Lifetime 90180 Owner's Manual

MODEL N° 90180

COPY

OWNER’S MANUAL

For Customer Service in mainland Europe:

E-mail: cs@lifetimeproducts.eu

Keep this Product ID Number and use when contacting Customer Service:

REGISTER YOUR PRODUCT ONLINE AT WWW.LIFETIME.COM

COPY

At Lifetime®, we are committed to providing innovative and quality products. While registering, you will have the opportunity to give us your feedback. Your

input is valuable to us.

• You can also opt in to receive new product notifi cations or promotions.

• In the unlikely event of a product recall or safety modifi cation, your registration provides the information we need to notify you

directly.

• Registration is fast, easy, and completely voluntary.

LIFETIME’S PROMISE TO YOU:

Maintaining your privacy is our long-standing policy at Lifetime

your personal data to other third parties, or allow them to use your personal data for their own purposes.

We invite you to read our privacy policy at www.lifetime.com

REGISTER today!

®

. And you can rest assured that Lifetime® will not sell or provide

Save this instruction in the event that the manufacturer has to be contacted for replacement parts.

Questions or Missing Parts?

TO SAVE TIME WHEN CONTACTING CUSTOMER SERVICE, PLEASE HAVE THE PRODUCT ID AVAILABLE BEFORE YOU CALL; IT’S LOCATED AT THE

FOR CUSTOMERS OUTSIDE THE U.S. OR CANADA, PLEASE CONTACT THE STORE FOR ASSISTANCE.

ID:

BOTTOM-LEFT CORNER OF THE FRONT PAGE OF THIS MANUAL.

**U.S. and Canada customers ONLY**

DO NOT CONTACT THE STORE!

CALL OUR CUSTOMER SERVICE DEPARTMENT at 1 (800) 225-3865

HOURS: 7:00 a.m. to 5:00 p.m. Monday through Friday (Mountain Standard Time)

**Call, or visit our Web site for Saturday hours**

SAFETY INSTRUCTIONS

FAILURE TO FOLLOW THESE WARNINGS MAY RESULT IN SERIOUS INJURY OR PROPERTY

DAMAGE AND WILL VOID WARRANTY.

To ensure safety, do not attempt to assemble this product without reading and following all instructions carefully. Check the entire

box and inside all packing materials for parts and/or additional instruction material. Before beginning assembly, identify and inventory

all parts and hardware using the parts and hardware lists and identifi ers in this document. Proper and complete assembly, use and

supervision are essential for proper orientation and to reduce the risk of accident or injury. A high probability of serious injury exists

if this product is not installed, maintained, and/or operated properly. Failure to comply with any of the warnings in this instruction

manual may result in serious personal injuries such as cuts, broken bones, nerve damage, paralysis, brain injury, or death. Failure to

comply may also result in property damage. Please heed all warnings and cautions.

• If using a ladder during assembly, use extreme caution.

• At least six capable adults are recommended for this operation.

• Assemble the pole properly. Failure to do so could cause serious injury or property damage.

Most injuries are caused by misuse and/or not following instructions. Use caution when using this system.

INSTRUCTION #1183320 B 2/6/2018

2

SAFE HANDLING OF THE GLASS BACKBOARD

COPY

BEFORE & DURING ASSEMBLY

1. Thoroughly inspect the Backboard before beginning assembly. Do not use the Backboard if there are any chips, cracks,

or other defects in the board. Call our Customer Service Department if any problems are found.

2. Use extreme caution when handling or working around the Backboard.

3. Keep tools, hardware, and other sharp and heavy objects away from the Backboard.

4. Never rest the Backboard directly on a hard surface, such as concrete or pavement. Always place cardboard or other

cushioning material between the Backboard and the ground or other hard surfaces.

5. Always lay the Backboard fl at. Never place it in a position where it might tip over and break.

6. Glass is very heavy. Always use at least two adults when picking up or moving the Backboard.

GENERAL HANDLING & CARE

1. Inspect the Backboard before each use. Do not use the Backboard if there are any chips, cracks, or other defects in the

board. If any signs of damage are found, follow the instructions for “Handling Broken Glass” below.

3. Use extreme caution when handling or working around the Backboard.

4. The Backboard was designed for use with a Basketball. Do not use other types of balls or other objects with the system.

Do not use this system for any purpose other than its designed purpose.

HANDLING BROKEN GLASS

At the fi rst sign of breakage:

1. Keep everyone, especially children, away from the immediate area of the Backboard.

2. Put on eye protection, and wear thick utility gloves and long sleeves. Small pieces of tempered glass may pop out of the

Backboard.

3. Lower the Backboard to its lowest height, and completely cover the Backboard with a tarp.

4. Do not remove the Backboard from the system without fi rst lowering the system to its lowest setting. Carefully read and

follow the “Removing Backboard from System” instructions below.

REMOVING BACKBOARD FROM SYSTEM

See Section 7 of this manual for instructions on how to safely remove the backboard from the system.

*Six adults required to

complete assembly*

Only adults should set up the product. Do not allow children

in the setup area until assembly is complete.

