Liftmaster LA412-S User Manual

LA412 & LA412-S

■

■

■

■

■

12 VOLT DC

SOLAR RESIDENTIAL SWING

GATE OPERATOR

O W N E R ' S M A N U A L

Large

Metal Control

Box (XLM)

Optional

FOR RESIDENTIAL USE ONLY

Please read this manual and the enclosed safety materials carefully!

Periodic checks of the operator by a qualified technician are required to ensure safe operation.

The model number is located inside the control box of your operator.

Serial #

Installation date

2 YEAR WARRANTY

TABLE OF CONTENTS

SAFETY 1-5

Safety Symbol and Signal Word Review 1 Safety Installation Information 2 Gate Construction Information 3 Important Safety Information 4-5

INTRODUCTION 6-7

Operator Specifications 6

Carton Inventory 6

Hardware Inventory 7

Additional Items for Purchase 7

Tools Needed 7

INSTALLATION 8-19

Overview of Typical Installation 8-9

Check Your Gate 10

Mounting Options 10

Manual Release 11

Determine the Position of the Pull-to-Open Bracket 11

Determine the Position of the "Optional" Push-to-Open Bracket 11

Assemble Gate Post Bracket (Pull-to-Open) 12

Attach Brackets to Gate Operator 12

Determine Mounting Location 13

Measuring and Marking for the Gate Bracket 13

Position Gate Operator on Gate 14

Test Gate Travel 15

Secure Post Bracket to Gate Post 15

Secure Gate Bracket to Gate 16

Warning Sign Placement 16

Standard Control Box 17-18

Large Metal Control Box (XLM) 19

WIRING 20-24

Connect the Gate Operator (Gate 1) to the Control Box 20

Set the Lock/Bipart Delay (Model LA412-S Only) 21

Connect the Gate Operator (Gate 2) to the Control Box (Model LA412-S Only) 22

Junction Box (Model LA412-S Only) 23-24

SOLAR PANEL INSTALLATION 25-28

ADJUSTMENT 29-32

Limits 29-31

Force Adjustment 32

Timer-to-Close 32

PROGRAMMING 33

Remote Controls 33

Keyless Entry 33

Erase All Codes 33

Test 33

OPERATION AND MAINTENANCE 34-35

Reset Button 34

Remote Control 34

Sleep Mode 34

Manual Release 35

Maintenance 35

TROUBLESHOOTING 36-39

Wiring Diagram 36

Diagnostic Chart 37

Troubleshooting Chart 38-39

REPAIR PARTS 40-41

Control Box 40

Gate Operator Arm 40

How to Order Repair Parts 41

WARRANTY POLICY 41

ACCESSORIES 42

SAFETY » SAFETY SYMBOL AND SIGNAL WORD REVIEW

When you see these Safety Symbols and Signal Words on the following pages, they

will alert you to the possibility of Serious Injury or Death if you do not comply

with the warnings that accompany them. The hazard may come from something

mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will alert you to the

possibility of damage to your gate and/or the gate operator if you do not comply

with the cautionary statements that accompany it. Read them carefully.

IMPORTANT

• BEFORE attempting to install, operate or maintain the operator, you must read

and fully understand this manual and follow all safety instructions.

• DO NOT attempt repair or service of your gate operator unless you are an

Authorized Service Technician.

NOTE

TEMPLATE BACK COVER

MECHANICAL

ELECTRICAL

1

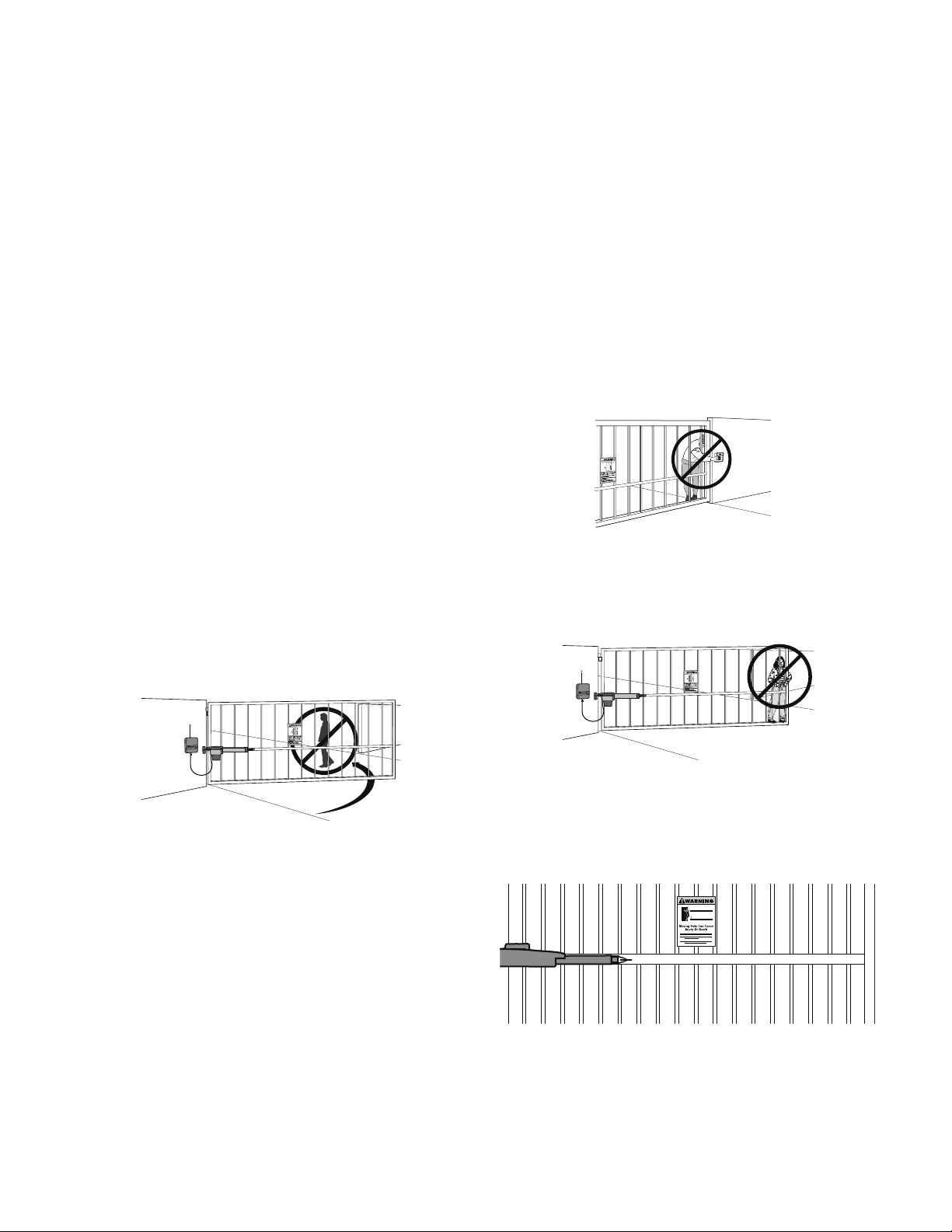

SAFETY » SAFETY INSTALLATION INFORMATION

1. READ and FOLLOW all instructions.

2. The gate operator is intended for use with Class I vehicular swing gates.

Class I denotes a vehicular gate operator (or system) intended for use in a

home of one to four single family dwellings, or a garage or parking area

associated therewith.

Install the gate operator only when the operator is appropriate for the

construction and the usage class of the gate.

3. Gate operating system designers, installers and users must take into account

the possible hazards associated with each individual application. Improperly

designed, installed or maintained systems can create risks for the user as well

as the bystander. Gate system design and installation must reduce public

exposure to potential hazards. Install the gate operator only when the

operator is appropriate for the construction of the gate and the usage class of

the gate. All exposed pinch points must be eliminated or guarded.

