Page 1

MODELS LGO50113R, LGO50113L

LGO50113XR & LGO50113XL

LIGHT DUTY GRILL OPERATOR

OWNER’S MANUAL

Serial # Box

Installation Date

2 YEAR WARRANTY

NOT FOR RESIDENTIAL USE

LISTED DOOR OPERATOR

Page 2

2

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will

alert you to the possibility of damage to your door and/or the

door operator if you do not comply with the cautionary

statements that accompany it. Read them carefully.

Mechanical

Electrical

• BEFORE attempting to install, operate or maintain the

operator, you must read and fully understand this manual

and follow all safety instructions.

• These instructions are intended to highlight certain safety

related issues. These instructions are not intended to be

comprehensive. Because each application is unique, it is the

responsibility of the purchaser, designer, installer and end

user to ensure that the total door system is safe for its

intended use.

TABLE OF CONTENTS

WARNING

WARNING

WARNING

WARNING

CAUTION

WARNING

WARNING

WARNING

WARNING

SPECIFICATIONS

Operator Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Operator Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

PREPARATION

Operator Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

INSTALLATION

Operator Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Door Operator System Illustration . . . . . . . . . . . . . . . . . . . . . . . .6

POWER & GROUND WIRING

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Three Prong Grounding Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Permanent Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

INSTALLATION OF DOOR CONTROLS

Three Button Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Two Button/Two Position Key Switch . . . . . . . . . . . . . . . . . . . . . .8

PROGRAMMING OPERATING MODES

To Change Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

ENTRAPMENT PROTECTION ACCESSORIES

Photo Eyes and Sensing Edges . . . . . . . . . . . . . . . . . . . . . . . . . .9

Connection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

ADJUSTMENTS

Limit Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Force Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

WIRING DIAGRAM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

TROUBLESHOOTING

Testing the Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

MAINTENANCE

Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

CONTROL CONNECTIONS

Three Button Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Two Button Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Sensing Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

ILLUSTRATED PARTS

Model LGO Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Repair Parts Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

WARRANTY POLICY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

OPERATOR NOTES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-19

REPAIR PARTS & SERVICE

. . . . . . . . . . . . . . . . . . . . . . .20

Page 3

3

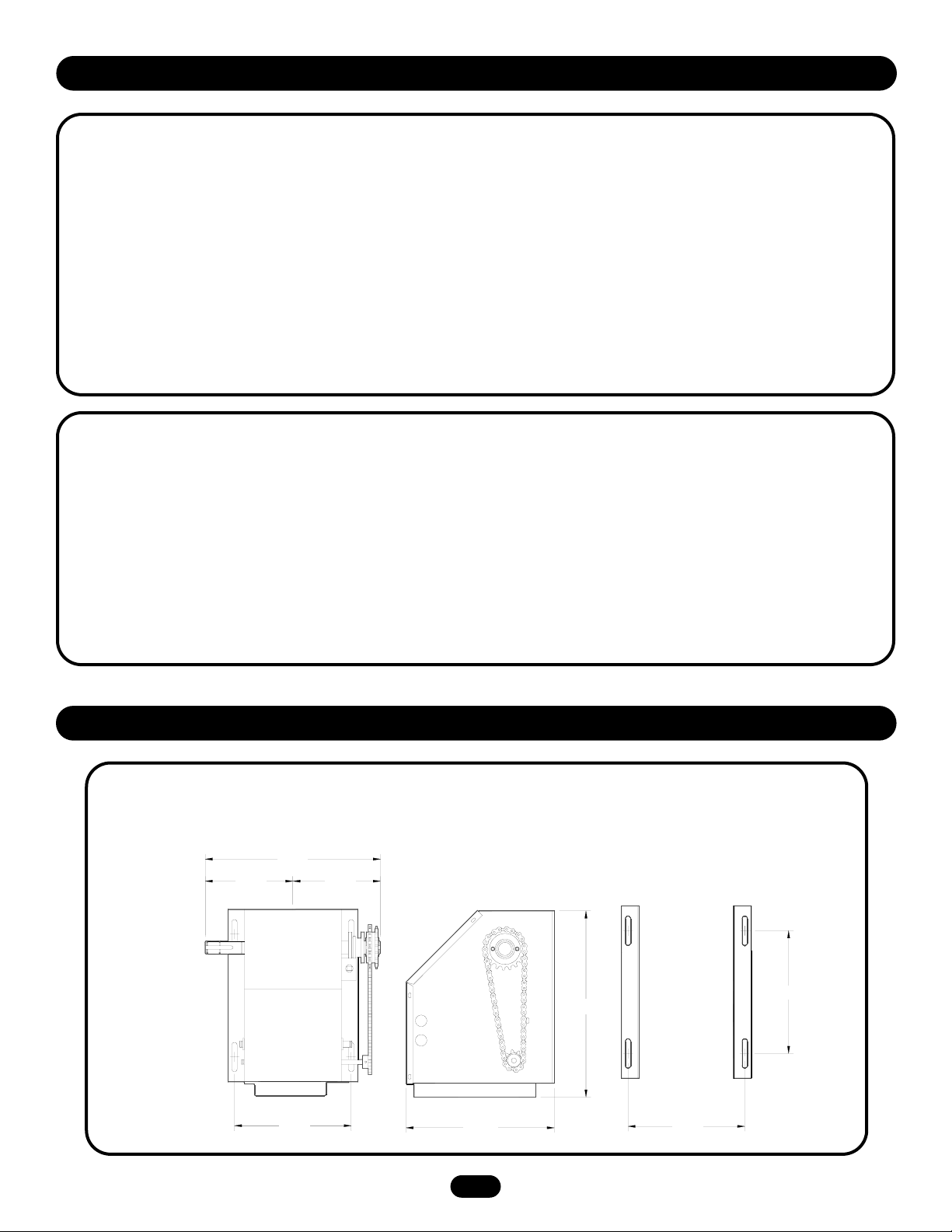

9.45"

11.42"

9.00"

14.31"

9.00"

6.75"

6.75"

13.5"

SAFETY

DISCONNECT: Floor level disconnect for emergency manual

door operation.

