Page 1

NOT FOR RESIDENTIAL USE

Serial #

(located on electrical box cover)

Installation Date

Wiring Type

2 YEAR WARRANTY

OWNER'S MANUAL

MODEL LGO

LIGHT DUTY GRILL OPERATOR

Page 2

SPECIFICATIONS

MOTOR

TYPE: ...............................Intermittent duty

HORSEPOWER: ..............1/2 Horsepower

SPEED: ............................1600 RPM

VOLTAGE:........................115V, 1 Phase, 60Hz

CURRENT: .......................See motor nameplate

MECHANICAL

DRIVE REDUCTION:

Primary: ............................Worm Gear 16:1

Secondary:........................#48 chain/ sprocket

Output: ..............................#41 chain.

ELECTRICAL

CONTROL STATION:.......NEMA 1 three button station.

OPEN/CLOSE/STOP or 2 button station OPEN/CLOSE.

RADIO: .............................The internal radio receiver will

not operate in D1 (constant pressure mode)

WIRING TYPES: ..............B2 (Standard) Momentary

contact to open, close and stop, plus wiring for sensing

device to reverse and auxiliary devices to open and

close with open override.

D1 (Optional) ....................Constant pressure to open

and close with wiring for sensing devices to stop.

LIMIT ADJUST: ................Linear driven, fully adjustable

screw type cams. Adjustable to 24 feet.

SAFETY

DISCONNECT: ....................Floor level disconnect for

emergency manual door operation.

PHOTO EYES : ....................Photo eyes to reverse

door.

OUTPUT SHAFT SPEED:.......

DOOR SPEED

door

:....................

40 R.P.M.

9” per sec. depending on

WEIGHTS AND DIMENSIONS

HANGING WEIGHT: .........40-45 LBS.

13.5”

6.75”

6.75”

LIFT MASTER PHOTO EYES P/N CPS-LN4 ARE

STRONGLY RECOMMENDED FOR ALL COMMER-

CIAL OPERATOR INSTALLATIONS. REQUIRED

WHEN ANY OTHER CONTROL (AUTOMATIC OR

MANUAL) IS USED.

9.45”

14.31”

9.00”

11.42”

2

9.00”

Page 3

SITE PREPARATIONS

TO AVOID DAMAGE TO DOOR AND OPERATOR,

MAKE ALL DOOR LOCKS INOPERATIVE.

SECURE LOCK(S) IN "OPEN" POSITION.

IF THE DOOR LOCK NEEDS TO REMAIN FUNCTIONAL, INSTALL AN INTERLOCK SWITCH.

DO NOT CONNECT ELECTRIC POWER UNTIL

INSTRUCTED TO DO SO.

KEEP DOOR BALANCED. STICKING OR BINDING

DOORS MUST BE REPAIRED. DOORS, DOOR

SPRINGS, CABLES, PULLEYS, BRACKETS AND

THEIR HARDWARE MAY BE UNDER EXTREME

TENSION AND CAN CAUSE SERIOUS PERSONAL

INJURY. CALL A PROFESSIONAL DOOR SERVICEMAN TO MOVE OR ADJUST DOOR SPRINGS

OR HARDWARE.

WARNING

CAUTION

WARNING

WARNING

WARNING

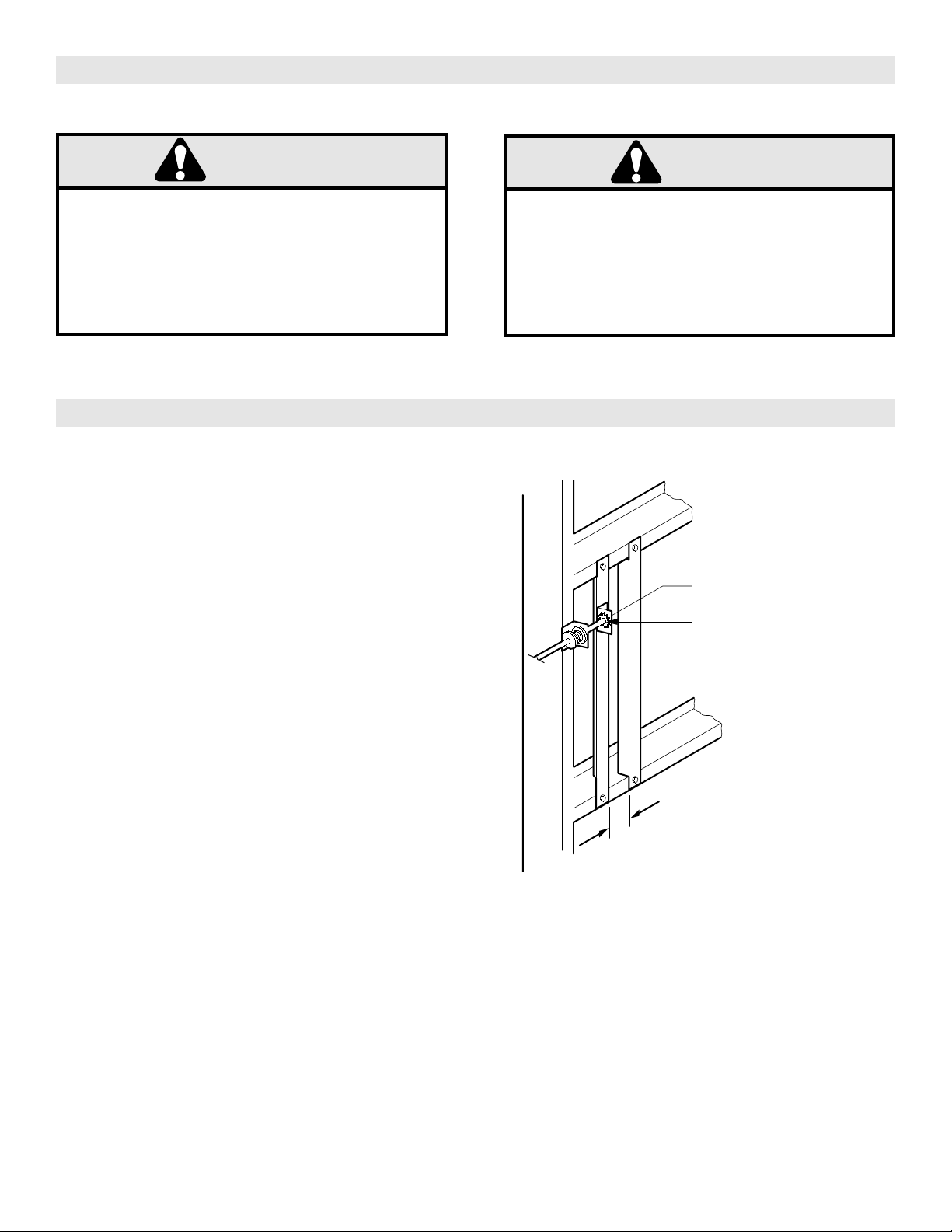

It is imperative that the wall or mounting surface provide

adequate support for the operator.

This surface must:

a) Be rigid to prevent play between operator

and door shaft.

b) Provide a level base.

c) Permit the operator to be fastened

securely and with the drive shaft parallel

to the door shaft.

The safety and wear of the operator will be adversely

affected if any of the above requirements are not met.

For metal buildings, fasten 2” x 2” x 3/16” (or larger) angle

iron frames to the building purlins. Retain 7” between

frames. Refer to figure 1.

7.00”

3

IMPORTANT SAFETY NOTES

CAUTION

WARNING

Shaft Support Bracket

with Bearing (Not Supplied)

Door Sprocket

2-1/4"