4. A gate operator can create high levels of force during normal operation.

Therefore, safety features must be incorporated into every installation.

Specific safety features include photoelectric sensors.

5. The gate must be properly installed and work freely in both directions prior to

the installation of the gate operator.

6. The gate must be installed in a location so that enough clearance is provided

between the gate and adjacent structures when opening and closing to reduce

the risk of entrapment. Swinging gates shall not open into public access areas.

7. The operator is intended for use only on gates used for vehicles. Pedestrians

must be supplied with a separate access opening. The pedestrian access

opening shall be designed to promote pedestrian usage. The pedestrian access

shall be located such that persons will not come in contact with the moving

vehicular gate.

8. Pedestrians should never cross the pathway of a moving gate. The gate

operator is not acceptable for use on any pedestrian gate. Pedestrians must be

supplied with a separate pedestrian access.

9. For an installation utilizing non-contact sensors (photoelectric sensors), see

product manual on the placement of non-contact sensors (photoelectric

sensors) for each type of application.

a. Care shall be exercised to reduce the risk of nuisance tripping, such as when

a vehicle trips the photoelectric sensor while the gate is still moving.

b. One or more non-contact sensors (photoelectric sensors) shall be located

where the risk of entrapment or obstruction exists, such as the perimeter

reachable by a moving gate or barrier.

10. For a gate operator utilizing a contact sensor such as an edge sensor:

a. A hard wired contact sensor shall be located and its wiring arranged so the

communication between the sensor and the gate operator is not subject to

mechanical damage.

b. One or more contact sensors shall be located on the inside and outside

leading edge of a swing gate. Additionally, if the bottom edge of a swing

gate is greater than 6 inches (152 mm) above the ground at any point in

its arc of travel, one or more contact sensors shall be located on the bottom

edge.

11. Never mount any device that operates the gate operator where the user can

reach over, under, around or through the gate to operate the controls.

Controls are to be placed at least 6 feet (1.8 m) from any part of the moving

gate:

• A hard wired control device shall be located and its wiring arranged so that

communication between the control device and the gate operator is not

subject to mechanical damage.

12. Controls intended to be used to reset an operator after 2 sequential activations

of the entrapment protection device or devices must be located in the line of

sight of the gate, or easily accessible controls shall have a security feature to

prevent unauthorized use. Never allow anyone to hang on or ride the gate

during the entire travel of the gate.

13. Each gate operator is provided with two safety warning placards. The placards

are to be installed on the front and back of the gate where they are plainly

visible. The placards may be mounted using cable ties through the four holes

provided on each placard. All warning signs and placards must be installed

where visible in the area of the gate.

14. To AVOID damaging gas, power, or other underground utility lines, contact

underground utility locating companies BEFORE digging.

15. SAVE THE INSTRUCTIONS.

2

SAFETY » GATE CONSTRUCTION INFORMATION

Vehicular gates should be installed in accordance with ASTM F2200: Standard Specification for Automated Vehicular Gate Construction. For a copy, contact ASTM directly at

610-832-9585 or www.astm.org.

1. GENERAL REQUIREMENTS

1.1 Gates shall be constructed in accordance with the provisions given for the

appropriate gate type listed, refer to ASTM F2200 for additional gate types.

1.2 Gates shall be designed, constructed and installed to not fall over more than

45 degrees from the vertical plane, when a gate is detached from the

supporting hardware.

1.3 Gates shall have smooth bottom edges, with vertical bottom edged

protrusions not exceeding 0.50 inches (12.7 mm) when other than the

exceptions listed in ASTM F2200.

1.4 The minimum height for barbed tape shall not be less than 8 feet (2.44 m)

above grade and for barbed wire shall not be less than 6 feet (1.83 m)

above grade.

3.1.3 A gap, measured in the horizontal plane parallel to the roadway, between a

fixed stationary object nearest the roadway, (such as a gate support post)

and the gate frame when the gate is in either the fully open position or the

fully closed position, shall not exceed 2-1/4 inches (57 mm), refer to ASTM

F2200 for Exception.

3.1.4 Positive stops shall be required to limit travel to the designed fully open and

fully closed positions. These stops shall be installed at either the top of the

gate, or at the bottom of the gate where such stops shall horizontally or

vertically project no more than is required to perform their intended

function.

3.1.5 All gates shall be designed with sufficient lateral stability to assure that the

gate will enter a receiver guide, refer to ASTM F2200 for panel types.

1.5 An existing gate latch shall be disabled when a manually operated gate is

retrofitted with a powered gate operator.

1.6 A gate latch shall not be installed on an automatically operated gate.

1.7 Protrusions shall not be permitted on any gate, refer to ASTM F2200 for

Exceptions.

1.8 Gates shall be designed, constructed and installed such that their movement

shall not be initiated by gravity when an automatic operator is disconnected.

1.9 A pedestrian gate shall not be incorporated into a vehicular gate panel or

that portion of the adjacent fence that the gate covers in the open position.

2. SPECIFIC APPLICATIONS

2.1 Any non-automated gate that is to be automated shall be upgraded to

conform to the provisions of this specification.

2.2 This specification shall not apply to gates generally used for pedestrian

access and to vehicular gates not to be automated.

2.3 Any existing automated gate, when the operator requires replacement,

shall be upgraded to conform to the provisions of this specification in effect

at that time.

3. VEHICULAR HORIZONTAL SLIDE GATES

3.1 The following provisions shall apply to Class I, Class II and Class III vehicular

horizontal slide gates:

3.1.1 All weight bearing exposed rollers 8 feet (2.44 m), or less, above grade

shall be guarded or covered.

3.2 The following provisions shall apply to Class IV vehicular horizontal slide

gates:

3.2.1 All weight bearing exposed rollers 8 feet (2.44 m), or less, above grade

shall be guarded or covered.

3.2.2 Positive stops shall be required to limit travel to the designed fully open and

fully closed positions. These stops shall be installed at either the top of the

gate, or at the bottom of the gate where such stops shall horizontally or

vertically project no more than is required to perform their intended

function.

4. VEHICULAR HORIZONTAL SWING GATES

4.1 The following provisions shall apply to Class 1, Class II and Class III vehicular

horizontal swing gates:

4.1.1 Gates shall be designed, constructed and installed so as not to create an

entrapment area between the gate and the supporting structure or other

fixed object when the gate moves toward the fully open position, subject to

the provisions in the 4.1.1.1 and 4.1.1.2.

4.1.1.1 The width of an object (such as a wall, pillar or column) covered by a swing

gate when in the open position shall not exceed 4 inches (102 mm),

measured from the centerline of the pivot point of the gate, refer to ASTM

F2200 for exception.

3.1.2 All openings located between 48 inches (1.22 m) and 72 inches (1.83 m)

above grade shall be designed, guarded or screened to prevent a

4 inch (102 mm) diameter sphere from passing through the openings

anywhere in the gate, and in that portion of the adjacent fence that covers

in the open position.

4.1.1.2 Except for the zone specified in Section 4.1.1.1, the distance between a

fixed object such as a wall, pillar or column, and a swing gate when in the

open position shall not be less than 16 inches (406 mm), refer to ASTM

F2200 for exception.

4.2 Class IV vehicular horizontal swing gates shall be designed, constructed and

installed in accordance with security related parameters specific to the

application in question.

3

SAFETY » IMPORTANT SAFETY INFORMATION

INSTALLATION

To prevent SERIOUS INJURY or DEATH; one or more non-contact sensors shall be

located where the risk of entrapment or obstruction exists.

To prevent SERIOUS INJURY or DEATH from a moving gate:

• Install warning signs on the front and back of the gate in PLAIN VIEW.

