Page 1

XDS2000 Dual-Channel Series

Digital Storage Oscilloscopes

User Manual

www.owon.com.cn

Page 2

Apr. 2018 edition V1.0.0

Copyright © LILLIPUT Company. All rights reserved.

The LILLIPUT's products are under the protection of the patent rights, including ones which have

already obtained the patent rights and those which are applied for. The information in this manual will

replace all materials published.

The information in this manual was correct at the time of printing. However, LILLIPUT will continue

to improve products and reserves the rights to change specification at any time without notice.

is the registered trademark of the LILLIPUT Company.

Fujian LILLIPUT Optoele ctr onics Technology Co., Ltd.

No. 19, Heming Road

Lantian Industrial Zone, Zhangzhou 363005 P.R. China

Tel: +86-596-2130430 Fax: +86-596-2109272

Web:

www.owon.com.cn E-mail: info@owon.com.cn

Page 3

General W arranty

OWON warrants that the product will be free from defects in materials an d workmanshi p

for a period of 3 years from the date of purchase of the product by the original purchaser

from the OWON Company. The warranty period for accessories such as probes is 12

months. This warranty only applies to the original purchaser and is not transfe rable to a

third party.

If the product proves defective during the warranty period, OWON will either repair t he

defective product without charge for parts and labour, or will provide a replacement in

exchange for the defective product. Parts, modules and replacement products used by

OWON for warranty work may be new or reconditioned like new. All replaced parts,

modules and products become the property of OWON.

In order to obtain service under this warranty, the customer must notify OWON of the

defect before the expiration of the warranty period. Customer shall be responsible for

packaging and shipping the defective product to OWON's designated service centre, a

copy of the customers proof of purchase is also required.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. OWON shall not be obligated to furnish

service under this warran t y a) to repai r dam age r esul tin g from attem pts by perso nnel other

than OWON representatives to install, repair or service the product; b) to repair dam age

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-OWON supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

Please contact the near est OWON's Sales and Service Offic es for services or a complet e

copy of the warranty statement.

For better after-sales service, please visit www.owon.com.cn and register the purchased

product online.

Excepting the after-sales services provided in this summary or the applicable warranty

statements, OWON will not offer any guarantee for maintenance definitely declared or hinted,

including but not limited to the implied guarantee for marketability and special-purpose

acceptability. OWON should not take any responsibilities for any indirect, special or consequent

damages.

Page 4

i

Table of Contents

1. General Safety Requirements .......................................................................................... 1

2. Safety Terms and Symbols ............................................................................................... 2

3. Junior User Guidebook ................................................................................................... 4

Introduction to the Structure of the Oscilloscope ..................................................................... 5

Front Panel ............................................................................................................................................... 5

Front Panel Menu Buttons ........................................................................................................................ 6

Rear Panel ................................................................................................................................................ 6

Control Area ............................................................................................................................................. 7

User Interface Introduction ........................................................................................................ 8

How to Implement the General Inspection ............................................................................. 10

How to Implement the Function Inspection ............................................................................ 10

How to Implement the Probe Compensation .......................................................................... 11

How to Set the Probe Attenuation Coefficient ........................................................................ 12

How to Use the Probe Safely..................................................................................................... 13

How to Implement Self-calibration .......................................................................................... 13

Introduction to the Vertical System ......................................................................................... 14

Introduction to the Horizontal System .................................................................................... 15

Introduction to the Trigger System ......................................................................................... 16

4. Advanced User Guidebook ............................................................................................ 17

How to Set the Vertical System ................................................................................................ 18

Use Mathematical Manipulation Function ............................................................................. 20

Waveform math ...................................................................................................................................... 21

User defined function ............................................................................................................................. 22

Digital Filter ........................................................................................................................................... 22

Using FFT function ................................................................................................................................ 22

Use Vertical Position and Scale Knobs .................................................................................... 25

How to Set the Horizontal System ........................................................................................... 25

Zoom the Waveform .............................................................................................................................. 26

How to Set the Trigger/Decoding System ................................................................................ 26

Single Trigger ......................................................................................................................................... 27

Alternate Trigger (Trigger mode: Edge) ................................................................................................ 35

Logic Trigge r.......................................................................................................................................... 35

Bus Trigger ............................................................................................................................................. 36

Bus Decoding ......................................................................................................................................... 42

How to Operate the Function Menu ........................................................................................ 46

How to Implement Sampling Setup ....................................................................................................... 46

How to Set the Display System .............................................................................................................. 48

Page 5

ii

How to Save and Recall a Waveform ..................................................................................................... 50

How to Record/Playback Waveforms .................................................................................................... 57

How to Clone a waveform ...................................................................................................................... 61

How to Implement the Auxiliary System Function S etting .................................................................... 63

How to Update your Instrument Firmware............................................................................................. 67

How to Measure Automatically.............................................................................................................. 68

How to Measure with Cursors ................................................................................................................ 72

How to Use Autoscale ............................................................................................................................ 75

How to Use Built-in Help ....................................................................................................................... 77

How to Use E xecutive Button s ............................................................................................................... 77

How to Print the Screen Image ............................................................................................................... 79

5. Communication with PC ............................................................................................... 80

Using USB Port .......................................................................................................................... 80

Using LAN Port ......................................................................................................................... 81

Connect directly ..................................................................................................................................... 81

Connect through a router ........................................................................................................................ 82

6. Demonstration ............................................................................................................... 85

Example 1: Measurement a Simple Signal .............................................................................. 85

Example 2: Gain of a Amplifier in a Metering Circuit .......................................................... 86

Example 3: Capturing a Single Signal ..................................................................................... 87

Example 4: Analyze the Details of a Signal ............................................................................. 88

Example 5: Application of X-Y Function ................................................................................ 90

Example 6: Video Signal Trigger ............................................................................................. 91

7. Tr oubleshooting ............................................................................................................. 93

8. Technical Specifications ................................................................................................ 94

Trigger .................................................................................................................................................... 96

General Technical Specifications ............................................................................................. 98

9. Appendix ........................................................................................................................ 99

Appendix A: Enclosure ............................................................................................................. 99

Appendix B: General Care and Cleaning ............................................................................... 99

Page 6

1.General Safety Requirements

1

1. General Safety Requirements

Before use, please read the following safety precautions to avoid any possible bodily

injury and to prevent this product or any other connected products from damage. In

order to avoid any contingent danger, ensure this product is only used within the

range specified.

Only the qualified technicians can implement the maintenance.

To avoid Fire or Personal Injury:

Connect the probe correctly. The grounding end of the probe corresponds to the

grounding phase. Please don't connect the grounding end to the positive phase.

Use Proper Power Cord. Use only the power cord supplied with the product and

certified to use in your country.

Connect or Disconnect Correctly. When the probe or test lead is connected to a

voltage source, please do not connect and disconnect the probe or test lead at random.

Product Grounded. This instrument is grounded through the power cord grounding

conductor. To avoid electric shock, the grounding conductor must be grounded. The

product must be grounded properly before any connection with its input or output

terminal.

When powered by AC power, it is not allowed to measure AC power source

directly, because the testing ground and power cord ground conductor are

connected together, otherwise, it will cause short circuit.

Check all Terminal Ratings. To avoid fire or shock hazard, check all ratings and

markers of this product. Refer to the user's manual for more information about ratings

before connecting to the instrument.

Do not operate without covers. Do not operate the instrument with covers or panels

removed.

Use Proper Fuse. Use only the specified type and rating fuse for this instrument.

Avoid exposed circuit. Do not touch exposed junctions and components when the

instrument is powered.

Do not operate if in any doubt. If you suspect damage occurs to the instrument, have

it inspected by qualified service personnel before further operations.

Use your Oscilloscope in a well-ventilated area. Make sure the instrument installed

with proper ventilation, refer to the user manual for more details.

Do not operate in wet conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Page 7

2.Safety Terms and Symbols

2

2. Safety Terms and Symbols

Safety Terms

Terms in this manual. The following terms may appear in this manual:

Warning: Warning indicates the conditions or practices that could result in

injury or loss of life.

Caution: Caution indicates the conditions or practices that could result in

damage to this product or other property.

Terms on the product. The following terms may appear on this product:

Danger: It indicates an injury or hazard may immediately happen.

Warning: It indicates an injury or hazard may be accessible potentially.

Caution: It indicates a potential damage to the instrument or other property might occur.

Safety Symbols

Symbols on the product. The following symbol may appear on the product:

Hazardous Voltage

Protective Earth Terminal

Test Ground

Refer to Manual

Chassis Ground

To avoid bod y damage and prevent product and connected equipment damage, carefully

read the following safety information before using the test tool. This product can only be

used in the specified applications.

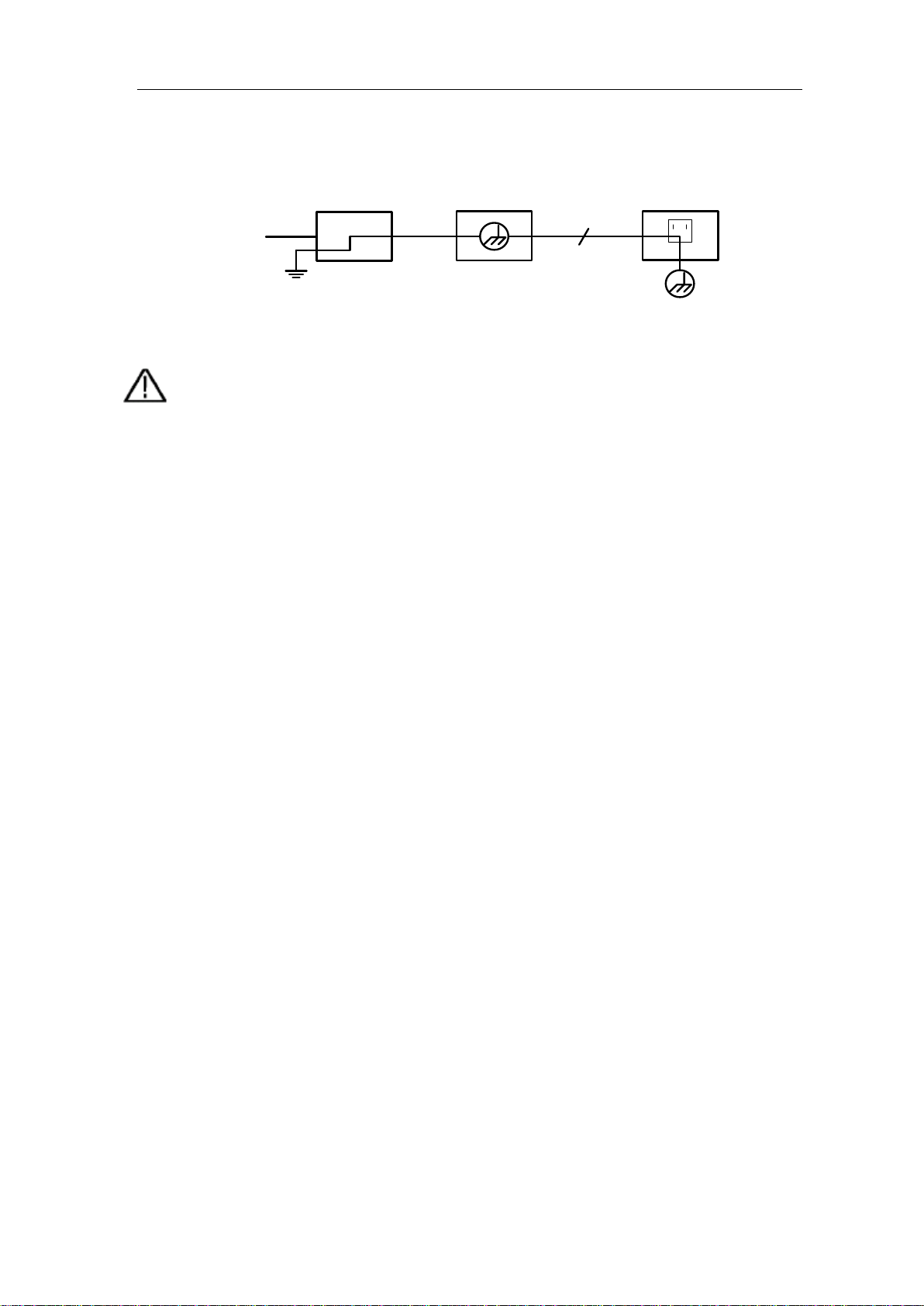

Warning:

The two channels of the oscilloscope are not electrically isolated. The channels should

adopt a common ground during measuring. To prevent short circuits, the 2 probe

Page 8

2.Safety Terms and Symbols

3

Ground Clip

Signal Input

Oscilloscope

Electrical Outlet

Probe

Power Cord

Warning:

To avoid fire or electrical shock

connected

42V peak (30Vrms) or on circuits of more than

4800VA

not apply input voltages above the rating of the instrument

because the probe tip voltage will directly transmit to the

grounds must not be connected to 2 different non-isolated DC levels.

