LIGHT COMMERCIAL - RESIDENTIAL DC

OPERATOR REQUIRES A

LIFTMASTER EXTERNAL

MONITORED ENTRAPMENT

PROTECTION DEVICE BE

INSTALLED IN ALL

ENTRAPMENT ZONES

OPERATOR REQUIRES A

LIFTMASTER EXTERNAL

MONITORED ENTRAPMENT

PROTECTION DEVICE BE

INSTALLED IN ALL

ENTRAPMENT ZONES

VEHICULAR SWING GATE OPERATOR

INSTALLATION MANUAL

LA500PKGUL

Single Arm Package

LA500DC

Primary 24 VDC Actuator Arm for single swing

gate applications

LA500DCS

Secondary 24 VDC Actuator Arm for dual

swing gate applications

• THIS PRODUCT IS TO BE INSTALLED AND

SERVICED BY A TRAINED GATE SYSTEMS

TECHNICIAN ONLY.

Model LA500UL

LiftMaster

300 Windsor Drive

Oak Brook, IL 60523

• This model is for use on vehicular passage gates

ONLY and not intended for use on pedestrian

passage gates.

• This model is intended for use in Class I, II, III

and IV vehicular swing gate applications.

• Visit LiftMaster.com to locate a professional

installing dealer in your area.

• This gate operator is compatible with myQ® and

Security+ 2.0® accessories.

Access installation and technical support guides or

register this product

Take a photo of the camera

1.

icon including the points ( ).

Send it in by texting the

2.

photo to 71403.

LA500PKGULTECH

TABLE OF CONTENTS

SAFETY 2

Safety Symbol and Signal Word Review ...................................................2

Usage Class ..............................................................................................3

UL325 Entrapment Protection Requirements ...........................................3

Safety Installation Information ..................................................................4

Gate Construction Information ..................................................................5

INTRODUCTION 6

Carton Inventory .......................................................................................6

Operator Specifications .............................................................................7

Site Preparation ........................................................................................8

Check your gate ........................................................................................8

INSTALLATION 9

Installation Tips ........................................................................................9

Step 1 Position the Brackets ...................................................................10

Step 2 Attach the Brackets ......................................................................11

Step 3 Install the Control Box .................................................................12

Step 4 Earth Ground Rod ........................................................................14

Step 5 Wire the Operator Arm to the Control Board ...............................14

Step 6 Dual Gate Setup ...........................................................................15

Step 7 Install Entrapment Protection ......................................................18

Wire Entrapment Protection Devices ......................................................19

Step 8 Power Wiring ...............................................................................20

Step 9 Finish Installation ........................................................................22

ADJUSTMENT 22

Limit and Force Adjustment ....................................................................22

Obstruction Test .....................................................................................24

PROGRAMMING 25

Remote Controls (Not Provided) ............................................................25

LiftMaster Internet Gateway (Not Provided) ...........................................26

Erase All Codes .......................................................................................26

Erase Limits ............................................................................................26

To Remove and Erase Monitored Entrapment Protection Devices ..........26

OPERATION 27

Gate Operator Setup Examples ...............................................................27

Control Board Overview ..........................................................................28

Manual Release .......................................................................................29

Reset Button ...........................................................................................29

Party Mode .............................................................................................29

Operator Alarm .......................................................................................30

Remote Control .......................................................................................30

ACCESSORY WIRING 31

External Control Devices .........................................................................31

Maglock ..................................................................................................32

Miscellaneous Wiring ..............................................................................32

EXPANSION BOARD 33

Expansion Board Overview .....................................................................33

Auxiliary Relays 1 and 2 .........................................................................34

Wiring Accessories to the Expansion Board ...........................................35

MAINTENANCE 36

Important Safety Instructions .................................................................36

Maintenance Chart ..................................................................................36

Batteries ..................................................................................................36

TROUBLESHOOTING 37

Diagnostic Codes ....................................................................................37

Diagnostic Codes Table ..........................................................................38

Control Board LEDs ................................................................................40

Troubleshooting Chart ............................................................................41

APPENDIX 44

Installation Types ....................................................................................44

Step 1 Position the Brackets ...................................................................44

Step 8 Solar Panels ................................................................................45

Limit Setup with a Remote Control .........................................................49

SAMS Wiring with the Relays Not Energized ..........................................50

REPAIR PARTS 51

Standard Control Box ..............................................................................51

Large Metal Control Box .........................................................................51

Gate Operator Arm ..................................................................................51

WIRING DIAGRAM 52

Standard Control Box ..............................................................................52

Large Metal Control Box .........................................................................53

ACCESSORIES 54

WARRANTY 56

SAFETY

Safety Symbol and Signal Word Review

When you see these Safety Symbols and Signal Words on the following pages, they will alert

you to the possibility of Serious Injury or Death if you do not comply with the warnings that

accompany them. The hazard may come from something mechanical or from electric shock.

Read the warnings carefully.

When you see this Signal Word on the following pages, it will alert you to the possibility of

damage to your gate and/or the gate operator if you do not comply with the cautionary

statements that accompany it. Read them carefully.

IMPORTANT NOTE:

• BEFORE attempting to install, operate or maintain the operator, you must read and fully

understand this manual and follow all safety instructions.

• DO NOT attempt repair or service of your gate operator unless you are an Authorized

Service Technician.

WARNING: This product can expose you to chemicals including lead, which are known to the State of California to cause cancer or birth defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov.

2

MECHANICAL

ELECTRICAL

SAFETY

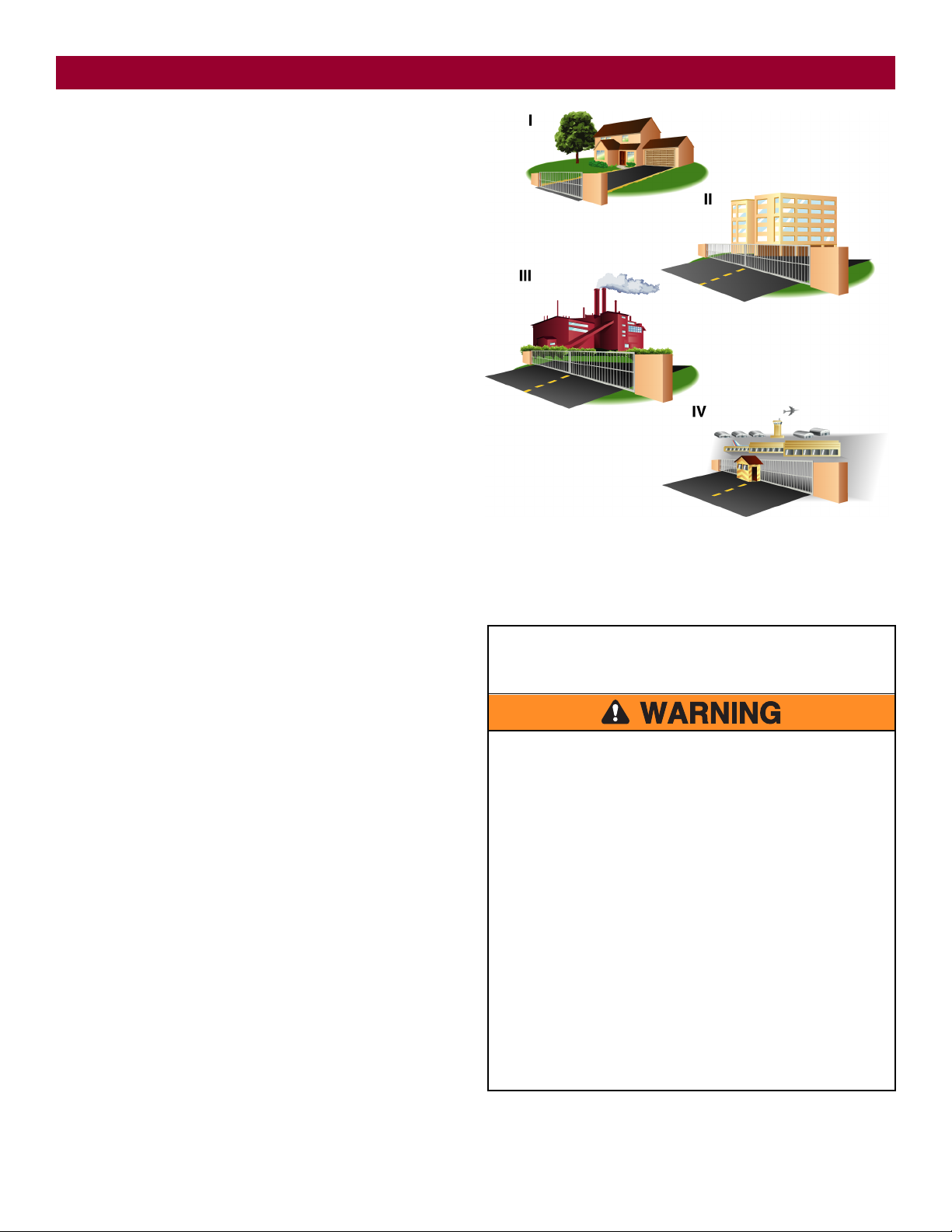

Usage Class

Class I - Residential Vehicular Gate Operator

A vehicular gate operator (or system) intended for use in garages or

parking areas associated with a residence of one-to four single families.