PHOTO EYES: Photo eyes to reverse door.

NOTE: LIFTMASTER PHOTO EYES P/N CPS-LN4 ARE

STRONGLY RECOMMENDED FOR ALL COMMERCIAL

OPERATOR INSTALLATIONS. REQUIRED WHEN ANY OTHER

CONTROL (AUTOMATIC OR MANUAL) IS USED.

MOTOR

TYPE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Intermittent Duty

HORSEPOWER: . . . . . . . . . . . . . . . . . . . . . . . . 1/2 Horsepower

SPEED: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1600 RPM

VOLTAGE: . . . . . . . . . . . . . . . . . . . . . . . . . 115V, 1 Phase, 60Hz

CURRENT: . . . . . . . . . . . . . . . . . . . . . . . . See Motor Nameplate

WEIGHTS AND DIMENSIONS

HANGING WEIGHT: 40-45 LBS.

ELECTRICAL

CONTROL STATION: NEMA 1 three button station.

OPEN/CLOSE/STOP or 2 button station OPEN/CLOSE.

RADIO: The internal radio receiver will not operate in D1

(constant pressure mode)

WIRING TYPES: B2 (Standard) Momentary contact to open,

close and stop, plus wiring for sensing device to reverse and

auxiliary devices to open and close with open override.

D1 (Optional) Constant pressure to open and close with wiring

for sensing devices to stop.

LIMIT ADJUST: Linear driven, fully adjustable screw type cams.

Adjustable to 24 feet.

MECHANICAL

DRIVE REDUCTION:

Primary: . . . . . . . . . . . . . . . . . . . . . . . . . . . .Worm Gear 16:1

Secondary: . . . . . . . . . . . . . . . . . . . . . . . .#48 Chain/Sprocket

Output: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#41 Chain

OUTPUT SHAFT SPEED: . . . . . . . . . . . . . . . . . . . . . . .40 R.P.M.

DOOR SPEED: . . . . . . . . . . . . . . .9" per sec. depending on door

OPERATOR SPECIFICATIONS

OPERATOR DIMENSIONS

Page 4

4

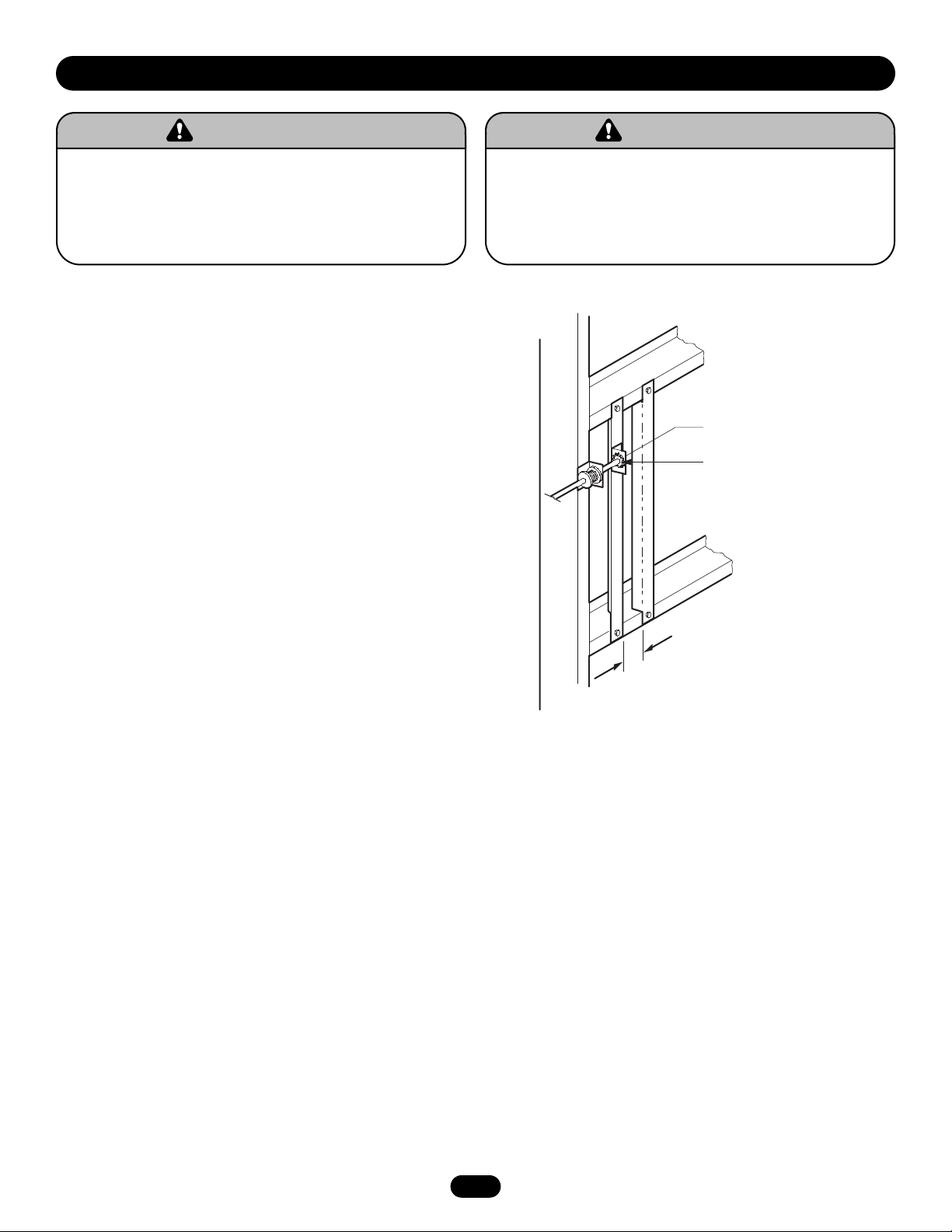

It is imperative that the wall or mounting surface provide adequate

support for the operator.

