OWNER’S MANUAL

with Assembly Instructions

8'x10' Outdoor Shed

Sentinel

8’ x 10’ Outdoor Shed

MODEL #6404

You could win $200!

Register your product at www.lifetime.com and receive three important benefi ts:

1. You automatically will be entered to win $200 in our monthly drawing!

2. In the unlikely event of a product recall or safety modifi cation, we can notify you immediately and directly.

3. You may choose to receive Preferred Customer Announcements and promotions regarding new Lifetime

products.

www.lifetime.com

Level Surface Notice:

Surface must be leveled before installation. We recommend building a level work space with a cement or patio style

surface. If the surface is not properly leveled, the Outdoor Shed will not assemble correctly. Proper surface leveling will

save you time in the long run, so please do not ignore this step.

Building Code Notice:

Consult all local building codes, as well as city and county ordinances, to ensure that the construction of the Outdoor

Shed does not require a building permit. Proper building permit documentation may be required in your neighborhood,

and it would be unfortunate to learn this after constructing the Shed.

Screwdriver Notice:

There is a 1/2” phillips head screwdriver bit included with the shed hardware. This bit can be used with any power

screwdriver or drill. The plastic pieces of your shed can be damaged by overtightening of screws. To avoid damage we

strongly recommend the use of a low-powered power screwdriver or a drill that has an adjustable clutch that is set on a

low torque setting. If neither is available, use a hand screwdriver. In any case, use caution to avoid overtightening the

screws.

Floor Puncture Notice:

Sharp objects may damage your fl oor. If resting sharp, heavy objects on your shed fl oor, place a block of wood between

the sharp object and fl oor.

Congratulations on your Lifetime® Outdoor Shed purchase. By following the instructions below, your new Lifetime shed

should provide you with years of service and enjoyment.

Cleaning and Care

The polyethylene walls and shelves are stain- and solvent resistant. To clean, use a mild soap and a soft-bristled brush. Abrasive

cleaning materials may scratch the plastic and are not recommended. Repair scratches or rust spots on the metal by sanding

the affected area lightly; using a rust preventative spray primer; and fi nally, spraying with a high-gloss spray enamel paint. Avoid

placing a direct heat source on or near surfaces unless using a heat barrier.

SAFETY INSTRUCTIONS

FAILURE TO FOLLOW THESE WARNINGS MAY RESULT IN SERIOUS INJURY OR PROPERTY DAMAGE AND WILL VOID

To ensure safety, do not attempt to assemble this shed without following the instructions carefully. Check entire box and

inside all packing material for parts and/or additional instruction material. Before beginning assembly, read the instructions

and identify parts using the hardware identifi er and parts list in this document. Proper and complete assembly, use and

supervision are essential for proper orientation and to reduce the risk of accident or injury.

WARRANTY.

• Do not use or store hot objects such as grills, blowtorches, welding equipment, etc. in the shed.

• If using a ladder during assembly, use extreme caution.

• Two capable adults are required for shed assembly. (It is also recommended that a third adult function as an

instruction reader.)

Most injuries are caused by misuse and/or not following instructions. Use

2

INSTRUCTION #1018238 8/28/2006

caution when using this shed.

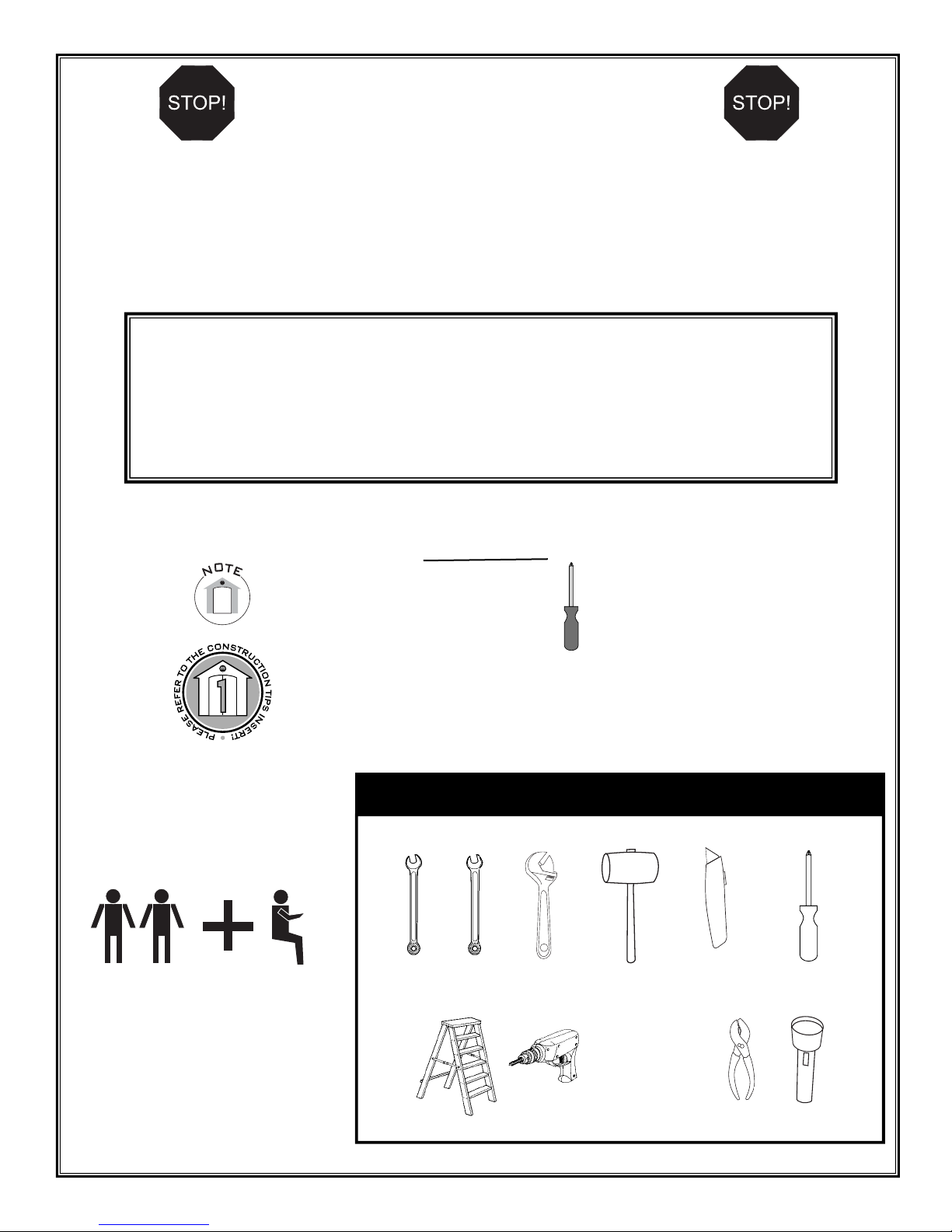

Read This First!

Before Beginning Assembly:

A. Read the “Congratulations” letter on pages 4-5.

B. Remove Parts List from the center of these instructions and

make sure all parts are present and in good condition.

C. Find the color “Construction Tips” fl yer and refer to it

during assembly.

**Do Not Contact the Store!**

For Assistance, including missing or broken parts,

Call Customer Service at:

1 (800) 225-3865

** Customers outside of the U.S. or Canada, please contact the store for assistance. **

KEY

Indicates a helpful hint or

important note.

Refers you to a specifi c step

in the full-color Construction

Tips fl yer.

Two Adults Required for Assembly

( + one Adult suggested as an instruction reader)

7/16” 3/8”

(2) (1)

Step Ladder

Indicates that a hand

screwdriver is required

for a step.

Suggested Tools & Materials

(Not Included):

Adjustable

(1)

Power Drill * Work Light

Rubber Mallet

(1)

Box Knife

(1)

Pliers

Phillips Head

(1)

Flashlight

(2)

(1)

* see “Screwdriver Notice” on page 2

(1)

(1)

(1)

3

IMPORTANT! Please Read

Dear Valued Customer,

®

Outdoor Storage Shed! We

We would like to congratulate you on your purchase of a Lifetime

are confi dent that you have made the perfect choice and you will be very pleased with your new

storage solution.

