Lifetime A-FRAME PLAYSET 90042, 90240 Assembly Instructions Manual

A-FRAME PLAYSET

MODEL #60091

MODEL 90042

• Before you start, prepare a level surface with the proper

Safety Zone (see page 12).

• 2+ people recommended for setup

ASSEMBLY INSTRUCTIONS

Save this instruction in the event that the manufacturer has

to be contacted for replacement parts.

TOOLS REQUIRED

1/2 in/po (≈13 mm)

(1)

(1)

(1)

(2)

3/16 in/po (≈5 mm)

(2, included)

(2)

(1)

(1)

5/16 in/po (≈8 mm)

(1)

1/4 in/po (≈6 mm)

(1)

TABLE OF CONTENTS

Icon Legend................................4

Warnings and Notices..................5

Safety Information.....................6

Safe Play Area..........................12

A-Frame Assembly....................13

Deck Support Assembly.............19

Deck Assembly..........................30

Parts Identifi er.........................i-iv

Climbing Wall and Chalkboard

Assembly................................. 37

Roof Assembly..........................43

Slide and Accessories Assembly ....

...............................................49

Swing Assembly........................55

Maintenance Instructions..........60

Registration..............................63

Warning Sticker........................64

Warranty...................................65

MODEL# AND PRODUCT ID

(you will need both when contacting us)

Model Number: 90042

Product ID:

ICON LEGEND

Indicates special heed should be taken when reading.

Indicates the parts to be used for a section.

Indicates no parts required for a specifi c section.

Indicates the hardware to be used for a section.

Indicates no hardware required for a specifi c page.

Indicates the tools to be used for a section.

Indicates to use/not to use an electric drill for a specifi c step.

Indicates the use of a centerlock nut. A nut with this marking will require some effort to tighten. This hardware was

designed with this feature in order to prevent loosening later.

USE A

USING A DRILL IS NOT RECOMMENDED FOR DRIVING BOL

A cordless drill can be used for driving screws;

however, care should be taken not to over

T YOUR OWN RISK!

TS.

-tighten or strip screws.

!

# 1175581_B

12/1/2016

4

W

ARNINGS & NOTICES

SAFETY INSTRUCTIONS

FAILURE TO FOLLOW THESE WARNINGS MAY RESULT IN SERIOUS INJURY OR PROPERTY DAMAGE AND WILL VOID WARRANTY.

Owner must ensure that all players know and follow these rules for safe operation of the system.

To ensure safety, do not attempt to assemble this product without following the instructions carefully. Check entire box and inside all packing

material for parts and/or additional instruction material. Before beginning assembly, read the instructions and identify parts using the hardware

identifi er and parts list in this document. Proper and complete assembly, use and supervision are essential for proper operation and to reduce the

risk of accident or injury. A high probability of serious injury exists if this product is not installed, maintained, and operated properly.

• If using a ladder during assembly, use extreme caution.

• Two capable adults are recommended for this operation.

• Be aware that parts can be damaged by overtightening the screws.

• All who participate in the assembly process should wear safety glasses throughout the assembly.

Most injuries are caused by misuse and/or not following instructions. Use caution when using this product.

5

**IMPORTANT SAFETY INFORMATION**

PLEASE READ BEFORE BEGINNING ASSEMBLY:

INSTALLATION & GROUND PREPARATION INSTRUCTIONS

• Place the equipment on a level, well-drained ground, not less than 6.6 ft (2.0 m) from any structure or obstruction such as a fence, garage, house, overhanging branches, laundry lines, or electrical

wires

• Provide enough room so that children can use the equipment safely. For example, for structures

with multiple play activities, a slide should not exit in front of a swing.

• Separate active and quiet activities from each other. For example, locate sandboxes away from

swings or use a guardrail or barrier to separate the sandbox from the movement of the swings.

• Do not install home playground equipment over concrete, asphalt, packed earth, grass, carpet, or any

other hard surface. A fall onto a hard surface can result in serious injury to the equipment user (see page 7).

• To prevent serious injury, warn children that they must not use the equipment until properly installed.

• Create a site free of obstacles that could cause injuries – such as low overhanging tree branches,

overhead wires, tree stumps and/or roots, large rocks, bricks, and concrete.

• Choose a level location for the equipment. This can reduce the likelihood of the play set tipping

over and loose-fi ll surfacing materials washing away during heavy rains.

PLAYGROUND AND SURFACE MATERIALS INSTRUCTIONS

• Use containment, such as digging out around the perimeter and/or lining the perimeter with landscape edging.

• Do not install loose fi ll surfacing over hard surfaces such as concrete or asphalt.

• Installations of rubber tiles or poured-in-place surfaces (other than loose-fi ll materials) generally

require a professional and are not “do-it yourself” projects.

• Use Playground Surfacing Materials (other than loose-fi ll material) which comply to the safety standard

ASTM F1292 Standard Specifi cation for Impact Attenuation of Surfacing Materials within the Use Zone of

Playground Equipment.

OPERATING INSTRUCTIONS

Observing the following instructions and warnings reduces the likelihood of serious or fatal injury:

• The maximum number of occupants that may safely use the entire play set including all

components is eight with a maximum weight of 900 pounds (408 kg).

• On-site adult supervision should be provided for children of all ages.

• Instruct children not to walk close to, in front of, behind, or between moving items.

• Do not move the equipment while it is in use.

• Instruct children not to twist swing chains or ropes or loop them over the top support bar since this

may reduce the strength of the chain or rope.

• Instruct children to avoid swinging empty seats.

• Teach children to sit in the center of the swings with their full weight on the seats.

• Instruct children not to use the equipment in a manner other than intended.

• Instruct children not to get off the equipment while it is in motion.

• To prevent entanglement and strangulation, dress children appropriately using well-fi tting shoes

and avoiding ponchos, scarves, jackets with neck drawstrings, helmets with straps, and other loosefi tting clothing that is potentially hazardous while using equipment.

• Instruct children not to play when the equipment is wet.

• Instruct children not to attach items to the playground equipment that are not specifi cally designed

for use with the equipment, such as, but not limited to, jump ropes, clothesline, pet leashes, cables

and chain as they may cause a strangulation hazard.

• Place the equipment no less than 6.6 ft. (2.0 m) from any structure or obstruction such as a fence,

garage, house, overhanging branches, laundry lines, or electrical wires.

• Impact surfacing needs to cover the entire recommended play area.

