®

VISIT THE LIFETIME WEB SITE:

WWW.LIFETIME.COM

**U.S. and Canada customers ONLY**

IF ASSISTANCE IS NEEDED,

DO NOT CONTACT THE STORE!!!

CALL OUR CUSTOMER SERVICE DEPARTMENT at 1 (800) 225-3865

HOURS: 7:00 a.m. to 5:00 p.m. Monday through Friday, 7:00 a.m. to 4:00 p.m. Saturday (Mountain Standard Time)

**For customers outside the U.S. or Canada, please contact the store for assistance.**

9/5/2002

WORLD CLASS® ACTION GRIP

MODEL #71793

WARNING

Failure to comply with any of the warnings

in these instructions may result in serious

personal injuries such as cuts, broken

bones, nerve damage, paralysis, brain

injury, or death. Failure to comply may

also result in property damage. Please

heed all warnings and cautions. To ensure

your safety, do not attempt to assemble

this system without reading and following

all instructions carefully. Identify and

inventory the parts using the Parts List.

BASKETBALL SYSTEM

ASSEMBLY INSTRUCTIONS

AND OWNERS MANUAL

*A MINIMUM OF TWO ADULTS

ARE REQUIRED FOR

ASSEMBLY*

Save this instruction in the event that the manufacturer has to be contacted for replacement parts.

INSTRUCTION #FH05600 C

1

PARTS LIST

ID Part # Description Qty

TP 830081 Top Pole 1

MP 800707 Middle Pole 1

BP 830181 Bottom Pole 1

RB 850163 Left Backboard Bracket 1

LB 850162 Right Backboard Bracket 1

AZ ZJ04299 Backboard 1

AA 500096 Pole Cap 1

AB 502005 Net 1

AD 504068 Counterbalance Spring 2

F028011 Warning Sticker (Applied) 1

AI F028010 Height Sticker 1

AJ 825601 Rim 1

AK 830204 Short Extension Arm 2

AL 830205 Long Extension Arm 2

AE 700506 Wood Block 1

AF AM01500 Rim Support Bracket 1

Main Hardware (HH01700C)

HA 300022 1/4" Centerlock Nut 2

HB 300029 1/2" x 7 1/8" Hex Bolt 5

HC 300110 1/4" x 2 3/4" Hex Bolt 2

HD 301008 1/2" Centerlock Nut 5

HE 302005 3/8" x 7" Hex Bolt 1

HF 302008 3/8" Centerlock Nut 1

HI 500013 9/16" x .592 Poly Spacer 4

HJ 500032 1/2" x 1/8 Spacer 4

HK 500037 1/2 x 1" Poly Spacer 2

HL 800324 1/2" x 2 5/16" Metal Spacer 2

HM BS00800 5/16 x 1 Screw 2

Rim Hardware (HH01900B)

RA 300066 5/16" Hex T-Nut 2

RK 300128 5/16" Jam Nut 2

RC 302014 5/16" Flat Washer 2

RD 302056 Rubber Washer 2

RE 302067 5/16" x 2 3/4" Tap Bolt 2

RF 302081 5 1/2 U-Bolt 1

RG 302090 5/16" Nylock Flange Nut 4

RJ 502060 Compression Spring 2

RI 804033 Spring Retainer Plate 1

HA

RA

RI

HARDWARE IS ACTUAL SIZE

(unless otherwise indicated)

HDHC

HJ

RC

RK

RE

HF HI

HK

RD

RG

HL

2

HE

HB

HM

(not actual size)

PARTS LIST

!

!

ID Part # Description Qty

AN A040031 Inner Channel 1

AO Z097015 Outer Tube 1

AP C050018 Channel Stop 1

AQ Z097017 Pole Bracket 1

AR C050019 Handle 1

AS C050017 Trigger 1

Action Grip™ Hardware (HH01300)

GA A070044 Lock Tab 1

GB B070040 1/4-20 x 1 1/2 Screw 2

GC B080015 Trigger Spring 1

GD BW00100 #6 Flat Washer 2

GE 300027 5/16 x 1 3/4 Hex Bolt 1

GF 300031 3/8 Flat Washer 2

GH 300095 5/16 Cap Nut 1

GI 300103 #6 x 3/8 Phillips Screw 2

HF 302008 3/8 Centerlock Nut 2

GK 302053 3/8 x 4 Hex Bolt 2

GL 800239 1/2 x 3 7/16 Spacer 2

Pole Joint Hardware (HD9139)

