Page 1

Installation Instructions

Hydraulic Models: HS670-100-S1

HS670-200-S1

Vehicular Slide Gate Operator

Doc 01-20228

Rev D

Page 2

2

Contents

Contents

General Information _____________________________________________ 3

Supplied Parts _____________________________________________________________ 3

Specifications _____________________________________________________________3

Dimensional Outline ________________________________________________________ 3

Safety Information_______________________________________________ 4

Safety Instructions__________________________________________________________ 4

Safety Precautions for Open-Roller Gates and Ornamental “Grill Type” Gates __________ 6

Pre-Installation Check-List ________________________________________ 8

Wiring Specifications _______________________________________________________8

Operator Features ______________________________________________ 11

Programmable Features_____________________________________________________ 13

Led Descriptions __________________________________________________________ 14

Installation____________________________________________________ 15

Step 1:

Step 2: Drive Rail ________________________________________________________ 16

Step 3:

Step 4: Vent Cap_________________________________________________________ 17

Step 5: Limit Shoes_______________________________________________________ 18

Step 6:

Step 7: Power Wire Connections ____________________________________________ 20

Step 8: Programming _____________________________________________________ 22

Step 9: Preliminary System Check Out _______________________________________ 26

Step 10: Accessory Installation_____________________________________________ 27

Concrete Pad______________________________________________________ 15

Operator Mounting_________________________________________________16

Suspension System_________________________________________________ 19

Required Maintenance___________________________________________ 28

Warranty______________________________________________________ 29

Doc 01-20228

Rev D

Page 3

General Information

Supplied Parts

General Information

3

Inspect the operator for any possible shipping

damage and any shortage of parts. Please

note that if accessories were ordered with this

unit, some may be packed separately.

! Install

Gate Warning Plates

on both sides

of the gate where they can be easily seen.

Do not

!!

run operator without vent cap

installed.

Part Description Qty.

¼ -20 Bolt 4

¼ Lockwasher 4

¼ -20 Hex Nut 4

10-24 Screw 4

10 Lockwasher 4

10-24 Hex Nut 4

Limit Shoe 2

Gate Warning Plate ! 2

Gate Safety Flyer 1

Vent Cap !! 1

Table 1

Specifications

MODEL HS670-100-S1 MODEL HS670-200-S1

Horsepower 1 H.P. 2 H.P.

Pump P.S.I. 600 1500

Gate Size & Weight Designed For Most Lengths & Weights of Slide Gates

Frequency of Use Designed for High Cycle Rates

Primary Voltages 120-230-460 1Ø & 3Ø 230-460 3Ø Only

Secondary Voltages 24 Vac/12 Vac 24 Vac/12 Vac

Table 2

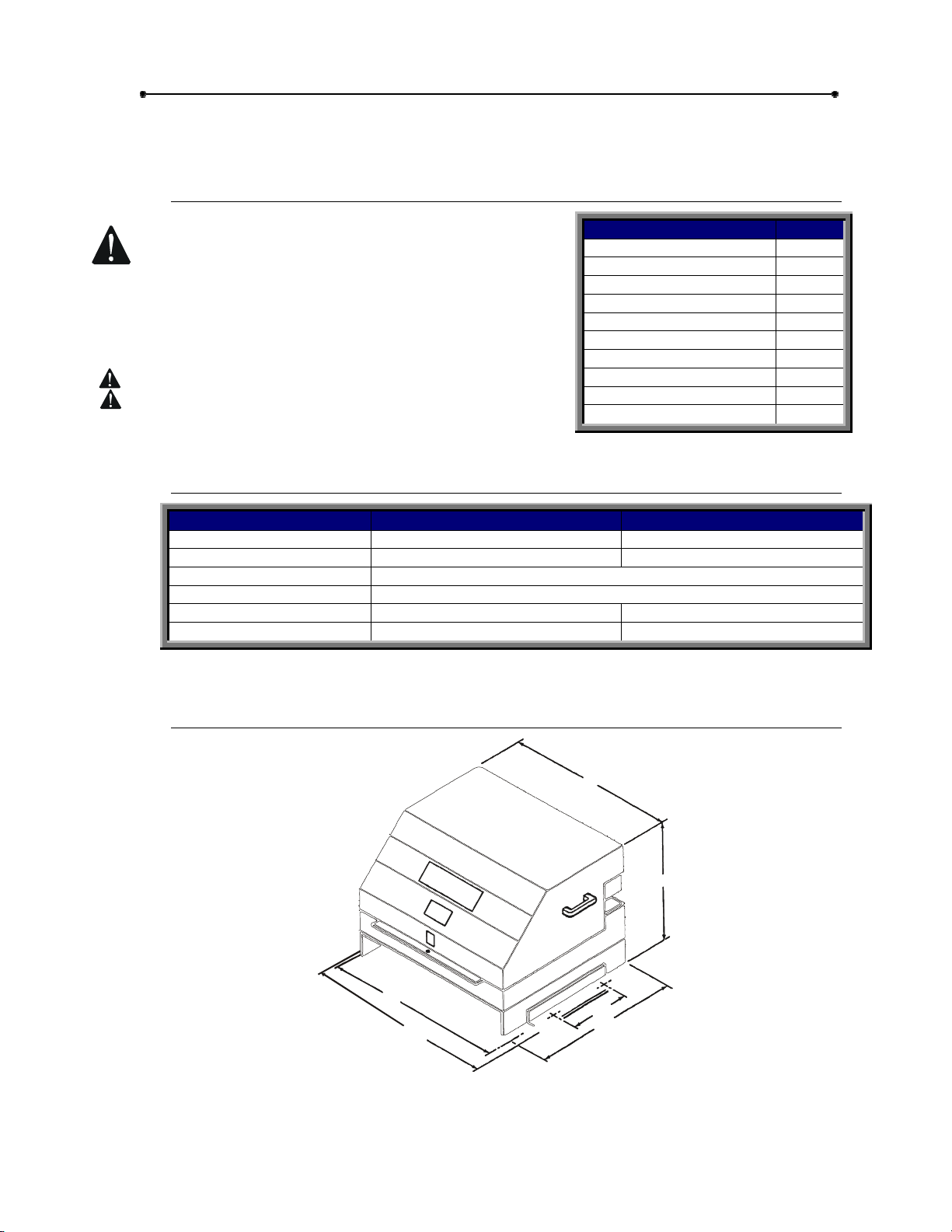

Dimensional Outline

29 3/4”

31 3/4”

27”

19 3/4”

14”

26 1/2”