6

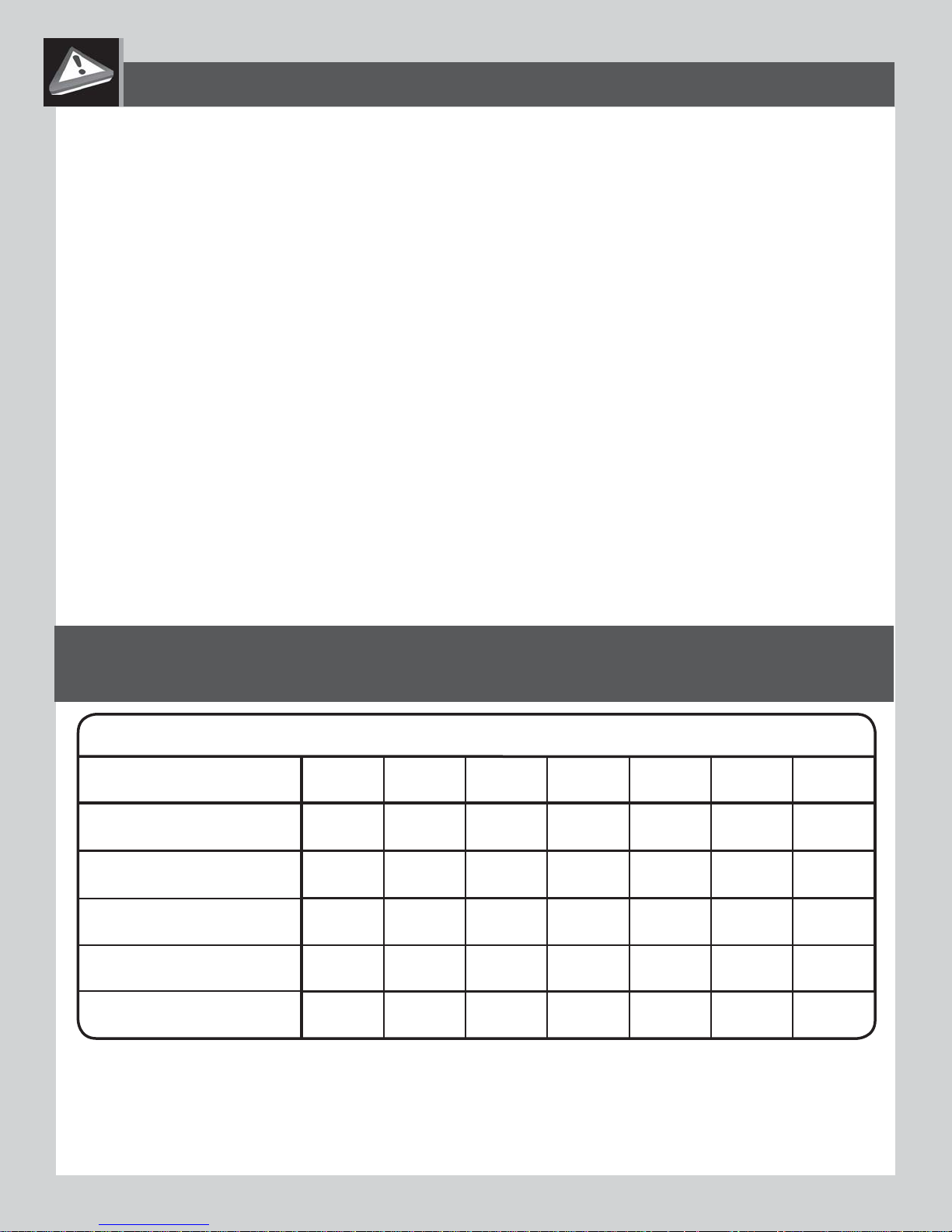

CONSUMER INFORMATION SHEET FOR PLAYGROUND SURFACING MATERIALS*

Select Protective Surfacing—One of the most important things you can

do to reduce the likelihood of serious head injuries is to install shockabsorbing protective surfacing under and around your play equipment.

The protective surfacing should be applied to a depth that is suitable for

the equipment height in accordance with ASTM Specifi cation F1292.

There are different types of surfacing to choose from; whichever product

you select, follow these guidelines:

Loose-Fill Materials—Maintain a minimum depth of 9 inches of loosefi ll

materials such as wood mulch/chips, engineered wood fi ber (EWF), or

shredded/recycled rubber mulch for equipment up to 8 feet high; and

9 inches of sand or pea gravel for equipment up to 5 feet high. NOTE:

An initial fi ll level of 12 inches will compress to about a 9-inch depth of

surfacing over time. The surfacing will also compact, displace, and settle,

and should be periodically refi lled to maintain at least a 9-inch depth.

Use a minimum of 6 inches of protective surfacing for play equipment

less than 4 feet in height. If maintained properly, this should be

adequate. (At depths less than 6 inches, the protective material is too

easily displaced or compacted.)

NOTE: Do not install home playground equipment over

concrete, asphalt, or any other hard surface. A fall onto a hard surface

can result in serious injury to the equipment user. Grass and dirt are not

considered protective surfacing because wear and environmental factors

can reduce their shock absorbing effectiveness. Carpeting and thin mats

are generally not adequate protective surfacing. Ground level equipment

– such as a sandbox, activity wall, playhouse or other equipment that has

no elevated play surface – does not need any protective surfacing.

Use containment, such as digging out around the perimeter and/or lining

the perimeter with landscape edging. Don’t forget to account for water

drainage.

Check and maintain the depth of the loose-fi ll surfacing material. To

maintain the right amount of loose-fi ll materials, mark the correct level

on play equipment support posts. That way you can easily see when to

replenish and/or redistribute the surfacing.

Do not install loose fi ll surfacing over hard surfaces such as concrete or

asphalt.

Poured-In-Place Surfaces or Pre-Manufactured

Rubber Tiles—You may be interested in using surfacing other than loosefi ll materials – like rubber tiles or poured-in-place surfaces.

Installations of these surfaces generally require a professional and are not

“do-it-yourself” projects.

Review surface specifi cations before purchasing this type of surfacing.

Ask the installer/manufacturer for a report showing that the product has

been tested to the following safety standard: ASTM F1292 Standard

Specifi cation for Impact Attenuation of Surfacing Materials within the

Use Zone of Playground Equipment. This report should show the specifi c

height for which the surface is intended to protect against serious head

injury. This height should be equal to or greater than the fall height –

vertical distance between a designated play surface (elevated surface for

standing, sitting, or climbing) and the protective surfacing below – of your

play equipment.

Check the protective surfacing frequently for wear.

Placements—Proper placement and maintenance of protective surfacing

is essential. Be sure to:

Extend surfacing at least 6.6 feet (2 m) from the equipment in all

directions.

For to-fro swings, extend protective surfacing in front of and behind the

swing to a distance equal to twice the height of the top bar from which

the swing is suspended.

For tire swings, extend surfacing in a circle whose radius is equal to

the height of the suspending chain or rope, plus 6.6 feet (2 m) in all

directions.

**The maximum fall height for this product is 108 in (274 cm).

We recommend using 9 in (23 cm) of Double Shredded Bark Mulch.**

TABLE 1 — Depth of Surfacing Material Required Based on Fall Heights

Material / Fall Height

Double Shredded Bark

Mulch

Wood Chips

Fine Sand

Fine Gravel

Shredded Tires***

*This information has been extracted from the CPSC publications “Playground Surfacing--Technical Information Guide” and

“Handbook for Public Playground Safety.”

***This data is from tests conducted by independent testing laboratories on a 6-inch depth of uncompressed shredded tire

samples produced by four manufacturers. It is recommended that persons seeking to install shredded tires as a protective surface

request test data from the supplier showing the critical height of the material when it was tested in accordance with ASTM F1292.

5 ft 6 ft 7 ft 9 ft 10 ft 11 ft 12 ft

(152 cm)

(183 cm) (213 cm)

(274 cm)

-- 6 in -- -- 9 in 12 in --

(15 cm)

-- 6 in 9 in -- -- -- 12 in

(15 cm) (23 cm) (30 cm)

6 in -- 9 in 12 in -- -- --

(23 cm)(15 cm)

(30 cm)

-- 6 in 9 in -- 12 in -- --

(15 cm)

(23 cm)

-- -- -- -- 6 in -- --

(305 cm) (335 cm) (366 cm)

(23 cm) (30 cm)

(30 cm)

(15 cm)

7

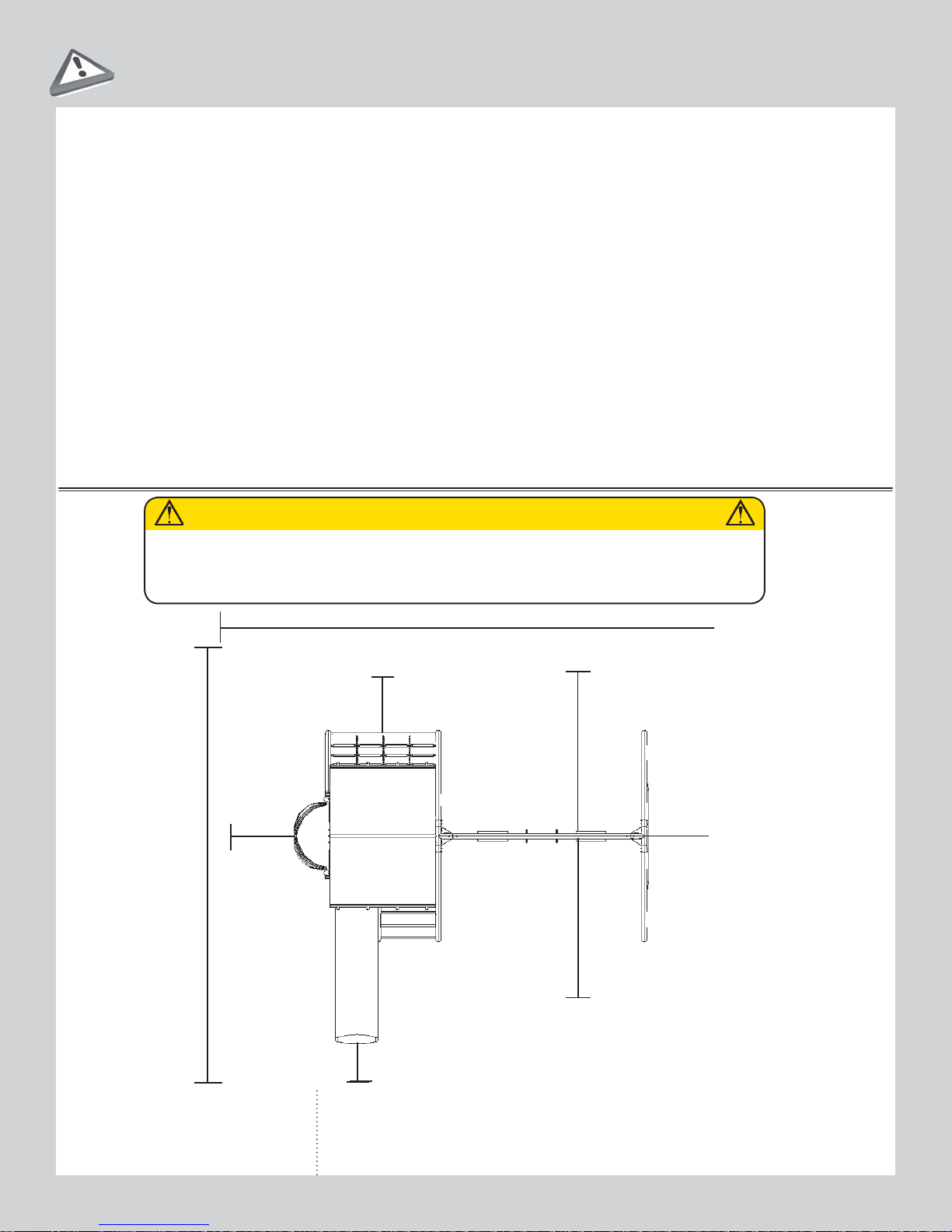

SAFE PLAY AREA

SAFETY ZONE —

Place the equipment no less than 6.6 ft. (2.0 m) from any structure or obstruction

such as a fence, garage, house, overhanging branches, laundry lines, or electrical wires. Make sure

the clearance in front of and behind the swings is at least twice the height of the swing bar. The impact

surfacing needs to cover the entire recommended play area. Refer to the example below.

