Page 1

Installation Instructions

Commercial Vehicular

Slide Gate Operator

Hydraulic Models: HS670-100-B2

HS670-200-B2

Doc 01-20221

Rev D

Page 2

2

IMPORTANT!

Installers: Leave this manual with the end user after completing the installation.

Limited One-Year Warranty

LiftMaster gate operators are warranted against deficiencies in material and

workmanship for a period of one (1) year from date of purchase, providing

recommended installation and maintenance procedures are followed. This warranty is

in lieu of all other warranties expressed or implied (some states do not allow limitations

on how long an implied warranty lasts, so this limitation may not apply to you) and shall

be considered void if damage was caused by fire, flood or lightening. The manufacturer

will not be responsible for any labor charges incurred in the removal or replacement of

deficient parts.

In case of failure due to deficiencies in material or workmanship during the warranty

period, the complete gate operator will be repaired or replaced items in warranty. For

information on how to obtain replacement parts or a replacement operator under terms

of this warranty, contact LiftMaster.

Doc 01-20221

Rev D

Page 3

Contents

Contents

General Information_____________________________________________4

Inspection ______________________________________________________________ 4

Specifications ___________________________________________________________ 4

Operator Information______________________________________________________ 5

Safety Information ______________________________________________6

Safety Instructions________________________________________________________ 6

Safety Precautions for Open-Roller Gates and Ornamental “Grill Type” Gates ________ 8

Pre-Installed Check List_________________________________________10

Wiring Specifications ____________________________________________________ 10

Installation ___________________________________________________13

Installation Notes________________________________________________________ 13

3

Step 1:

Step 2: Drive Rail ______________________________________________________ 15

Step 3:

Step 4: Vent Cap_______________________________________________________ 16

Step 5: Limit Shoes_____________________________________________________ 17

Step 6:

