Page 1

Installation Tools

• tin snips • large zip ties

• assorted screw drivers • fabric flexible duct

• electric drill - class II rated

• hammer • mastic tape

• wire strippers • alum. foil duct tape

• knife • zip ties

• caulking gun • 1/2” I.D. drain hose

• smoke pencil

Balancing Tools

• Pitot Tube Balancing Kit

[Case, 8 ft. vinyl tubing, Pitot tube,

magnehelic gauge (0 - 0.25”), and

mounting plate]

•

Pitot Tube with instructions

and Digital Manometer (with resolution of

0 - 0.25” - must read to 1/100ths of an inch)

Heat Recovery Ventilators (HRV) are designed to provide

fresh air while exhausting an equal amount of stale air.

The HRV is equipped with an aluminum core. The device

uses the stale air that is being exhausted to condition the

fresh air as it is being brought in.

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

Required Tools................................................................1

Application.......................................................................1

General ...........................................................................1

Table of Contents............................................................1

Engineering Data ............................................................2

Motorized Damper Assembly..........................................3

Clearances & Requirements ...........................................4

Installation....................................................................4-6

Electrical .........................................................................7

Dehumidistat Operation ..................................................8

Air Flow Balancing .....................................................9-10

Maintenance .................................................................11

Application

General

Table of Contents

Required Tools

* LEAVE FOR HOMEOWNER

NOTE: Due to ongoing research and product development, specifications,

ratings and dimensions are subject to change without notice.

