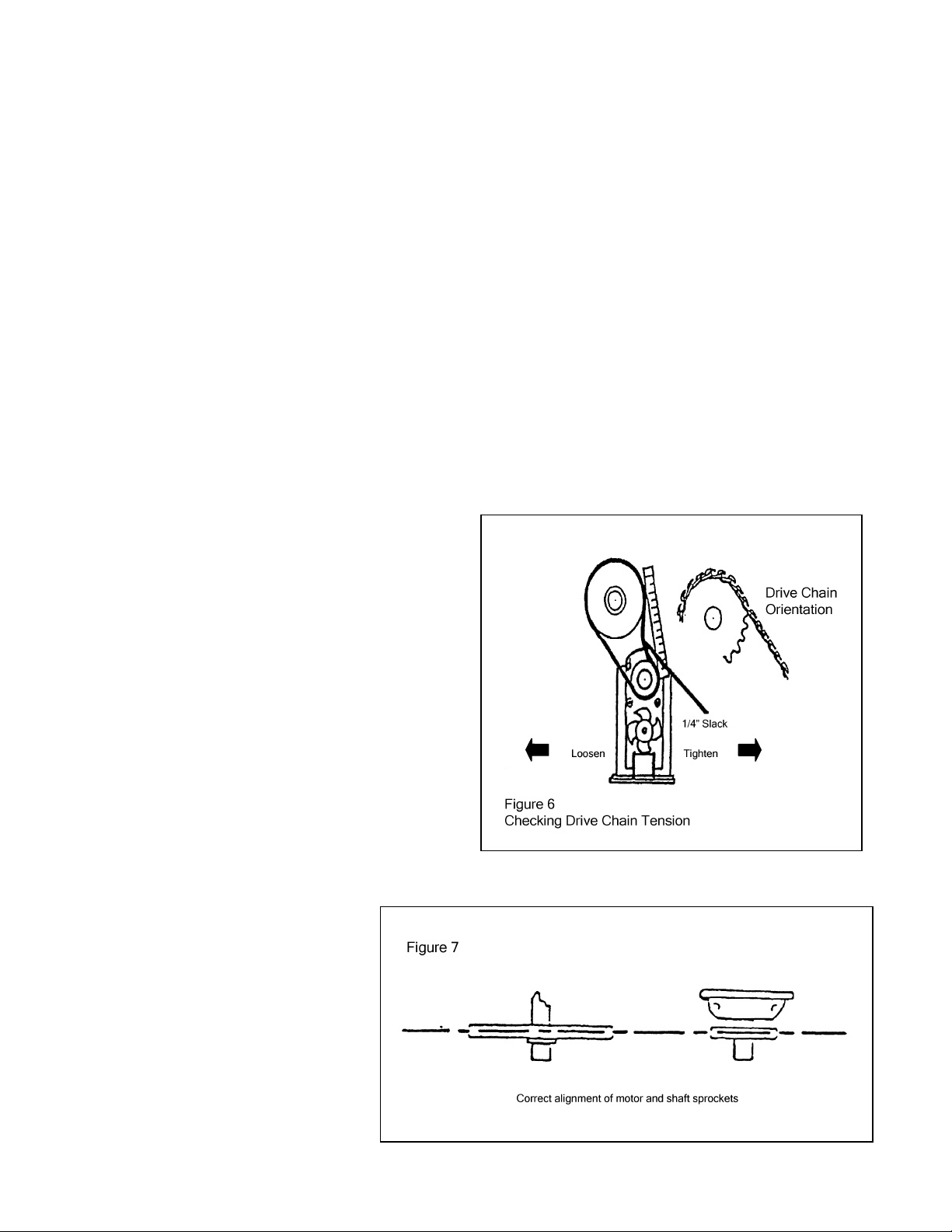

9. Replace drive chain over sprockets.

10. Slide motor to right until drive chain is taut.

There should be approximately ¼” play in the

drive chain.

11. Check drive chain alignment. Tighten drive

sprocket set screws.

12. Reattach motor leads to on/off switch and

conveyor speed control. (Refer to appropriate

wiring diagram).

H – DRIVE CHAIN

1. With outer case removed (Section A), loosen

the 2 motor mounting bracket retaining bolts

on underside of unit, but DO NOT remove.

2. Slide motor to the left to loosen drive chain

tension.

3. Remove drive chain.

4. Install new chain over sprockets with open

looped side of chain facing out

5. Slide motor to right to tighten drive chain

tension. There should be approximately ¼”

plat in the drive chain.

6. Check for proper drive chain alignment.

(See figure 6 & 7)

7. Tighten motor mounting bracket retaining

bolts on underside of unit.

I – DRIVE (MOTOR) SPROCKET

NOTE: RT-2AR models use a 10T sprocket

1. With outer case removed (Section A) and drive

chain removed (Section H), loosen the set

screw on sprocket with a ¼” Allen wrench and

removed sprocket.

2. Install new sprocket on motor shaft making sure

Allen screw rests on the flat of the shaft.

3. Replace drive chain (Section H).

J – REAR (CONVEYOR) SHAFT SPROCKET

NOTE: RT-2AR models use a 40T sprocket.

1. With outer case removed (Section A) and drive

chain removed (Section H), loosen the 2 set

screws on sprocket with a 1/16” Allen wrench

and remove sprocket.

2. Install new sprocket on conveyor shaft aligning

the 2 set screws with the holes on the shaft.