This Outdoor Storage Shed is part of the family of brands created and manufactured by

®

Lifetime

Products, Inc. Like all of our products, you can be assured that the quality of your

Lifetime Outdoor Storage Shed is the best in the world! All of our sheds are made in the USA,

something that is very important to us. And, we back that quality up by off ering the best

warranty in the business – A 10-year warranty that covers everything on the shed… top to

bo om!

All of our sheds are built with the highest-quality steel and polyethylene parts. The design and

construction of our steel-reinforced double-wall panels is second to none. All of our exposed

steel parts and trusses are powder coated and we only use high-impact polyethylene plastic.

What makes polyethylene so special? It has superior strength and durability, and, it won’t crack

or degrade outdoors.

®

Outdoor Storage Shed, please

So now that you know the quality you are ge ing in a Lifetime

take the time to READ THIS INSTRUCTION MANUAL!

We have taken great care in providing the best possible form of instructions to help you put

your new Outdoor Storage Shed together. Before you get started, PLEASE read the following

preparation tips to help you get started!

We can assure you, your construction experience will be a lot more enjoyable if you do!

PREPARATION TIPS:

• The fi rst step is simple… RELAX! You have made a great purchase, but Rome was not built

in a day. Plan to spend a good part of your a ernoon pu ing together your fi ne Outdoor Storage

Shed. Our philosophy is, if it comes together quickly and easily, it surely will come apart quickly

and easily! Your Lifetime

®

Outdoor Storage Shed will surely last for years if you are patient, and

take all the time necessary to put it together as we have instructed.

• Grab a friend to join in on the fun! This is not a one-person endeavor. We have found that not

only will things go smoother if you have two or more people participating in the construction of

the shed, but it will go quicker as well. So, the more the merrier!

• Make sure you have all the tools necessary for constructing your new shed. We have included

a 1/2 “ Phillips head screwdriver bit that may be used with any power screwdriver or drill.

This bit is your friend… please use it. The plastic pieces of your shed may become damaged

by overtightening the screws. To avoid this damage, we strongly recommend the use of a lowpowered power screwdriver or a drill that has an adjustable clutch that is set on a low-torque

4

- 1 -

se ing. If neither is available, use a hand screwdriver. If a hand screwdriver is all you have, take

several breaks… your wrist will need it!

• You will also need two small step ladders (when it comes time to do the roof!), a 7/16” wrench

and a 3/8” wrench.

• The small wood block in your shed box is there for a reason. DO NOT THROW THE WOOD

BLOCK AWAY, it is necessary for a aching the wall panels to the fl oor.

• Read through the entire instruction manual and “Construction Tips” insert before you start.

It’s always a great practice to get a feel for the fl ow of the process and to familiarize yourself with

the parts involved. But, try not to get ahead of yourself and start the process out of order.

• FOLLOW THE INSTRUCTIONS IN ORDER! Everything goes together in a certain order,

and we have learned what that correct order should be. In our state-of-the-art research and

testing facility, we have painstakingly created these instructions. The order of construction is

there for a reason, and some parts simply will not fi t if built out of order. Just follow along with

the order in the instructions and everything will fi t together and things will go very smooth.

• Refer to the color “Construction Tips” insert for the trickier construction spots. We have

identifi ed a few places during construction where it can get a bit tricky, that is why we included

the color insert. This full-color instruction extra was created to be er guide you through the

process. Use it and you will be a much happier Outdoor Storage Shed builder.

• YOUR SHED MUST BE BUILT ON A LEVEL SURFACE! If the spot you have chosen to place

your wonderful new Outdoor Storage Shed is not level, the shed will not assemble correctly!

We recommend a level cement or patio style surface. Your shed is meant to last a long time, so

provide the proper foundation for it before you start to build.

• Before you build it, make sure you are allowed to build it! Consult all building codes, as well

as city and county ordinances, to ensure that you do not require a building permit to construct

your Outdoor Storage Shed. Proper building permit documentation may be required in your

er your Outdoor Storage Shed is

neighborhood, and it would be quite unfortunate to learn this a

already built!

Now that you’re ready to begin the construction of your wonderful new Outdoor Storage

Shed, step back, take a deep breath, get yourself a large cold beverage and enjoy yourself. We

guarantee that a er spending the right amount of time in building your shed, you will be able to

enjoy it for years to come.

®

Thanks for choosing Lifetime

Outdoor Storage, and have fun!

- 2 -

5

1

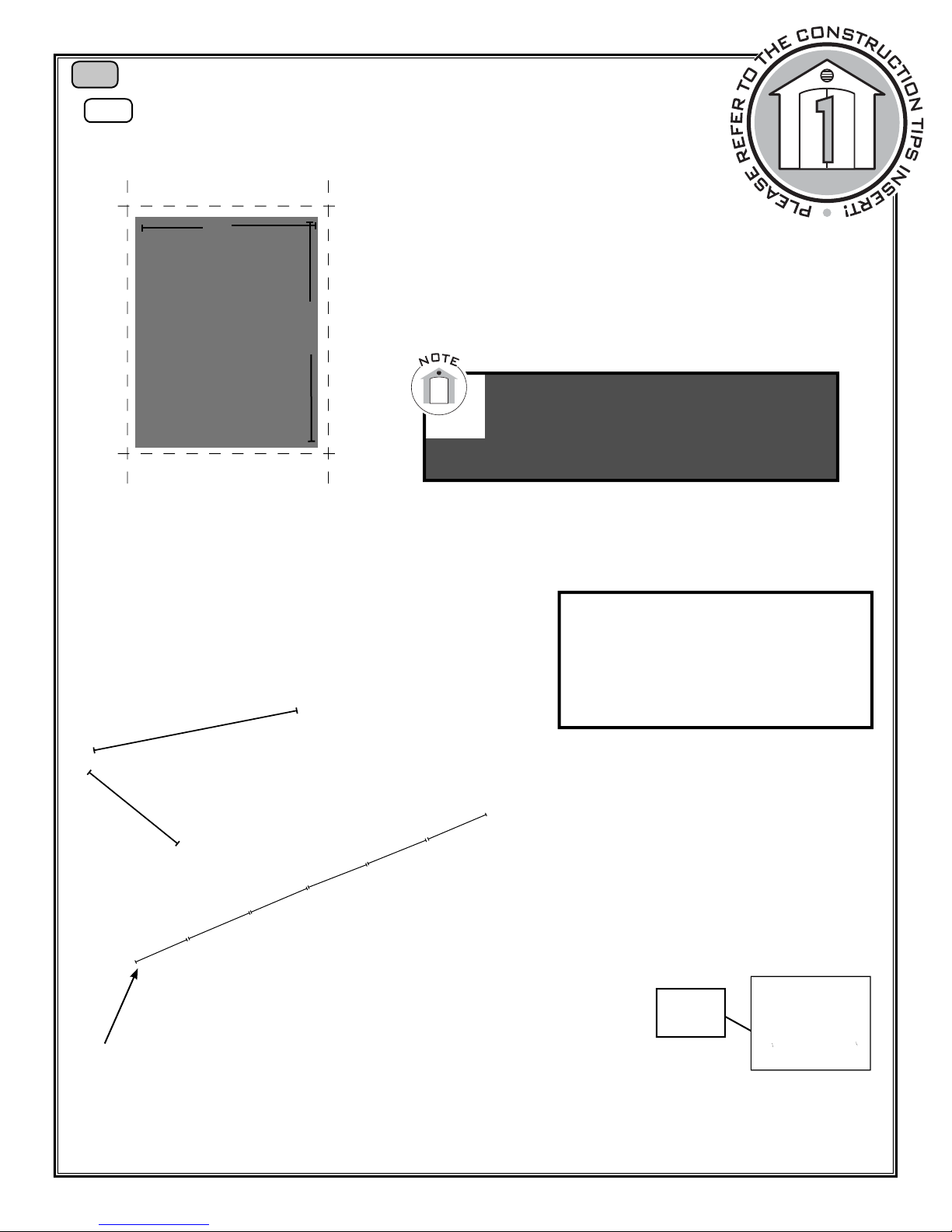

Site Selection

The actual dimensions of your shed (at its widest and longest points) are 8’ x 10’. Be sure

1a

to select a site that will accommodate these measurements. The base of the shed is

slightly smaller than this, so you will need to create a level surface that is at least 93.5” x

118.25”. We recommend using a level cement or patio style surface. This will provide the

best long-term performance for your shed.

