Page 1

LIFEFITNESS.COM

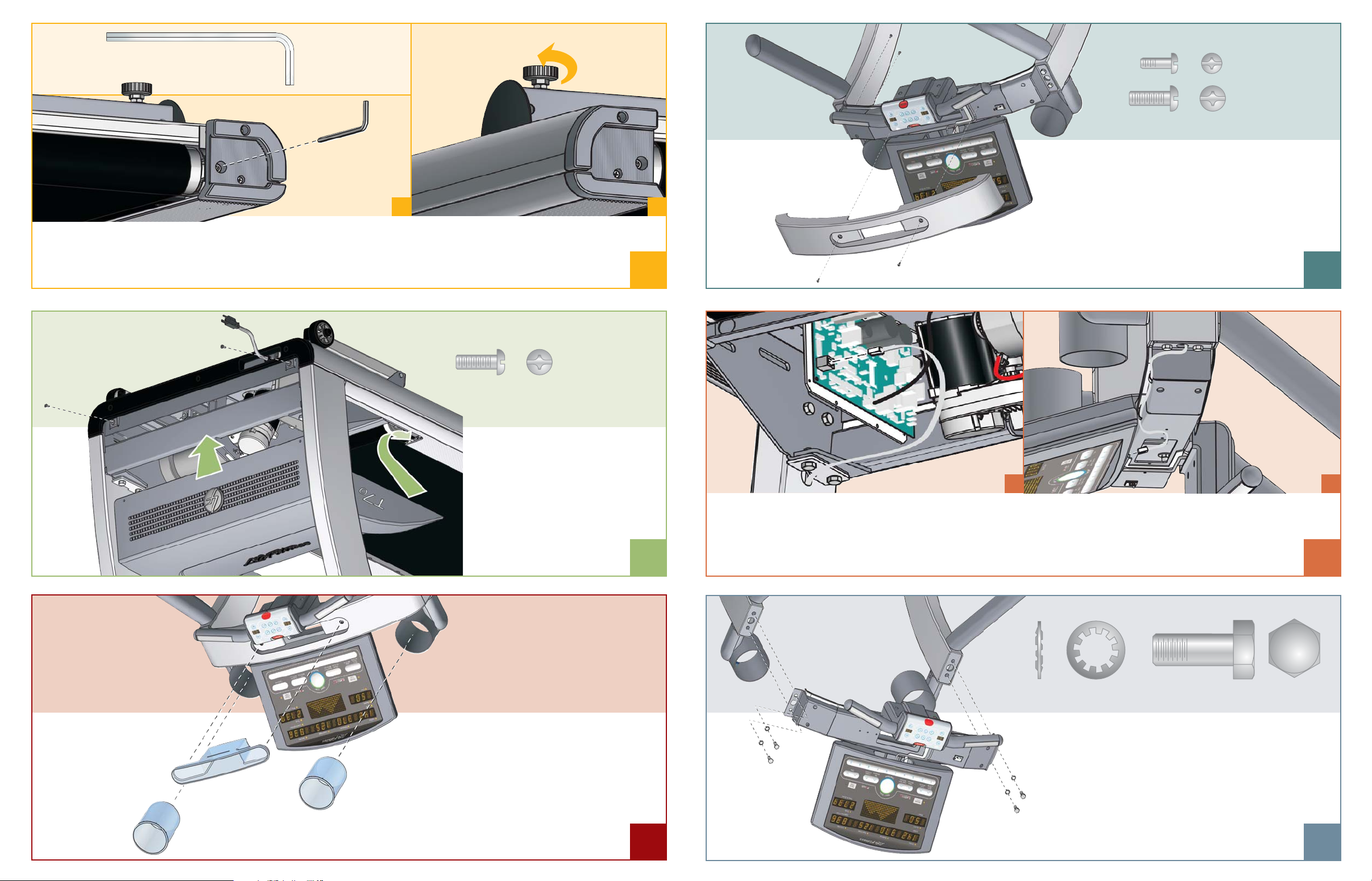

© 2005 Life Fitness, a division of Brunswick Corporation. All rights reserved. Life Fitness is a trademark of Brunswick Corporation. CO-039-05 (09.05)

OK59-01311-0000

Actual Size

B

A

Hardware Needed

Finger tighten the (8) bolts at this time.

the procedure to attach the right upright.

internal tooth washers as shown. Repeat

using (4) M10 x 25mm bolts and (4) M10

Bolt the left upright to the treadmill base

3

T

Where does your workout take you?

LIFECYCLE EXERCISE BIKES | TREADMILLS | TOTAL-BODY ELLIPTICAL CROSS-TRAINERS | STAIRCLIMBERS | GYM SYSTEMS

Life Fitness offers a full line of premier fitness equipment for the home.

E 1 Hex key wrench

D 4 #6 x 3/8" long phillip screws

C 2 #10 x 1/2" phillips self tapping screws

B 12 M10 internal tooth star washers

A 12 M10 x 25mm long hex head bolt

Item Qty Description

Check the Hardware List

B

Series

T

motor cover and screws aside.

cover from the back clips. Set the

it forward, detaching the motor

front of the motor cover and slide

front of the treadmill base. Lift the

the front of the motor cover to the

Remove the (2) screws securing

2

Warning: Do not lift treadmill by console.

Warning: Do not lift treadmill with forklift.

rear tread roller and wheel forward off of the bottom box.

Tear down front lip of bottom box. Lift the treadmill by the

uprights and console bridge and remove plastic wrapping.

Remove the top of the cardboard box. Pull out the console

A

1

Treadmill User Manual: T5-0, T5-5, & T7-0

ASSEMBLY INSTRUCTIONS

Page 2

page in

E

How to Center the Striding Belt

Hardware Needed

B

A

section of the user manual (B).

How To

the

If necessary, use the provided hex key wrench to center the striding belt. See

Level the treadmill using the leveling feet (A). Once the treadmill is level, lock the feet in place with the jam nuts.

9

Actual Size

C

Actual Size

D

C

Hardware Needed

over tighten them.

Tighten the screws securely but do not

covers before tightening the screws.

to align the edges of the top and bottom

to the bridge/console assembly. Be sure

from the bottom, secure the bridge cover

the top and (4) #6 x 3/8 Phillips screws

Using (2) #10 x 1/2" Phillips screws from

6

Hardware Needed

over tighten them.

screws securely but do not

removed screws. Tighten the

cover using the (2) previously

frame. Secure the motor

lower the front down to the

motor cover into the clips and

cover tilted upward, slide the

With the front of the motor

Re-install the motor cover.

8

B

Actual Size

A

as shown. Feed any excess cable into the center hole of the right upright.

to the console board located at the bottom of the display console (A). Route the console cable through the cable clips

the cable jack to the motor controller board as shown (B). Connect the remaining cable jack (near the bridge assembly)

cable access hole as shown (B). Carefully pull approximately 18" of cable through the cable access hole and connect

Feed one end of the console cable down through the center hole of the right upright (A) and then out the bottom

5

AB

Hardware Needed

Press firmly to ensure they are fully seated.

into their respective locations as shown.

Insert the water bottle holders and CD tray

7

(from step 3) securely.

Now tighten the bottom (8) upright bolts

Tighten the (4) bolts securely.

(4) M10 internal tooth washers as shown.

uprights using (4) M10 x 25mm bolts and

Bolt the bridge/console assembly to the

4

Loading...

Loading...