Page 1

Instruction Sheet Number 1104FES

Page 1 of 2 Installation Procedure for Convertible IC/Non IC Frame-In-Kits

Read and understand these instructions before installing fixture.

This fixture is intended for installation in accordance with the National Electrical Code and local regulations. To assure full compliance with local codes and

regulations, check with your local electrical inspector before installation. To prevent electrical shock, turn off electricity at fuse box before proceeding.

Retain these instructions for maintenance reference.

Warranty information on back – retain this sheet.

Installation Procedure for Convertible IC/Non IC

Frame-In-Kits 1104F13ES/18ES/26ES and 1004F13ES/18ES/26ES

Frame-In-Kits 1104F13RES/18RES/26RES and 1004F13RES/18RES/26RES

1104 Series FIK Use 1100 Series Trims (Finishing Sections) Only

1004 Series FIK Use 1000 Series Trims (Finishing Sections) Only

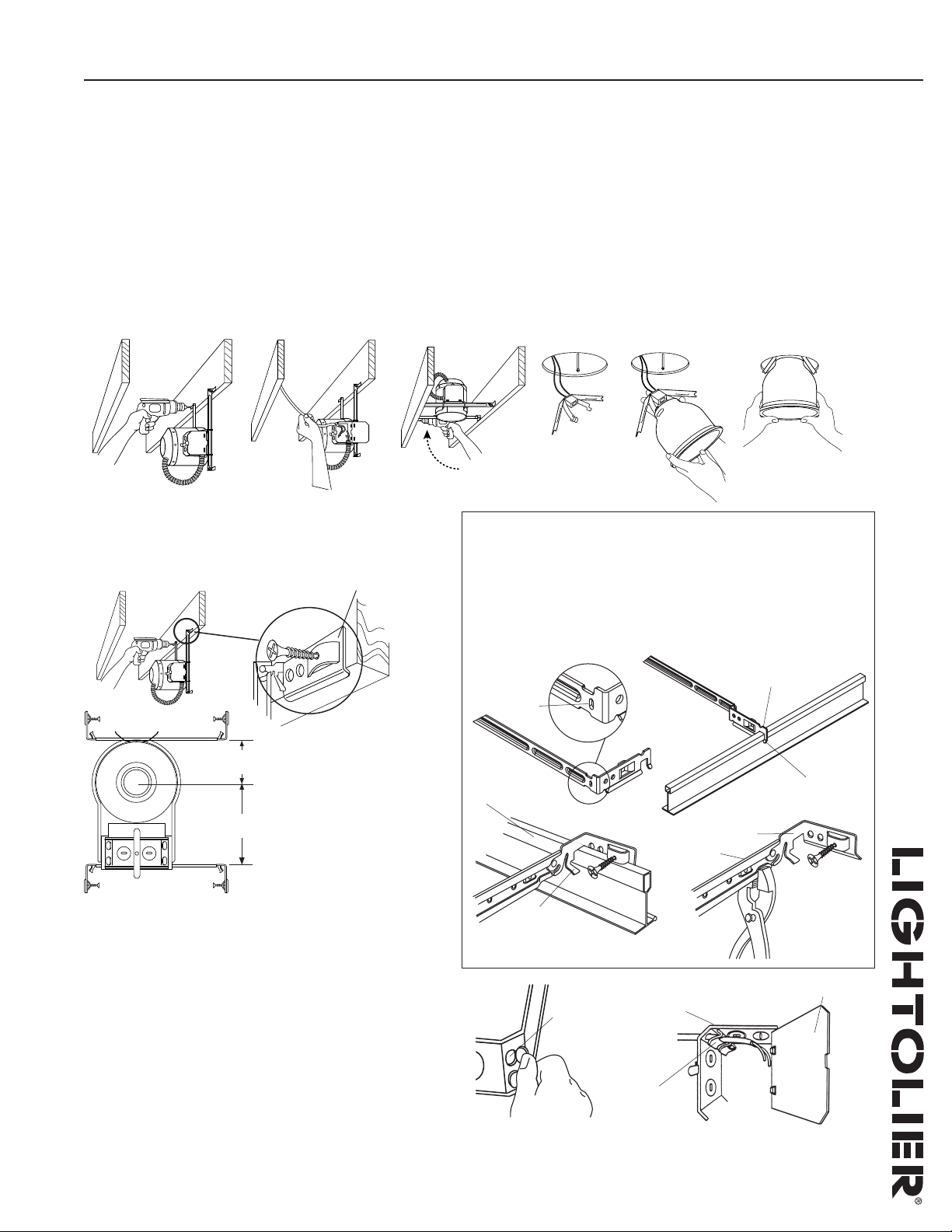

New Construction

Fig. A

Frame-In

1. Frame-In (Fig. A)

Locate fixture along joist and line up bottom edge of hinged mounting bar

with the bottom of joist and fasten in place.

2. Wire-In (Fig. B)

Open hinged J-BOX COVER fully to its locked position (lift slightly to unlock).

Open hinged KNOCK OUT to allow NON-METALLIC CABLE to enter

JUNCTION BOX. Push CABLE through CLAMP.

Note: Wiring and connections must not be placed in JUNCTION BOX in a

manner which will interfere with the CLAMPS action to provide strain relief.

Wire to SUPPLY LEADS. WHITE FIXTURE LEAD to NEUTRAL SUPPLY LEAD.