PA 300121 1/4" x 4" Carriage Bolt 2

PB 300127 1/4" Cap Nut 2

GA

(Not actual size)

GF

PA PB

HARDWARE IS ACTUAL SIZE

(unless otherwise indicated)

GB GD

GH GI GK

GC GE

(Not actual size)

GL

Tools and Materials Required For Assembly

(Not Included)

1. Adjustable Wrench

2. 7/16 Wrenches (2)

3. 1/2 Wrenches (2)

4. 9/16 Wrenches (2)

5. 3/4 Wrenches (2)

6. 3/8 Wrench

7. Hammer or Mallet

8. Tape Measure

9. Water Supply

10. Concrete mix

(six 90-lb. bags)

11. Phillips Screwdriver

12. Shovel

13. Marker

14. 3 Length of Rebar

15. Carpenters Level

STOP

A. Identify and inventory all parts using the Parts List. Keep the hardware

BEFORE BEGINNING ASSEMBLY

STOP

bags and their contents separate. If any parts are missing, call our Customer

Service Department.

B. Test fit all Bolts by inserting them into their respective holes. If necessary,

carefully scrape away any excess powder coating buildup from inside the

holes. Do not scrape away all of the powder coating. Bare metal may rust.

You may need to pound some Bolts into place with a hammer.

C. Purchase six 90-lb bags of concrete ready-mix and a 3' length of rebar.

Choose the location of your pole carefully! Avoid putting the pole near

overhead power or utility lines. When digging the footing, consider the location

of any underground utilities.

3

SAFETY INSTRUCTIONS

Failure to follow these safety instructions may result in serious injury or property damage and will void the warranty. The owner must ensure that all players

know and follow these rules for safe operation of the system. Proper and complete assembly, use and supervision is essential for proper operation and to reduce the

risk of accident or injury. A high probability of serious injury exists if this system is not installed, maintained, or operated properly.

If using a ladder during assembly, use extreme caution. Follow all warnings and cautions on the ladder carefully. Two people are required for assembly. Before

digging, contact the appropriate agency to locate underground power, gas and/or water lines. Do not install the system within 20 feet of overhead power lines. Seat

the pole sections properly. Failure to do so could allow the pole sections to separate during play and/or transport of the system. Climate, corrosion, or misuse could

result in system failure. If technical assistance is required, contact the manufacturer. Minimum operational height is 7 6 to the Rim.

Most injuries are caused by misuse and/or failure to follow instructions. Use caution when using the system.

