Page 1

Models TFP3000, TFPC3000, TFP3000HEPA, TFPC3000HEPA

Exhaust

Air

Supply

Air

Operation and Installation Manual

Console Portable Models

TFPC3000 and TFPC3000HEPA

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

TFP Questions & Answers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Materials Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Preferred Installation Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

LEAVE MANUAL FOR HOMEOWNER

NOTE: Due to ongoing research and product development, specifications, ratings and dimensions are subject to change without notice.

Whole House Models

TFP3000 and TFP3000HEPA

Type 1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Type 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Type 3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-10

Operating Instructions and Annual Check-up . . . . . . . . . . . . . . .11

Medical prescription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

TFP-3000

0108

Page 2

Overview

Exhaust Air

Supply Air

TFP

Collector

TI-127TFP

Part #65-503

TFP

Collector

TI-127TFP

Part #65-503

Primary TFP Collector

Replace collector

annually

Secondary TFP Collector

Replace collector

every 2 years

(Due to the performance

characteristics of the

TFP collector, the secondary

collector needs to be

replaced only every

2 years)

HEPA

F

ilt

er

TI-128HEPA

P

art

#

6

5-502

TFP

Collector

T

I-127TFP

P

art #6

5-503

Replace collector

annually

Replace filter

every 3 years

(Due to the performance

characteristics of the

TFP collector, the Hepa

filter only needs to be

replaced every 3 years)

60-TFPC-3000

CAUTION/ATTENTION

BLUE

BLACK

BLACK

BLACK

G

Neutral WHITE

Line BLACK

Ground GREEN

HIGHSPEED

OFF

LOW SPEED

DEFOND

SWITCH

120VAC

60Hz

FANMOTOR

1

2

3

TRANSFORMER

TERMINALBLOCK

BLACK

WHITE

RED

BLUE

WHITE

RED

BLACK

BLACK

BLUE

RED

WHITE

WHITE

WHITE

BROWN

G

GREEN/YELLOW

370V50/60HZ

CAPACITOR

10

UF

TFPCONSOLE MODEL

WIRINGDIAGRAM

Exhaust

Air

Supply

Air

ModelTFPC3000

TFP

Collector

T

TFP

Collector

T

Wash prefilter (foam)

every6months

Primary TFP Collector

Replace collector

annually

SecondaryTFPCollector

Replace collector

every2years

(Duetotheperformance

characteristics of the

TFPcollectorthesecondary

collector needs to be

replaced only every

2years)

Rubber mounting

pads forTFPC

tostand on

Exhaust

Air

Supply

Air

ModelTFPC3000HEPA

HEPA

F

ilt

er

TFP

Collector

T

Replace collector

annually

Replace collector

every3years

(Duetotheperformance

characteristics of the

TFPcollectortheHepa

filter only needs to be

replaced every 3 years)

CONSOLE

MODEL

6

0-TFPC-3000

CAUTION /ATTENTION

B

LUE

B

LACK

B

LACK

B

LACK

G

N

eutral

W

HITE

L

ine

B

LACK

G

round

G

REEN

H

IGH SPEED

OFF

LOW SPEED

DEFOND

SWITCH

120 VAC

6

0Hz

FAN MOTOR

1

2

3

T

RANSFORMER

T

ERMINAL BLOCK

B

LACK

W

HITE

R

ED

B

LUE

W

HITE

RED

BLACK

B

LACK

B

LUE

R

ED

W

HITE

WHITE

W

HITE

B

ROWN

G

G

REEN/YELLOW

3

70V~50/60H

Z

C

APACITOR

1

0

UF

T

FPCONSOLE MODEL

W

IRING DIAGRAM

E

xhaust

A

ir

S

upply

A

ir

M

odel TFPC3000

T

FP

Collector

T

T

FP

Collector

T

W

ash prefilter (foam)

every 6 months

Primary TFP Collector

R

eplace collector

a

nnually

S

econdary TFP Collector

R

eplace collector

every2years

(

Due to the performance

c

haracteristics of the

TFP collectorthe secondary

c

ollector needs to be

r

eplaced only every

2

years)