8’

93.5”

NOTICE: Shed Extension Kits are available for this shed.

Please consider possible shed expansion when planning the

site for your shed. See inside the back cover of this manual for

information on ordering Extension Kits.

10’

8’

118.25”

10’

Surface must be leveled before installation. If

the surface is not properly leveled, the outdoor

shed will not assemble or function correctly.

Proper surface leveling will save you time in the long

run, so please do not ignore this step.

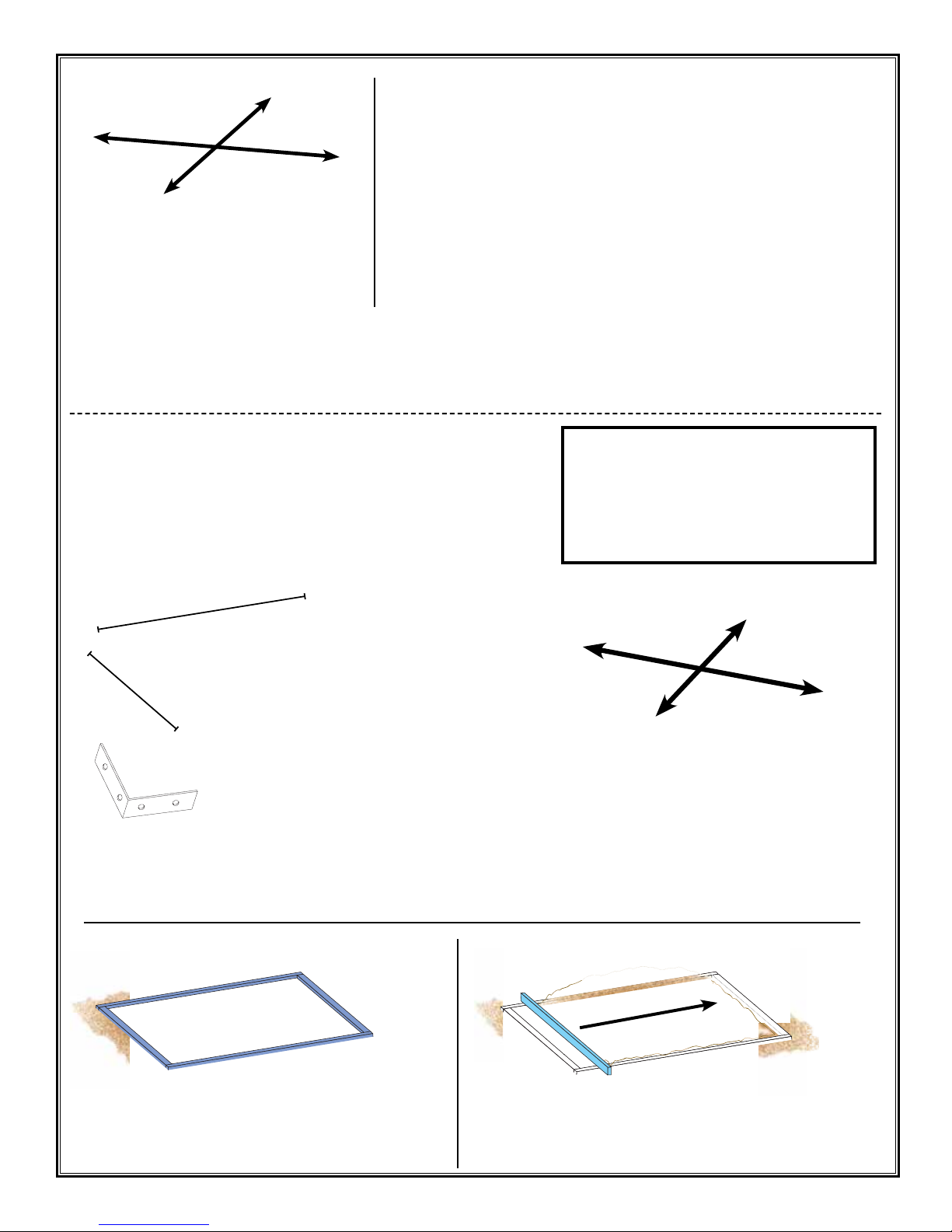

Alternate Site Preparation

Wherever possible you should use the surfaces described above. When this is not possible, we

recommend you use one of the following options:

Note: Any platform or similar structure should be built above ground in order to avoid water pooling inside shed.

Item Qty.

OPTION 1: Wood Platform

Be sure you use lumber that is treated and approved for

outdoor use. Build outside frame to 93 1/2” x 118 1/4” outside

dimensions:

118 1/4”

2” x 4” x 90 1/2” treated board* 8

2” x 4” x 118 1/4” treated board* 2

48” x 93 1/2”’ Plywood (ACX)** 2

22 1/4” x 93 1/2” Plywood (ACX)** 1

16d 3” common nails 32

8d 1 1/2” common nails 36

* All lumber must be rated for outdoor use.

** Trim 4’ x 8’ sheets to this size.

93 1/2”

16”

16”

15.25”

To be sure to have studs

in the correct location to

nail plywood in the next

step, start measuring here

& measure from center to

center.

6

16”

16”

16”

Place the 2” x 4” x 90 1/2” boards

on the inside of the frame. Nail each

board in place with the 16d nails.

B

A

Square up the frame by measuring

from corner to corner. Measurement

A should equal Measurement B.

Place platform in the desired location. If platform does not

rest level on the ground, build up low points with loose dirt

until platform is stable.

Line up a large sheet of outdoor

rated plywood (48” x 93.5”) with

the end of the frame (same end

you measured from). Nail plywood

in place.

Place next large sheet.

Cut last sheet of plywood

to fi t remaining space

(22”x93.5”) on frame. Nail

plywood in place.

Drill 3 evenly spaced 1/2” drain

holes in plywood between each 2” x

4” joist.

OPTION 2: Filled Wood Frame

Be sure you use lumber that is treated and approved for outdoor use.

Cut outside frame to 8’ x 10’ outside dimensions:

Be sure that

Item Qty.

2” x 4” x 7’ 5” treated board* 2

2” x 4” x 10’ treated board* 2

8d 1 1/2” common nails 16

1” ‘L’ bracket 4

“Pea” gravel 9.8 cu. ft. (aprox.)

Leveling board (2” x 4” x 10’) 1

frame is level.

* Must be rated for outdoor use

10’

A

B

8’

Square up the frame by measuring from

corner to corner. Measurement A should

equal Measurement B.

Nail an L-bracket on each corner of

the frame with 8d nails.

Place platform in the desired location. If platform does not rest level on the ground, build up low points with

loose dirt or “Pea” gravel, until platform is stable.

Once all boards are level and do not wobble,

pack “Pea” gravel or dirt around the outside of

the frame, and slope away from frame.

Use aprox. 9.8

cu. ft. of “pea”

gravel.

Now fi ll the inside of the frame with “Pea” gravel. Use

a leveling board to scrape off extra fi ll material and to

level the surface.

7

Before Beginning!

Remove the Parts List from the center of this manual, and locate

color “Construction Tips” insert in box.