CAUTION

• Slide can get hot in direct sunlight. It is not recommended that a slide be installed facing south.

6.6 feet

(2,0 m)

29 feet 8 inches (9,04 m)

27 feet 9 inches (8,46 m)

6.6 feet

(2,0 m)

14 feet (4,27 m)

6.6 feet

(2,0 m)

14 feet (4,27 m)

Playset dimensions:

13.11' (4,24 m) x 15.9' (4,8 m)

Recommended play area:

29.8' (9,04 m) x 27.9' (8,46 m)

(2,0 m)

6.6 feet

12

1

A-FRAM

E ASSEMBLY

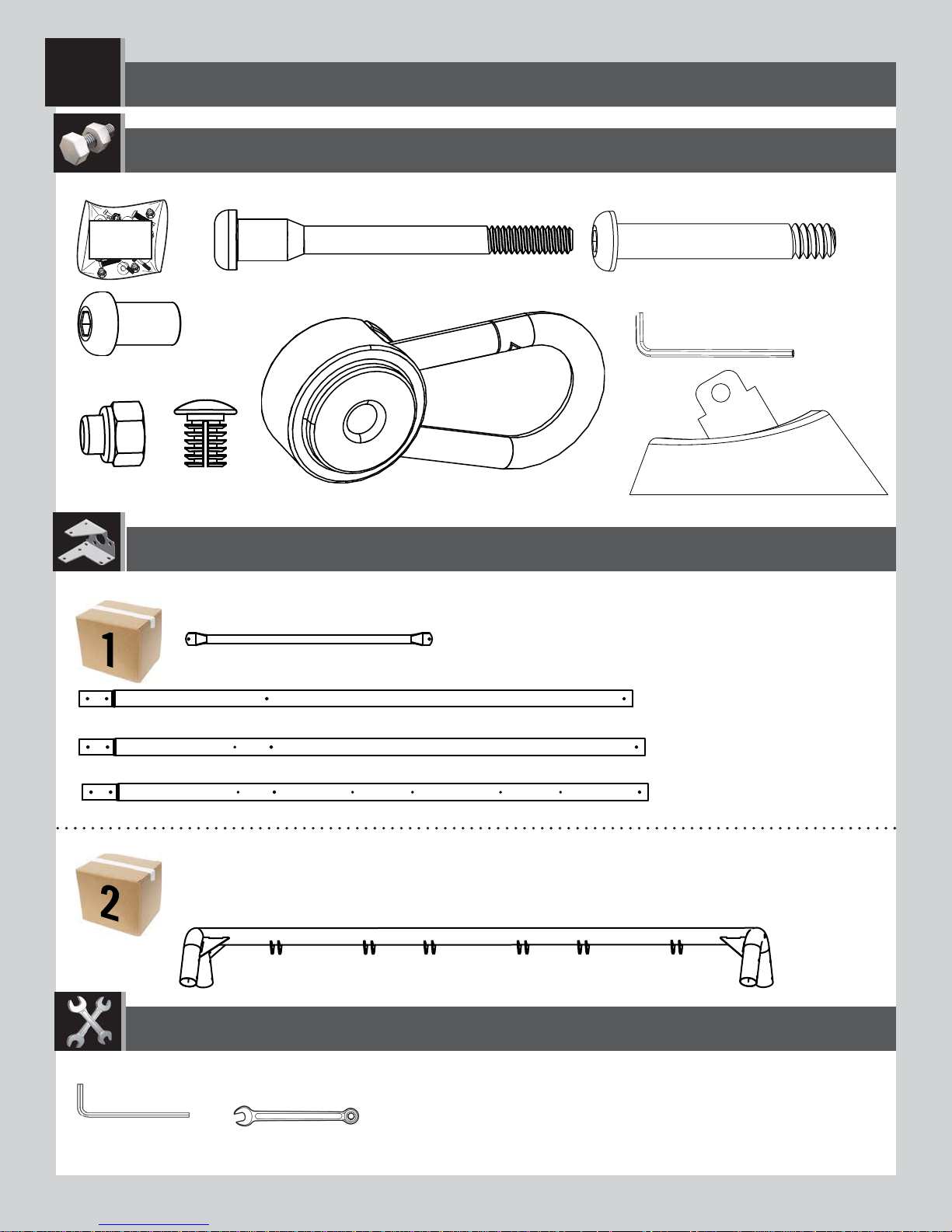

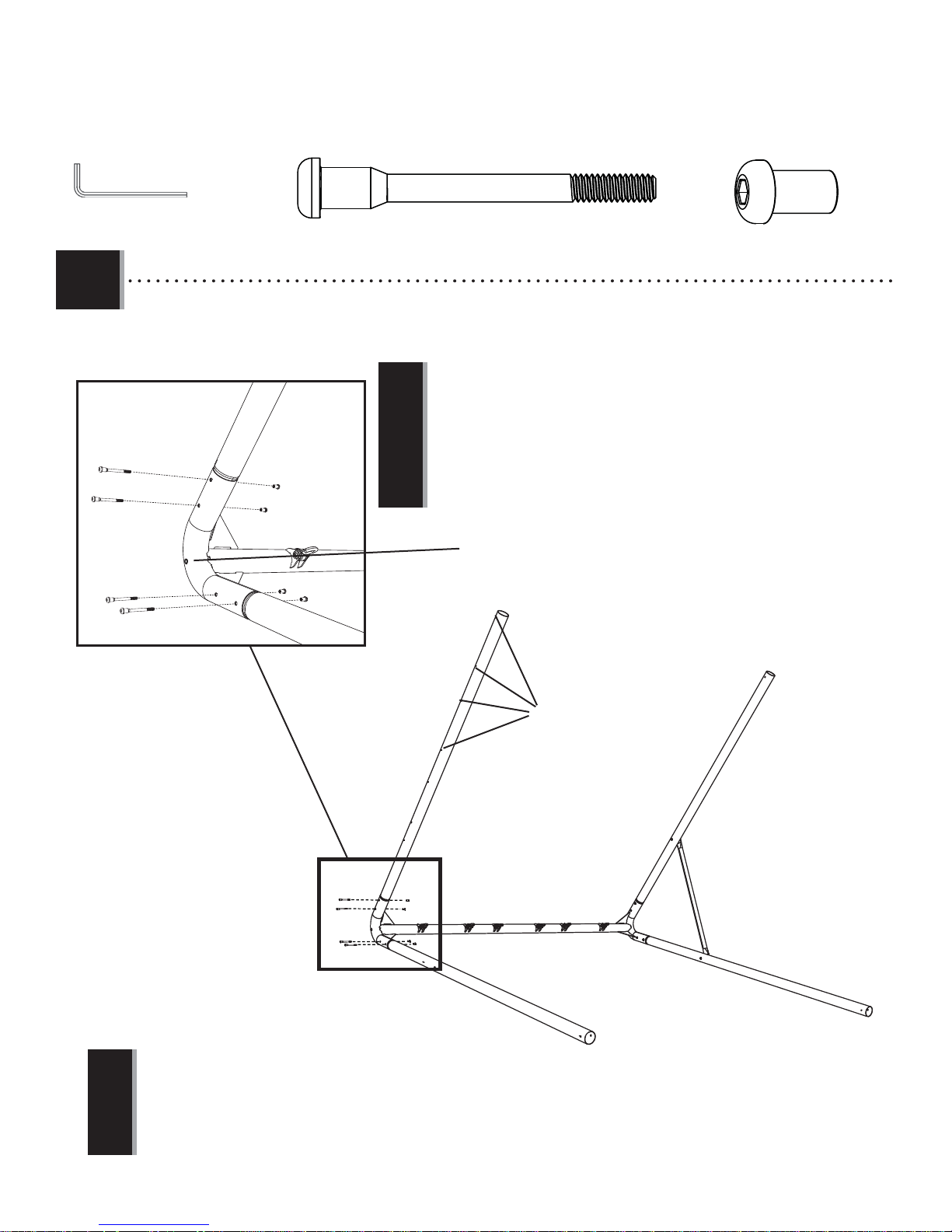