BLACK FIXTURE LEAD to HOT (120V) SUPPLY LEAD. BARE FIXTURE WIRE to

SUPPLY GROUND. Use wirenuts (local hardware item). Place all electrical

connections in the J-Box and close the J-Box cover.

3. Swing-Up (Fig. C)

Extend MOUNTING BAR to reach opposite joist and fasten in place. Adjust

to desired position along MOUNTING BAR and lock in place.

Fig. B

Wire-In

3” 1004IC

3 3/4” 1104IC

5 1/4” 1004IC

6 1/4” 1104IC

Hinged Mounting Bar

Fig. C

Swing-Up

Fig. D

Close-In

For suspended ceilings:

• Rotate HINGED BAR ENDS to position shown below and fully extend bars.

• Crimp bottom of edge of CHANNEL to prevent rotation of HINGED

BAR ENDS.

• Bend NON-HINGED end of mounting bar at featured hole location and

extend out.

• Position notched area of MOUNTING BARS onto T-BAR and lock by bending

TAB underneath T-BAR BEAD as shown.

BEND AT HOLE

T-BAR

TAB

HINGED

KNOCK OUT

Fig. E

Snap-On

HINGED BAR ENDS

CHANNEL

NON-METALLIC

SHEATHED CABLE

(12 OR 14

GAUGE ONLY)

CABLE

CLAMP

JUNCTION BOX

Fig. F

Push-Up

TAB

BEND TAB TO LOCK

J-BOX COVER

Lightolier a Genlyte company www.lightolier.com

631 Airport Road, Fall River, MA 02720 • (508) 679-8131 • Fax (508) 674-4710

We reserve the right to change details of design, materials and finish.

© 2005 Genlyte Group LLC • C1205

Page 2

Instruction Sheet Number 1104FES

LAMP

RED

BLUE

RED

BLUE

BALLAST

NUETRAL

(WHITE)

HOT

(BLACK)

GROUND

REMOVE

INSERT

BALLAST WIRE

CONNECTORS

WIRE RELEASE

BLADE

(BY OTHERS)