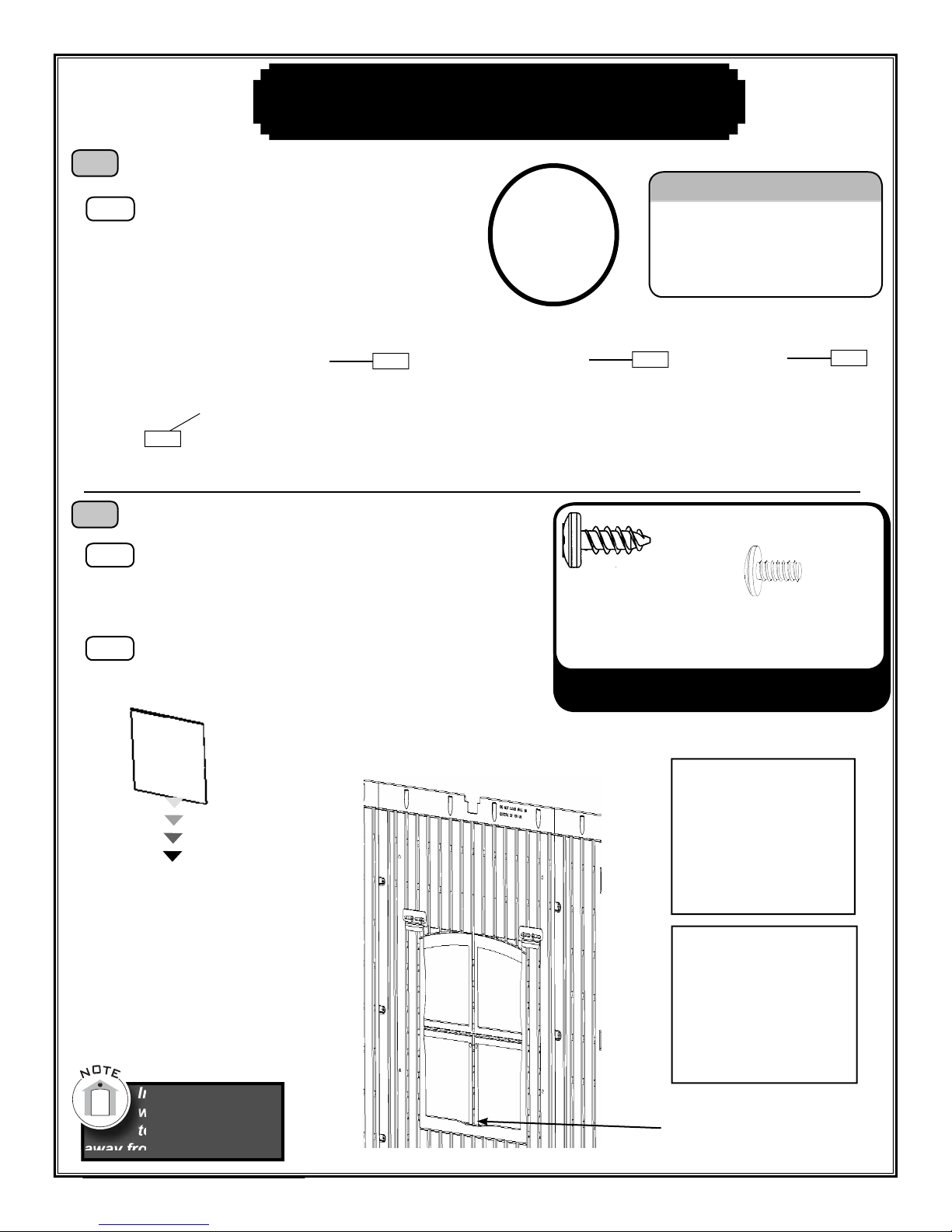

2

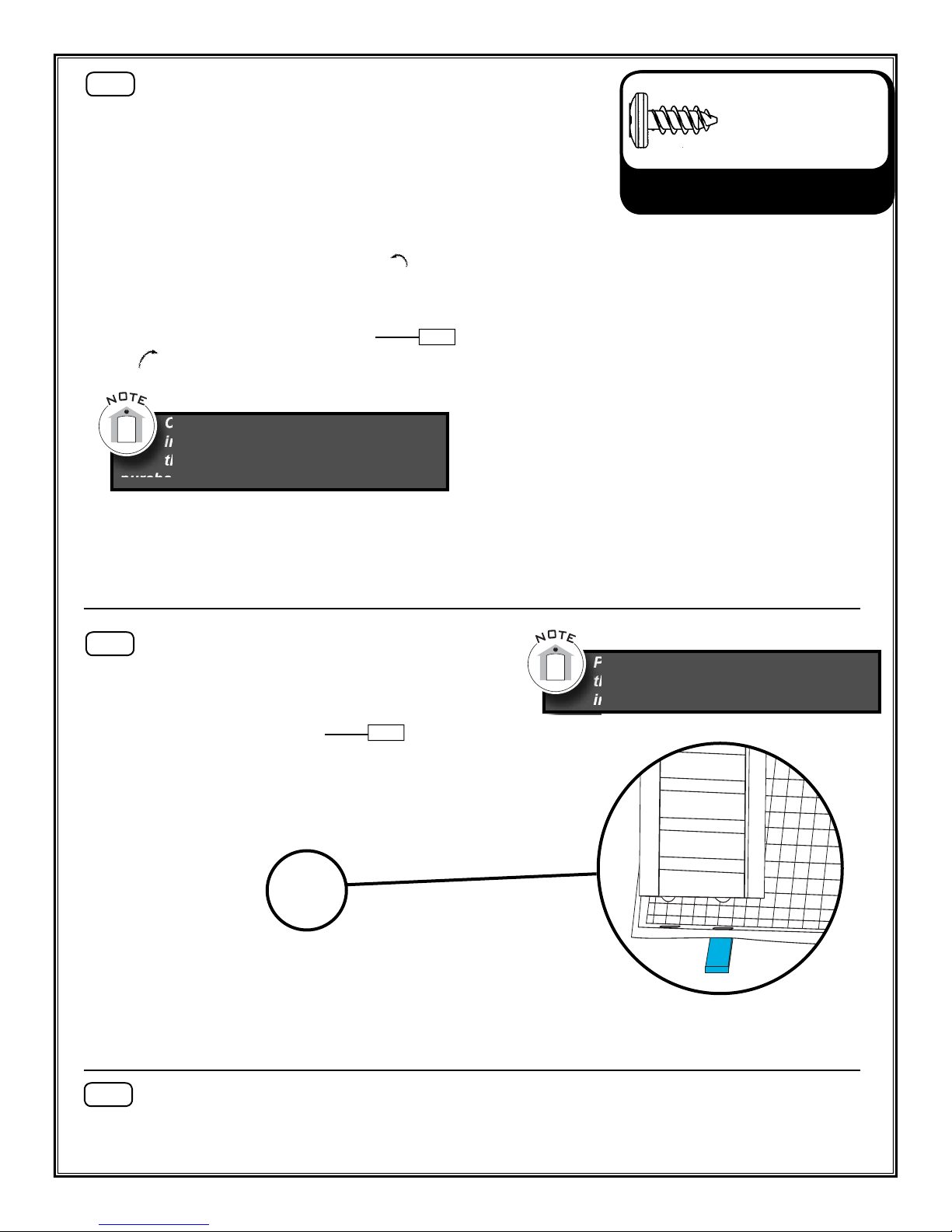

(as shown) and fi t tabs into slots and lay Center Floor

Panel fl at. Add next Center Panel (110) and last Outer

Panel (109).

3

Attach a Window Latch (HQ) above each corner of the Window

as shown. When tightening Screws (SS), ensure the Window

Latches slide freely.

second Window.

Assemble Floor

Lay Outer Floor Panel (109) fl at on the ground.

2a

Hold a Center Floor Panel (110) at an angle

1.

110

109

Assemble Window

Remove plastic sheeting from Window (AA) and slide

3a

Window into slot on the Window Wall Panel (125).

Do not overtighten. Insert Screw (TC) into the hole in the

3b

window. Set panel aside. Repeat steps 3a and 3b for the

2.

Sharp objects may damage your

floor. If resting sharp, heavy

objects on your shed fl oor, place a

block of wood between the sharp

object and fl oor.

110

SS (8)

HQ (4)

Hardware Bags:

1001632

CAUTION

3.

109

TC (2)

1015974

1004015

Screwdriver

Insert window

with bent edge at

top and pointing

away from the wall.