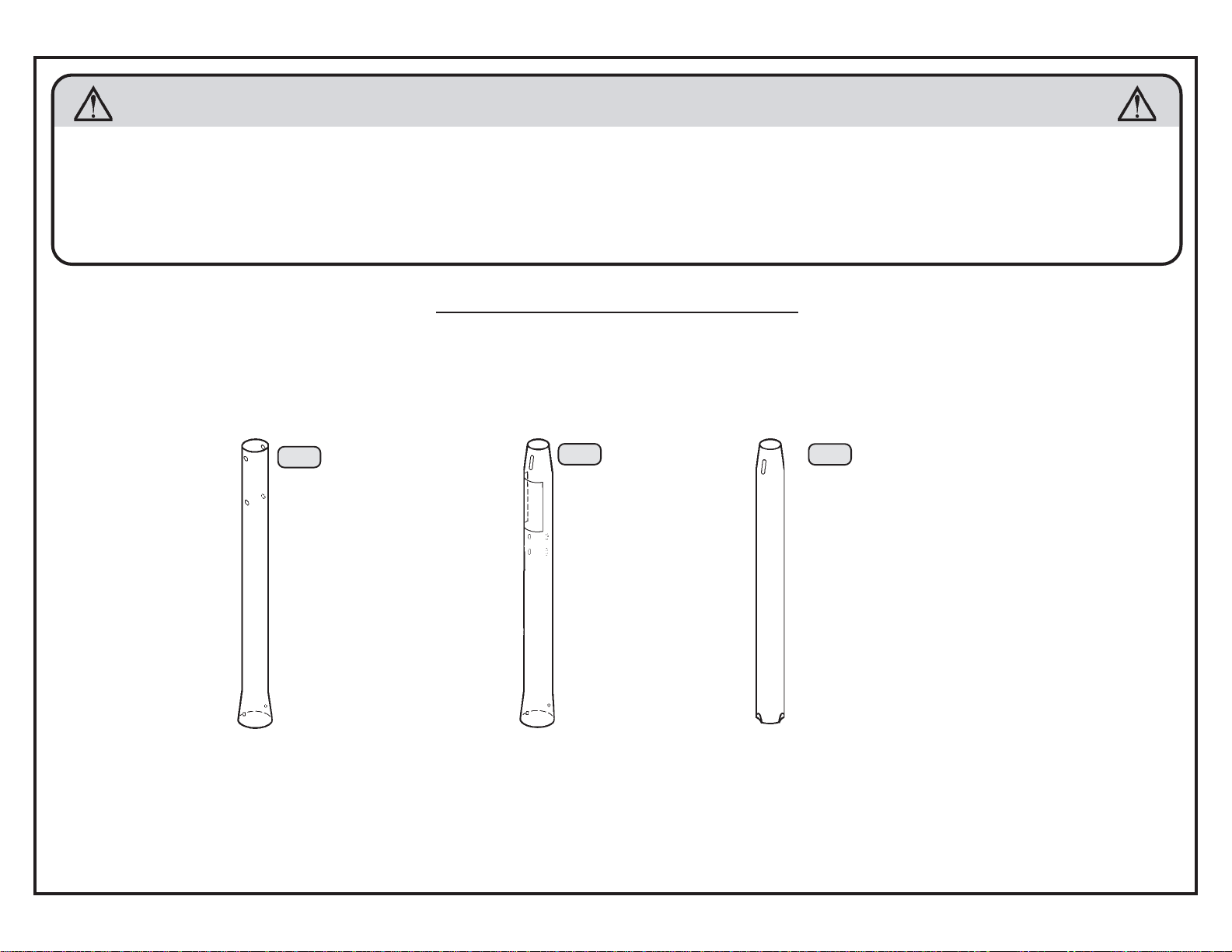

POLE SECTION IDENTIFICATION

Identify the pole sections before beginning assembly. Failure to assemble the pole sections correctly may result in severe

personal injury or property damage as described on Page One.

ONCE THE POLE SECTIONS HAVE BEEN SEATED, THEY CANNOT BE SEPARATED.

Note: Tapers and flares are exaggerated in the illustrations.

4

TP

Top Pole:

Four holes

at the top of

the pole and

two square

holes at the

bottom.

MP

Middle Pole:

Two slots at

the top of the

pole, four

holes in the

middle and

two square

holes at the

bottom.

Warning

Sticker.

BP

Bottom Pole:

Two slots at

the top of the

pole, dimples

at the bottom.

Required For

This Page:

9/16 Wrenches

HH01300

GK

(2)

HF

1

cementing the pole into the

ground permanently. See Page 11

Dig a round hole 24" deep and 18"

in diameter. The edge of the hole

should be flush with the edge of the

The Ground Sleeve

provides an alternative to

for more information.

playing surface.

(2)

18

2

Measure 14.5" up

from the dimpled

end of the Bottom

Pole (BP) and

make a mark (do

BP

not scratch the

powder coating).

3

Mix 5 1/2 bags of concrete. Save 1/2 bag

of concrete to use later in the assembly.

Fill the hole with concrete.

Insert the Bottom Pole up to the 14.5 mark

and 4 away from the playing surface.

4

Insert a 3/8 x 7 Hex

Bolt (HE) into the slots in

the pole and rotate the

pole so the Hex Bolt is

parallel to the playing

surface.

4"

HE

GF

(2)

GL

(2)

24

5

Check the pole several times within the first

hour to make sure that all sides are vertical

concrete. The 14.5 mark must remain level

Form the cement so it slopes away

from the pole to allow water runoff.

Failure to do so may result in

premature rusting of the pole.

Place the 1/2" x 3' rebar (not included)

inside the Bottom Pole (BP).

and that the pole does not sink into the

with the playing surface.

Rebar

Allow 1-4 hours

for the concrete

to set.

14.5

A thicker mix of

concrete will dry

stronger.

6

Allow the concrete to set for at least 72 hours (3 days)

Do not continue until the concrete has set

for 1 to 4 hours.

Remove the Hex Bolt from the top of the pole.