01-20221F1

Figure 1

Doc 01-20228

Rev D

Page 4

4

Safety Information

Safety Information

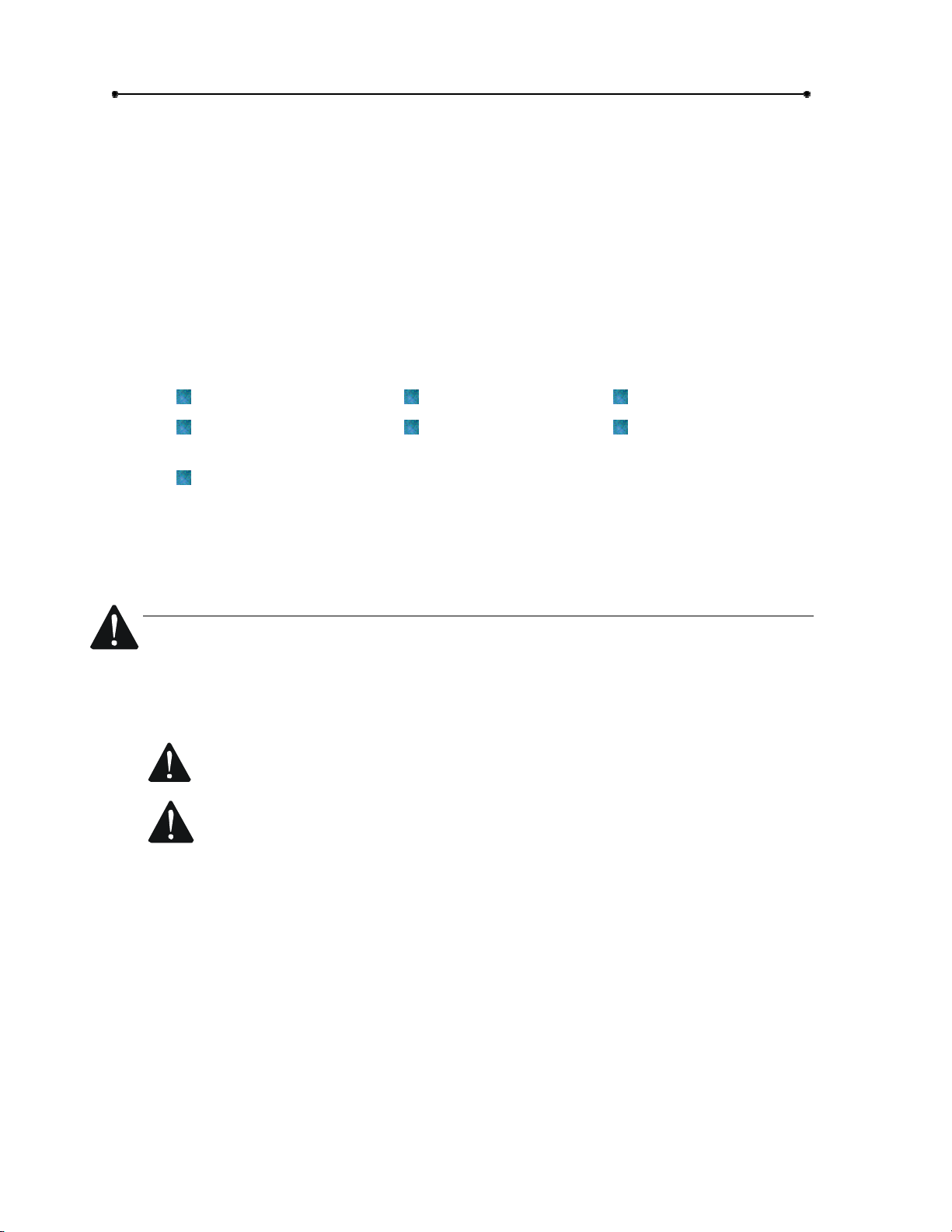

Vehicular gate systems provide convenience and security. Gate systems are

comprised of many component parts. The gate operator is only one component. Each

gate system is specifically designed for an individual application.

Gate operating system designers, installers and users must take into account the

possible hazards associated with each individual application. Improperly designed,

installed or maintained systems can create risks for the user as well as the bystander.

Gate systems design and installation must reduce public exposure to potential hazards.

A gate operator can create high levels of force, in its function as a component part of a

gate system. Therefore, safety features must be incorporated into every design.

Specific safety features include:

Gate Edges Enclosed Track Vertical Posts

Guards for exposed

rollers

Screen Mesh

Important instructions follow. These instructions are intended to highlight certain safety

related issues. These instructions are not intended to be comprehensive. Because

each application is unique, it is the responsibility of the purchaser, designer, installer

and end user to ensure that the total gate system is safe for its intended use.

Photo-electric

Sensors

Instructional and

Precautionary Signage

Safety Instructions

Select instructions are highlighted with this precautionary symbol (see left margin).

Failure to follow these selected instructions can result in serious injury or death.

STEP 1: BEFORE INSTALLATION

1

Confirm gate operator model is specified by Installation and Maintenance

Manual for application type, gate size and frequency or use.

2

Confirm ALL appropriate safety features, such as gate edges, photo-electric

sensors, vertical posts and enclosed tracks, are specified.

3

Confirm gate system design reduces pinch points and protects against

entrapment.

4

Confirm gate system design has pedestrian access separate from vehicular

entrance.

5

6

7

8

9

10

Doc 01-20228

Rev D

Confirm gate system design reduces traffic backup.

Confirm warning signage is included in design.

Confirm gate moves freely before installation of operator

Repair or service worn or damaged gate hardware before installation of

operator.

To avoid installation hazards, review the gate system operation and

installation procedures, such as manual disconnect mechanism procedure.

Confirm control design prohibits unauthorized use.

Page 5

STEP 2: DURING INSTALLATION

1

Disconnect power at service panel before making any electrical connection.

2

Avoid pinch points, be aware of all moving parts.

3

Adjust clutch or load sensing device to minimum force setting.

4

Do not over-tighten cutch or adjust force setting above minimum.

5

Install controls where user cannot touch gate while operating controls.

6

Install controls where user has full view of gate operation.

7

Install two or more warning signs on the gate to alert persons in the area of

automatic gate operation. Warning signs must be conspicuous.

Safety Information

5

8

Install operator inside fence line.

fence line.

9

Secure gate operator cover.

STEP 3: AFTER INSTALLATION

1

Test all safety features.

2

Train end user about basic functions and safety features of gate system.

3

Leave Installation and Maintenance Manual and Safety Instructions with

end user.