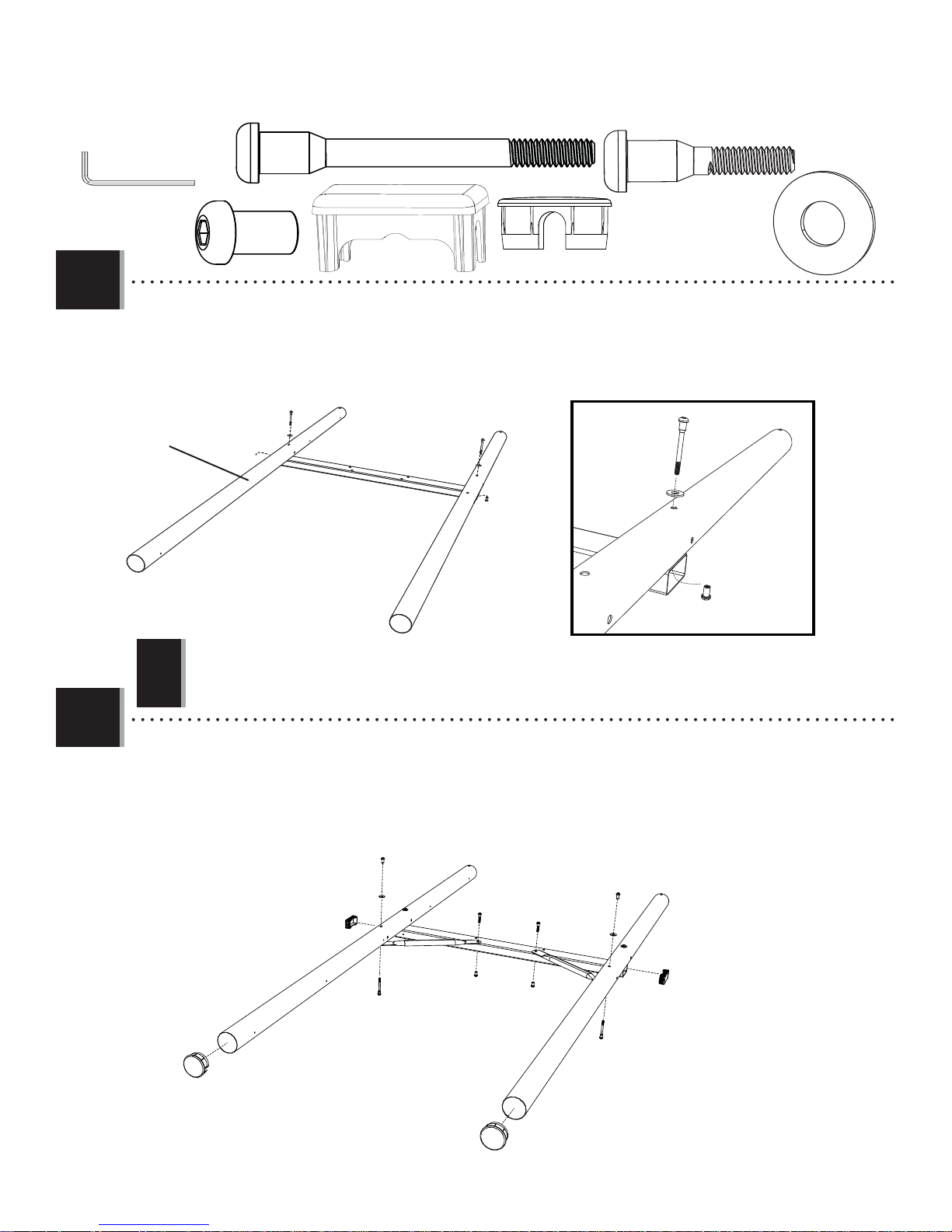

HARDWARE REQUIRED

Hardware Bag / Sac d’accessoires / Bolsa de herraje

CAM

BTS (x10)

AAN (x6)

ARO (x6)

PARTS REQUIRED

CONTENTS OF BOX 1

CBI (x1)

CBG (x2)

DSA (x10)

DZR (x6)

EEO (x2)

DZQ (x6)

BFD (x3)

CBE (x1)

CBF (x1)

CONTENTS OF BOX 2

TOOLS REQUIRED

3/16 in/po (≈5 mm)

(2)

1/2 in/po (≈13 mm)

(1)

CB0 (x1)

13

X SECTION 1 (CONTINUED)

TOOLS AND HARDWARE REQUIRED

3/16 in/po (≈5 mm)

(2)

1/2 in/po (≈13 mm)

(1)

DZR (x6)

AAN (x6)

DZQ (x6)