TI-FAE-001

1207

MODELS 94-EXCHANGER, 94-EXCHANGER-MD, 99-MD-KIT

See page 3 for 99-MD-KIT installation instructions

ATTENTION

INSTALLATION INSTRUCTION FOR FRESH AIR EXCHANGER

Page 2

2

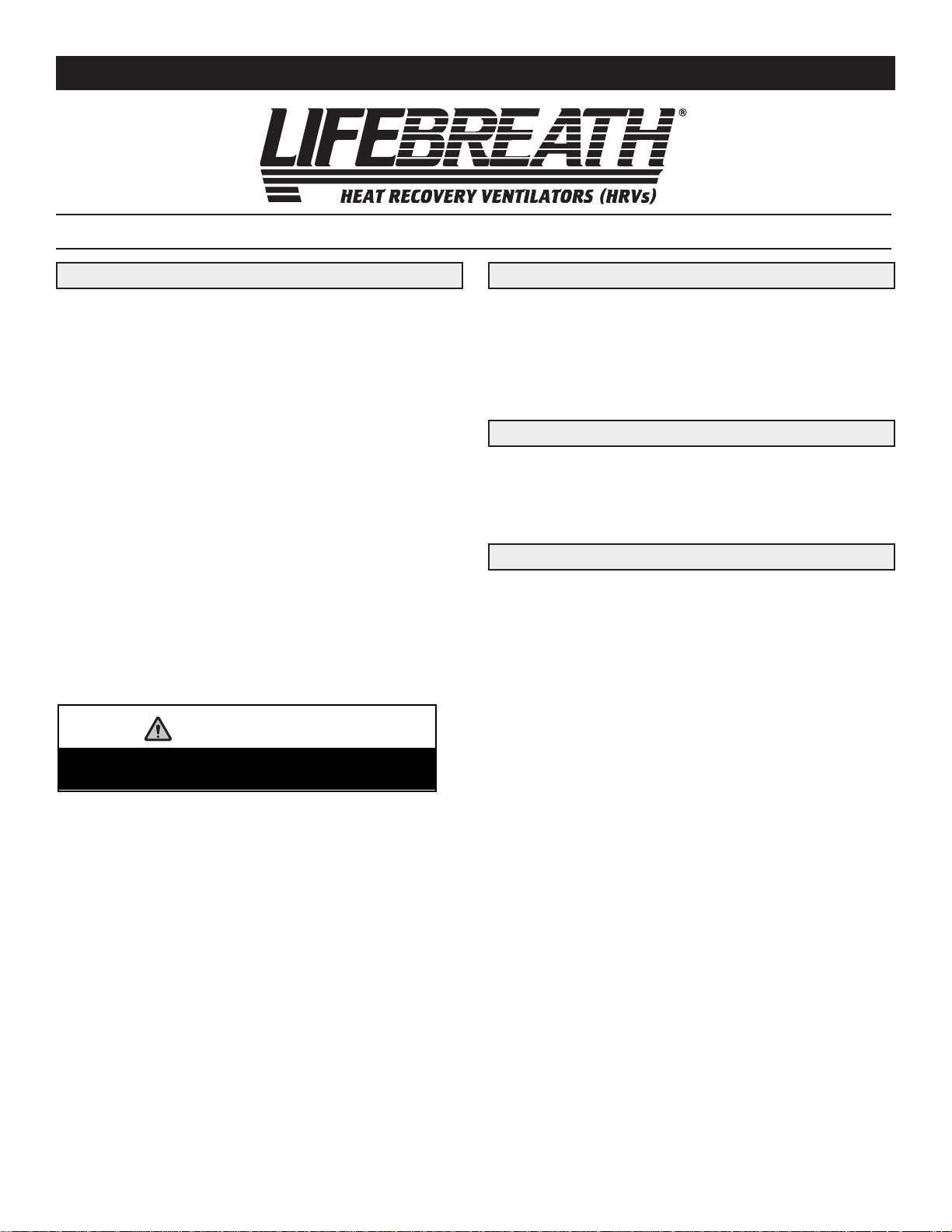

MODEL 94-EXCHANGER-MD - Includes 24 volt motorized damper

21.25"

(540 mm)

STALE AIR

TO OUTSIDE

FRESH AIR

FROM OUTSIDE

STALE AIR

FROM INSIDE

FRESH AIR

TO INSIDE

15"

(380 mm)

18.75"

(475 mm)

*All Duct Connections 6" (150mm)

FILTER

BALANCING

COLLARS

FILTER

ALUMINUM HEAT

EXCHANGE CORE

*NOTE: Front clearance

of 25 inches (635 mm)

is recommended

for servicing unit.

DRAIN

SPOUT -1/2" O.D.

(DRAIN TUBING - 1/2" I.D.)

TAP E

TO DRAIN

TEE

CONNECTOR

DRAIN

SPOUT - 1/2" O.D.

1204

Engineering Data - HRV

Dimensions HRV

inches (mm)

Dimensions HRV

inches (mm)

WARRANTY:

Lifetime warranty on Aluminum Heat Exchange Core.

Five year warranty on all other parts.

MODEL 94-EXCHANGER - No damper. Optional kit (99-MD-KIT) can be added

Typical airflow is between 0 cfm and 130 cfm.

Typical airflow is between 60 cfm and 130 cfm.

Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#: _________________________________________

Submitted by: ____________________________________

FILTER

FRESH AIR

FROM OUTSIDE

ALUMINUM HEAT

EXCHANGE CORE

STALE AIR

TO OUTSIDE

(DRAIN TUBING - 1/2" I.D.)

(540 mm)

24 VOLT MOTORIZED DAMPER

DRAIN

SPOUT -1/2" O.D.

TAP E

21.25"

TO DRAIN

TEE

CONNECTOR

FILTER

STALE AIR

FROM INSIDE

BALANCING

COLLARS

FRESH AIR

TO INSIDE

DRAIN

SPOUT - 1/2" O.D.

*All Duct Connections 6" (150mm)

15"

(380 mm)

18.75"

(475 mm)

*NOTE: Front clearance

of 25 inches (635 mm)

is recommended

for servicing unit.