Step 7: Manual Operation________________________________________________ 21

Step 8: Factory Installed Accessories_______________________________________ 22

Step 9: Electrical Wiring_________________________________________________ 23

Step 10: Reversing Device ________________________________________________ 23

Concrete Pad____________________________________________________ 13

Mounting ______________________________________________________ 16

Suspension System_______________________________________________ 19

Left Hand/Right Hand Conversion ________________________________24

Operator Check-Out ____________________________________________25

And Finally… _________________________________________________26

Required Maintenance Services ____________________________________________ 26

Doc 01-20221

Rev D

Page 4

4

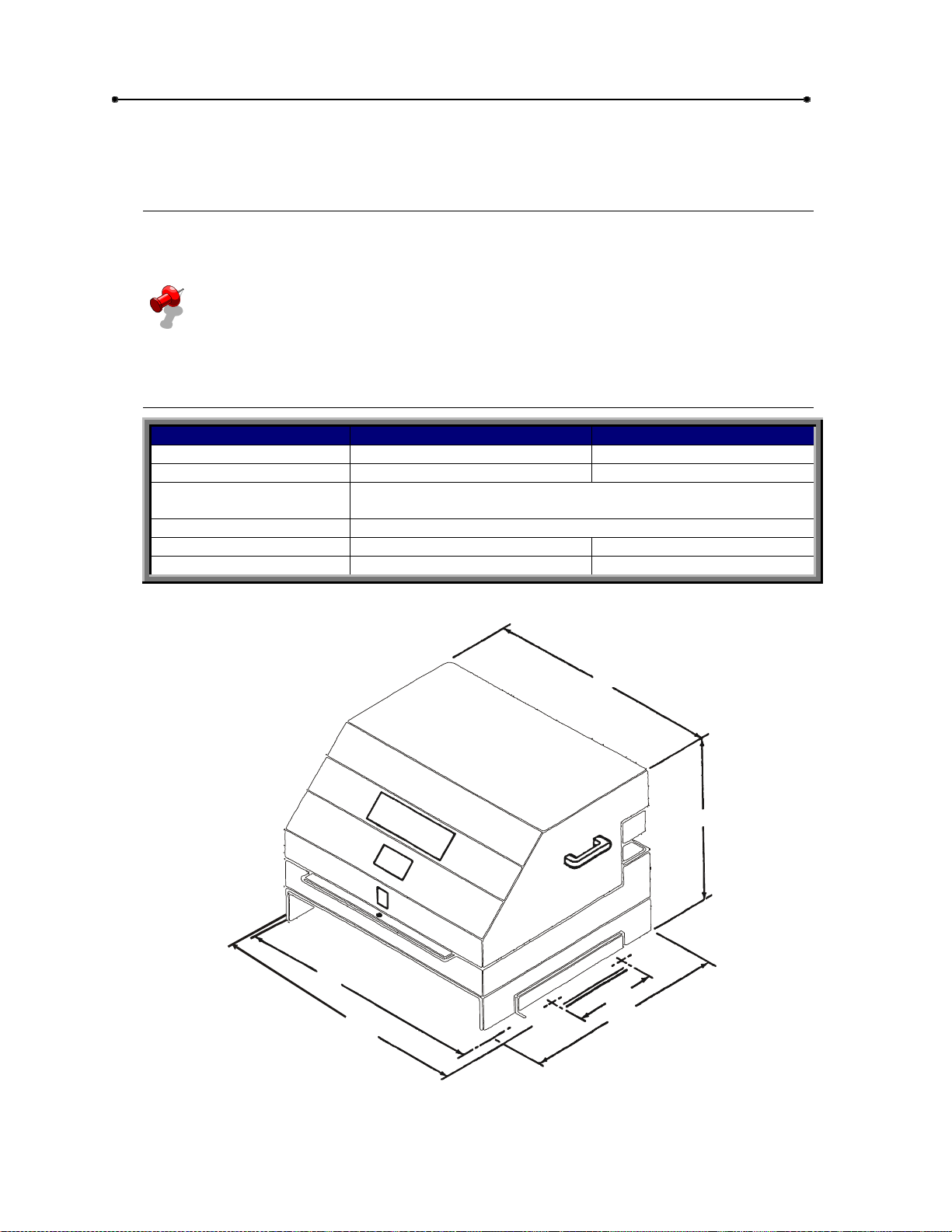

General Information

General Information

Inspection

Inspect the operator carefully for any possible shipping damage. Using the packing list

supplied with the unit as a guide, check for any shortage of parts.

IMPORTANT NOTE

Do not run operator without vent cap installed. For more detailed information

about electrical, hydraulic and mechanical systems, see the troubleshooting guide

supplied with the unit.

Specifications

MODEL HS670-100 MODEL HS670-200

H.P. 1 2

GATE SPEED 15 TO 18”/SEC. 15 TO 18”/SEC.

MAX. GATE SIZE DESIGNED FOR MOST LENGTHS AND WEIGHTS OF SLIDE

GATES

FREQUENCY OF USE DESIGNED FOR VERY HIGH RATES

PRIMARY VOLTAGES 120-230-460 120-230-460

SECONDARY VOLTAGE 24 VAC. 24 VAC.

29 3/4”

31 3/4”

Table 1

27”

19 3/4”

14”

26 1/2”