This surface must:

a. Be rigid to prevent play between operator and door shaft.

b. Provide a level base.

c. Permit the operator to be fastened securely and with the drive

shaft parallel to the door shaft.

The safety and wear of the operator will be adversely affected if

any of the above requirements are not met.

For metal buildings, fasten 2"x 2" x 3/16" (or larger) angle iron

frames to the building purlins. Retain 7" between frames.

7.00"

PREPARATION

To avoid damage to door and operator, make all door locks

inoperative. Secure lock(s) in “OPEN” position.

If the door lock needs to remain functional, install an interlock

switch.

DO NOT connect electric power until instructed to do so.

WARNING

WARNING

Keep door balanced. Sticking or binding doors MUST be

repaired. Doors, door springs, cables, pulleys, brackets and

their hardware may be under extreme tension and can cause

SERIOUS PERSONAL INJURY or DEATH. Call a professional

door serviceman to move or adjust door springs or hardware.

WARNING

WARNING

Shaft Support Bracket

with Bearing (Not Provided)

Door Sprocket

5-1/2"

Page 5

Be sure door sprocket

is properly aligned with

drive sprocket before

securing to the shaft.

5

OPTIMUM DISTANCE

12-15"

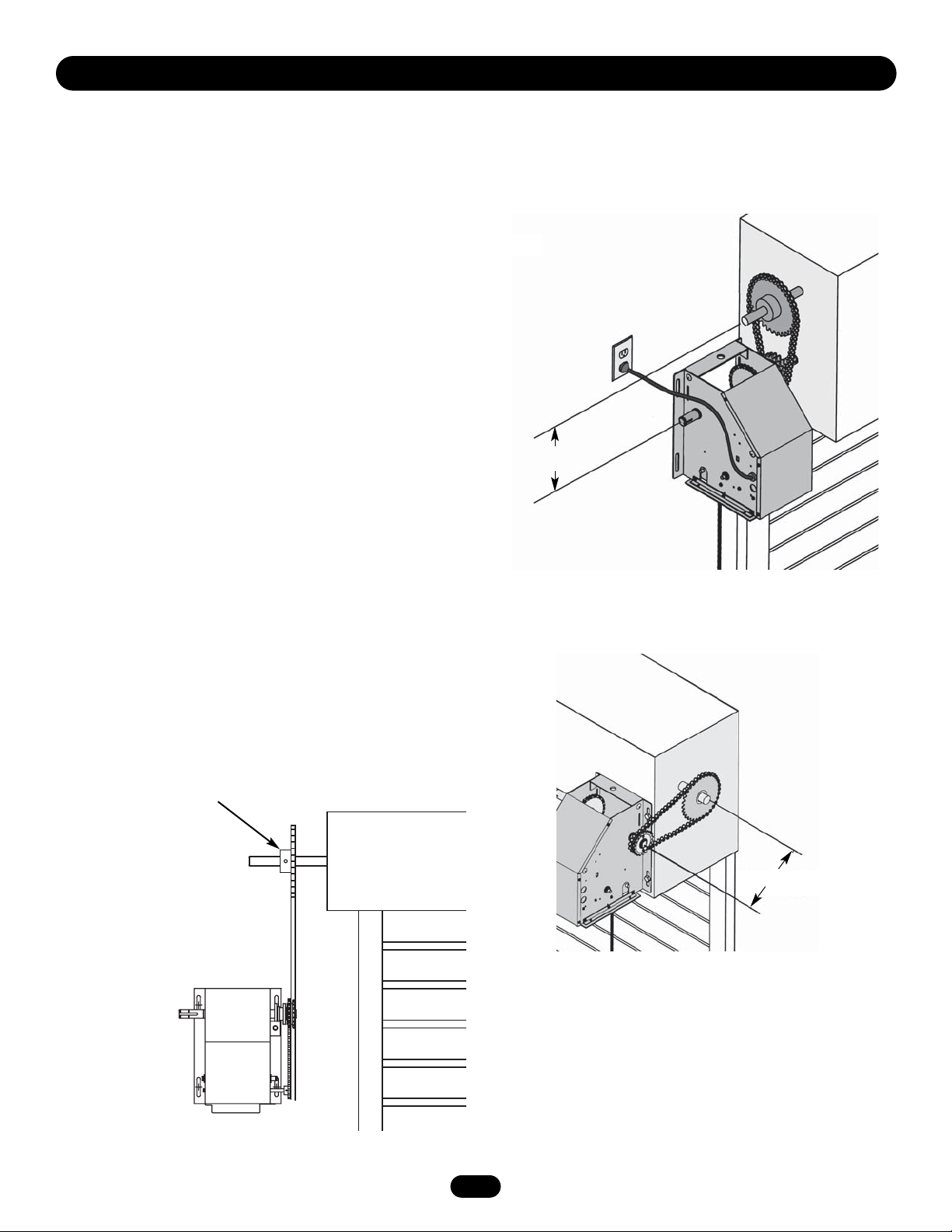

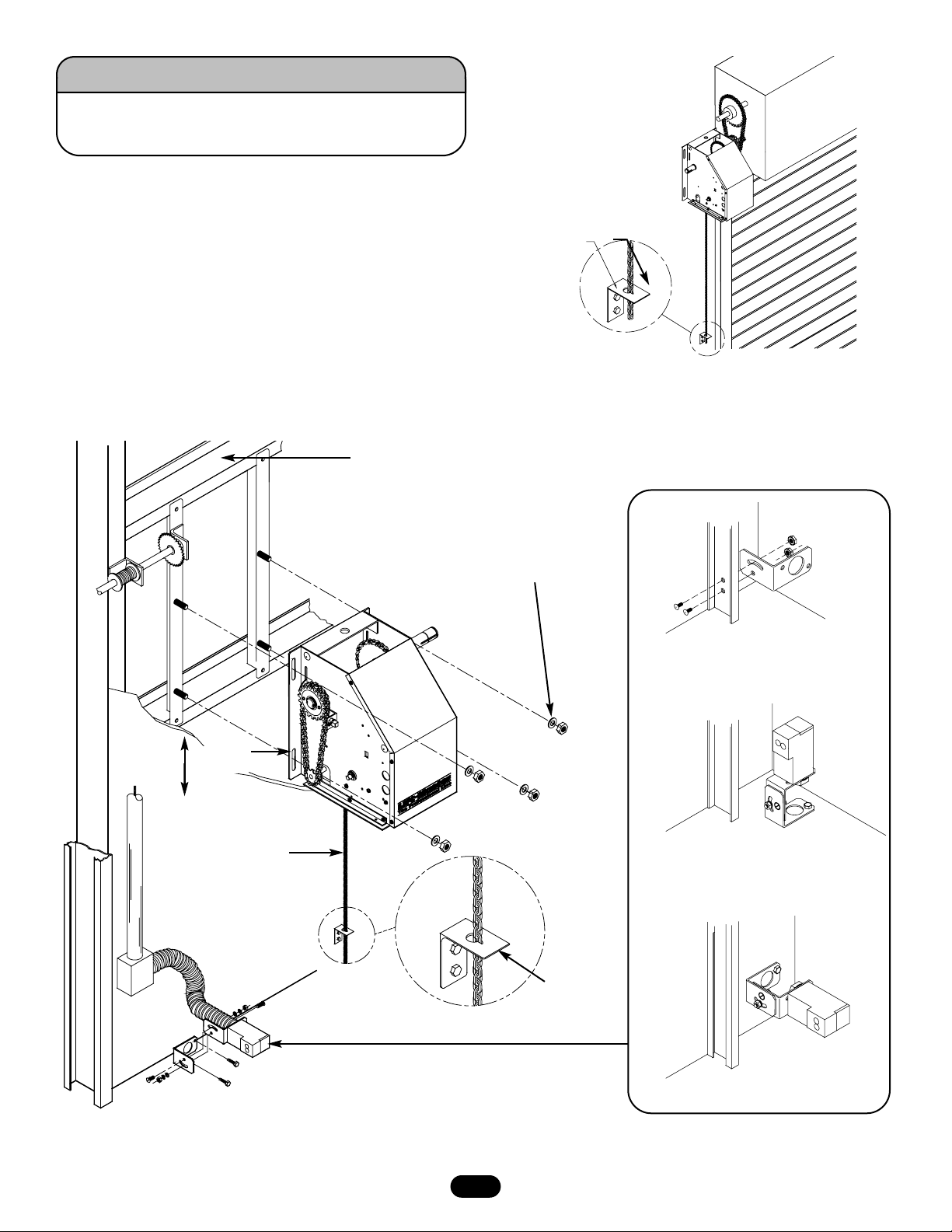

Before your operator is installed, be sure the door has been properly aligned and is working smoothly. The operator may be wall

mounted or mounted on a bracket or shelf. If necessary, refer to the preparation on page 3. Refer to the instructions below that suit

your application.

INSTALLATION

OPERATOR MOUNTING

1. Wall Mount: The operator should generally be installed below

the door shaft, and as close to the door as possible (Figure 1).

Bracket or Shelf Mount: The operator may be mounted either

above or below the door shaft (Figure 2).

IMPORTANT: The shelf or bracket must provide adequate support,