• Permanently secure each warning sign in a suitable manner using fastening

holes.

WIRING

To reduce the risk of SEVERE INJURY or DEATH:

• BEFORE installing power wiring or control stations be sure to follow ALL

specifications and warnings described below.

• ANY maintenance to the operator or in the area near the operator MUST NOT

be performed until the batteries are disconnected. Upon completion of

maintenance the area MUST be cleared and secured, at that time the unit

may be returned to service.

SOLAR PANEL INSTALLATION

ALWAYS wear protective gloves and eye protection when changing the battery or

working around the battery compartment.

• DO NOT use flooded lead acid battery.

• Flooded lead acid batteries will produce gases when discharging and

recharging which can explode.

• DO NOT dispose of battery in fire. Battery may explode. Check with local

codes for disposal instructions.

• ALL electrical connections MUST be made by a qualified individual.

• DO NOT install ANY wiring or attempt to run the operator without consulting

the wiring diagram. We recommend that you install an optional reversing

edge BEFORE proceeding with the control station installation.

To AVOID damaging gas, power or other underground utility lines, contact

underground utility locating companies BEFORE digging.

To avoid SERIOUS INJURY or DEATH:

• Disconnect ALL electric and battery power BEFORE performing ANY service or

maintenance.

To reduce the risk of FIRE or INJURY to persons use ONLY LiftMaster part

29-NP712 for replacement batteries.

ADJUSTMENT

Without a properly installed safety reversal system, persons (particularly small

children) could be SERIOUSLY INJURED or KILLED by a closing gate.

• Too much force on gate will interfere with proper operation of safety reversal

system.

• NEVER increase force beyond minimum amount required to close gate.

• NEVER use force adjustments to compensate for a binding or sticking gate.

• DO NOT connect solar panel(s) when power supply is connected.

• DO NOT connect more than 30W (3 solar panels).

• If one control (force or travel limits) is adjusted, the other control may also

need adjustment.

• After ANY adjustments are made, the safety reversal system MUST be tested.

Gate MUST reverse on contact with a rigid object.

4

SAFETY » IMPORTANT SAFETY INFORMATION

PROGRAMMING

To prevent possible SERIOUS INJURY or DEATH from a moving gate or

garage door:

• ALWAYS keep remote controls out of reach of children. NEVER permit children

to operate, or play with remote control transmitters.

• Activate gate or door ONLY when it can be seen clearly, is properly adjusted,

and there are no obstructions to door travel.

OPERATION AND MAINTENANCE

To reduce the risk of SEVERE INJURY or DEATH:

• READ AND FOLLOW ALL INSTRUCTIONS.

• NEVER let children operate or play with gate controls. Keep the remote control

away from children.

• ALWAYS keep people and objects away from the gate. NO ONE SHOULD

CROSS THE PATH OF THE MOVING GATE.

• Test the gate operator monthly. The gate MUST reverse on contact with a rigid

object or stop when an object activates the non-contact sensors. After

adjusting the force or the limit of travel, retest the gate operator. Failure to

adjust and retest the gate operator properly can increase the risk of INJURY

or DEATH.

• ALWAYS keep gate or garage door in sight until completely closed.

NEVER permit anyone to cross path of moving gate or door.

• Use the emergency release ONLY when the gate is not moving.

• KEEP GATES PROPERLY MAINTAINED. Read the ownerʼs manual. Have a

qualified service person make repairs to gate hardware.

• The entrance is for vehicles ONLY. Pedestrians MUST use separate entrance.

• Disconnect ALL power BEFORE performing ANY maintenance.

• SAVE THESE INSTRUCTIONS.

TROUBLESHOOTING

To protect against fire and electrocution:

• DISCONNECT power and battery BEFORE installing or servicing operator.

For continued protection against fire:

• Replace ONLY with fuse of same type and rating.

5

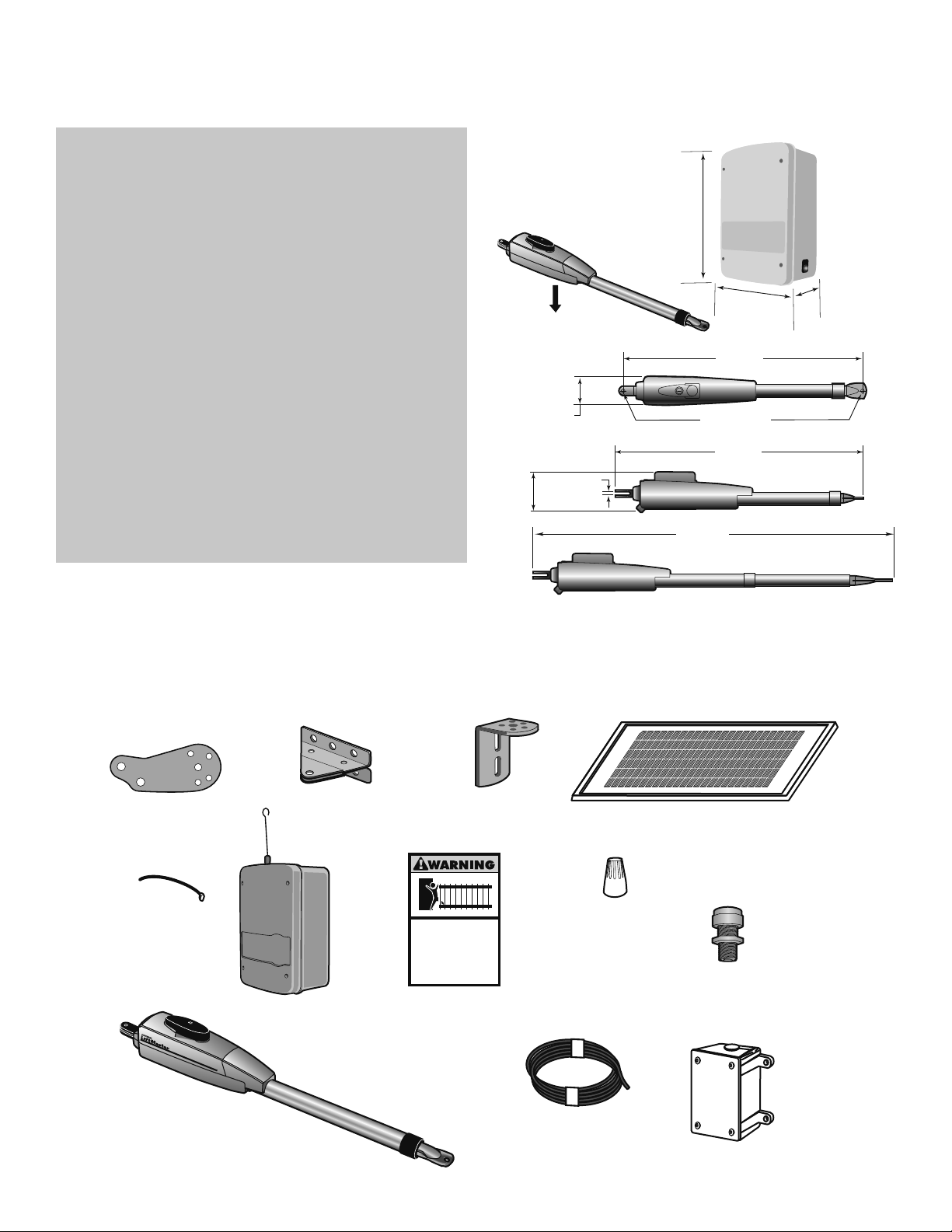

INTRODUCTION » OPERATOR SPECIFICATIONS + CARTON INVENTORY

OPERATOR SPECIFICATIONS

Main Supply (Motor): 12 Vdc Battery run

Accessory Power: 12 V nominal Class II battery

voltage source is limited to:

•

Solar or AC Cable up to

50 feet - 500 mA

•

•

Battery Charger Supply

(Optional): 14.5 Vac, 30 VA max.