8

HQ

HQ

Place screw (TC) in this hole to

keep window from sliding up

too far. Insert until fl ush with the

window

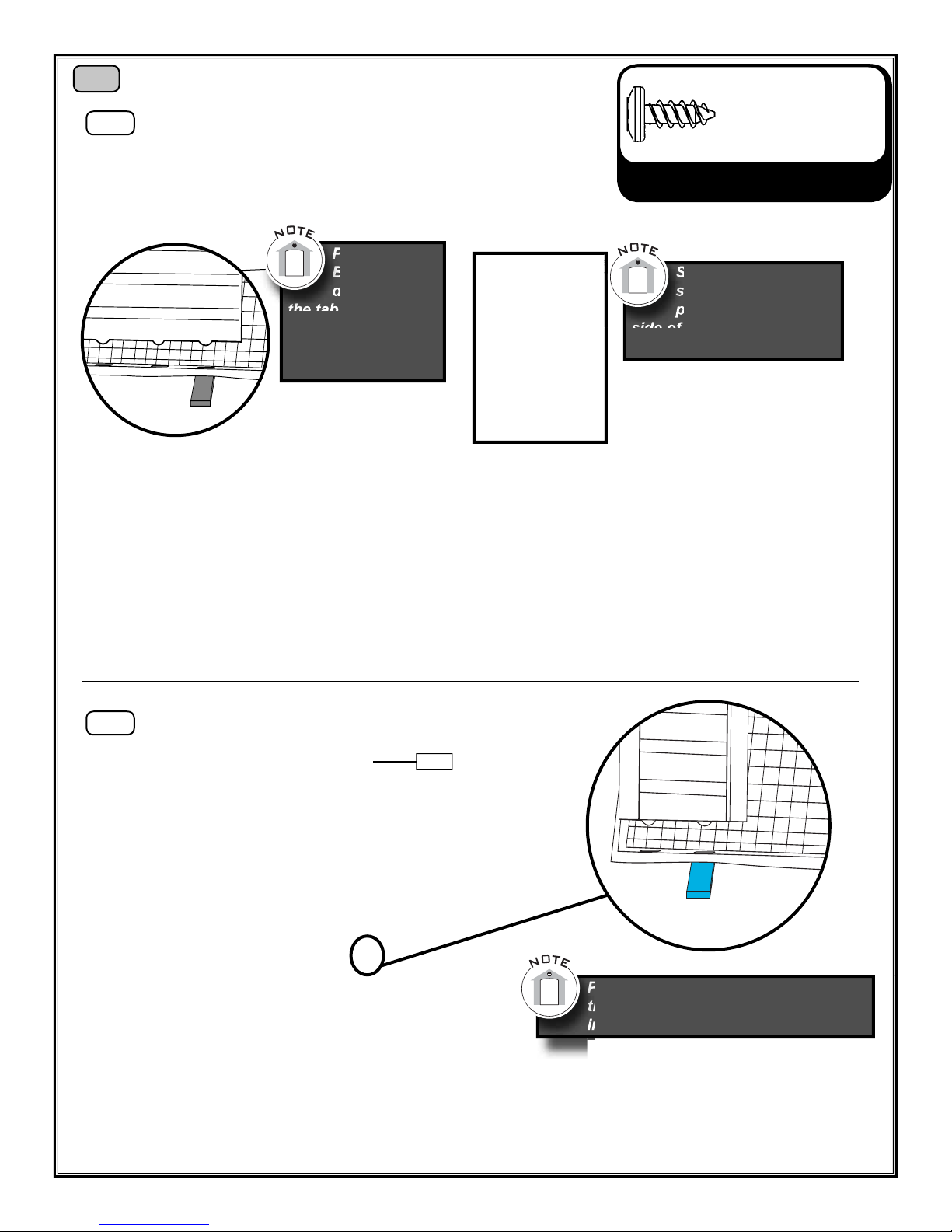

4

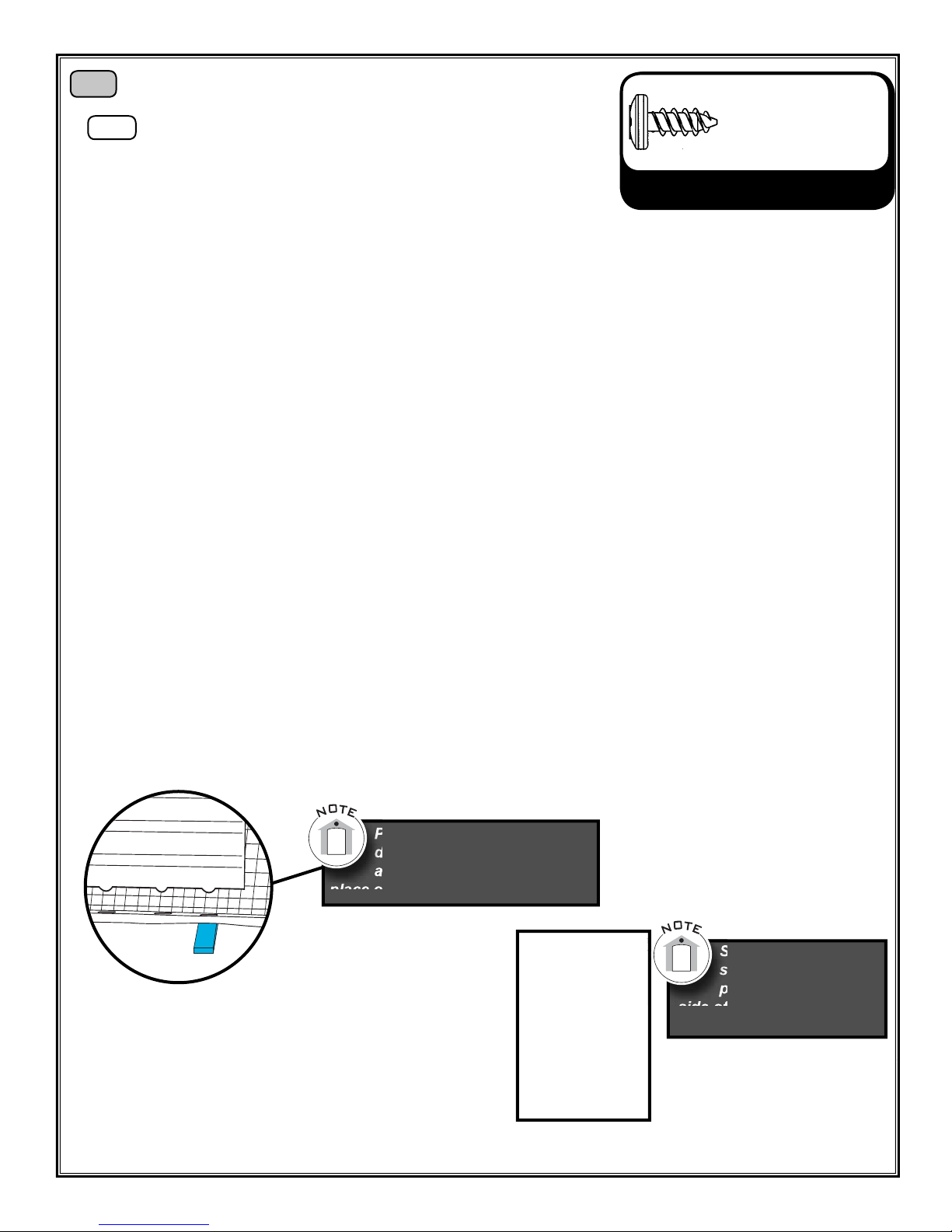

under fi rst tab, then pull down on Corner Panel until tab snaps into place. Move block

under the next tab and repeat.

Assemble Front Corner

Fold Left Corner Panel (105). Fit tabs of panel into the front left corner (while

4a

facing shed) of your fl oor. Place a Wood Block (BC) under Floor Panel, directly

105

Place Wood Block (BC) directly

under the tab you are inserting. Snap

tabs into place one at a time.

Fold up edges of Corner Shelf (121). Line-up holes in Corner

4b

Shelf with top set of pre-made holes in Left Corner Panel and

secure with Screws (SS).

Corner Shelf should only be placed

in top set of holes. See inside the

back cover for information on

purchasing additional shelves.

121

Hardware

Bags:1001632

SS (4)

Screwdriver

Top holes

9

5

Assemble Left Wall and Back Corners

Snap Wall Panels (108) into place along the side of shed. Ensure

5a

holes line up and then secure panels together with Screws (SS).

NOTE: The Window Wall Panel (125) may be inserted into any side Wall

Panel position; however, you should place one Window Wall Panel off-

center. You will then have enough wall space for your shelving. See page

11.

Place Wood

Block (BC)

directly under

the tab you are

inserting. Snap tabs

into place one at a

time.

Do Not Over-Tighten Screws

1.

2.

SS (20)

Hardware Bags:

1001632

Second person

should apply

pressure on opposite

side of the wall for easy

insertion of screws.

Screwdriver

3.

Fold Right Corner Panel (104). Snap into place and secure with

5b

Screws (SS).

104

Place Wood Block (BC) directly under

the tab you are inserting. Snap tabs

into place one at a time.