The diagram of the oscilloscope ground wire connection:

It is not allowed to measure AC power when the oscilloscope is AC powered.

, when the oscilloscope input signal

is more than

, please take note of below items:

Only use accessory insulated voltage probes and test lead.

Check the accessories such as probe before use and replace it if

there are any damages.

Remove probes, test leads and other accessories immediately after

use.

Remove USB cable which connects oscilloscope and computer.

Do

oscilloscope. Use with caution when the probe is set as 1:1.

Do not use exposed metal BNC or banana plug connectors.

Do not insert metal objects into connectors.

Page 9

3.Junior User Guidebook

4

3. Junior User Guidebook

This chapter deals with the following topics mainly:

Introducti on to th e str uct ure of the os ci ll os co pe

Introducti on to th e u ser interface

How to implem ent the general inspection

How to implement the function inspection

How to make a probe com pensation

How to set the probe att en ua ti on co eff ic ie n t

How to use the probe safely

How to implement an auto-calibration

Introducti on to th e ver tic al system

Introducti on to th e ho riz on ta l sy stem

Introducti on to th e tri gg er syste m

Page 10

3.Junior User Guidebook

5

8

2

5

3

7

4

6

1

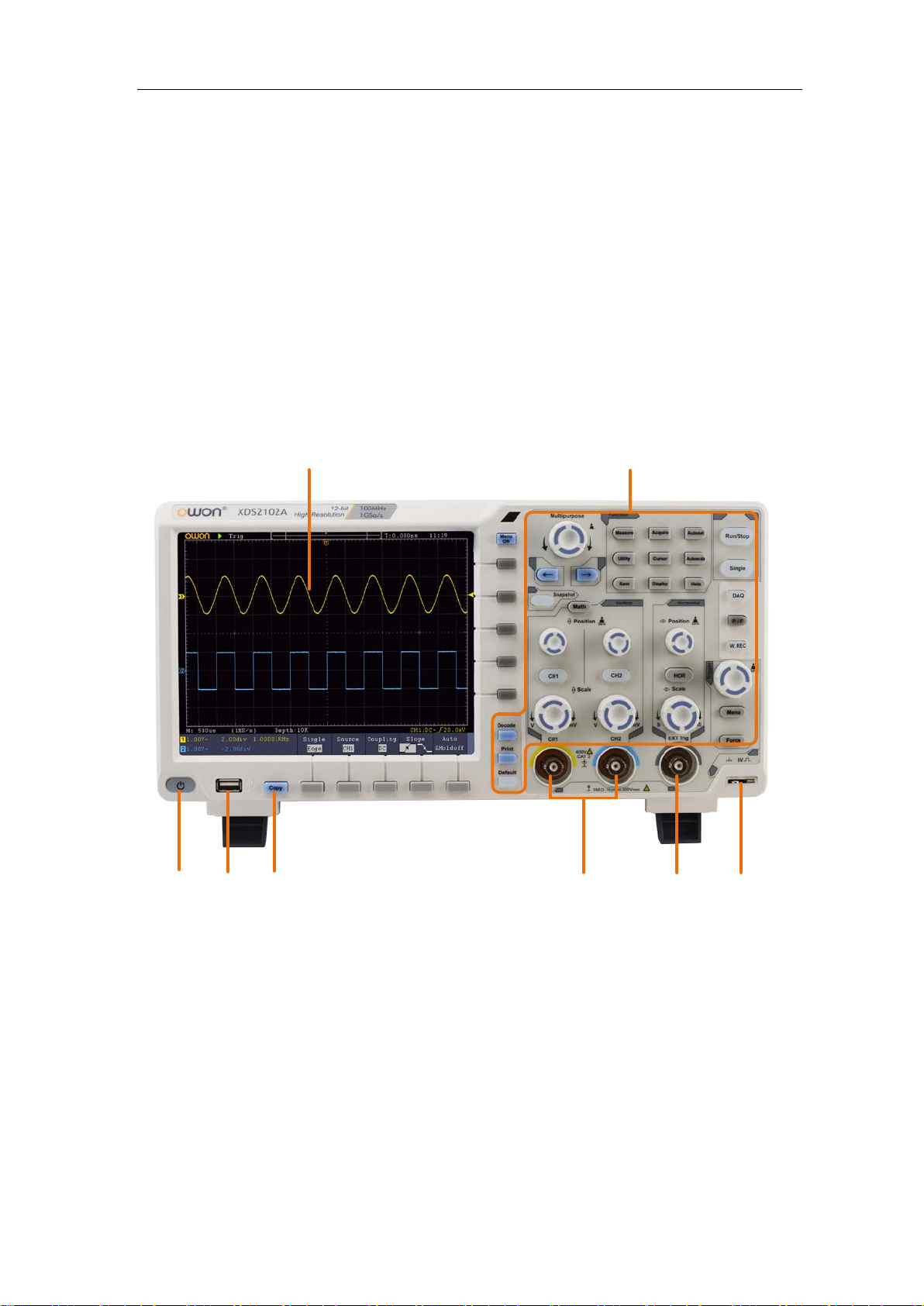

Introduction to the Structure of the Oscilloscope

This chapter makes a simple description of the operation and function of the front panel of

the oscilloscope, enabling you to be familiar with the use of the oscilloscope in the

shortest time.

Front Panel

The front panel has knob s and function buttons. The 5 buttons in the column on the right

side of the display screen or in the row under the display screen are menu selection

buttons, through which, you can set the different options for the current menu. The other

buttons are function buttons, through which, you can enter different function menus or

obtain a specific function application directly.

Figure 3-1 Front panel

1. Display area

2. Control (button and knob) area

3. Probe Compensation: Measurement signal (5V/1kHz) output.

4. EXT Trigger Input

5. Signal Input Channel

6. Copy button: You can save the waveform by just pressing this button in any user

interface.

7. USB Host port: It is used to transfer data when external USB equipment connects to

the oscilloscope r e gard ed as "host device". For exampl e: Saving th e wavefo rm to USB

flash disk needs to use this port.

Page 11

3.Junior User Guidebook

6

Select the right menu item

Select the bottom menu item

Remove the left and right menu

9

8

7 6

11

1

2

5

3

4

10

8. Power on/off

Backlight of this button:

Red light: The oscilloscope is turned off (connects with AC Power);

Green light: The oscilloscope is turned on (powered by AC Power).

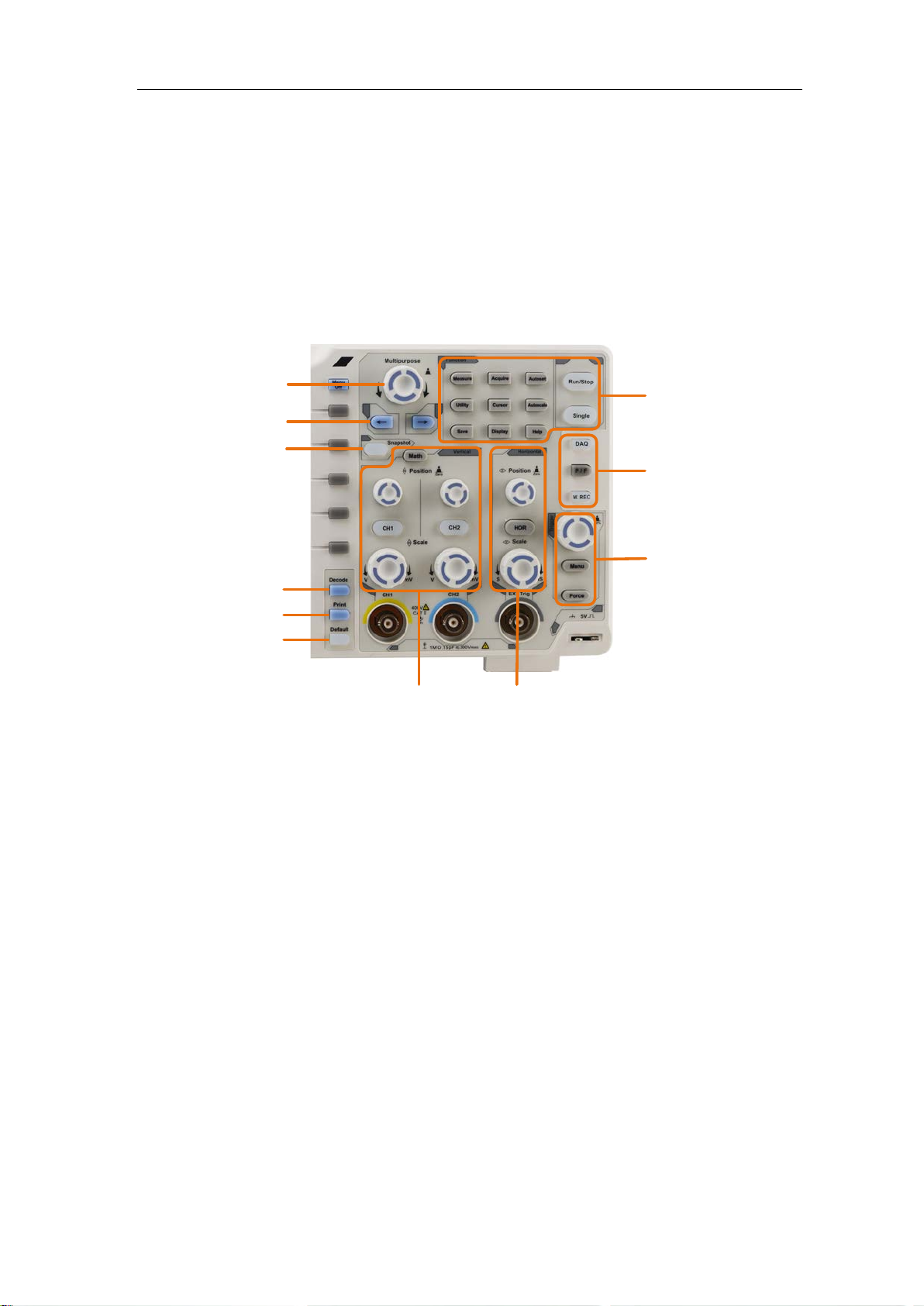

Front Panel Menu Buttons

Figure 3-2 Menu Buttons

Rear Panel

Figure 3-3 Rear Panel

1. Handle

2. Air vents

3. AC power input jack

4. Fuse

5. Foot stool: Adjust the tilt angle of the oscilloscope.

6. VGA port: To connect the oscilloscope with a monit or or a projector as VGA output

(optional).

7. LAN port: the network port which can be used to connect with PC.

Page 12

3.Junior User Guidebook

7

8

7

6

1

2

3

11

10

5

4

9

8. USB Device port: It is used to transfer data when ex t ernal US B equi pm ent con nect s t o

the oscilloscope regarded as "slave device". For example: to use this port when

connect PC to the oscilloscope by USB.

9. Lock Hole: You can lock the oscilloscope to a fixed location using the security lock

(please buy it yourself) to secure the oscilloscope.

10. AV Port: AV signal output port (optional).

11. Trig Out(P/F) port: Trigger signal output or Pass/Fail output.

Control Area

Figure 3-4 Control Are a Overview

1. Function button area: Total 11 buttons

2. DAQ: Multimeter Recorder (This function is not available in XDS2000 series.)

P/F: Pass/Fail

W.REC: Waveform Record

3. Trigger control area with 2 buttons and 1 knob.

The Trigger Level knob is to adjust trigger voltage. Other 2 buttons refer to trigger

system setting.

4. Horizontal control area with 1 button and 2 knobs.

"HOR" button refer to horizontal system setting menu, "Horizontal Position" knob

control trigger position, "Horizontal Scale" control time base.

5. Vertical control area with 3 buttons and 4 knobs.

"CH1" and "CH2 " correspond to setting menu in CH1 and CH2, "Math" button refer

to math menu, the math menu consists of six kinds of operations, including CH1-CH2,

CH2-CH1, CH1+CH2, CH1*CH2, CH1/CH2 and FFT. T wo "Vertical Position" knob

control the vertical position of CH1/CH2, and two "Scale" knob control voltage scale

of CH1, CH2.

Page 13

3.Junior User Guidebook

8

1

3

15

10

23

20

6

7

8

9

12

13

16

17

18

22

24

5

14

21

2

4

19

11

4

12

6. Default: Call out the factory settings.

7. Print

8. Turn on/off Decode function.

9. Snapshot

10. Direction key: Move the cursor of the focused parameter.

11. M knob (Multipurpose knob): when a symbol appears in the menu, it indicates

you can turn the M knob to select the menu or set the value. You can push it to close

the menu on the left and right.