3

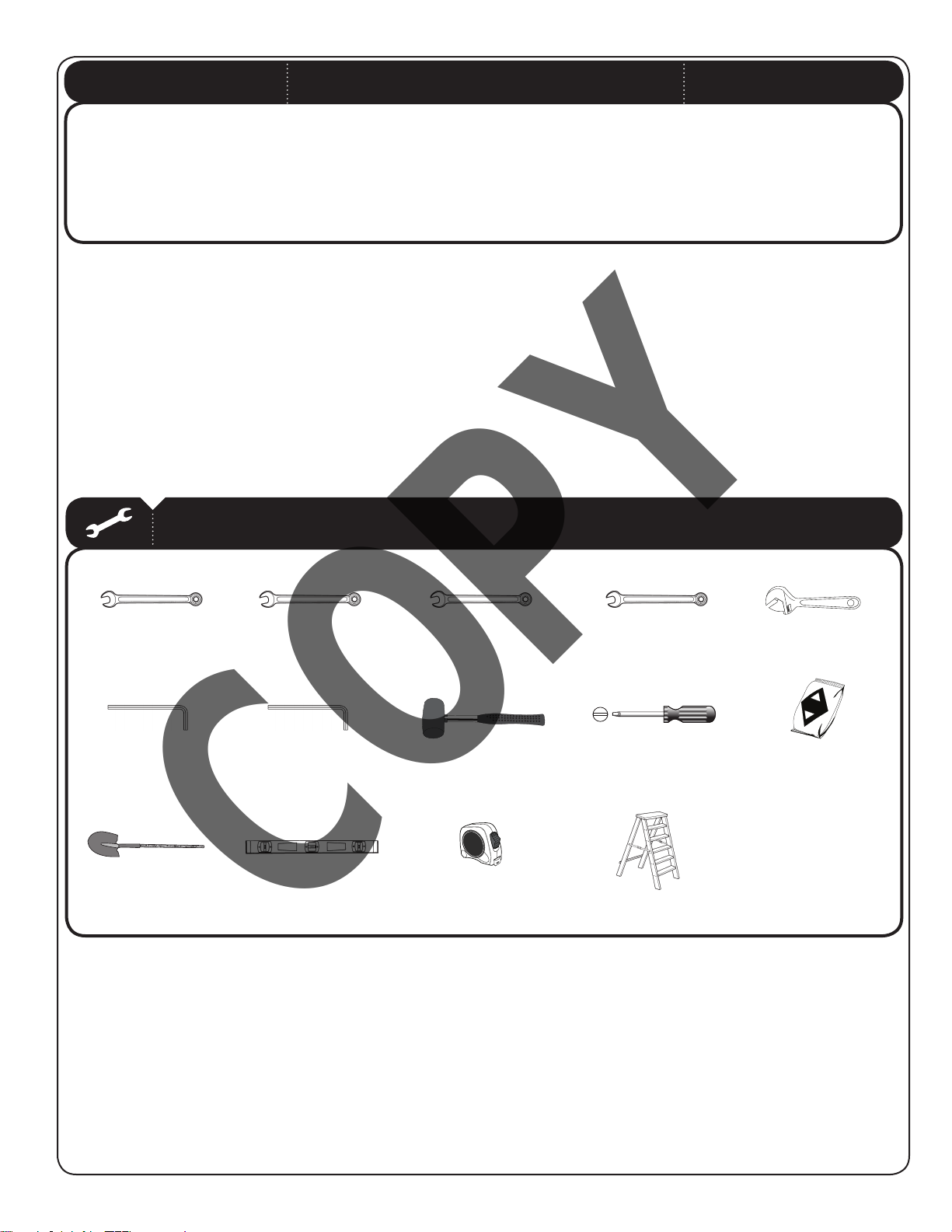

BEFORE BEGINNING ASSEMBLY

COPY

A. Keep the hardware bags and their contents separate. If any parts are missing, call our Customer

Service Department.

B. Test fi t all Bolts by inserting them into their respective holes. If necessary, carefully scrape away any

excess powder coating buildup from inside the holes. Do not scrape away all of the powder coating.

Bare metal may rust. You may need to pound some Bolts into place with a hammer or mallet.

*This system comes in 3 boxes.

Do not attempt assembly until all 3 boxes have arrived.*

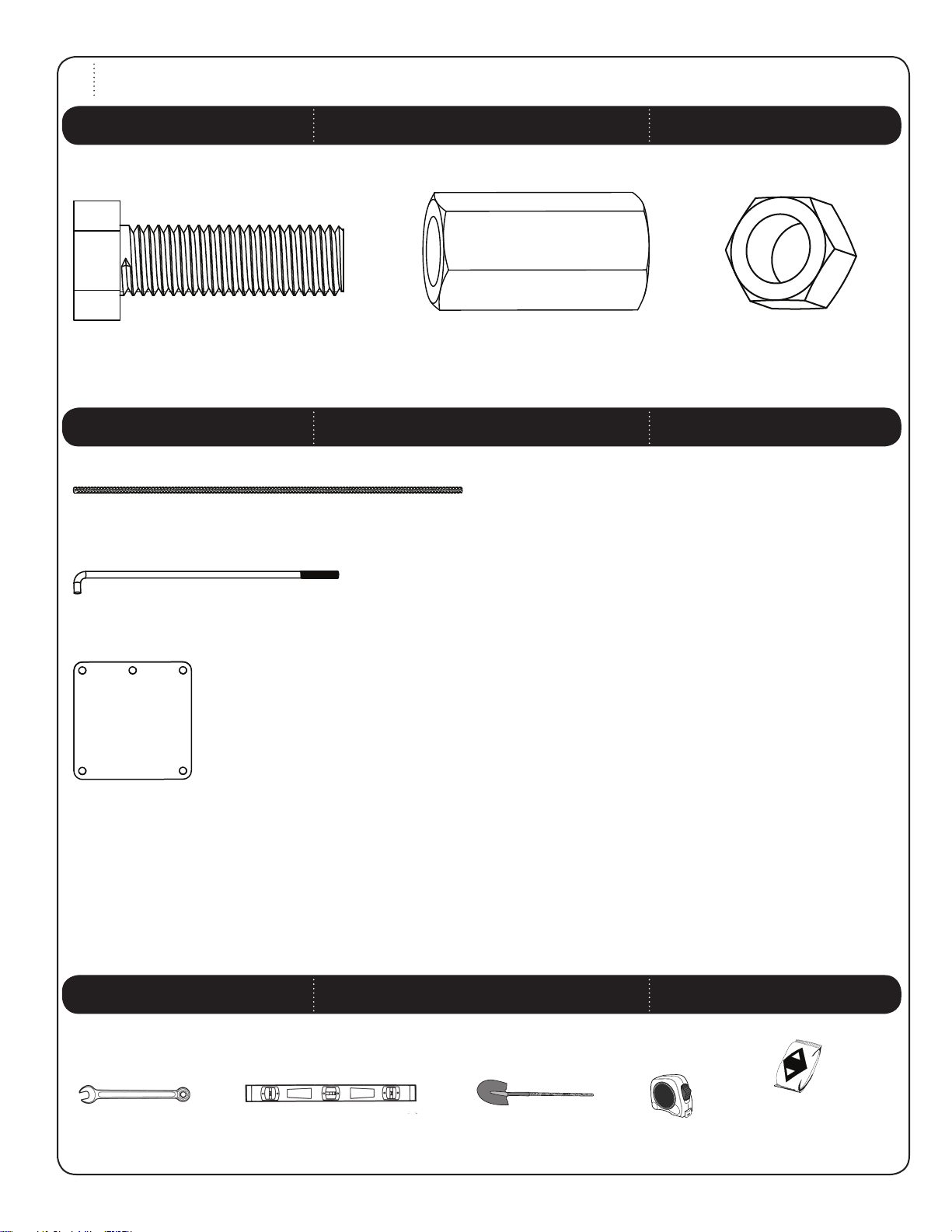

TOOLS AND PARTS REQUIRED FOR THIS ASSEMBLY

1/2”

(2)

1/4” Allen Wrench

(1)

Shovel Carpenter’s Level

(1) (1)

3/8” Allen Wrench

3/4”

(1)

(1)

9/16”

(2)

Rubber Mallet

(1)

Tape Measure

(1)

15/16”

(2)

Flathead Screwdriver

(1)

Ladder

(2+)

Adjustable Wrench

(1, optional)

Cement

(1,680 lb / 762 kg)

4

ASSEMBLY GUIDES

ASSEMBLY GUIDES

Refer to the following areas throughout the instructions

Refer to the following areas throughout the instructions

to assist in the assembly process:

to assist in the assembly process:

This area is located at the top, left-hand

This area is located at the top, left-hand

corner of the page and indicates which tools

corner of the page and indicates which tools

and hardware are needed to complete the

and hardware are needed to complete the

assembly steps on a page.

assembly steps on a page.

This area is located at the top, right-hand

This area is located at the top, right-hand

corner of the page and shows an image of the

corner of the page and shows an image of the

product with shaded parts indicating which

product with shaded parts indicating which

section is being assembled.

section is being assembled.