FIGURE 1

Page 4

OPERATOR MOUNTING

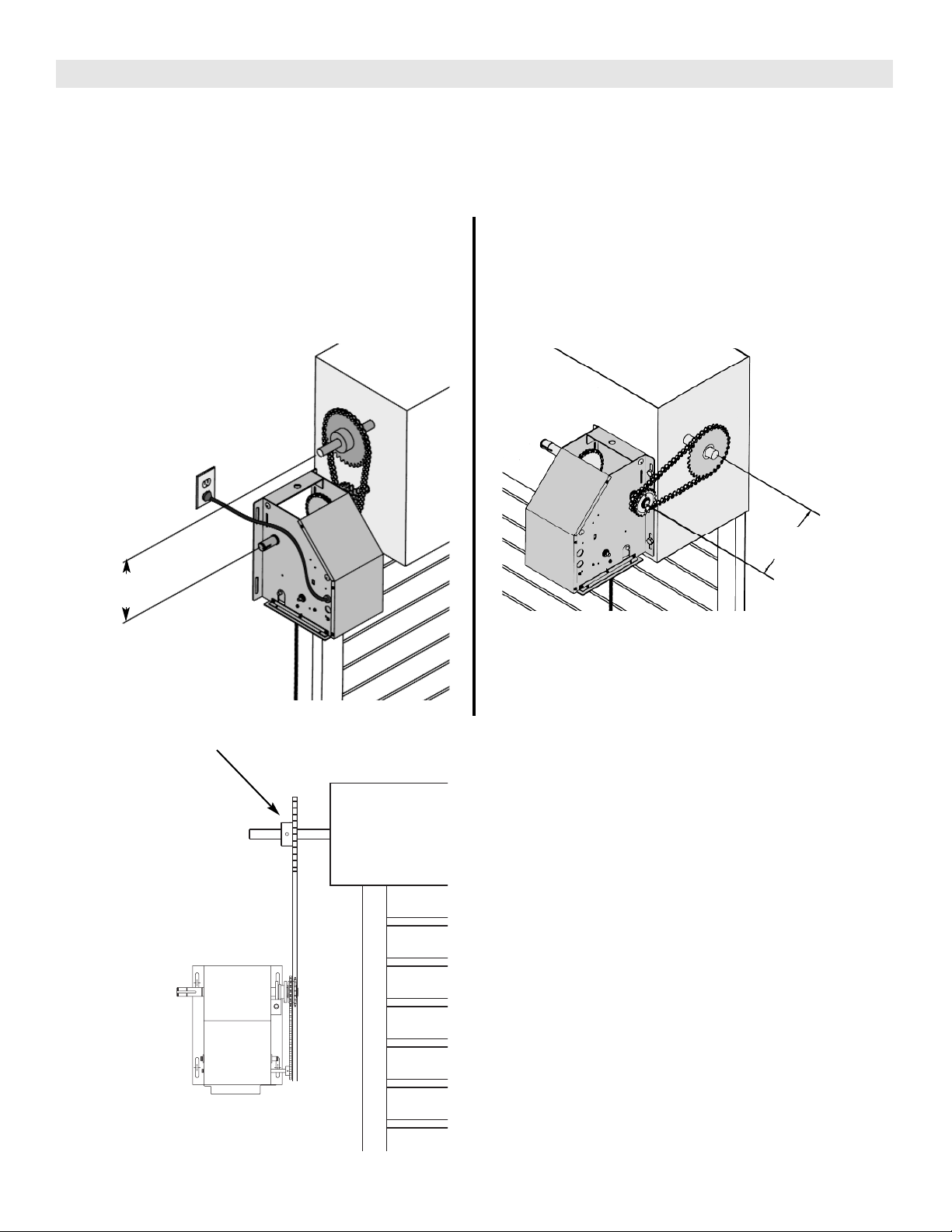

Before your operator is installed, be sure the door has been properly aligned and is working smoothly. The operator may

be wall mounted or mounted on a bracket or shelf. If necessary, refer to the operator preparations on page 3. Refer to

the illustration and instructions below that suits your application.

1a. Wall Mounting

The operator should generally be installed below the

door shaft, and as close to the door as possible. The

optimum distance between the door shaft and opera

tor drive shaft is between 12” - 15”. Refer to figure 2.

FIGURE 2

OPTIMUM DISTANCE

12-15”

1b. Bracket or Shelf Mounting

The operator may be mounted either above or below

the door shaft. The optimum distance between the

door shaft and operator drive shaft is between 12” 15”. Refer to figure 3.

FIGURE 3

OPTIMUM DISTANCE

12-15”

IMPORTANT: The shelf or bracket must provide adequate support, prevent play between

operator and door shaft, and permit operator

to be fastened securely and with the drive

shaft parallel to the door shaft.

Be sure door sprocket is

properly aligned with

drive sprocket before

securing to the shaft.

FIGURE 4

IMPORTANT: The shelf or bracket must provide adequate support, prevent play between operator and

door shaft, and permit operator to be fastened

securely and with the drive shaft parallel to the door

shaft.

1c. Place door sprocket on the door shaft. Do not insert

the key at this time.

2. Place drive sprocket on the appropriate side of the

operator.

3. Wrap drive chain around door sprocket and join roller

chain ends together with master link.

4. Raise operator to approximate mounting position and

position chain over operator sprocket.

5. Raise or lower operator until the chain is taut (not

tight). Make sure the operator output shaft is parallel

to door shaft and sprockets are aligned. When in

position, secure the operator to wall or mounting

bracket.

6. Insert keys and align sprockets and secure. Refer to

figure 4.

4

Page 5

5

EMERGENCY MANUAL OPERATION

This operator has a floor level disconnect chain to disconnect the door from the door operator.

a) To disengage, pull the chain and secure in the disengaged position by slipping the end through the keyhole

bracket mounted on the wall. Or if emergency egress

device is used, pull handle to disengage operator from

the door.

b) The door may now be pushed up or pulled down

manually. Release the disconnect chain to operate the

door again electrically. Refer to figure 5.

KEYHOLE BRACKET

FIGURE 5

DOOR OPERATING SYSTEM ILLUSTRATION

ALTERNATE MOUNTING

FOR OPTIONAL PHOTO EYES

RIGID MOUNTING SURFACE

TO ADJUST

TENSION

KEYHOLE

BRACKET

MOUNTING HARDWARE

NOT SUPPLIED

TRACK MOUNT

FLOOR MOUNT

WALL MOUNT

PULL CHAIN FOR

MANUAL OPERATION

Page 6

POWER WIRING

THREE PRONG GROUNDING PLUG

To reduce the risk of shock, this operator has a grounding

type plug, that has a third (grounding) pin. This plug will

only fit into a grounding type outlet. If this plug does not

fit into the outlet, contact a qualified electrician to install

the proper outlet. Do not change the plug in any way.

Refer to figure 6.

PERMANENT WIRING

If permanent wiring is required by your local code,

refer to the following procedure:

To make a permanent connection through the 7/8” diameter hole in the side of the operator:

1. Remove the opener cover screws and set the cover

aside. Refer to figure 8.

2. Remove the 3-prong cord.

3. Connect the black (line) wire to the screw on the brass

terminal; the white (neutral) wire to the screw on the

silver terminal; and the ground wire to the green

ground screw. The opener must be grounded. Refer

to figure 7.

4. Re-install the cover.

To prevent electrocution, remove power from the

garage door opener and from the circuit you plan to

use for the permanent connection.

FIGURE 6

FIGURE 7

GROUND WIRE

GROUND

SCREW

BLACK

WIRES

FIGURE 8

LOOSEN 2 COVER SCREWS FOR ACCESS

TO POWER/ CONTROL WIRING AND LIMIT/

FORCE ADJUSTMENTS.

WHITE

WIRES

6

Page 7

7

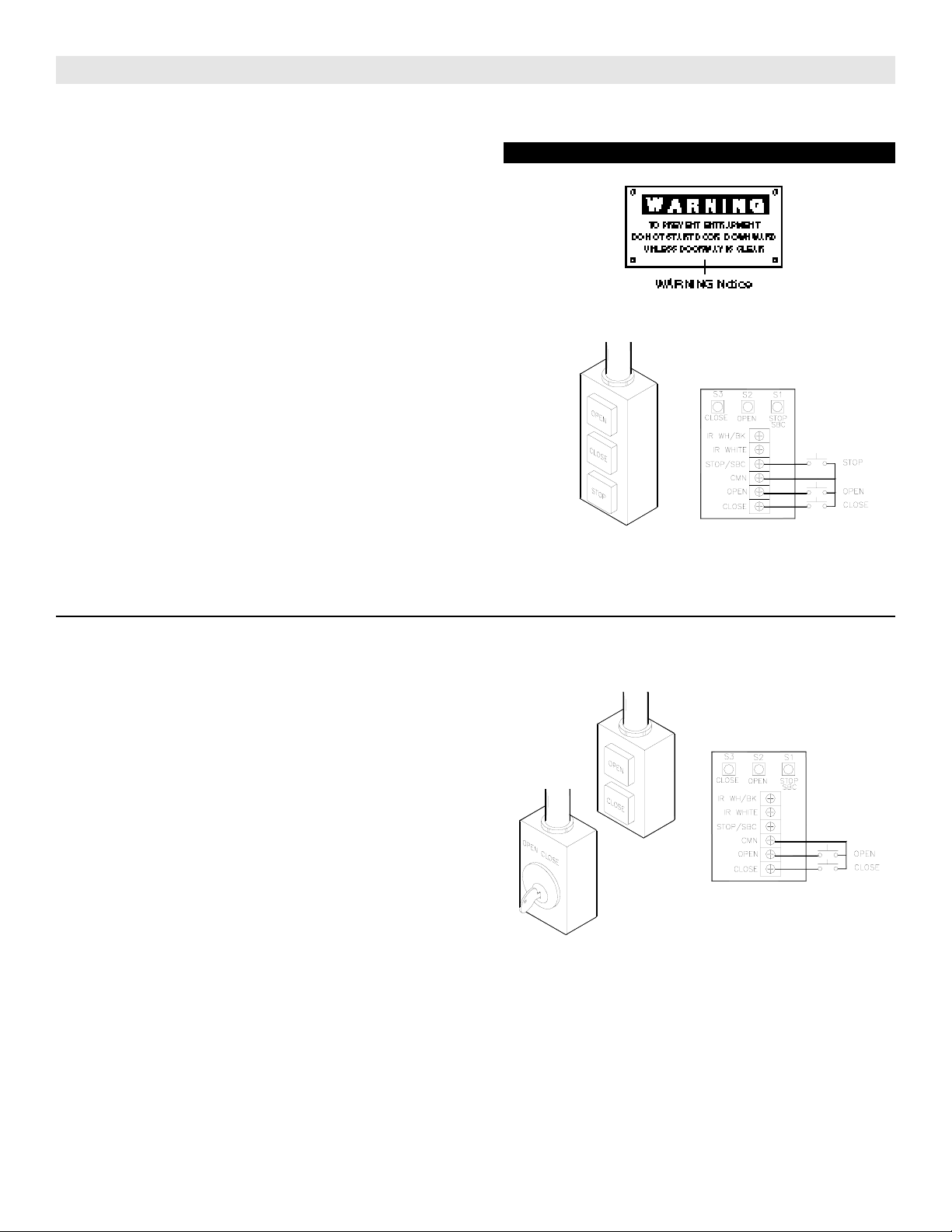

INSTALLATION OF DOOR CONTROLS

TWO-BUTTON/TWO POSITION KEY SWITCH:

Operator must be programmed to D1 Mode, See programming instructions below.