Maximum Gate Length

and Weight: 16 feet at 550 lbs.

Temperature: -20° C to 50° C (-4° F to 122° F)

Fuse Protection Battery: 20 Amp

Protection Fuse Battery 2: ATC 20 A

Solar Power Max: 12 V at 30 Watts max.

AC Cable 50 feet up to

250 feet - 250 mA

AC Cable 250 feet up to

1000 feet - 100 mA

NOTE:

Increased accessory power drawn from

the operator will shorten the battery life.

Weight: 13.2 lbs. (6 kg.)

(10.2 cm)

4.5"

(11.2 cm)

4"

.25"

(0.635 cm)

14"

(35.6 cm)

53.5"

(136 cm)

(25.4 cm)

36.3"

(92.1 cm)

.475" DIA.

(1.2 cm DIA.)

37.4"

(95 cm)

RESET

10"

6"

(15.2 cm)

CARTON INVENTORY

This operator comes with the hardware to install on a gate that pulls-to-open. If your application requires the gate to be pushed open, accessory kit 50-19503 is required.

Pull-to-Open Bracket

Model LA412 (1)

Model LA412-S (2)

Cable Ties (4)

Gate Operator

Model LA412 (1)

Model LA412-S (2)

Gate Bracket

Model LA412 (1)

Model LA412-S (2)

Standard Control Box (1)

with 2 Batteries

Post Bracket

Model LA412 (1)

Model LA412-S (2)

Moving Gate Can Cause

Injury or Death

KEEP CLEAR! Gate may move at any

time without prior warning.

Do not let children operate the gate or

play in the gate area.

This entrance is for vehicles only

Pedestrians must use separate entrance

Warning Signs (2)

Wire Nuts (6)

Model LA412 ONLY

Extension Cable

Model LA412-S ONLY

12V 10W Solar Panel

Model SOLPNL10W12V (1)

Watertight Connector

Model LA412-S ONLY (2)

Junction Box

Model LA412-S ONLY

6

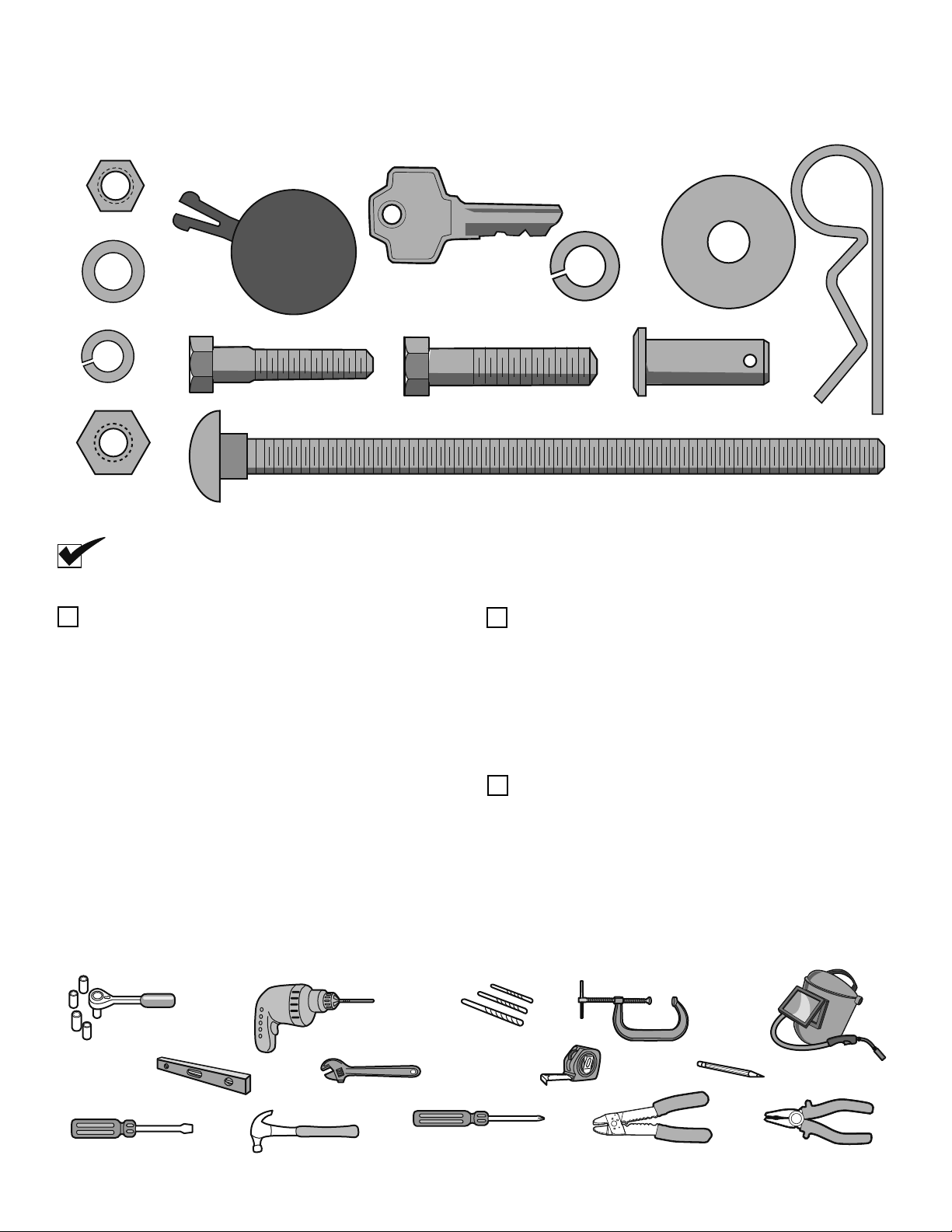

INTRODUCTION » HARDWARE INVENTORY + ADDITIONAL ITEMS FOR PURCHASE + TOOLS NEEDED

HARDWARE INVENTORY

NOTE:

Hardware quantities shown below are for LA412. Quantities are doubled for LA412-S.

Hex Nut 5/16"-18 (1)

Key (2)

Flat Washer 5/16" (1)

Lock Washer 5/16" (1)

Hex Nut 3/8"-16 (3)

Keylock Cap

Hex Bolt 5/16"-18 x 1-1/2" (1)

ADDITIONAL ITEMS FOR PURCHASE

The following items are REQUIRED to complete the installation:

ALL MODELS:

HARDWARE

• 5/16" mounting hardware for gate bracket.

• The following hardware is needed to mount the control box depending on the

mounting surface:

Wood: Four #8 1-1/4" zinc plated wood screws.

Metal: Four #10-32x6" zinc plated machine screws with nut and lock washers.

Concrete, Brick, etc.: Four 1/4" x 1-3/4" masonry screws.

Post: U-bolt size will vary depending on post. The U-bolt thread sizes for the

control boxes are:

1/4" - standard control box

3/8" - XLM control box

Lock Washer 3/8" (3)

Hex Bolt 3/8"-16 x 1-1/2" (1)

Carriage Bolt 3/8" x 5-15/16" (2)

Flat Washer 3/8" (3)

Pin (2)

PHOTOELECTRIC SENSORS

The Model 50-220 photoelectric sensors are intended for installation with the

operators covered in this manual.

To order call 1-800-528-2806 or visit www.liftmaster.com.

LA412-S ONLY:

CONDUIT

UL Listed outdoor electrical conduit with 3/4" diameter to hold the extension cable

between the junction box and the control box.

Hairpin Clip (2)

TOOLS NEEDED

During assembly, installation and adjustment of the operator, instructions will call for

tools as illustrated below.