Do not

install operator on public side of

Doc 01-20228

Rev D

Page 6

6

Safety Information

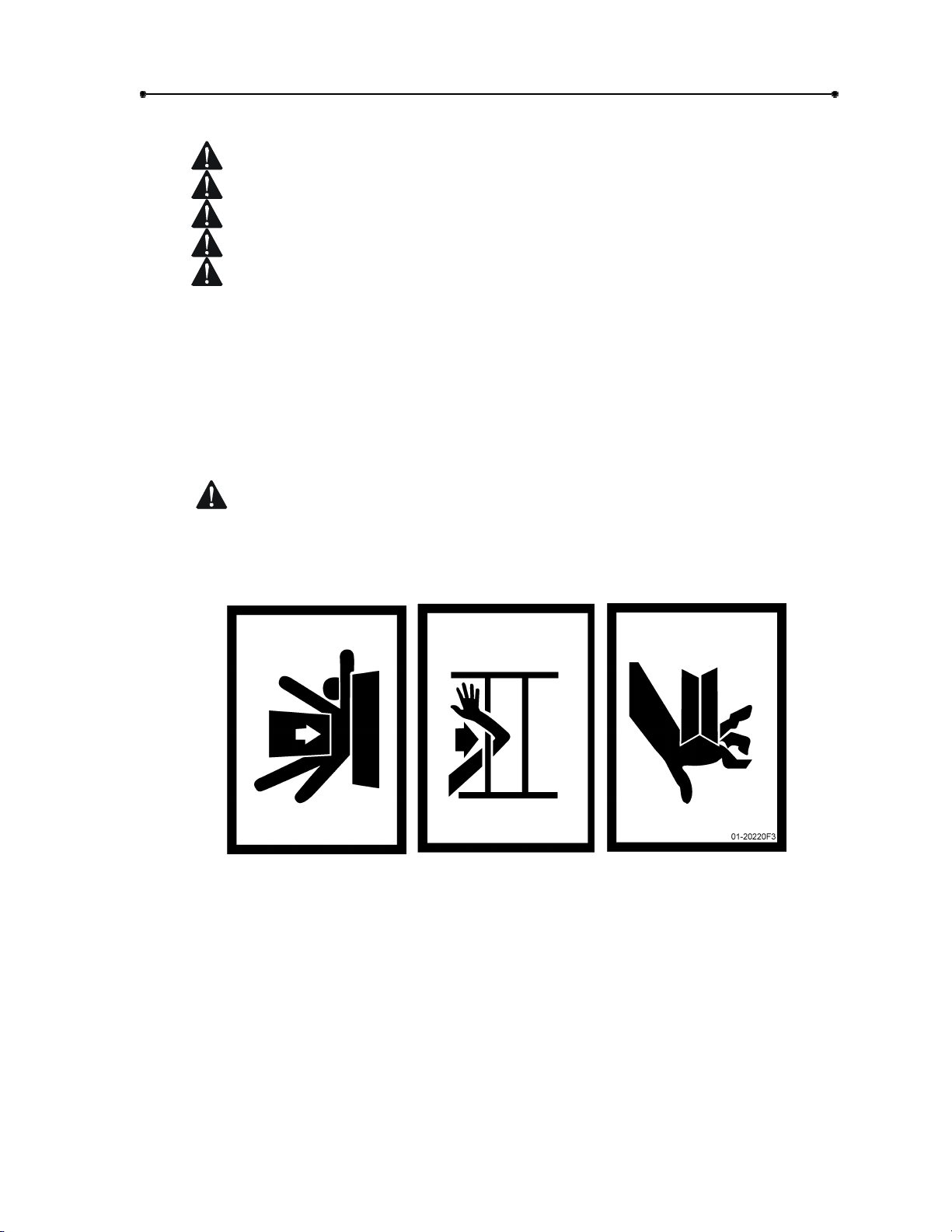

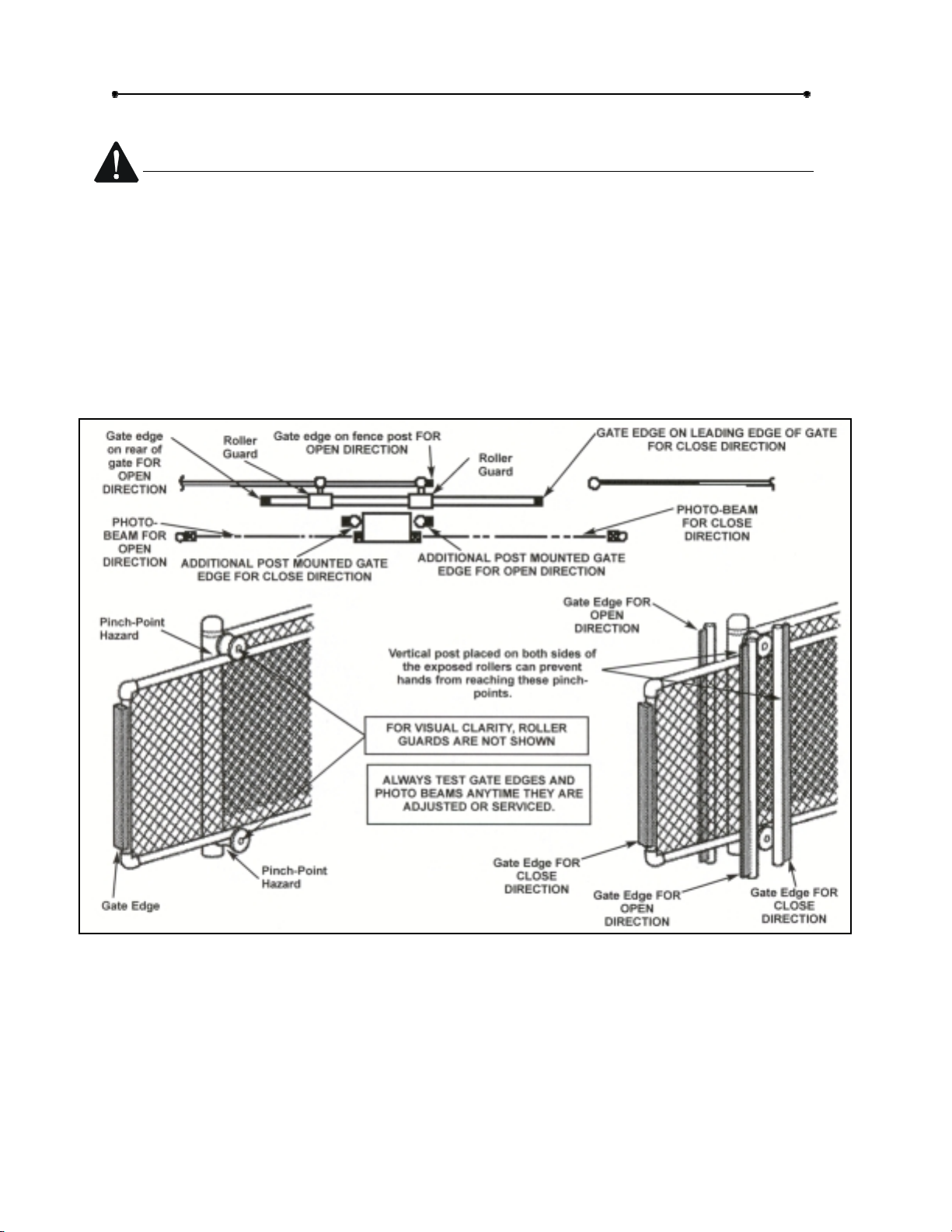

Safety Precautions for Open-Roller Gates and

Ornamental “Grill Type” Gates

OPEN-ROLLER GATES

Injuries occur when people get their or feet caught between the top or bottom of the

gate and the gate roller. This potential pinch-point should be guarded against at all

times. Enclosed style gate tracks are available for refitting of these rollers from

many fence suppliers. Also, roller guards are available for installing over the

rollers.

One ore more contact sensors shall be located at the leading edge, trailing edge,

and post-mounted both inside and outside of a vehicular horizontal slide gate.