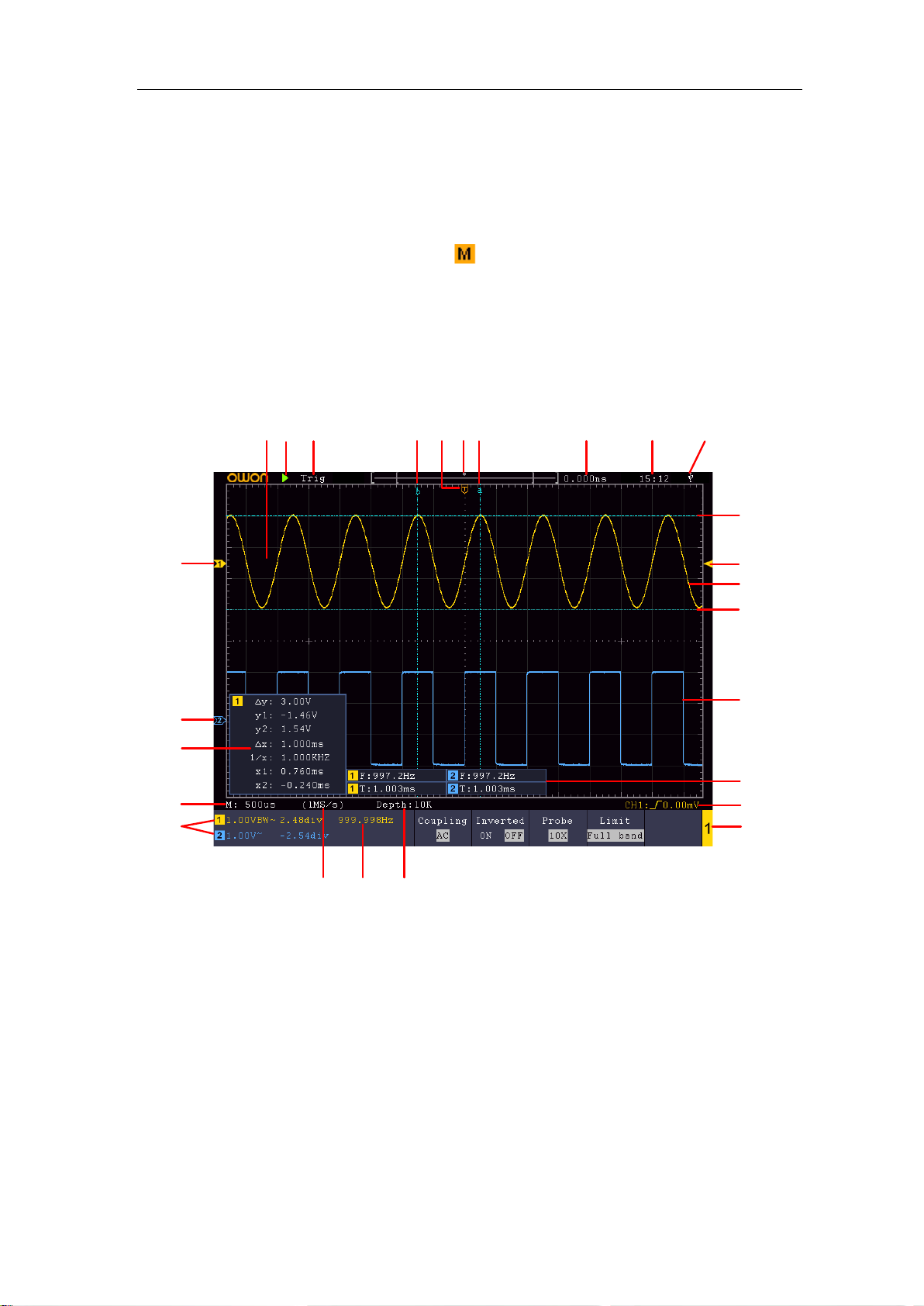

User Interface Introduction

1. Waveform Display Area.

2. Run/Stop

3. The state of trigger, including:

Auto: Automatic mode and acquire waveform without triggering.

Trig: Trigger detected and acquire waveform.

Ready: Pre-triggered data captured and ready for a trigger.

Scan: Capture and display the waveform continuously.

Stop: Data acquisition stopped.

4. The two blue dotted lines indicates the vertical position of cursor measurement.

Figure 3-5 Illustrative Drawing of Display Interfaces

Page 14

3.Junior User Guidebook

9

5. The T pointer indicates the horizontal position for the trigger.

6. The pointer indicates the trigger position in the record length.

7. It shows present triggering value and displays the site of present window in

internal memory.

8. It shows setting time.

9. It indicates that there is a USB disk connecting with the oscilloscope.

10. The pointer shows the trigger level position.

11. The waveform of CH1.

12. The two blue dotted lines indicate the horizontal position of cursor measurement.

13. The waveform of CH2.

14. It indicates the measured type and value of the corresponding channel. "T" means

period, "F" means frequency, "V" means the average value, "Vp" the peak-peak

value, "Vr" the root-mean-square value, "Ma" the maximum amplitude value,

"Mi" the minimum amplitude value, "Vt" the Voltage value of the waveform's

flat top value, "Vb" the Voltage value of the waveform's flat base, "Va" the

amplitude value, "Os" the overshoot value, "Ps" the Preshoot value, "RT" the rise

time value, "FT" the fall time value, "PW" the +width value, "NW" the -Width

value, "+D" the +Duty value, "-D" the -Duty value, "PD" the Delay A->B

value, "ND" the Delay A->B value, "TR" the Cycle RMS, "CR" the Cursor

RMS, "WP" the Screen Duty, "RP" the Phase, "+PC" the +Pulse count, "-PC"

the - Pulse count, "+E" the Rise edge count, "-E" the Fall edge count, "AR" the

Area, "CA" the Cycle area.

15. The icon shows the selected trigger type, e.g. represents triggering on the

rising e dge for an Edge trigger. The reading shows the trigger level value of the

corresponding channel.

16. Channel identifier of current bottom menu.

17. The readings show the record length.

18. The frequency of the trigger signal.

19. The readings show current sample rate.

20. The readings indicate the corresponding Voltage Division and the Zero Point

positions of the channels. "BW" indicates bandwidth limit.

The icon shows the coupling mode of the channel.

"—" indicates direct current coupling

"~" indicates AC coupling

" " indicates GND coupling

21. The reading shows the setting of main time base.

22. It is cursor measure window, showing the absolute values and the readings of the

cursors.

23. The blue pointer shows the grounding datum point (zero point position) of the

waveform of the C H2 channel. If the pointer is not displayed, it means that this

channel is not opened.

24. The yellow pointer indicates the grounding datum point (zero point position) of

Page 15

3.Junior User Guidebook

10

the waveform of the CH1 channel. If the pointer is not displayed, it means that

the channel is not opened.

How to Implement the General Inspection

After you get a new oscilloscope, it is recommended that you should make a check on the

instrument according to the following steps:

1. Check whether there is any damage caused by transportation.

If it is found that the packaging carton or the foamed plastic protection cushion has

suffered serious damage, do not throw it away first till the complete device and its

accessories succeed in the electrical and mechanical property tests.

2. Check the Accessories

The supplied access ories have been already described in the "Appendix A: Enclosure"

of this Manual. You can check wh ether ther e is any loss of accesso ries wi th referenc e

to this description. If it is found that there is any accessory lost or dam a ged , pl ease get

in touch with the distributor of OWON responsible for this service or the OWON's

local offices.

3. Check the Complete Instrument

If it is found that there is damage to the appearance of the instrument, or the

instrument can not work normally, or fails in the performance test, please get in touch

with the OWON's distributor responsible for this business or the OWON's local

offices. If there i s damag e to the inst rument caus ed by the t ransportat ion, pl ease keep

the package. With the transportation department or the OWON's distributor

responsible for this business informed about it, a repairing or replacement of the

instrument will be arranged by the OWON.

How to Implement the Function Inspection

Make a fast funct ion check to verif y the normal operation of the instrument, according to

the following steps:

1. Connect the po wer cord to a power source. Long press the

bottom left of the instrument.

The instrument carries out all self-check items and shows the Boot Logo. Push the

Utility button, select Function in the bottom menu. Select Adjust in the left menu,

select Default in the bottom menu. The default att enuati on coe fficient set val ue of th e

probe in the menu is 10X.

button on the

2. Set the Switch in the Oscilloscope Probe as 10X and Connect the Oscilloscope

with CH1 Channel.

Align the slot in the probe with the plug in the CH1 connector BNC, and then tighten

Page 16

3.Junior User Guidebook

11

the probe with rotating it to the right side.

Connect the probe tip and the ground clamp to the connector of the probe

compensator.