Class II - Commercial/General Access Vehicular

Gate

A vehicular gate operator (or system) intended for use in a commercial

location or building such as a multi-family housing unit (five or more

single family units), hotel, garages, retail store, or other buildings

accessible by or servicing the general public.

Class III - Industrial/Limited Access Vehicular

Gate

A vehicular gate operator (or system) intended for use in an industrial

location or building such as a factory or loading dock area or other

locations not accessible by or intended to service the general public.

Class IV - Restricted Access Vehicular Gate

Operator

A vehicular gate operator (or system) intended for use in a guarded

industrial location or building such as an airport security area or other

restricted access locations not servicing the general public, in which

unauthorized access is prevented via supervision by security personnel.

UL325 Entrapment Protection Requirements

l

A minimum of two independent* monitored entrapment protection

devices are required to be installed at each entrapment zone

l Every installation is unique. It is the responsibility of the installer to

install external monitored entrapment protection devices in each

entrapment zone

l This vehicular swing gate operator will operate only after installation

of a minimum of two independent* monitored entrapment protection

devices in either the open or close direction. If no entrapment zone

exists in the other direction of gate travel, then the inherent (built into

the operator) is all that is required in that direction.

l Entrapment protection device types include inherent (built into the

operator), monitored external photoelectric sensors or monitored

external edge sensors

l This operator is provided with an inherent entrapment protection

device built into the operator that serves as one of the two

independent devices

* Independent - the same type of device shall NOT be used for both

entrapment protection devices.

IMPORTANT SAFETY

To reduce the risk of INJURY or DEATH:

l READ AND FOLLOW ALL INSTRUCTIONS.

l NEVER let children operate or play with gate controls. Keep the

remote control away from children.

l ALWAYS keep people and objects away from the gate. NO ONE

SHOULD CROSS THE PATH OF THE MOVING GATE.

l Test the gate operator monthly. The gate MUST reverse on contact

with an object or reverse when an object activates the noncontact

sensors. After adjusting the force or the limit of travel, retest the

gate operator. Failure to adjust and retest the gate operator properly

can increase the risk of INJURY or DEATH.

l Use the emergency release ONLY when the gate is not moving.

l KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual.

Have a qualified service person make repairs to gate hardware.

l The entrance is for vehicles ONLY. Pedestrians MUST use separate

entrance.

INSTRUCTIONS

l SAVE THESE

INSTRUCTIONS.

3

Safety Installation Information

SAFETY

1. Vehicular gate systems provide convenience and security. Gate systems

are comprised of many component parts. The gate operator is only one

component. Each gate system is specifically designed for an individual

application.

2. Gate operating system designers, installers and users must take into

account the possible hazards associated with each individual

application. Improperly designed, installed or maintained systems can

create risks for the user as well as the bystander. Gate systems design

and installation must reduce public exposure to potential hazards.

3. A gate operator can create high levels of force in its function as a

component part of a gate system. Therefore, safety features must be

incorporated into every design. Specific safety features include:

l Edges Sensors (contact)

l Photoelectric Sensors

l Vertical Posts

l Instructional and Precautionary Signage

4. Install the gate operator only when:

a. The operator is appropriate for the construction and the usage

class of the gate.

b. All exposed pinch points are eliminated or guarded, and guarding

is supplied for exposed rollers.

5. The operator is intended for installation only on gates used for

vehicles. Pedestrians must be supplied with a separate access opening.

The pedestrian access opening shall be designed to promote pedestrian

usage. Locate the gate such that persons will not come in contact with

the vehicular gate during the entire path of travel of the vehicular gate.

6. The gate must be installed in a location so that enough clearance is

supplied between the gate and adjacent structures when opening and

closing to reduce the risk of entrapment. Swinging gates shall not open

into public access areas.

7. The gate must be properly installed and work freely in both directions

prior to the installation of the gate operator.

8. Permanently mounted access controls intended for users to activate,

must be located at least 6 feet (1.8m) away from any moving part of

the gate and where the user is prevented from reaching over, under,

around or through the gate to operate the controls. Outdoor or easily

accessible controls shall have a security feature to prevent unauthorized

use. Exception: Emergency access controls only accessible by

authorized personnel (e.g. fire, police) may be placed at any location in

the line-of-sight of the gate.

9. The Stop and/or Reset (if provided separately) must be located in the

line-of-sight of the gate. Activation of the reset control shall not cause

the operator to start.

10. A minimum of two (2) WARNING SIGNS shall be installed in the area

of the gate. Each placard is to be visible by persons located on the side

of the gate on which the placard is installed.

11. For a gate operator utilizing a non-contact sensor:

a. Reference owner’s manual regarding placement of non-contact

sensor for each type of application. See Install Entrapment

Protection section.

b. Care shall be exercised to reduce the risk of nuisance tripping,

such as when a vehicle trips the sensor while the gate is still

moving.

c. One or more non-contact sensors shall be located where the risk of

entrapment or obstruction exists, such as the perimeter reachable

by a moving gate or barrier.

12. For a gate operator utilizing a contact sensor such as an edge sensor:

a. One or more contact sensors shall be located where the risk of

entrapment or obstruction exists.

b. A hard wired contact sensor shall be located and its wiring

arranged so the communication between the sensor and the gate

operator is not subject to mechanical damage.

c. A wireless device such as one that transmits radio frequency (RF)

signals to the gate operator for entrapment protection functions

shall be located where the transmission of the signals are not

obstructed or impeded by building structures, natural landscaping

or similar obstruction. A wireless device shall function under the

intended end-use conditions.

d. One or more contact sensors shall be located on the inside and

outside leading edge of a swing gate. Additionally, if the bottom

edge of a swing gate is greater than 4 inches (10.1 cm) but less

than 16 inches (406 mm) above the ground at any point in its arc

of travel, one or more contact sensors shall be located on the

bottom edge.

4

SAFETY

Gate Construction Information

Vehicular gates should be installed in accordance with ASTM F2200: Standard Specification for Automated Vehicular Gate Construction. For a copy,

contact ASTM directly at 610-832-9585 or www.astm.org.

1. General Requirements

1.1 Gates shall be constructed in accordance with the provisions

given for the appropriate gate type listed, refer to ASTM F2200

for additional gate types.

1.2 Gates shall be designed, constructed and installed to not fall

over more than 45 degrees from the vertical plane, when a

gate is detached from the supporting hardware.

1.3 Gates shall have smooth bottom edges, with vertical bottom

edged protrusions not exceeding 0.50inches (12.7 mm) when

other than the exceptions listed in ASTM F2200.

1.4 The minimum height for barbed tape shall not be less than 8

feet (2.44m) above grade and for barbed wire shall not be

less than 6 feet (1.83m) above grade.

1.5 An existing gate latch shall be disabled when a manually

operated gate is retrofitted with a powered gate operator.

1.6 A gate latch shall not be installed on an automatically operated

gate.

1.7 Protrusions shall not be permitted on any gate, refer to ASTM

F2200 for Exceptions.

1.8 Gates shall be designed, constructed and installed such that

their movement shall not be initiated by gravity when an

automatic operator is disconnected, in accordance with the

following.

1.8.1 Vehicular horizontal swing gate. Shall not result in

continuous, unimpeded movement in either direction along

the arc of its path of travel.

1.9 For pedestrian access in the vicinity of an automated vehicular

gate, a separate pedestrian gate shall be provided. The

pedestrian gate shall be installed in a location such that a

pedestrian shall not come in contact with a moving vehicular

access gate. A pedestrian gate shall not be incorporated into

an automated vehicular gate panel.

3. Vehicular Horizontal Swing Gate

3.1 The following provisions shall apply to Class I, Class II and Class III

vehicular horizontal swing gates:

3.1.1 Gates shall be designed, constructed and installed so as not to

create an entrapment area between the gate and the supporting

structure or other fixed object when the gate moves toward the fully

open position, subject to the provisions in 3.1.1.1 and 3.1.1.2

3.1.1.1 The width of an object (such as a wall, pillar or column) covered by

a swing gate when in the open position shall not exceed 4inches

(102mm), measured from the center line of the pivot point of the

gate. Exception: For a gate not in compliance with this provision,

the defined area must be provided with entrapment protection per

UL325.

3.1.1.2 Except for the zone specified in Section 3.1.1.1, the distance

between a fixed object such as a wall, pillar or column, and a swing

gate when in the open position shall not be less than 16inches

(406mm). Exception: For a gate not in compliance with this

provision, the defined area must be provided with entrapment

protection per UL325.