Doc 01-20228

Rev D

Figure 2

Page 7

Safety Information

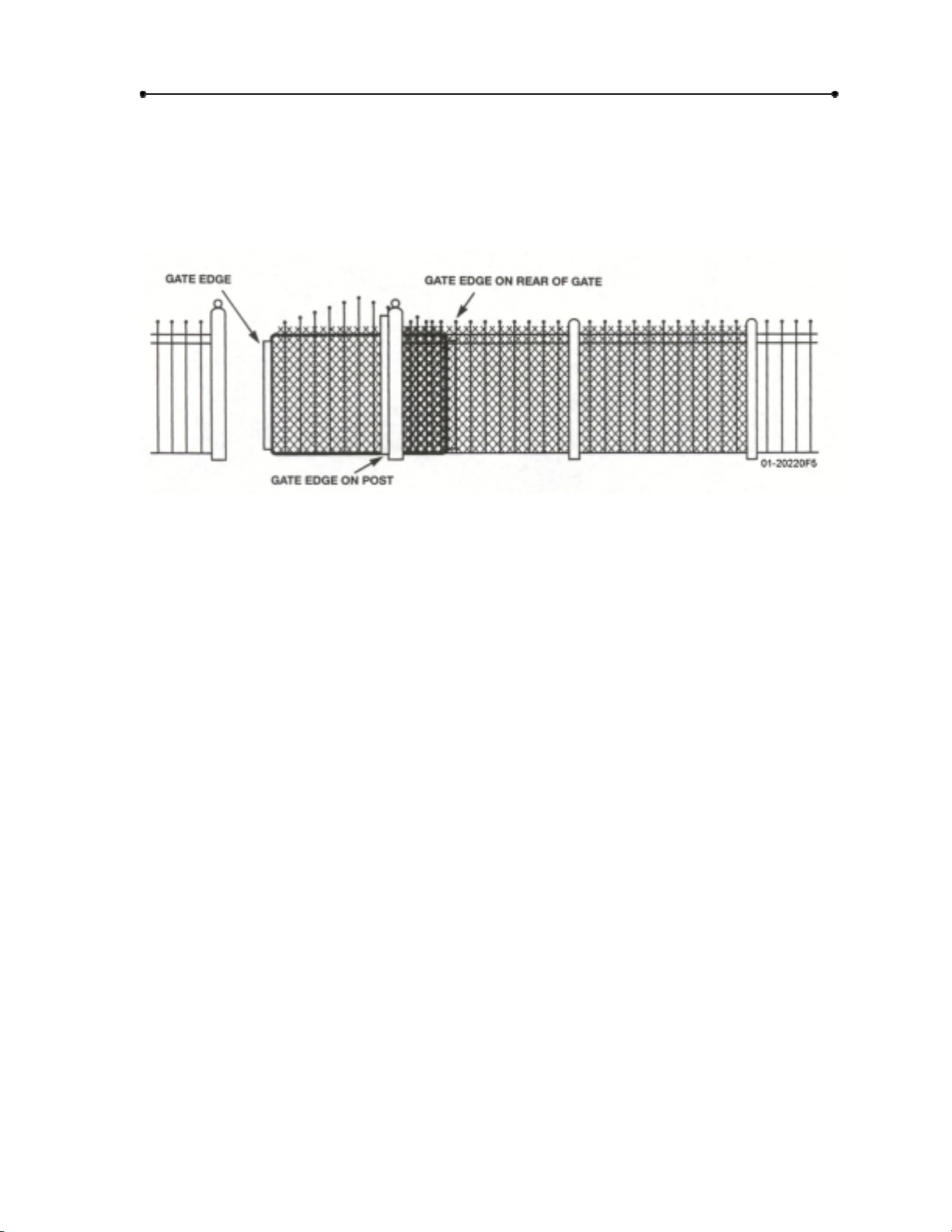

ORNAMENTAL “GRILL TYPE” GATES

Injuries occur when people put their hands and arms through openings in the grill

and the gate is operated. They cannot retract their arms and it gets caught between

the moving gate grill and the stationary fence post or fence. This potential hazard

can be averted by placing a screen mesh on the gate to prevent access through

openings anywhere the gate may travel.

Figure 3

7

Doc 01-20228

Rev D

Page 8

8

Pre-Installation Check-List

Pre-Installation Check-List

BACKFRAME

2 FT.

GATE

OPENING

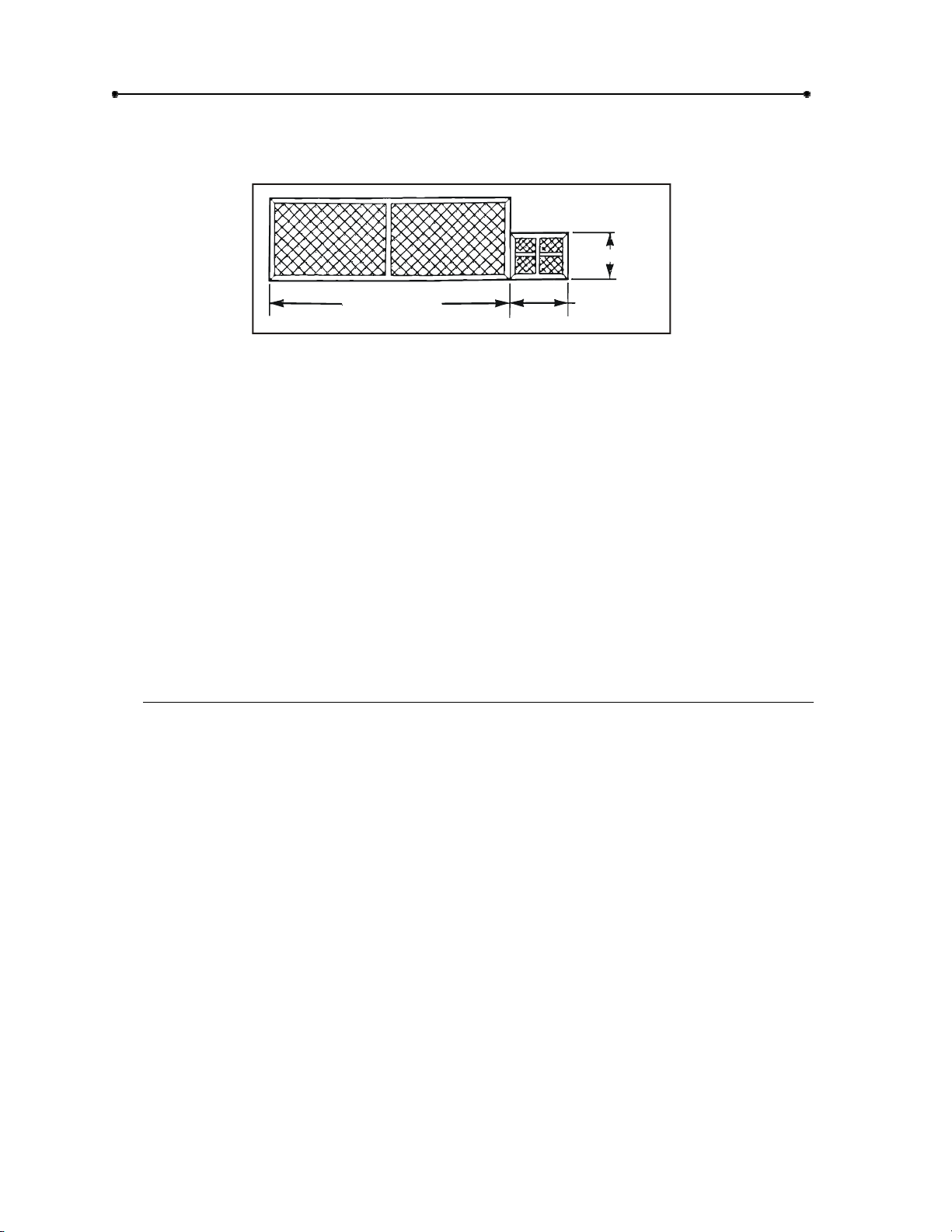

Figure 4

Φ

Check the gate. It

adjust or repair the gate prior to operator installation. The gate

plumb.

Φ

Some gates may only be as wide as the gate opening. They may require a

backframe to be constructed to allow for chain attachments See Figure 4.

Φ

Double check the size and weight of the gate to make sure that this operator is

proper for this application.

Φ

If wiring has already been installed, check to make sure it meets the following

specifications and requirements.

must

operate smoothly and freely. If necessary, lubricate,

3 FT. MIN.

01-20228 F8

must

Wiring Specifications

A.

The distances shown are measured in feed from the operator to the power

source.

be level and

B.

These calculations are based on the National Electrical Code and allows for a

5% voltage drop.

C.

Supply voltage must be within 10% of the operator’s rating under load

conditions.

D.

These calculations are based on stranded copper wire.

E.

It is highly recommended that only 90% of the distances shown be used; this will

allow for a 10% safety factor.

F.

For dual units, the distance shown should be cut in half.

G.

When wire larger than 12 gauge is used, a separate junction box will be required

for operator power connections (not supplied).

H.

All local codes must be strictly adhered to.

I.

Do not run control wires in the same conduit with power wires.

J.

Do not run parallel conductor cable for controls.