1. Locate the door control within sight of the door at a

minimum height of 5 feet where small children cannot

reach, and away from all moving parts of the door and

door hardware.

2. Fasten the door control button securely with 6AB X 1-

1/2” screws. If installing into drywall, drill 5/32” holes and

use anchors provided.

3. Run the wire up the wall to the opener. Use insulated

staples to secure the wire in several places. Be careful

not to pierce the wire with a staple.

4. Receiver terminal screws are located inside the oper-

ator access panel on the interface board. Connect each

wire to the corresponding interface board terminals- The

“OPEN” terminal of the wall control connects to “OPEN”,

the “CLOSE” terminal of the wall control connects to

“CLOSE”, and the common terminal of the wall control

connects to “CMN”. Refer to figure 10.

THREE BUTTON STATION (STANDARD)

Operator must be programmed to B2 Mode, See programming instructions below.

1. Locate the door control within sight of the door at a

minimum height of 5 feet where small children cannot

reach, and away from all moving parts of the door and

door hardware.

2. Fasten the door control button securely with 6AB X 1-

1/2” screws. If installing into drywall, drill 5/32” holes and

use anchors provided.

3. Run the wire up the wall to the opener. Use insulated

staples to secure the wire in several places. Be careful

not to pierce the wire with a staple.

4. Receiver terminal screws are located inside the oper-

ator access panel on the interface board. Connect each

wire to the corresponding interface board terminals- The

“OPEN” terminal of the wall control connects to “OPEN”,

the “CLOSE” terminal of the wall control connects to

“CLOSE”, the “STOP” terminal connects to “SBC /

STOP”, and the common terminal of the wall control connects to “CMN”. Refer to figure 9.

MOUNT WARNING NOTICE

FIGURE 10

FIGURE 9

Page 8

PROGRAMMING OPERATING MODES

To Change Operating Modes: (Factory Set to B2 Mode)

1. Press and hold the LEARN button (The learn LED will light).

NOTE: IF THE LEARN/MODE BUTTON IS HELD FOR 5 SECONDS, ALL LEARNED TRANSMITTERS WILL BE

ERASED.

2. To learn the appropriate mode: While holding the LEARN button, press the corresponding button on the interfaceboard.

B2 Mode: CLOSE Button (S3)

D1 Mode: OPEN Button (S2)

3. Release both buttons. The LEARN LED gives a visual indication of the mode programmed.

B2 Mode = 2 Blinks

D1 Mode = 1 Blink

IMPORT

connected and sending a pulse prior to programming. See programming instructions above.

ANT NOTE: When optional photo eyes (IR’s) are used, Wiring Mode B2 must be reprogrammed. IR’s must be

SAFETY EDGE

SENSING EDGES

All types of sensing edges with an isolated normally open

(N.O.) output are compatible with your operator. This

includes pneumatic and electric edges. If your door does

not have a bottom sensing edge and you wish to purchase one, contact the supplier of your operator.

If not pre-installed by the door manufacturer, mount the

sensing edge on the door according to the instructions

provided with the edge. The sensing edge may be electrically connected by either coiled cord or take-up reel.

Refer to the steps below.

Important Notes:

a) To install a sensing edge, ask for sensing edge con-

nection kit LGOSE. This must be installed in order to

add a sensing edge. Refer to instructions and figure 11 on page 9.

b) Proceed with Limit Switch Adjustments before making

any sensing edge wiring connections to operator as

described below.

c) Electrician must hard-wire the junction box to the oper-

ator electrical box in accordance with local codes.

TAKE-UP REEL: Take-up reel should be installed 12"

above the top of the door.

COIL CORD: Connect operator end of coil cord to junction box (not supplied) fastened to the wall approximately halfway up the door opening.

8

Page 9

9

CONNECTING SAFETY EDGE

IR WH/BK

IR WHITE

STOP/SBC

CMN

OPEN

CLOSE

CLOSE OPEN STOP

S3 S2 S1

a) Run the wires from the edge to the operator. Use a take-up reel or coil cord for this purpose.

b) Refer to local codes for all wiring requirements.

c) Connect one side of the edge to the sensing edge cutout switch (white wire) using the wire nut supplied.

d) Connect the other side of the sensing edge to the interface board (IR WH/BK) terminal.

e) Run the door in the close direction, activate edge, and confirm that the door reverses. Refer to figure 11.

SENSING EDGE

SWITCH

EDGE

WIRE

NUT

Page 10

LIMIT ADJUSTMENTS

1. To adjust limit nuts depress retaining plate to allow nut

to spin freely. After adjustment, release plate and

ensure it seats fully in slots of both nuts.

2. To increase door travel, spin nut away from actuator.

To decrease door travel, spin limit nut toward

actuator.

TO AVOID SERIOUS PERSONAL INJURY OR DEATH

FROM ELECTROCUTION, DISCONNECT ELECTRIC

POWER BEFORE MANUALLY MOVING LIMIT NUTS.

3. Adjust open limit nut so that door will stop in open

position with the bottom of the door even with top of

door opening.

4. Repeat Steps 1 and 2 for close cycle. Adjust close limit

nut so that actuator is engaged as door fully seats at

the floor. Refer to figure 12.

FIGURE 12

MAKE SURE THE LIMIT NUTS ARE POSITIONED BETWEEN THE LIMIT

SWITCH ACTUATORS BEFORE PROCEEDING WITH ADJUSTMENTS.

If other problems persist, call our toll-free number for

assistance 1 (800)528-2806

FORCE ADJUSTMENTS

The open/down force adjustments are made by adjusting

two control knobs inside the operator end panel. One

knob controls the drive force adjustment. The second

knob controls the sensitivity, which is the change of force

as seen by the operator.

To set the forces

1. Adjust the drive force to minimum and the sensitivity

to minimum.

2. Increase the drive force in 10 degree increments until

the door travels freely from limit to limit.

3. Increase the sensitivity in 10 degrees until the door

begins to reverse/stop in mid-travel.

4. Decrease the sensitivity by 10 degrees and run the

door through a complete cycle to confirm normal

operation. Refer to figure 13.

If the door stops normal travel of open/close to the limits,

decrease the dive and sensitivity knobs to minimum and

repeat steps 2 through 4.

FIGURE 13

10

DRIVE FORCE

SENSITIVITY

Page 11

11

IR BK\WH

IR WHITE

STOP/SBC

CMN

OPEN

CLOSE

CLOSE

OPEN STOP

GY

GY

BRYE

MOTOR

CAPACITOR

BL RD

WH

1

2

3

BK

WH

RD

IN

POWER

9

8

7

6

5

4

3

2

1

RPM

OPEN CLOSE

YE

YE

GY/WH

BR

PU

WH

BK

BL

RD

YE

PU

GY/WH

GY

GROUND

DEVICE

SENSING

GN

BK

WH

OPEN

CLOSE

CONTROL WIRING

POWER WIRING

THREE

BUTTON

WALL CONTROL

GN

BK

WH

STOP

WIRING DIAGRAM

Page 12

TESTING THE OPERATOR

Turn on power. Test all controls and safety devices to

make sure they are working properly. It will be necessary

to refer back to page 9 for fine adjustment of the limit

switches.

IMPORTANT NOTES:

1. Do not leave operator power on unless all safety and

entrapment protection devices have been tested and are

working properly.

2. Be sure you have read and understand all Safety

Instructions included in this manual.

3. Be sure the owner or person(s) responsible for opera-

tion of the door have read and understand the Safety

Instructions, know how to electrically operate the door in a

safe manner, and know how to use the manual disconnect operation of the door operating system.

DO NOT PLACE HANDS OR TOOLS IN OR NEAR

THE OPERATOR WHEN THE POWER IS ON OR

WHEN TESTING CONTROL OR SAFETY DEVICES.

ALWAYS DISCONNECT POWER BEFORE SERVICING OR ADJUSTING THE OPERATOR.

TROUBLE SHOOTING

Situation Probable cause & solution

The door operates from the door control,

but not from the remote control

The door doesn’t open completely

The door opens but won’t close

The door reverses for no apparent

reason

The operator does not operate from

either the door control or the remote

control

Are you in the correct operating mode?

Is the remote programmed?

If the door has been working properly, but now doesn’t

open all the way, re-adjust the force setting

Check the safety reversal system, check the sensitivity

Remove any obstruction, and check the safety reversing

system. In two-button mode, check for shorted wires to the

reversing edge. Check drive force and sensitivity adjustments.

Are you in the proper operating mode for the wall control?

Is the wall control properly wired to the interface board?