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

#

#

SEC

SEC

This area is usually located in the bottom,

This area is usually located in the bottom,

left-hand corner of a step and indicates that

left-hand corner of a step and indicates that

special attention is needed to perform a

special attention is needed to perform a

particular part of a step.

particular part of a step.

These areas are usually located in the bottom,

These areas are usually located in the bottom,

right-hand corner of a step and indicate that

right-hand corner of a step and indicate that

damage to the product or serious injury may

damage to the product or serious injury may

occur if the caution or warning is not heeded.

occur if the caution or warning is not heeded.

Throughout the Parts & Hardware List, Part

Throughout the Parts & Hardware List, Part

& Hardware Identifi ers, and instructions

& Hardware Identifi ers, and instructions

are three-letter IDs. These IDs are below

are three-letter IDs. These IDs are below

the images of the parts and hardware to

the images of the parts and hardware to

help you locate and identify the parts and

help you locate and identify the parts and

hardware during assembly. These IDs are not

hardware during assembly. These IDs are not

necessarily on the parts themselves.

necessarily on the parts themselves.

Note:

Note:

!

!

CAUTION

CAUTION

WARNING

WARNING

ADZ (x10)

ADZ (x10)

1/4” x 5/8” Pan-Head Screw

1/4” x 5/8” Pan-Head Screw

ID Item Description Qty

CZA Parts Box 1

ALG Pole 1

AKD Upper Extension Arm 2

AKE Lower Extension Arm Assembly 1

AJR Gas Spring 2

AKG Gas Spring Cover 2

ALS Lifter Arm 2

AEZ 36” Rebar 4

AEI J-Bolt 4

AKT J-Bolt Template 1

CXY Left Cam Plate 1

CXZ Right Cam Plate 1

AMT Warning Sticker (Applied to Pole) 1

HARDWARE LIST

ID Item Description Qty

CZD Setup Hardware

AEO 5/8” x 2” Hex Bolt 1

CYV 5/8” Hex Nut Coupler 1

AER 5/8” Hex Nut 8

CZE Handle to Pole Assembly Hardware

CYL 5/16” x 5” Grade 2 Bolt 1

EKW .5” x 8.75” Bolt 3

EKV .625” x 8.875” Bolt 1

CYC 5/8” Large Poly Spacer 2

EKO 1/2” x 1 5/8” Spacer 4

CYQ 5/8” x 1” Spacer 1