Doc 01-20228

Rev D

Page 9

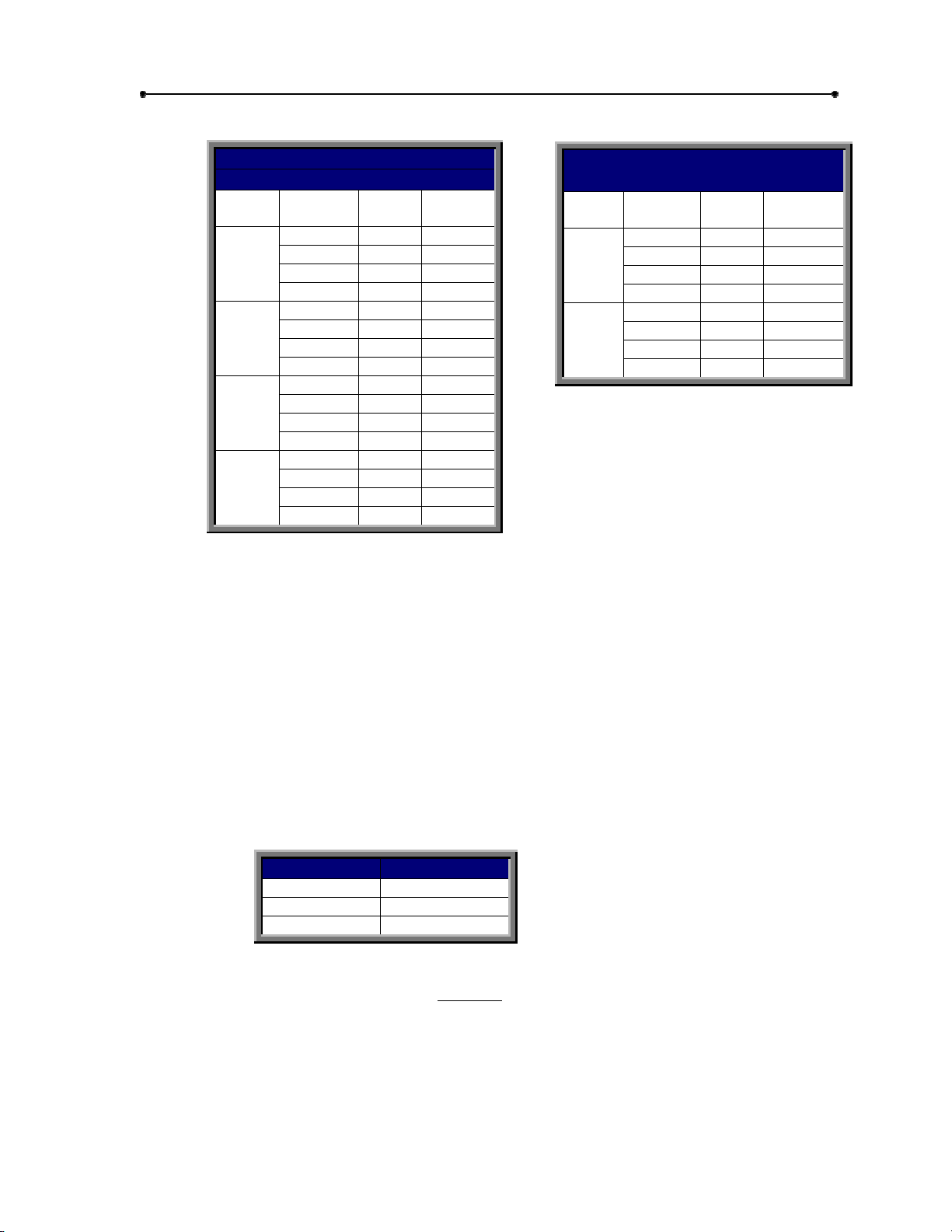

POWER WIRING

Pre-Installation Check-List

9

VOLT.

H.P.

230

1HP

460

1HP

230

2HP

460

2HP

THREE PHASE

MAX. DIST. (FT.)

SINGLE

UNIT

343 171 12

546 273 10

868 434 8

1381 690 6

1593 796 12

2533 1266 10

4029 2014 8

6407 3203 6

181 90 12

289 144 10

459 229 8

731 365 6

796 398 12

1266 633 10

2014 1007 8

3203 1601 6

DUAL

Table 3

UNIT

WIRE

GAUGE

VOLT

H.P.

115

HP

230

1HP

SINGLE PHASE

MAX. DIST. (FT.)

SINGLE

UNIT

56 28 12

89 44 10

143 71 8

227 113 6

226 113 12

359 113 10

572 179 8

909 286 6

DUAL

UNIT

WIRE

GAUGE

CONTROL WIRING

DIST./FT. WIRE GAUGE

800 18

1200 16

2000 14

Table 5

FORMULA L = (V) x (D)

L = Max. one way dist.

V = Voltage Drop (5%)

D = Cross Section area of conductor (cir.mil.)

Table 4

(2K) x (I)

Doc 01-20228

Rev D

Page 10

10

Pre-Installation Check-List

K= Resistivity of conductor (24)

I = Motor F.L.A. (NEMA suggested)

WIRE GAUGE DIAMETER OHMS/1000FT.

16 1/20” 4 Ω

14 1/16” 2.5 Ω

12 1/12” 1.6 Ω

10 1/10” 1Ω

81/8”.6 Ω

Table 6

Doc 01-20228

Rev D

Page 11

Operator Features

E

D

FG H

Operator Features

I

11

C

B

A

J

A. MOTOR 1 AND 2 H.P.

The motors used in the HS670-100 and

HS670-200 are T.E.F.C. (totally enclosed,

fan cooled) 3450 R.P.M. They incorporate

a built-in manual reset thermal overload.

B. DIRECTIONAL VALVE

3 position, 4 way. It incorporates 2

solenoids which are 24 Vdc. Rectified

from 24 Vac.

C. BYPASS VALVE

Incorporates a handle at side of pump.

When positioned downward, it will allow

manual operation of the gate.

D. VENT CAP

When removed, you may add ATF

Transmission fluid.

Must

be on during

operator operation.

E. LIMIT SWITCH

Oilitight and watertight. Nema 3, 4, & 13

construction. Open switch for right hand,

close switch for left hand.

Figure 5

0

1

2

2

-

F

0

8

2

1

F. DRIVE WHEELS

Polyurethane material on a steel or

aluminum hub. HS670-100 = 1 – ½”

wide 6” dia. HS670-200 = 2” wide 6”

dia.

G. HYDRAULIC MOTOR

Roller vane, free wheeling type with a

displacement of 12 in./3.

H. SUSPENSION SYSTEM

Incorporates two compression

springs. See also page 19.

I. LIMIT SWITCH

Close switch for right hand and open

switch for left hand.

J. RELIEF VALVE

Built into pump. Set at 600 p.s.i. for

HS670-100 and 1500 p.s.i. for

HS670-200.

Doc 01-20228

Rev D

Page 12

12

Operator Features

DIGITAL MICROPROCESSOR DISPLAY CONTROL BOARD

This is the main circuit board for the gate system (see Figure 5). It contains all the

logic and intelligence for the system. It is isolated from voltage spikes and surges

by the isolation interface board and also by an isolation transformer. This board

contains all the LED’s and the programming buttons and display.

ISOLATION INTERFACE BOARD

This circuit board (see Figure 5) protects the digital mircoprocessor display control

board. All the inputs and outputs go thorough this board. This board contains all

the relays that send and receive signals that are processed by the digital control

board.

DIGITAL MICROPROCESSOR

DISPLAY CONTROL BOARD

“UNDERNEATH

”

ISOLATION INTERFACE

BOARD “ON TOP”

01-20228F2

Figure 5

MAXIMUM RUN SHUT OFF CIRCUIT

This is a self learning circuit. It will take the average amount of time between the

opening cycle and the closing cycle and add 10 seconds to it. If this time should be

reached during operation, then this circuit will shut off the operator.

REVERSAL DELAY CIRCUIT

Built in sounder will activate four seconds prior to and during gate movement.

Sound level is adjustable. Four second delay is programmable.

NOTE:

The four second delay is programmable. See program

information.