WIRE RELEASE

SLOTS

Page 2 of 2 Installation Procedure for Convertible IC/Non IC Frame-In-Kits

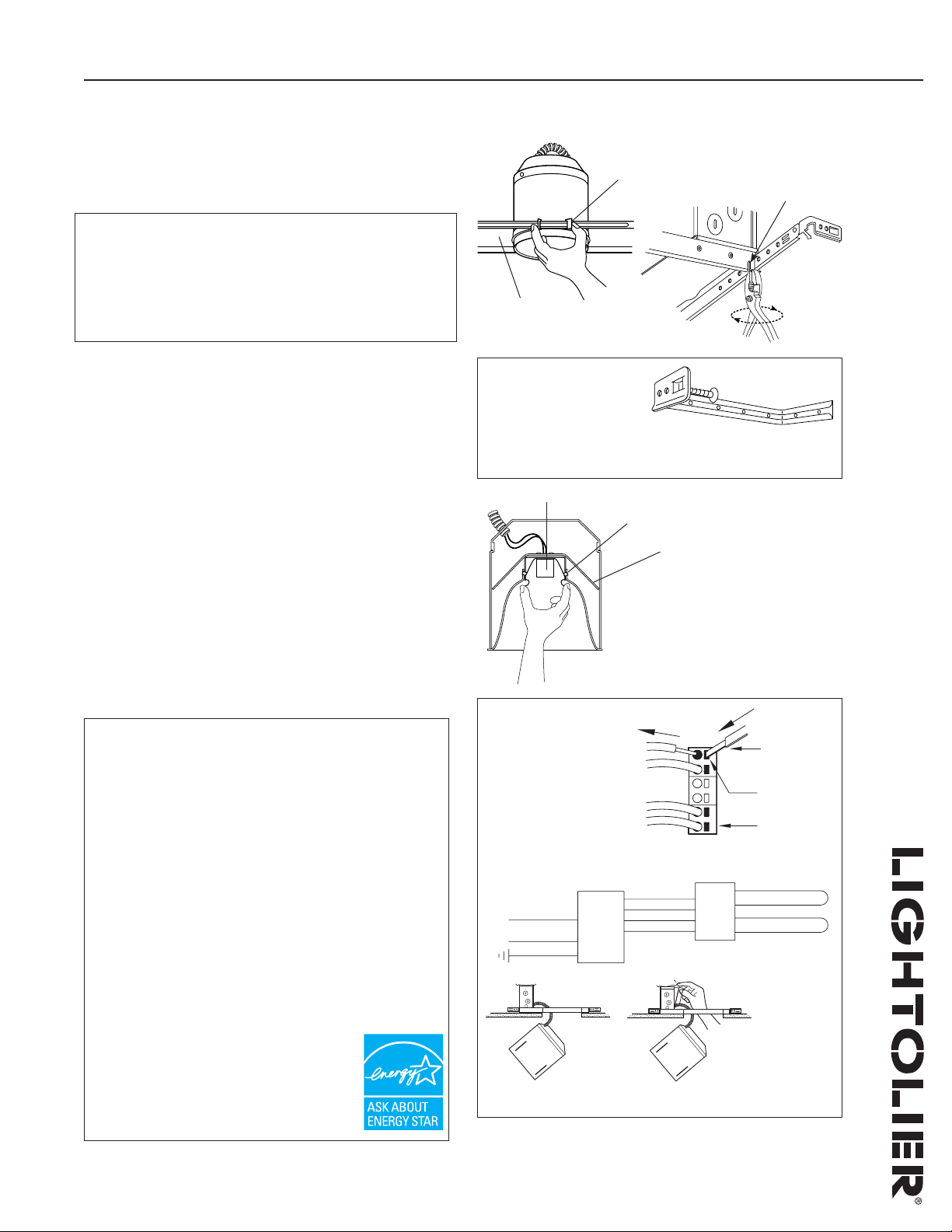

4. Close-In (Fig. D)

Install plasterboard or other dry type ceiling. Hole in board can be cut either

on the floor or after the board is secured to the ceiling using HOUSING

opening as cutting guide. HOUSING is secured by 3 screws which allow

adjustment for variable ceiling thicknesses.

5. Airseal® Installation (optional)

Option 1: Install LAS56 Flange Gasket Kit (available separately).

Option 2: Install a bead of silicone caulking compound between the ceiling

opening and edge of HOUSING. Housings are tested in accordance with

ASTM E 283 (max 2 cfm @ 75 pa) and comply with WSEC & MEC when

installed as instructed. NOTE: If factory installed tape or knockouts are

removed from vertical adjustment slots in housing wall LAS56 Flange Gasket

Kit must be used (available separately).

6. Snap-On (Fig. E)

Important - Insert SOCKET HOLDER in neck

of REFLECTOR making sure SPRING TABS

fully engage into SLOTS in REFLECTOR.