3. Replace drive chain (Section H).

RT-2AR Service Manual

3

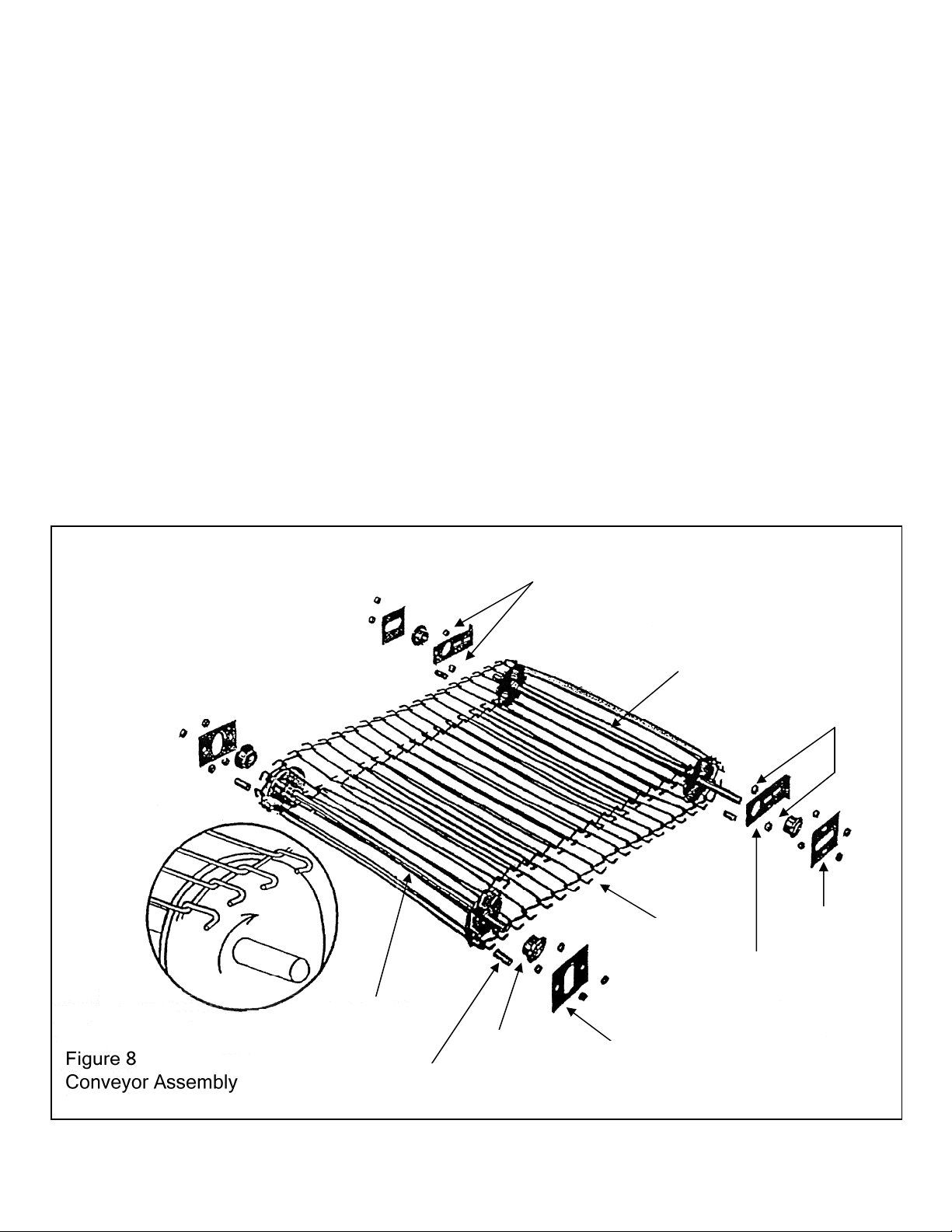

K – CONVEYOR CHAIN

Figure 8

5. With outer case removed (Section A), loosen

motor mounting bracket retaining bolts on

underside of unit, and slide motor to the left.

6. Loosen rear shaft adjusting bracket nuts and

bearing retaining bracket nuts on both sides of

unit.

7. Slide rear conveyor shaft forward to loosen

tension.

8. Separate the chain at any link and slide out

from front of unit.

9. Before installing new chain, check for proper

orientation (See Figure 8) and correct number

of links.

10. Starting at front of unit, slide chain under front

shaft and push towards rear of unit. Bring

chain up and over rear shaft assembly and

pull towards front. Connect links. CAUTION:

MAKE SURE CHAIN IS NOT INSTALLED AT

AN ANGLE.

1. Push back on rear shaft assembly until

excess slack is removed from chain. Holding

tension, tighten both the rear shaft adjusting

brackets and bearing retaining brackets on

both sides of unit.

2. Check for proper tension. There should be

approximately 3/8” to ¾” space between the

conveyor chain and the ledge on the inside of

the unit cavity.

3. Slide motor to the right to tighten drive chain

tension. There should be approximately ¼”

play in the drive chain.

4. Tighten motor mounting bracket retaining

bolts on underside of unit.

Spacer Nuts

Rear Shaft

Assembly

Wire Belt

Spacer Nuts

Bearing

Retainer

Tension Adjusting

Bracket

Front Shaft

Assembly

Front Spacer

RT-2AR Service Manual

4

Bearing

Bearing

Retainer