Deep Well Sockets

and Wrench

1/2", 5/8", 7/16", 9/16"

and 1/4"

Carpenter's Level

Screwdriver

Drill

Adjustable End Wrench

Hammer

Drill Bits

1/2", 3/16", 5/16"

and 5/32"

Phillips Head Screwdriver

2

1

Tape Measure

Clamps

Pencil

Welder (Optional)

Wire Cutters (Optional)Wire Strippers (Optional)

7

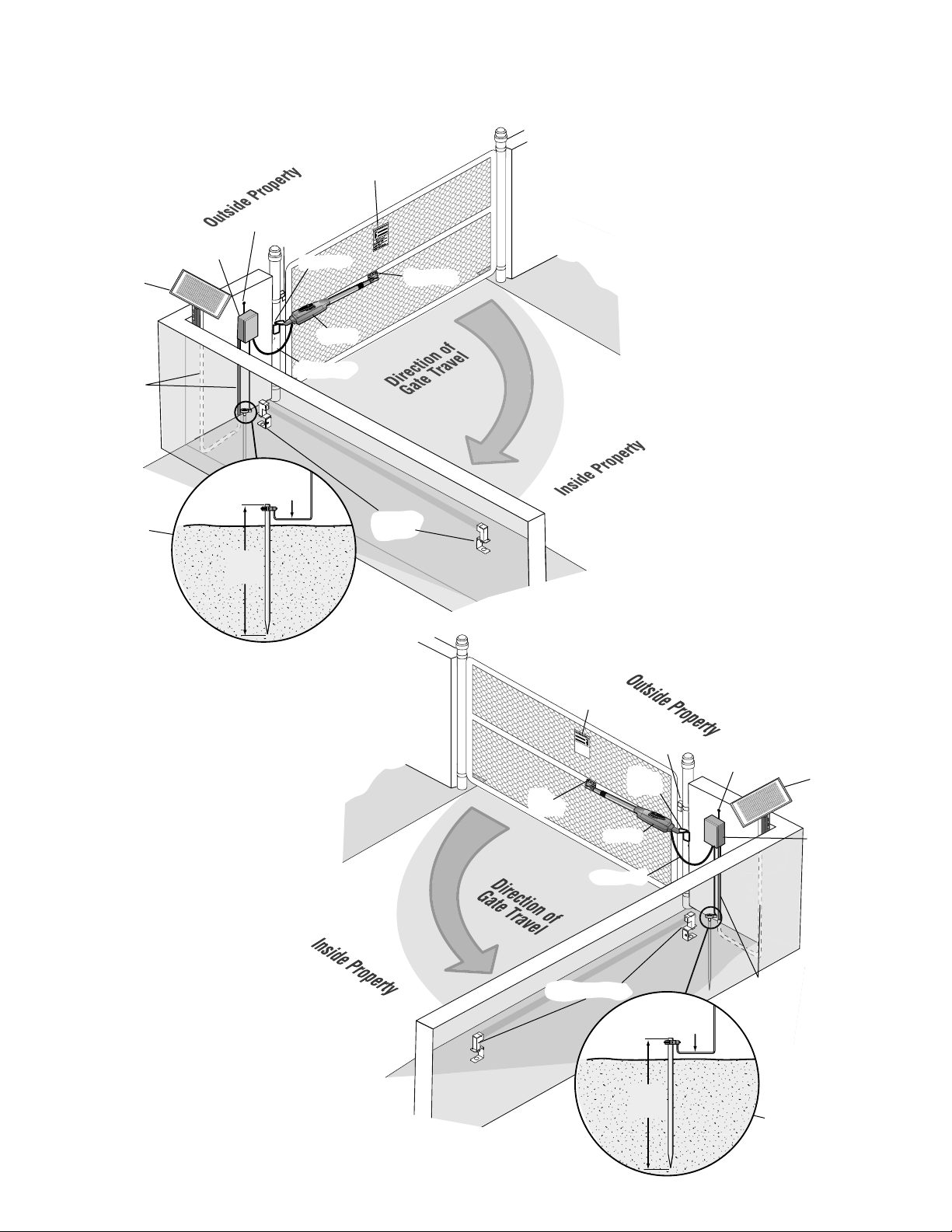

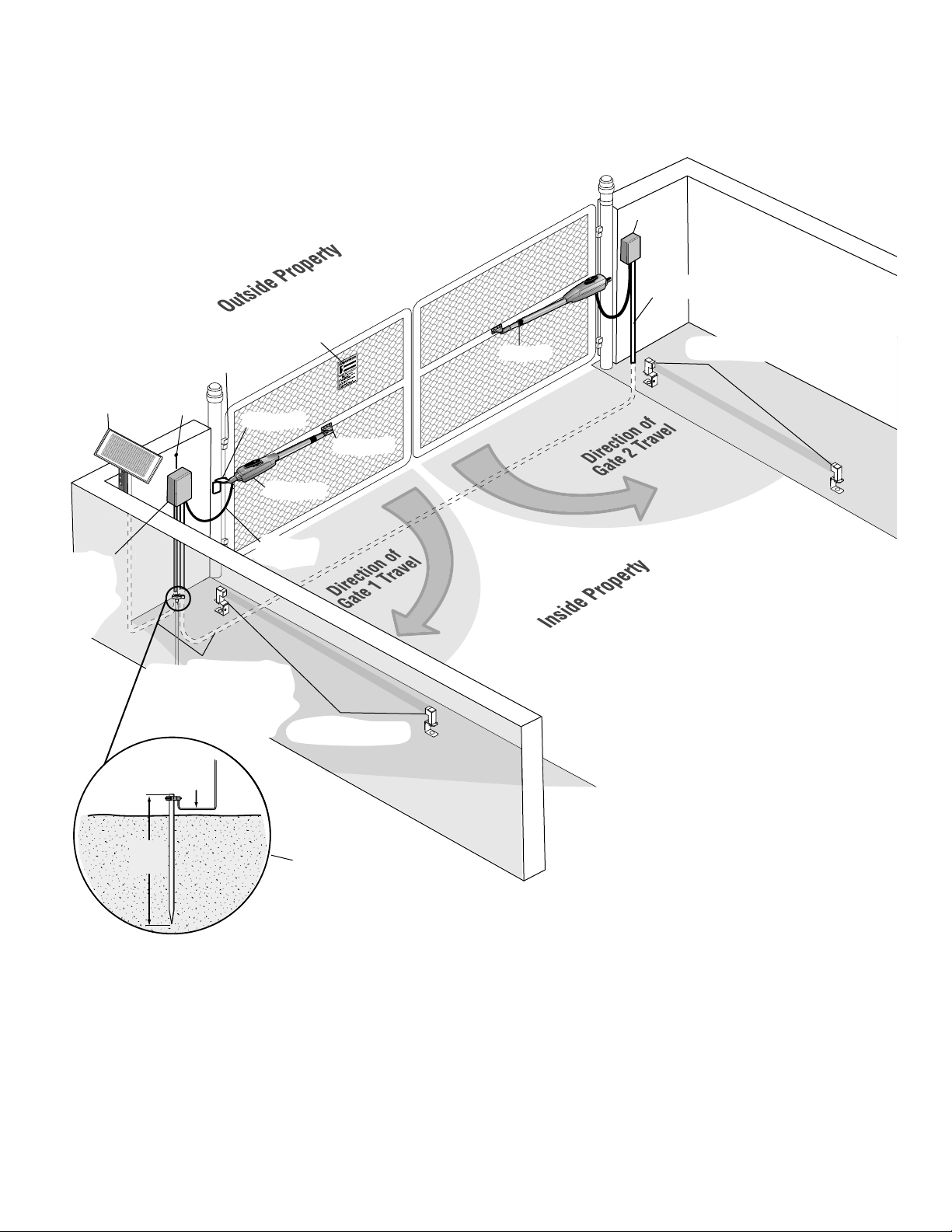

INSTALLATION » OVERVIEW OF TYPICAL INSTALLATION

Mov

ing Gate Can Cause

Inj

ury or Death

KEEP

CL

EAR!