prevent play between operator and door shaft, and permit

operator to be fastened securely and with the drive shaft parallel

to the door shaft.

NOTE: The optimum distance between the door shaft and operator

drive shaft is between 12" - 15".

2. Place door sprocket on the door shaft. Do not insert the key

at this time.

3. Place drive sprocket on the appropriate side of the operator.

4. Wrap drive chain around door sprocket and join roller chain

ends together with master link.

5. Raise operator to approximate mounting position and position

chain over operator sprocket.

6. Raise or lower operator until the chain is taut (not tight).

Make sure the operator output shaft is parallel to door shaft

and sprockets are aligned. When in position, secure the

operator to wall or mounting bracket.

7. Insert keys and align sprockets and secure (Figure 3).

Figure 1

Figure 2

Figure 3

OPTIMUM DISTANCE

12-15"

Page 6

6

Keyhole Bracket

MANUAL OPERATION

This operator has a floor level disconnect chain to disconnect the

door from the door operator.

a. To disengage, pull the chain and secure in the disengaged

position by slipping the end through the keyhole bracket

mounted on the wall. If emergency egress device is used, pull

handle to disengage operator from the door.

b. The door may now be pushed up or pulled down manually.

Release the disconnect chain to operate the door again

electrically.

DOOR OPERATING SYSTEM ILLUSTRATION

ALTERNATE MOUNTING

FOR OPTIONAL PHOTO EYES

Rigid Mounting Surface

Keyhole

Bracket

Mounting Hardware

(Not Provided)

Track Mount

Floor Mount

Wall Mount

Pull Chain for

Manual Operation

Turn off power to the operator BEFORE manually operating

your door.

WARNING

CAUTION

WARNING

WARNING

To Adjust

Tension

Page 7

Ground Wire

Ground

Screw

White

Wires

Black

Wires

Figure 3

7

THREE PRONG GROUNDING PLUG

To avoid installation difficulties, do not run the operator at this time.