EKN 5/8” x .9” Small Spacer 4

AAX 1/2” Centerlock Nut 3

CYN 5/16” Nylock Nut 1

EIP 5/8” Centerlock Nut 1

AEG 1/2” Plastic Washer 2

AEH 5/8” Plastic Washer 2

AJZ Dark Lithium Grease (not pictured) 1

AKH Silicone Grease (White) (not pictured) 1

CZF Extension Arms to Pole Assembly Hardware

CYI 5/8” x 11 1/4” Grade 5 Bolt 2

CYJ 5/8” x 8 1/4” Grade 5 Bolt 1

CYU 1/2” x 3 3/4” Grade 2 Bolt 4

DEF 1/2” x 9” Grade 8 Bolt 1

CYO 5/8” x 4 3/4” Spacer 1

CYQ 5/8” x 1” Spacer 2

CYP 5/8” x 2.9” Rubber Spacer 2

AEG 1/2” Plastic Washer 4

AEH 5/8” Plastic Washer 4

CYM 1/2” x 7/8” Washer 4

CYF 1/2” Grade 2 Nylock Nut 5

CYG 5/8” Grade 2 Nylock Nut 3

PARTS LIST

ID Item Description Qty

CZB Parts Box 2

AJI Backboard 1

CZC Parts Box 3

ALX Rim 1

AKZ Net 1

AKI Lift Handle 1

AMA Rim Cover Plate 1

CYA Handle Bracket 2

AMO Trigger Pin 1

AKX Handle Lock Bracket 1

ALC Pad Lock with Key (not pictured) 1

AKP Height Sticker 1

ID Item Description Qty

BCR Backboard to Pole Assembly Hardware

CYJ 5/8” x 8 1/4” Grade 5 Bolt 1

CYT 1/2” x 1 1/4” Grade 2 Bolt 2

AEH 5/8” Plastic Washer 2

AEG 1/2” Plastic Washer 6

CYG 5/8” Grade 2 Nylock Nut 1

CYF 1/2” Grade 2 Nylock Nut 2

CZG Pole to J-Bolt Template Assembly Hardware

ADL 5/8” Nylock Nut 4

AMS 5/8” Nylon Cap 4

BIP 5/8” USS Washer 8

CUA 5/8” Lock Washer 4

BCS Rim to Backboard Assembly Hardware

ABY 3/8” x 1 3/4” Hex Bolt 4

ADU M8 x 0.8 Panhead Screw 2

AAF 3/8” Flat Washer 8

AAA 3/8” Nylock Nut 4

6

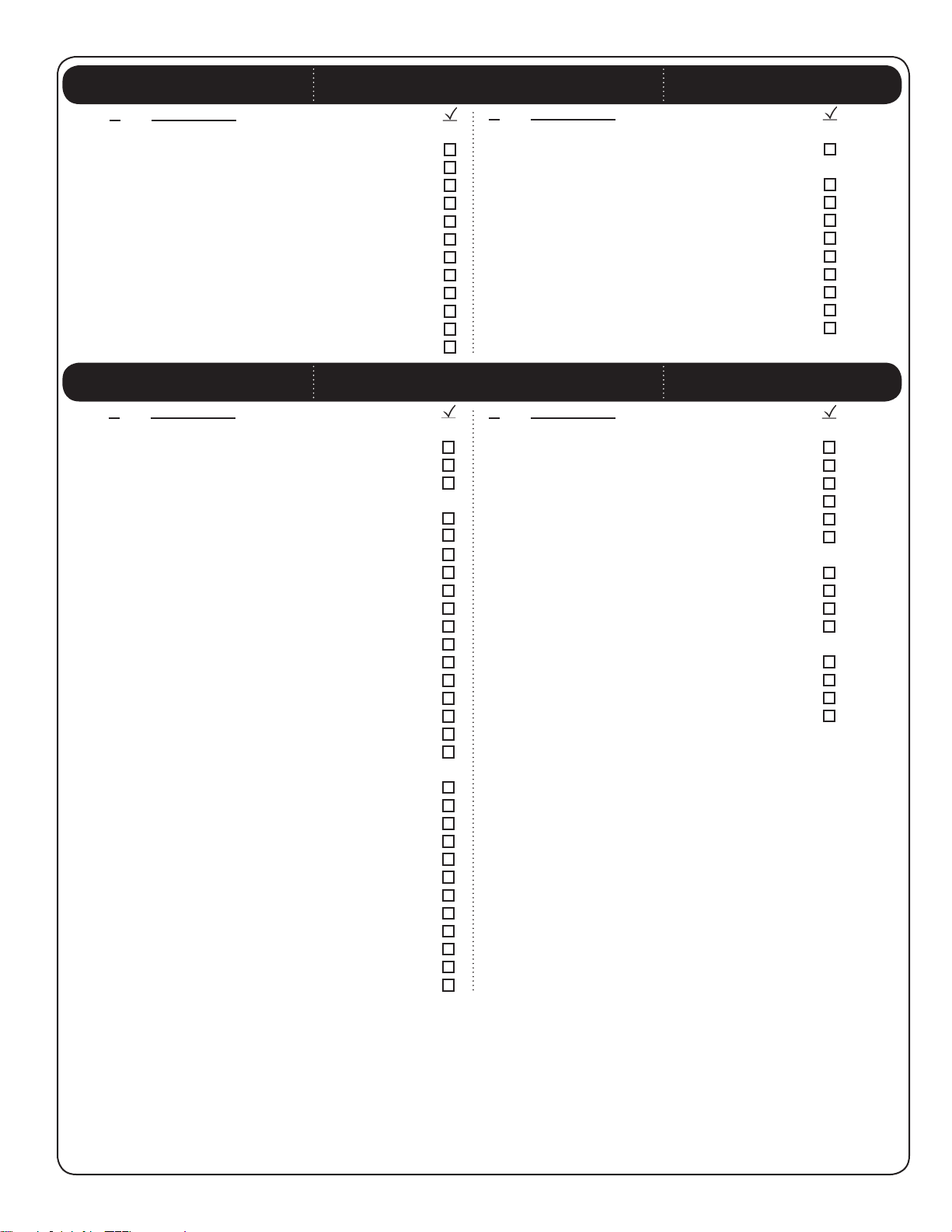

Parts shown at 10% of Actual Size

AKE (x1)

Lower Extension Arm Assembly

AKD (x2)

Upper Extension Arm

PARTS IDENTIFIER

AKZ (x1)

Net

AJR (x2)

Gas Spring

AKG (x2)

Gas Spring Cover

AEZ (x4)

36” Rebar

ALS (x2)

Lifter Arm

AEI (x4)

J-Bolt

ALX (x1)

Rim Assembly

AMA (x1)

Rim Cover Plate

AKI (x1)

Lift Handle

AKP (x1)

Height Sticker

AKT (x1)

J-Bolt Template

7

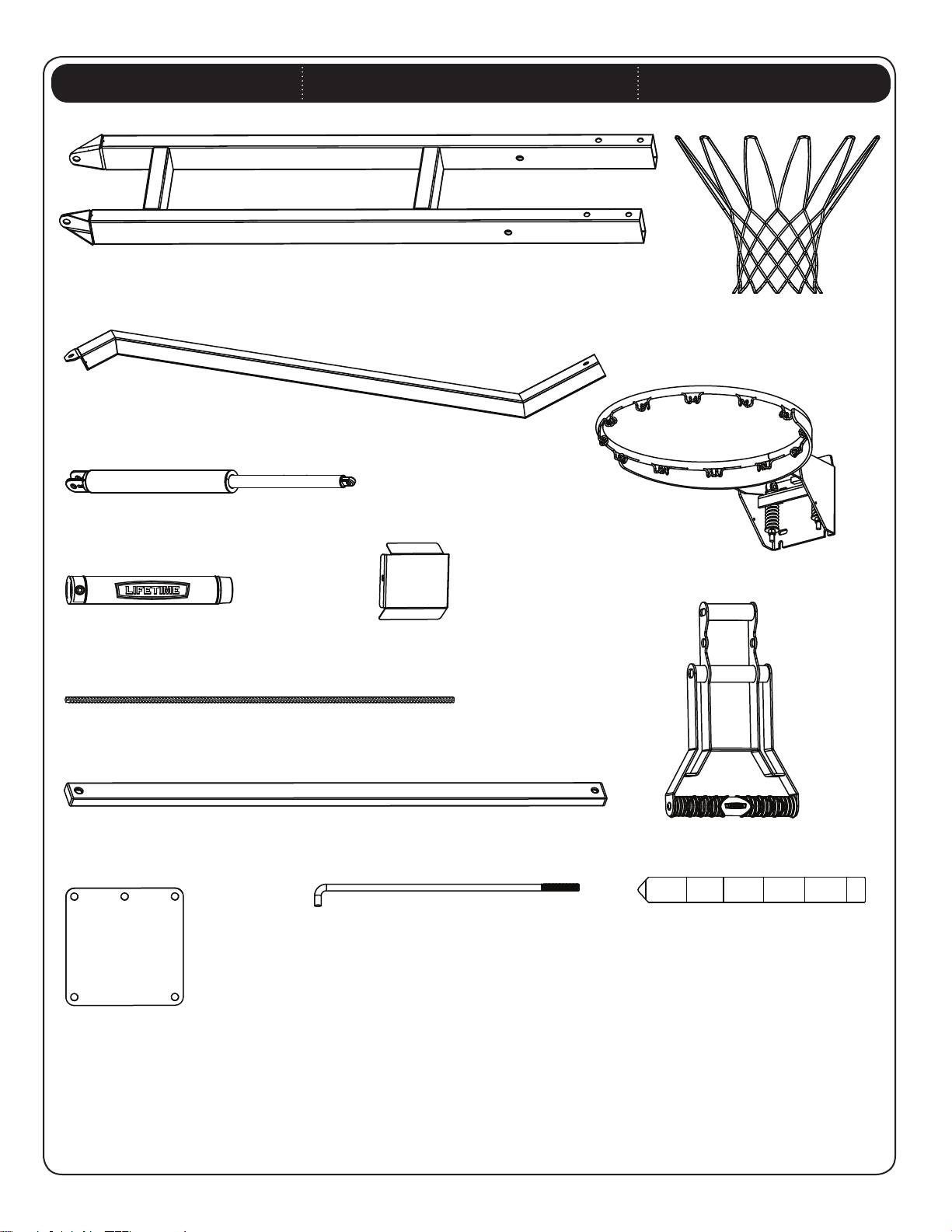

Parts shown at 5% of Actual Size

ALG (x1)

Pole

AJI (x1)

Backboard

PARTS IDENTIFIER

Part shown at 25% of Actual Size

CXY (x1)

Left Cam Plate

AKX (x1)

Handle Lock Bracket

CXZ (x1)

Right Cam Plate

CYA (x2)

Handle Bracket

AMO (x1)