Gate may move at an

y

time

wi

thout

prior war

n

in

g.

Do

no

t let ch

ildren op

er

ate t

h

e gate or

play i

n

th

e gate

area.

This e

nt

r

ance is for

vehicl

es o

nly

Pede

strians mu

st use sep

arate entra

nce

12

gauge

wire

8 ft.

(2.4 m)

12

gauge

wire

8 ft.

(2.4 m)

12 Gauge

Wire

8 feet

(2.4 m)

12 Gauge

Wire

8 feet

(2.4 m)

LEFT-HAND GATE

Warning Sign

Antenna

Control Box with Batteries

Solar Panel

(Facing South)

Hinge

Post Bracket

Gate Bracket

PVC Conduit (not

provided) to protect the

power cable for solar and

low voltage wire from

lawn mowers and string

trimmers.

Earth Ground Installation

(Optional)

RIGHT-HAND GATE

Operator

Operator Cable

Photoelectric

Sensors

Gate

Bracket

NOTE: One or more non-contact sensors shall be located

where the risk of entrapment or obstruction exists at

either the opening or closing direction. Care shall be

exercised to reduce the risk of nuisance tripping, such as

when a vehicle, trips the sensor while the gate is still

moving.

Warning Sign

Hinge

Post

Antenna

Bracket

Operator

Solar Panel

(Facing South)

Control Box with

Batteries

Operator Cable

Photoelectric Sensors

PVC Conduit (not provided) to protect the

power cable for solar and low voltage wire

from lawn mowers and string trimmers.

Earth Ground

Installation (Optional)

8

INSTALLATION » OVERVIEW OF TYPICAL INSTALLATION

12 Gauge

Wire

8 feet

(2.4 m)

DUAL GATE

Warning Sign

Hinge

Solar Panel

(Facing South)

Antenna

Post Bracket

Gate Bracket

Gate 1

Gate 2

Junction Box

Extension Cable

Photoelectric Sensors

Control Box with

Batteries

PVC Conduit (not provided) to protect the

power cable for solar and low voltage wire

from lawn mowers and string trimmers.

12

gauge

wire

8 ft.

(2.4 m)

Operator Cable

Earth Ground

Installation (Optional)

Photoelectric Sensors

NOTE: One or more non-contact sensors shall be located

where the risk of entrapment or obstruction exists at

either the opening or closing direction. Care shall be

exercised to reduce the risk of nuisance tripping, such as

when a vehicle, trips the sensor while the gate is still

moving.

9

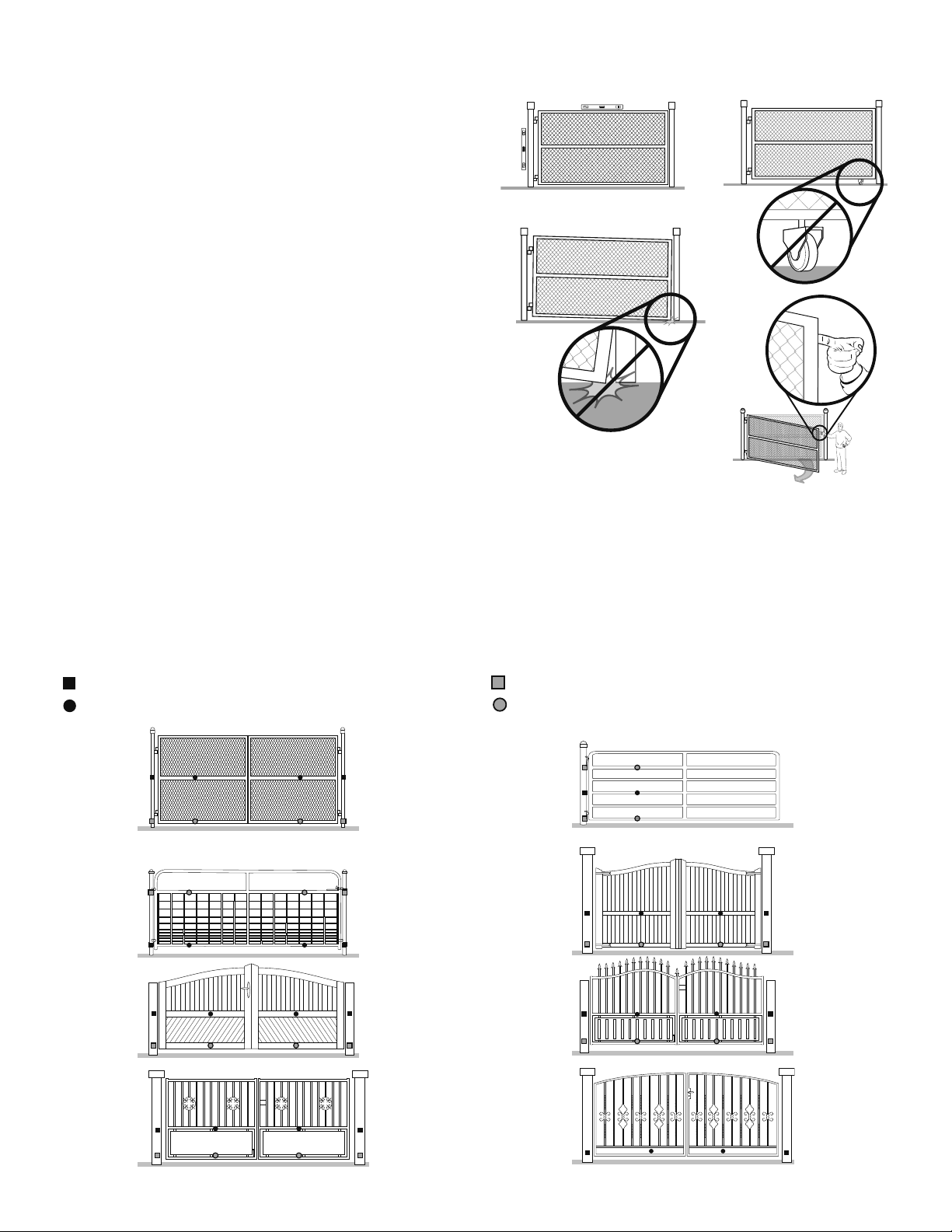

INSTALLATION » CHECK YOUR GATE + MOUNTING OPTIONS

CHECK YOUR GATE

A

Gate MUST be level. Gate and gate post MUST be plumb.

A

Remove ANY/ALL wheels from the bottom of gate.

B

Gate MUST NOT hit or drag across ground.

C

Gate MUST swing freely and be supported entirely by its hinges.

D

C

B

D

MOUNTING OPTIONS

Mounting locations vary depending on type and style of your gate. Minimum

distance from the ground should not be less than 4 inches (10.2 cm) from the

bottom of the gate operator arm.