3.2 Class IV vehicular horizontal swing gates shall be designed,

constructed and installed in accordance with security related

parameters specific to the application in question.

2. Specific Applications

2.1 Any non-automated gate that is to be automated shall be

upgraded to conform to the provisions of this specification.

2.2 This specification shall not apply to gates generally used for

pedestrian access and to vehicular gates not to be automated.

2.3 When the gate operator requires replacement, the existing gate

shall be upgraded to conform to the provisions of this

specification.

2.4 When the gate of an automated gate system requires

replacement, the new gate shall conform to the provisions of

this specification.

5

Carton Inventory

NOT SHOWN: Documentation packet and hardware bag

INTRODUCTION

Optional Accessories (not provided)

Large Metal Control Box (Model LA500CONTXLMUL)

Ideal for installations that require additional room in the control box

(batteries not included).

Large Metal Control Box for Solar Applications

(Model XLSOLARCONTUL)

Required for solar installations (batteries not included). Requires two

33AH batteries, battery tray, and solar battery harness, see Accessories.

6

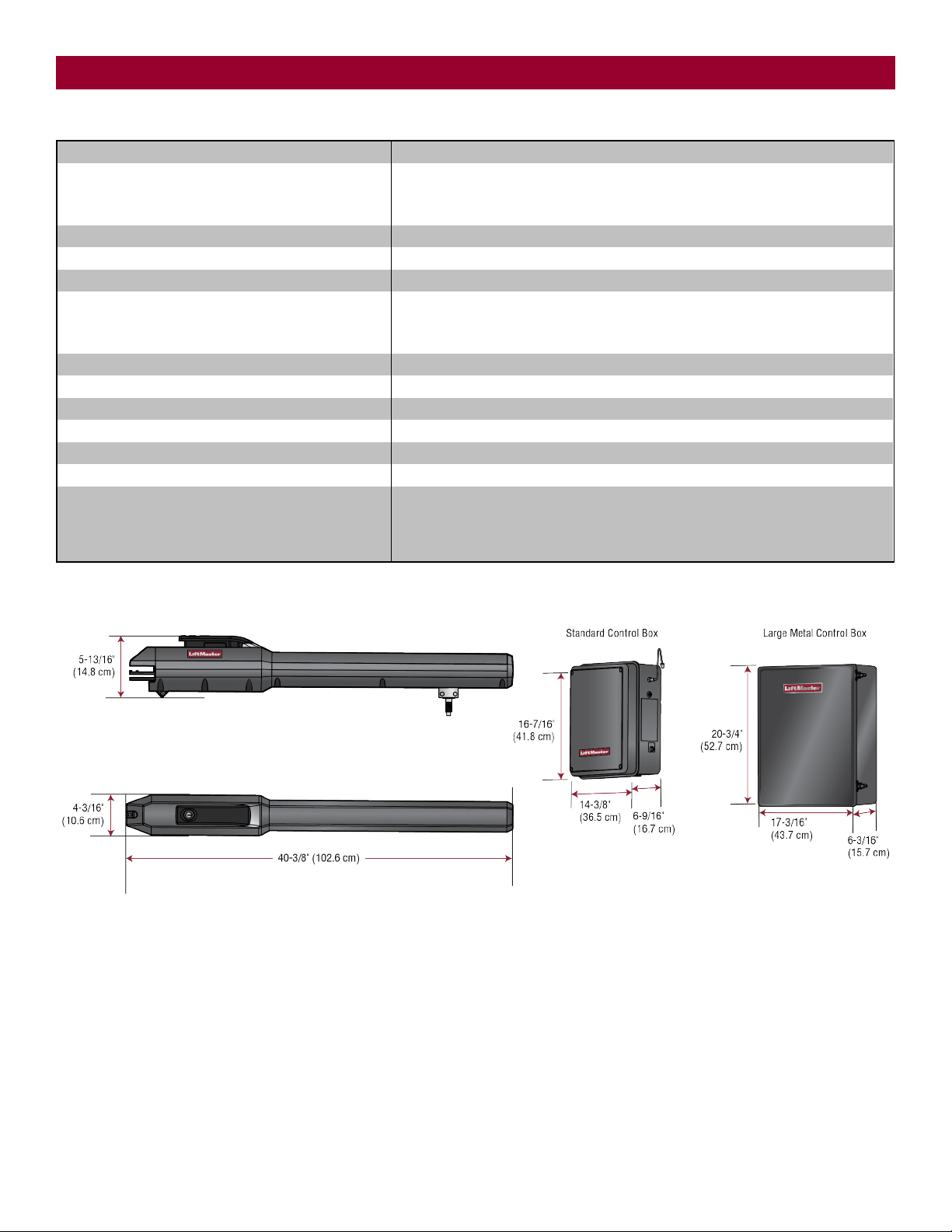

Operator Specifications

INTRODUCTION

Usage Classification

Main AC Supply

System Operating Voltage

Accessory Power

Solar Power Max

Maximum Gate Weight/Length

90 Degree Travel Time*

Maximum Travel Range*

Maximum Daily Cycle Rate

Maximum Duty Cycle

Operating Temperature

Expansion Board

External Entrapment Protection Device Inputs (non-

contact and/or contact)

*Travel time and range are affected by A and B mounting dimensions, see INSTALLATION.

Class I, II, III, & IV

120 Vac, 2 Amps (8 Amps including Accessory Outlets)

OR

240 Vac, 1 Amp

24 Vdc Transformer Run / Battery Backup

24 Vdc, 500mA max. for ON + SW (switched)

24 Vdc at 60 watts max.

1600 lbs. (725.7kg) / 8 ft (2.4 m)

800 lbs. (362.9 kg) / 16 ft (4.9 m)

600 lbs. (272.2 kg) / 18 ft (5.5 m)

15-18 seconds

115 degrees

300 cycles / day

Continuous

-40°C to 60°C (-40°F to 140°F)

Provided

Main board - up to 2 close entrapment protection devices and 1 open entrapment

protection device.

Expansion board - up to 3 entrapment protection devices configurable to either close or

open direction and up to 4 edge sensors using wireless edge sensor kit model LMWEKITU.

7

INTRODUCTION

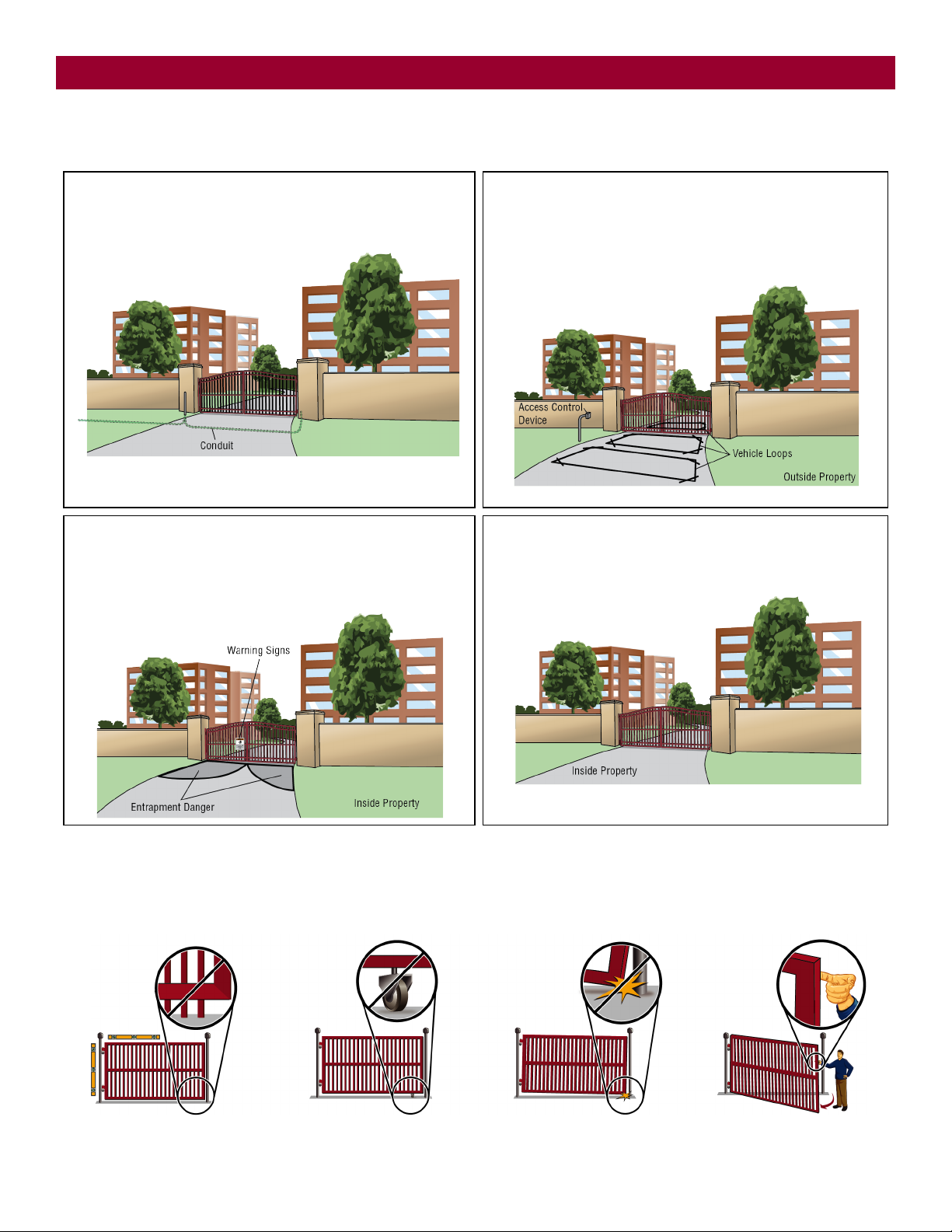

Site Preparation

Check the national and local building codes BEFORE installation.