To reduce the risk of electric shock, this operator has a grounding

type plug with a third grounding pin. This plug will only fit into a

grounding type outlet. If the plug does not fit into the outlet you

have, contact a qualified electrician to install the proper outlet. Do

not change the plug in any way (Figure 1).

PERMANENT WIRING

If permanent wiring is required by your local code, refer to the

following procedure:

To make a permanent connection through the 7/8" diameter hole

in the side of the operator:

1. Remove the cover screws and set the cover aside (Figure 2).

2. Remove the 3-prong cord.

3. Connect the black (hot) wire to the screw on the brass terminal;

the white (neutral) wire to the screw on the silver terminal; and

the ground wire to the green ground screw. The operator must

be grounded (Figure 3).

4. Re-install the cover.

Cover Screws

Figure 1

Figure 2

POWER WIRING & GROUND WIRING

To reduce the risk of SEVERE INJURY or DEATH:

• ANY maintenance to the operator or in the area near the

operator MUST not be performed until disconnecting the

electrical power and locking-out the power via the operator

power switch. Upon completion of maintenance the area MUST

be cleared and secured, at that time the unit may be returned

to service.

• Disconnecting power at the fuse box BEFORE proceeding.

Operator MUST be properly grounded and connected in

accordance with local electrical codes. The operator should be

on a separate fused line of adequate capacity.

• ALL electrical connections MUST be made by a qualified

individual.

• DO NOT install ANY wiring or attempt to run the operator

without consulting the wiring diagram. We recommend that

you install an optional reversing edge before proceeding with

the control station installation.

• ALL power wiring should be on a dedicated circuit and well

protected. The location of the power disconnect should be

visible and clearly labeled.

• ALL power and control wiring MUST be run in separate

conduit.

• BEFORE installing power wiring or control stations be sure to

follow all specifications and warnings described below. Failure

to do so may result in SEVERE INJURY to persons and/or

damage to operator.

WARNING

WARNING

Page 8

8

TWO-BUTTON/TWO POSITION KEY SWITCH

Operator must be programmed to D1 Mode. See programming

instructions, page 9.

1. Locate the door control within sight of the door at a minimum

height of 5 feet where small children cannot reach, and away

from all moving parts of the door and door hardware.

2. Fasten the door control button securely with 6AB X 1-1/2"

screws. If installing into drywall, drill 5/32" holes and use

anchors provided.

3. Run the wire up the wall to the operator. Use insulated staples

to secure the wire in several places. Be careful not to pierce

the wire with a staple.

4. Receiver terminal screws are located inside the operator

access panel on the interface board. Connect each wire to the

corresponding interface board terminals: the “OPEN” terminal

of the wall control connects to “OPEN,” the “CLOSE” terminal

of the wall control connects to “CLOSE,” and the common

terminal of the wall control connects to “CMN” (Figure 2).

THREE BUTTON STATION (STANDARD)

Operator must be programmed to B2 Mode. See programming

instructions, page 9.

1. Locate the door control within sight of the door at a minimum

height of 5 feet where small children cannot reach, and away

from all moving parts of the door and door hardware.

2. Fasten the door control button securely with 6AB X 1-1/2"

screws. If installing into drywall, drill 5/32" holes and use

anchors provided.

3. Run the wire up the wall to the operator. Use insulated staples

to secure the wire in several places. Be careful not to pierce

the wire with a staple.

4. Receiver terminal screws are located inside the operator

access panel on the interface board. Connect each wire to the

corresponding interface board terminals: the “OPEN” terminal

of the wall control connects to “OPEN,” the “CLOSE” terminal

of the wall control connects to “CLOSE,” the “STOP” terminal

connects to “SBC/STOP,” and the common terminal of the wall

control connects to “CMN” (Figure 1).

WARNING

MOUNT WARNING NOTICE

INSTALLATION OF DOOR CONTROLS

Figure 1

Figure 2

WAR N ING

TO PREVENT ENTRAPMENT

DO NOT START DOOR DOWNWARD

UNLESS DOORWAY IS CLEAR

Warning Notice

Page 9

9

PHOTO EYES AND SENSING EDGES

Sensing devices supplied for door industry type operators with an

isolated normally open (N.O.) dry contact output are compatible

with your operator. This includes pneumatic and electric edges,

and through beam and retro reflective photo eyes. If your door

does not have bottom safety photo eyes or a sensing edge and

you wish to add a safety device to your application, please

contact your local LiftMaster Authorized Dealer.

If not pre-installed by the door manufacturer, mount the sensing

edge on the door according to the instructions provided with the

edge. The sensing edge may be electrically connected by either

coiled cord or take-up reel.

IMPORTANT NOTES:

• To install a sensing edge, ask for sensing edge connection kit

LGOSE. This must be installed in order to add a sensing edge.

Refer to instructions on page 10.

• Proceed with Limit Switch Adjustments before making any

sensing edge wiring connections to operator as described

below.

• Electrician must hard-wire the junction box to the operator

electrical box in accordance with local codes.

TAKE-UP REEL: Take-up reel should be installed 12" above the top

of the door.

COIL CORD: Connect operator end of coil cord to junction box

(not provided) fastened to the wall approximately halfway up the

door opening.

TO CHANGE OPERATING MODES

(FACTORY SET TO B2 MODE):

1. Press and hold the LEARN button (The learn LED will light).

NOTE: If the learn/mode button is held for 5 seconds, all learned

transmitters will be erased.

2. To learn the appropriate mode: While holding the LEARN button,

press the corresponding button on the interfaceboard.

B2 Mode: CLOSE Button (S3)

D1 Mode: OPEN Button (S2)

3. Release both buttons. The LEARN LED gives a visual indication of

the mode programmed.

