Page 1

A

A

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE INSTALLING FIXTURE

This fixture is intended for installation in accordance with the National Electrical Code and local regulations. To

assure full compliance with local codes and regulations, check with your local electrical inspector before

installation. To prevent electric shock, turn off electricity at fuse box before proceeding.

INSTRUCTION SHEET NO.

IS:C12

A1204

Page 1 of 2

INSTALLATION PROCEDURE FOR: 12” DIA. H.I.D. C12 SERIES REFLECTOR TRIM TO

WARNING: USE ONLY REFLECTOR TRIMS PROVIDED BY LIGHTOLIER. USE OF OTHER MANUFACTURES’ REFLECTOR

C12 SERIES FRAME-IN KIT AND C12CS/C12CW CYLINDER (ORDER SEPARATELY)

TRIMS MAY VOID THE UNDERWRITERS LABORATORIES LISTING AND COULD CONSTITUTE A FIRE HAZARD.

IF A NON-IC TYPE RECESSED FRAME-IN KIT IS USED, DO NOT INSTALL INSULATION ABOVE NOR WITHIN

INSTRUCTIONS FOR INSTALLING C12E28V SERIES DOWNLIGHT

REFLECTOR TRIM

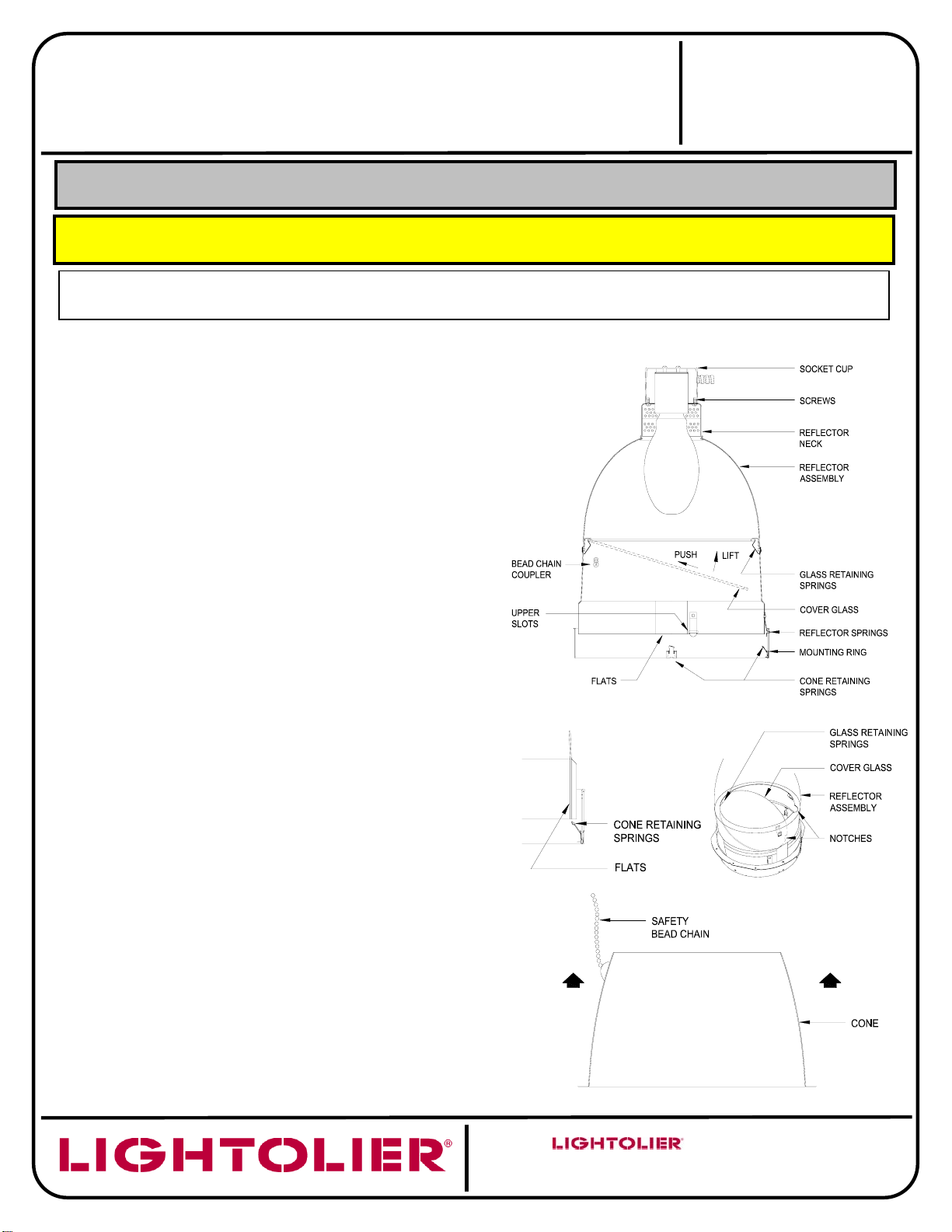

1. Attach SOCKET CUP to REFLECTOR ASSEMBLY by aligning (3) SCREWS

with key slots in REFLECTOR NECK, then tighten screws. (Fig. 1)

2. Position REFLECTOR ASSEMBLY into MOUNTING RING of Frame-In

Kit or Cylinder, align (4) FLATS in REFLECTOR ASSEMBLY with (4)

CONE RETAINING SPRINGS, and align REFLECTOR SPRINGS with

UPPER SLOTS in MOUNTING RING (Fig. 1 & 2). Then raise REFLECTOR

ASSEMBLY, to snap in place. (FIG. 1)

3. Before lamping, make sure power is disconnected to fixture.

Install lamp into lampholder.

4. Install COVER GLASS (required for enclosed lamp rated

fixture), line-up the edge of COVER GLASS with one spring

opposite notch on REFLECTOR ASSEMBLY and gently

push glass outward, then lift glass upward into position.

Rotate COVER GLASS so that NOTCH in COVER GLASS

is away from NOTCH in REFLECTOR ASSEMBLY. (Fig. 1 & 3)

5: Hook SAFETY BEAD CHAIN onto BEAD CHAIN COUPLER.