MID OPEN CIRCUIT

When a control device is wired into this circuit, it will open the gate to a position

slightly greater than ½ way from the full closed position or if gate is less than ½ way

open. If gate should be more than ½ way open, then the control device will open

the gate to the full open position. If the time delay to close is enabled, the operator

will automatically close from the “mid-open” position.

VEHICLE REVERSE CIRCUIT

If this circuit is energized while gate is closing, gate will stop and reverse to full

open position. If energized while gate is at the full open or stopped between limits,

it will not allow the gate to be closed.

Doc 01-20228

Rev D

Page 13

Operator Features

VEHICAL OPEN CIRCUIT

A device connected to this circuit will only open the gate. If gate is closing, it will

cause the gate to stop and reverse to the full open position.

EXTERNAL WARNING CIRCUITS

Many different types of signaling systems can be connected to the operator to act

as external warnings. See the electrical diagram supplied with operator for more

information.

THREE BUTTON CONTROL CIRCUIT

Sequence of operation is, open/stop/close. Stop will override all other functions. If

closing, open will cause operator to stop and reverse to full open. If opening, close

will cause operator to stop and reverse to full close position.

ONE BUTTON CONTROL CIRCUIT

Sequence of operation – open, stop, close, stop. If power has been interrupted, will

always open with first activation.

Programmable Features

13

PROGRAM 1 (R.H./L.H.)

Will automatically set up motor rotation, limit switch functions and directional logic

for the operator.

PROGRAM 2 (MASTER/SLAVE)

Will set up two (2) operators to act as one, using common controls.

PROGRAM 3 (4 SECOND DELAY)

This program will allow you to enable or disable the 4 sec. delay before the gate

begins its open or close direction. See the Warning on page 14.

PROGRAM 4 (OBSTRUCTION SENSING CLOSE)

Will determine the response the operator will make when the gate meets an

obstruction while closing.

PROGRAM 5 ( OBSTRUCTION SENSING OPEN)

Will determine the response the operator will make when the gate meets an

obstruction while opening.

PROGRAM 6 (EXTERNAL REVERSE DEVICE)

Will program the system to accept either a normally open or normally closed

contact type external obstruction sensing device.

PROGRAM 7 & 8 (TIME DELAY TO CLOSE)

These two independent programs will allow the gate to automatically close from the

full open or mid open position after a programmed amount of time.

PROGRAM 9 (GATE LOCK)

This program will allow the use of different types of gate locks to be used with the

system.

Doc 01-20228

Rev D

Page 14

14

Operator Features

Led Descriptions

Color Name Description

Green Program

Red External Reverse

Red Maximum Run

Red N/A

Red Right Hand/Left Hand

Red Gate Closing

Red Gate Opening

Red Power

“ON” when in program mode, “OFF” when in

operational mode.

“ON” when an external reverse device was

activate, “OFF” with next input.

“ON” when maximum run circuit shut operator off,

“OFF” with next input.

“ON” when operator is programmed R.H., “OFF”

when operator is programmed L.H., “BLINKS”

when operator has not been programmed for

either.

“ON” anytime sounder is activated prior to and

during closing.

“ON” anytime sounder is activated prior to and

during opening.

“ON” when operator electric power is on. “OFF”

when the operator has no power. “BLINKS”

when the control voltage of the operator drops

below 18 VAC, or if power was lost then restored.

Table 7

NOTES: Program 2 (Master/Slave)

If for some reason both operators must be handed the same (both R.H.

or L.H.). Then both operators must be programmed as SLAVES. All

controls will be connected to either operator. You will still need the

three (3) wire interconnect between the two operators.

Please be aware that these operators are transmitting data through the

master/slave interconnection. It is very similar to a RS232 connection.

very important

It is

power wires and positioned far away from power lines or conduits. If

the mater/slave interconnection receives any type of voltage

interference or noise, neither of the two operators will function properly.

that these three wires be shielded from any and all

WARNING

very important

It is

The only situations where the delay would be disabled is for extreme security

installations where the need for the gate to immediately open or close is required.

IMPORTANT NOTE:

was reversed to open by either of the external obstruction circuits, (ref. adaptions

6 & 7 on wiring diagram). The operator will require a manual signal to close the

gate. The time delay to close will function normally after the manual signal.

that the four second delay be enabled for most applications.

The time delay to close feature will NOT activate if the gate

Doc 01-20228

Rev D

Page 15

Installation

INSTALLATION NOTES

Installation

15

Installation shown is for a right-

handed unit (on right side of gate

opening when inside looking out).

Left-handed is opposite.

Step 1:

Concrete Pad

1

Layout concrete pad as detailed.

2

Locate conduit, as required, prior to pouring concrete.

3

Pour concrete, insuring that pad is level and above the ground line. Pad must

be a minimum of 24 inches in depth or below the frost line, whichever is

greater.

4

Allow concrete to set at lease 2 days before installing unit.

5

Locate four (4) ½” threaded anchors (not supplied) or other means of fastening

as shown. Anchors must be positioned accurately and be secure in the

concrete.

NOTES

Always use separate conduits for

power wiring and control wiring.

For detailed information on the

emergency disconnect system,

see instructions supplied with it.

If there is existing concrete at area of unit

mounting, use dimensioning procedure

described in step 1. You may need to modify

any conduit locations to suit your application.

This is only a suggested

layout, other pad layouts are

possible.

You may want to install extra

conduit for future wiring

considerations.

“GATE”

SHOWN

OPEN

AS

REQ’D.

5 7/8

0

1

2

-

2 3/4”

0

2

2

ANCHOR LOCATION

MARKED “Z”

Z

OPTIONAL EMERGENCY

DISCONNECT

Z

CONDUIT

1

F

6

29 3/4”

35”

3”

X

X

X

X

+ 7 1/2”

Z

26 1/2”

14”

Z

3 7/8”

3 3/4”

2 5/8”

X = 1 3/4”

+ = CRITICAL DIMENSION

Figure 7

Doc 01-20228

Rev D

Page 16

16

Installation

Step 2:

Important:

Step 3: Operator Mounting

Drive Rail

The drive should be:

Level and parallel to the gate and

operator.

As close as possible to the 11-1/2”

dimension.

Very securely mounted to the gate

and backframe.

The length of the drive rail should

be the gate opening width plus 2

to 3 feet.

1

Remove the outer cover from the operator.

2

Carefully secure the concrete pad with the drive wheels facing the gate.

IMPORTANT NOTE:

and drive rail. By loosening the bolts securing the mounting logs to the

unit, the operator can be slightly adjusted up or down. Retighten bolts.

The operator

Figure 6

must

be lever the parallel with the gate

01-20228F3

CAUTION

Make sure that the drive rail and wheels are aligned properly (see Figure

8).

01-20228F4

Figure 7

Doc 01-20228

Rev D

Page 17

Installation

17

Step 4:

Remove the threaded plug from the pump tank and install the vent cap in its place.

Vent Cap

IMPORTANT NOTE

Never run the operator without the vent cap in place.

Figure 8

01-202 21F8

Doc 01-20228

Rev D

Page 18

18

Installation

Step 5:

1

2

3

4

5

Limit Shoes

Manually open the gate to the full open position.

Locate the open limit switch lever and mark its position on the drive rail.

Manually close the gate to the full close position.

Locate the close limit switch lever and mark its position on the drive rail.

Manually open the gate about halfway. Per drawings below, measure and drill

holes. Mount both limit shoes to underside of drive rail.

IMPORTANT NOTES

The limit shoes are slotted, so minor adjustments may be made later for

fine tuning of the full open and close positions. Also, note that the limit

switches themselves may be slightly adjusted up or down.

It is highly suggested that gate stops be installed to the gate at the full

open and closed positions.

Due to the fact that this unit has no brake, there will be some gate coasting

and, depending on gate weight, it could be considerable, so it might drift

past the limits.