Mix the remaining 1/2 bag of concrete and pour the

concrete into the Bottom Pole until it is just below the

slots in the top of the pole. Tamp the concrete down

with a broom handle to remove any air pockets.

Do not overfill the pole or you may not be

able to assemble the rest of the pole

sections.

Clean all excess concrete off the

outside surface of the pole.

before continuing with the assembly.

STOP!

The concrete must cure for at least 72 hours (3 days) before

installing the rest of the system. In humid climates or wet

weather, allow additional time for the concrete to cure. Do not

proceed until the curing process is complete.

Playing

Surface

7

HF

GK

GF

Small

holes

MP

Completely tighten the Nuts.

GL

Large

holes

AQ

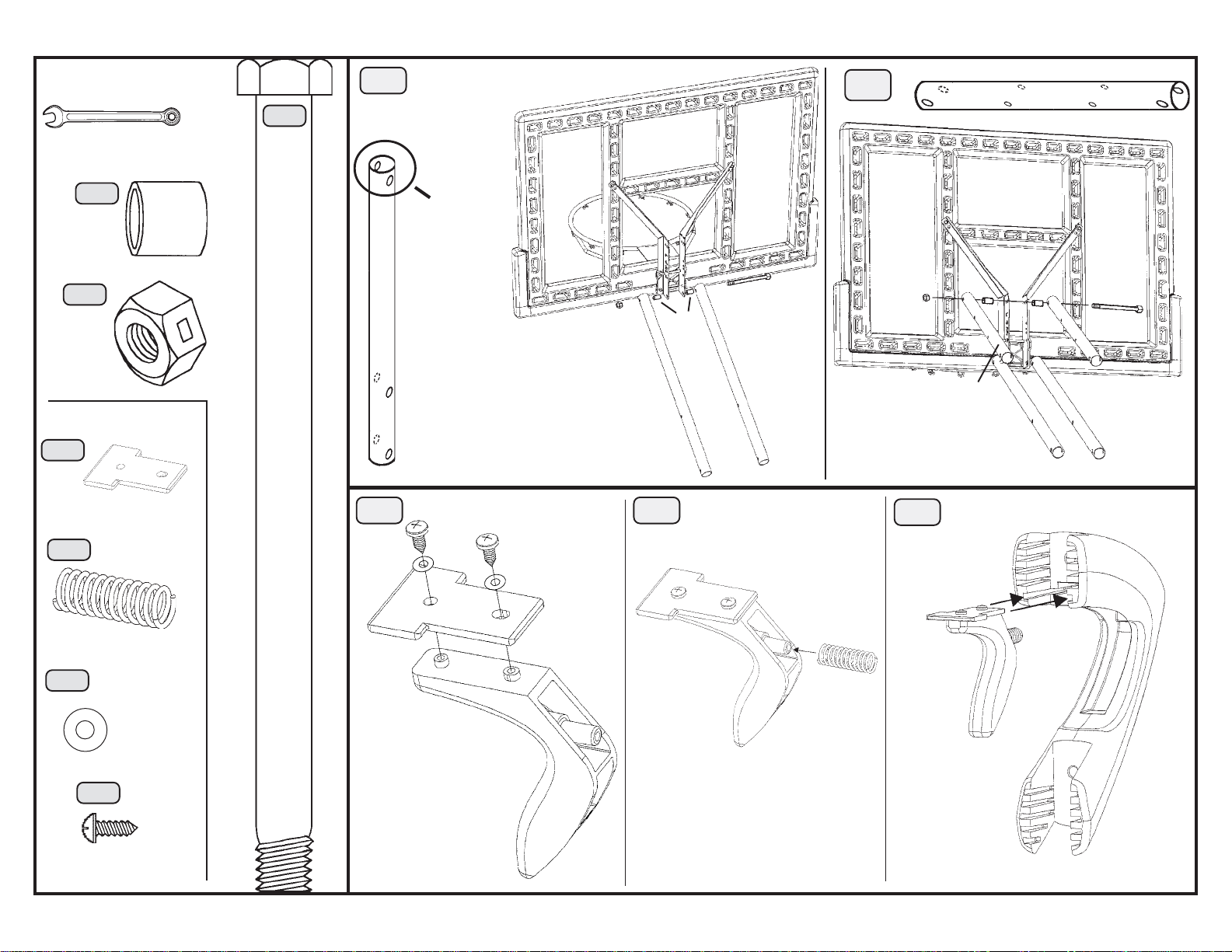

5

Required For This Page:

7/16 Wrenches

1/2 Wrenches

HD9139

HH01900B

RA

PB

(2)

RC

(2)

PA

(2)

RD

(2)

RE

HH01700C

HL

(2)

(1)

(1)

(2)

HC

8

TP

MP

10

Do not jam the poles

together until instructed.