Trench

Trench and install conduit. Before trenching, contact underground utility

locating companies. Conduit must be UL approved for low and high

voltage.

Safety

Entrapment protection devices are required to protect against any

entrapment or safety conditions encountered in your gate application.

Install a warning sign (two provided) on the inside and outside of the

property, where easily visible.

Additional Accessories

The vehicle loops allow the gate to stay open when vehicles are

obstructing the gate path. Suggested for vehicles 14 feet (4.27 m) or

longer. Vehicle loops are not required but are recommended. Before

installing your Access Control Device(s) be sure to complete a site

survey and determine the best device for your site needs.

Gate

Gate must be constructed and installed according to ASTM F2200

standards (refer to page 4). Gate must fit specifications of operator (refer

to specifications).

Check your gate

Gate MUST be level. Gate and gate

post MUST be plumb. Gate MUST

have a smooth bottom edge, no

protrusions should exist.

Remove ANY/ALL wheels from the

bottom of gate.

Gate MUST NOT hit or drag across

ground

8

Gate MUST swing freely and be

supported entirely by its hinges.

INSTALLATION

l To AVOID damaging gas, power or other underground utility lines,

contact underground utility locating companies BEFORE digging more

than 18 inches (46 cm) deep.

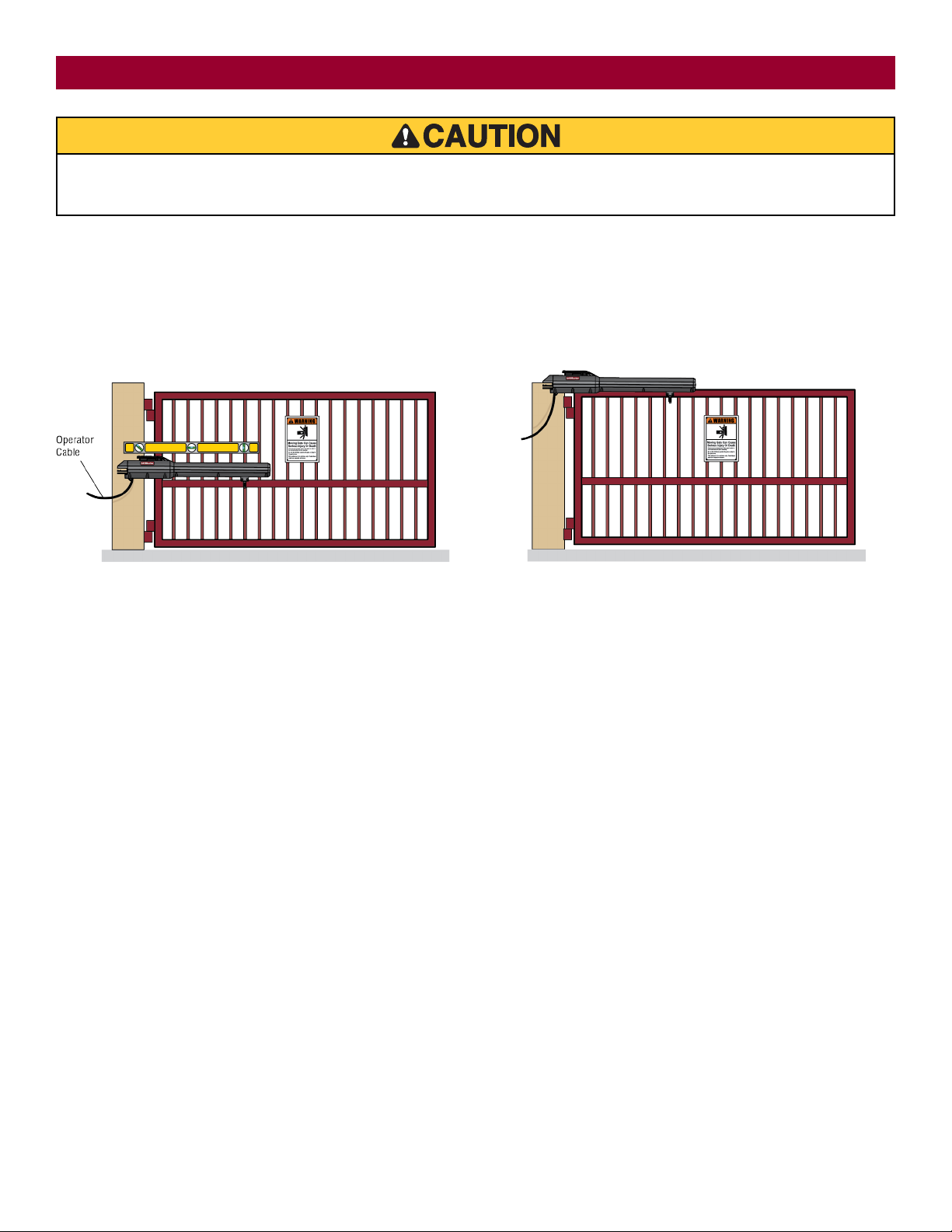

Installation Tips

Do's

l Weld a horizontal bar across entire gate on any installation for

strength. Make sure that the operator is mounted level or it will not

function properly.

l Make sure there is slack in the operator cable.

Don'ts

l DO NOT install upside down.

l DO NOT install next to sprinklers or any area that may expose the

bottom of operator to water.

l DO NOT install on uphill or downhill gates.

l ALWAYS wear protective gloves and eye protection when changing

the battery or working around the battery compartment.

l The operator can be mounted on top of the gate frame.

l The operator must be installed at least 12" (30 cm) from the ground.

l DO NOT install on ANY pedestrian passageways, doorways, or gates.

l DO NOT over-bend the operator cable. Doing this will cause the wires to

eventually break.

l DO NOT weld the crossbar on just a few pickets, or they could bend.