Rubber mounting

p

ads for TFPC

t

ostand on

Exhaust

A

ir

S

upply

A

ir

M

odel TFPC3000HEPA

HEPA

F

ilte

r

TFP

C

ollector

T

R

eplace collector

annually

R

eplace collector

e

very3years

(Due to the performance

characteristics of the

TFP collectorthe Hepa

f

ilter onlyneeds to be

r

eplaced every 3 years)

C

ONSOLE

MODEL

Exhaust Air

Supply Air

Rubber mounting

pads for TFPC to

stand on

Rubber mounting

pads for TFPC to

stand on

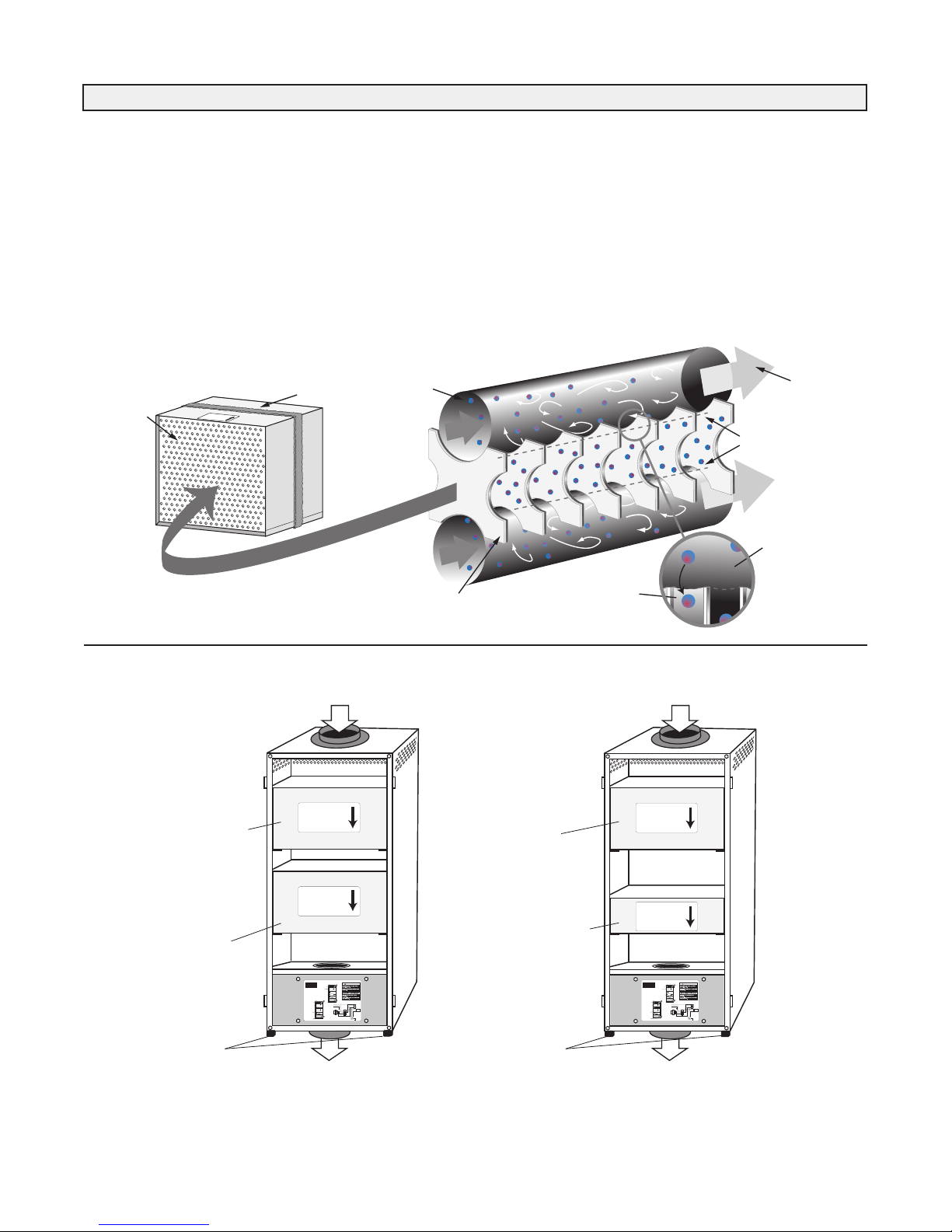

Particles are forced out into

areas of no turbulence... and stay

there because there is no airflow

Fabric particle collector

and aluminum spacer panels

Particles in

airstream

Velocity fluctuations

force particles to areas

of no flow

No airflow between

these lines

Clean air

The Turbulent Flow Precipitation Principle

Turbulent

airflow

Turbulent

airflow

T

F

P

C

o

l

l

e

c

t

o

r

P

ar

t

#

6

5

5

0

3

Fabric particle

collector and

aluminum

spacer panels

Foam gasket

Magnified detail of collector panel

TFP3000 Flow Thru Collector

The Li fe br ea th TFP A ir C le an er uses "Turbulent Flow

Precipitation" to remove th e millions of dangerous air borne

particles in your home. This technology is based on the Dullien

Principle which removes tiny airborne particles which enter the

lungs and can cause respiratory problems.

The quiet operating unit has a 2-speed selector switch, along with

a high efficiency fan motor, and a foil faced insulated cabinet that

is easy to clean.

TFP

2

TFP HEPA

Page 3

InstallationOverview

TFP (Turbulent Flow Precipitator) Technology removes health

threatening particles from the air far more effectively than most

other residential cleaners. It operates continuously at maximum

efficiency without the need for constant adjustment and cleanout.

Unlike some air cleaners, it introduces absolutely no ozone into

your home. It cleans the air throughout your home, benefiting all

the family, all the time. The TFP allows air to circulate freely,

without putting any extra load on your air distribution system.

TFP Questions & Answers

Why do I need a TFP Air Cleaner?

The air in today's homes is 3 to 5 times more polluted than outdoor

air creating health problems such as asthma, allergies, headaches,