RECOMMENDED:

= Gate post bracket mounting locations

= Gate bracket mount locations

OPTIONAL:

= Gate post bracket mounting locations

= Gate bracket mount locations

10

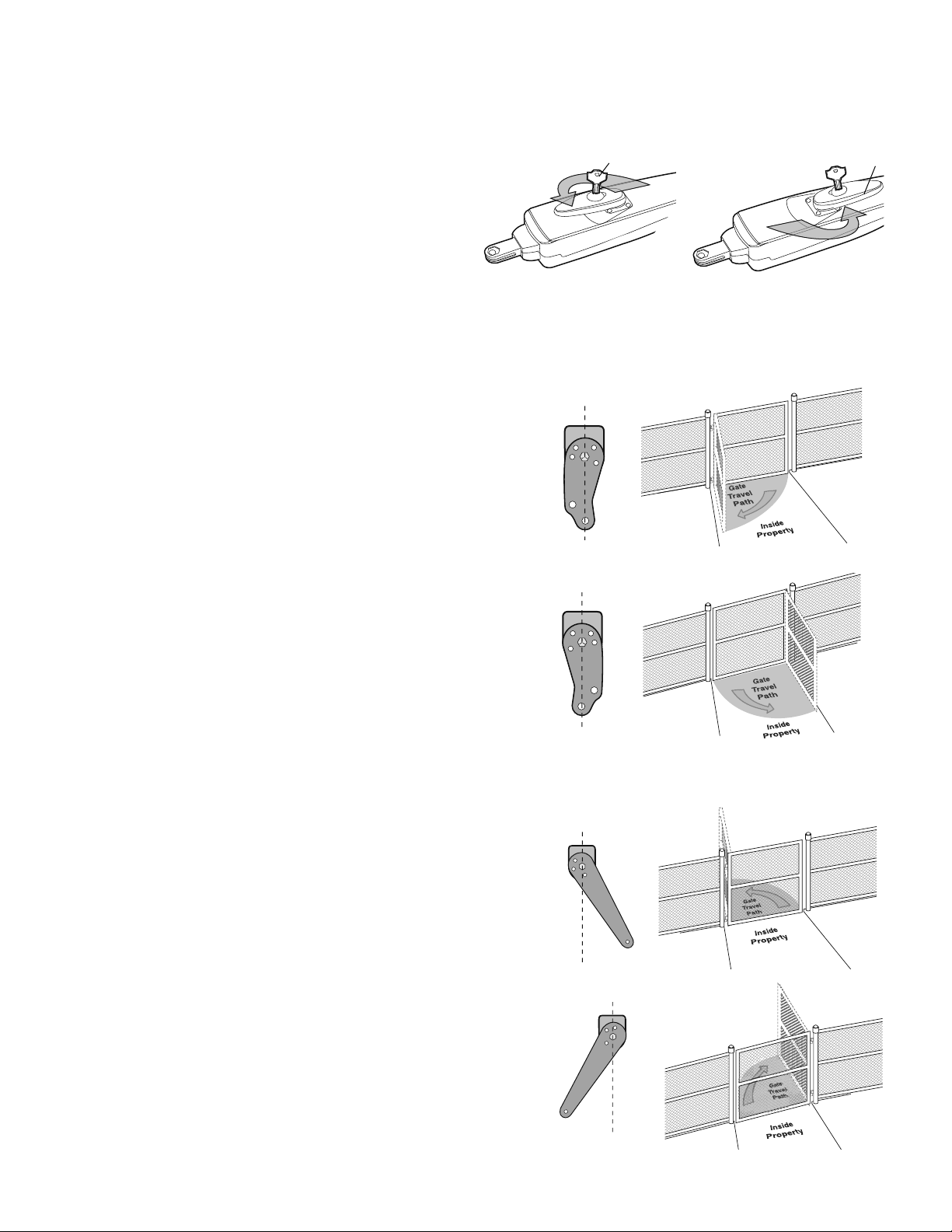

INSTALLATION » MANUAL RELEASE + DETERMINE POSITION OF THE PULL-TO-OPEN BRACKET

+ DETERMINE POSITION OF THE "OPTIONAL" PUSH-TO-OPEN BRACKET

MANUAL RELEASE

Insert the key into the lock and turn it 180° counterclockwise.

1

Turn the release lever 180° counterclockwise.

2

The operator is now in manual mode.

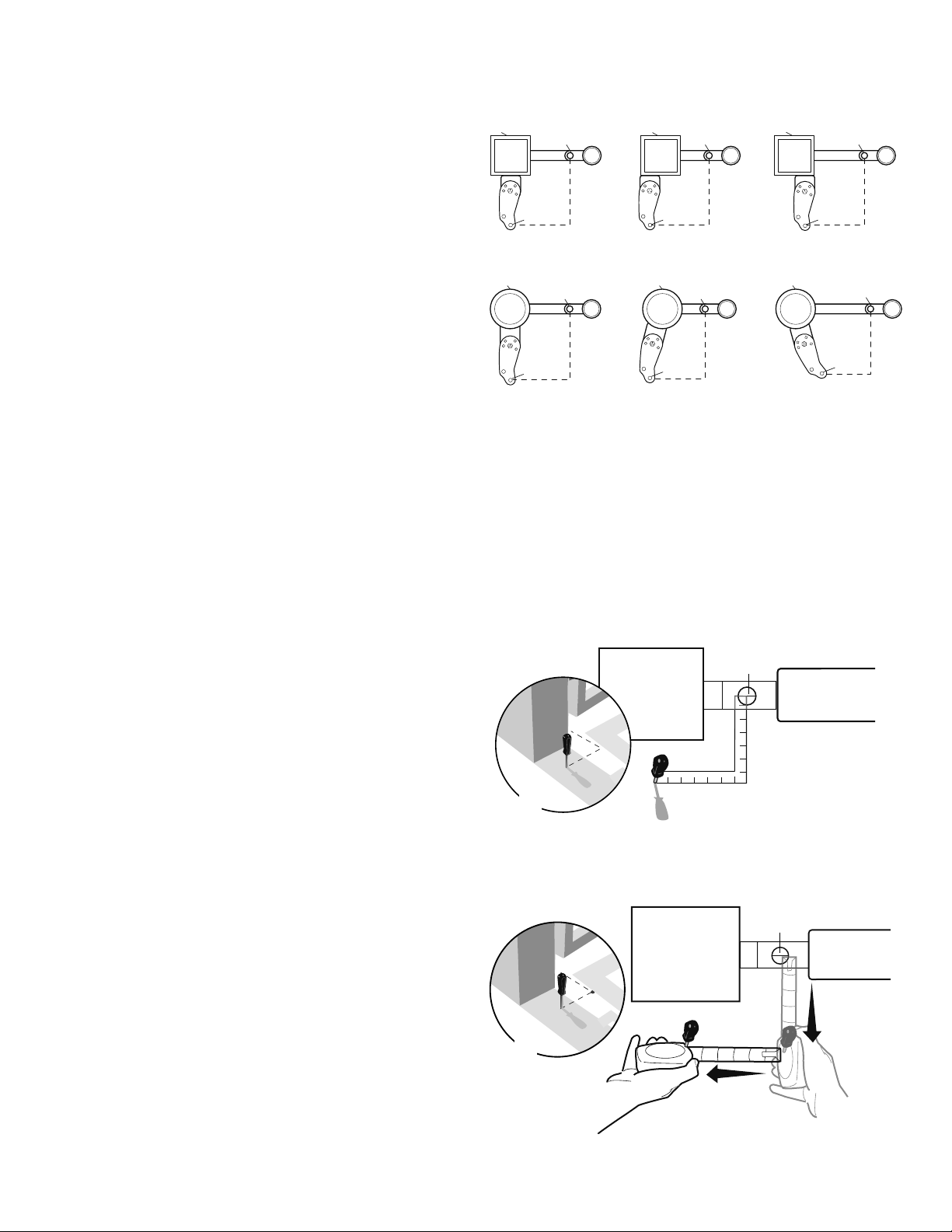

DETERMINE POSITION OF THE PULL-TO-OPEN BRACKET

The Pull-To-Open bracket can be assembled to work on a Left-Hand or a

Right-Hand gate.

Review the gate types and select the type of installation you will require.