12

Page 13

13

HOW TO ORDER REPAIR PARTS

OUR LARGE SERVICE ORGANIZATION

SPANS AMERICA

INSTALLATION AND SERVICE INFORMATION

ARE AVAILABLE 6 DAYS A WEEK

CALL OUR TOLL FREE NUMBER - 1-800-528-2806

HOURS 7:00 TO 3:30 p.m. (Mountain Std. Time)

MONDAY Through SATURDAY

WHEN ORDERING REPAIR PARTS

PLEASE SUPPLY THE FOLLOWING INFORMATION:

PART NUMBER DESCRIPTION MODEL NUMBER

ADDRESS ORDER TO:

THE CHAMBERLAIN GROUP, INC.

Electronic Parts & Service Dept.

2301 N. Forbes Blvd., Suite 104

Tucson, AZ 85745

MAINTENANCE SCHEDULE

**

Use SAE 30 Oil (Never use grease or silicone spray).

Repeat ALL procedures.

Do not lubricate motor. Motor bearings are rated for continuous operation.

Inspect and service whenever a malfunction is observed or suspected.

CAUTION: BEFORE SERVICING, ALWAYS DISCONNECT OPERATOR FROM POWER SUPPLY.

Check at the intervals listed in the following chart.

EVERY EVERY EVERY

ITEM PROCEDURE 3 MONTHS 6 MONTHS 12 MONTHS

Drive Chain Check for excessive slack.

Check & adjust as required.

Lubricate.*

z

z

Sprockets Check set screw tightness

z z

Fasteners Check & tighten as required

z z

Manual Disconnect Check & Operate

z z

Bearings & Shafts Check for wear & lubricate

z z

Page 14

ILLUSTRATED PARTS – MODEL LGO

5

7

L16

E7

L15

L10

L18

L14

10

11

D13

L13

E10

E15

L3

L11

L7

L4

E1

E8

E2

E16

3

4

8

D6

8

D1

D2

9

D12

D7

D11

D13

E6

E11

E9

1

D5

D3

E17

2

L6

9

R8

L2

E4

L5

R7

L9

E14

E13

E3

L1

R1

R2

R6

R5

O4

D8

D4

O5

L17

R3

R3

L12

D10

O3

L8

E12

L7

R5

R9

S2

S3

L6

S4

R4

O1

R10

O6

S1

4

M3

M1

L20

O2

O3

M2

O5

O4

O6

D14

D9

D9

14

Page 15

15

INDIVIDUAL COMPONENTS

ITEM PART # DESCRIPTION QTY

1

2

3

4

5

6

7

8

9

10

11

Frame

Frame, Spacer

Bracket,Panel Shield Mtg.

Screw, #8-32 X 3/8” long

Rivet

Screw, Captive Mounting

Hinge

Bolt,Carriage Head, 5/16-18 X 1”

Nut, Serrated Flange, 5/16-18

Cover

Limit Frame

2

3

1

14

3

2

1

6

6

1

1

10-15643

10-15637

10-15645

82-WX08-06T

80-487-7

82-WS08-08C

80-15636

82-RN31-08

84-FN-31

10-15644

10-15642

K72-16421 LIMIT SHAFT KIT

ITEM PART # DESCRIPTION QTY

L1

L2

L3

L4

L5

L6

L7

L8

Shaft, Limit 3/8”

Limit Nut

Sprocket, 9 Tooth

Roll Pin, 1/8” dia X 1”

Bushing, 3/8” I.D., Keyed

E-Ring, 3/8”

Shim Washer, 3/8”dia. X .050 Thk

Shim Washer 3/8”dia. X .010 Thk

1

2

1

1

2

2

2

6

11-15647

13-10024

15-48B9A1

86-RP04-100

12-10028

87-E-038

80-10025

80-10026

K72-16423 DISCONNECT SHAFT KIT

ITEM PART # DESCRIPTION QTY

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

Lever, Release

Shaft, Disconnect

Sprocket Assy

Disconnect Hub

Sash Chain, 12’

Support Bracket

Bevel Gear Yoke

Spring, Compression

E-Ring, 1”, Plated

Key, Disconnect, 1/4 X 1/4 X 7/8”

Screw, #10-32, H.H. Socket

Lock Washer, #10, ZP

Cotter Pin, 1/8 X 1-3/4” Long

Roll Pin, 1/8” dia X 1” Long

Washer, 1” I.D. X 1-1/16” Thk

1

1

1

1

1

1

1

1

2

2

2

2

4

2

1

10-11394

11-15648

75-11377

07-11419

19-8A-12

10-11358

10-11023

18-10467

87-E-100

80-11416

82-SH10-12

85-LS-10

86-CP04-112

86-RP04-100

80-206-11

ELECTRONICS

ITEM PART # DESCRIPTION QTY

E1

E2

E3

E4

E5

E6

E7

E8

E9

E10

E11

E12

E13

E14

E15

E16

E17

PCB Assy, LGO April Logic

Screw, #8-32 X 3/8” Long

Capacitor, Motor

Bracket, Capacitor

Screw, #8-32

Terminal Block, 120 Volt

Shield, PCB Panel

Standoff, End Panel

PCB, 3 Button Interface

Washer, Term. Cup #8, Ground

Ground Screw

Power Cord, 4 Foot

Strain Relief, Power Cord

Bracket, 120 Volt Terminal Block

Bracket, PCB Interface

Standoff Assy. PCB Interface

Screw, #8-32

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

4

3

79-16088

82-WX08-06T

030B0432

10-10351

171A0384

001B3878

10-15639

80-15649

79-15491

216A0149

171A0453

026B0073

028A0078

10-15641

10-15640

75-13705

171A0384

K72-16422 OUTPUT SHAFT KIT

ITEM PART # DESCRIPTION QTY

O1

O2

O3

O4

O5

O6

Shaft, Output,1”

Sprocket, 1” I.D., 32 Tooth

Bushing, 1” I.D., Keyed

Shim Washer, 1” I.D., .015 Thk

E-Ring, 1”

Roll Pin, 5/16” X 2” Long

1

1

2

6

2

1

11-15646

15-48B32LXX

12-10715

80-206-10

87-E-100

86-RP10-200

K72-16425 REDUCTION SHAFT KIT

ITEM PART # DESCRIPTION QTY

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

Shaft, Reduction, 1/2”

Drive Gear, 1/2” I.D.

Roll Pin, .187 X 15/16” Long

Sprocket, 1/2” I.D., 12 Tooth

Bushing, 1/2” I.D., Keyed

Shim Washer, 1/2” I.D., .030 Thk

E-Ring, 1/2”

Chain, #48, 54 Pitch

Roll Pin, 3/16” X 15/16” Long

Worm Gear

1

1

2

1

2

4

2

1

1

1

11-15645

081B0045

146A0053

15-48B12CXX

011S0041

216A0148

158A0030

022A0003

146A0053

081C0179

K75-16424 MOTOR KIT

ITEM PART # DESCRIPTION QTY

M1

M2

M3

Motor

Bracket, Motor Assy

Bearing, Oil Impregnated

1

1

1

123D0155

012D0381

011A0034

K75-16426 RPM SENSOR KIT

ITEM PART # DESCRIPTION QTY

S1

S2

S3

S4

PCB

Bracket, PCB

Interrupter Cup

Ring, Interrupter Cup

1

1

1

1

001B3000

093D0148

158A0062

158A0040

K74-16420 LIMIT SWITCH KIT

ITEM PART # DESCRIPTION QTY

L9

L10

L11

L12

L13

L14

L15

L16

L17

L18

Screw, #10-32 x 1/2”

Depress Plate

Spring, Depress Plate

Screw, Depress Plate

Nut, Depress Plate

Standoff, Limit Switch

Screw, Limit Switch

Nut Plate, Through

Nut Plate, Threaded

Limit Switch

4

1

2

2

2

2

4

2

2

2

82-WX10-08T

10-10013

18-10036

82-PX06-16

84-LH-06

31-12542

82-PX04-20

10-12806

10-12553

23-10041

REPAIR PARTS KITS – MODEL LGO

Refer to the parts lists below for replacement kits available for your operator. If optional modifications and/or accessories

are included with your operator, certain components may be added or removed from these lists. Individual components of

each kit may not be available. Please consult a parts and service representative regarding availability of individual components.

Page 16

CLOSE

OPEN

CMN

SBC/STOP

CMN

IR BK\WH

IR WHITE

OPEN

CLOSE

CMN

SBC/STOP

CONTROL CONNECTIONS

ATTENTION ELECTRICIAN

USE 16 GAUGE OR HEAVIER

FOR ALL CONTROL WIRING.

THREE BUTTON STATION TWO BUTTON STATION

SINGLE BUTTON STATION SENSING DEVICES

Page 17

GUIDE D'UTILISATION

MODÈLE LGO

DISPOSITIF D'ACTIONNEMENT DE PORTES À

GRILLAGE À FAIBLE PUISSANCE

GARANTIE DE 2 ANS

N° de série

(situé sur le couvercle du coffret électrique)

Date d'installation

Type de câblage

USAGE INDUSTRIEL UNIQUEMENT

Page 18

9,45"

(24,00 cm)

11,42"

(29,01 cm)

9,00"

(22,86 cm)

14,31"

(36,35 cm)

9,00"

(22,86 cm)

6,75"

(17,15 cm)

6,75"

(17,15 cm)

13,5"

(34,29 cm)

2

CARACTÉRISTIQUES

DISPOSITIFS DE SÉCURITÉ

DÉCONNEXION :............................Dispositif de déconnexion au

sol pour ouvrir ou fermer la porte manuellement en urgence.