10

NOTE: Shelving Locations

Keep in mind where you would like your shelving. You install shelving on Shelf Support Channels. The

Channels may be installed on the Window Wall Panel when Window Wall Panel is in any position. However,

you can only install the shelving on regular Wall Panels when those two Wall Panels are adjacent.

Here

Here

Window in

Left Position

Only Here

Window in

Middle Position

Here

Here

Window in

Right Position

Shelf Support Channels can also

be installed in the Window Wall

Panel, as shown.

11

Fold up edges of Corner Shelf (121). Line-up holes in Corner

5c

Shelf with top set of pre-made holes in Corner Panel and secure

with Screws (SS).

SS (4)

Corner Shelf should only be placed

in top set of holes. See inside

the back cover for information on

purchasing additional shelves.

121

Hardware

Bags:1001632

Screwdriver

Top holes

5d

(SS).

5e

Skip the back wall and fold the second Left Corner

Panel (105). Snap into place and fasten with Screws

105

Repeat step 5c for this Corner Panel.

Place Wood Block (BC) directly under

the tab you are inserting. Snap tabs

into place one at a time.

12

6

Assemble Right Wall and Last Corner

Assemble the right wall as you did the left wall by snapping Wall

6a

Panels (108) into place along the side of shed. Window Wall

Panel (125) may be inserted into any side Wall Panel position. Ensure

holes line up and then secure panels together with Screws (SS).

NOTE: The Window Wall Panel (125) may be inserted into any side Wall

Panel position; however, you should place one Window Wall Panel off-

center. You will then have enough wall space for your shelving. See page

14.

SS (20)

Hardware Bags:

1001632

Screwdriver

Place Wood Block (BC)

directly under the tab you

are inserting. Snap tabs into

place one at a time.

Second person

should apply

pressure on opposite

side of the wall for easy

insertion of Screws.

Do Not OverTighten Screws

13

NOTE: Shelving Locations

Keep in mind where you would like your shelving. You install shelving on Shelf Support Channels. The Channels

may be installed on the Window Wall Panel when Window Wall Panel is in any position. However, you can only install

the shelving on regular Wall Panels when those two Wall Panels are adjacent.

Here

Here

Window in

Left Position

Only Here

Window in

Middle Position

Here

Here

Window in

Right Position

14

Shelf Support Channels can also

be installed in the Window Wall

Panel, as shown.

Fold up edges of the last Corner Shelf (121). Line-up holes in

6b

Corner Shelf with top set of pre-made holes in Right Corner Panel

and secure with Screws (SS).

SS (4)

Corner Shelf should only be placed

in top set of holes. See inside

the back cover for information on

purchasing additional shelves.

121

Hardware

Bags:1001632

Screwdriver

Top holes

15

7

End Channel (AG) onto the door.

Left Door Assembly

Rest Left Door (118) with front side down. Position Deadbolt

7a

Latches (HM) in slots at top and bottom of door, and slide Door

(Not Actual Size)

Hardware Bags:

1015974

HM (4)

Rubber Mallet (1)

Back of

Door

bolt Latches).

Install Left Door Handle (BB). Set door aside.

7b

Door End Channel fi ts

onto door with the fl at

side up (facing the Dead

TOP

BOTTOM

HC (4)

HM

HM

VC (6)

You may need to nudge the

Door End Channel to make

the holes line up with the

gap in the door.

1. 2.

HC

HP

Repeat steps 7a and 7b for the second Left Door.

7c

HL

Back of

Door

BB

HL (4)

Hardware Bags:

1015974

VC

PB

PB (6)

7/16” Wrenches (2)

Screwdriver

CAUTION

Do not overtighten. Overtightening

may damage parts and void

warranty.

16

8

Right Door Assembly

Rest Right Shed Door (119) with front side down, and slide Door End Channel (AG) onto the door.

8a

Back of

Door

8b

Fit Thumb Lever Knobs

1.

into Handle Grooves.

Groove

Knob

HG

BA

Rotate the Thumb Lever into

2.

the handle. Slide forward

until the Knobs fi t into the

holes in the handle.

HG

Knobs snap

into Holes

BA

Hardware Bags:

1015974

3.

PB

VC

PB

VC

VC (6)

PB (6)

Screwdriver

HG

BA

CAUTION

Do not overtighten. Overtightening

may damage parts and void

warranty.

Attach the Handle and Thumb lever to the

Door.

17

8c

HR

Install Handle Latch assembly onto the Right Shed Door.

HA

HI

HB (4)

HH (4)

HR (4)

HH

HB

HN

Attach Door Spring (HD) to Handle assembly. Set the door aside.

8d

Hardware Bags:

1015974

7/16” Wrenches (2)

You may need to nudge the

Door End Channel to make

the holes line up with the gap in

the door.

(Not Actual Size)

Hardware Bags: 1015974

Screwdriver

HD (2)

HD

Repeat steps 8a, 8b, 8c and 8d for the second Right Door.

8e

18

HI

HA

Use pliers to pull

spring down and hook

into bottom hole.

Before Beginning Assembly

Remove this Parts List and Hardware Identifi er

from the Instructions and take an inventory of all

Box 1 (Larger Box)

parts in both boxes.

Two Adults Required for Assembly

( + one Adult suggested as an instruction reader)

Parts List

ID Reorder # Part # Description Qty

Main Hardware

109 CB10999 109 Outer Floor Panel 2

110 CB11099 110 Center Floor Panel 2

111 CB11182D 111 Front Gable 2

114 1009262 1009258 Roof Panel 8

115 CB11580C 115 Front Roof Cap 1

116 CB11680C 116 Rear Roof Cap 1

118 ZS11881C 118 Left Shed Door 2

119 1009334 1002607 Right Shed Door 2

121 CB12180 121 Corner Shelf 4

126 ZS12680 126 32” Short Shelf 2

AC 1001866 Roof Truss Brace 3

AD AR02406 Roof Truss Channels 6

AF AR02706 Shelf Support Channel 2

AG AR02820 Door End Channel 4

AH ZP07606 Gable Support Sq. Tube 2

AI ZS01006 Roof Support 8

AJ 1009232 Skylight 4

Box 2 (Smaller Box)

ID Reorder # Part # Description Qty

117 CB11780C Center Roof Cap 3

104 ZS10482 104 Right Corner Panel 2

105 ZS10582 105 Left Corner Panel 2

108 ZS10882 1013592 Wall Panel 4

125 ZS12582 125 Window Wall Panel 2

126 ZS12680 32” Short Shelf 1

AA ZS01200 Window 2

Shed Parts Box [1016058]

ID Reorder # Part # Description Qty

Main Hardware

AB 1009266 16” Pegboard Strip 2

AE 1009333 Shelf Support Bracket 6

BA 1015792 Right Door Handle 2

BB 1009123 Left Door Handle 2

BC IA01400 Wood Block 1

BD IA01500 Wood Shim 4

Truss Support Hardware Bag [1001884]

SA BB04500 Threaded Rod 3

HL BN00300 1/4” Cap Nut 6

Skylight Hardware Bag [HH11600]

LA BS05900 #10 x .5” Pan-head Screw 26

LB BW01200 #10 Fender Washer 26

ID Reorder # Part # Description Qty

Vent Hardware Bag [HH11900] x2

VA CH08381 Louvered Vent 1

VB DA03700 Vent Screen 1

PB BS05800 #10 x .75” Pan-head Screw 6

VC BW01300 #10 Washer 6

Door Handle Hardware Bag [1015974] x2

HA AC00100 Latch 1

HB 1000118 1/4” x 2” Carriage Bolt 2

HC 1000109 1/4” x 1.5” Carriage Bolt 2

HD BG01600 Door Spring 1

PB BS05800 #10 x .75” Pan-head Screw 7

VC BW01300 #10 Washer 6

HG 1015832 Thumb Lever 1

HH BA05700 .375” x .56” Steel Spacer 2

HI ZP07820 Latch Cover Plate 1

HL BN00300 1/4” Cap Nut 2

HO CK00600 Spacer, Door Hinge 2

HM CH11999 Deadbolt Latch 2

HN AG04120 Rt Door Latch (rnd hole) 1

HP AG04020 Lt Door Latch (oval hole) 1

HQ 1007360 Window Latch 2

HR 300022 1/4” Center Lock Nut 2

Front Gable Hardware Bag [HH12100] x2

GA BS05700 .25” x 1.125” Pan-head Scr. 7

GB CF03399 End Plug 2

Truss Hardware Bag [1015232]

TA 1001865 Truss Connector 3

HK BN01600 #10 Cap Nut 20

TC BS06100 #10 x 3/8” Pan-Head Scr. 21

TD DA04000 L-Key w/Phillips Head 1

TE BA07000 #2 Phillips Bit 1

Shed Screw Hardware Bag [1001632]

SS BS07500 .25” x .625” Screw 238

Tool Clip Assortment [HH12500]

CA BA06500 Pegbrd J-Hook 3

CB BA06600 Pegbrd L-Hook 3

CC BA06700 Pegbrd Toolholder 2

CD BA06800 Pegbrd 2” Dbl Arm Hook 1

CE BA06900 Pegbrd 4’ Dbl Arm Hook 1

Pegboard Screw Hardware Bag [1011398]

PB BS05800 #10 x 3/4” Pan-head Screw 11

Door Gap Flap Hardware Bag [1004034]

FA CH14199 Lt Gap Flap 1

FB CH14499 Rt Gap Flap 1

LA BS05900 #10 x .5” Pan-head Screw 4

*Part Numbers are listed when different from the Reorder Number.