B2 Mode = 2 Blinks

D1 Mode = 1 Blink

PROGRAMMING OPERATING MODES

ENTRAPMENT PROTECTION ACCESSORIES

IMPORTANT NOTE: When optional photo eyes (IR’s) are used,

Wiring Mode B2 must be reprogrammed. IR’s must be connected

and sending a pulse prior to programming. See programming

instructions above.

It is strongly recommended that a safety photo eye or sensing

edge be used in conjunction with the operator.

WARNING

CAUTION

WARNING

WARNING

Page 10

10

CONNECTION PROCEDURE

1. Run the wires from the edge to the operator. Use a take-up

reel or coil cord for this purpose.

2. Refer to local codes for all wiring requirements.

3. Connect one side of the edge to the sensing edge cutout

switch (white wire) using the wire nut supplied.

4. Connect the other side of the sensing edge to the interface

board (IR WH/BK) terminal.

5. Run the door in the close direction, activate edge, and confirm

that the door reverses.

Wire

Nut

Sensing Edge

Switch

S3

Close

S2

Open

Edge

S1

Stop

IR WH/BK

IR WHITE

STOP/SBC

CMN

OPEN

CLOSE

Page 11

11

LIMIT SWITCH ADJUSTMENT

1. To adjust limit nuts, depress retaining plate to allow nut to

spin freely. After adjustment, release plate and ensure it seats

fully in slots of both nuts.

2. To increase door travel, spin nut away from actuator. To

decrease door travel, spin limit nut toward actuator.

3. Adjust open limit nut so that door will stop in open position

with the bottom of the door even with top of door opening.

4. Repeat Steps 1 and 2 for close cycle. Adjust close limit nut so

that actuator is engaged as door fully seats at the floor.

FORCE ADJUSTMENT

The open/down force adjustments are made by adjusting two

control knobs inside the operator end panel. One knob controls

the drive force adjustment. The second knob controls the

sensitivity, which is the change of force as seen by the operator.

To set the forces

1. Adjust the drive force to minimum and the sensitivity to

minimum.

2. Increase the drive force in 10 degree increments until the door

travels freely from limit to limit.

3. Increase the sensitivity in 10 degrees until the door begins to

reverse/stop in mid-travel.

4. Decrease the sensitivity by 10 degrees and run the door

through a complete cycle to confirm normal operation.

If the door stops normal travel of open/close to the limits,

decrease the dive and sensitivity knobs to minimum and repeat

steps 2 through 4.

DRIVE FORCE SENSITIVITY

NOTE: Make sure the limit nuts are positioned between the

limit switch actuators before proceeding with adjustments.

ADJUSTMENTS

To avoid SERIOUS PERSONAL INJURY or DEATH from

electrocution, disconnect electric power BEFORE manually

moving limit nuts.

WARNING

WARNING

Page 12

12

IR BK\WH

IR WHITE

STOP/SBC

CMN

OPEN

CLOSE

CLOSE

OPEN STOP

GY

GY BRYE

MOTOR

CAPACITOR

BL

RD

WH

1

2

3

BK

WH

RD

IN

POWER

9

8

7

6

5

4

3

2

1

RPM

OPEN CLOSE

YE

YE

GY/WH

BR

PU

WH

BK

BL

RD

YE

PU

GY/WH

GY

GROUND

DEVICE

SENSING

GN

BK

WH

OPEN

CLOSE

CONTROL WIRING

POWER WIRING

THREE

BUTTON

WALL CONTROL

GN

BK

WH

STOP

WIRING DIAGRAM

Page 13

13

TESTING THE OPERATOR

Turn on power. Test all controls and safety devices to make sure

they are working properly. It will be necessary to refer to page 11

for fine adjustment of the limit switches.

IMPORTANT NOTES:

• Do not leave operator power on unless all safety and

entrapment protection devices have been tested and are

working properly.

•. Be sure you have read and understand all Safety Instructions

included in this manual.

• Be sure the owner or person(s) responsible for operation of the

door have read and understand the Safety Instructions, know

how to electrically operate the door in a safe manner, and know

how to use the manual disconnect operation of the door

operating system.

TROUBLESHOOTING GUIDE

SITUATION PROBABLE CAUSE & SOLUTION

The door operates from the door control, but not from

the remote control.

The door doesn’t open completely.

The door opens but won’t close.

The door reverses for no apparent reason.

The operator does not operate from either the door

control or the remote control.

Are you in the correct operating mode?

Is the remote programmed?

If the door has been working properly but now doesn’t open

all the way, readjust the force setting.

Check the safety reversal system; check the sensitivity.

Remove any obstruction and check the safety reversing

system. In two-button mode, check for shorted wires to the

reversing edge. Check drive force and sensitivity adjustments.

Are you in the proper operating mode for the wall control?

Is the wall control properly wired to the interface board?

TROUBLESHOOTING

Do NOT place hands or tools in or near the operator when the

power is on or when testing control or safety devices. To avoid

SERIOUS PERSONAL INJURY or DEATH from electrocution,

ALWAYS disconnect electric power BEFORE servicing or

adjusting the operator.

WARNING

WARNING

Page 14

14

Use SAE 30 Oil (Never use grease or silicone spray).

Repeat ALL procedures.

Do not lubricate motor. Motor bearings are rated for

continuous operation.

Inspect and service whenever a malfunction is observed or

suspected.

CAUTION: BEFORE SERVICING, ALWAYS DISCONNECT

OPERATOR FROM POWER SUPPLY.

Check at the intervals listed in the following chart.

ATTENTION ELECTRICIAN

Use 16 gauge or heavier for all control wiring.