01-20221F1

Doc 01-20221

Rev D

Figure 1

Page 5

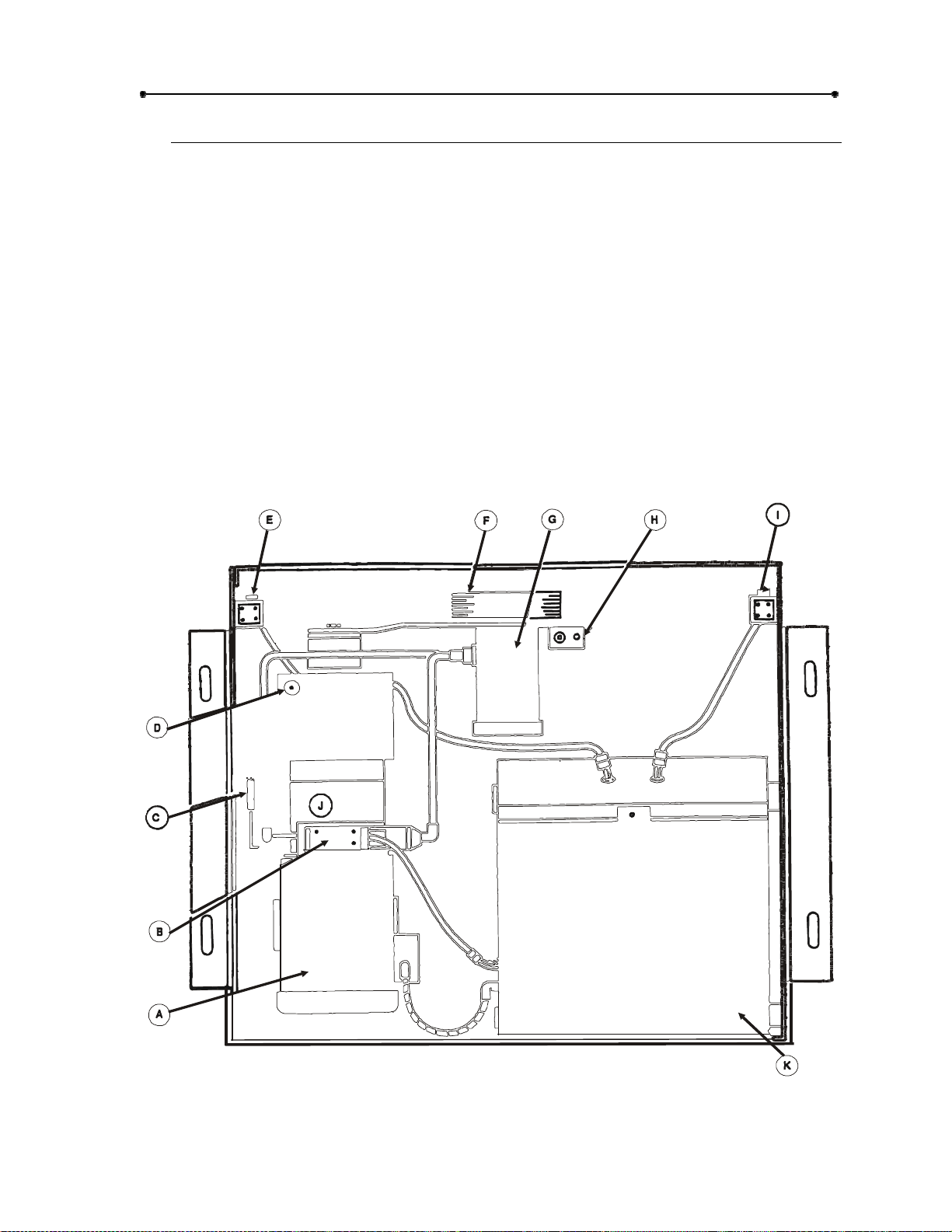

General Information

Operator Information

A. A.C. MOTOR-HS670-100 = 1 H.P./3450 R.P.M. HS690-200 = 2 H.P./3450

R.P.M. Both have continuous duty rating. And built-in manual reset overload.

B. DIRECTIONAL VALVE – 2 position, 4 way 24 vac.

C. BYPASS VALVE – For manual operation.

D. VENT CAP – When removed, add fluid here.

E. LIMIT SW ITCH – is open switch for R.H. and close switch for L.H.

F. DRIVE WHEELS – HS670-100 = 1 ½” x 6”. HS670-200 = 2” x 6”.

G. HYDRAULIC MOTOR – Roller Vane Type. Displacement = 12 in./3.

H. SUSPENSION SYSTEM – See instructions.

I. LIMIT SWITCH – is close switch for R.H. and open switch for L.H.

J. RELIEF VALVE – Built into pump.

K. CONTROL PANEL

5

Figure 2

01-20221F2

Doc 01-20221

Rev D

Page 6

6

Safety Information

Safety Information

Vehicular gate systems provide convenience and security. Gate systems are

comprised of many component parts. The gate operator is only one component. Each

gate system is specifically designed for an individual application.

Gate operating system designers, installers and users must take into account the

possible hazards associated with each individual application. Improperly designed,

installed or maintained systems can create risks for the user as well as the bystander.

Gate systems design and installation must reduce public exposure to potential hazards.

A gate operator can create high levels of force, in its function as a component part of a

gate system. Therefore, safety features must be incorporated into every design.

Specific safety features include:

Gate Edges Enclosed Track Vertical Posts

Guards for exposed

rollers

Screen Mesh

Important instructions follow. These instructions are intended to highlight certain safety

related issues. These instructions are not intended to be comprehensive. Because

each application is unique, it is the responsibility of the purchaser, designer, installer

and end user to ensure that the total gate system is safe for its intended use.

Photo-electric

Sensors

Instructional and

Precautionary Signage

Safety Instructions

Select instructions are highlighted with this precautionary symbol (see left margin).

Failure to follow these selected instructions can result in serious injury or death.

STEP 1: BEFORE INSTALLATION

1 Confirm gate operator model is specified by Installation and Maintenance

Manual for application type, gate size and frequency or use.

2 Confirm ALL appropriate safety features, such as gate edges, photo-electric

sensors, vertical posts and enclosed tracks, are specified.

3 Confirm gate system design reduces pinch points and protects against

entrapment.

4 Confirm gate system design has pedestrian access separate from vehicular

entrance.

5 Confirm gate system design reduces traffic backup.

6 Confirm warning signage is included in design.

7 Confirm gate moves freely before installation of operator

8 Repair or service worn or damaged gate hardware before installation of

9 To avoid installation hazards, review the gate system operation and

10 Confirm control design prohibits unauthorized use

Doc 01-20221

Rev D

operator.

installation procedures, such as manual disconnect mechanism procedure.

Page 7

Safety Information

STEP 2: DURING INSTALLATION

1 Disconnect power at service panel before making any electrical connection.

2 Avoid pinch points, be aware of all moving parts.

3 Adjust clutch or load sensing device to minimum force setting.

4 Do not over-tighten cutch or adjust force setting above minimum.

5 Install controls where user cannot touch gate while operating controls.

6 Install controls where user has full view of gate operation.

7 Install two or more warning signs on the gate to alert persons in the area of

automatic gate operation. Warning signs must be conspicuous.

8 Install operator inside fence line. DO NOT install operator on public side of

fence line.

9 Secure gate operator cover.

STEP 3: AFTER INSTALLATION

1 Test all safety features.

7

2 Train end user about basic functions and safety features of gate system.

3 Leave Installation and Maintenance Manual and Safety Instructions with

end user.