9

INSTALLATION

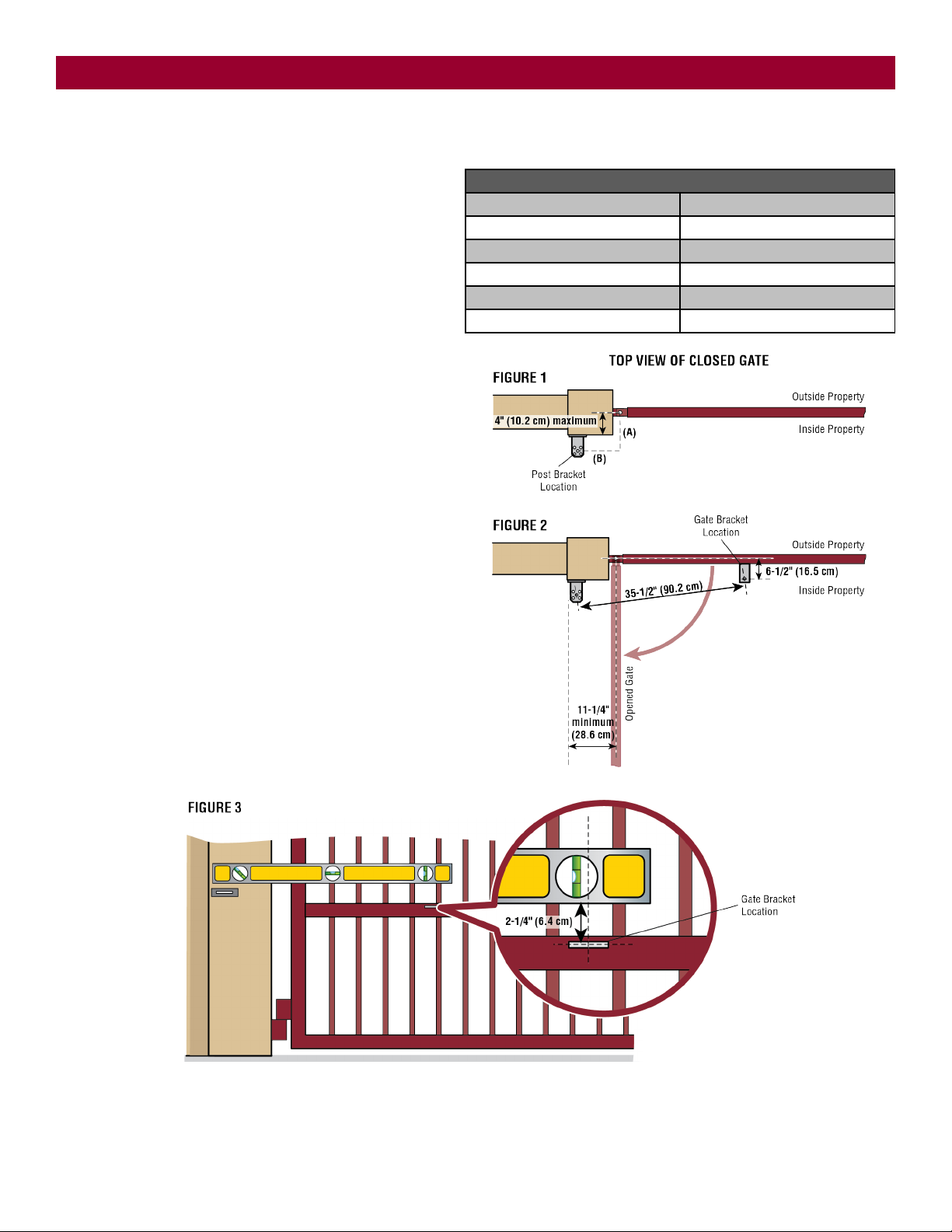

Step 1 Position the Brackets

If this operator is a replacement for a Miracle-One™ operator, use the

existing post bracket and gate bracket. Remove the Miracle-One™

operator from the brackets and proceed to the next step.

If your application is Push-to-Open, refer to the illustrations in the

Appendix.

The measurements shown below are typical for a standard installation.

Your installation may be different. The gate bracket MUST be installed in

an area that can withstand heavy forces. Additional reinforcement steel

plates may be necessary for mounting.

1. Close the gate.

2. Choose a vertical mounting location for the post bracket.

3. Place a measuring tape under the center of the gate hinge point and

measure out dimension A (see chart).

4. Use a screwdriver or dowel rod to temporarily mark the location of

the first measurement (Figure 1).

5. Measure out dimension B (see chart) from the previous mark. Use a

screwdriver to mark the location of the second measurement

(Figure1).

6. Align the post bracket as close as possible above the screwdriver or

dowel rod and tack weld the post bracket in the desired vertical

position.

7. Position a level on the post bracket and measure 35-1/2" (90.2 cm)

over from the center hole of the post bracket and mark the location

on the gate (Figure 2).

8. Measure 2-1/4" (6.4 cm) down from the previous mark and center

the bracket on this mark (Figure 3). Tack weld the gate bracket in this

position.

NOTES:

l There should only be a maximum of 4" (10.2 cm) from the center of

the hinge to the edge of the post or column (Figure 1). If the distance

is greater than 4" (10.2 cm) entrapment protection for this area is

required.

l While the gate is in the fully open position, the operator needs a

clearance of 11-1/4" (28.6 cm) as shown (Figure 2).

NOTE: The ideal installation measurements are A = 7-3/4" (19.7 cm) and B = 81/2" (21.6 cm). If different measurements are used, the sum of A and B cannot

be greater than 18" (45.7 cm).

DIMENSION CHART

A B

7-3/4" (19.7 cm) 8-1/2" (21.6 cm)

8-1/2" (21.6 cm) 7-3/4" (19.7 cm)

9" (22.9 cm) 9" (22.9 cm)

9" (22.9 cm) 8-1/2" (21.6 cm)

7-1/2" (19.1 cm) 7-1/2" (19.1 cm)

10

INSTALLATION

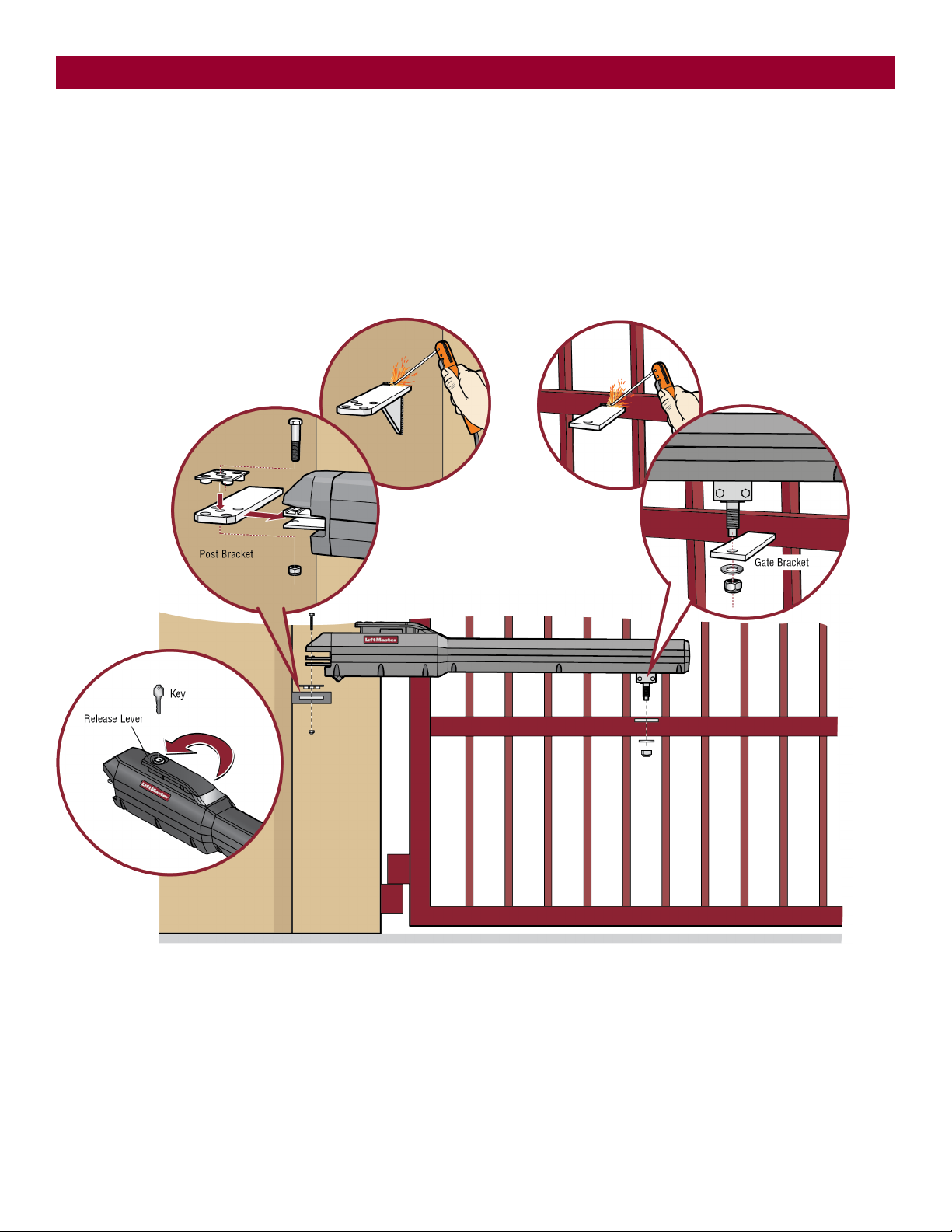

Step 2 Attach the Brackets

1. Insert the key into the lock and turn it 180 degrees counterclockwise.

Turn the release lever 180 degrees counterclockwise. The operator is

now in manual mode.

2. Position the operator on the brackets and make sure the operator is

level and positioned correctly on the gate.

3. Remove the operator from the gate.

4.

Completely weld around the post bracket and gate bracket.NOTE:

Brackets may need additional reinforcement by welding flat stock as

shown.

5. Attach the operator to the post bracket with the bolt, mounting plate,

and nut as shown.

6. Attach gate bracket to operator with the bolt, washer, and nut as

shown. Tighten the nut until it reaches the bottom of the gate bracket,

then turn the nut a half turn, making sure not to overtighten. Make sure

the trolley does not reach the fully open or fully closed position.

NOTE: Extra force may be needed to move the trolley back and forth.

For dual gate applications, repeat the previous installation steps to install the second operator.