Trigger Pin

8

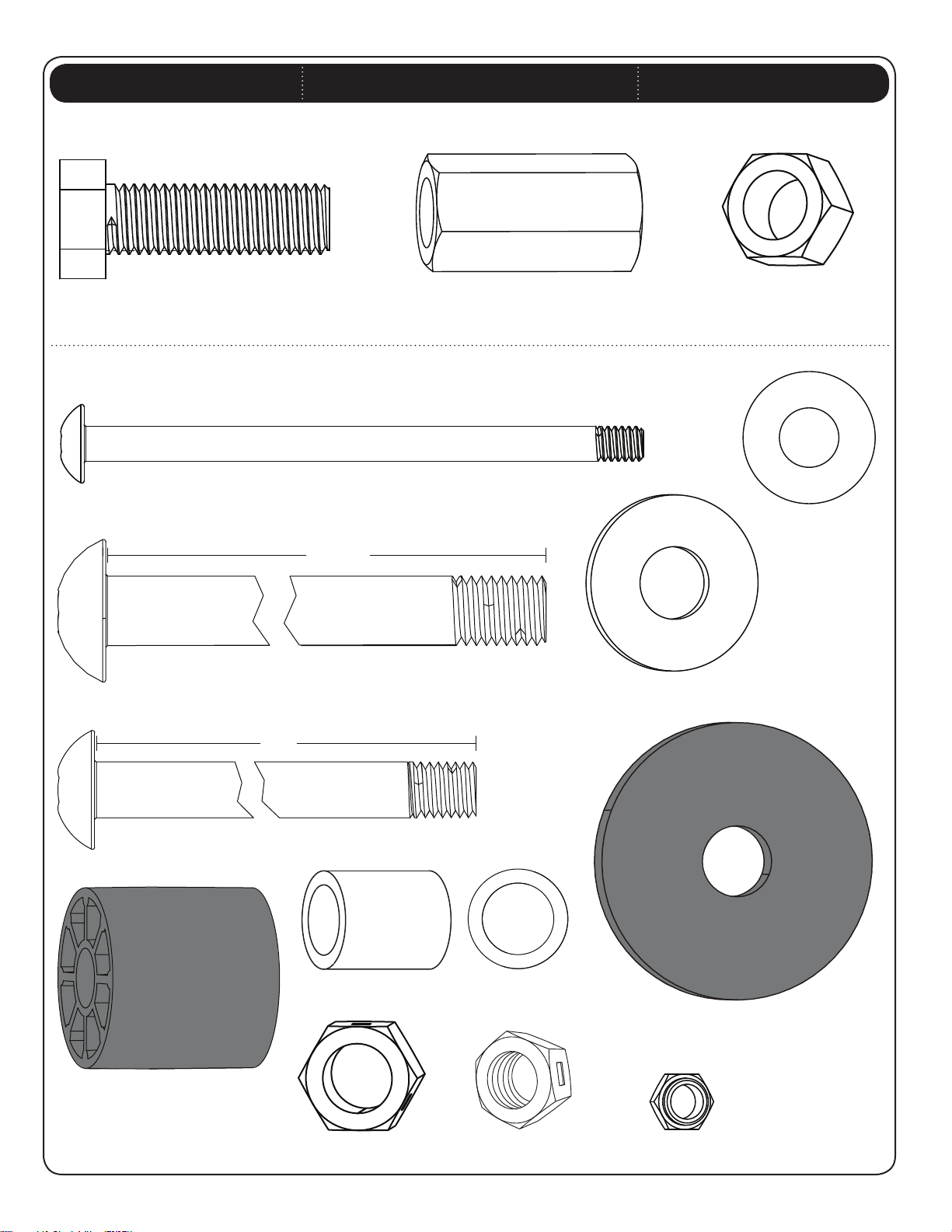

SETUP HARDWARE [CZD]

Hardware shown at Actual Size

HARDWARE IDENTIFIER

AEO (x1)

5/8” x 2” Hex Bolt

HANDLE TO POLE ASSEMBLY HARDWARE [CZE]

Hardware shown at Actual Size

CYL (x1)

5/16” x 5” Grade 2 Bolt

8.875”

EKV (x1)

.625” x 8.875”Bolt

(Not actual length)

CYV (x1)

5/8” Hex Nut Coupler

AER (x8)

5/8” Hex Nut

AEG (x2)

1/2” Plastic Washer

AEH (x2)

5/8” Plastic Washer

EKW (x3)

.5” x 8.75”Bolt

EKO (x4)

1/2” x 1 5/8” Spacer

8.75”

(Not actual length)

CYQ (x1)

5/8” x 1” Spacer

EIP (x1)

5/8” Centerlock Nut

EKN (x4)

5/8” x .9” Spacer

AAX (x3)

1/2” Centerlock Nut

9

CYC (x2)

5/8” Large Poly Spacer

CYN (x1)

5/16” Nylock Nut

HARDWARE IDENTIFIER

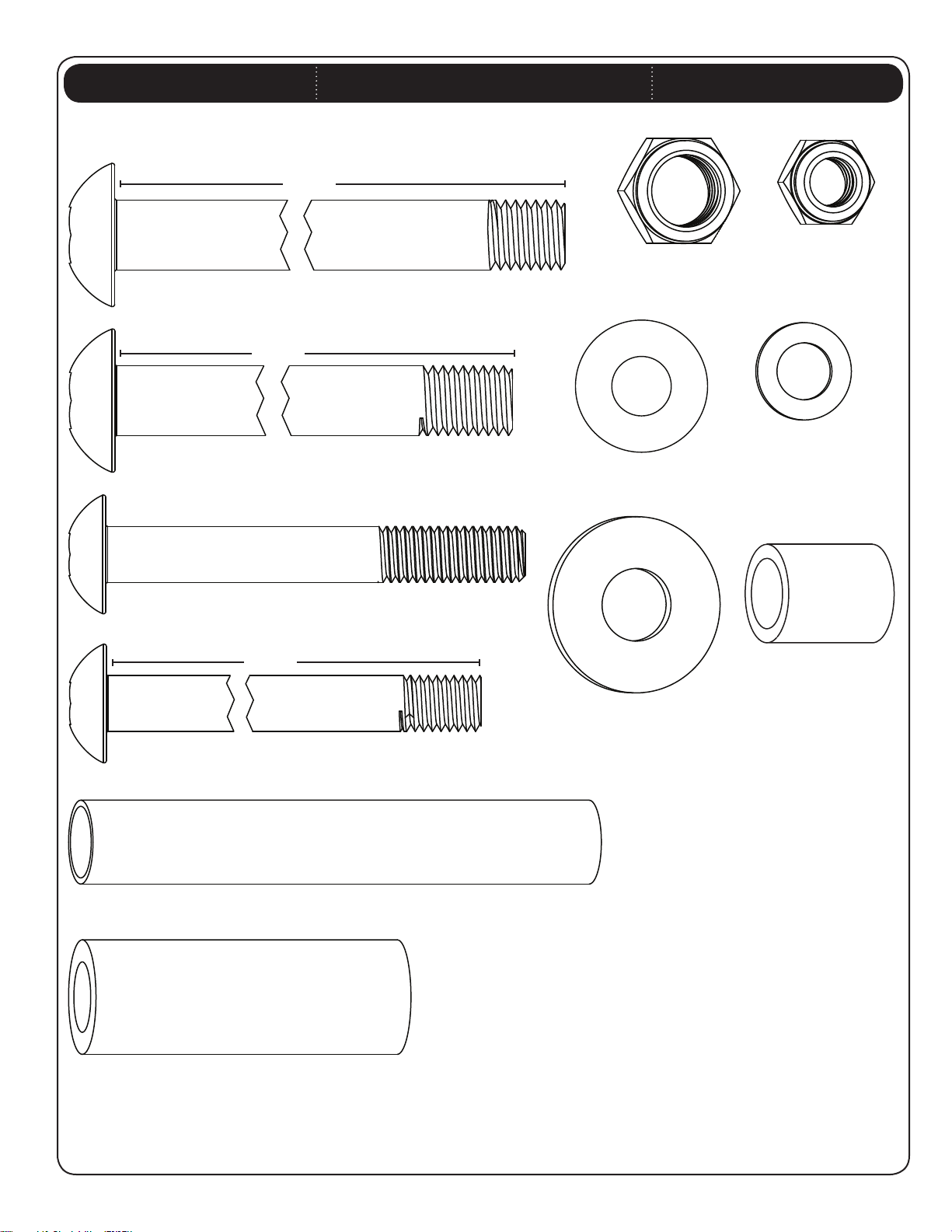

EXTENSION ARMS TO POLE ASSEMBLY HARDWARE [CZF]