OPEN

CLOSE

CMN

SBC/STOP

CLOSE

OPEN

CMN

IR BK\WH

IR WHITE

SENSING DEVICES

THREE BUTTON STATION TWO BUTTON STATION

MAINTENANCE SCHEDULE

CONTROL CONNECTIONS

EVERY EVERY EVERY

ITEM PROCEDURE 3 MONTHS 6 MONTHS 12 MONTHS

Drive Chain Check for excessive slack.

Check and adjust as required.

Lubricate.

Sprockets Check set screw tightness.

Fasteners Check and tighten, as required.

Manual Disconnect Check and operate.

Bearings and Shafts Check for wear and lubricate.

Page 15

15

5

L11

L13

L10

L15

L16

E7

7

E2

E1

E8

E14

L9

L12

11

L14

L18

L17

4

10

E12

S2

S3

R10

S1

M1

M2

E11

E4

E17

2

E15

E9

E10

E3

E13

E6

M3

9

8

4

3

E16

9

8

D6

D2

D7

D12

D11

L4

L3

1

D13

D1

D5

D13

R1

R5

R4

R3

R9

L8

L1

L6

L7

R2

L20

R3

R5

R7

R6

L6

L5

L7

L2

O6

O2

O6

O4

O5

O3

D4

D8

O4

D10

D9

O5

O3

O1

R8

D9

D14

D3

ILLUSTRATED PARTS

Page 16

16

MODEL LGO REPAIR PARTS KITS

Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or accessories are included

with your operator, certain components may be added or removed from these lists. Individual components of each kit may not be

available. Please consult a parts and service representative regarding availability of individual components.