Make sure the square

portion of the Bolt is

completely inside the

square hole.

Square holes

PB

PB

Secure only finger

RB

PA

tight now.

PA

9A

Strike the pole on

the Wood Block

(AE) 5 to 6 times

on each end.

Do not hit your

feet with the

pole, as serious

injury could

Failure to seat the pole sections together

and secure the Carriage Bolts could

cause the pole sections to separate,

resulting in property damage or personal

injuries as listed on Page One.

11

Make sure the U-Bolt is in

TP

occur.

AE

WARNING

the notches.

MP

9B

the Middle Pole. It must measure

longer than 83 5/8, strike it again on

the wood. If it is still too long, do not

Completely tighten the Cap

Measure from the top of the

Top Pole to the bottom of

83 5/8 or less. If it measures

complete assembly. Call our

Customer Service Department.

Nut installed in Step 8.

WARNING

Do not overtighten the Cap Nut. If the

end of the Bolt breaks through the

plastic cap, call our Customer Service

Department at the number on Page

One. Exposed threads on the end of the

Bolt may cause serious injuries such as

those listed on Page One.

12

RC

RE

RD

6

TP

83 5/8

MP

RA

HA

(2)

LB

RF

RB

HC

LB

HA

HA

Completely tighten the Nuts (HA).

HL

The Tap Bolts (RE)

should be at the outer

HC

edge of the holes.

RD

Tighten the T-Nuts (RA) only until the

Rubber Washers (RD) begin to bulge.

Required For This Page:

1/2 Wrenches

3/8 Wrench

HH01900B

(2)

RK

RG

(4)

13

Lay the Backboard on a

bench or table.

The U-Bolt (RF) goes through the

top holes in the Backboard. The Rim

Support Bracket (AF) lines up with

the lower holes in the Backboard

Brackets and Backboard.

RK

RG

Only hand tighten

the Nuts (RG).

AF

Tighten the Jam Nuts (RK) onto

the U-Bolt as far as they will go.

14

RG

RI

RJ

Only hand tighten the

Nuts (RG) now.

Tightening these Nuts later will

adjust the Rim tension.

RI

(1)

(not

actual

size)

HH01700C

HM

(2)

15

Bend the Backboard Brackets (LB & RB) out.

LB

RB

Use a 3/8 wrench to attach the Screws (HM) through the top holes in

the Backboard Brackets and into the Backboard.

HM

Completely tighten all Rim hardware.

HM

7

8

Required For This Page:

3/4 Wrenches

Screwdriver

HH01700C

HI

(4)

HD

(2)

HH01300

GA

(1)

(Not actual size)

GC

(1)

HB

(2)

16

Attach this end

Arms (AL) to

the Backboard

18

GI

GD

of the Long

Extension

Brackets

Tighten until the Nut is

flush with the Bolt.

GI

GD

HD

AL

19

HI

HB

AL

17

HI

HD

AK

Tighten the Nut until it is flush with the Bolt.

AK

HB

HI

AK

20

AR

(Not actual size)

(2)

GD

(2)

GI

AS

GA

AS

AS

GC

Required For

This Page:

3/4 Wrenches

1/2 Wrenches

Screwdriver

HH01300

GB (2)

HB

(2)

21

AO

Remove the Inner

Channel that is packaged

inside the Outer Tube

(AO) before attaching the

Handle (AR).

AR

22

**2 Adults Required For

This Step**

The Backboard and Rim

should be on the ground

resting on cardboard with the

Extension Arms facing up.

AK

HB

HB

23

AN

AI

GEGH(1)

(1)

HH01700C

HD

(2)

GB

GB

24

AN

AN

AK

HD

AR

The Backboard must be on the opposite side

of the pole as the Pole Bracket.

Squeeze the Trigger while inserting the

Inner Channel into the Outer Tube.

Insert the slotted end first.