Doc 01-20221

Rev D

Page 8

8

Safety Information

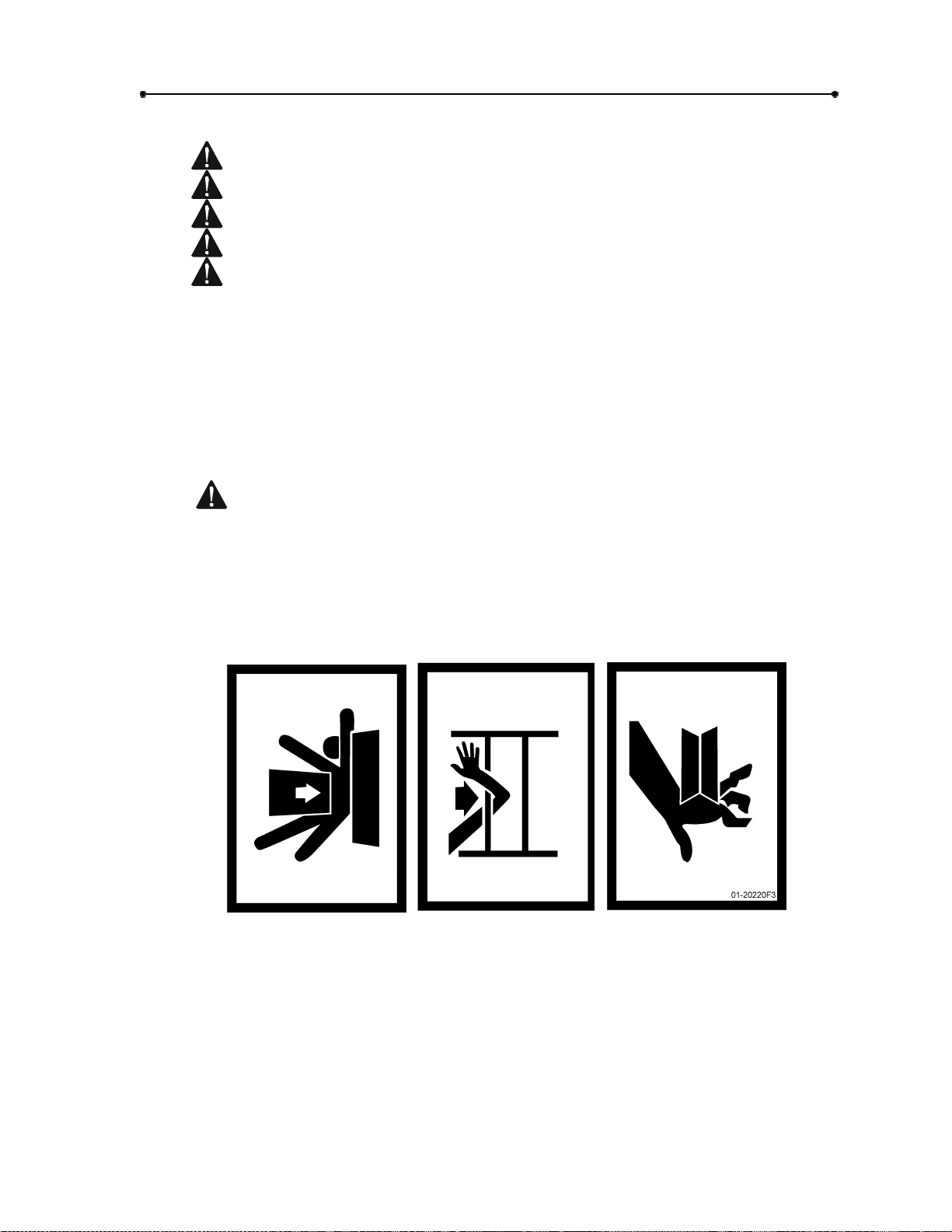

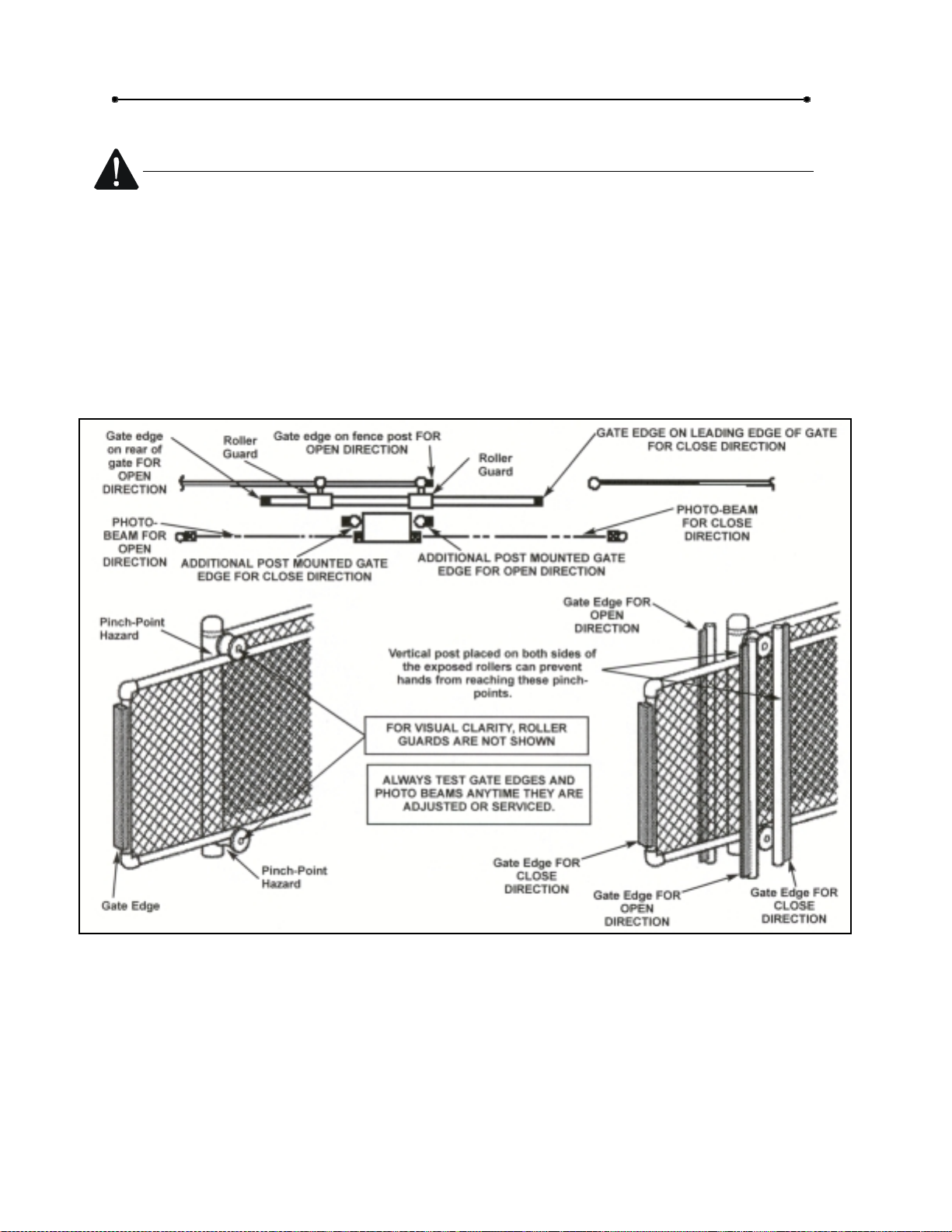

Safety Precautions for Open-Roller Gates and Ornamental “Grill Type” Gates

OPEN-ROLLER GATES

Injuries occur when people get their or feet caught between the top or bottom of the

gate and the gate roller. This potential pinch-point should be guarded against at all

times. Enclosed style gate tracks are available for refitting of these rollers from

many fence suppliers. Also, roller guards are available for installing over the

rollers.

One ore more contact sensors shall be located at the leading edge, trailing edge,

and post-mounted both inside and outside of a vehicular horizontal slide gate.