and fatigue for the home's occupants. The Lifebreath TFP Air

Cleaner will remove 99% of these polluting particles from your

home creating a clean and comfortable environment for you and

your family.

Will I notice a difference in the amount of dust in

my home?

We have received numerous testimonials from satisfied customers

attesting to the significant drop in dust found in the homes where a

TFP is installed.

Does the TFP generate harmful ozone?

The TFP series is an induced airflow system which requires no

electric charge.

Is the TFP a patented unique technology or just

another filter?

Airia Energy Systems hold the patent for this TFP technology.

The TFP series are the only one of its kind.

How much maintenance is involved? How often do

the filters need to be replaced?

As tested under average household dust loading, the TFP should

be inspected annually. Typically the primary collector should be

replaced annually and the secondary collector should be replaced

every 2 years.

Location

The TFP should be installed in a conditioned space with easy

access for maintenance and an annual check up. A TFP is usually

installed in a basement area where air flow noise will be negligible

to the occupants.

Materials Supplied

1 TFP

4 Mounting Brackets

4 Hanging Straps

2 Collar Connections

4 Port Collar Screws

8 Mounting Bracket Screws

4 Pieces of Mounting Foam

1 Set of Installation/Operating Instructions

1 Wiring Diagram

1 Warranty Card

Preferred Installation Options

There are three basic installation options. Select the best method

for your needs.

1. TFP to a Forced Air System; use Return/Return Method

(horizontal or vertical TFP installation)

2. TFP to a Fully Dedicated HRV System

- recommended when you wish to clean the incoming air from

the HRV

3. Stand Alone System – recommended for homes without forced

air systems (ie. radiantly heated homes).

Options

Optional Installation Kit: Part# 99-7TFP

Includes:

– two 7” Duct Connection Collars

– 12.5’ of 7” Duct

– four Nylon Duct Zip Ties

3

Page 4

info@lifebreath.com

Note:

Minimum 16"

(406 mm) required

for ser vice

All duct connections are 7" (178 mm)

OFF/LOW/HIGH

SWITCH

3

4.25"

870 mm

1

4.5"

368 mm

1

4.75"

375 mm

16"