AO

HD

HJ

AO

25

AO

AL

AP

AL

26

AI

GE

AN

The bottom of the Sticker (AI)

lines up with the bottom edge

of the Inner Channel (AN).

Tighten the Nut securely.

GH

HJ

(4)

AN

AO

Slide the Outer Tube

(AO) up to the 10 mark

and release the Trigger

so it clicks into place.

WARNING

Do not overtighten the Cap Nut. If the end of

the Bolt breaks through the plastic cap, call our

Customer Service Department at the number

on Page One. Exposed threads on the end of

the Bolt may cause serious injuries such as

those listed on Page One.

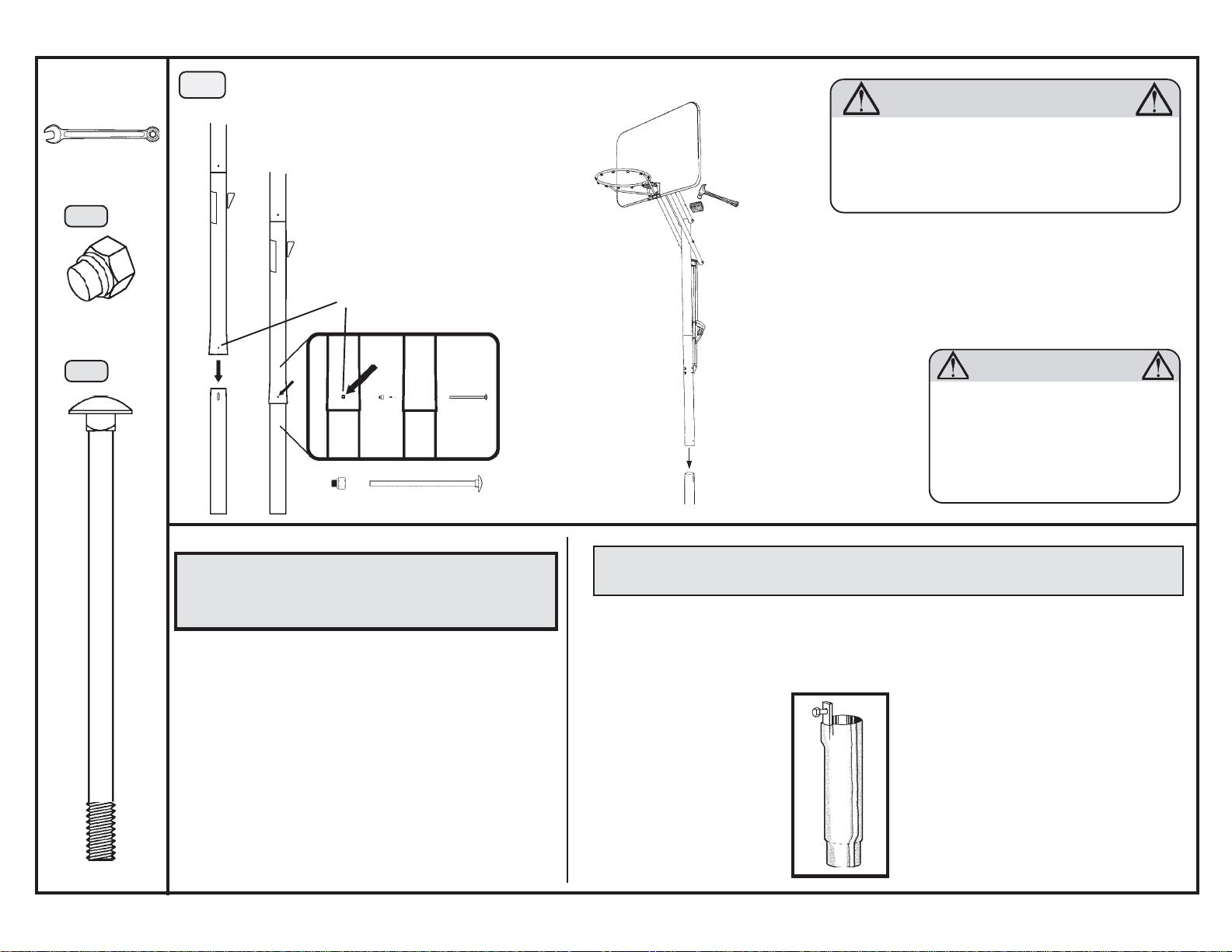

9

10

Required For

This Page:

3/4 Wrenches

9/16 Wrenches

HH01700C

(2)

HK

(1)

HD

HB

(1)

HE

(1)

27

29

**2 People Required For

This Step**

HK

AO

HB

Completely tighten the Nut.