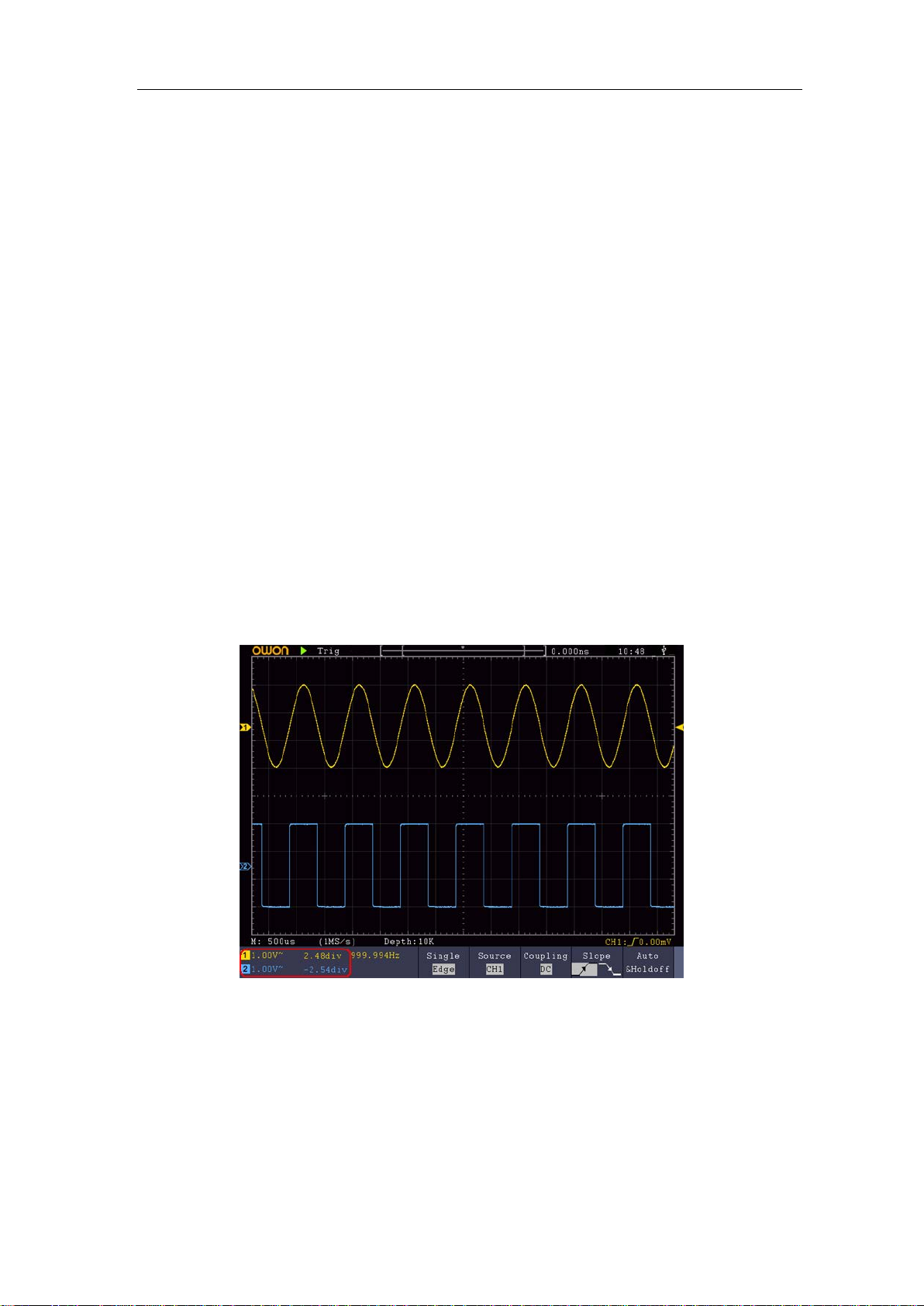

3. Push the Autoset Button on the front panel.

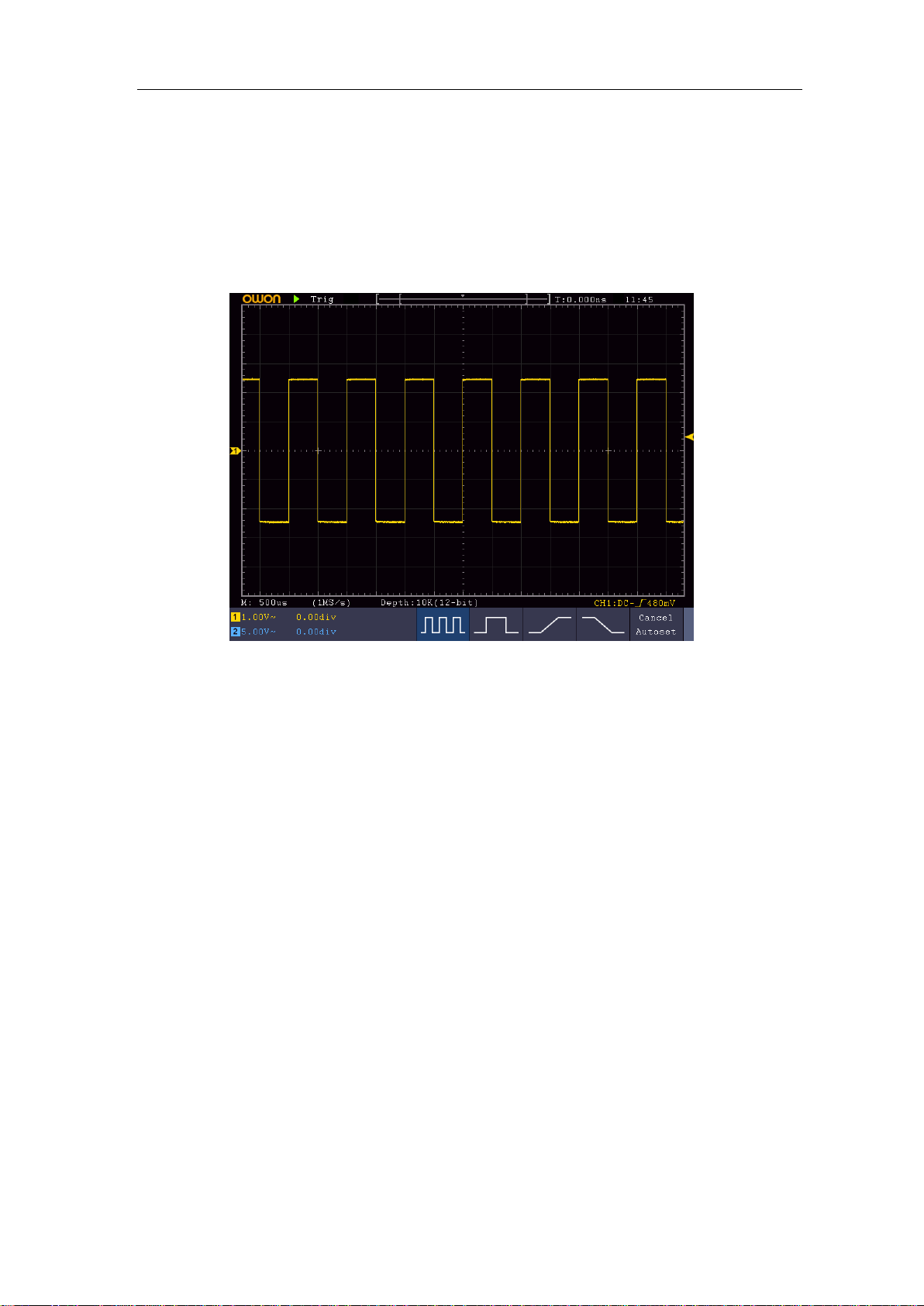

The square wave of 1 KHz frequency and 5V peak-peak value will be displayed in

several seconds (see Figure 3-6).

Figure 3-6 Auto set

Check CH2 by repeating Step 2 and Step 3.

How to Implement the Probe Compensation

When connect the probe with any input channel for the first time, make this adjustment to

match the probe with the input channel. The probe which is not compensated or presents a

compensation deviation will result in the measuring error or mistake. For adjusting the

probe compensation, please carry out the following steps:

1. Set the attenuation coefficient of the probe in the menu as 10X and that of the switch

in the probe as 10X (see "How to Set the Probe Attenuation Coefficient" on P12), and

connect the probe with the CH1 channel. If a probe hook tip is used, ensure that it

keeps in close touch with the probe. Connect the probe tip with the signal connector

of the probe compensator and connect the reference wire clamp with the ground wire

connector of the probe connector, and then push the Autoset button on the front

panel.

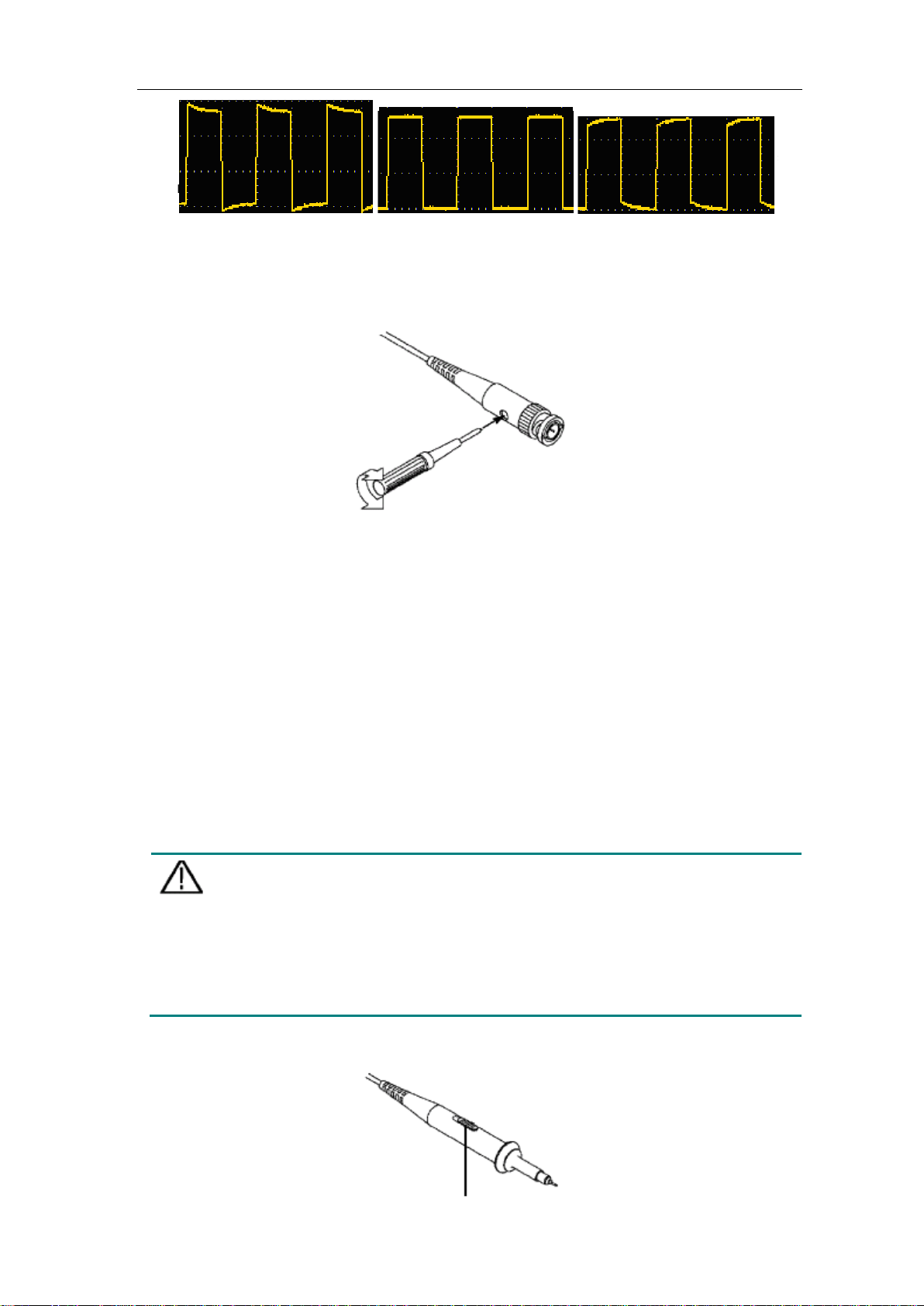

2. Check the displayed waveforms and regulate the probe till a correct compensation is

achieved (see Figure 3-7 and Figure 3-8).

Page 17

3.Junior User Guidebook

12

Caution:

in the

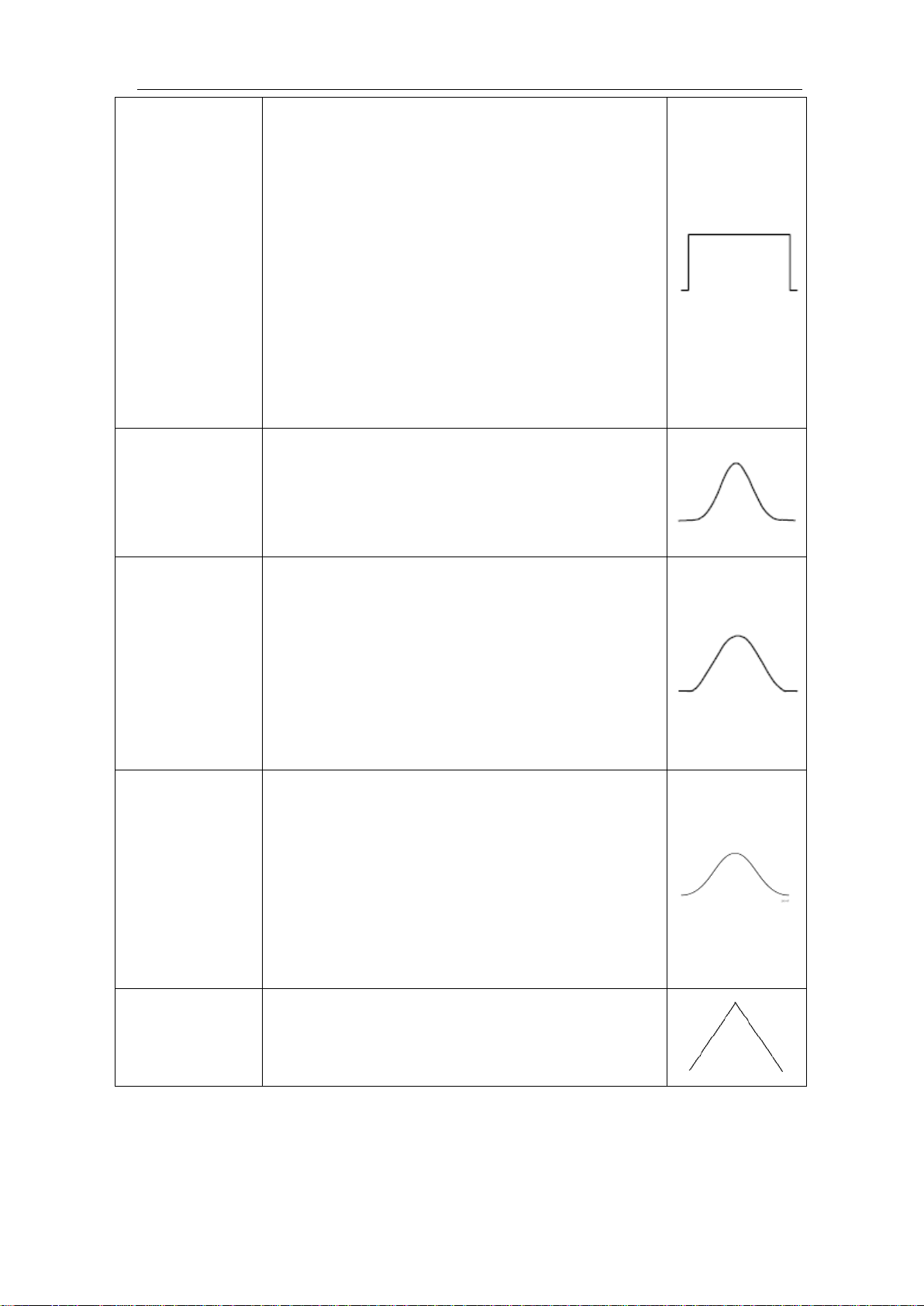

Overcompensated Compensated correctly Under compensated

Figure 3-7 Displayed Waveforms of the Probe Compensation

3. Repeat the steps mentioned if needed.

Figure 3-8 Adjust Probe

How to Set the Probe Attenuation Coefficient

The probe has several attenuation coefficients, which will influence the vertical scale

factor of the oscilloscope.

To change or check the probe attenuation coefficient in the menu of oscilloscope:

(1) Push the function menu button of the used channels (CH1 or CH2 button).

(2) Select Probe in the bottom menu; select Attenu in the right menu, turn the M knob to

select the proper value corresponding to the probe.

This setting will be valid all the time before it is changed again.

The default attenuation coefficient of the probe on the instrument is preset to

10X.

Make sure that the set value of the attenuation switch in the probe is the

same as the menu selection of the probe attenuation coefficient

oscilloscope.