406 mm

F

RONT

S

IDE

END

Exhaust

Air

Supply

Air

C

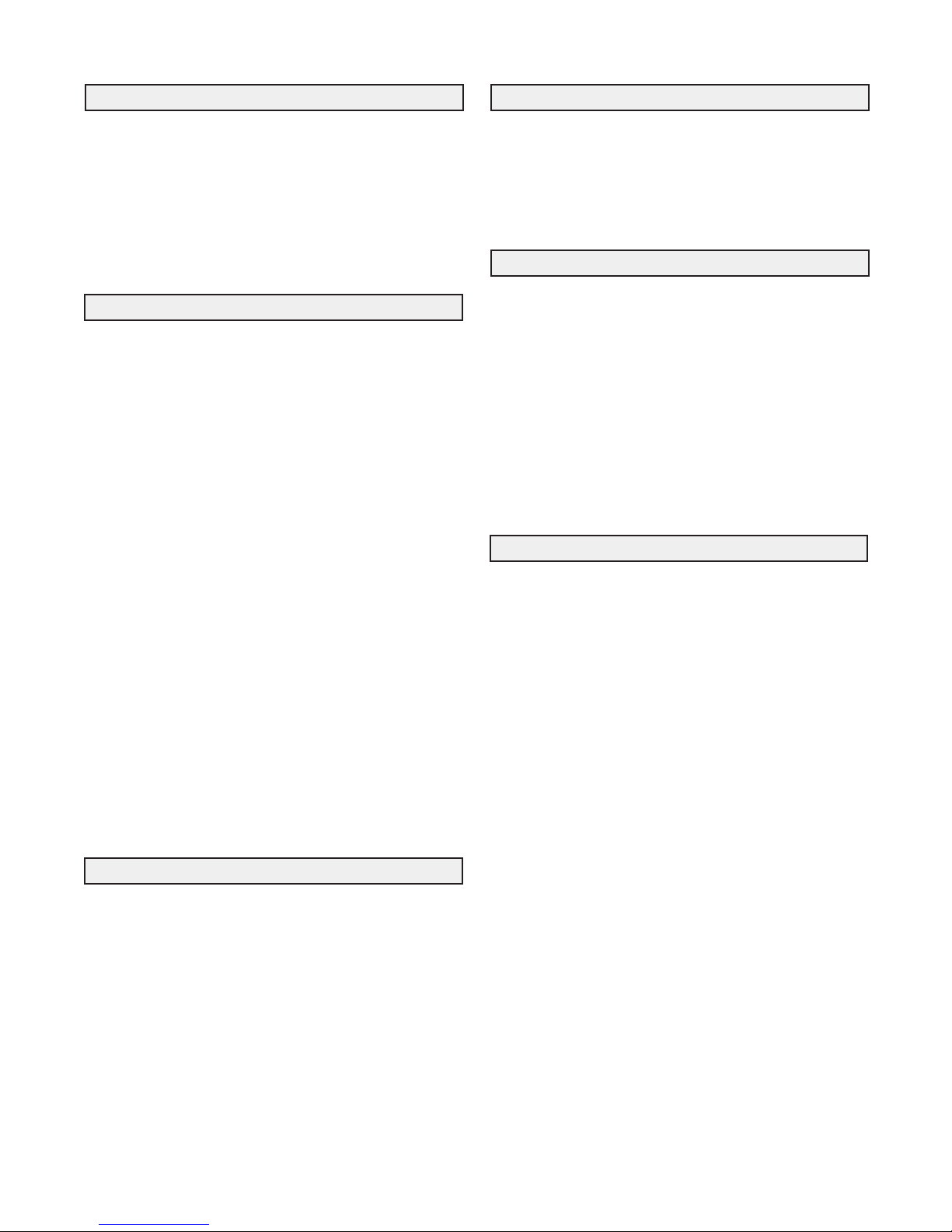

Specifications TFP3000 and TFPC3000

Motors and Blowers

2 speed, high efficiency PSC Motor - 150 cfm/75 cfm.

110 watts - 120 VAC - standard three prong plug to receptacle.

The TFP is equipped with a standard power supply on 5’5”

(1.6 meters) cable.

OFF/LOW/HIGH Speed Selector Switch

Select 75 cfm (Low) or 150 cfm (High).

Airflow

150cfm @ .4" WC (High Speed)

75 cfm @ .4" WC (Low Speed)

Collectors

Model TFP3000 - Two replaceable TFP collectors

Model TFPC3000 CONSOLE - Two replaceable TFP collectors

• Easy to remove for cleaning and replacement

• Annual inspection recommended

Case

Twenty gauge prepainted galvanized steel (G60) for superior

corrosion resistance

Weight

55 lbs. (24.4 Kgs)

Electrical Codes

Conforms to CSA and UL standards

Mounting the Wholehouse TFP - very flexible

a. Mount to the furnace return

b. Mount between the HRV and the furnace

c. Hang from a joist and duct to the furnace

d. Stand alone installation

Warranty

Units carry a five year warranty on all replacement

parts except the collectors/filters.