MARK CENTERLINE

MARK CENTERLINE

1-1/16”

LIMIT SWITC H

2”

3”

LIMIT SHOE

CENTERLINE MARKS

1/4”-20 SCR.

WASHER & NUT

Figure 11

DRIVE RAIL

9/32” DIA.

HOLES

LIMIT SWITC H

2”

01-20221F9

3”

BOTTOM OF

DRIVE RAIL

Doc 01-20228

Rev D

Page 19

Installation

19

Step 6:

The suspension system is semi-factory set; simply loosen the suspension separator bolt

completely. This will allow both wheels to pinch the drive rail.

If more or less pressure is required, adjust both upper and lower suspension spring lock

nuts as desired.

Suspension System

NOTE:

it is not removed, make sure that it can not interfere with suspension system.

IMPORTANT NOTES

It is suggested that the separator bolt be removed and left with unit. If

Both springs should apply about the same amount of pressure.

If using the LiftMaster drive rail, make sure that the drive rail guide

wheel is positioned properly. See Figure 9.

Important

pressure on the drive wheels so they can pinch together on the drive

rail. This system also allows the drive wheels to “float” so the can

follow any slight misalignment of the drive rail. If the springs are over

tightened, it will reduce their life span. But, on the other hand, if they

are under tightened, the drive wheels may slip on the drive rail.

: Adjust the suspension system properly. This system puts

Figure 9

01-20221F10

Doc 01-20228

Rev D

Page 20

20

Installation

Step 7:

Power Wire Connections

CAUTION

Make sure power is disconnected at main power supply and at power disconnect

switch on the unit before proceeding.

1

Secure all electrical power connections to the power wiring terminal strip.

Single phase to L1, L2 and GROUND. Three phase to L1, L2, L3 and

GROUND.

2

Connect all controls to the control wiring terminal strip. Refer to the electrical

diagram supplied with the unit.

IMPORTANT NOTE:

can her the pump running by the gate does not move:

Make sure the manual bypass valve is in the automatic operation

position.

If the bypass valve is OK, disconnect the main power supply and

reverse any two wire connections at the power terminal strip.

POWER DISCONNECT

On three-phase units, when unit is first run, if you

SWITCH

Doc 01-20228

Rev D

GROUND

01-20228F5

POWER TERMINAL

STRIP

Figure 10

Do not operator until instructed! Operator must be

programmed before operation.

Page 21

Installation

21

MANUAL OPERATION

The pump is equipped with a manual bypass valve. By positioning the valve

handle down (manual operation), the gate can be back-driven open or closed.

A back-up to this is the suspension separator bolt. By tightening this bolt, the drive

wheels will be pushed off by the drive rail.

NOTE:

When manually opening or closing the gate, it is not, in the

beginning, easy to get the gate started. Since fluid has accumulated in the

drive motors, it will take a good size push to get the gate started.

01-20221 F11

Figure 13

FACTORY INSTALLED ACCESSORIES

Most factory-installed accessories are located on or under the control panel and are

already wired into it.

NOTE:

way.

By removing one bolt, the entire control panel can be pivoted out of the

Figure 14

Doc 01-20228

Rev D

Page 22

22

Installation

Step 8:

Programming

This gate controller has (9) programmable options which must be set prior to gate

operation. To program the controller, press and hold the “FUNCTION” select push

button for 2 seconds. When the board enters the program mode, the green program

LED will turn on and the two display panels will become active.

When the controller enters the program mode and the program LED turns on, the

“FUNCTION” display panel will display “0” (zero) and the “OPTION” display panel will

display “0” (zero).

To exit the program mode, at any time, press and hold the “FUNCTION” select push

button for 2 seconds. The program LED will turn off, indicating that you are out of the

program mode. The board will reset as if first powered on.

PROGRAM

EXT. REVERSE

MAX. RUN

OBSTRUCTION

RIGHT HAND

CLOSING

OPENING

POWER

Figure 11

01-20228F6

Doc 01-20228

Rev D

Page 23

Installation

23

PROGRAM 1:RIGHT HAND/LEFT HAND OPERATION

0 = NOT SELECTED - OPERATOR WILL NOT FUNCTION IN THIS MODE.

1 = RIGHT HANDED - OPERATOR WILL MOVE GATE FROM LEFT TO

RIGHT TO OPEN.

2 = LEFT HANDED - OPERATOR WILL MOVE GATE FROM RIGHT TO LEFT

TO OPEN.

Program 1 determines whether the operator is “right handed” or “left handed”. To

determine which type your gate controlled needs to be set to, observe the

installation from the operator side of the gate. If the operator is on the right side of

the gate. If the operator is on the right side of the opening, the operator is “right

handed”. If the operator is on the left side of the opening, it is “left handed”.

Press the FUNCTION select button to set the function to “1”. The option display

will show a “0”, “1” or “2”. Option “0” is the factory setting and does not allow gate

movement. This option must be changed to either a “1” for right hand or “2” for left

hand. Pressing the “OPTION” button will change the option between “1” and “2”.

When the correct option for your application is indicated, press the “FUNCTION”

select button to save this selected option and to step to the next program.

PROGRAM 2:MASTER/SLAVE OPERATION

0 = SINGLE GATE OPERATOR INSTALLATION.

1 = MASTER GATE OPERATOR – PROGRAMS THE SLAVE AT POWER

UP.

2 = SLAVE GATE OPERATOR – PROGRAMMED BY THE MASTER AT

POWER UP.

Program 2 selects whether the installation is a single operator or dual operators

with common controls.

If the “FUNCTION” display shows “2”, proceed on as follows. If it does not show “2”

then press the “FUNCTION” select button to set the display to “2”. The “OPTION”

display will indicate a “0”, “1” or “2”. The “0” option is the factory setting and is for

single operation gates. This option can be changed to “1” or “2” for dual gate

operators. Pressing the “OPTION” select button will change the option between

“0”, “1” or “2”, where option “1” is for master operation and “2” is for slave operation.

A master operator will automatically program its slave when it is powered up and

when the program mode is ended. The master will automatically set the slave up

as a slave. If the master was programmed for right hand, the slave will be set for

left hand and visa versa. All other programmed options (i.e. time delay to close,

reversal options, etc.), will be copied directly from the master to the slave. When

the correct option for your application is indicated, press the “FUNCTION” select

button to save this selected option and to step to the next program.

IMPORTANT NOTE:

interconnection wires in place between the two operators for the master/slave

system to work. Reference the wiring diagram supplied with units.

The two operators (master/slave) must have the 3

Doc 01-20228

Rev D

Page 24

24

Installation

PROGRAM 3:FOUR SECOND PRE-OPERATION DELAY

0 = FOUR SECOND DELAY “OFF”.

1 = FOUR SECOND DELAY “ON”.

Program 3 selects whether or not there will be a four (4) second delay prior to gate

movement. During the delay, the sounder will beep.

If the “FUNCTION” display shows “3”, proceed on as follows. If it does not show “3”

then press the “FUNCTION” select button to set the display to “3”. The “OPTION”

will indicate a “0” or “1”. The “1” option is the factory setting. By pressing the

“OPTION” select button you can change this setting to “0”.

WARNING

Unless the job site is an extremely high security installation, program 3

should always be set to “ON”.

PROGRAM 4:REVERSE WHEN CLOSING

0 = REVERSE FOR 2 SECONDS THEN STOP

1 = REVERSE TO FULL OPEN POSITION

Program 4 determines the response of the gate operator to an obstruction from the

external obstruction signal while closing.

With “FUNCTION” display showing “4”, press the “OPTION” select button to select

either “0” or “1”. The factory setting is “1”.

PROGRAM 5:REVERSE WHEN OPENING

0 = REVERSE FOR 2 SECONDS THEN STOP.