The Part Number will appear on most of the plastic parts.

19

104

111

Shed Parts

(Not Actual Size)

105

109 110108

114

115

119

Back view

PULL OUT THIS PAGE

AC

116

Front view

121

AD

126

117

AA

125

AE

118

Front view Back view

AK

AG

20

AH

AF

AI

AJ BA

AB

BB HA

HD

VA

VB

7/16” 3/8”

HG

HI

TA

HM

GB

FA

Suggested Tools & Materials

(Not Included):

Adjustable

Rubber Mallet

FB

Box Knife

HN

HQ

Phillips Head

HP

SA

PULL OUT THIS PAGE

FOR EASY REFERENCE

(2) (1)

Step Ladder

(2)

*See “Screwdriver Notice” on page 2

**U.S. and Canada customers ONLY**

IF ASSISTANCE IS NEEDED, DO NOT CONTACT THE STORE!!!

CALL OUR CUSTOMER SERVICE DEPARTMENT at 1 (800) 225-3865

HOURS: 7:00 a.m. to 5:00 p.m. Monday through Friday (Mountain Standard Time)

**For customers outside the U.S. or Canada, please contact the store for assistance.**

(1)

Power Drill * Work Light

(1)

**Call or visit our Web site for Saturday hours**

(1)

(1)

Pliers

(1)(1)

(1)

Flashlight

(1)

21

Shed Hardware

(Actual Size)

LA

PB

TD

LB

HH

HK

TE

HB

FOR EASY REFERENCE

HC

PULL OUT THIS PAGE

HL

GA

TC

VC

SS

HO

HR

22

9

Front Gable Assembly

Insert End Plugs (GB) into ends of Gable Support Square Tube

9a

(AH). Attach Gable Support Square Tube to Front Gable (111),

and secure with Screws (GA).

Only use a hand

screwdriver on this step

GB

GA

Hardware Bags:

HH12100

AH

The Square Tube must be

oriented with the fl at rectangle

hole up, and the fl at oval holes

facing away from the gable.

GA (12)

Screwdriver

9b

Install Vent (VA) and Screen (VB) into the Front Gable, using Screws

(PB) and Washers (VC).

VA

VB

VC

PB

screws.

PB (10)

VC (10)

Hardware Bags:

HH11900

Second person should apply

pressure on opposite side of

the Gable for easy insertion of

Screwdriver

Repeat steps 9a and 9b for the second Gable.

9c

23

10

Install Doors and Front Gable

10a

Slide one Spacer (HO) onto bottom hinge pin of Left Shed Door

and place pin into indent in fl oor.

HO (4)

Hardware Bags: 1015974

HO

One person should hold doors

in place until they are secured to

the front Gable.

10b

Slide one Spacer (HO) onto bottom hinge pin of Right Shed Door

and place pin into indent in fl oor.

One person should hold doors

in place until they are secured

with to front Gable.

24

HO

10c

Install Front Gable assembly by sliding it over the Hinge Pin in each door.

Top Hinge pins fi t into

holes on underside of

Front Gable

10d

Secure both sides of Front Gable with Screws (SS).

Hardware Bags:

1001632

SS (12)

Screwdriver

10d

Repeat steps 10a, 10b, 10c and 10d for the Doors and Gable on the other side of the shed.

25

11

Screws (TC) and Cap Nuts (HK).

Assemble Truss

11a

Attach Brace (AC) to two Roof Truss Channels (AD)

(one on each side of Brace). Secure Brace with

TD (1)

TC (20)

HK (20)

Follow picture above

to connect Brace to a

Truss Channel at each

end of the Brace.

AD

AD

(HK).

AC

Use L-key (TD) to hold

screw (TC) in place

while tightening nut

Hardware Bags: 1015232

TC

5/16” Wrench (1)

The nut goes on

the outside of the

truss.

HK

AC

11b

parallel. Completely tighten all hardware.

Use Truss Connector (TA) to attach Roof Truss Channels at top. Secure with Screws (TC) and Cap

Nuts (HK). Before completely tightening, lay assembly on its side to ensure Channels and Brace are

Ensure Truss

Connector is aligned

with the Truss

Channels.

TC

TA

HK

26

11c

Slide a Threaded Rod (SA) through the Truss Support

Brace and the top of the Truss Connector.

HL (6)

SA (3)

11d

Hardware Bags:

1001884

SA

Secure the top and bottom of the Threaded Rod with a 1/4” Cap Nut (HL).

HL

3/8” Wrench (1)

11e

Repeat Steps 11a - 11d for each Truss.

WARNING

Do not overtighten the Cap Nut. If the end of

the Bolt breaks through the plastic cap, call our

Customer Service Department at the number

on Page One. Exposed threads on the end of

the Bolt may cause serious injuries.

HL

27

12

Truss & Roof Installation

12a

Place a Truss into the fi rst set of notches behind the Front Gable.

Be sure to carefully read and follow the roof installation instructions and

notes. Following each step in the order listed will minimize potential

complications during installation.

12b

into the notch in the

Truss.

Place a Roof Panel (114) onto the Truss and the Front Gable. Ensure the alignment nub in the Roof

Panel fi ts into notch on the Truss.

Nub

Truss Channel

Ensure the

nub in the

Roof Panel fi ts

Top of Roof Panel

Roof Panel

Bottom of Roof

Panel

28

12c

Secure the Roof Panel to the Front Gable and Truss Channel

with all but the very top Screws (SS).

Use a fl ashlight to check

that holes line-up before

inserting screws.

Only use a hand

screwdriver on this step

AI

(not actual size)

Hardware Bags:

1001632

A second person

on a ladder should

apply downward

pressure while attaching

roof parts.

AI (1)

SS (7)

Screwdriver

Slide the metal Roof Support (AI) into place

between the Roof Panel and Gable/Truss.

Insert top Screws (SS).

12d

edge with Screws (SS).

Bottom lip of Roof Panel fi ts over wall panel and ridge fi ts into

the top of the wall. Secure the Roof Panel along the bottom

Ensure the ridge in the

bottom of the Roof Panel

fi ts into the top of the wall.

The Roof Support fi ts into

the notches in the Roof

Panel (as shown).

Roof Panel Ridge

Roof Panel

Wall

SS (4)

Hardware Bags:

1001632

Screwdriver

29

12e

Follow steps 12b-12d and install a Roof Panel and Roof

Support on opposite side.

(Not actual size)

AI (1)

SS (11)

Position the Front Roof Cap (115) as shown. Secure to Front

12f

Gable with Screws (SS).

Hardware Bags:

1001632

Hardware Bags:

1001632

Screwdriver

SS (4)

Screwdriver

30

12g

Install next Truss.

12h

Follow steps 12b - 12d to place the next Roof Panels (114) and

Roof Supports (AI). Repeat for other side.

(Not actual size)

Hardware Bags:

1001632

AI (2)

SS (20)

Screwdriver

Position Roof Cap (117) next to Front Roof Cap. Attach to

12i

Truss with Screws (SS).

Hardware Bags:

1001632

SS (4)

Screwdriver

31

Connect centers of Front Roof Cap (115) and Roof Cap (117)

12j

with Screws (SS).