Hardware shown at Actual Size

11 1/4”

CYI (x2)

5/8” x 11 1/4” Grade 5 Bolt

(Not actual length)

8 1/4”

CYG (x3)

5/8” Grade 2

Nylock Nut

CYF (x5)

1/2” Grade 2

Nylock Nut

CYJ (x1)

5/8” x 8 1/4” Grade 5 Bolt

CYU (x4)

1/2” x 3 3/4” Grade 2 Bolt

DEF (x1)

1/2” x 9” Grade 8 Bolt

(Not actual length)

(Not actual length)

9”

CYM (x4)

1/2” x 7/8” Washer

AEG (x4)

1/2” Plastic Washer

CYQ (x2)

5/8” x 1” Spacer

AEH (x4)

5/8” Plastic Washer

CYO (x1)

5/8” x 4 3/4” Spacer

CYP (x2)

5/8” x 2.9” Rubber Spacer

10

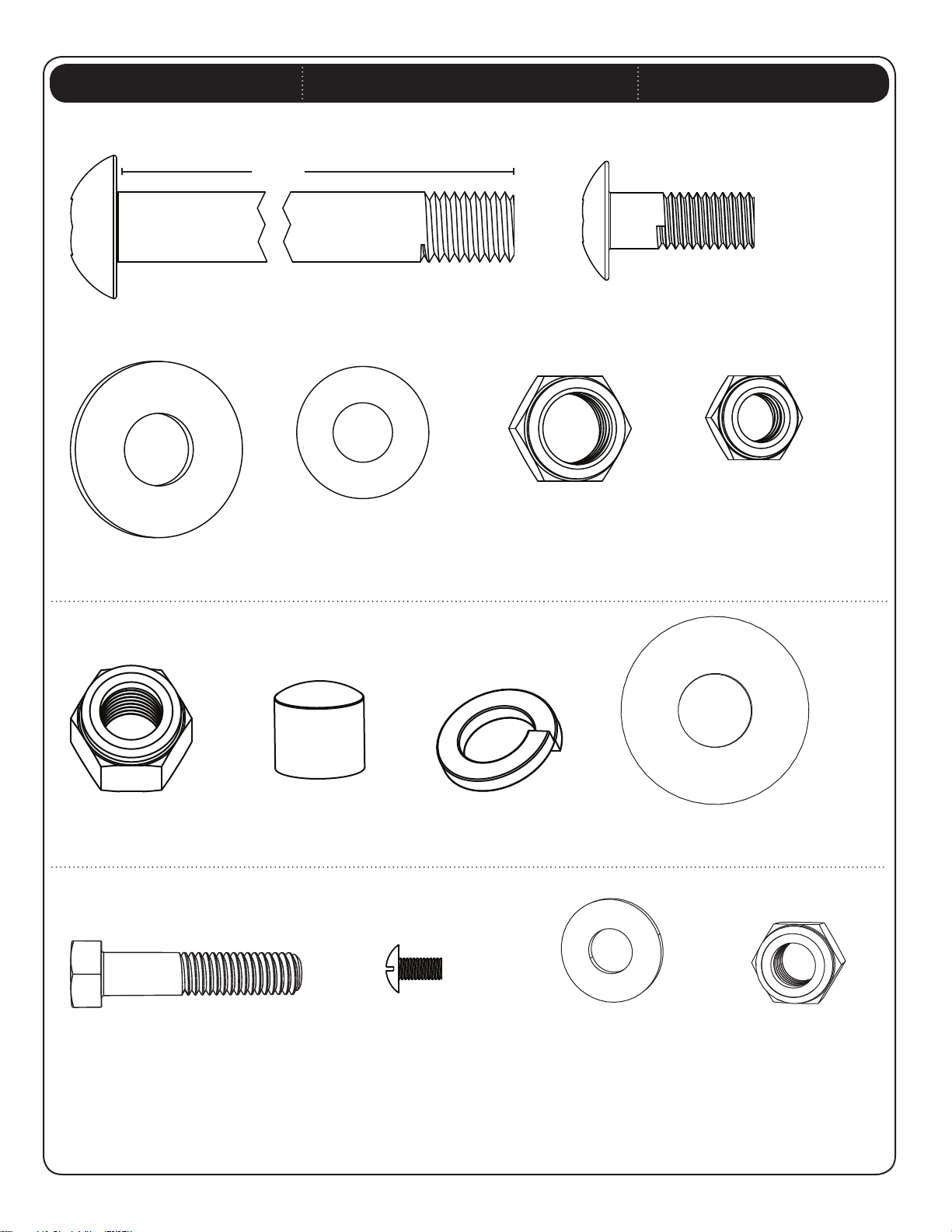

HARDWARE IDENTIFIER

BACKBOARD TO POLE ASSEMBLY HARDWARE [BCR]

Hardware shown at Actual Size

8 1/4”

(Not actual length)

CYJ (x1)

5/8”-11 x 8 1/4” Grade 5 Bolt

AEG (x6)

1/2” Plastic Washer

AEH (x2)

5/8” Plastic Washer

CYT (x2)

1/2” x 1 1/4” Grade 2 Bolt

CYG (x1)

5/8”-11 Grade 2 Nylock Nut

CYF (x2)

1/2”-13 Grade 2 Nylock Nut

POLE TO J-BOLT ASSEMBLY HARDWARE [CZG]

Hardware shown at Actual Size

ADL (x4)

5/8” Nylock Nut

AMS (x4)

5/8” Nylon Cap

RIM TO BACKBOARD ASSEMBLY HARDWARE [BCS]

Hardware shown at Actual Size

ABY (x4)

3/8” x 1 3/4” Hex Bolt

CUA (x4)

5/8” Lock Washer

ADU (x2)

M8 x 0.8mm

Panhead Screw

AAF (x8)

3/8” Flat Washer

BIP (x8)

5/8” Flat Washer

AAA (x4)