HK

AL

Hook the Springs (AD) into the #2 holes in the Backboard Brackets.

HD

AL

28

Remove the plastic film

from the Backboard.

Use the holes closest to the pole.

Tighten all Nuts securely now.

HF

30

HE

Attach the Net.

HF (1)

Use the closed end

of a wrench to pull

the Springs up and

over the Bolt.

AD

Please call our Customer

Service Department at

the number on Page One

to obtain replacement

Nets. Our Nets are

shorter than average to

reduce the risk of

entanglement.

Required For

This Page:

7/16 Wrench

Hammer/Mallet

HD9139

(1)

PB

31

MP

**2 People Required For This Step**

With the Backboard facing the playing

surface, line up the holes in the Middle Pole

with the slots in the Bottom Pole. Carefully lift

the system onto the Bottom Pole.

Make sure the square portion of the Bolt

is completely inside the square hole.

Square holes

Completely

tighten the Cap

Nuts (PB) now.

WARNING

Failure to seat the pole sections together and secure

the Carriage Bolts could cause the pole sections to

separate, resulting in severe personal injuries such as

broken bones, cuts, nerve, spinal cord or brain injury,

or death. Property damage may also occur.

AE

Place the Wood Block

(AE) on the Top Pole

and strike it firmly with a

hammer or mallet six or

seven times.

PA

(1)

BP

PB

PB

PA

PA

Operation of the height

adjustment system

The adjustable system may be adjusted from 7 1/2 feet

to 10 feet in 6-inch increments.

Hold the Handle tightly and squeeze the Trigger. Raise

the Handle to lower the Backboard, or lower the Handle

to raise the Backboard.

WARNING

Do not overtighten the Cap Nut. If the

Insert the Pole

Cap (AA) into the

top of the pole.

Accessories available for more basketball fun!

PRODUCT DESCRIPTION MODEL #

Universal Ground Sleeve 0023

Universal Ground

Sleeve #0023

The Universal Ground Sleeve

enables the pole to be cemented

in, yet still removable. The

sleeve sits flush with the ground

after installation. Fits 3.5"

diameter poles.

end of the Bolt breaks through the

plastic cap, call our Customer Service

Department at the number on Page

One. Exposed threads on the end of the

Bolt may cause serious injuries such

as those listed on Page One.

For price and freight information call

our Customer Service Department.

To place orders, use a Master

Card or Visa and call our Customer Service Department:

LIFETIME PRODUCTS, INC.

P.O. BOX 160010

BLDG. D-11, FREEPORT

CENTER

CLEARFIELD, UT 84016-0010

1-800-225-3865

11

12

ADJUSTING

SYSTEM HEIGHT

Lower

Raise

TO RAISE:

pull trigger, then slide the handle

down. (SEE ILLUSTRATION)

TO LOWER:

pull trigger, then slide the handle

up. (SEE ILLUSTRATION)

Grip handle and

Grip handle and

CAUTION

WATCH FOR

PINCH

POINTS

CUSTOMER SERVICE

(USA/CANADA ONLY)

1-800-225-3865

#F028011

WARNING

• Failure to comply with these warnings could

result in broken bones, cuts, nerve damage,

spinal cord or brain injury, or death.

• Keep hands away from all moving parts while

raising or lowering the rim.

• DO NOT HANG FROM ANY P ART OF THE UNIT,

including the backboard, support braces, rim,

or net.

• DO NOT allow children to adjust the unit.

• DO NOT slide, climb, or play on the pole.

• Keep organic material away from the pole

base. Grass, litter, etc. could cause corrosion

and/or deterioration.

• Check pole system twice a year for signs of

corrosion (rust, pitting, chipping) and repaint

with exterior enamel paint. If rust has

penetrated through the pole or any component,

replace damaged parts immediately.

• Check the unit before each use for stability.

• Inspect unit before each use for loose hardware, excessive wear and signs of corrosion.

Repair before use.

• Use caution when performing dunk-type

activities on this unit.

• All players must wear a mouth guard while

playing close to the net. During play, use

extreme caution to keep each player's face

away from the backboard, rim and net.