CELLULES PHOTO-ÉLECTRIQUE : Cellules photo-électriques permettant d'inverser la trajectoire de la porte.

IL EST FORTEMENT RECOMMANDÉ D'ÉQUIPER TOUTES LES

INSTALLATIONS DE TYPE COMMERCIAL DE CELLULES

PHOTO-ÉLECTRIQUES LIFT MASTER (N° DE PIÈCE :

CPS-LN4). CES DERNIÈRES SONT OBLIGATOIRES LORSQUE

TOUT AUTRE PANNEAU DE COMMANDE EST UTILISÉ

(AUTOMATIQUE OU MANUEL).

MOTEUR

TYPE :...................................Service intermittent

PUISSANCE : .......................1/2 hp

VITESSE : .............................1 600 tr/min

TENSION : ............................115 V, monophasé, 60 Hz

COURANT : ..........................Voir la plaque

signalétique du moteur

POIDS ET DIMENSIONS

POIDS AU LEVAGE : ......40 à 45 lb

CIRCUIT ÉLECTRIQUE

PANNEAU DE COMMANDE : ........Panneau de commande NEMA

1 à 3 boutons, OUVRIR/FERMER/ARRÊT (OPEN/CLOSE/STOP)

ou panneau de commande à 2 boutons OUVRIR/FERMER

(OPEN/CLOSE).

RADIO : ...........................................Le récepteur radio intégré ne

fonctionnera pas en mode D1 (mode avec pression constante).

TYPES DE CÂBLAGE : .................B2 (standard) Contact momen-

tané sur OPEN, CLOSE et STOP avec branchement d'un capteur

d'inversion et dispositifs auxiliaires d'ouverture et de

fermeture avec commande prioritaire d'ouverture.

D1 (en option) .................................Pression constante sur OPEN

et CLOSE, avec branchement d'un capteur pour arrêter la trajectoire de la porte.

RÉGLAGE DE FIN DE COURSE : Cames à vis entièrement réglables, linéaires. Réglables jusqu'à 24 pieds (7,3 m).

MÉCANIQUE

RÉDUCTION DE LA TRANSMISSION :

Primaire :............................Vis sans fin 16:1

Secondaire :.......................Pignon et chaîne n

° 48

Sortie :................................Chaîne n

° 41

RÉGIME DE SORTIE

:........

40 tr/min

VITESSE DE LA PORTE : 9" par seconde selon le

type de porte.

Page 19

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

REMARQUES IMPORTANTES SUR LA SÉCURITÉ

ATTENTION

AFIN D'ÉVITER D'ENDOMMAGER LA PORTE OU

L'APPAREIL, ASSUREZ-VOUS QUE LES VERROUS DE LA PORTE SOIENT INOPÉRANTS.

BLOQUEZ LE(S) VERROU(S) POUR QU'IL(S)

RESTE(NT) « OUVERT(S) ».

SI LE VERROU DE LA PORTE DOIT RESTER

FONCTIONNEL, INSTALLEZ UN INTERRUPTEUR

DE VERROUILLAGE.

NE BRANCHEZ PAS L'ALIMENTATION ÉLECTRIQUE TANT QU'ON NE VOUS A PAS DONNÉ

CONSIGNE DE LE FAIRE.

PRÉPARATION DES LIEUX

Le mur et les surfaces de fixation doivent absolument

fournir un support adéquat pour le dispositif d'action-

nement.

Ces surfaces doivent :

a) être rigides afin d'éviter qu'il n'y ait du jeu entre

le dispositif d'actionnement et l'arbre de la porte;

b) fournir une base à niveau;

c) permettre au dispositif d'actionnement d'être fixé

solidement, avec l'arbre d'entraînement parallèle

à l'arbre de la porte.

AVERTISSEMENT

VEILLEZ À CE QUE LES PORTES SOIENT

TOUJOURS BIEN ÉQUILIBRÉES. LES PORTES

QUI ACCROCHENT OU QUI COINCENT DOIVENT

ÊTRE RÉPARÉES. IL EST POSSIBLE QUE LES

PORTES, LES RESSORTS DE PORTE, LES

CÂBLES, LES POULIES, LES FIXATIONS ET

AUTRES PIÈCES SOIENT SOUMIS À UNE FORTE

TENSION, CE QUI PEUT ENTRAÎNER DE GRAVES

BLESSURES. POUR DÉPLACER OU RÉGLER LES

RESSORTS DE PORTE OU TOUTE AUTRE PIÈCE,

FAITES APPEL À UN TECHNICIEN SPÉCIALISÉ

DANS LE DOMAINE.

La sécurité et la durée de vie du dispositif d'actionnement

seront sérieusement compromises si l'une ou l'autre des

conditions mentionnées ci-dessus n'est pas respectée.

Pour les constructions en métal, fixez des équerres en

métal de 2" x 2" x 3/16" (ou plus larges) aux pannes du

bâtiment. Gardez une distance de 7" entre chaque

équerre. Voir le schéma 1.

3

Page 20

4

MONTAGE DU DISPOSITIF D'ACTIONNEMENT

1b. Fixation sur support ou étagère

Le dispositif d'actionnement peut être fixé soit

au-dessus, soit en dessous de l'arbre de la porte. La

distance optimale entre l'arbre de la porte et l'arbre

d'entraînement de l'appareil se situe entre 12" et 15".

Reportez-vous au schéma 3.

1a. Fixation au mur

En général, le dispositif d'actionnement doit être

installé en dessous de l'arbre de la porte et aussi

près de la porte que possible. La distance optimale

entre l'arbre de la porte et l'arbre d'entraînement de

l'appareil se situe entre 12" et 15". Reportez-vous au

schéma 2.

IMPORTANT : L'étagère ou le support de fixation doivent

être suffisamment solides. Ils doivent être placés de façon

à éviter qu'il y ait du jeu entre l'arbre de la porte et le

dispositif d'actionnement et de façon à ce que le dispositif

d'actionnement soit solidement fixé, son arbre d'entraînement parallèle à l'arbre de la porte.

1c. Placez le pignon de porte sur l'arbre de la porte. N'insérez

pas encore la clavette.

2. Placez le pignon d'entraînement sur le côté approprié de

l'appareil.

3. Enroulez la chaîne d'entraînement autour du pignon de

porte et attachez les deux extrémités de la chaîne à

rouleaux au maillon de fermeture.

4. Soulevez le dispositif d'actionnement environ jusqu'à sa

position de montage et placez la chaîne sur le pignon du

dispositif d'actionnement.

5. Relevez ou abaissez le dispositif d'actionnement jusqu'à ce

que la chaîne soit tendue (sans être raide). Assurezvous que l'arbre de sortie du dispositif d'actionnement soit

parallèle à l'arbre de la porte et que les pignons soient

alignés. Lorsqu'il est en position, fixez solidement le dispositif d'actionnement au mur ou sur le support de fixation.

6. Insérez les clavettes, alignez les pignons et serrez (voir le

schéma 4).

DISTANCE OPTIMALE

DE 12" À 15"

DISTANCE OPTIMALE

DE 12" À 15"

Assurez-vous que le

pignon de porte soit

correctement aligné avec

le pignon d’entraînement

avant de le fixer à l’arbre.

IMPORTANT : L'étagère ou le support de fixation doivent être

suffisamment solides. Ils doivent être placés de façon à éviter

qu'il y ait du jeu entre l'arbre de la porte et le

dispositif d'actionnement et de façon à ce que le dispositif

d'actionnement soit solidement fixé, son arbre d'entraînement

parallèle à l'arbre de la porte.

SCHÉMA 3

SCHÉMA 2

Avant d'installer votre dispositif d'actionnement, assurez-vous que la porte soit correctement alignée et qu'elle fonctionne

aisément. Le dispositif d'actionnement peut être fixé sur le mur, sur un support ou une étagère. Le cas échéant, reportezvous aux consignes de préparation de la page 3 pour l'installation du dispositif. Voir les illustrations et les instructions cidessous qui conviennent à l'utilisation désirée.

SCHÉMA 4

Page 21

FONCTIONNEMENT MANUEL D'URGENCE

Ce dispositif d'actionnement est muni d'une chaîne de

déconnexion au sol permettant de déconnecter la porte du

mécanisme.

a) Pour déconnecter, tirez sur la chaîne et fixez-la en

position déconnectée en insérant l'extrémité dans l'orifice

de la fixation de blocage installée au mur. Si le dispositif

de sortie d'urgence est utilisé, tirez sur la poignée pour

déconnecter le dispositif d'actionnement de la porte.

b) La porte peut maintenant être ouverte ou fermée

manuellement. Relâchez la chaîne de déconnexion pour

réactiver le dispositif d'actionnement. Reportez-vous au

schéma 5.