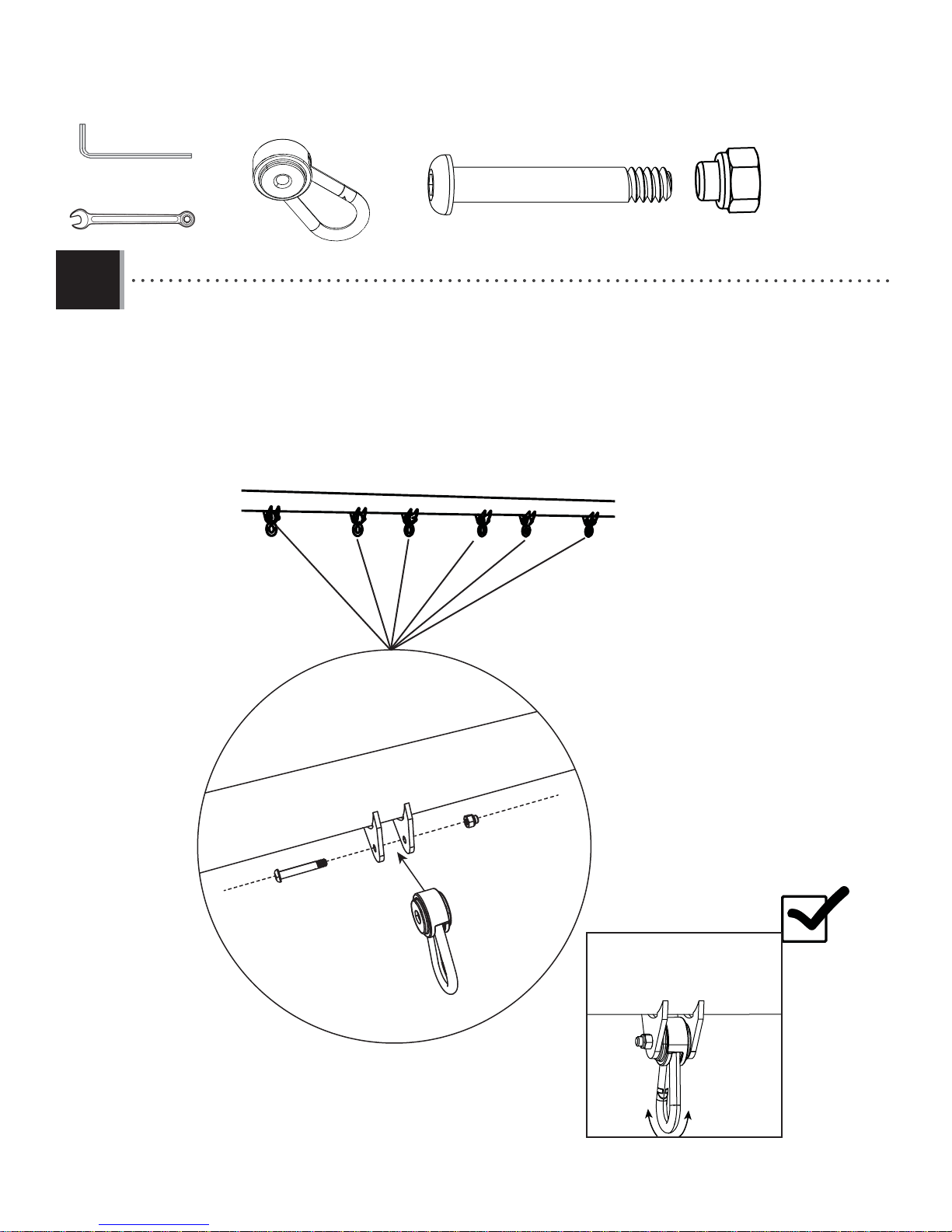

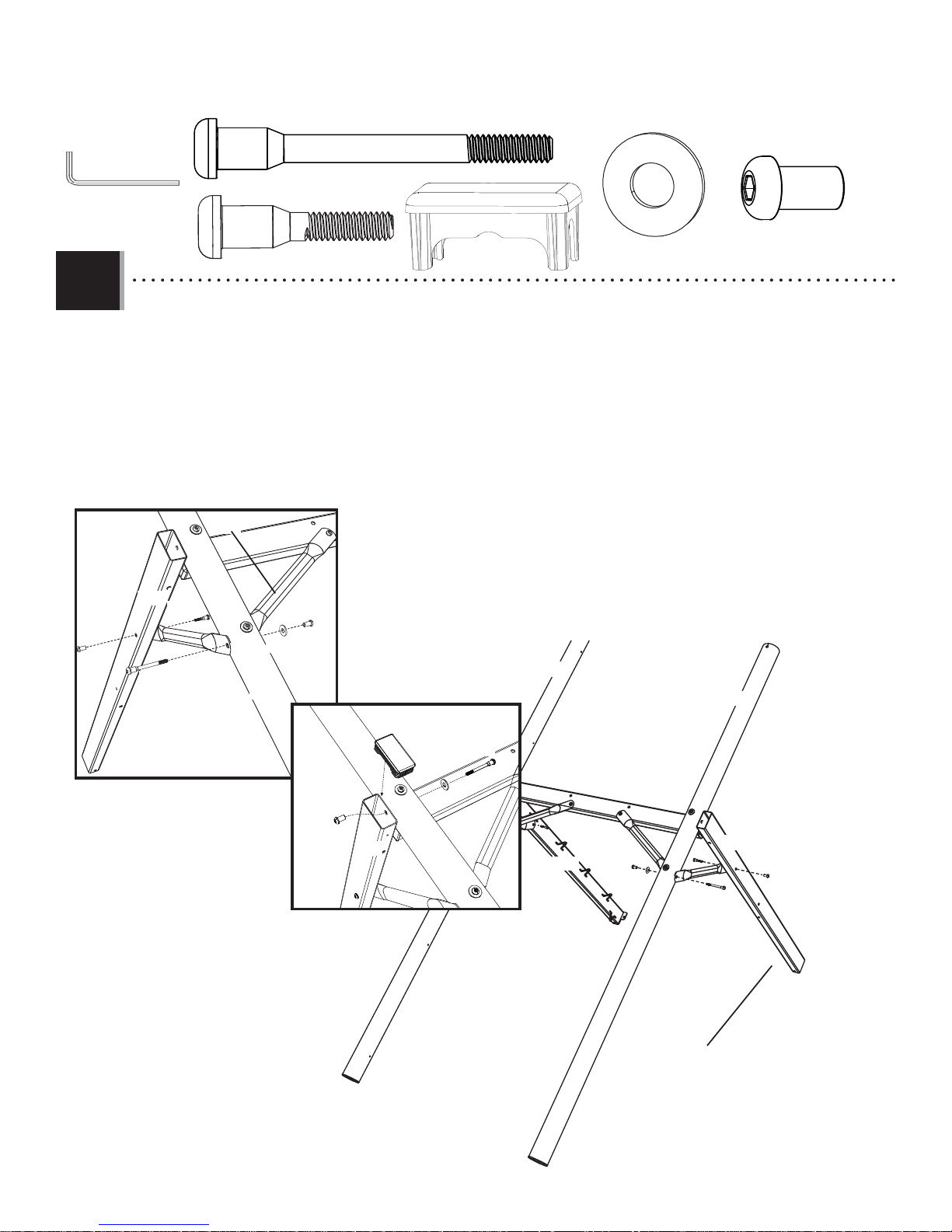

1.1

• Attach the Pendulums (DZQ) to the Swing Bar (CB0) using the hardware indicated. Do this for each set of brackets

on the Swing Bar.

CBO

DZR

AAN

DZQ

14

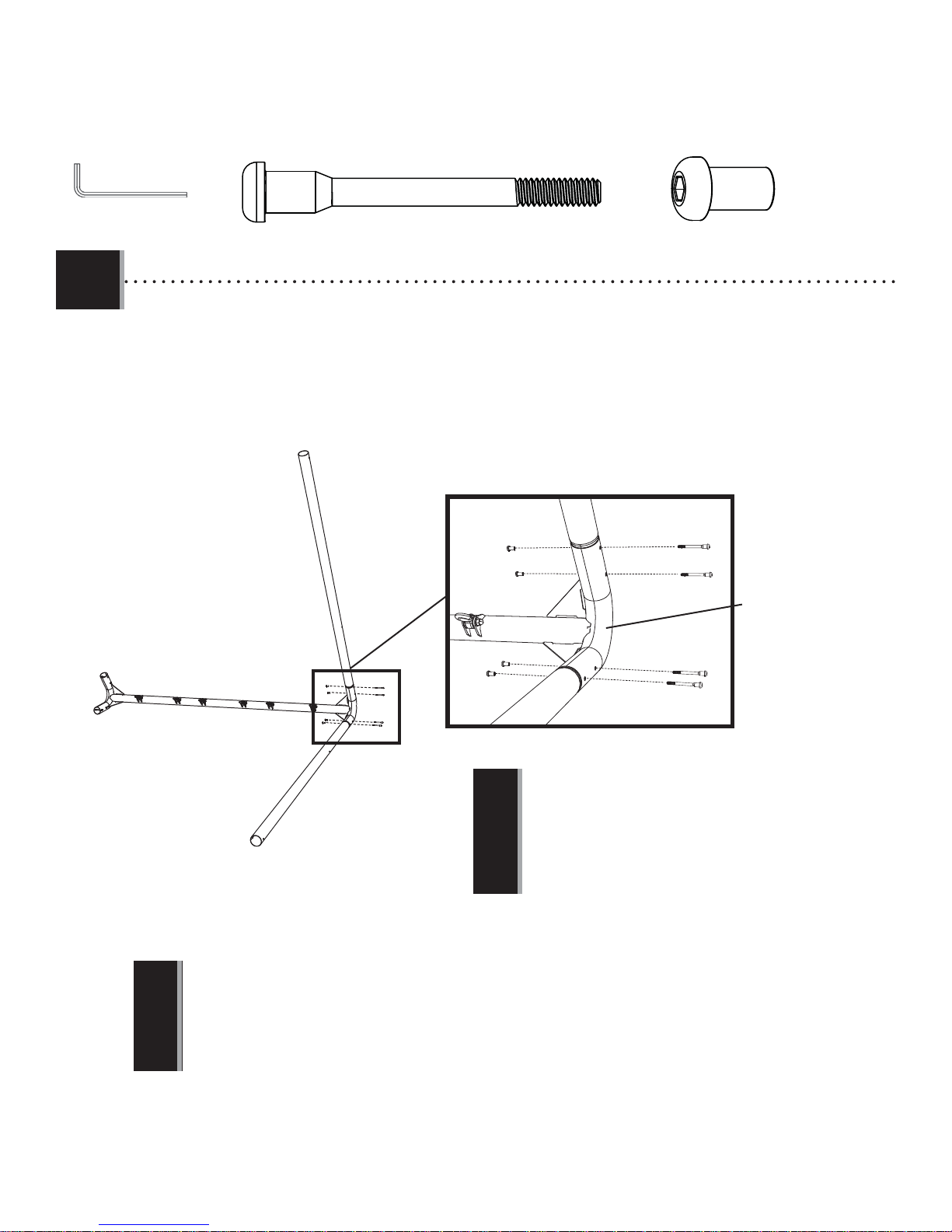

X SECTION 1 (CONTINUED)

TOOLS AND HARDWARE REQUIRED

3/16 in/po (≈5 mm)

6

1.2

(2)

• Insert the two A-Frame Poles (CBG) into the end of the Swing Bar (CBO) that does not have a nut insert in the location

shown, and secure the Poles with the hardware indicated.

CBG

DSA (x4)

BTS

BTS (x4)

DSA

No Nut Insert Here

CBO

• If your A-Frame pole has a dimpled hole, make sure the dimpled

CBG

!

• A band of red tape can be found at the end of the Swing Bar with a nut insert. Make sure this is NOT a nut insert on this end of

the Swing Bar.

!

hole faces away from the Swing Bar.