1 = STOP

Program 5 determines the response of the gate operator to an obstruction from the

external obstruction circuit, (#6 on wiring diagram), while opening.

With “FUNCTION” display showing “5”, press the “OPTION” select button to choose

either “0” or “1”. The factory setting is “1”.

IMPORTANT NOTE:

device (adaption #6 on wiring diagram). Adaption #5, shown on wiring

diagram (vehicle reverse device), will always stop and reverse a closing

gate to the full open position. Adaption #7, will only react in the closing

direction.

Programs 4 & 5 are only for the external obstruction

Doc 01-20228

Rev D

Page 25

Installation

25

PROGRAM 6:EXTERNAL REVERSE DEVICE SELECT

0 = External reverse device with normally closed contacts.

1 = External reverse device with normally open contacts.

This program determines which polarity of signal on the external obstruction device

will cause the gate operator to react. If a device with normally open contacts is

used, then this option should be set to “1”. If the device has normally closed

contacts then this option should be set to “0”. The factory setting is “1”.

When the correct option is displayed, press the “FUNCTION” select button to save

the choice and to step to the next program.

PROGRAM 7:TIME DELAY TO CLOSE ENABLE/DISABLE

0 = Time delay to close “OFF”.

1 = Time delay to close “ON”.

This program enables or disables the automatic time delay to close option.

When the correct option is displayed, press the “FUNCTION” select button to save

the choice and to step to the next program.

NOTE:

program 8. By pressing the “FUNCTION” select button twice you will go to

program 9.

If timer to close option is et to disable, you will not need to do

PROGRAM 8:TIME DELAY TO CLOSE “TIME”

0 = 2 SECONDS

1 = 15 SECONDS

2 = 30 SECONDS

3 = 60 SECONDS (1 MINUTE)

4 = 90 SECONDS (1-1/2 MINUTES)

5 = 120 SECONDS (2 MINUTES)

6 = 180 SECONDS (3 MINUTES)

7 = 240 SECONDS (4 MINUTES)

This program sets the time from when the gate is fully open to the time when its will

automatically begin to close.

By pressing the “OPTION” select button, choose the time that will be required for

this gate application. Once the selection has been made, press the “FUNCTION”

select button to save this selection and to step to the next program.

Doc 01-20228

Rev D

Page 26

26

Installation

PROGRAM 9:GATE LOCK TYPE SELECT

0 = LOCK OUTPUT NORMALLY “OFF”.

1 = LOCK OUTPUT NORMALLY “ON”.

If a gate lock is to be used with the operator, this program determines the state of

the built-in lock relay contacts and how they will turn on an off.

By pressing the “OPTION” select button, choose either option “0” or “1”. Option “0”

would normally be selected if you are using a solenoid activated type lock system.

The built-in lock relay’s contacts will be open when gate is closed. They will close

for one second before the gate begins to open, and open up tow seconds after the

gate has begun moving. Option “1” would normally be selected if you are using a

magnetic type lock system. The built-in lock relay’s contacts will be closed while

the gate is closed. They will open up one second before the gate begins to open

and remain open. With either selection the contacts will be closed when the gate

begins to close.

NOTE:

operator. If no lock system is to be used, it does not matter which option

is shown in the display.

This was the last programming option. To exit program mode, press and hold the

“FUNCTION” select button for 2 seconds. The green program LED will turn off.

You may not proceed to step 8.

IMPORTANT NOTE:

open and to the full closed positions), before the maximum run timer and

the R.P.M. sensor will function. They both must learn their proper

settings. Also, anytime the operator is reprogrammed it MUST be run one

complete cycle.

Step 9:

Before adding any options, accessories or adaptions, it is highly recommended that you

check out the system and its programs. If you have not already done so, temporarily

connect a 3 button station to the control terminal strip, see below or see wiring diagram

supplied with operator. Test for proper open, stop and closing of the gate. Test for

proper operation of all programs that were programmed into the system. Once

everything checks out okay, then proceed to adding on the accessory items for this job

site.

Preliminary System Check Out

For wiring information see electrical diagram supplied with

The operator MUST be run one full cycle, (to the full

Doc 01-20228

Rev D

NOTE:

each one is attached check it for proper operation before adding the next.

We recommend that, if more than one accessory item is used, after

Page 27

Installation

27

Step 10:

Accessory Installation

See page 8 for wiring distance and wire gauge information.

See wiring diagram for more information.

Important:

Make sure that the two (2) gate caution signs are secured to the gate: one

on the inside and one on the outside. They must be easily visible.

WARNING

If exterior controls such as keyswitch, card reader or pushbutton station are to

be incorporated into this system, make sure the controls are installed where

the user cannot touch the gate while operating controls. Install the controls

where the used had full view of gate operation.

NOTES

0

1

-

2

0

2

2

8

F

7

Figure 12

Both item 6 & 7 can be programmed for the close direction, reference

program #4.

Only item 6 can be programmed for the open direction, reference program

#5.

Item 7 is for use with photo-beam type systems. Item 6 is for use with gate

edge type systems.

Doc 01-20228

Rev D

Page 28

28

Installation

Required Maintenance

Normal Usage

ITEM

External safety

systems

Gate caution signs

Manual operation

Gate

Accessories

Electrical

Frame bolts Check for tightness

Total unit

Fluid levels (D) Keep at least ¾ full

Fittings Check for leaks

Drive rail Check for damage

Drive wheels Check for wear

MAINTENANCE

Month3Months6Months12Months

Check for proper operation

Make sure they are

present

Check & operate by-pass

valve

Inspect for wear or

damage

Check all for proper

operation

Inspect all wire

connections

Inspect for wear or

damage

Check at least once every

1

√

√

√

COMPLETE CHECK

√

√

√

√

√

√

√

√

NOTES:

Doc 01-20228

Rev D

Table 8

When servicing, always disconnect operator from electrical power supply.

Severe or high cycle usage will require more frequent maintenance checks.

Inspection and service should be preformed anytime a malfunction is

observed or suspected.

Use only “ATF” automatic transmission fluid. If using the optional cold

weather fluid (Royco 756) only replace with the same.

When servicing, please do some “house cleaning” of the operator and the

area around the operator. Pick up any debris in the area. Clean the

operator if needed.

Page 29

Warranty

LIMITED ONE-YEAR WARRANTY

LiftMaster gate operators are warranted against deficiencies in material and

workmanship for a period of one (1) year from date of purchase, providing

recommended installation and maintenance procedures are followed. This

warranty is in lieu of all other warranties expressed or implied (some states do not

allow limitations on how long an implied warranty lasts, so this limitation may not

apply to you) and shall be considered void if damage was caused by fire, flood or

lightening. The manufacturer will not be responsible for any labor charges incurred

in the removal or replacement of deficient parts.

In case of failure due to deficiencies in material or workmanship during the warranty

period, the complete gate operator will be repaired or replaced items in warranty.

Required Maintenance

29

Doc 01-20228

Rev D

Page 30

COPYRIGHT 2001

ALL RIGHTS RESERVED

This document is protected by copyright and may not be copied or adapted without the prior written

consent of LiftMaster. This documentation contains information proprietary to LiftMaster and such

information may not be distributed without the prior written consent of LiftMaster. The software and

firmware included in the LiftMaster product as they relate to this documentation are also protected by

copyright and contain information proprietary to LiftMaster.

FOR TECHNICAL SUPPORT

Call our toll free numbers:

(800) 323-2276

(800) 998-9197

Installation and service information is

available six days a week.

TO ORDER REPAIR PARTS

Call our toll free numbers:

(800) 528-2806

(800) 998-9197

Prepare to provide the following

information when ordering repair parts:

Part Number

"

Part Name

"

Model Number

"

Loading...

Loading...