K75-16424 MOTOR KIT

ITEM PART # DESCRIPTION QTY

M1 --- Motor 1

M2 --- Bracket 1

M3 11A34 Bearing, Oil Impregnated 1

K72-16422 OUTPUT SHAFT KIT

ITEM PART # DESCRIPTION QTY

O1 11-15646 Output Shaft, 1" 1

O2 15-48B32LXX Sprocket, 1" I.D., 32 Tooth 1

O3 12-10715 Bushing, 1" I.D., Keyed 2

O4 80-206-10 Shim Washer, 1" I.D., .015 Thk 6

O5 87-E-100 E-Ring, 1" 2

O6 86-RP10-200 Roll Pin, 5/16" X 2" Long 1

ELECTRONICS

ITEM PART # DESCRIPTION QTY

E1 K001A5251-4 Logic Board 1

E2 82-WX08-06T Screw, #8-32 X 3/8" Long 2

E3 29-10339 Capacitor 1

E4 10-10351 Capacitor Bracket 1

E5 171A384 Screw, #8-32 1

E6 1B3878 Terminal Block, 120 Volt 1

E7 --- Shield, PCB Panel 1

E8 --- Standoff 2

E9 K79-15491 PCB, 3 Button Interface 1

E10 216A149 Washer, Term. Cup #8, Ground 1

E11 --- Ground Screw 1

E12 41B4245 Power Cord, 4 Foot 1

E13 --- Strain Relief, Power Cord 1

E14 10-15641 Bracket, 120 Volt Terminal Block 1

E15 10-15640 Bracket, PCB Interface 1

E16 75-13705 Standoff Assy. PCB Interface 4

E17 171A0384 Screw, #8-32 3

K72-16423 DISCONNECT SHAFT KIT

ITEM PART # DESCRIPTION QTY

D1 10-11394 Release Lever 1

D2 11-15648 Disconnect Shaft 1

D3 75-11377 Sprocket 1

D4 07-11419 Disconnect Hub 1

D5 19-8A-12 Sash Chain, 12' 1

D6 --- Support Bracket 1

D7 10-11023 Bevel Gear Yoke 1

D8 18-10467 Spring, Compression 1

D9 87-E-100 E-Ring, 1", Plated 2

D10 80-11416 Key, Disconnect, 1/4 X 1/4 X 7/8" 2

D11 82-SH10-12 Screw, #10-32, H.H. Socket 2

D12 85-LS-10 Lock Washer, #10, ZP 2

D13 86-CP04-112 Cotter Pin, 1/8 X 1-3/4" Long 4

D14 86-RP04-100 Roll Pin, 1/8" dia X 1" 2

D15 80-206-11 Washer, 1" I.D. X 1-1/16" Thk 1

INDIVIDUAL COMPONENTS

K72-16421 LIMIT SHAFT KIT

K72-16425 REDUCTION SHAFT KIT

K75-16426 RPM SENSOR KIT

K74-16420 LIMIT SWITCH KIT

ITEM PART # DESCRIPTION QTY

S1 --- RPM Board 1

S2 --- Bracket 1

S3 --- Interrupter Cup 1

ITEM PART # DESCRIPTION QTY

R1 --- Shaft, Reduction, 1/2" 1

R2 81B45 Drive Gear, 1/2" I.D. 1

R3 146A53 Roll Pin, .187 X 15/16" Long 2

R4 15-48B12CXX Sprocket, 1/2" I.D., 12 Tooth 1

R5 --- Bushing, 1/2" I.D., Keyed 2

R6 216A148 Shim Washer, 1/2" I.D., .030 Thk 4

R7 158A30 E-Ring, 1/2" 2

R8 22A3 Chain, #48, 54 Pitch 1

R9 146A53 Roll Pin, 3/16" X 15/16" Long 1

R10 81C179 Worm Gear 1

ITEM PART # DESCRIPTION QTY

L9 --- Screw, #10-32 x 1/2" 4

L10 --- Depress Plate 1

L11 146A53 Roll Pin, .187 X 15/16" Long 2

L12 82-PX06-16 Screw #6-32 x 1" 2

L13 84-LH-06 Nut #6-32 2

L14 31-12542 Standoff 2

L15 82-PX04-20 Screw #4-40 4

L16 10-12806 Nut Plate, Through 2

L17 10-12553 Nut Plate, Threaded 2

L18 23-10041 Limit Switch 2

ITEM PART # DESCRIPTION QTY

L1 --- Limit Shaft 3/8" 1

L2 13-10024 Limit Nut 2

L3 15-48B9A1 Sprocket, 9 Tooth 1

L4 86-RP04-100 Roll Pin, 1/8" dia X 1" 1

L5 12-10028 Bushing, 3/8" I.D., Keyed 2

L6 87-E-038 E-Ring, 3/8" 2

L7 80-10025 Shim Washer, 3/8"dia. X .050 Thk 2

L8 80-10026 Shim Washer 3/8"dia. X .010 Thk 6

ITEM PART # DESCRIPTION QTY

1 10-15643 Frame 2

2 --- Frame, Spacer 3

3 --- Bracket,Panel Shield Mtg. 1

4 --- Screw, #8-32 X 3/8" long 14

5 --- Rivet 3

6 --- Screw, Captive Mounting 2

7 --- Hinge 1

8 --- Bolt,Carriage Head, 5/16-18 X 1" 6

9 --- Nut, Serrated Flange, 5/16-18 6

10 10-15644 Cover 1

11 10-15642 Limit Frame 1

Page 17

LIFTMASTER®TWO YEAR LIMITED WARRANTY

The Chamberlain Group, Inc. warrants to the first retail purchaser of this product, for the structure in which this product is originally

installed, that it is free from defect in materials and/or workmanship for a period of two years from the date of purchase. The proper

operation of this product is dependent on your compliance with the instructions regarding installation, operation, maintenance and

testing. Failure to comply strictly with those instructions will void this limited warranty in its entirety.

If, during the limited warranty period, this product appears to contain a defect covered by this limited warranty, call 1-800-528-2806,

toll free, before dismantling this product. Then send this product, pre-paid and insured, to our service center for warranty repair. You

will be advised of shipping instructions when you call. Please include a brief description of the problem and a dated proof-of-purchase

receipt with any product returned for warranty repair. Products returned to Seller for warranty repair, which upon receipt by Seller are

confirmed to be defective and covered by this limited warranty, will be repaired or replaced (at Seller’s sole option) at no cost to you

and returned pre-paid. Defective parts will be repaired or replaced with new or factory-rebuilt parts at Seller’s sole option.

ALL IMPLIED WARRANTIES FOR THE PRODUCT, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO THE TWO YEAR LIMITED

WARRANTY PERIOD SET FORTH ABOVE, AND NO IMPLIED WARRANTIES WILL EXIST OR APPLY AFTER SUCH PERIOD. Some states

do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. THIS LIMITED

WARRANTY DOES NOT COVER NON-DEFECT DAMAGE, DAMAGE CAUSED BY IMPROPER INSTALLATION, OPERATION OR CARE

(INCLUDING, BUT NOT LIMITED TO ABUSE, MISUSE, FAILURE TO PROVIDE REASONABLE AND NECESSARY MAINTENANCE,

UNAUTHORIZED REPAIRS OR ANY ALTERATIONS TO THIS PRODUCT), LABOR CHARGES FOR REINSTALLING A REPAIRED OR

REPLACED UNIT, OR REPLACEMENT OF BATTERIES.

THIS LIMITED WARRANTY DOES NOT COVER ANY PROBLEMS WITH, OR RELATING TO, THE GARAGE DOOR OR GARAGE DOOR

HARDWARE, INCLUDING BUT NOT LIMITED TO THE DOOR SPRINGS, DOOR ROLLERS, DOOR ALIGNMENT OR HINGES. THIS

LIMITED WARRANTY ALSO DOES NOT COVER ANY PROBLEMS CAUSED BY INTERFERENCE. ANY SERVICE CALL THAT

DETERMINES THE PROBLEM HAS BEEN CAUSED BY ANY OF THESE ITEMS COULD RESULT IN A FEE TO YOU.

UNDER NO CIRCUMSTANCES SHALL SELLER BE LIABLE FOR CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES ARISING IN

CONNECTION WITH USE, OR INABILITY TO USE, THIS PRODUCT. IN NO EVENT SHALL SELLER’S LIABILITY FOR BREACH OF

WARRANTY, BREACH OF CONTRACT, NEGLIGENCE OR STRICT LIABILITY EXCEED THE COST OF THE PRODUCT COVERED HEREBY.

NO PERSON IS AUTHORIZED TO ASSUME FOR US ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF THIS PRODUCT.

Some states do not allow the exclusion or limitation of consequential, incidental or special damages, so the above limitation or

exclusion may not apply to you. This limited warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

WARRANTY POLICY

17

Page 18

18

OPERATOR NOTES

Page 19

19

OPERATOR NOTES

Page 20

© 2005, The Chamberlain Group, Inc.

01-32369B All Rights Reserved Printed in Mexico

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION

SPANS AMERICA

INSTALLATION AND SERVICE INFORMATION

ARE AVAILABLE 6 DAYS A WEEK

CALL OUR TOLL FREE NUMBER

1-800-528-2806

HOURS 6:00 a.m. TO 7:00 p.m. (Central Std. Time)

MONDAY Through FRIDAY

HOURS 8:00 a.m. TO 6:00 p.m. (Central Std. Time)

SATURDAY

www.liftmaster.com

WHEN ORDERING REPAIR PARTS

PLEASE SUPPLY THE FOLLOWING INFORMATION:

PART NUMBER DESCRIPTION MODEL NUMBER

ADDRESS ORDER TO:

THE CHAMBERLAIN GROUP, INC.

Electronic Parts & Service Dept.

6020 S. Country Club Road

Tucson, AZ 85706

REPAIR PARTS & SERVICE

Loading...

Loading...