SCHÉMA DU SYSTÈME D'ACTIONNEMENT DE PORTES

SURFACE DE FIXATION RIGIDE

SCHÉMA 5

FIXATION DE BLOCAGE

POSSIBILITÉS DE FIXATION

DES CELLULES

PHOTO-ÉLECTRIQUES

FACULTATIVES

POUR

RÉGLER LA

TENSION

TIREZ SUR LA CHAÎNE

POUR ACTIONNER LA

PORTE MANUELLEMENT

MATÉRIEL DE FIXATION

NON FOURNI

FIXATION SUR RAIL

FIXATION AU SOL

FIXATION

DE BLOCAGE

FIXATION AU MUR

5

Page 22

FIL DE MISE

À LA TERRE

VIS DE MISE

À LA TERRE

FILS

BLANCS

FILS

NOIRS

6

ALIMENTATION ÉLECTRIQUE

Afin d'éviter toute électrocution, débranchez

l'alimentation électrique du dispositif d'ouverture

de la porte de garage et du circuit que vous

prévoyez utiliser pour le branchement permanent.

DESSERREZ LES DEUX VIS DU COUVERCLE POUR

ACCÉDER AU CÂBLAGE DES FILS D'ALIMENTATION

ET DE COMMANDE ET POUR LES RÉGLAGES DE FIN

DE COURSE ET DE FORCE.

SCHÉMA 6

SCHÉMA 7

SCHÉMA 8

FICHE DE MISE À LA TERRE À TROIS BROCHES

Afin de réduire tout risque d'électrocution, ce dispositif

d'actionnement est muni d'une fiche de mise à la terre

comportant une troisième broche. Cette fiche ne peut

s'introduire que dans une prise de mise à la terre. Si vous

n'arrivez pas à introduire cette fiche dans la prise, faites

appel à un électricien qualifié pour installer la prise

appropriée. En aucun cas vous ne devez changer la

fiche. Voir le schéma 6.

BRANCHEMENT PERMANENT

Si un branchement permanent est nécessaire confor-

mément aux codes locaux, suivez les étapes

ci-dessous :

Pour effectuer un branchement permanent en utilisant

l'ouverture de 7/8" de diamètre située sur le côté du

dispositif d'actionnement :

1. Enlevez les vis du couvercle du dispositif d'ouverture

et mettez le couvercle de côté. Voir le schéma 8.

2. Retirez le câble à trois broches.

3. Branchez le fil noir (sous tension) sur la vis qui se

trouve sur la borne en cuivre, le fil blanc (neutre), sur

la vis qui se trouve sur la borne en argent et le fil de

mise à la terre, sur la vis verte de mise à la terre. Le

dispositif d'ouverture doit être mis à la terre. Voir le

schéma 7.

4. Remettez le couvercle.

Page 23

INSTALLATION DES COMMANDES DE LA PORTE

PANNEAU DE COMMANDE À TROIS BOUTONS

(MODÈLE STANDARD)

Le dispositif d'actionnement doit être programmé sur le

mode B2. Voir les instructions de programmation cidessous :

1. Installez le panneau de commande de façon à ce que la

porte soit visible, à une hauteur minimale de 5 pieds, hors

de portée des enfants et suffisamment loin de la porte et de

ses éléments.

2. Fixez solidement le panneau de commande de la porte à

l'aide de vis 6AB x 1-1/2". Si vous l'installez sur une cloison

sèche, percez des trous de 5/32" et utilisez les pièces

d'ancrage qui vous ont été fournies.

3. Faites parcourir le fil le long du mur jusqu'au dispositif

d'actionnement. Utilisez des crampons isolés afin de fixer le

fil à différents endroits. Veillez à ne pas percer le fil avec les

crampons.

4. Les vis de la borne du récepteur sont situées à l'intérieur

du panneau d'accès du dispositif d'actionnement, sur la

carte interface. Branchez chaque fil à la borne correspondante de la carte interface. La borne « OPEN » du panneau

de commande mural doit être branchée sur « OPEN », la

borne « CLOSE » du panneau de commande mural, sur

« CLOSE », la borne « STOP », sur « SBC/STOP » et la

borne commune du panneau de commande mural, sur

« CMN ». Voir le schéma 9.

SCHÉMA 9

INSTALLEZ LA NOTICE DE SÉCURITÉ

INTERRUPTEUR À CLÉ À DEUX BOUTONS/À DEUX

POSITIONS

Le dispositif d'actionnement doit être programmé sur le

mode D1. Voir les instructions de programmation

ci-dessous :

1. Installez le panneau de commande de façon à ce que la

porte soit visible, à une hauteur minimale de 5 pieds, hors

de portée des enfants et suffisamment loin de la porte et de

ses éléments.

2. Fixez solidement le panneau de commande de la porte à

l'aide de vis 6AB x 1-1/2". Si vous l'installez sur une cloison

sèche, percez des trous de 5/32" et utilisez les pièces

d'ancrage qui vous ont été fournies.

3. Faites parcourir le fil le long du mur jusqu'au dispositif

d'actionnement. Utilisez des crampons isolés afin de fixer le

fil à différents endroits. Veillez à ne pas percer le fil avec les

crampons.

4. Les vis de la borne du récepteur sont situées à l'intérieur

du panneau d'accès du dispositif d'actionnement, sur la

carte interface. Branchez chaque fil à la borne correspondante de la carte interface. La borne « OPEN » du panneau

de commande mural doit être branchée sur « OPEN », la

borne « CLOSE » du panneau de commande mural, sur

« CLOSE » et la borne commune du panneau de

commande mural, sur « CMN ». Voir le schéma 10.

SCHÉMA 10

7

Page 24

8

CAPTEURS

Tous les types de capteurs équipés d'une borne de sortie

isolée normalement ouverte (NO) sont compatibles avec

votre appareil, y compris les capteurs pneumatiques et

électriques. Si votre porte n'est pas équipée de capteurs

dans le bas, et que vous désirez en acheter, communiquez

avec le fournisseur de votre appareil.

Si les capteurs n'ont pas été installés au préalable par le

fabricant de votre porte, fixez-les sur la porte en suivant les

instructions qui accompagnent les capteurs. Ceux-ci

peuvent être branchés électriquement à l'aide d'un cordon à

spirale ou d'une bobine enrouleuse. Suivez les étapes

ci-dessous.

Remarques importantes :

a) Pour installer un capteur, demandez l'ensemble de

connexion du capteur LGOSE. Ce dernier doit être instal-

lé

avant d'ajouter un capteur. Reportez-vous aux instructions et au schéma 11 de la page 9.

b) Commencez par procéder aux réglages des interrupteurs

de fin de course avant de brancher les capteurs au

dispositif d'actionnement, comme décrit ci-dessous.

c) Un électricien doit relier, à l'aide d'un câble, la boîte de

dérivation au coffret électrique du dispositif d'actionnement, conformément aux codes locaux.

BOBINE ENROULEUSE : Les bobines enrouleuses

doivent être fixées à 12" au-dessus de la porte.

CORDON À SPIRALE : Branchez l'extrémité du cordon à

spirale du dispositif d'actionnement à la boîte de dérivation

(non fournie) qui est fixée sur le mur à mi-hauteur environ

de l'ouverture de porte.

DISPOSITIFS DE SÉCURITÉ

PROGRAMMATION DES MODES DE FONCTIONNEMENT

Pour changer le mode de fonctionnement : (réglé en usine sur le mode B2)

1. Appuyez sur le bouton LEARN (bouton de mémorisation) et maintenez-le enfoncé (la DEL de mémorisation s'allumera).

REMARQUE : LORSQU'ON APPUIE SUR LE BOUTON DE MÉMORISATION DU MODE PENDANT 5 SECONDES,

TOUS LES ÉMETTEURS MÉMORISÉS SONT EFFACÉS.

2. Pour mémoriser le mode approprié : Pendant que vous maintenez le bouton LEARN enfoncé, appuyez sur le bouton

correspondant de la carte interface.

Mode B2 : Bouton CLOSE (S3)

Mode D1 : Bouton OPEN (S2)

3. Relâchez les deux boutons. La DEL du bouton LEARN indique visuellement le mode programmé.

Mode B2 = 2 clignotements

Mode D1 = 1 clignotement

REMARQUE IMPORT

ANTE : Lorsque les cellules photo-électriques (IR) facultatives sont utilisées, le mode de câblage B2

doit être reprogrammé. Les cellules photo-électriques infrarouges doivent être connectées et doivent envoyer un signal avant

que le mode ne soit programmé. Voir les instructions sur la programmation ci-dessus.

Page 25

BRANCHEMENT DU DISPOSITIF DE SÉCURITÉ

a) Amenez les fils du capteur jusqu'au dispositif d'actionnement en vous aidant d'une bobine enrouleuse ou d'un cordon

à spirale.

b) Pour connaître les exigences en matière de branchement, consultez les codes locaux.

c) Branchez l'un des côtés du capteur à l'interrupteur coupe-circuit de sécurité (fil blanc) à l'aide du serre-fils fourni.

d) Branchez l'autre côté du capteur à la borne de la carte interface (IR WH/BK).

e) Activez la commande de fermeture de la porte, activez le capteur, puis vérifiez que la trajectoire de la porte s'inverse

bien. Reportez-vous au schéma 11.