3/8”-16 Nylock Nut

11

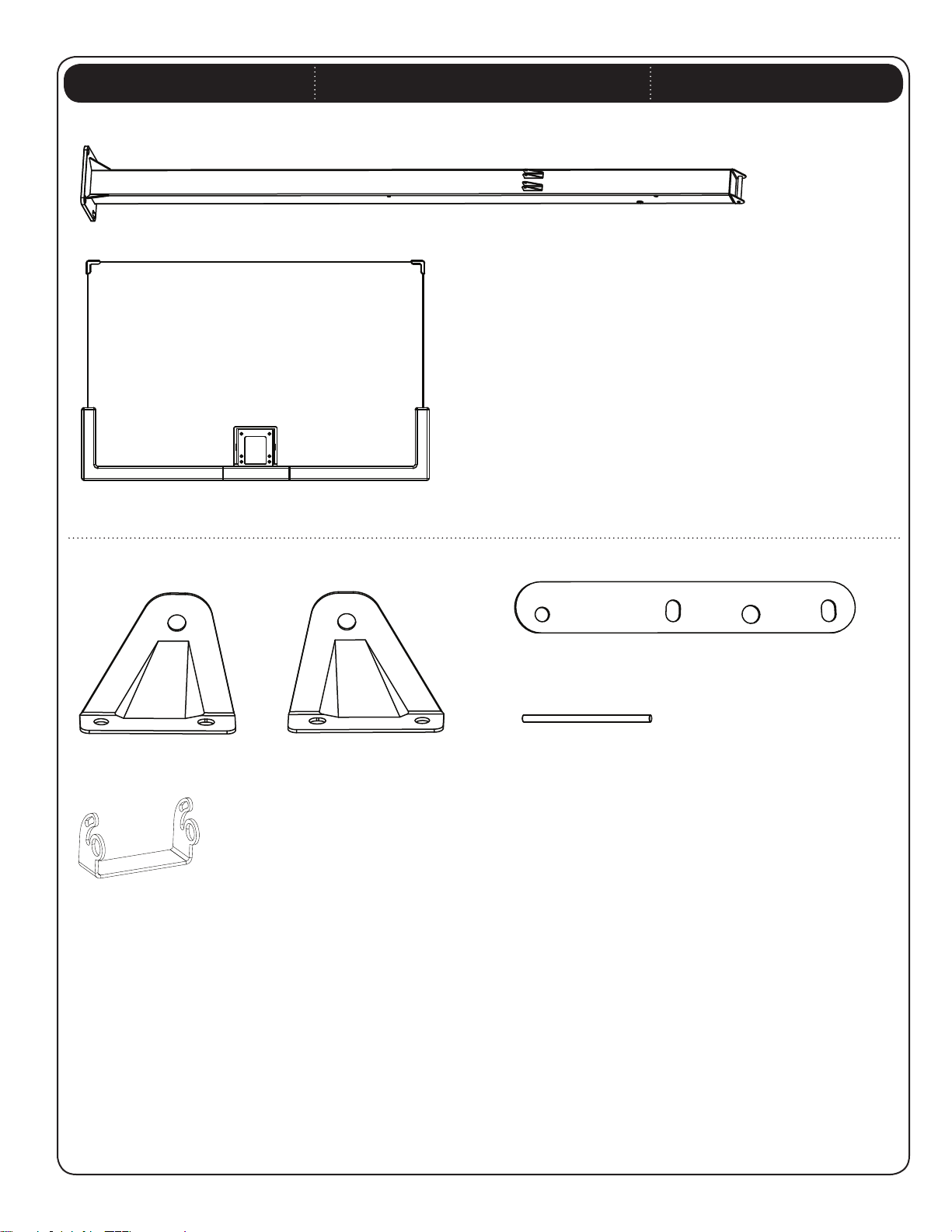

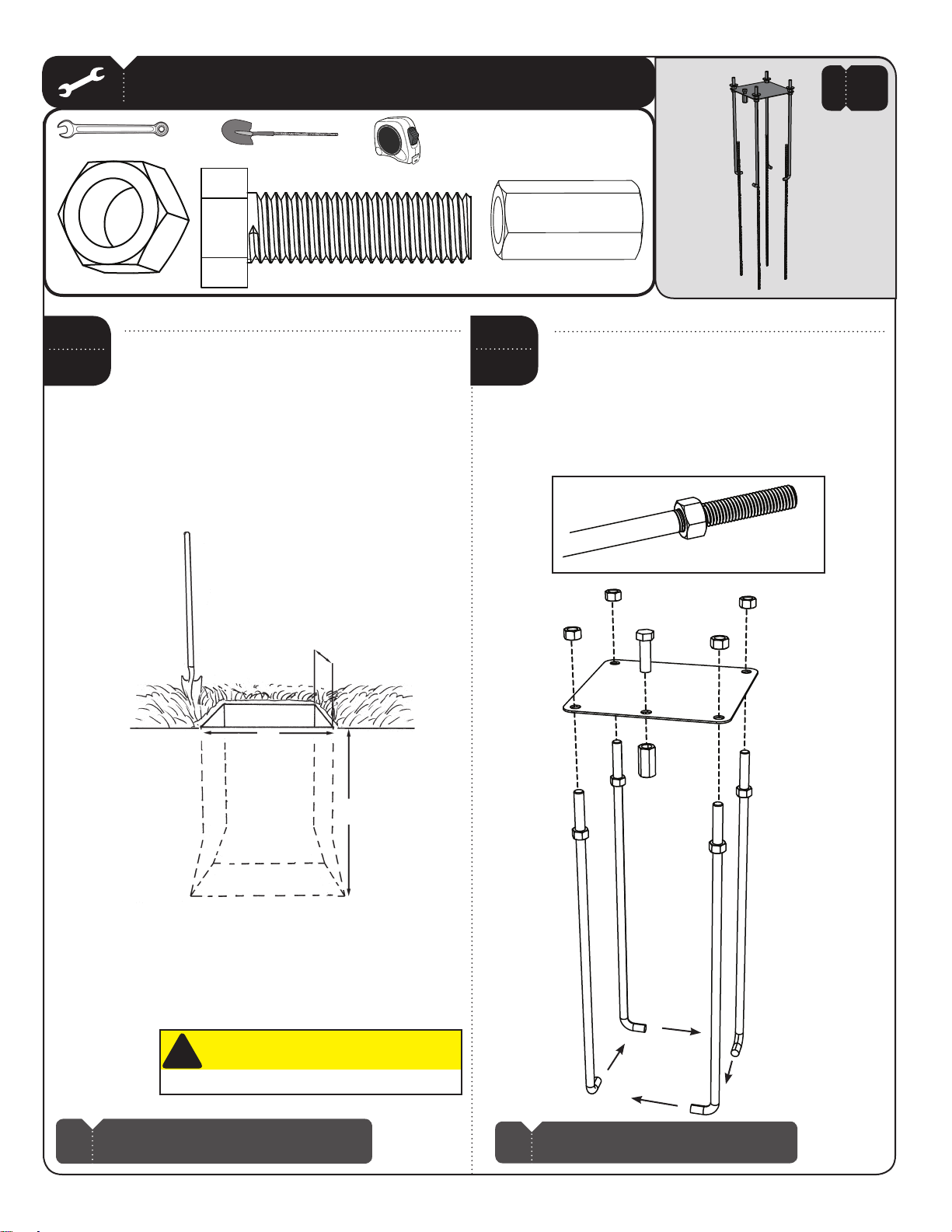

SETUP

1

SEC

SETUP HARDWARE [CZD]

Hardware shown at Actual Size

HARDWARE REQUIRED

AEO (x1)

5/8” x 2” Hex Bolt

Parts shown at 10% of Actual Size

AEZ (x4)

36” Rebar

AEI (x4)

J-Bolt

CYV (x1)

5/8” Hex Nut Coupler

PARTS REQUIRED

AER (x8)

5/8” Hex Nut

AKT (x1)

J-Bolt Template

15/16" Wrench

(x2)

TOOLS USED (NOT INCLUDED)

Carpenter’s Level Shovel

12

Tape Measure

Cement

(1,680 lb / 762 kg)

15/16” (x2)

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

(not actual size)

1

SEC

SEC

1.1

AER (x8)

Dig a hole 48” deep and 21” square. The edge of

the hole should be flush with the edge of the playing

court. If you live in an area where frost heaves

may pose a problem, consult your local building

inspector to determine the appropriate hole depth.