Page 3

3

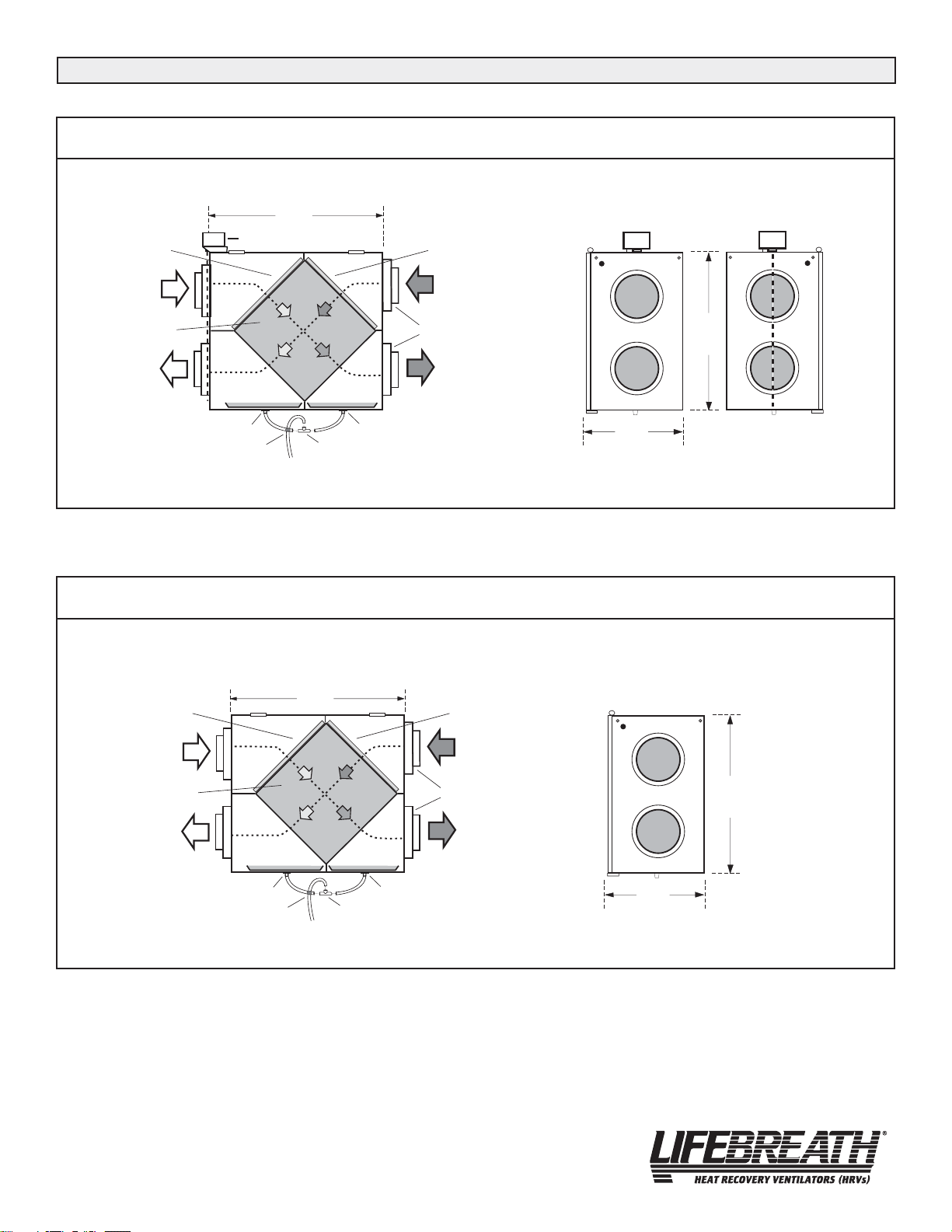

Motorized Damper Assembly

Mount the damper motor by aligning the four (4) holes in

the mounting plate to the four holes on the unit’s top plate.

This will automatically align the damper motor coupling

with the damper shaft.

Align the damper in the fully closed position. Using a 1/8”

Allen key to tighten the set screw.

Dampers should now be in the fully closed position with no

power. Identify desired wiring diagram in this guide.

Activating the damper motor should open flaps to 90˚.

Damper collar

Damper

door

1/8" Allen Key

Damper rod

Set

screw

Damper collar

Damper

door

Set

screw

Page 4

4

Location Selection

The HRV must be located in a heated space where it will

be possible to conveniently service the unit. Typically the

HRV would be located in the mechanical room or an area

close to the outside wall where the weather hoods will be

mounted. If a basement area is not convenient or does not

exist, a utility or laundry room may be used.