Doc 01-20221

Rev D

Figure 3

Page 9

Safety Information

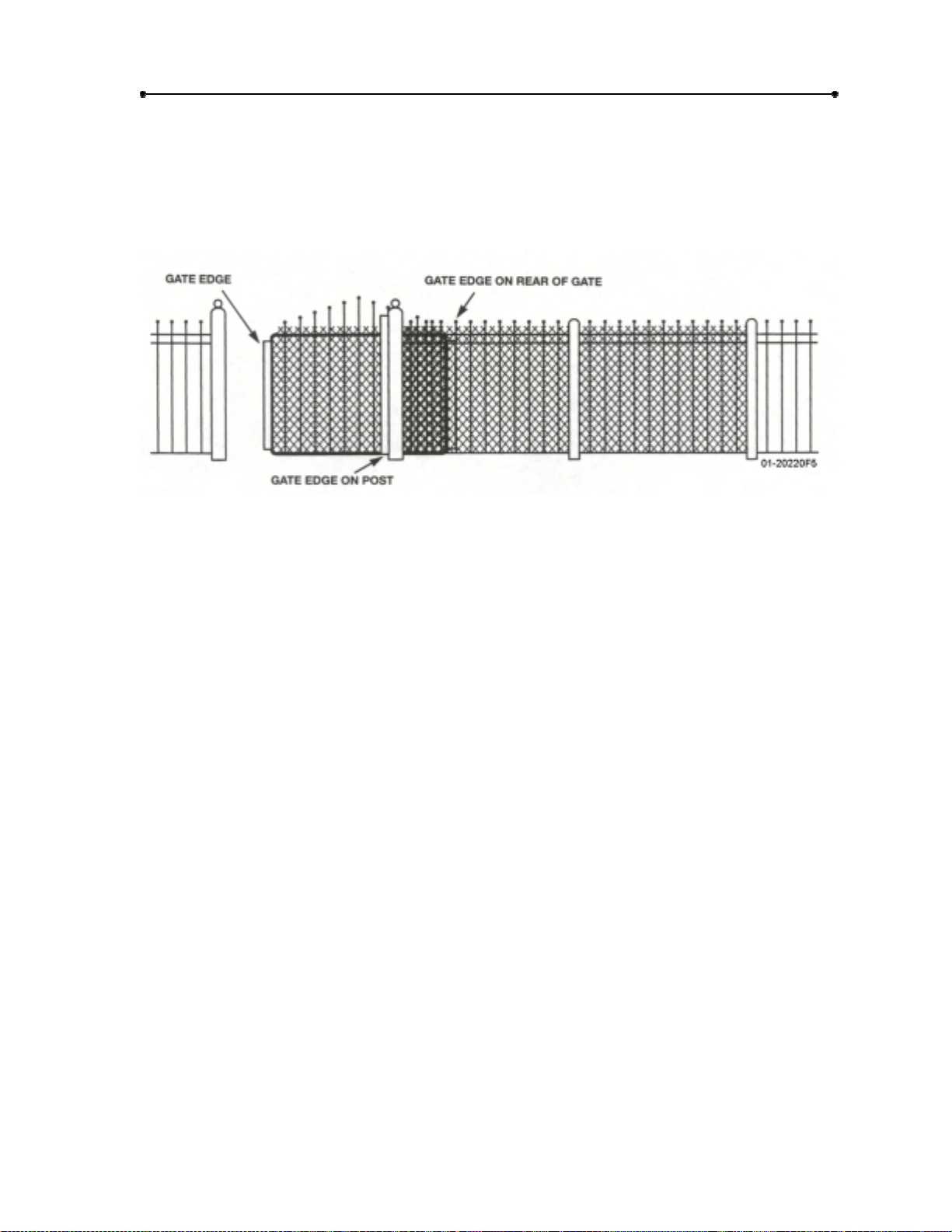

ORNAMENTAL “GRILL TYPE” GATES

Injuries occur when people put their hands and arms through openings in the grill

and the gate is operated. They cannot retract their arms and it gets caught between

the moving gate grill and the stationary fence post or fence. This potential hazard

can be averted by placing a screen mesh on the gate to prevent access through

openings anywhere the gate may travel.

Figure 4

9

Doc 01-20221

Rev D

Page 10

10

Pre-Installed Check-List

Pre-Installed Check-List

1 Check the gate. It must operate freely. If necessary, lubricate or adjust gate to

operator installation. The gate should be level and plumb.

2 Overhead, tracked, or roller tracked gates may require back frame to be constructed

to allow for drive rail attachment.

3 If wiring has already been installed, check that it meets the following wiring

specifications.

Wiring Specifications

1 Knowing operator voltage and phase, select selection that corresponds.

2 The distance shown on the chart is the length of the wire measured in feet from

the operator to the power source. (do not exceed maximum distance.)

3 If your power distance is greater than the figures shown, it is recommended that

the power utility company be notified for a service feeder. Where feasible, a

higher voltage or three-phase operator should be used.

4 When wire larger than 12 gauge is used, a separate junction box will be needed

for operator power connection. (not supplied.)

5 Select control wire gauge form chart. If greater distance or

Lighter gauge wire is required, consult manufacture.

6 Wire run calculations are based on the national electrical code, article 430,

allowing 5% voltage drop.

7 Supply voltage must be within 10% of the operator rating under load conditions.

8 Connect power accordance with local codes.

9 Wire table is based on stranded copper wire. Wire insulation must be suitable to

application.

POWER WIRING

THREE PHASE

MAX. DIST. (FT.)

VOLT.

H.P.

SINGLE UNIT

DUAL

UNIT

WIRE

GAUGE

230

1HP

343

171

12

SINGLE PHASE

MAX. DIST. (FT.)

VOLT

H.P.

SINGLE

UNIT

DUAL UNIT

WIRE

GAUGE

115

HP

56

28

12

Doc 01-20221

Rev D

Page 11

546

273

10

868

434

8

1381

690

6

460

1HP

1593

796

12

2533

1266

10

4029

2014

8

6407

3203

6

230

2HP

181

90

12

289

144

10

459

229

8

731

Pre-Installed Check-List

89

44

10

143

71

8

227

113

6

230

1HP

226

113

12

359

113

10

572

179

8

909

286

6

115

2HP

29

14

12

46

23

10

74

37

8

118

59

6

11

Doc 01-20221

Rev D

Page 12

12

Pre-Installed Check-List

365

6

460

2HP

796

398

12

1266

633

10

2014

1007

8

3203

1601

6

230

2HP

110

55

12

175

87

10

280

140

8

445

222

6

Table 3

Table 2

CONTROL WIRING

VOLTAGE MAX DIST. (FT.) WIRE GAUGE

24 vac

For longer control wiring distances, LiftMaster “Long distance Interface” (LDI) should be

used.

102 14

163 12

Table 4

Doc 01-20221

Rev D

Page 13

Installation

Installation Notes

Installation show is for a right-handed unit (on right side of gate opening when

inside looking out). Left-handed is opposite. For L.H. conversion, see page 24.

If there is existing concrete at area of unit mounting, use dimensioning

procedure described in step 1. Conduit locations may require modifications to

suit your application.

Installation

13

Step 1:

See Figure 5.

Concrete Pad

1 Layout concrete pad as detailed.

2 Locate conduit, as required, prior to pouring concrete.

3 Pour concrete, insuring that pad is level and above the ground line. Pad must

be a minimum of 24 inches in depth or below the frost line, whichever is

greater.

4 Allow concrete to set at least 2 days before installing unit.

5 Locate four (4) ½” threaded anchors (not supplied) or other means of fastening

as shown. Anchors must be positioned accurately and be secure in the

concrete.

NOTES

Always use separate conduits for power wiring and control wiring.

You may want to install extra conduit for future wiring

considerations.

For detailed information on the emergency disconnect system, see

instructions supplied with it.

This in only a suggested layout, other pad layouts are possible.

Doc 01-20221

Rev D

Page 14

14

Installation

“GATE”

SHOWN

OPEN

AS

REQ’D.