15

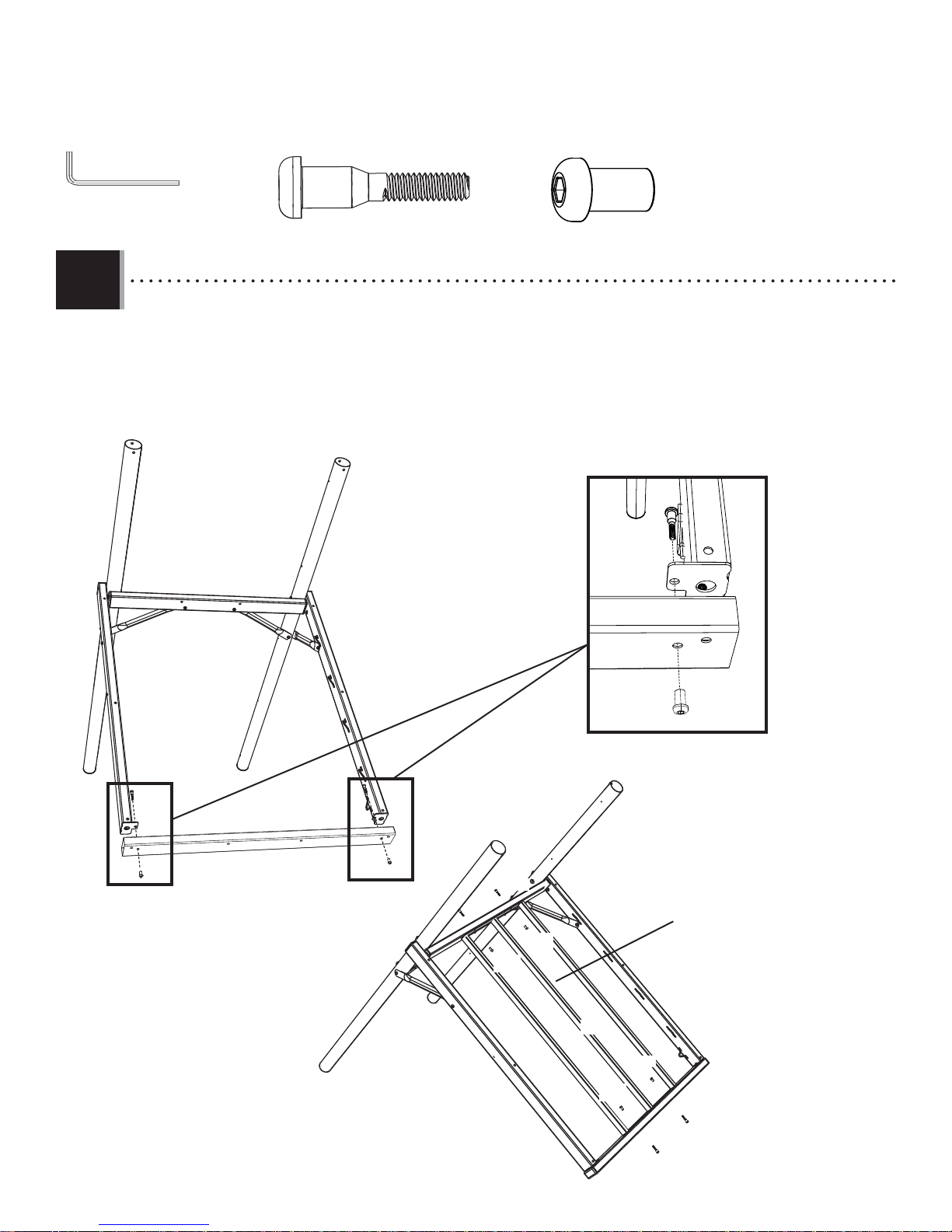

X SECTION 1 (CONTINUED)

TOOLS AND HARDWARE REQUIRED

3/16 in/po (≈5 mm)

1.3

(2)

• Attach the Turnbar (CBI) to the A-Frame Poles with the hardware indicated.

DSA (x2)

BTS

BTS (x2)

DSA

BTS

CBI

DSA

16

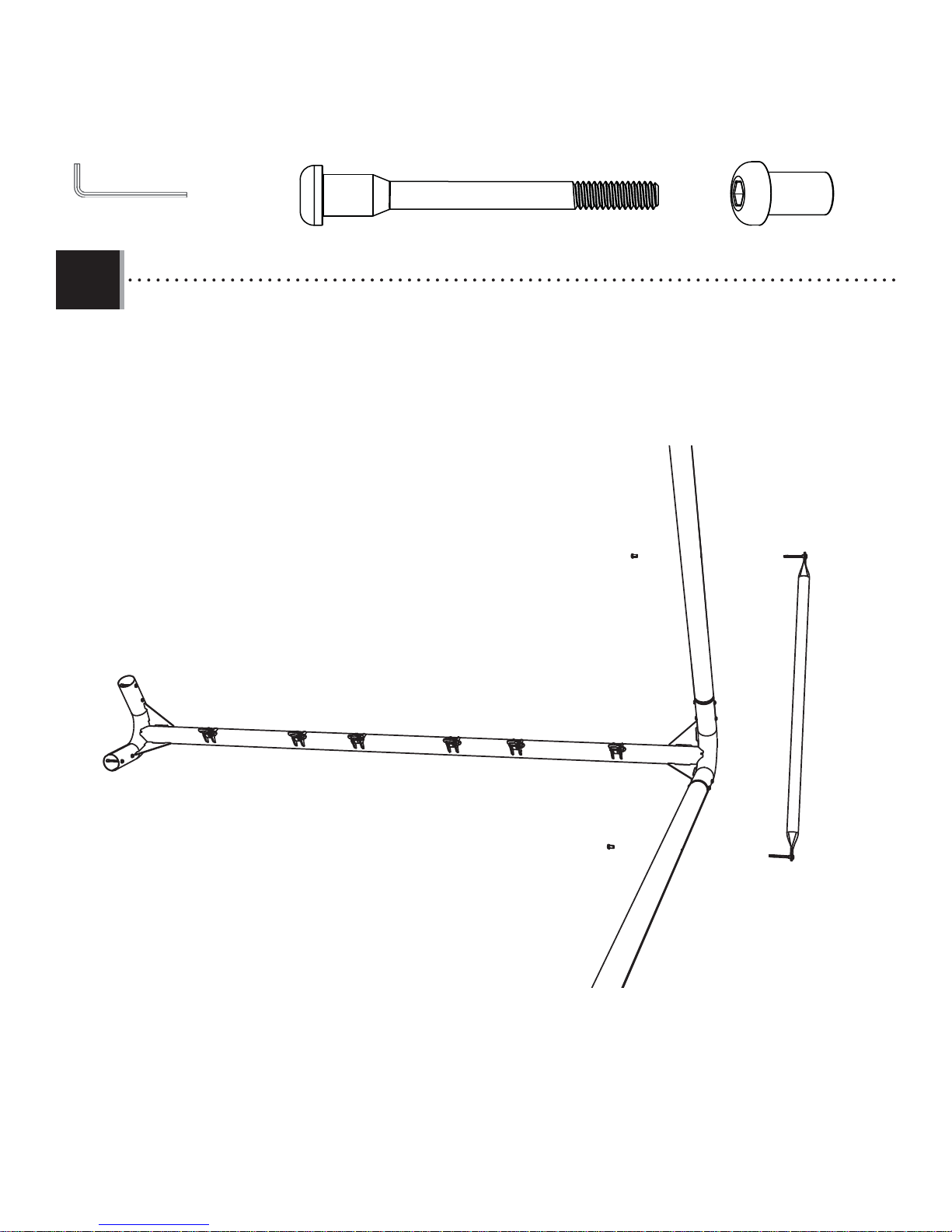

X SECTION 1 (CONTINUED)

TOOLS AND HARDWARE REQUIRED

3/16 in/po (≈5 mm)

1.4

DSA

DSA

DSA

(2)

• Attach the Ladder-side Pole (CBF) and the Net-side Pole (CBE) to the Swing Bar (CBO) in the location indicated.

DSA (x4)

• A band of red tape can be found at the end of the Swing Bar with a nut insert.

Make sure there is a nut insert on this side.

!

DSA

BTS

BTS

Insert Nut Here

BTS

BTS

BTS (x4)

Four holes face out

CBF

CBO

CBE

• Be sure the four holes that run the length of the Ladder-side Pole are facing away from the A-Frame. These holes will be used to

assemble the Ladder later in the assembly.

!