Attic installations are not normally recommended due to:

A) the complexity of work to install

B) freezing conditions in the attic

C) difficulty of access for service and cleaning

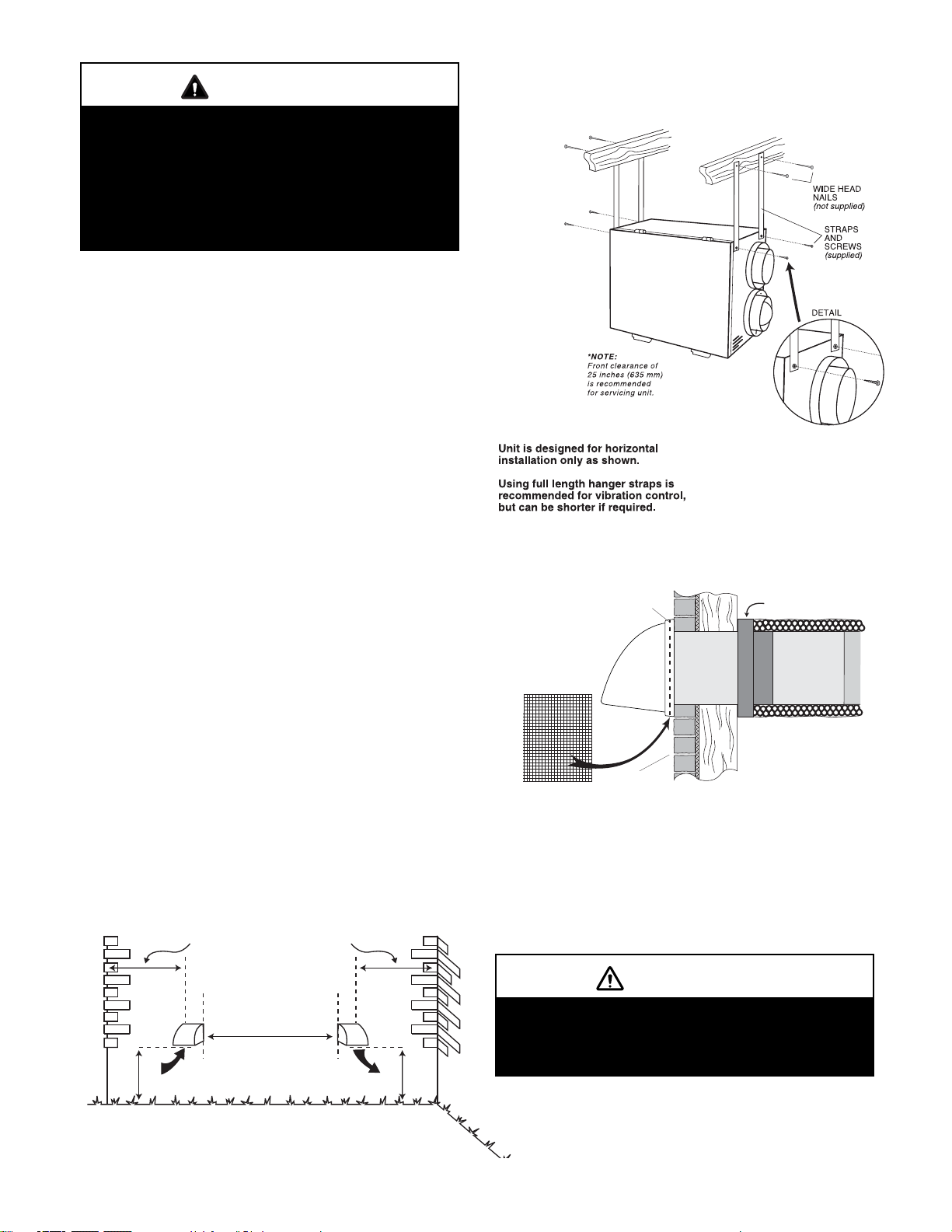

The HRV unit must be installed in a horizontal position as

shown in the illustration below. The unit should be suspended using the provided hanging straps. If necessary,

the unit may be installed on a platform: however, the cabinet should be isolated from the platform to prevent

vibration transmission. The unit must be level. Sufficient

clearance at the front of the access door is required for

servicing the air filters and core. A minimum of 25"

(635mm) clearance is recommended so the door can be

opened. Four PVC reinforced polyester hanging straps are

provided for hanging the HRV from the basement floor

joists.