5 7/8

0

2

1

-

2 3/4”

0

2

2

1

F

ANCHOR LOCATION

MARKED “Z”

+ 7 1/2”

Z

Z

OPTIONAL EMERGENCY

DISCONNECT

26 1/2”

14”

Z

X

3”

Z

X

3 7/8”

CONDUIT

6

X

X

29 3/4”

35”

3 3/4”

2 5/8”

X = 1 3/4”

+ = CRITICAL DIMENSION

Figure 5

Doc 01-20221

Rev D

Page 15

Installation

15

Step 2:

Drive Rail

IMPORTANT NOTES

It is very important that the drive rail be:

Level and parallel to the gate and operator.

As close as possible to the 11 ½” dimension.

Very securely mounted to the gate and back frame.

1 If using your own drive rail, see detail of LiftMaster drive rail for proper

dimensions.

2 The length of the drive rail should be the gate opening width plus

2-3 feet.

3 It is suggested that the drive rail be made out of or coated with a

material that will inhibit rust.

4 If you are using the LiftMaster anti-skid tape or another means of anti-

skid, install it to the rail now.

Figure 6

01-20221F7

Doc 01-20221

Rev D

Page 16

16

Installation

Step 3:

Mounting

1 Remove the cover from the operator.

2 Carefully secure the operator to the concrete pad with the drive wheel facing the

gate.

IMPORTANT NOTE

Operator must be level and parallel with the gate and drive rail. By loosening

the bolts securing the mounting legs to the unit, the operator can be slightly

adjusted up or down. Retighten bolts.

Make sure that the drive rail and wheels are aligned properly. See detail

below. Also see page 15.

Step 4:

Vent Cap

Remove the threaded plug from the pump tank and install the vent cap in its place. Do

not throw plug away. Leave it with unit.

IMPORTANT NOTE

Never run the operator without the vent cap in place.

IMPORTANT: DO NOT

USE COVER HANDLES

TO MOVE UNIT

REMOVE BOLT TO

TAKE COVER OFF

Doc 01-20221

Rev D

LOOSEN SCREWS TO

REMOVE COVER

VENT CAP

THREADED

PLUG

TANK

01-20221F8

Figure 7

Page 17

Installation

17

Step 5:

See Figure 8.

Limit Shoes

1 Manually open the gate to the full position.

2 Locate the open limit switch lever and mark its position.

3 Manually close the gate to the full close position.

4 Locate the close limit switch lever and mark its position on the drive rail.

5 Manually open the gate about halfway. Per drawings below, measure and

drill holes. Mount both limit shoes to underside of drive rail.

IMPORTANT NOTES

The limit shoes are slotted, so minor adjustments may be made later

for the fine tuning of the full open and close position. Also, note that

the limit switches themselves may be slightly adjusted up or down.

It is highly suggested that gate stops be installed to the gate at the full

open and closed positions.

Due to the fact that this unit has no brake, there will be some gate

coasting and, depending on gate weight, it could be considerable, so it

might drift past the limits.

If coasting is a problem and a precise stop is needed, part number 410.1726

(supplied) should be installed. See directions.

Doc 01-20221

Rev D

Page 18

18

Installation

Doc 01-20221

Rev D

01-20221F9

Figure 8

Page 19

Installation

19

Step 6:

See Figure 10.

The suspension system is semi-factory set; simply loosen the suspension separate or

bolt completely. This will allow both wheels to pinch the drive rail.

If more or less pressure is required, adjust both upper and lower suspension spring lock

nuts as desired.

Suspension System

NOTE

It is suggested that the separator bolt be removed and left with unit. If it is not

removed, make sure that it can not interfere with suspension system.

IMPORTANT NOTES

Both springs should apply about the same amount of pressure.

If using the LiftMaster drive rail, make sure that the drive rail guide wheel is

positioned properly. See Figure 9.

It is very important that the suspension system is adjusted properly. This

system puts pressure on the drive wheels so they can pinch together on the

drive rail. This system also allows the drive wheels to “float” so they can follow

any slight misalignment of the drive rail. If the springs are overtightened, it will

reduce their life span. But on the other hand, if they are under-tightened, the

drive wheels may slip on the drive rail.

Doc 01-20221

Rev D

Page 20

20

Installation

Doc 01-20221

Rev D

01-20221F10

Figure 9

Page 21

Installation

21

Step 7:

The pump is equipped with a manual bypass valve. By positioning the valve handle

down (manual operation), the gate can be back-driven open or closed.

A back-up to this is the suspension separator bolt. By tightening this bolt, the drive

wheels will be pushed off the drive rail.

Manual Operation

NOTE

When manually opening or closing the gate, it is not I the beginning, easy to get

the gate started. Since fluid has accumulated in the drive motors, it will take a

good size push to get the gate started.

Figure 10

01-20221F11

Doc 01-20221

Rev D

Page 22

22

Installation

Step 8:

Most factory-installed accessories are located on or under the control panel and are

already wired into it.

Factory Installed Accessories

NOTE

By removing one bolt, the entire control panel can be pivoted out of the way.

Doc 01-20221

Rev D

Figure 11

Page 23

Installation

23

Step 9:

Electrical Wiring

Make sure power is disconnected at main power supply and at power disconnect switch

on the unit before proceeding.

1 Secure all electrical power connections to the power wiring terminal strip.

Single phase to L1, L2 and GROUND. Three phase to L1, L2, L3 and

GROUND.