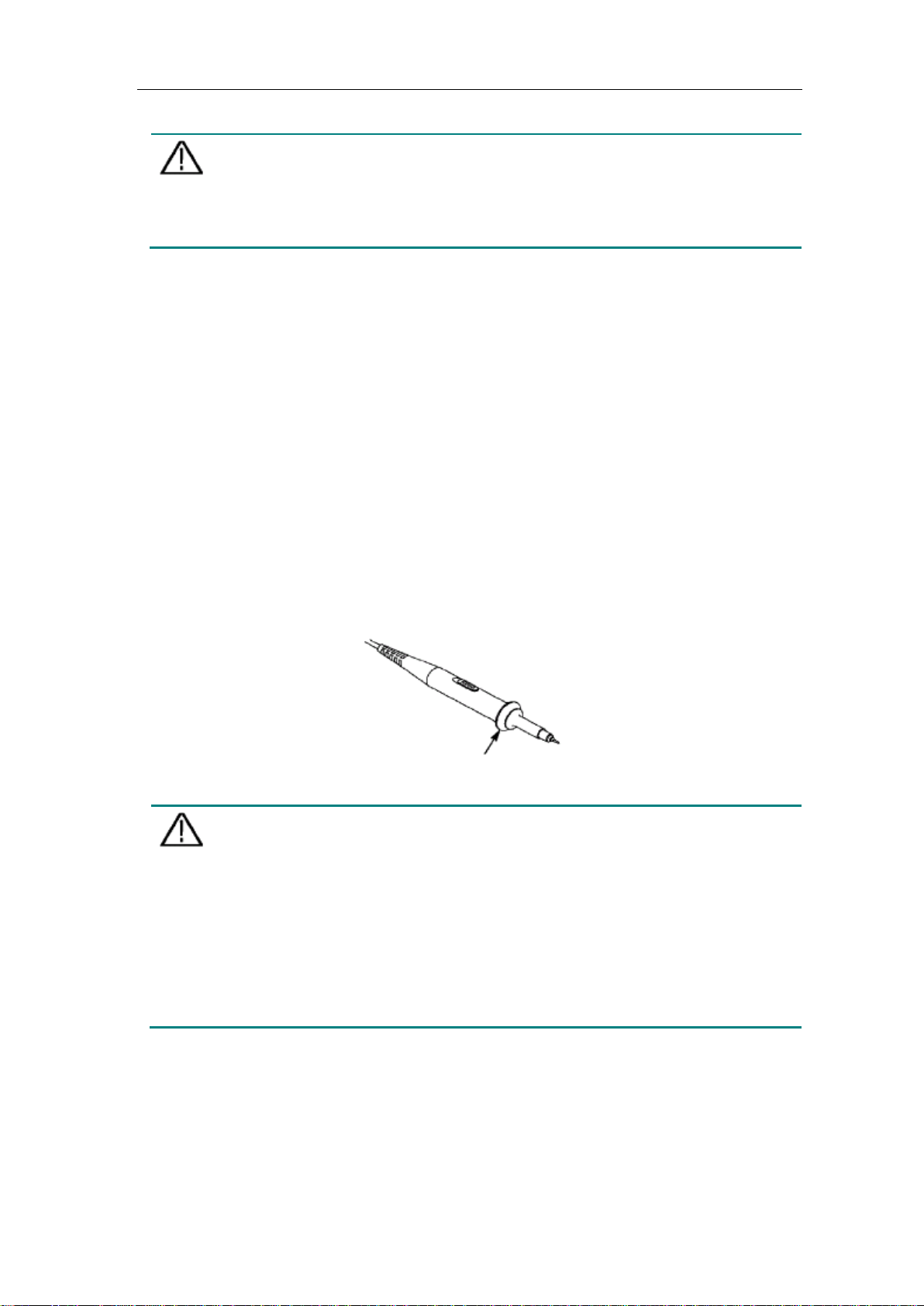

The set values of the probe switch are 1X and 10X (see Figure 3-9).

Page 18

3.Junior User Guidebook

13

Caution:

connect the probe to the

Figure 3-9 Attenuation Switch

When the attenuation switch is set to 1X, the probe will limit the bandwidth

of the oscilloscope in 5MHz. To us e the full bandwidth of the oscilloscope,

the switch must be set to 10X.

Identify the Probe Attenuation Coefficient Automatica lly

The oscilloscope can identify the probe attenuation coefficient of the 100:1 (impedance

5K±20%) or 10:1 (impedance 10K±20%) probe with the identifying pin. When you

attach the probe, the oscilloscope set the attenuation automatically on the oscilloscope

vertical menu for the channel to match the probe.

For example, if you attach a 10:1 probe with the identifying pin, the screen will prompt

"The probe attenuation factor is X10", and set the attenuation to 10X automatically on the

oscilloscope vertical menu for the channel.

How to Use the Probe Safely

The safety guard ring around the probe body protects your finger against any electric

shock, shown as Figure 3-10.

Figure 3-10 Finger Guard

Warning:

To avoid electric shock, always keep your finger behind the safety guard

ring of the probe during the operation.

To protect you from suffering from the electric shock, do not touch any

metal part of the probe tip when it is connected to the power supply.

Before making any measurements, always

instrument and connect the ground terminal to the earth.

How to Implement Self-calibration

The self-calibration application can make the oscilloscope reach the optimum condition

rapidly to obtain the most accurate measurement value. You can carry out this application

program at any time. This program must be executed whenever the change of ambient

Page 19

3.Junior User Guidebook

14

temperature is 5℃ or over.

Before performing a self-calibration, disconnect all probes or wires from the input

connector. Push the Utility button, select Function in the bottom menu, select Adjust. in

the left menu, select Self Cal in the bottom menu; run the program after everything is

ready.

Introduction to the Vertical System

As shown in Figure 3-11, there are a few of buttons and knobs in Vertical Contro ls. The

following practices will gradually direct you to be familiar with the using of the vertical

setting.

Figure 3-11 Vertical Control Zone

1. Use the Vertical Position knob to show the signal in the center of the waveform

window. The Vertical Position knob functions the regulating of the vertical display

position of the signal. Thus, when the Vertical Position knob is rotated, the pointer

of the earth datum point of the channel is directed to move up and down following

the waveform.

Measuring Skill

If the channel is under the DC coupling mode, you can rapidly measure the DC

component of the signal through the observation of the difference betw een the wave

form and the signal ground.

If the channel is under the AC mode, the DC component would be filtered out. This

mode helps you display the AC component of the signal with a higher sensitivity.

Vertical offset back to 0 shortcut key

Turn the Vertical Position knob to change the vertical display position of channel

and push the position knob to set the vertical display position back to 0 as a shortcut

key, this is especially helpful when the trace position is far out of the screen and w ant

it to get back to the screen center immediately.

2. Change the Vertical Setting and Observe the Consequent State Information Change.

Page 20

3.Junior User Guidebook

15

With the information displayed in the status bar at the bottom of the waveform

window, you can determine any changes in the channel vertical scale factor.

Turn the Vertical Scale knob and change the "Vertical Scale Factor (Voltage

Division)", it can be found that the scale factor of the channel corresponding to

the status bar has been changed accordingly.

Push buttons of CH1, CH2 and Math, the operation menu, symbols, waveforms

and scale factor status information of the corresponding channel will be displayed

in the screen.

Introduction to the Horizontal System

Shown as Figure 3-12, there are a button and two knobs in the Horizontal Controls. The

following practices will gradually direct you to be familiar with the setting of horizontal

time base.

Figure 3-12 Horiz ontal Cont rol Zone

1. Turn the Horizontal Scale knob to change the horizontal time base setting and

observe the consequent status information change. Turn the Ho rizontal Scale knob to

change the horizontal time base, and it can be found that the Horizontal Time Base

display in the status bar changes accordingly.

2. Use the Horizontal Position knob to adjust the horizontal position of the signal in the

waveform window. The Horizontal Position knob is used to control the triggering

displacement of the signal or for other special applications. If it is applied to

triggering the displacement, it can be observed that the waveform moves horizontally

with the knob when you rotate the Horizontal Position knob.

Triggering displacement back to 0 shortcut key

Turn the Horizontal Position knob to change the horizontal position of channel and

push the Horizontal Position knob to set the triggering displacement back to 0 as a

shortcut key.

3. Push the Horizontal HOR button to switch between the normal mode and the wave

Page 21

3.Junior User Guidebook

16

zoom mode.

Introduction to the Trigger System

As shown in Figure 3-13, there are one knob and three buttons make up Trigger Controls.

The following practices will direct you to be familiar with the setting of the trigger system

gradually.

Figure 3-13 Trigger Control Zone

1. Push the T rigger Menu button and call out the trigger menu. With the operations of

the menu selection buttons, the trigger setting can be changed.

2. Use the Trigger Level knob to change the trigger level setting.

By turning the Trigger Lev el knob, the trigger i ndicator in the screen will move up

and down. With the movement of the trigger indicator, it can be observed that the

trigger level value displayed in the screen changes accordingly.

Note: Turning the Trigger Level knob can change trigger lev el value and it is als o

the hotkey to set trigger level as the vertical mid point values of the amplitude of the

trigger signal.

3. Push the Force button to force a trigger signal, which is mainly applied to the

"Normal" and "Single" trigger modes.

Page 22

4.Advanced User Guidebook

17

4. Advanced User Guidebook

Up till now, you have already been familiar with the basic operations of the function areas,

buttons and knobs in the front panel of the oscilloscope. Based the introduction of the

previous Chapter, the user should have an initial knowledge of the determination of the

change of the oscilloscope setting through observing the status bar. If you have not been

familiar with the above-mentioned operations and methods yet, we advise you to read the

section of Chapter 3 "Junior User Guidebook".

This chapter will deal with the following topics mainly:

How to Set the Vertical System

How to Set the Horizontal System

How to Set the Trigger/Decoding System

How to Implement the Sampling Setup

How to Set the Display System

How to Save and Recall Waveform

How to Record/Playback Waveforms

How to Clone a waveform

How to Implement the Auxiliary System Function Setting

How to Update your Instrument Firmware

How to Measure Automatically

How to Measure with Cursors

How to Use Autoscale

How to Use Built-in Help

How to Use Executive Buttons

How to Print the Screen Image

It is recommended that you read this chapter carefully to get acquainted the various

measurement functions and other operation methods of the oscilloscope.

Page 23

4.Advanced User Guidebook

18

Function

Menu

Setting

Description

DC

GROUND

Pass both AC and DC components of the input signal.

Disconnect the input signal.

ON

OFF

Display inverted waveform.

Display original waveform.

Turn the M knob to set the Amps/Volts ratio. The

Volts/Amp ratio is automatically calculated.

Full band

Get full bandwidth.

Limit the channel bandwidth to 20MHz to reduce

How to Set the Vertical System

The VERTICAL CONTROLS includes three menu buttons such as CH1, CH2 and

Math, and four knobs such as Vertical Position, Vertical Scale for each channel.

Setting of CH1 and CH2

Each chann el has an indep endent verti cal men u and each item is set res pect ively bas ed on

the channel.

To turn waveform s on or off (ch ann e l, math)

Pushing the CH1, CH2, or Math buttons have the following effect:

• If the waveform is off, the waveform is turned on and its menu is displayed.

• If the waveform is on and its menu is not displayed, its menu will be displayed.

• If the waveform is on and its menu is displayed, the waveform is turned off and its menu

goes away.

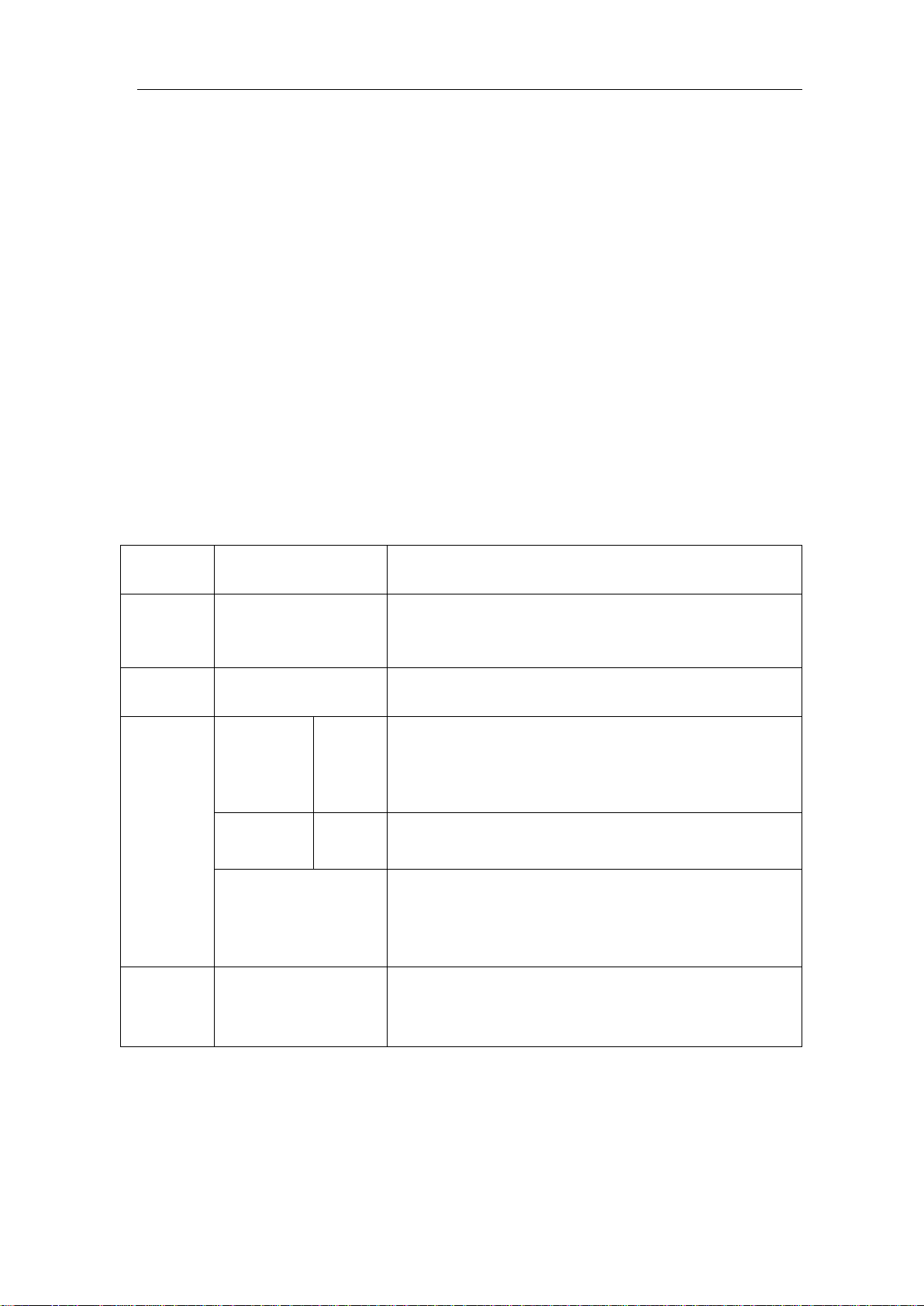

The description of the Channel Menu is shown as the following list:

Coupling

Inverted

Probe

Limit

1. To set channel coupling

AC

Attenu

MeasCurr

A/V (mA/V)

V/A (mV/A)

20M

0.001X

to

1000X

YES

NO

Block the DC component of the input signal.