7. Push-Up (Fig. F)

Push REFLECTOR TRIM straight up until

it is tight against ceiling.

8. To remove trim (Fig. G):

• Turn off power to fixture

See Separate

Reflector Trim

}

Instruction Sheets

• Remove lamp

• Squeeze REFLECTOR SPRING from inside until the TRIM disengages.

• To retrieve SOCKET HOLDER, pull on one of the SOCKET SPRING LEGS

to disengage.

9. Ballast Replacement (Fig. H)

NOTE: Ballast replacement must be performed by a “qualified electrician.”

1. Turn power OFF.

2. DO NOT CUT WIRES. Release all wires from BALLAST WIRE

CONNECTORS by inserting small blade tool with insulated handle into

WIRE RELEASE SLOTS.

NOTE: Ballast Kits generally are supplied with this special wire release tool.

3. If Ballast is not equipped with push-in wire connectors, disconnect

Ballast from socket wires by removing wire nuts (4).

MOUNTING BAR

For Tight Spaces:

MOUNTING BAR CHANNELS

can be shortened and used as

nailing legs in tight spaces.

Simply remove INNER BAR

from holed CHANNEL, bend CHANNEL at appropriate point

and use extra screw to secure it to the joist. (Fig. D)

SOCKET

SQUEEZE CLIP

Squeeze to adjust,

release to lock

REFLECTOR SPRING

SOCKET SPRING

Fig. G

Remove Trim

Deform Material Here

for Additional Lock

TWO (2) YEAR LIMITED WARRANTY Exclusively For Energy Star®‚ Qualified Luminaires: Lightolier

warrants to you, the original purchaser, for a period of two years from the date of original retail

purchase, this product to be free from defects in materials and workmanship, when properly installed

and under normal conditions of use. Lightolier, at its sole option, will repair or replace, free of charge,

any Lightolier product found defective in workmanship or materials. The purchaser is responsible

for any costs associate with removal and re-installation of the product and shipping to and from the

manufacturer.

For warranty claims on defective ballasts within the said two-year period, Lightolier will provide a

replacement ballast of identical type and function (but not necessarily brand name) free of charge.

Lightolier is not responsible for any costs incurred to physically replace the ballast in the light fixture.

Ballast manufacturer's warranties may extend beyond a two-year time period. For defective ballast

claims outside the Lightolier warranty period, please contact the ballast manufacturer per the information noted on the ballast label.

THE MANUFACTURER LIMITS THE DURATION OF THE IMPLIED WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THE PRODUCT TO THE LIMITED

WARRANTY PERIOD SET FORTH ABOVE, AND OTHERWISE DISCLAIMS ALL IMPLIED WARRANTIES

WITH RESPECT TO THE PRODUCT AND ITS PARTS. Some states disallow certain limitations on implied

warranties, so you should consult your state law if you have a question regarding this Limitation and

disclaimer. The manufacturer disclaims any and all liability for incidental, consequential, special or

indirect damage arising out of any claimed breach of warranty or otherwise. However, some states do

not allow exclusion or limitation of such damages, so this disclaimer may not apply to you. The remedy

provided in this Limited Warranty for defective products is the purchaser's sole and exclusive remedy,

subject to your state law. Further, this Warranty gives you specific legal rights, and you may also have

other rights, which may vary from state to state.

No agent, employee or representative of Lightolier has any authority

to bind Lightolier to any affirmation, representation or warranty concerning

goods sold by Lightolier except as specifically included herein.

For all warranty claims, please call Lightolier at (866) 660-5483.

PROVIDE THIS WARRANTY TO THE END USER.

END USER SHOULD RETAIN THIS DOCUMENT FOR WARRANTY RECORDS.

Fig. H

Ballast

Replacement

U.S. and Foreign

Patents Pending

Lightolier a Genlyte company www.lightolier.com

631 Airport Road, Fall River, MA 02720 • (508) 679-8131 • Fax (508) 674-4710

We reserve the right to change details of design, materials and finish.

© 2005 Genlyte Group LLC • C1205

Loading...

Loading...