Bell out the bottom of the hole as illustrated. We

recommend building a form to keep the top of the

concrete straight and square. Place the form so it

is level with the playing surface.

AEO (x1)

21”

CYV (x1)

SEC

1.2

Thread a 5/8” Hex Nut (AER) all the way onto each

J-Bolt (AEI). Slide the threaded ends of the J-Bolts

through the corner holes in the J-Bolt Template (AKT)

and secure them completely with 5/8” Hex Nuts (AER).

Insert the 5/8” x 2” Hex Bolt (AEO) through the center

hole in the J-Bolt Template and tighten the Nut

Coupler (CYV) onto the Bolt as far as it will go.

AER

AEI

AER

AEO

AKT

21”

!

Before digging, call to locate any buried utility lines.

Note: There must be a 3-foot area behind the pole

!

to allow the user to adjust the Rim height.

CAUTION

48”

CYV

AER

AEI

Note: Make sure the curved ends of the J-Bolts

!

are in a rectangular pattern as shown.

13

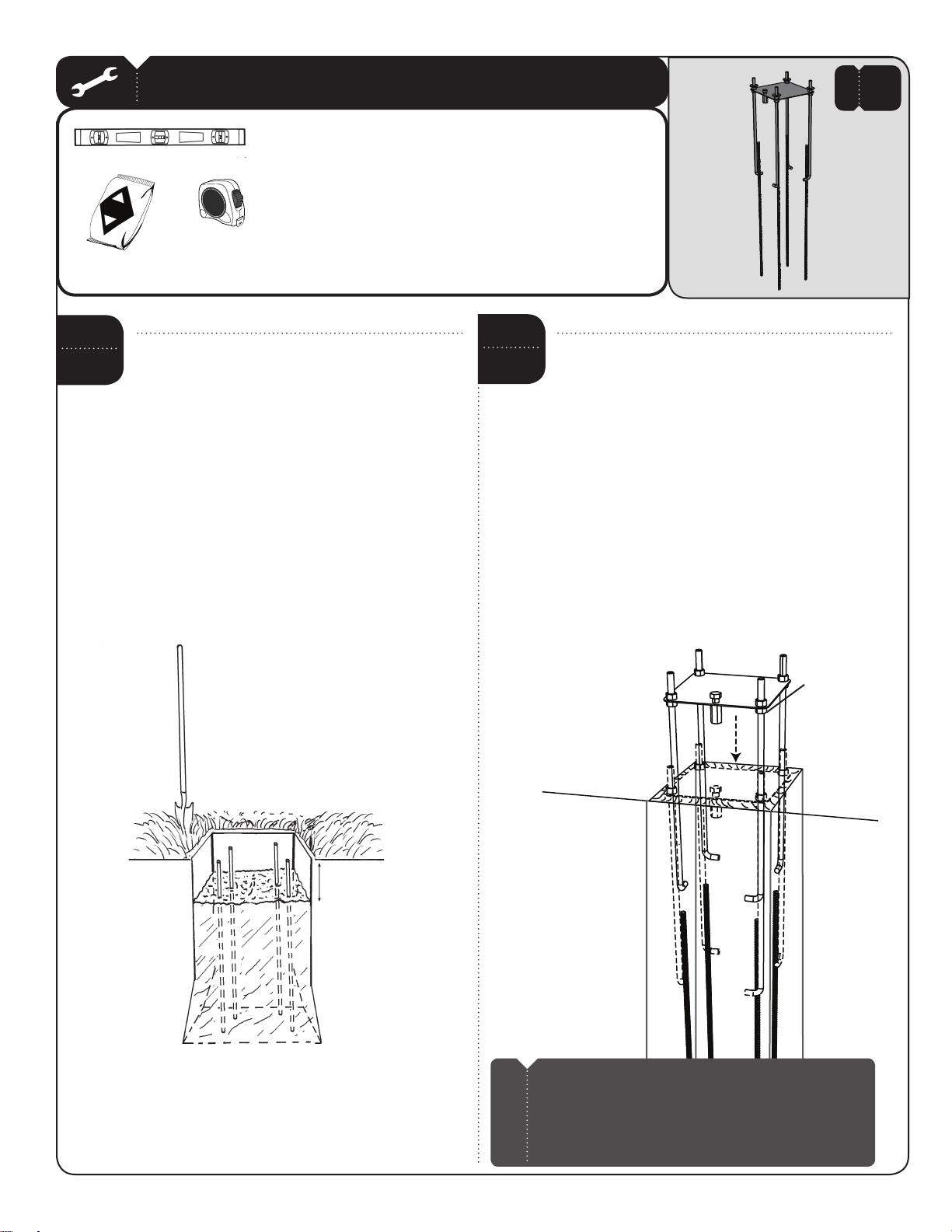

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

(1,680 lb / 762 kg)

(Not to scale)

NO HARDWARE REQUIRED FOR THIS PAGE

1

SEC

SEC

1.3

If you are using concrete mix, mix the concrete

according to the instructions on the bags. Please

note that a thicker mix of concrete will dry stronger.

Pour the concrete into the hole, stopping about 18

inches from the top of the hole.

Push the four pieces of 36” Rebar (AEZ) firmly to the

bottom of the hole. The Rebar should be arranged

in a square about 8 inches wide in the center of

the hole so each piece will be next to the J-Bolts

when they are placed in the cement.

Finish filling the hole to the top with concrete. The

top of the concrete should reach about 1/2” above

the playing surface and slope down toward the

playing surface to allow water runoff.

SEC

1.4

Center the J-Bolt Template (AKT) over the hole. The front

of the Template is the side with the Nut Coupler (CYV) and

should be toward the playing surface.

Insert the J-Bolts (AEI) into the concrete and agitate the

Template assembly to eliminate any air bubbles.

Push the J-Bolts into the cement until the Template

is resting flat against the cement. Form the cement

into a downward slope toward the playing surface

to allow water runoff. The lower four 5/8” Hex Nuts (AER)

and the Nut Coupler will be in the concrete permanently.

Clean off any concrete on the J-Bolt Template or the

exposed portion of the J-Bolts. Using a carpenter’s

level, make sure the Template is square to the playing

surface. Plate should be level and about 1/2” above

the playing surface for water to drain off of the steel.

AKT

CYV

AER

AEZ

18”

14

AEI

Playing surface

Note: You are now finished with the initial assembly steps. DO

!

NOT PROCEED WITH THE ASSEMBLY until the concrete has fully

cured. Curing will take a minimum of 72 hours (3 days). In

humid climates or wet weather, allow additional time for the

concrete to cure. Never use the system without first following

the cementing instructions.

Loading...

Loading...