Step by 1 – 2 – 5. Match this to the probe attenuation

factor to have an accurate reading of vertical scale.

If you are measuring current by probing the voltage

drop across a resistor, choose YES.

range is 100 mA/V - 1 KA/V.

Amps/Volts ratio = 1/Resistor value

display noise.

Taking the Channel 1 for example, the measured signal is a square wave signal containing

the direct current bias. The operation steps are shown as below:

(1) Push the CH1 button to show the CH1 SETUP menu.

(2) Select Coupling in the bottom menu.

Page 24

4.Advanced User Guidebook

19

(3) Select DC in the right menu. Both DC and AC components of the signal are passed.

(4) Select AC in the right menu. The direct current component of the signal is blocked.

2. To adjust the probe attenuation

For correct measurem ent s, the attenuation coeffi cien t settings in the operating menu of the

Channel should always match what is on the probe (see "How to Set the Probe Attenuation

Coefficient" on P12). If the attenuation coefficient of the probe is 1:1, the menu setting of

the input channel should be set to X1.

Take the Channel 1 as an example, the attenuation coefficient of the probe is 10:1, the

operation steps are shown as follows:

(1) Push the CH1 button to show the CH1 SETUP menu.

(2) Select Probe in the bottom menu. Select Attenu in the right menu, turn the M knob to

set it as 10×.

3. To measure current by probing the voltage drop across a resistor

Take the Channel 1 as an examp le, if you are measuring current by probing the voltage

drop across a 1Ω resistor, the operation steps are shown as follows:

(1) Push the CH1 button to show CH1 SETUP menu.

(2) Select Probe in the bottom menu. In the right menu, set MeasCurr as YES, the A/V

radio menu will appear below. Select it; turn the M knob to set the Amps/Volts ratio.

Amps/Volts ratio = 1/Resistor value. Here the A/V radio should be set to 1.

4. To invert a waveform

Waveform inverted: the displayed signal is turned 180 degrees against the phase of the

earth potential.

Taking the Channel 1 for example, the operation steps are shown as follows:

(1) Push the CH1 button to show the CH1 SETUP menu.

(2) Select Inverted in the bottom menu, switch to ON. the waveform is invert ed. Push

again to switch to OFF, the waveform goes back to its original one.

5. To set bandwidth limit

When high frequency components of a waveform are not important to its analysis, the

bandwidth limit control can be used to reject frequencies above 20 MHz.

Taking the Channel 1 for example, the operation steps are shown as below:

(1) Push the CH1 button to show CH1 SETUP menu.

(2) Select Limit in the bottom menu.

(3) Select Full band in the right menu. The high frequenc y of the signal will be allowed

to pass.

(4) Select 20M i n the right menu. The bandwidth is limited to 20 MHz. The frequencies

above 20MHz will be rejected.

Page 25

4.Advanced User Guidebook

20

Function Menu

Setting

Description

CH1

CH2

CH1

CH2

(div)

the vertical position of the Math

waveform

Vertical

(V/div)

Turn the M knob to adjust the vertical division of the Math

waveform

Switch to select the horizontal position or

M knob to adjust it

Position value

Switch to select the vertical position or

division of the FFT waveform,

turn the M knob to adjust it

User

Function

Use Mathematical Manipulation Function

The Mathematical Manipulation function is used to show the results of the addition,

multiplication, division and subtraction operations between two channels, the FFT

operation for a channel, advanced math feature including Intg, Diff, Sqrt, user defined

function, and digital filter. Press the Math button to display the menu on the bottom.

The Waveform Calculation menu:

Dual Wfm

Math

Factor1

Sign + - * / Select the sign of mathematical manipulation

Factor2

Vertical

Source

Window

Turn the M knob to adjust

CH1

CH2

Hamming

Rectangle

Blackman

Hanning

Kaiser

Select the signal source of the factor1

Select the signal source of the factor2

Select CH1 as FFT source.

Select CH2 as FFT source.

Select window for FFT.

Bartlett

FFT

Format

Hori (Hz)

Vertical

Intg, Diff, Sqrt, and user defined function

V RMS

Decibels

Radian

Degrees

Position value

Time base value/

Division value/

V RMS and Decibels are

time base of the FFT waveform, turn the

vertical

Page 26

4.Advanced User Guidebook

21

CH1

CH2

Only the signals whose frequencies are

can pass the filter.

Only the signals whose frequencies are

greater than the current cutoff frequency

can pass the filter.

Only the signals whose frequencies are

and lower than the current cutoff

frequency upper can pass the filter.

Only the signals whose frequencies are

lower than the current cutoff frequency

or greater than the current cutoff

frequency upper can pass the filter.

Retangular

Blackman

cut-off fre

upper down

Vertical

(div)

Turn the M knob to adjust the vertical

position of Math waveform

Enable or disable FFT peak search.

peak.

DIR

channel

type

window

low-pass

high-pass

band-pass

band-reject

Tapered

Triangular

Hanning

Hamming

Select channel

lower than the current cut-off frequency

greater than the cutoff frequency down

down

Select window for digital filter

Turn the M knob to set cut-off frequency

Dynamic marker ▽ marks the FFT

FFT Peak

or

ON

OFF

Waveform math

Taking the additive operation between Channel 1 and Channels 2 for example, the

operation steps are as follows:

1. Press the Math button to display the math menu in the bottom. The pink M wavefor m

appears on the screen.

2. Select Dual Wfm Math in the bottom menu.

3. In the right menu, select Factor1 as CH1.

4. Select Sign as + in the right menu.

5. In the right menu, select Factor2 as CH2.

6. Select Vertical (div) in the right menu, turn the M knob to adjust the vertical position

of Math waveform.

Page 27

4.Advanced User Guidebook

22

Channel

Confirm

Clear

Operators

Integral

Differential

Square root

Expression

7. Select Vertical (V/div) in the right menu, turn the M knob to adjust the vertical division

of Math waveform.

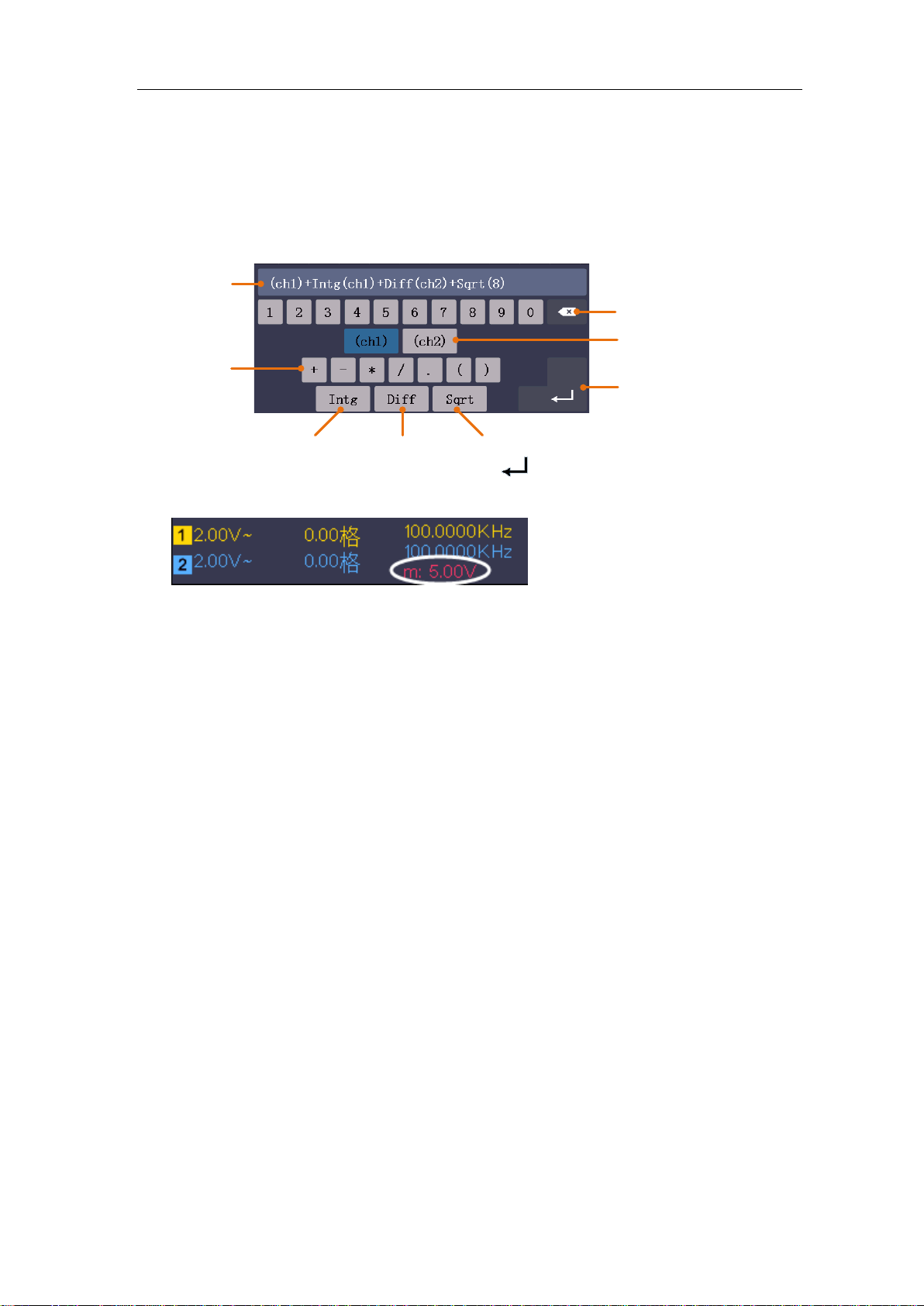

User defined function

1. Press the Math button to display the math menu in the bottom.

2. Select User Function in the bottom menu, an expression input keyboard pops up.

3. Create an expression. When done, choose

in the keyboard to confirm

division of Math waveform is displayed at the left bottom of screen.

. The

Digital Filter

Digital filter provides 4 types of filters (low pass, high pass, band pass and band reject).

The specified frequencies can be filtered by setting the cut-off frequenc y.

1. Press the Math button to display the math menu in the bottom.

2. Select DIR in the bottom menu.

3. In the right menu, select channel as CH1 or CH2.

4. In the right menu, select type, select the desired filter type.

5. In the right menu, select window, select the desired window.

6. When low-pass or high-pass type is selected, select cut-off fre in the right menu.

When band-pass or band-reject type is selected, select upper or down in the right

menu. Turn M knob to adjust the frequency.

7. In the right menu, select Vertical (d iv), turn M knob to adjust the vertical position of

Math waveform. The voltage division of Math waveform is the same as the selected

channel.

Note: On the Scan format, digital filter is disabled.

Using FFT function

The FFT (fast Fourier transform) math function mathematically converts a time-domain

waveform into its frequency components. It is very useful for analyzing the input signal on

Oscilloscope. You can match these frequencies with known system frequencies, such as

system clocks, oscillators, or power supplies.

Page 28

4.Advanced User Guidebook

23

It has slightly better

Transients or bursts where the signal levels

before and after the event are significantly

FFT function in this oscilloscope transforms 8192 data points of the time-domain signal

into its frequency components mathematically (the record length should be 10K or abov e).