Options

65-503R - One replacement TFP Collector

65-502R - One replacement HEPA filter

Optional Installation Kit: Part # 99-TFP

Includes - two 7” Duct Connection Collars

- 12.5’ of 7” Non-insulated Flex Duct

- four Nylon Duct Zip Ties

TFP3000

Model TFP 3000 & TFPC3000 Particle Capture Rate

• A human hair is 100

Particle Size Percentage

(microns) Caught

5 or more 99%

2 - 3 97%

1 95%

0.5 - 0.9 90%

microns wide.

• Spores and pollen

are all larger than 8

microns.

• A micron is 1/1000 of

a millimetre, or less

than 1/2 of 1/10,000

of an inch.

Console Portable

Model TFPC3000

Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#: _________________________________________

Submitted by: ____________________________________

4

Page 5

info@lifebreath.com

N

ote:

Minimum 16"

(

406 mm) required

for service

All duct connections are 7" (178 mm)

OFF/LOW/HIGH

SWITCH

34.25"

8

70 mm

14.5"

3

68 mm

14.75"

3

75 mm

1

6"

406 mm

FRONT

SIDE

E

ND

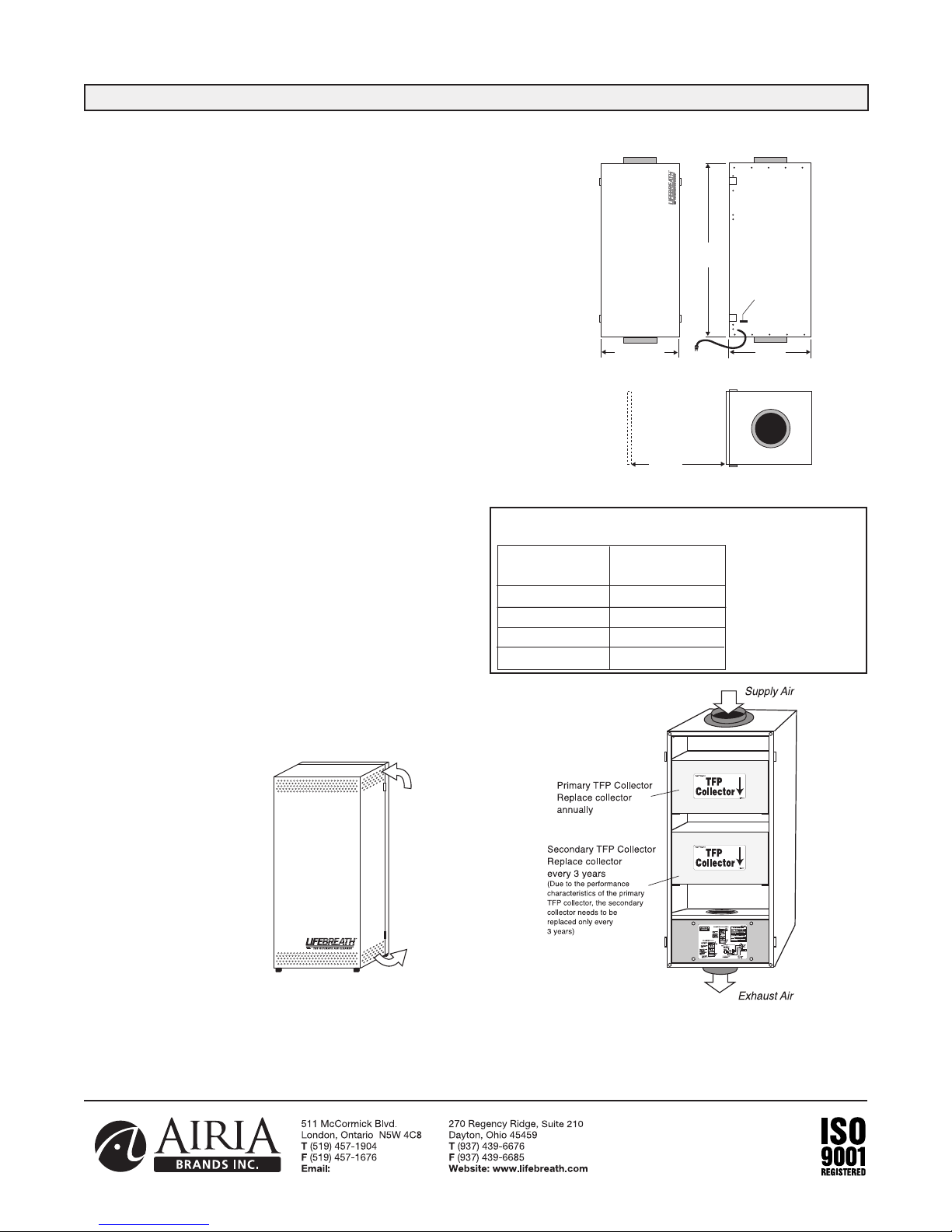

Specifications TFP3000HEPA and TFPC3000HEPA

Exhaust

Air

Supply

Air

Motors and Blowers

2 speed, high efficiency PSC Motor - 150 cfm/75 cfm.

110 watts - 120 VAC - standard three prong plug to receptacle.

The TFP is equipped with a standard power supply on 5’5”

(1.6 meters) cable.

OFF/LOW/HIGH Speed Selector Switch

Select 75 cfm (Low) or 150 cfm (High).

Airflow

150cfm @ .4" WC (High Speed)

75 cfm @ .4" WC (Low Speed)

Collectors

Model TFP3000 - One replaceable TFP collector and one

replaceable HEPA filter

Model TFPC3000HEPA CONSOLE - One replaceable TFP

collector and one replaceable HEPA filter

• Easy to remove for cleaning and replacement

• Annual inspection recommended

Case

Twenty gauge prepainted galvanized steel (G60) for superior

corrosion resistance

Weight

55 lbs. (24.4 Kgs)

Electrical Codes

Conforms to CSA and UL standards

Mounting the Wholehouse TFP - very flexible

a. Mount to the furnace return