SS (2)

Only use a hand

screwdriver on

this step

12k

Install the next Truss, two Roof Panels (114) and Roof Cap

(117).

Hardware Bags:

1001632

Screwdriver

CAUTION

Only hand tighten screws in

Roof Caps. Do not overtighten.

Overtightening may damage Roof

Caps and void warranty.

(Not actual size)

Hardware Bags:

1001632

AI (2)

SS (20)

Screwdriver

32

12l

Install the last two Roof Panels and Roof Supports.

(Not actual size)

Hardware Bags:

1001632

AI (2)

SS (22)

Screwdriver

12m

Install last Roof Panel and Roof Support.

(Not actual size)

Hardware Bags:

1001632

AI (1)

SS (11)

Screwdriver

33

12n

Position and Secure Center Roof Cap (117) along Truss.

SS (4)

12o

Connect centers of Roof Caps (117).

Only use a hand

screwdriver on

this step

Hardware Bags:

1001632

1001632

Screwdriver

SS (2)

#2 Screwdriver (1)

CAUTION

Only hand tighten screws in

Roof Caps. Do not overtighten.

Overtightening may damage Roof

Caps and void warranty.

12p

12q

Position and Secure Rear Roof Cap (116) along Rear Gable.

Connect Rear & Center Roof Caps.

1001632

1001632

SS (4)

#2 Screwdriver (1)

SS (2)

#2 Screwdriver (1)

34

13

Skylight Installation

LA (24)

13a

13b

13c

Pre-fold Skylights (AJ) before installing.

Push folded Skylight up through opening; open Skylight; use

tabs to pull Skylight down into place.

Fasten Skylight in place with Washer (LB) and Screws (LA) (pull

on tabs while inserting Screw to provide resistance).

Repeat for all Skylights.

Only use a hand

screwdriver on this step

LB (24)

HH11600

#2 Screwdriver (1)

LB

LA

14

14a

Pegboard Installation

Using a Level, position the 16” Pegboard Strip (AK) in the

desired locations. Screw the Pegboard to the wall using

#10 x 3/4” Screws (PB). See Note.

PB

PB (10)

Hardware Bags: 1011398

Screwdriver, Level

The Pegboard Strips are

screwed directly into the

plastic. Line up Strip anywhere

on wall so the holes are over plastic

(and not over a groove in the wall).

Be sure that the Pegboard Strip is level

before inserting screws.

Repeat step 14a for second Pegboard Strip.

14b

35

15

Shelf Installation

15a

Place Short Shelves (126) on brackets and secure with Screws

(SS).

NOTICE

1001632

Hardware Bags:

1001632

SS (8)

#2 Screwdriver (1)

Screwdriver

The total weight placed on shelves hung

on each Wall Panel cannot exceed 100

pounds (45 kg).

Additional Shelf Locations

Additional Shelves and Support Channels can be purchased from Customer

Service. These Shelves and Support Channels can be installed on any

wall containing a truss notch and a column of screw holes. See Page 37 for

additional information.

Shelf Support Channels can also

be installed in the Window Wall

Panel, as shown.

36

Additional Shelves and parts can be purchased

from Customer Service:

1 (800) 225-3865

** Customers outside of the U.S. or Canada, please contact

the store for assistance. **

NOTE: Shelving Locations

Keep in mind where you would like your shelving. You install shelving on Shelf Support Channels (one Channel per

Wall Panel) so Shelves will span across Wall Panels. The Channels may be installed on the Window Wall Panel

when Window Wall Panel is in any position. However, you can only install the shelving on regular Wall Panels when

those two Wall Panels are adjacent.

Here

Here

Window in

Left Position

Only Here

Window in

Middle Position

Here

Here

Window in

Right Position

Shelf Support Channels can also

be installed in the Window Wall

Panel, as shown.

37

16

Align Doors

16a

(Fig. 2). If doors need further adjustment, insert another shim under the front corner opposite of the fi rst shim. If the

doors still needs further adjustment, stack additional shims (one at a time) alternating between the back and front

shims.

16b

In some cases, the shed doors may not completely line up at the tops (Fig. 1). When this happens, identify

which side is higher and use a shim (BD) to slightly raise the back corner of the high side until doors line up

High Side

High side

Low side

Fig. 1

Shim should be placed at

the corner, running directly

under one wall.

After aligning doors, cut off any portion of wood shim that is still exposed. From inside the shed, drive a 1”

nail through the shim into the fl oor to hold it in place.

First

Shim

Fig. 2

Second

Shim

Anchor the Shed

17

17a

shed.

After assembling your shed, you need to anchor it to the ground through the four indentations in the shed

fl oor. Consult your local hardware store for suggestions on the best hardware to use for anchoring your

10’

8’

WARNING

Failure to anchor your shed may result in

property damage and/or personal injury.

10’

8’

38

Install Gap Flaps on Doors

18

18a

between the top of the door and the Gable.

Install the Gap Flaps (FA & FB) inside each door as shown. Before

completely tightening Screws (LA), slide Flap up until it covers any gap

1001693

Hardware Bags:

1004034

LA (4)

#2 Screwdriver (1)

Screwdriver

FB

FA

Enhance your Lifetime® Outdoor Shed by purchasing the following Shed Accessories:

Model #

0110 Corner Shelf (2 pack)

Two 10” radius Shelves with hardware.

0130 32” Shelf Kit w/ hardware (3 pack)

Three 32” x 10” Steel-Reinforced Shelves with shelf brackets and hardware.

0190 Shelf Support Channel

Two Shelf Support Channels that allow the 32” shelves on either of the side walls of your shed.

6420 30” Shed Extension Kit

Extend your shed two and a half feet for the ultimate storage building.

To purchase shed accessories, visit us at:

www.buylifetime.com

Or call: 1 (800) 424-3865

0110 0130 6420

39

LIFETIME OUTDOOR SHED EQUIPMENT

10-YEAR LIMITED FACTORY WARRANTY

THE MANUFACTURER RESERVES THE RIGHT TO MAKE SUBSTITUTIONS TO WARRANTY

CLAIMS IF PARTS ARE UNAVAILABLE OR OBSOLETE.

1. Lifetime outdoor sheds are warranted to the original purchaser to be free from defects in material or

workmanship for a period of ten years from the date of original retail purchase. The word “defects” is defi ned

as imperfections that impair the use of the product. Defects resulting from misuse, abuse or negligence will

void this warranty. This warranty does not cover defects due to improper installation, alteration or accident.

This warranty does not cover damage caused by vandalism, rusting, “acts of nature” or any other event

beyond the control of the manufacturer.

2. This warranty is nontransferable and is expressly limited to the repair or replacement of defective product. If

the product is defective within the terms of this warranty , Lifetime Products, Inc. will repair or replace defective

parts at no cost to the purchaser. Shipping charges to and from the factory are not covered and are the

responsibility of the purchaser. Labor charges and related expenses for removal, installation or replacement

of the shed or its components are not covered under this warranty.

3. This warranty does not cover scratching or scuffi ng of the product that may result from normal usage. In

addition, defects resulting from intentional damage, negligence, unreasonable use or hanging from the truss

will void this warranty.

4. Liability for incidental or consequential damages is excluded to the extent permitted by law. While every

attempt is made to embody the highest degree of safety in all equipment, freedom from injury cannot be

guaranteed. The user assumes all risk of injury resulting from the use of this product. All merchandise is sold

on this condition, and no representative of the company may waive or change this policy.

5. This warranty is expressly in lieu of all other warranties, expressed or implied, including warranties of

merchantability or fi tness for use. Neither Lifetime Products, Inc., nor any representative assumes any other

liability in connection with this product.

ALL WARRANTY CLAIMS MUST BE ACCOMPANIED BY A SALES RECEIPT.

REPORT PRODUCT DEFECTS IN WRITING TO:

Lifetime Products, Inc., PO Box 160010 Clearfi eld, UT 84016-0010

or call (800) 225-3865 M-F 8 a.m. to 5 p.m. MST.

Please include your dated sales receipt and photographs of damaged parts.

To register the product, visit our website at www.lifetime.com

R

PO Box 160010 • Freeport Center, Bldg. D-11 Clearfi eld, Utah 84016-0010

40

www.lifetime.com

©2004 Lifetime Products, Inc.

T: 800-225-3865 • F: 801-728-1907

Loading...

Loading...