The final frequency contains 4096 points ranging from 0Hz to Nyquist frequency.

Taking the FFT operation for example, the operation steps are as follows:

1. Press the Math button to display the math menu in the bottom.

2. Select FFT in the bottom menu.

3. In the right menu, select Source as CH1.

4. In the right menu, select Window. In the left menu, turn the M knob to select the

proper window type.

5. In the right menu, select Format. In the left menu, turn the M knob to select

amplitude unit (V RMS, Decibels) or phase unit (Radian, Degrees).

6. Select Hori (Hz) in the r ight menu; select repeatedly to make the symbol in front

of the horizontal position value (the upper one), turn the M knob to adjust the

horizontal position of FFT waveform; then select to make the symbol in front of

the time base value below, turn the M knob to adjust the time base of FFT waveform.

7. Select Vertical in the right menu; do the same operations as above to set the vertical

position and vertical division.

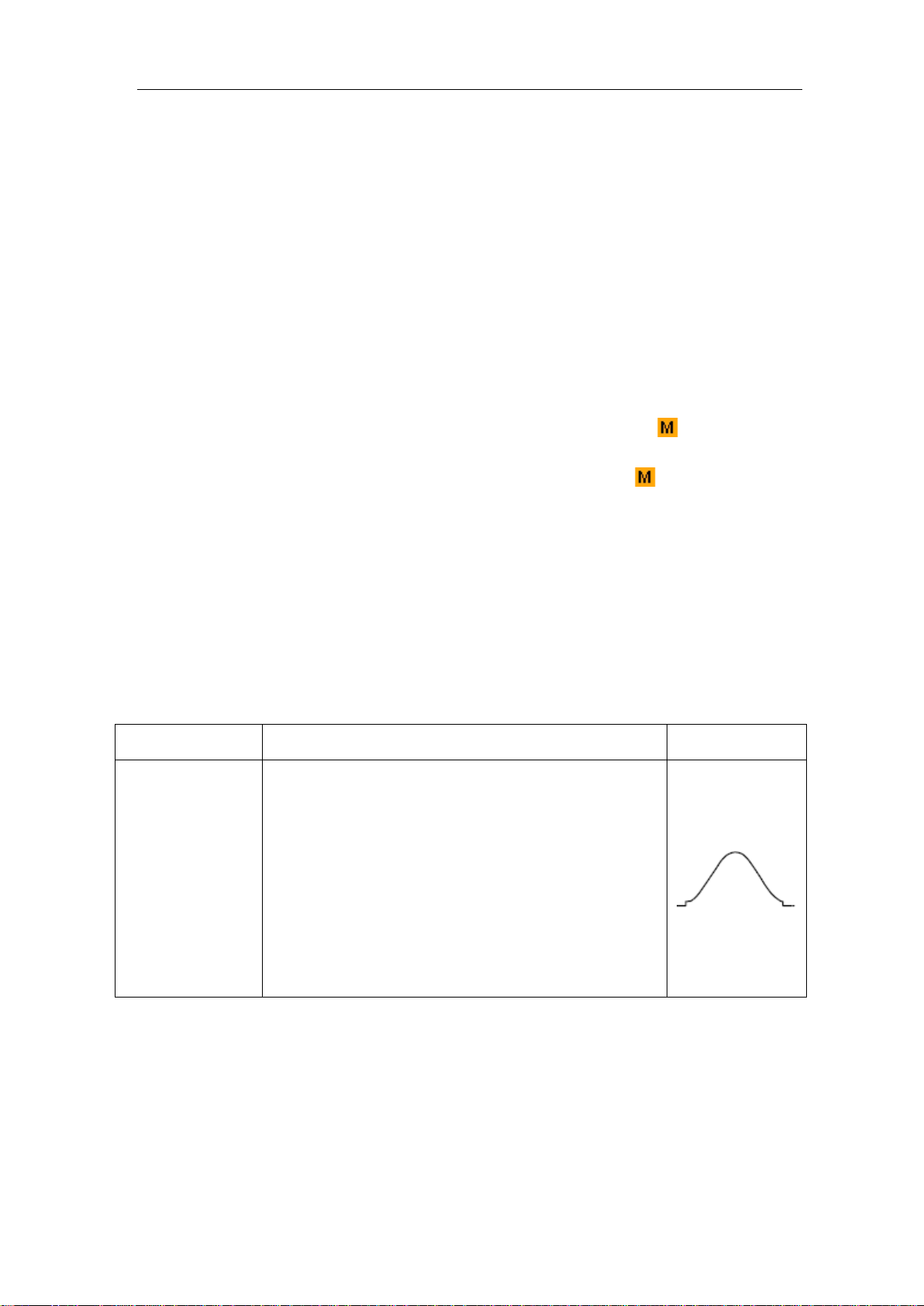

To select the FFT window

■ There are 6 FFT windows. Each one has trade-offs between frequency resolution and

magnitude accuracy. What you want to measure and your source signal characteristics

help you to determine which window to use. Use the following guidelines to select the

best window.

Type Characteristics Window

Better solution for magnitude than Rectangle, and

good for frequency as well.

frequency resolution than Hanning.

Recommend to use for:

Hamming

Sine, periodic and narrow band random noise.

different.

Page 29

4.Advanced User Guidebook

24

repetitive signals and measuring frequency

Transients or bursts where the signal levels

before and after the event are significantly

The frequency resolution when using the Kaiser

The Bartlett window is a slightly narrower variant

Best solution for frequency, worst for magnitude.

Best type for measuri ng the frequency spect rum of

non

components near DC.

Recommend to use for:

Rectangle

Blackman

Hanning

Transients o r burs ts, the signal level bef ore and

after the event are nearly equal.

Equal-amplitude sine waves with frequencies

those are very close.

Broadband random noise with a relatively slow

varying spectrum.

Best solution for magnitude, worst for frequency.

Recommend to use for:

Single frequency waveforms, to find higher

order harmonics.

Good for magnitude, but poorer frequency

resolution than Hamming.

Recommend to use for:

Sine, periodic and narrow band random noise.

different.

window is fair; the spectral leakage and amplitude

accuracy are both good.

Kaiser

The Kaiser window is best used when frequencies

are very close to the same value but have widely

differing amplitudes (the side lobe level and shape

factor are closest to the traditional Gaussian RBW ).

This window is also good for random signals.

Bartlett

of the triangular window, with zero weight at both

ends.

Notes for using FFT

Use the default dB scale for details of multiple frequencies, even if they have very

different amplitudes. Use the Vrms scale to compare frequencies.

Page 30

4.Advanced User Guidebook

25

DC component or offset can cause incorrect magnitude values of FFT waveform. To

minimize the DC component, choose AC Coupling on the source signal.

To reduce r andom noise and aliased components in repetitive or single-sho t events, set

the oscilloscope acquisition mode to average.

What is Nyquist freque nc y?

The Nyquist frequ ency is the highes t frequency that any real-time digitizing oscilloscope

can acquire without aliasing. This frequency is half of the sample rate. Frequencies above

the Nyquist frequency will be under sampled, which causes aliasing. So pay more

attention to the relation between the frequency being sampled and measured.

Use Vertical Position and Scale Knobs

1. The Vertical Position knob is used to adjust the vertical positions of the

waveforms.

The analytic resolution of this control knob changes with the vertical division.

2. The Vertical Scale knob is used to regulate the vertical resolution of t he wave

forms. The sensitivity of the vertical division steps as 1-2-5.

The vertical position and vertical resolution is displ ayed at the left bottom corner of

the screen (see Figure 4-1).

Figure 4-1 Information about Vertical Position

How to Set the Horizontal System

The HORIZONTAL CONTROLS includes the Horizontal HOR button and such

knobs as Horizontal Position and Horizontal Scale.

1. Horizontal Position knob: this knob is used to adjust the horizontal positions of

Page 31

4.Advanced User Guidebook

26

Main Window

Time base of

Zoom window

Selected portion

Horizontal position of

Zoom window

Zoom Window

all channels (include those obtained from the mathematical manipulation), the

analytic resolution of which changes with the time base.

2. Horizontal Scale knob: it is used to set the horizontal scale factor for setting the

main time base or the window.

3. Horizontal HOR button: push it to switch between the normal mode and the

wave zoom mode. For more detailed operations, see the introductions below.

Zoom the Waveform

Push the Horizontal HOR button to enter wave zoom mode. The top half of the

display shows the Main window and the bottom half displays the Zoom window. The

Zoom window is a magnified portion of the Main window.

In normal mode, the Horizontal Position and Horizontal Scale knobs are used to

adjust the horizontal position and time base of the Main window.

In wave zoom mode, the Horizontal Position and Horizontal Scale knobs are used

to adjust the horizontal position and time base of the Zoom window.

How to Set the Trigger/Decoding System

Trigger determines when DSO starts to acquire data and display wav efo rm . O nce

trigger is set correctly, it can convert the unstable display to meaningful

waveform.

When DSO starts to acq uire data, it will collect enough data to draw waveform

on left of trigger point. DSO continues to acquire data while waiting for trigger

condition to occur. Once it detects a trigger it will acquire enough data

continuously to draw the waveform on right of trigger point.

Trigger control area consists of 1 knob and 2 menu buttons.

Trigger Level: The knob that set the trigger level; push the knob and the level

Page 32

4.Advanced User Guidebook

27

will be set as the vertical mid point values of the amplit ude of the trigger

signal.

Force: Force to create a trigger signal and the function is mainly used in

"Normal" and "Single" mode.

Trigger Menu: The button that activates the trigger control menu.

Trigger Control

The oscilloscope provides four trigger types: single trigger, altern ate trigger, logic

trigger and bus trigger. Each type of trigger has different sub menus.

Two ways to enter trigger mode:

Key operation: Press Trigger Menu panel button, then bottom menu Trigger Type,

select Single, ALT, Logic or Bus Trigger on the popup right

menus, rotate M knob to choose different trigger types.

Single trigger: Use a trigger level to capture stable waveforms in two channels

simultaneously.

Alternate trigger: Trigger on non-synchronized signals.

Logic trigger: Trigger the signal according to the condition of logic relationship.

Bus trigger: Set bus timing trigger.

The Single Trigger, Alternate Trigger, Logic Trigger and Bus Trigger menus

are described respecti vel y as follo ws:

Single Trigger

Single trigger has eight types: edge trigger, video trigger, slope trigger, pulse trigger,

runt trigger, windows trigger, timeout trigger and Nth edge trigger.

Edge Trigger: It occurs when the trigger input passes through a specified voltage

level with the specified slope.

Video Trigger: Tri gger on fields or lines for standard video signal.

Slope Trigger: The oscilloscope begins to trigger according to the signal rising or

falling speed.

Pulse Trigger: Find pulses with certain widths.

Runt Trigger: Trigger pulses that pass through one trigger level but fail to pass

through the other trigger level.

Windows Trigger: Provide a high trigger level and l ow tri gger level, the oscill oscope

triggers when the input signal passes through the high trigger level or

the low trigger level.

Timeout Trigger: The oscilloscope triggers when the time interval from when the

rising edge (or the falling edge) passes through the trigger level to

when the neighbouring falling edge (or the rising edge) passes

Page 33

4.Advanced User Guidebook

28

Menu

Settings

Instruction

Single Mode

Edge

Set vertical channel trigger type as edge trigger.

CH1

AC Line

Channel 1 as trigger signal.

AC power line as trigger signal.

AC

Block the direct current component.

component pass. (LF menu is only for certain models)

Trigger on rising ed ge

Trigger on falling edge

Auto

Reset

Acquire waveform even no trigger occurs

knob to set time interval

Set Holdoff time as default value (100 ns).

through the trigger level is greater than the timeout time set.

Nth Edge Trigger: The oscilloscope triggers on the Nth edge that appears on the

specified idle time.

The eight trigger modes in Single Trigger are described respectively as follows:

1. Edge Trigger

An edge trigger occurs on trigger level value of the specified edge of input signal.

Select Edge trigger mode to trigger on rising edge or falling edge.

In Edge Trigger mode, the tri gger setting information is displayed on bottom right of

the screen, for example, ,indicates that trigger type is edge,

trigger source is CH1, coupling is DC, and trigger level is 0.00mV.

Edge menu list:

Source

Coupling

Slope

Mode

Holdoff

CH2

EXT

EXT/5

DC

HF

LF

Normal

Single

Holdoff

Channel 2 as trigger signal.

External trigger as trigger signal

1/5 of the external trigger signal as trigger signal.

Allow all component pass.

Block the high-frequency signal, only low-frequency

component pass.

Block the low-frequency signal, only high-frequency

Acquire waveform when trigger occurs

When trigger occurs, acquire one waveform then stop

100 ns - 10 s, turn the M

before another trigger occur, press panel

button to move cursor to choose which digit to be set.

Trigger Level: trigger level indicates vertical trig position of the channel, rotate trig

level knob upward and downward to move trigger level, during setting, an oran ge red

dotted line displays to show trig position, and the value of trigger level changes at the

right corner, after setting, dotted line disappears.