b. Mount between the HRV and the furnace

c. Hang from a joist and duct to the furnace

d. Stand alone installation

Warranty

Units carry a five year warranty on all replacement

parts except the collectors/filters.

Options

65-503R - One replacement TFP Collector

65-502R - One replacement HEPA filter

Optional Installation Kit: Part # 99-TFP

Includes - two 7” Duct Connection Collars

- 12.5’ of 7” Non-insulated Flex Duct

- four Nylon Duct Zip Ties

TFP3000HEPA

Model TFP3000HEPA & TFPC3000HEPA Particle Capture Rate

Particle Size (microns) Percentage Caught

.3 or more 99.7%

• Model TFP3000HEPA - 99.97% efficient at .3 microns.

• A human hair is 100 microns wide.

• Spores and pollen are all larger than 8 microns.

• A micron is 1/1000 of a millimetre, or less than 1/2 of 1/10,000 of an

inch.

Console Portable

Model

TFPC3000HEPA

Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#: _________________________________________

Submitted by: ____________________________________

5

Page 6

Metal Hanging

Straps (Supplied)

& Mounting Bolts

7" Collar

Foam

Air

Cleaner

Return Air

Forced Air

Furnace

Return Air

Supply Air

TYPE 1 INSTALLATION - Option A Standard Design

The furnace fan and/or HRV must operate

continuously for Type 1 and Type 2 installations.

If they do not operate continuously, then

interlocking them electrically with the TFP is

acceptable. Consult a certified electrician.

ATTENTION

Figure 2

TFP Directly Connected to Forced Air Heating

System

1. Install 7” collar (provided) on top and bottom of TFP (Fig. 1).

Use (4) 8/32” X 3/8” screws (provided).

2. Remove protective backing from pieces of foam and stick

them to the 4 corners of the TFP on the side being mounted

against the plenum.

3. Remov e t he 4 m oun ting bolts from the back of the TFP

cabinet. (Fig. 1)

4. Attach top and bottom mounting brackets (provided) vertical to

the TFP cabinet and reinstall mounting bolts.