Position CONE so that bead chain is about horizontal, then push

CONE up into MOUNTING RING, then turn CONE clockwise

slightly for tight fit onto ceiling. CONE RETAINING SPRINGS will

hold cone in place. (Fig. 1 & 4)

TO RELAMP

Disconnect power to fixture, then reverse installation

instructions above.

TO INSPECT AND REPLACE BALLAST

Disconnect power to fixture. Remove Cone. Detach REFLECTOR

SSEMBLY by disengage REFLECTOR SPRINGS, move it to side

of fixture in the plenum, or in cylinder, remove from cylinder. See

IS:C4-C12 (Frame-In Kit), and IS:C12CS (Cylinder), for ballast

replacement. After service reverse Installation steps.

Care and Maintenance of REFLECTOR TRIM finish

If handling of REFLECTOR TRIM with anodized finish is required, the use

of clean white or plastic film gloves is recommended to avoid fingerprints.

nodized surfaces can be cleaned by the following methods:

1. Wipe off with a soft, clean, dry, lint-free cloth.

2. Wipe off with a soft clean cloth dampened in mild detergent solution.

3. Rinse, then wipe dry with lint-free cloth or paper towel.

4. Wipe off with a clean cloth dampened with a solution of wetting agent

and water (such as 2 oz. Per gallon “Pluronic L62-LF” by Wyandotte

Products). Wipe dry.

5. Use a liquid wax such as Glass Wax®. Avoid gritty cleaning agents.

3 INCHES (76mm) OF ANY PART OF THE LUMINAIRE (LIGHTING FIXTURE)

FIG. 1

FIG. 2 FIG. 3

FIG. 4

631 Airport Road, Fall River, MA 02720

a Genlyte company

Page 2

A

READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE INSTALLING FIXTURE

This fixture is intended for installation in accordance with the National Electrical Code and local regulations. To

assure full compliance with local codes and regulations, check with your local electrical inspector before

installation. To prevent electric shock, turn off electricity at fuse box before proceeding.