2. Video Trigger

Choose video trigger to trigger on fields or lines of NTSC, PAL or SECAM standard

video signals.

Page 34

4.Advanced User Guidebook

29

MENU

SETTING

INSTRUCTION

Single Mode

Video

Set vertical channel trigger type as video trigger

CH1

CH2

Select CH1 as the trigger source

Select CH2 as the trigger source

NTSC

SECAM

Line

Synchronic trigger in video line

knob to set the line number

Mode

Holdoff

MENU

SETTING

INSTRUCTION

Single

Mode

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

slope

knob to set slope

In Video Trigger mode, the trigger setting information is displayed on bottom right of

the screen, for exam ple, ,indicates that trigger typ e is Video, trigger

source is CH1, and Sync type is Even.

Video Trigger menu list:

Source

Modu

Sync

PAL

Field

Odd

Even

Line NO.

Select video modulation

Synchronic trigger in video field

Synchronic trigger in video odd filed

Synchronic trigger in video even field

Synchronic trigger in designed video line, turn the M

Auto Acquire waveform even no trigger occurred

3. Slope Trigger

Slope trigger sets the oscilloscope as the positive/negative slope trigger within the

specified time.

In Slope Trigger mode, the trigger setting information is displayed on bottom right of

the screen, for exam ple, ,indicates that trigger type is slope,

trigger source is CH1, slope is rising, 0.00mV is the differential between up level and

low level threshold.

Slope trigger menu list:

Slope Set vertical channel trigger type as slope trigger.

Source

When

Slope selecting

Set slope condition; turn the M

time, press panel button to move cursor to

choose which digit to be set.

Page 35

4.Advanced User Guidebook

30

High level

Slew rate

Adjust M knob to set the High level upper limit.

Slew rate = (High level - Low level) / Settings

Auto

Reset

Acquire waveform even no trigger occurred

Set Holdoff time as 100 ns

MENU

SETTING

INSTRUCTION

Set vertical channel trigger type as pulse trigger.

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

AC

DC

Not allow DC portion to pass.

Allow all portion pass.

Polarity

Auto

Reset

Acquire waveform even no trigger occurred

Set Holdoff time as 100 ns

Threshold

&SlewRate

Mode

Holdoff

Low level

Normal

Single

Holdoff

Adjust M knob to set Low level lower limit.

Acquire waveform when trigger occurred

When trigger occurs, acquire one waveform then stop

100 ns – 10 s, turn the M knob to set time interval

before another trigger occur, press panel

button to move cursor to choose which digit to be set.

4. Pulse Width Trigger

Pulse trigger occurs according to the width of pulse. The abnormal signals can be

detected through setting up the pulse width condition.

In Pulse Width Trigger mode, the trigger setting information is displayed on bottom

right of the screen, for example, ,indicates that trigger type

is pulse width, trigger source is CH1, coupling is DC, polarity is positive, and trigger

level is 0.00mV.

Pulse Widt h Trigger menu list:

Single Mode Pulse

Source

Coupling

when

Normal

Mode

Holdoff

Single

Holdoff

Choose the polarity

Select pulse width condition and adjust the M knob

to set time, press panel button to move

cursor to choose which digit to be set.

Acquire waveform when trigger occurred

When trigger occurs, acquire one waveform then stop

100 ns - 10 s, adjust M knob to set time interval

before another trigger occur, press panel

button to move cursor to choose which digit to be set.

Page 36

4.Advanced User Guidebook

31

MENU

SETTING

INSTRUCTION

Single

Mode

Set vertical channel trigger type as runt trigger.

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Up Level

Low Level

Adjust the M knob to set the up level threshold.

Adjust the M knob to set the low level threshold.

Positive Polarity, the oscilloscope triggers on the

negative runt pulse.

5.Runt Trigger

Trigger pulses that pass through one trigger level but fail to pass through the other

trigger level. Shown as below figure,

In Runt Trigger mode, the trigger setting information is displayed on bottom right of

the screen, for example, ,indicates that trigger type is runt,

trigger source is CH1, polarity is positive, 0.00mV is the differential between up level

and low level threshold.

Runt Trigger

Runt Trigger menu list:

Runt

Source

Threshold

Polarity

Condition

positive runt pulse.

Negative Polarity, the oscilloscope triggers on the

Adjust the M knob to set pulse width, press

panel button to move cursor to choose which digit to be

set.

Trigger when runt pulse is greater than the set pulse

width.

Trigger when runt pulse equals to the set pulse width.

Trigger when runt pulse is lower than the set pulse

width.

Page 37

4.Advanced User Guidebook

32

Auto

Reset

Acquire waveform even no trigger occurred

Set Holdoff time as 100 ns

MENU

SETTING

INSTRUCTION

Single

Mode

Set vertical channel trigger type as Windows trigger.

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Up Level

Low Level

Adjust the M knob to set the up level threshold.

Adjust the M knob to set the low level threshold.

Positive Polarity, the oscilloscope triggers on the

negative Windows pulse.

Enter: Triggers when the trigger signal enters the

Exit: Triggers when the trigger signal exits the

Time: Specify the hold time of the input signal after

entering the specified trigger level. The oscilloscope

triggers when the accumulated hold time is greater than

Mode

Holdoff

Normal

Single

Holdoff

Acquire waveform when trigger occurred

When trigger occurs, acquire one waveform then stop

100 ns - 10 s, adjust M knob to set time interval before

another trigger occur, press panel button to

move cursor to choose which digit to be set.

6.Windows Trigger

Provide a high trigger level and low trigger level, the oscilloscope triggers when the

input signal passes through the high trigger level or the low trigger level.

In Windows Trigger mode, the trigger setting information is displayed on bottom right

of the screen, for example, ,indicates that trigger type is

windows, trigger source is CH1, polarity is positive, 0.00mV the differential between

up level and low level threshold.

Windows Trigger menu list:

Windows

Source

Threshold

Polarity

Condition

positive Windows pulse.

Negative Polarity, the oscilloscope triggers on the

specified trigger level range.

specified trigger level range.

the windows time. Available range is 30ns-10s, default

100ns.

Page 38

4.Advanced User Guidebook

33

Auto

Reset

Acquire waveform even no trigger occurred

Set Holdoff time as 100 ns

MENU

SETTING

INSTRUCTION

Single

Mode

Set vertical channel trigger type as Timeout trigger.

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Edge

Start timing when the rising edge of the input signal

passes through the trigger level.

Set idle time. Idle time means the minimum time of idle

clock before searching data that can meet trigger

conditions. Available range is 30ns-10s, default 100ns.

Auto

Reset

Acquire waveform even no trigger occurred

Set Holdoff time as 100 ns

Mode

Holdoff

Normal

Single

Holdoff

Acquire waveform when trigger occurred

When trigger occurs, acquire one waveform then stop

100 ns - 10 s, adjust M knob to set time interval before

another trigger occur, press panel button to

move cursor to choose which digit to be set.

7.Time out Trigger

The oscilloscope triggers when the time interval from when the rising edge (or the

falling edge) passes through the trigger level to when the neighbouring falling edge

(or the rising edge) passes through the trigger level is greater than the timeout time

set.

In Timeout Trigger mode, the trigger setting information is displayed on bottom right

of the screen, for example, ,indicates that trigger type is Timeout,

trigger source is CH1, edge is positive, 0.00mV is up level or low level threshold.

Timeout Tri gg er menu list:

Timeout

Source

Edge

Configure Idle T ime

Normal

Mode

Holdoff

Single

Holdoff

passes through the trigger level.

Start timing when the falling edge of the input signal

Acquire waveform when trigger occurred

When trigger occurs, acquire one waveform then stop

100 ns - 10 s, adjust M knob to set time interval before

another trigger occur, press panel button

move cursor to choose which digit to be set.

8.Nth Edge trigger

The oscilloscope triggers on the Nth edge that appears on the specified idle time. As

figure shown below, the oscilloscope should trigger on the second falling edge after

Page 39

4.Advanced User Guidebook

34

MENU

SETTING

INSTRUCTION

Single

Mode

CH1

CH2

Select CH1 as the trigger source.

Select CH2 as the trigger source.

Edge

Trigger on the rising edge of the input signal when

voltage level meets the specified trigger level.

Set idle time before the edge counting in Nth Edge

to be set. Available range is 30ns-10s, default 100ns.

the specified idle time and the idle time should be set to P1/P2/P3/P4 < Idle Time < M.

Wherein, M, P1, P2, P3 and P4 are positive or negative pulse width participating in

the counting.

In Nth Edge Trigger mode, the trigger setting information is displayed on bottom right

of the screen, for example, ,indicates that trigger type is Nth

Edge, trigger source is CH1, -150V is up level or low level threshold.

Nth Edge Trigger menu list:

Nth Edge Set vertical channel trigger type as Nth Edge trigger.

Source

Edge

Idle T ime

Configure

Edge Num

Nth Edge Trigger

voltage level meets the specified trigger level.

Trigger on the falling edge of the input signal when

Trigger. Adjust M knob to set idle time press

panel button to move cursor to choose which digit

Set the edge number value of “N” in Nth Edge trigger.

Page 40

4.Advanced User Guidebook

35

Auto

Reset

Acquire waveform even no trigger occurred

Set Holdoff time as 100 ns

Menu

Settings

Instruction

Alternate Mode

Edge

Set vertical channel trigger type as edge trigger.

CH1

CH2

Channel 1 as trigger signal.

Channel 2 as trigger signal.

AC

DC

Block the direct current component.

Allow all component pass.

Auto

Reset

Acquire waveform even no trigger occurs

Set Holdoff time as default value (100 ns).

MENU

SETTING

INSTRUCTION

Mode

Logic

Set vertical channel trigger type as Log i c trigger.

Mode

Holdoff

Normal

Single

Holdoff

Acquire waveform when trigger occurred

When trigger occurs, acquire one waveform then stop

100 ns - 10 s, adjust M knob to set time interval before

another trigger occur, press panel button

move cursor to choose which digit to be set.

Alternate Trigger (Trigger mode: Edge)

Trigger signal comes from two vertical channels when alternate trigger is on. This

mode is used to observe two unrelated signals. Trigger mode is edge trigger.

Alternate trigger (Trigger Type: Edge) menu list:

Source

Coupling

Slope

Mode

Holdoff

Holdoff

Trigger on rising ed ge

Trigger on falling edge

100 ns - 10 s, turn the M knob to set time interval

before another trigger occur, press panel

button to move cursor to choose which digit to be

set.

Logic Trigger

Trigger according to logic relation.

In Logic Trigger mode, the trigger setting information is displayed on bottom right of

the screen, for example, , indicates that

trigger type is Logic, logic mode is AND, CH1 high level and trigger level is 0.00mV,

CH2 high level and trigger level is 0.00mV.

Logic Trigg er menu list:

Page 41

4.Advanced User Guidebook

36

AND

XOR

Set logic mode as AND.

Set logic mode as XOR.

CH1

Set CH1 as High Level, Low level, high or low level,

at the same time.

Goes True

Trigger when condition turns True from False.

set time

Goes False

Is True >

Is True <

Auto

Reset

Acquire waveform even no trigger occurred

Set Holdoff time as 100 ns

Logic

Mode

Input Mode

Out Mod

OR

XNOR

CH2

Is True =

Set logic mode as OR.

Set logic mode as XNOR.

Rise and Fall.

Set CH2 as High Level, Low level, high or low level,

Rise and Fall.

Note:When input mode of one channel is set as Rise or

Fall, the other channel could not be set as Rise and Fall

Trigger when condition turns False from True.

Trigger when the time of true condition is more than

the set time

Trigger when the time of true condition is lower than

the set time

Trigger when the time of true condition is equal to the

Mode

Holdoff

Normal

Single

Holdoff

Acquire waveform when trigger occurred

When trigger occurs, acquire one waveform then stop

100 ns - 10 s, adjust M knob to set time interval before

another trigger occur, press panel button

move cursor to choose which digit to be set.

Bus Trigger

1. RS232 Trigger

RS232 is a serial communication mode used in the data transmission between PCs or

between PC and Terminal. A character is transmit ted as a f rame of data wh ich consist

of 1bit start bit, 5-8bits data bits, 1bit check bit and 1-2 stop bits.

In RS232 bus trigger mode, the trigger setting information is displayed on bottom

right of the screen, for example, ,indicates that trigger type

is RS232, CH1 trigger level is 0.00mV.

Format as shown in the figure below,

Page 42

4.Advanced User Guidebook

37

MENU

SETTING

INSTRUCTION

Sour

ce

CH1

Select CH1 as the trigger source.

Select CH2 as the trigger source.

CH2

Pola

Nor

mal

Select polarity of data transmission as Normal. Select

Inve

rted

Trigger on the start frame of position. After choosing

this condition, press Configure to enter detailed

settings.

Trigger when error frame is detected. After choosing

this condition, press Configure to enter detailed

settings.

Trigger when Chk Error is detected. After choosing