5. Lift the TFP into position. Edge of TFP must be positioned on

plenum to allow clearance needed for latches.

6. In stall the (4) 8/32” X 3/4” mounting sc rews (provided)

through the brackets and into position. Tighten and secure.

7. TFP should now sit securely against the plenum with the foam

in between.

8. Cut 2 - 7" holes in the return air plenum. Install ducting to join

TFP to the return air plenum (Fig. 2).

Figure 1

NOTE: Do not support the weight of the TFP on the duct.

Duct must be open and not pinched.

NOTE: Due to possible noise transfer through the duct system,

it may be preferable in some situations to hang the TFP a short

distance from the plenum, and connect by running flexible

duct in g between t he m. Four n yl on hanging st ra ps ar e

provided for this option.

6

Page 7

TYPE 1 INSTALLATION - Option B Horizontal Design

minimum 40 inches

ForcedAir

Furnace

Return Ai r

Supply Air

Air

Cleaner

The furnace fan and/or HRV must operate

continuously for Type 1 and Type 2 installations.

If they do not operate continuously, then

interlocking them electrically with the TFP is

acceptable. Consult a certified electrician.

ATTENTION

ForcedAir

Furnace

Return Ai r

Supply Air

Air

Cleaner

The furnace fan and/or HRV must operate

continuously for Type 1 and Type 2 installations.

If they do not operate continuously, then

interlocking them electrically with the TFP is

acceptable. Consult a certified electrician.

ATTENTION

Use Option B when Option A is not practical.

TYPE 1 INSTALLATION - Option C Vertical Design

Use Option C when Option A

is not practical.

7

Page 8

The room in which the “breathing T” is open

should be free of combustion equipment such as

gas hot water tanks and furnaces. If the “T”

must be exposed in these areas, a pressure test

(spillage or backdraft test) should be conducted

on the combustion equipment after everything is

installed.

CAUTION

TYPE 2 INSTALLATION To a Fully Dedicated HRV System

Breather Tube

(Standard

Galvanized

"Tee" Fitting)

Fresh Air

to House

Fresh Air

to House

Stale Air

from house

Air

Cleaner

HRV/ERV

Breather

Te e

Outdoors

Figure 3

TFP Connected to Heat Recovery Ventilator

Location

The TFP should be located in the main trunk of th e fre sh ai r to

house line, after the Heat Recovery Ventilator (HRV) and before

any branch lines. (Fig. 3)

Mounting

1. Locate mounting bolts (4) on side of TFP cabinet for vertical

hanging (Fig. 3) and remove.

2. Meas ure dist ance betwe en th e bolts and m ark i t on the

floor/header joist where the TFP is to be hung.

3. Fasten hanging straps to floor joists using wide head nails or

screws with washers.

4. Insert hanging bolts through prepunched holes in straps and lift

TFP into position. Tighten and secure bolts.

Ducting

1. Install (2) 7” collars (provided) on TFP cabinet with (8)

8/32” X 3/8” sheet metal screws provided.

2. The ducting between the TFP and the HRV, and between the

TFP and the main supply trunk line to the house, should be

kept as straight as possible.

3. A relief opening or breathing T is required to prevent pressure

differences.

4. A short piece (1-2 foot) of flexible ducting should be used on

both sides of the TFP (Fig. 3). This will reduce vibration and

noise transfer if present.

NOTE: Please refer to the HRV installation manual for proper

ducting of that appliance.

Breathing T

The “Breathing T” is designed to assist in neutralizing pressure

differences which can occur between the HRV and the TFP when

joined together. The “Breathing T” should be situated in an area

with suitable indoor air quality (IAQ). Avoid mechanical rooms

and workshops. If required, an external connection should be made

from the “Breathing T” to an area with suitable IAQ (the air

should be free of fumes, vapors, odors, or large airborne particles

etc.).

8

Page 9

TYPE 3 INSTALLATION Independent Duct System (No HRV)

This installation configuration is

recommended for homes without

forced air systems (i.e. radiantly

heated homes). The duct should be

sized and designed to achieve a

sweeping action from one end of the

home to the other. Considerations

may include strategic clean air

placement for allergy or asthma

sufferers.