11

INSTALLATION

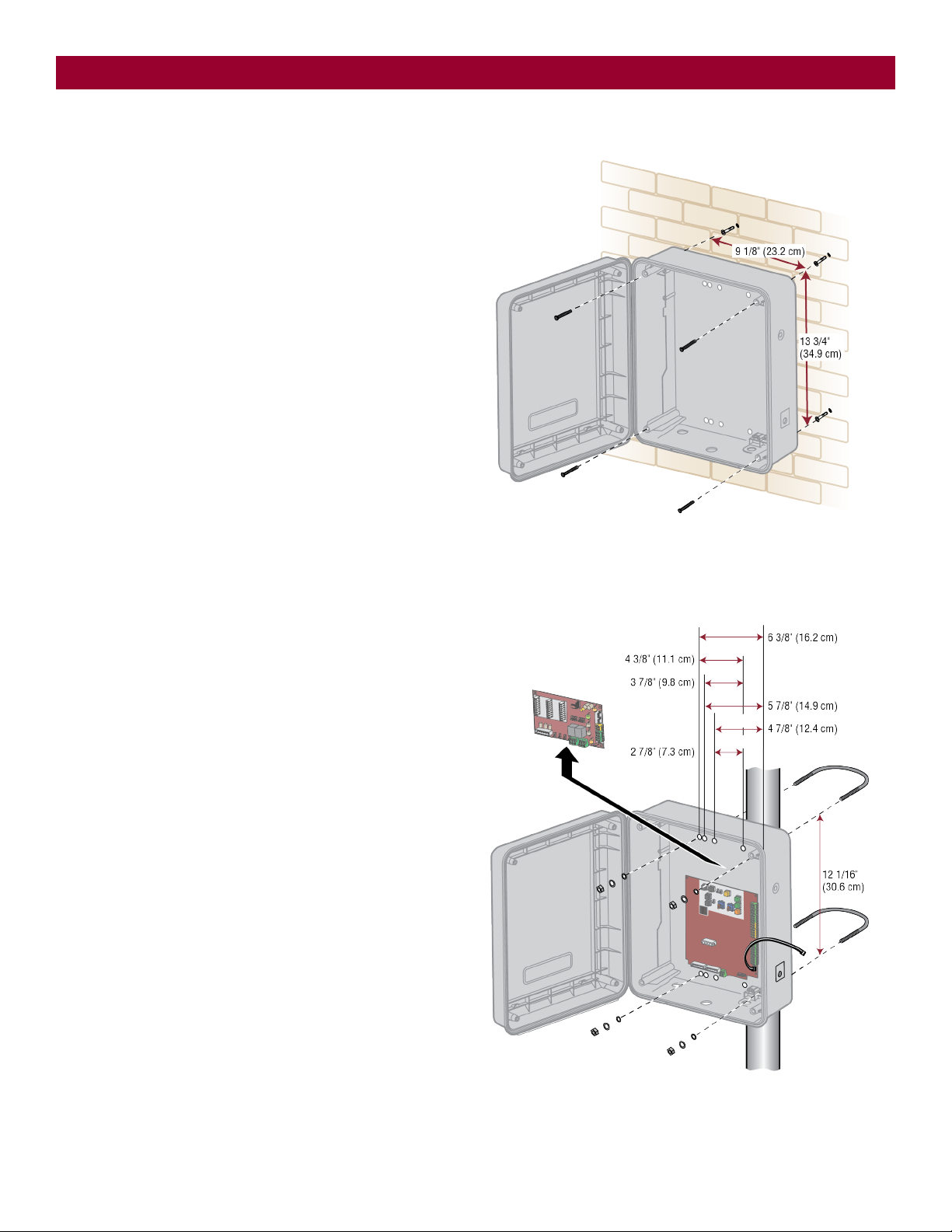

Step 3 Install the Control Box

Standard Control Box

The control box MUST be mounted within 5 feet (1.52 m) of the gate

operator. Mount the control box as high as possible for best radio

reception. Make sure the control box is level.

NOTE: The expansion board DOES NOT need to be removed for a wall or

column mount installation.

1. Remove the screws and open the control box.

2. Disconnect the "Main Board" connector from the expansion board.

3. Remove the expansion board by removing the screws.

4. Select the mounting holes (according to your application) and

remove the knockouts using a screwdriver and hammer.

5. Secure the control box to mounting surface.

A.

Wall or Column: Use the provided screws (4).

B.

Post: Use U-bolts and rubber washers (not provided) to ensure

a watertight seal. Make sure the U-bolts do not protrude more

than 3/4 inch from the control box because this can short the

control board.

6. Reinstall the expansion board and connect the "Main Board"

connector to the expansion board.

12

INSTALLATION

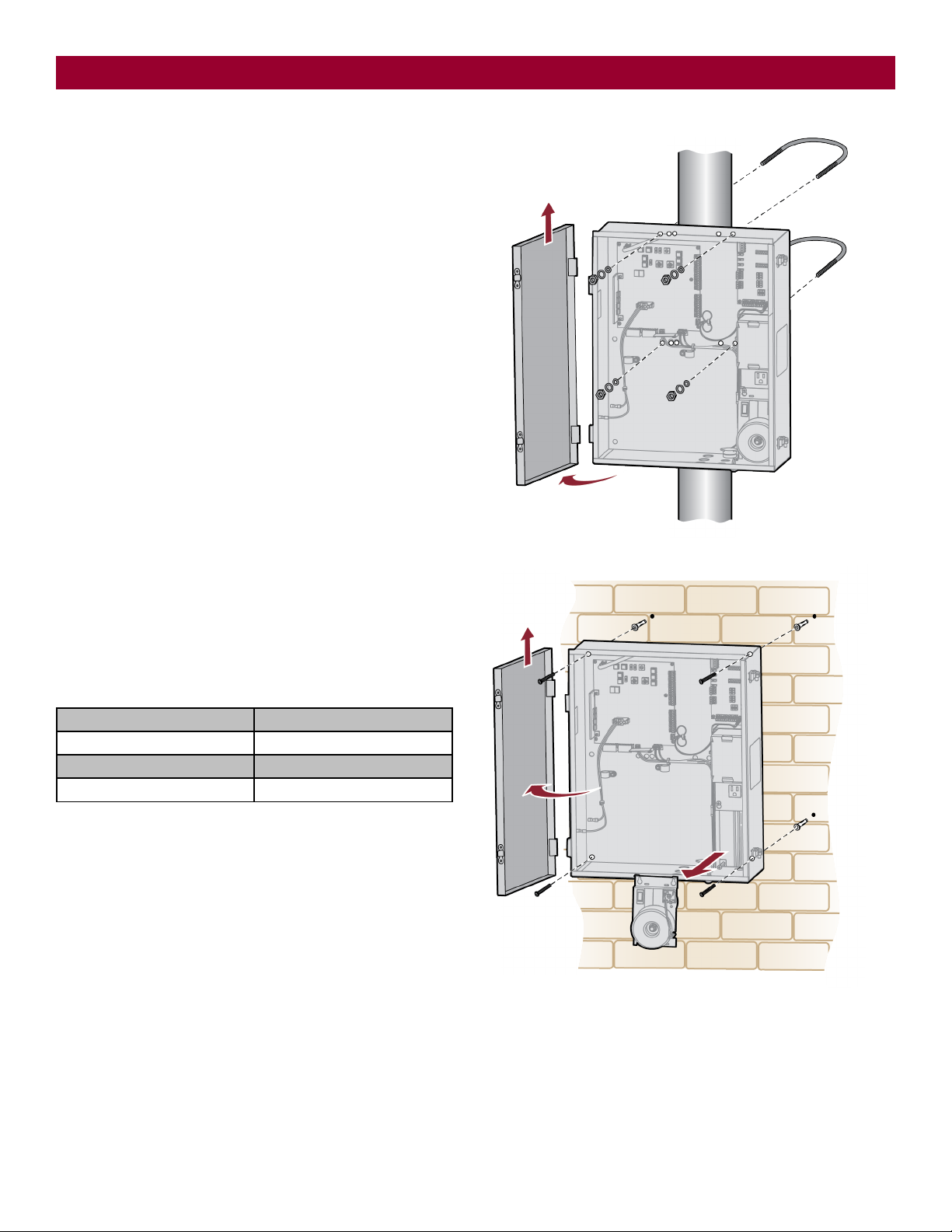

Large Metal Control Box

The control box MUST be mounted within 5 feet (1.52 m) of the gate

operator. Mount the control box as high as possible for best radio

reception. Make sure the control box is level.

NOTE: The Large Metal Solar Control Box (Model XLSOLARCONTUL)

does not have the electrical outlets or the expansion board shown in the

images.

Wall or Column Mount

1. Open the control box. The control box door may be removed by

opening the door 90°. Lift the door from the hinges and set aside

until the installation is complete.

2. Remove the toroid assembly from the control box by loosening the

three screws and lifting the assembly up and out.

3. Use knock outs located at the 4 corners of the control box and knock

out using a screwdriver and hammer.

4. Secure the control box to mounting surface using the provided

screws (4).

Post Mount

NOTE: The post mount option is not recommended for the 33AH battery

application.

1. Open the control box. The control box door may be removed by

opening the door 90°. Lift the door from the hinges and set aside

until the installation is complete.

2. The control box can be mounted to a post with 'U' bolts (refer to

chart). The knock out will accommodate a 3/8" diameter 'U' bolt.