SCHÉMA 11

SERRE-FILS

INTERRUPTEUR DE

SÉCURITÉ

CLOSE OPEN STOP

CAPTEUR

S3 S2 S1

IR WH/BK

IR WHITE

STOP/SBC

CMN

OPEN

9

CLOSE

Page 26

10

DÉBRANCHEZ L'ALIMENTATION ÉLECTRIQUE AVANT

DE RÉGLER MANUELLEMENT LES ÉCROUS DE FIN DE

COURSE AFIN D'ÉVITER TOUTE ÉLECTROCUTION QUI

POURRAIT ENTRAÎNER DES BLESSURES CORPORELLES GRAVES OU MORTELLES.

Si d'autres problèmes persistent, composez notre numéro

sans frais pour assistance 1-800-528-2806.

1. Pour régler les écrous de fin de course, appuyez sur

la plaque d'arrêt pour permettre aux écrous de tourner

librement. Une fois les réglages terminés, replacez la

plaque en vous assurant qu'elle s'emboîte correctement dans les rainures des deux écrous.

2. Pour augmenter la trajectoire de la porte, tournez

l'écrou à l'opposé de l'actionneur. Pour diminuer la

trajectoire de la porte, tournez l'écrou de fin de course

vers l'actionneur.

3. Réglez l'écrou de fin de course d'ouverture de façon à

ce que la porte reste ouverte, avec le bas de la porte

au même niveau que le haut de l'ouverture de porte.

4. Répétez les étapes 1 et 2 pour la fermeture. Réglez

l'écrou de fin de course de fermeture de façon à ce que

l'actionneur fonctionne dès que la porte arrive au sol.

Reportez-vous au schéma 12.

RÉGLAGE DES INTERRUPTEURS DE FIN DE COURSE

RÉGLAGES DE LA FORCE

Les réglages de la force d'ouverture et de fermeture se font à

l'aide de deux boutons de commande qui se trouvent à l'intérieur

du panneau d'extrémité du dispositif d'actionnement. Un premier

bouton permet de régler la force d'entraînement. Le second

bouton règle la sensibilité, qui constitue le changement de force

tel que perçu par le dispositif d'actionnement.

Pour régler les forces :

1. Réglez la force d'entraînement et la sensibilité au minimum.

2. Augmentez la force d'entraînement par paliers de 10 degrés

jusqu'à ce que la porte s'ouvre et se ferme librement d'un bout à

l'autre.

3. Augmentez la sensibilité par paliers de 10 degrés jusqu'à ce

que la porte commence à inverser sa trajectoire ou qu'elle

s'arrête à mi-parcours.

4. Diminuez la sensibilité par paliers de 10 degrés et actionnez

la porte pour un cycle complet afin de vous assurer qu'elle

fonctionne correctement. Voir le schéma 13.

Si la porte s'arrête lors de sa phase d'ouverture ou de fermeture,

ramenez la force d'entraînement et la sensibilité au minimum et

répétez les étapes 2 à 4.

FORCE D’ENTRAÎNEMENT

SENSIBILITÉ

AVANT DE PROCÉDER AUX RÉGLAGES, ASSUREZ-VOUS QUE LES ÉCROUS DE FIN DE COURSE

SOIENT POSITIONNÉS ENTRE LES ACTIONNEURS DES INTERRUPTEURS DE FIN DE COURSE.

SCHÉMA 12

SCHÉMA 13

Page 27

IR BK\WH

IR WHITE

STOP/SBC

CMN

OPEN

CLOSE

CLOSE

OPEN STOP

GY

GY

BRYE

MOTOR

CAPACITOR

BL

RD

WH

1

2

3

BK

WH

RD

IN

POWER

9

8

7

6

5

4

3

2

1

RPM

OPEN CLOSE

YE

YE

GY/WH

BR

PU

WH

BK

BL

RD

YE

PU

GY/WH

GY

GROUND

DEVICE

SENSING

GN

BK

WH

OPEN

CLOSE

CONTROL WIRING

POWER WIRING

THREE

BUTTON

WALL CONTROL

GN

BK

WH

STOP

SCHÉMA DE CÂBLAGE

BRANCHEMENT DES FILS DE COMMANDE

NOIR

BLANC

ROUGE

JAUNE

GRIS

GRIS/BLANC

BRUN

JAUNE

VIOLET

JAUNE

BLANC

NOIR

BLEU

ROUGE

BRANCHEMENT DE L’ALIMENTATION

VERT

NOIR

VIOLET

GRIS

TR/MIN

JAUNE

NOIR

BLANC

CONDENSATEUR

BLANC

GRIS/BLANC

BRUN

CAPTEUR

VERT

ALIMENTATION

TERRE

BLANC

BLEU

PANNEAU DE

COMMANDE

MURAL À TROIS

BOUTONS

MOTEUR

ROUGE

GRIS

11

Page 28

12

TESTEZ LE DISPOSITIF

Branchez l'alimentation. Testez toutes les commandes et

tous les dispositifs de sécurité pour vous assurer qu'ils

fonctionnent correctement. Pour régler adéquatement les

interrupteurs de fin de course, vous devrez vous reporter

à la page 9.

REMARQUES IMPORT

ANTES :

1. Ne laissez pas le dispositif en marche tant que les

dispositifs de sécurité et de protection n'ont pas été testés

et qu'ils ne fonctionnent pas correctement.

2. Assurez-vous d'avoir lu toutes les consignes de sécu-

rité de ce manuel et de les avoir bien comprises.

3. Assurez-vous que le propriétaire ou la (les) person-

ne(s) responsables(s) du fonctionnement de la porte aient

lu et compris les consignes de sécurité, qu'ils savent faire

fonctionner la porte électriquement en toute sécurité et

qu'ils savent utiliser le dispositif manuel de déconnexion

du système d'actionnement de la porte.

NE PLACEZ PAS VOS MAINS OU DES OUTILS PRÈS

OU À L'INTÉRIEUR DU DISPOSITIF LORSQU'IL EST

EN MARCHE OU LORSQUE VOUS TESTEZ LES

COMMANDES OU LES DISPOSITIFS DE SÉCURITÉ.

N'OUBLIEZ JAMAIS DE COUPER L'ALIMENTATION

ÉLECTRIQUE AVANT DE PROCÉDER À L'ENTRETIEN OU AUX RÉGLAGES DU DISPOSITIF.

EXEMPLES DE PANNES

Situation Cause probable et solution

La porte peut être actionnée à partir du panneau

de commande, mais pas avec la commande à distance

La porte ne s'ouvre pas complètement

La porte s'ouvre, mais ne se ferme pas

La porte inverse sa trajectoire sans raison apparente.

Le dispositif d'actionnement ne fonctionne ni avec le

panneau de commande, ni avec la commande à distance.

Êtes-vous sur le bon mode de fonctionnement?

La commande à distance est-elle programmée?

Si la porte fonctionnait correctement jusque là et qu'elle

ne s'ouvre plus complètement, recommencez le réglage des forces.

Vérifiez le système d'inversion de sécurité; vérifiez la sensibilité.

Enlevez toute obstruction et vérifiez le système d'inversion de sécurité. En mode à deux boutons, vérifiez les courts-circuits au niveau

du branchement du capteur d'inversion. Vérifiez le réglage de la

force d'entraînement et de la sensibilité.

Êtes-vous sur le bon mode de fonctionnement pour la commande

murale?

La commande murale est-elle correctement branchée à la carte

interface?

Page 29

PROGRAMME D'ENTRETIEN

Procédez aux vérifications nécessaires

pour chaque cycle de fonctionnement mentionné ci-dessous.

TOUS LES TOUS LES TOUS LES

ITEM PROCÉDURE 3 MOIS 6 MOIS 12 MOIS

Chaîne d'entraînement Vérifiez que la chaîne ne soit pas trop détendue.

Procédez aux ajustements nécessaires.

Huilez.

*

Pignons Vérifiez que les vis de pression soient bien serrées.

Pièces de fixation Vérifiez et resserrez si nécessaire.

Déconnexion manuelle Vérifiez le système et testez-le.

Roulements et arbres Vérifiez l'état d'usure et huilez.

de transmission

Utilisez l'huile S.A.E. 30 (n'utilisez jamais de graisse ou de silicone en bombe).

**

Reprenez TOUTES les procédures.

Ne huilez pas le moteur. Les roulements du moteur sont conçus pour fonctionner en continu.

Procédez à une inspection et faites les réparations nécessaires chaque fois que vous observez ou que

vous soupçonnez un défaut.

ATTENTION : AVANT TOUTE MANIPULATION, COUPEZ L'ALIMENTATION ÉLECTRIQUE DU DISPOSITIF

D'ACTIONNEMENT.

z

z z

z z

z z

z z

z

COMMENT COMMANDER LES PIÈCES DE RECHANGE

NOTRE SERVICE TECHNIQUE

EMBRASSE TOUTE L'AMÉRIQUE.

RENSEIGNEMENTS SUR L'INSTALLATION ET L'ENTRETIEN

DISPONIBLES 6 JOURS PAR SEMAINE.

COMPOSEZ NOTRE NUMÉRO SANS FRAIS : 1-800-528-2806

HEURES D'OUVERTURE : 7 H 00 À 15 H 30 (heure normale des Rocheuses)

DU LUNDI AU SAMEDI.

LORSQUE VOUS COMMANDEZ DES PIÈCES DE RECHANGE,

VEUILLEZ NOUS COMMUNIQUER LES RENSEIGNEMENTS SUIVANTS

:

NUMÉRO DE PIÈCE DESCRIPTION NUMÉRO DE MODÈLE

ENVOYEZ VOTRE COMMANDE À :

THE CHAMBERLAIN GROUP INC.