2 Connect all controls to the control wiring terminal strip. Reference the electrical

diagram supplied with the unit.

IMPORTANT NOTE

On three-phase units, when unit is first run, if you can hear the pump running

but the gate does not move:

1 Make sure the manual bypass valve is in the automatic operation

position. See page 21.

2 If the bypass valve is OK, disconnect the main power supply and

reverse any two wire connections at the power terminal strip.

POWER TERMINAL

STRIP

POWER DISCONNECT

GRD.

SWITCH

CONTROL

TERMINAL

STRIP

“CONTROL”

PANEL

T3 T2

3-BUTTON

STATION

MULTIPLE

3-BUTTON

STATION

T1 L1L2L3 112

1

2

3

1

2

3

4

1

0

OPEN

STOP

CLOSE

STOP

CLOSE

2

-

2

0

OPEN

1

2

F

3

1

454

23

SINGLE INPUT

OPEN ONLY

Push button, Radio,

Loops, Keyswitch, etc.

SINGLE INPUT

OPEN/CLOSE

Push button, Radio,

Loops, Keyswitch, etc.

NOTE:

Must be used with a

“Stop” control for full

control of the gate.

REVERSE DEVICE

Edges, Loops,

Photo Cells, etc.

10

610

1

4

16

4

5

Figure 12

Step 10:

Reversing Device

Due to the amount of force this opener can generate, please install a sensing edge on

the gate. It is imperative and beneficial to the customer, LiftMaster, and yourself that

the installation is as safe as possible.

Doc 01-20221

Rev D

Page 24

24

Installation

Left Hand/Right Hand Conversion

When switching the unit from right hand to left hand or vice-versa:

1 Put the by-pass valve handle in the manual position (down).

2 Push in the directional valve manual override 5 times.

3 Remove and reverse the two (2) hoses, shown below.

4 Return the by-pass valve to the automatic position (up).

5 The limit switch connectors, at the top of the control panel must be reversed.

Doc 01-20221

Rev D

01-212 21F14

Figure 13

Page 25

Left Hand / Right Hand Conversion

Operator Check-Out

OPERATED CHECK-OUT WITH ALL CONTROLS CONNECTED

1 Switch the power disconnect switch to “on”.

2 Press the “open” button, allow unit to run about 10 seconds, then press the

“stop” button.

NOTE

When unit is first started, gate may not move immediately. This is

caused by the fluid being circulated through the system.

3 Press the “close” button. Allow unit to run until the open limit switch shuts the

system down.

25

Press

4

the system down.

5 Press the “close” button and test all safety features that have been installed.

6 Check out all optional controls that have been installed.

7 Test the 90-second run feature. Do this by positioning the manual bypass

valve handle to the manual position. Activate the unit. The unit will run but

the gate should not move. After approximately 90 seconds, the unit should

automatically shut off.

8 Check out manual operation of the gate.

9 Return the bypass valve handle to the automatic operation position.

the “open” button. Allow unit to run until the open limit switch shuts

NOTE

For troubleshooting, see guide supplied. It is recommended that the

M.R.D be adjusted to 2 times run time of gate. Example: if gate takes 15

seconds to open, then set M.R.D. to 30 seconds.

Doc 01-20221

Rev D

Page 26

26

Operator Check-Out

And Finally…

Install gate caution signs on both the inside and outside of the gate.

Re-install the control panel cover and the operator cover.

If the operator got greasy or dirty, please clean it.

Clean-up the area around the operator and gate.

Look around for any of your tools that may be left.

Please, leave the customer both this manual and the troubleshooting guide.

Let the customer know that you’re done and possibly review with them the

system that is installed. Go over how it works, accessories and their locations,

maintenance requirements, etc.

Required Maintenance Services

Check at least once every 6 months

Gate

Frame/Bolts

Electrical

Safety Systems

Fluid Level

Fittings

Drive Rail

Drive Wheels

Manual Operation

Inspect for wear or damage

Check & tighten

Inspect all wire connections

Check & test

Keep at lease ¾ full +

Check for leaks

Check for damage

Check for wear

Check & test

√

√

√

!

√

√

√

√

√

!Check at least once per month.

CAUTION

When servicing, always disconnect operator from power.

Doc 01-20221

Rev D

Table 5

Use only “ATF” automatic transmission fluid.

For complete maintenance information, see the maintenance manual.

Page 27

COPYRIGHT 2001

ALL RIGHTS RESERVED

This document is protected by copyright and may not be copied or adapted without the prior written

consent of LiftMaster. This documentation contains information proprietary to LiftMaster and such

information may not be distributed without the prior written consent of LiftMaster. The software and

firmware included in the LiftMaster product as they relate to this documentation are also protected by

copyright and contain information proprietary to LiftMaster.

FOR TECHNICAL SUPPORT

Call our toll free numbers:

(800) 323-2276

(800) 998-9197

Installation and service information is

available six days a week.

TO ORDER REPAIR PARTS

Call our toll free numbers:

(800) 528-2806

(800) 998-9197

Prepare to provide the following

information when ordering repair parts:

" Part Number

" Part Name

" Model Number

Loading...

Loading...