17

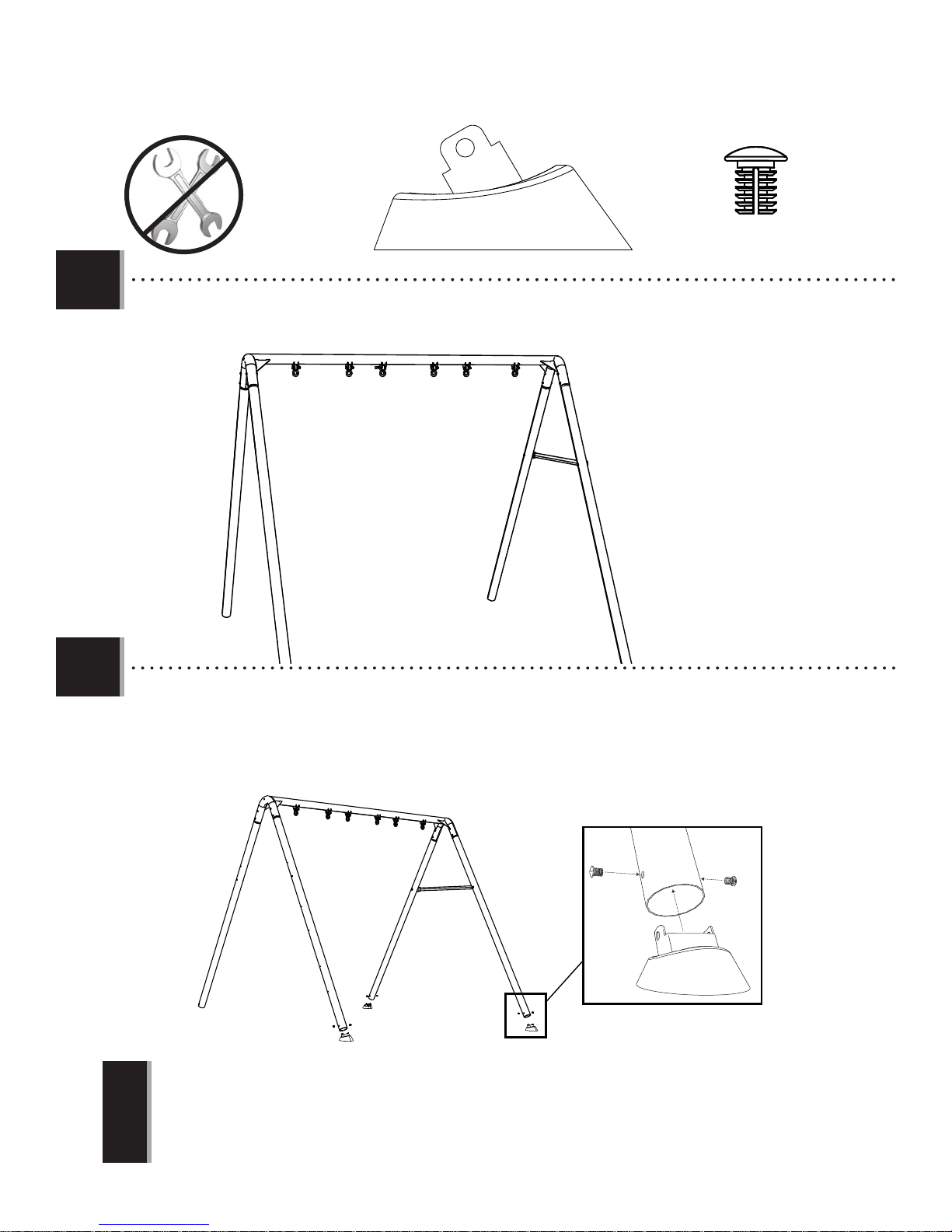

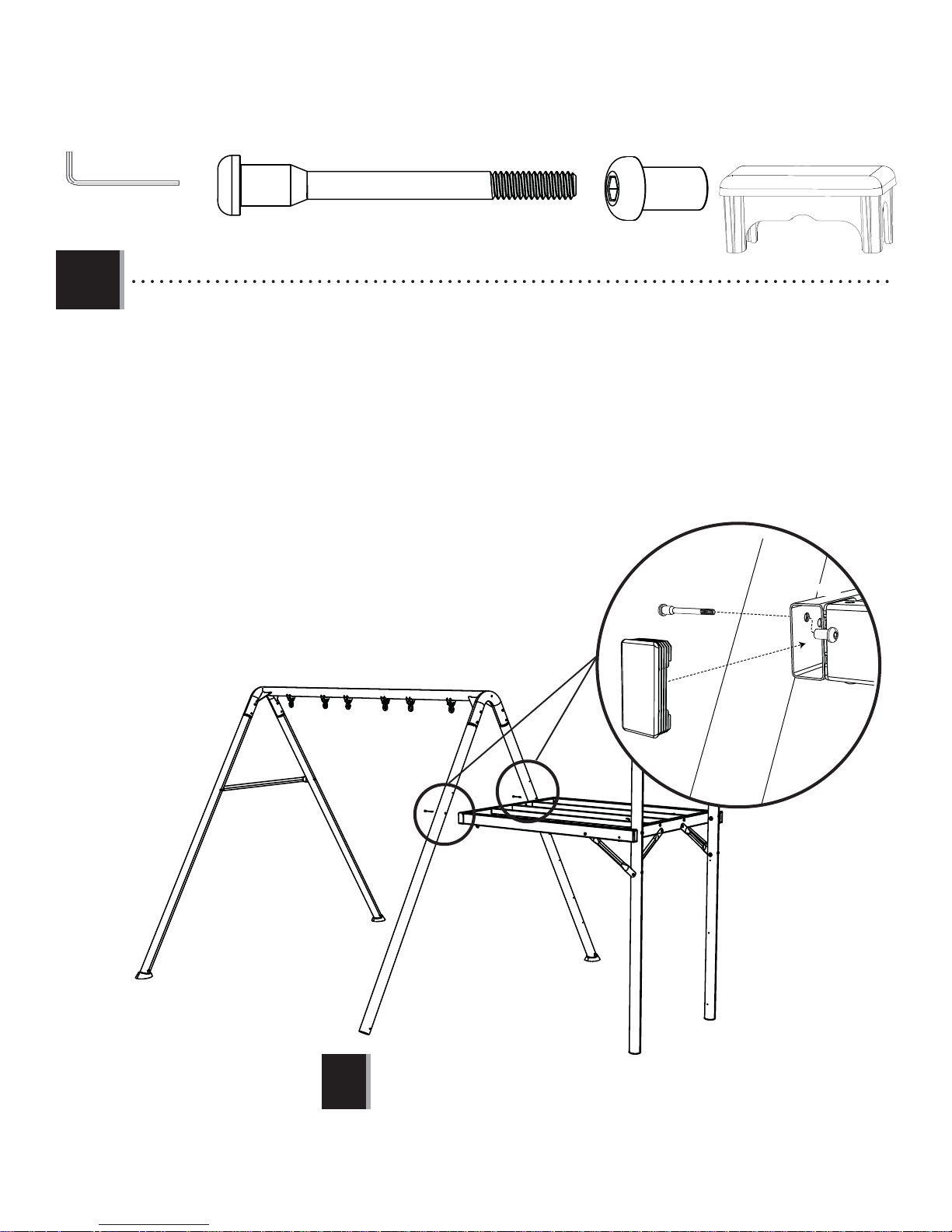

X SECTION 1 (CONTINUED)

TOOLS AND HARDWARE REQUIRED

1.5

• Using at least two people, slowly rotate the A-Frame assembly upright.

6

ARO (x6)

BFD (x3)

1.6

• Have one person hold the A-Frame assembly steady as another lifts each leg. Attach the A-Frame Foot Caps (BFD)

and secure them with the Cap Plugs (ARO).

ARO

BFD

• Only three of the four poles will receive Foot Caps (BFD) during this step. Do not install a Foot Cap on the Net-side Pole (CBE) until

instructed later in the assembly.

ARO

!