Select center mounting holes (top and bottom) and knock out using

a screwdriver and hammer.

3. Secure the control box to mounting surface with U-bolts and rubber

washers (not provided) to ensure a watertight seal.

Wall or Column Mount

Post Mount

TYPE AND SIZE 'U' BOLT OPENING

Standard 3" Round Pipe 3-1/2"

Standard 4" Square Post 4"

Standard 6" Square Post 6"

13

INSTALLATION

To reduce the risk of SEVERE INJURY or DEATH:

l ANY maintenance to the operator or in the area near the operator

MUST NOT be performed until disconnecting the electrical power (AC

or solar and battery) and locking-out the power via the operator power

switch. Upon completion of maintenance the area MUST be cleared

and secured, at that time the unit may be returned to service.

l Disconnect power at the fuse box BEFORE proceeding. Operator

MUST be properly grounded and connected in accordance with

national and local electrical codes. NOTE: The operator should be on a

separate fused line of adequate capacity.

Step 4 Earth Ground Rod

Use the proper earth ground rod for your local area. The ground wire

must be a single, whole piece of wire. Never splice two wires for the

ground wire. If you should cut the ground wire too short, break it, or

destroy its integrity, replace it with a single wire length.

1. Install the earth ground rod within 3 feet (.9 m) of the operator.

2. Run wire from the earth ground rod to the control box.

NOTE: If the operator is not grounded properly the range of the remote

controls will be reduced and the operator will be more susceptible to

lightning and surge damage.

l ALL electrical connections MUST be made by a qualified individual.

l DO NOT install ANY wiring or attempt to run the operator without

consulting the wiring diagram.

l ALL power wiring should be on a dedicated circuit and well protected.

The location of the power disconnect should be visible and clearly

labeled.

l ALL power and control wiring MUST be run in separate conduit.

Step 5 Wire the Operator Arm to the Control Board

1. Choose a knockout in the bottom of the control box.

2. Insert the operator cable through the provided watertight connector.

3. Insert the operator cable and watertight connector into the knockout.

4. Slide the connector nut onto the operator cable.

5. Connect the operator cable wires to the connector according to the

colored label on the connector (white to white, red to red, etc.).

6. Plug the connector into the GATE 1 terminal on the control board as

shown.

7. Tighten the connector nut.

If installing one operator, proceed to page 18. If installing two

operators, go to the following page.

14

INSTALLATION

Step 6 Dual Gate Setup

There are two options for dual gate communication: wired or wireless. Follow the directions according to your application. Do not use wired and

wireless communication simultaneously. Wired dual gate applications will have a longer battery standby time than wireless applications. Wireless dual

gates will require the installation of two control boxes, one for each operator arm.

Wireless Setup

Install a second operator arm and control box:

Install a second operator arm and control box by following installation

steps 1-5.

To activate the wireless feature:

1. Choose an operator to be the network primary operator. All wireless

accessories will need to be programmed to the primary operator.

NOTE: We recommend that all accessories and board configurations

are set on the primary operator.

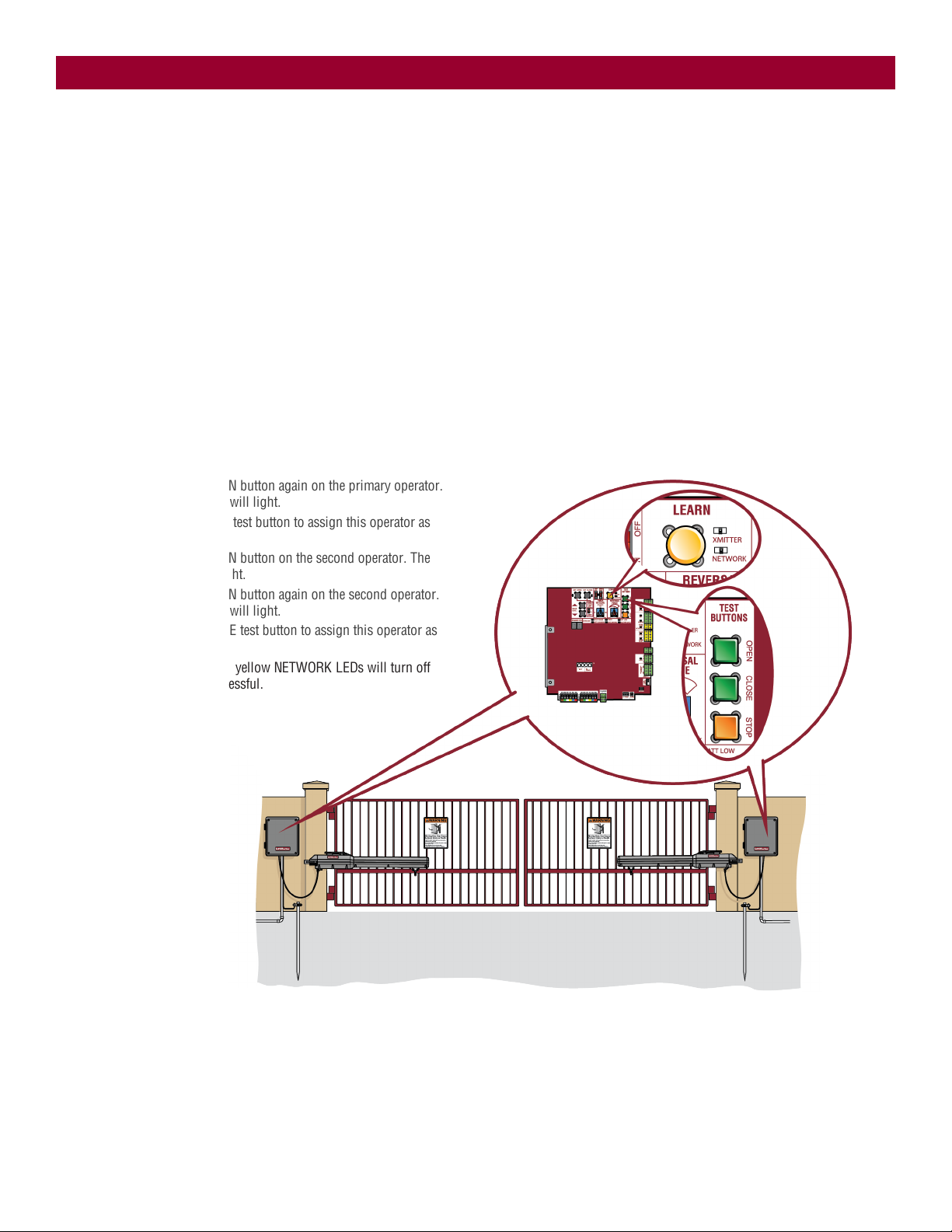

2. Press and release the LEARN button on the primary operator. The

green XMITTER LED will light. NOTE: The operator will time out of

programming mode after 180 seconds.

3. Press and release the LEARN button again on the primary operator.

The yellow NETWORK LED will light.

4. Press and release the OPEN test button to assign this operator as

network primary.

5. Press and release the LEARN button on the second operator. The

green XMITTER LED will light.

6. Press and release the LEARN button again on the second operator.

The yellow NETWORK LED will light.

7. Press and release the CLOSE test button to assign this operator as

network second.

Both operators will beep and the yellow NETWORK LEDs will turn off

indicating programming is successful.

To deactivate the wireless feature:

1. Press and release the LEARN button on either operator. The green

XMITTER LED will light.

2. Press and release the LEARN button again on the same operator. The

yellow NETWORK LED will light.

3. Press and hold the LEARN button for 5 seconds. The yellow

NETWORK LED will blink (operator will beep) then turn off indicating

successful deactivation.

4. Repeat the steps for the other operator.

15

INSTALLATION

Wired Setup

Install a second operator arm:

Install a second operator arm by following installation steps 1-2.