Electronic Parts & Service Dept.

2301 N. Forbes Blvd., Suite 104

Tucson, AZ 85745

13

Page 30

14

5

L11

L13

L10

L15

L16

E7

7

E2

E1

E8

E14

L9

L12

11

L14

L18

L17

4

10

E12

S2

S3

S4

R10

S1

M1

M2

E11

E4

E17

2

E15

E9

E10

E3

E13

E6

M3

9

8

4

3

E16

9

8

D6

D2

D7

D12

D11

L4

L3

1

D13

D1

D5

D13

R1

R5

R4

R3

R9

L8

L1

L6

L7

R2

L20

R3

R5

R7

R6

L6

L5

L7

L2

O6

O2

O6

O4

O5

O3

D4

D8

O4

D10

D9

O5

O3

O1

R8

D9

D14

D3

PIÈCES ILLUSTRÉES - MODÈLE LGO

Page 31

ENSEMBLES DES PIÈCES DE RECHANGE - MODÈLE LGO

Consultez les listes de pièces ci-dessous pour déterminer les ensembles de rechange disponibles pour votre dispositif d'actionnement.

Si votre appareil a subi des modifications et/ou est équipé d'accessoires en option, certains composants peuvent être ajoutés ou

retranchés de ces listes. Les composants individuels de chaque ensemble peuvent ne pas être disponibles. Veuillez consulter un

représentant du service des pièces de rechange et de l'entretien pour savoir si un composant individuel est disponible.

COMPOSANTS INDIVIDUELS

ITEM N° DE PIÈCE DESCRIPTION QUANTITÉ

1

2

3

4

5

6

7

8

9

10

11

10-15643

10-15637

10-15645

82-WX08-06T

80-487-7

82-WS08-08C

80-15636

82-RN31-08

84-FN-31

10-15644

10-15642

Châssis

Plaque d'écartement du châssis

Support de fixation du panneau de protection

Vis, n° 8-32 x 3/8" de long

Rivet

Vis prisonnière

Charnière

Boulon de carrosserie, 5/16"-18 x 1"

Écrou à bride cannelée, 5/16"-18

Couvercle

Châssis des interrupteurs de fin de course

K72-16421 ENSEMBLE DE L'ARBRE DE FIN DE COURSE

ITEM N° DE PIÈCE DESCRIPTION QUANTITÉ

11-15647

L1

13-10024

L2

15-48B9A1

L3

86-RP04-100

L4

12-10028

L5

87-E-038

L6

80-10025

L7

80-10026

L8

K74-16420 ENSEMBLE DE L'INTERRUPTEUR DE FIN DE COURSE

ITEM N° DE PIÈCE DESCRIPTION QUANTITÉ

82-WX10-08T

L9

10-10013

L10

18-10036

L11

82-PX06-16

L12

84-LH-06

L13

31-12542

L14

82-PX04-20

L15

10-12806

L16

10-12553

L17

23-10041

L18

Arbre de fin de course, 3/8"

Écrou de fin de course

Pignon à 9 dents

Goupille cylindrique, 1/8" de diam. x 1"

Douille clavetée, 3/8" de diam. int.

Bague en E, 3/8"

Rondelle de réglage, 0,375" de diam. x

0,050" d'épaisseur

Rondelle de réglage, 0,375" de diam. x

0,010" d'épaisseur

Vis, n° 10-32 x 1/2"

Plaque de dépression

Ressort de la plaque de dépression

Vis de la plaque de dépression

Écrou de la plaque de dépression

Entretoise de l'interrupteur de fin de course

Vis de l'interrupteur de fin de course

Écrou de passage de la plaque

Écrou fileté de la plaque

Interrupteur de fin de course

K72-16425 ENSEMBLE DE L'ARBRE DE RÉDUCTION

ITEM N° DE PIÈCE DESCRIPTION QUANTITÉ

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

11-15645

081B0045

146A0053

15-48B12CXX

011S0041

216A0148

158A0030

022A0003

146A0053

081C0179

Arbre de réduction, 1/2"

Roue menante, 1/2" de diam. int.

Goupille cylindrique, 0,187" x 0,938" de long

Pignon à 12 dents, 1/2" de diam. int.

Douille clavetée, 1/2" de diam. int.

Rondelle de réglage, 1/2" de diam. int., 0,030"

d'épaisseur

Bague en E, 1/2"

Chaîne n° 48, 54 pas

Goupille cylindrique, 3/16" x 15/16" de long

Vis sans fin

2

3

1

14

3

2

1

6

6

1

1

1

2

1

1

2

2

2

6

4

1

2

2

2

2

4

2

2

2

1

1

2

1

2

4

2

1

1

1

K72-16423 ENSEMBLE DE L'ARBRE DE DÉCONNEXION

ITEM N° DE PIÈCE DESCRIPTION

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

10-11394

11-15648

75-11377

07-11419

19-8A-12

10-11358

10-11023

18-10467

87-E-100

80-11416

Levier de débrayage

Arbre de déconnexion

Assemblage de pignon de chaîne

Moyeu du dispositif de déconnexion

Chaîne à châssis, 12'

Support de fixation

Manille de la roue conique

Ressort de pression

Bague en E lamée, 1"

Clavette du dispositif de déconnexion,

1

1

1

1

1

1

1

1

2

2

1/4" x 1/4" x 7/8"

D11

D12

D13

D14

82-SH10-12

85-LS-10

86-CP04-112

86-RP04-100

Vis à tête hexagonale en cavité, n° 10-32

Rondelle de blocage galvanisée, n° 10

Goupille fendue, 1/8" x 1-3/4" de long

Goupille cylindrique,

2

2

4

2

1/8" de diam. x 1" de long

D15

80-206-11

Rondelle, 1" de diam. int. x 1-1/16"

1

d'épaisseur

COMPOSANTS ÉLECTRONIQUES

ITEM N° DE PIÈCE DESCRIPTION QUANTITÉ

79-16088

E1

Ensemble de la carte à circuit imprimé

1

du modèle LGO April Logic

82-WX08-06T

E2

E3

E4

E5

E6

E7

030B0432

10-10351

171A0384

001B3878

10-15639

Vis, n° 8-32 x 3/8" de long

Condensateur du moteur

Support du condensateur

Vis, n° 8-32

Plaquette de connexions, 120 V

Panneau de protection de la carte à

2

1

1

1

1

1

circuit imprimé

80-15649

E8

E9

79-15491

Entretoise du panneau d'extrémité

Interface à 3 boutons de la carte à

2

1

circuit imprimé

216A0149

E10

E11

E12

E13

E14

171A0453

026B0073

028A0078

10-15641

Rondelle de borne de terre n° 8

Vis de borne de terre

Cordon d'alimentation, 4'

Bride du cordon d'alimentation

Support de la plaquette de connexions

1

1

1

1

1

de 120 V

10-15640

E15

Support de l'interface de la carte à

1

circuit imprimé

75-13705

E16

Ensemble d'entretoises de l'interface de

4

la carte à circuit imprimé

171A0384

E17

Vis, n° 8-32

3

K72-16422 ENSEMBLE DE L'ARBRE DE SORTIE

ITEM N° DE PIÈCE DESCRIPTION QUANTITÉ

11-15646

O1

15-48B32LXX

O2

12-10715

O3

80-206-10

O4

87-E-100

O5

86-RP10-200

O6

Arbre de sortie, 1"

Pignon à 32 dents, 1" de diam. int.

Douille clavetée, 1" de diam. int.

Rondelle de réglage, 1" de diam. int.,

0,015" d'épaisseur

Bague en E, 1"

Goupille cylindrique, 5/16" x 2" de long

1

1

2

6

2

1

K75-16426 ENSEMBLE DU CAPTEUR DE VITESSE

ITEM N° DE PIÈCE DESCRIPTION QUANTITÉ

S1

S2

S3

S4

001B3000

093D0148

158A0062

158A0040

Carte à circuit imprimé

Support de la carte à circuit imprimé

Cuvette d'interruption

Bague de la cuvette d'interruption

1

1

1

1

K75-16424 ENSEMBLE DE MOTEUR

ITEM N° DE PIÈCE DESCRIPTION QUANTITÉ

M1

M2

M3

123D0155

012D0381

011A0034

Moteur

Support de l'assemblage du moteur

Roulement imprégné d'huile

15

1

1

1

Page 32

CLOSE

OPEN

CMN

SBC/STOP

CMN

IR BK\WH

IR WHITE

OPEN

CLOSE

CMN

SBC/STOP

PANNEAU DE COMMANDE À

BOUTON UNIQUE

PANNEAU DE COMMANDE À 3 BOUTONS PANNEAU DE COMMANDE À 2 BOUTONS

BRANCHEMENTS DU PANNEAU DE COMMANDE

AVERTISSEMENT AUX ÉLECTRICIENS :

UTILISEZ UN FIL DE CALIBRE 16 OU

PLUS POUR TOUT CÂBLAGE DU

CIRCUIT DE COMMANDE.

CAPTEURS

SBC/STOP

CMN

OPEN

CLOSE

CMN

OPEN

CLOSE

SBC/STOP

CMN

IR BK\WH

IR WHITE

Loading...

Loading...