•Never play on damaged equipment.

• DO NOT wear jewelry (rings, watches,

necklaces, etc.) while using the system.

Serious personal injury may occur if jewelry is

caught on rim or net.

OWNERS MUST ENSURE THAT ALL PLA YERS

KNOW AND FOLLOW THESE RULES FOR SAFE

OPERATION OF THIS UNIT.

POLE CARE AND SYSTEM MAINTENANCE

The life of your basketball system depends on many variables. The climate, exposure to corrosives such as

salt, pesticides, or herbicides, and excessive use or misuse can all contribute to pole failure, which may

cause property damage or personal injury.

Check your basketball system frequently for loose hardware, excessive wear, and signs of corrosion. For safety

reasons, and to prolong the life of your basketball system, you must take the following preventive measures.

a. Check all Nuts and Bolts. If any are loose, tighten them.

b. Check all parts for excessive wear and tear. If necessary, replace any parts that have been worn or damaged

through usage. Check the Pole Cap for cracks or tears that could let water into the pole. Contact our

Customer Service Department for replacement parts.

c. Inspect the Warning Sticker on the pole. If it is ripped, faded, or illegible, call our Customer Service

Department to request a replacement Sticker.

d. Check all pole sections for visible rust or chipped or cracked paint. If either are present, do the following:

1. Use an emery cloth to completely remove any rust or chipped paint.

2. Clean the area with a damp cloth and allow it to dry.

3. Apply two coats of a rust preventative, high gloss enamel paint to the area. Allow the paint to dry

between coats.

IF RUST HAS PENETRATED THROUGH THE POLE ANYWHERE, REPLACE IT

IMMEDIATELY!

Basketball Equipment

5-Year Limited Factory Warranty

Lifetime Products, Inc. reserves the right to make substitutions to warranty claims if parts are unavailable or obsolete.

1. Lifetime basketball systems are warranted to the original purchaser to be free from defects in material and workmanship for a period of five years from the date

of original retail purchase. The word "defects" is defined as imperfections that impair the use of the product. Defects resulting from misuse, abuse or negligence

will void this warranty. This warranty does not cover defects due to improper installation, alteration or accident. This warranty does not cover damage caused by

vandalism, rusting, "acts of nature" or any other event beyond the control of the manufacturer.

2. This warranty is nontransferable and is expressly limited to the repair or replacement of defective basketball equipment. If the equipment is defective within the

terms of this warranty, Lifetime Products, Inc. will repair or replace defective parts at no cost to the purchaser. Shipping charges to and from the factory are not

covered and are the responsibility of the purchaser. Labor charges and related expenses for removal, installation or replacement of the basketball system or its

components are not covered under this warranty.

3. This warranty does not cover scratching or scuffing of the product that may result from normal usage. In addition, defects resulting from intentional damage,

negligence, unreasonable use or hanging from the net or rim will void this warranty.

4. Liability for incidental or consequential damages is excluded to the extent permitted by law. While every attempt is made to embody the highest degree of safety

in all equipment, freedom from injury cannot be guaranteed. The user assumes all risk of injury resulting from the use of this product. All merchandise is sold on

this condition, and no representative of the company may waive or change this policy.

5. This product is not intended for institutional or commercial use; Lifetime Products, Inc. does not assume any liability for such use. Institutional or commercial use

will void the warranty.

6. This warranty is expressly in lieu of all other warranties, expressed or implied, including warranties of merchantability or fitness for use. Neither Lifetime

Products, Inc., nor any representative assumes any other liability in connection with this product.

ALL WARRANTY CLAIMS MUST BE ACCOMPANIED BY A SALES RECEIPT.

REPORT PRODUCT DEFECTS IN WRITING TO:

Lifetime Products, Inc., PO Box 160010, Bldg. D-11, Clearfield, UT 84016-0010 or call (800) 225-3865, M-F 8 a.m. to 5 p.m. MST.

Please include your dated sales receipt and photographs of damaged parts.

TO REGISTER YOUR PRODUCT, VISIT OUR WEBSITE AT

WWW.LIFETIME.COM

13

14

®

To register your product, visit our website at

www.lifetime.com

®2002 Lifetime Products

PO Box 160010

Freeport Center, Bldg. D-11

Clearfield, UT 84016-0010 USA

Loading...

Loading...