Install the extension cable and junction box:

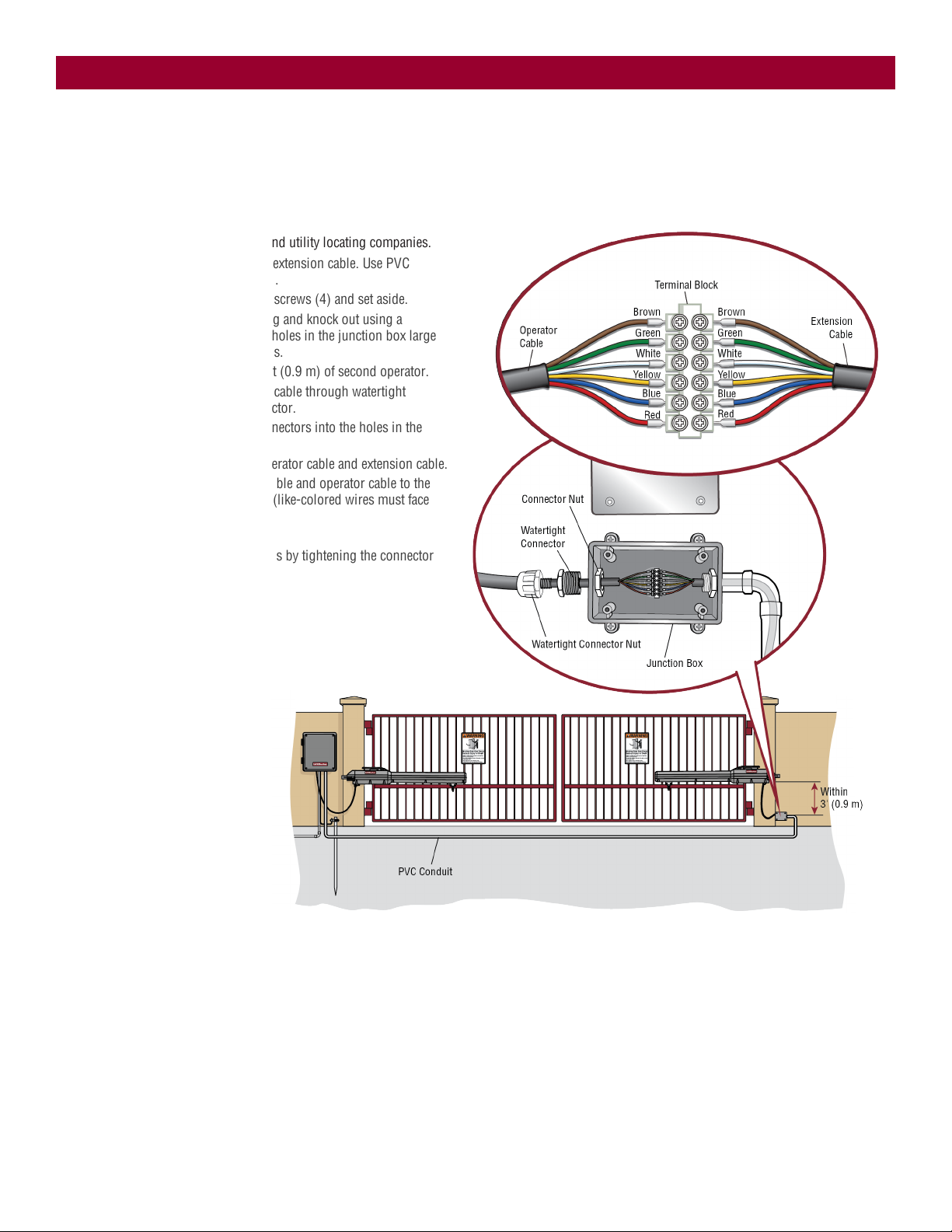

Before digging, contact local underground utility locating companies.

1. Trench across driveway to bury the extension cable. Use PVC

conduit to prevent damage to cables.

2. Open the junction box by removing screws (4) and set aside.

3. Select holes to be used for mounting and knock out using a

screwdriver and hammer. Drill two holes in the junction box large

enough for the watertight connectors.

4. Mount the junction box within 3 feet (0.9 m) of second operator.

5. Route operator cable and extension cable through watertight

connector nut and watertight connector.

6. Insert the cables and watertight connectors into the holes in the

junction box.

7. Slide the connector nut onto the operator cable and extension cable.

8. Connect the wires from extension cable and operator cable to the

terminal block connector as shown (like-colored wires must face

each other).

9. Put wires inside of junction box.

10. Secure operator and extension cables by tightening the connector

nut.

11. Reinstall cover.

16

INSTALLATION

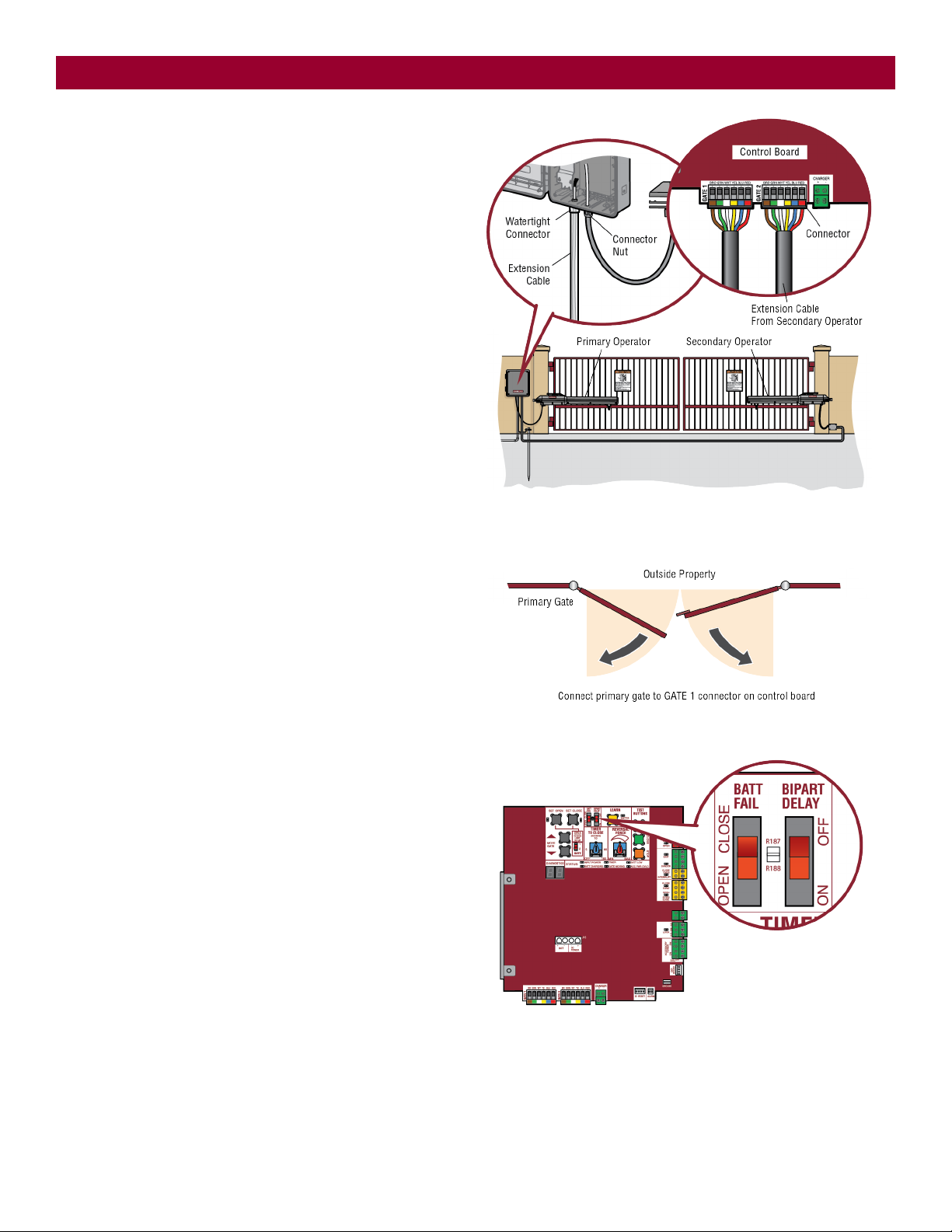

Wire the secondary operator arm to the control board:

1. Choose a knockout in the bottom of the control box.

2. Insert the extension cable through the watertight connector.

3. Insert the extension cable and watertight connector into the

knockout.

4. Slide the connector nut onto the operator cable.

5. Connect the extension cable wires to the connector according to the

colored label on the connector (white to white, red to red, etc.).

6. Plug the connector into the GATE 2 terminal on the control board as

shown.

7. Tighten the connector nut.

Set the bipart delay (single control box):

Occasionally in dual gate installations, one gate will need to open first

and close second. This would happen if there was an ornamental

overhang on one gate or if using a solenoid lock, for example. This gate

is called the Primary gate and needs to be connected to Gate 1

connections on the control board. Thus, it is preferred that the control

box be installed on the same side as this gate. If there is no appropriate

location on that side for the control box, then mount the control box on

the opposite side, but connect the operator closest to the control box to

the Gate 2 connector and the operator on the opposite side to the Gate 1

connector.

1. The BIPART DELAY switch on the control board needs to be set to

the ON position.

The illustration shows a dual gate configuration with a decorative

overlapping piece on the outside of the gate.

Set the bipart delay (dual control box)

The BIPART DELAY switch is used with dual control box applications

and serves two functions:

l

BIPART DELAY: The BIPART DELAY is used in applications where a

mag-lock, solenoid lock, or decorative overlay would require one

gate to close before the other. The control box with the BIPART

DELAY switch ON will delay from the close limit when opening and

be the first to close from the open limit.

l

SYNCHRONIZED CLOSE: The BIPART DELAY is also used in

applications where one gate travels a longer distance than the other.

To synchronize the closing of the gates, set the BIPART DELAY

switch to ON for both control boxes.

17

Loading...

Loading...