Suggested Air Cleaner locations:

• Mechanical Room

• Attic (Extra consideration

is required to ensure heat loss

through duct work is minimized)

• Closet

Figure 4

TFP Independent Installation No HRV, Radiant

Heating System

Location

1. A TFP is usually installed in a basement area where air flow

noise will be negligible to the occupants.

2. A central location between the clean air supply grille and

return grille is recommended.

Mounting

Refer to “Mounting” under Type 2 Installations.

Ducting

1. Install ( 2) 7” collars (provided) on TFP cabinet with (8)

8/32” X 3/8” sheet metal screws provided (Fig.4).

2. Ducting will usually consist of one return with grille from one

side of the home, and one supply with grille at the opposite

end of the home (Fig. 4).

3. Ductwork should be no smaller than the size of

the port collars (7”) on the TFP.

4. Ductwork should be kept as short and straight as possible to

allow for good air circulation.

Note: For installations of more than one return or supply

(greater than .5 e.s.p.), it is often necessary to add an in-line

fan to the system as a booster.

9

Page 10

Ép

u

r

a

te

u

r

d

'

a

i

r

Bureau ou salle de classe

Espace climatisé

Air

Cleaner

TYPE 3 INSTALLATION Alternative Applications

Office or Classroom Application

Work Table Application

10

Page 11

Operating Instructions and Annual Check-up

Disconnect all power sources before attempting

any service.

CAUTION

Prescription

for

Health Care Product

PATIENT NAME

ADDRESS

PHYSICIAN NAME

ADDRESS

PHYSICIAN SIGNATURE

Your doctor has prescribed the use of an Air Cleaner

to aid in the relief of your medical condition.

For allowable tax deduction or insurance purposes, please

retain a completed copy of this form for your records.

TFP-03

Prescription

for

Health Care Product

PATIENT NAME

ADDRESS

PHYSICIAN NAME

ADDRESS

PHYSICIAN SIGNATURE

Your doctor has prescribed the use of an Air Cleaner

to aid in the relief of your medical condition.

For allowable tax deduction or insurance purposes, please

retain a completed copy of this form for your records.

TFP-03

Operating Instructions

It is recommended the unit run continuously to provide the full

benefits of particulate removal. Use the OFF/LOW/HIGH speed

selection switch to select high (150cfm) or low (75(cfm) speed.

Maintenance

Annual inspection is recommended for cleaning and replacement

of the Collectors/HEPA filter. Discard and replace the collectors

when requi red. Nor mally th e primary col lector i s r eplaced

annually and the secondary collector is replaced every 2 years.

As each home has differences o f s ize, occupancy, location,

infiltration rates and homeowner needs, it is hard to estimate when

the collectors will need to be changed.

The collectors will slide out. Some discolouration of the collector

medium can be expected and when loose dust falls from the

collector, it is time to replace it. Turn off the TFP, furnace fan and

HRV. Open the door and slide out the collectors to check buildup

Medical Prescription

and do an annual inspection of overall unit. Before replacing any

collectors, vacuum any dust inside the cabinet or surrounding area.

When replacing the collectors, make sure the directional arrows

are noted and the collectors are installed correctly. Close the door

and restart TFP, furnace and HRV fan.

When your TFP is installed with a forced air heating system you

are still required to use the recommended furnace filter. This may

be a good time to inspect this filter as well.

When new collectors are required, call your dealer.

Model TFP3000 - Two replaceable TFP collectors

Model TFP3000HEPA - 1 TFP Collector, 1 HEPA filter

The TFP may qualify for an insurance and/or a medical tax

deduction with a physician's prescription.

11

Page 12

Wiring Diagram

BLUE

BLACK

BLACK

BLACK

G

N

eutral

WHITE

Line BLACK

Ground GREEN

H

IGH SPEED

OFF

L

OW SPEED

DEFOND

S

WITCH

1

20 VAC

60 Hz

FAN MOTO R

1

2

3

TRANSFORMER

TERMINAL BLOCK

BLACK

WHITE

BLUE

WHITE

BLUE

BLACK

BLACK

BLUE

RED

WHITE

RED

G

GREEN/YELLOW

3

70V~50/60H

Z

C

APAC ITOR

10

UF

DOOR

SWITCH

RED

RED

BROWN

CAUTION /ATTENTION

info@lifebreath.com

12

Loading...

Loading...