18

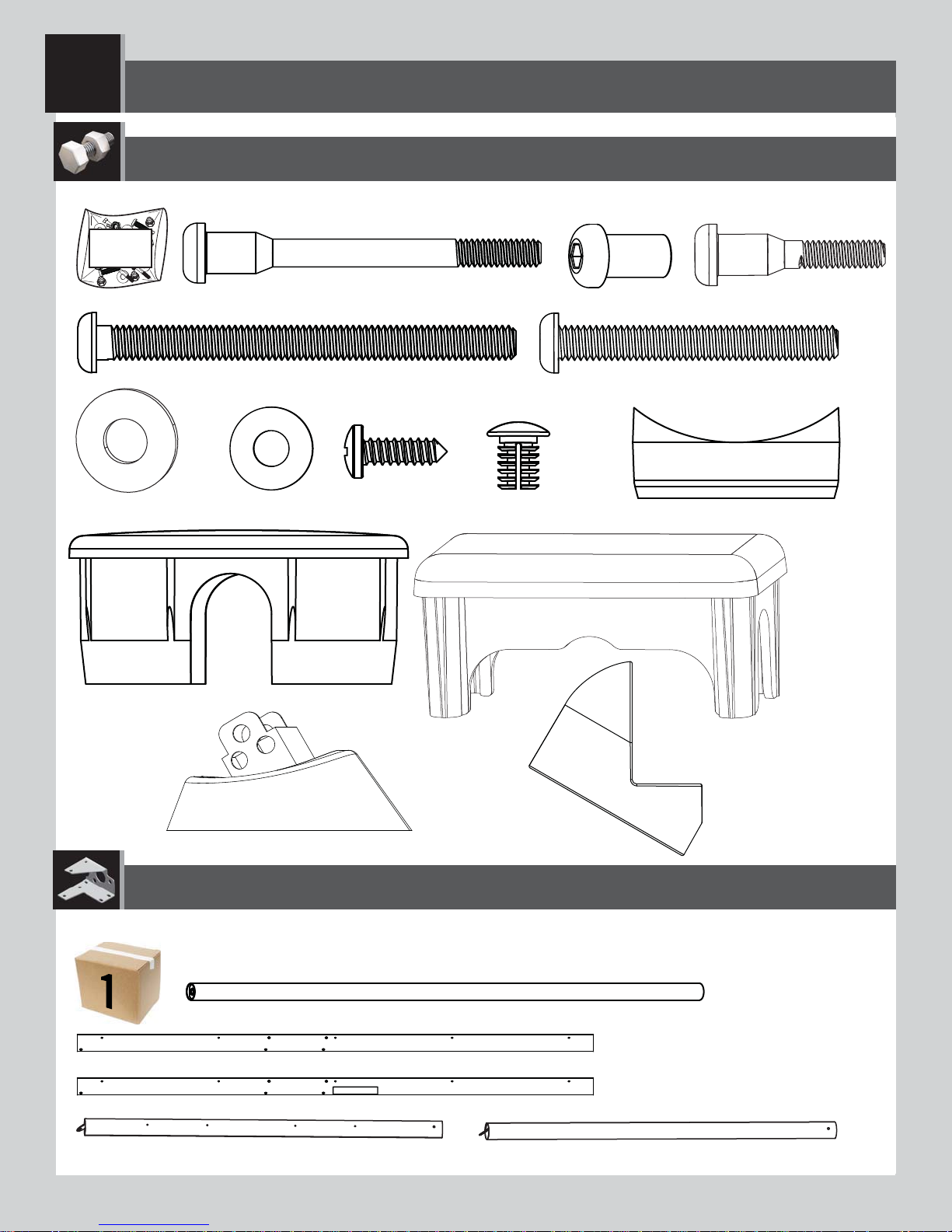

2

DECK SUPPORT ASSEMBLY

H

Hardware Bag

CAI

ARDWARE REQUIRED

DSA (x10)

ATV (x2)

AAF (x8) ARL (x3)

ASV (x2)

ARV (x8)

ARO (x2)

EII (x6)

ARU (x1)

BTS (x20)

ARY (x2)

DXY (x10)

BFD (x3)

PARTS REQUIRED

CONTENTS OF BOX 1

CBN (x1)

CBJ (x1)

CBK (x1)

CAZ (x1)

CAC (x2)

CAY (x1)

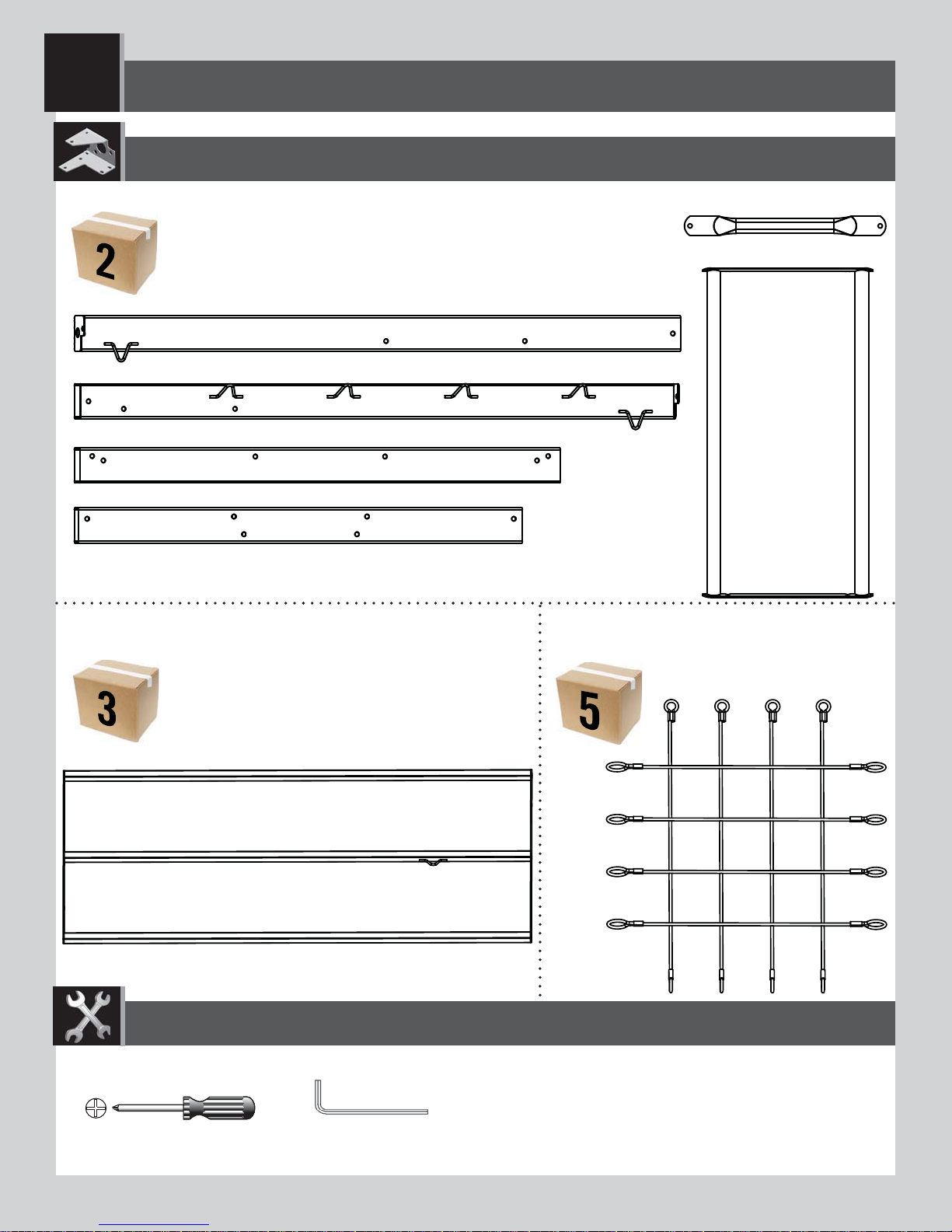

19

2

DECK SUPPORT ASSEMBLY

PARTS REQUIRED

CONTENTS OF BOX 2

CBC (x1)

CBB (x1)

CBD (x1)

CBP (x4)

CBQ (x2)

CBA (x1)

CONTENTS OF BOX 3

CBL (x1)

CONTENTS OF BOX 5

CBM (x1)

TOOLS REQUIRED

(1)

3/16 in/po (≈5 mm)

(2)

20

X SECTION 2 (CONTINUED)

TOOLS AND HARDWARE REQUIRED

3/16 in/po (≈5 mm)

(2)

DSA (x4)

DXY (x2)

AAF (x4)

2.1

Warning Sticker

• Attach the Wall-side Deck Support (CBA) to the Left Vertical Pole (CBK) and Right Vertical Pole (CBJ) and secure with the

BTS (x6)

hardware indicated.

CBK

• Make sure the fi ve small holes that run the length of each Vertical Pole are facing each other before completing this step.

EII (x2)

CBA

ASV (x2)

DSA

AAF

CBJ

BTS

!

!

2.2

• Attach two Cross Braces (CBP) to the Left Vertical Pole and Right Vertical Pole in the position indicated and secure

with the hardware indicated.

BTS

BTS

AAF

EII

DSA

ASV

EII

AAF

DSA

CBP

DXY

BTS

DXY

CBP

BTS

ASV

!

21

X SECTION 2 (CONTINUED)

TOOLS AND HARDWARE REQUIRED

6

3/16 in/po (≈5 mm)

(2)

2.3

BTS

DSA (x4)

BTS (x6)

DXY (x2)

• Attach the Deck Support Tube, Net-side (CBB) to the Left Vertical Tube (CBK) using the hardware indicated. Make sure a

Cross Brace (CBP) is secured between the Support Tube and the Vertical Pole. Repeat this step to attach the Deck

Support Tube, Ladder-side (CBC) to the Right Vertical Tube (CBJ) as pictured.

CBP

CBB

DXY

BTS

AAF

DSA

CBK

EII (x2)

CBK

AAF (x4)

CBJ

BTS

CBB

EII

DSA

AAF

CBC

CBB

Hook on Deck Support (CBC) points downward

22

X SECTION 2 (CONTINUED)

TOOLS AND HARDWARE REQUIRED

3/16 in/po (≈5 mm)

(2)

DXY (x6)

6

BTS (x6)

2.4

• Attach the Deck Support Tube, Swing-side (CBD) to the Deck Support Assembly using the hardware indicated. Install

the Inside Deck Support (CBL) in the position indicated and secure with the hardware indicated.

DXY

BTS

CBD

DXY

23

DXY

BTS

Hook on Inside Deck Support points downward

BTS

CBL

BTS

BTS

DXY

DXY

X SECTION 2 (CONTINUED)

TOOLS AND HARDWARE REQUIRED

3/16 in/po (≈5 mm)

2.5

(2)

DSA (x2)

• Attach the Deck Support Assembly to the A-Frame Assembly using the hardware indicated. Insert a Rectangular

Plug (EII) in each end of the Deck Support Tube, Swing-side (CBD) once hardware is secure. Repeat this on the opposite

side of the assembly to secure the Deck Support Assembly to both Poles.

BTS (x2)

DSA

EII (x2)

CBD

BTS

EII

• This step requires two people.

!

24

Loading...

Loading...