1

NOTE:

If the Pull-To-Open bracket is not assembled correctly you will

damage the operator.

1

1

LEFT-HAND GATE

RIGHT-HAND GATE

Key

Release Lever

2

OR

DETERMINE POSITION OF THE "OPTIONAL" PUSH-TO-OPEN BRACKET

(NOT PROVIDED. SEE ACCESSORIES)

The Push-To-Open bracket can be assembled to work on a Left-Hand or a

Right-Hand gate.

Review the gate types and select the type of installation you will require.

1

LEFT-HAND GATE

1

RIGHT-HAND GATE

11

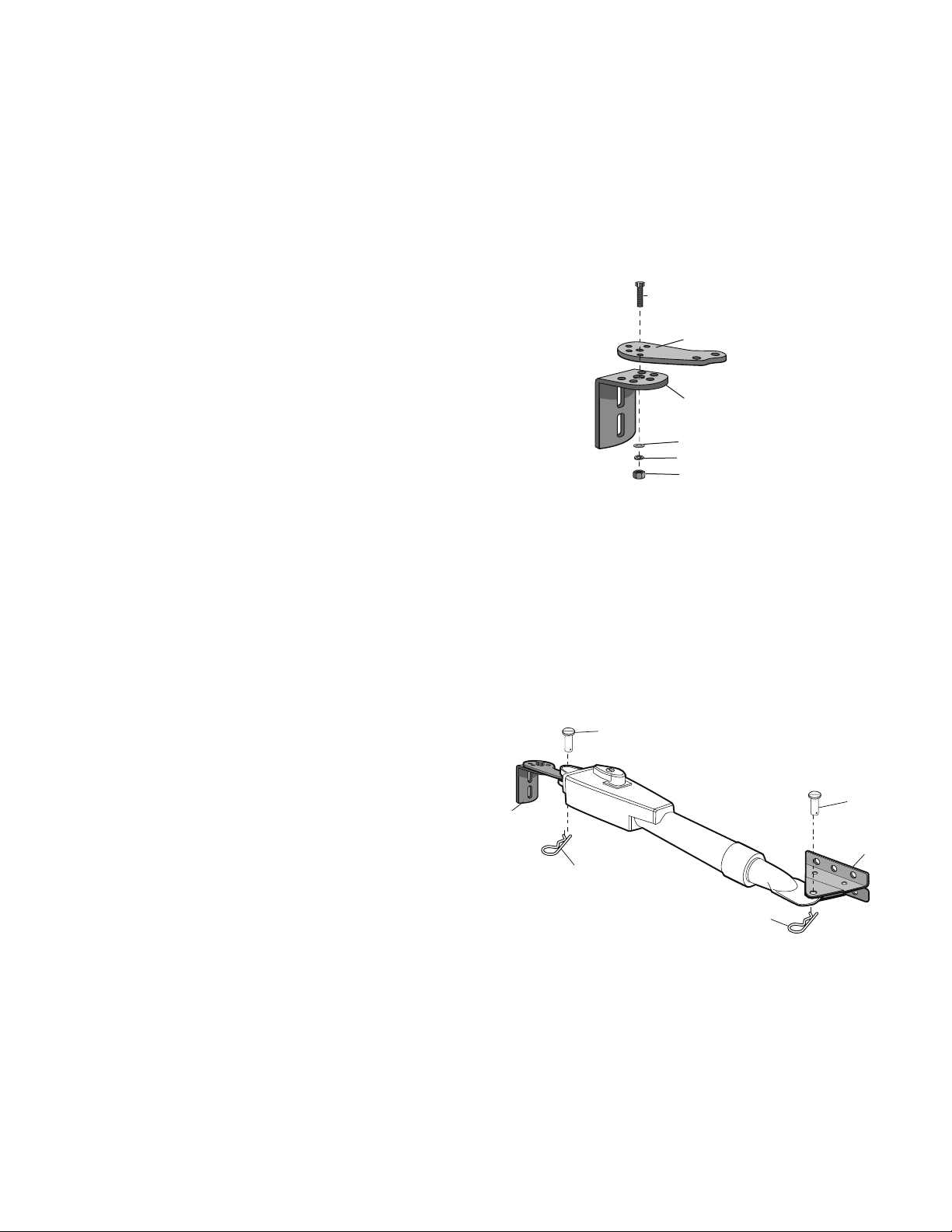

INSTALLATION » ASSEMBLE GATE POST BRACKET (PULL-TO-OPEN) + ATTACH BRACKETS TO GATE OPERATOR

All the illustrations on the following pages display a

typical Left-Hand Gate installation. For push-to-open

installations refer to instructions with push-to-open kit

50-19503.

ASSEMBLE GATE POST BRACKET (PULL-TO-OPEN)

Hex Bolt 3/8"

Hex Bolt 3/8"

Assemble gate post bracket by placing pull-to-open bracket on top of post

1

bracket.

Extension

Bracket

Pull-to-Open Bracket

Insert the bolt through both brackets and secure with washer, lock washer

2

and nut.

ATTACH BRACKETS TO GATE OPERATOR

Attach post bracket assembly to operator using pins and hairpin clips.

1

Attach gate bracket to operator using pins and hairpin clips.

2

1

Post Bracket Assembly

1

Post Bracket

Post Bracket

Washer

Washer

Lock Washer

Lock Washer

Nut

2

Pin

Nut

Pin

12

Hairpin Clip

Hairpin Clip

2

Gate Bracket

INSTALLATION » DETERMINE MOUNTING LOCATION + MEASURING AND MARKING FOR THE GATE BRACKET

DETERMINE MOUNTING LOCATION

The gate post bracket assembly can be mounted several places on the gate post.

Refer to the illustrations on page 10 for the ideal mounting location.

Refer to the illustrations to determine the appropriate dimensions for the

Pull-To-Open bracket.

NOTE:

It may be necessary to add shims (angle iron, sheets of metal or wood) to

the gate post to achieve the required dimensions.

MEASURING AND MARKING FOR THE GATE BRACKET

Before proceeding, begin with the gate in the fully closed position. There are two

methods for determining the proper location of the post brackets:

• Paper template (Located on the back page of this manual. Must be cut out.)

• Tape measure.

Either method will work depending on preference.

TEMPLATE METHOD

Gate Post

Gate Post

Gate Hinge Point

Operator

Hinge

Point

7" (18 cm)

Gate Hinge Point

Operator

Hinge Point

7" (18 cm)

7" (18 cm)

7" (18 cm)

Gate Post

Gate Post

TOP VIEW

Gate Hinge Point

Operator

Hinge Point

7" (18 cm)

Gate Hinge Point

Operator

Hinge Point

7" (18 cm)

7" (18 cm)

7" (18 cm)

Gate Hinge Point

Gate Post

Gate Post

Gate Hinge Point

Operator

Hinge Point

7" (18 cm)

Gate Hinge Point

Operator

Hinge Point

7" (18 cm)

1

7" (18 cm)

7" (18 cm)

Close the gate.

1

Place the template (provided on the back page of this manual) under the center

of the gate hinge point.

2

Use a screwdriver or dowel rod to temporarily mark the location in front of the

3

gate post.

TAPE MEASURE METHOD

Close the gate.

1

Place the measuring tape under the center of the gate hinge point and measure

out 7 inches (18 cm).

2

Use a screwdriver or dowel rod to temporarily mark the location of the first

3

measurement.

Measure 7 inches (18 cm) from the previous mark.

4

Use the screwdriver or dowel rod to mark the location of the second

5

measurement.

5

3

Gate Post

TOP VIEW

Gate Post

4

7" (18 cm)

2

Gate Hinge Point

2

Gate

1

Gate

7" (18 cm)

3

13

Loading...

Loading...