INSTRUCTION SHEET NO.

IS:C12

A1204

Page 2 of 2

INSTALLATION PROCEDURE FOR: 12” DIA. H.I.D. C12 SERIES REFLECTOR TRIM TO

C12 SERIES FRAME-IN KIT AND C12CS/C12CW CYLINDER (ORDER SEPARATELY)

WARNING: USE ONLY REFLECTOR TRIMS PROVIDED BY LIGHTOLIER. USE OF OTHER MANUFACTURES’ REFLECTOR

TRIMS MAY VOID THE UNDERWRITERS LABORATORIES LISTING AND COULD CONSTITUTE A FIRE HAZARD.

IF A NON-IC TYPE RECESSED FRAME-IN KIT IS USED, DO NOT INSTALL INSULATION ABOVE NOR WITHIN

3 INCHES (76mm) OF ANY PART OF THE LUMINAIRE (LIGHTING FIXTURE)

INSTRUCTIONS FOR INSTALLING C12E28FL AND C12E28PL

SERIES LENSLITE DOWNLIGHT REFLECTOR TRIM

INSTALLING SOCKET CUP TO REFLECTOR

1: Attach SOCKET CUP to REFLECTOR ASSEMBLY by aligning (3)

SCREWS with key slots in REFLECTOR NECK, then tighten screws.

(Fig. 1)

2: Raise REFLECTOR ASSEMBLY/SOCKET CUP into MOUNTING RING

of Frame-In Kit or Cylinder, align REFLECTOR SPRINGS with upper

slots in MOUNTING RING until springs snap in place. (Fig. 1)

3: Before lamping, make sure power is disconnected to fixture.

Install lamp into lampholder, (Fig. 1)

4. After REFLECTOR ASSEMBLY is installed, attach LENS BAFFLE by

squeezing TORSIONTITE SPRINGS together and insert through

SLOTS in REFLECTOR, then push up. (Fig.1)

5. For tamper proof installation, remove SET SCREW from outside of

LENS BAFFLE and re-install it with the allen wrench socket head facing

inside of LENS BAFFLE. Turn SET SCREW until socket head is about

1/8” inside baffle. Do not over turn. (Fig. 2) If SET SCREW was

properly installed, LENS BAFFLE should not pull down.

TO RELAMP

Disconnect power to fixture. Back out SET SCREW if used for tamper

proof installation. Lift lens up and grip top edge of baffle then pull down.

TO INSPECT AND REPLACE BALLAST

Disconnect power to fixture. Back out SET SCREW if used for tamper

proof installation. Lift lens up and grip top edge of baffle then pull down and

detaching TORSIONTITE SPRINGS. Detach REFLECTOR ASSEMBLY

by disengage REFLECTOR SPRINGS, move it to side of fixture in the

plenum, or in cylinder, remove from cylinder. See IS:C4-C12 (Frame-In Kit)

and IS:C12CS (Cylinder) for ballast replacement. After service, reverse

Installation steps.

FIG. 1

Care and Maintenance of REFLECTOR TRIM finish

If handling of REFLECTOR TRIM with anodized finish is required, the use

of clean white or plastic film gloves is recommended to avoid fingerprints.

nodized surfaces can be cleaned by the following methods:

1. Wipe off with a soft, clean, dry, lint-free cloth.

2. Wipe off with a soft clean cloth dampened in mild detergent

3. solution. Rinse, then wipe dry with lint-free cloth or paper towel.

4. Wipe off with a clean cloth dampened with a solution of wetting agent

and water (such as 2 oz. Per gallon “Pluronic L62-LF” by Wyandotte

Products). Wipe dry.

5. Use a liquid wax such as Glass Wax®. Avoid gritty cleaning agents.

FIG.2

a Genlyte company

631 Airport Road, Fall River, MA 02720

Loading...

Loading...