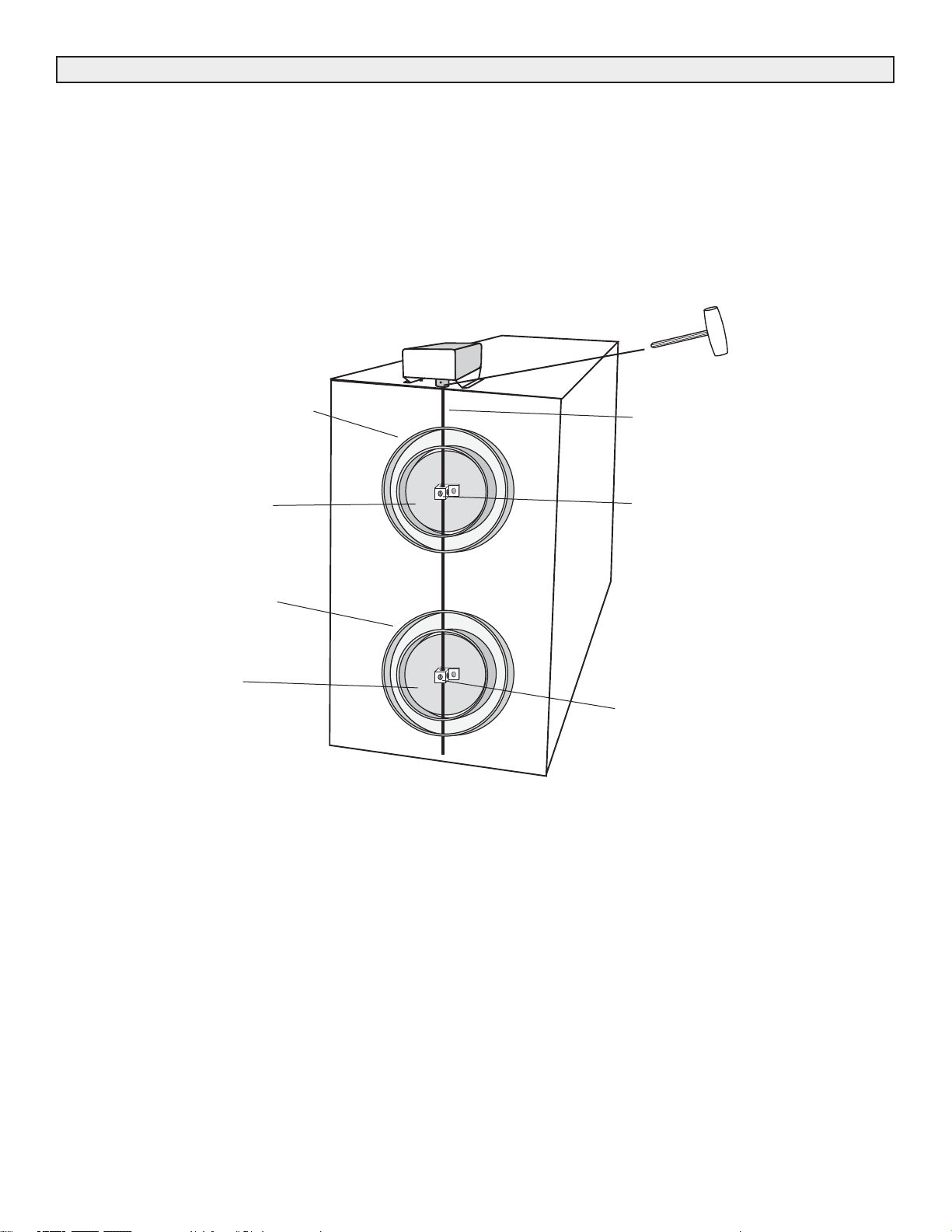

Suspending the Unit

The hanging straps should be attached to the unit at the

top end corners (mounting screws are already located on

the HRV case). Securely fasten the other end of the straps

to the floor joists with wide head nails (not supplied), making sure the UNIT IS LEVEL. The straps are designed to

reduce the possibility of noise, resonance or harmonics;

therefore using the full length of the strap between the

HRV and the floor joists is recommended.

Weather Hood Location and Installation

Weatherhood kit includes two fixed-cover hoods with a

1/4” (6mm) mesh screen.

Exhaust Weather Hood Requirements

• At least 6' (2 m) from the ventilation air intake*

• At least 18" (457mm) above ground or above the

depth of expected snow accumulation*

Installation

Connecting Appliances to the HRV

The following appliances should not be connected to the

HRV:

• clothes dryer

• range top

• stovetop fan

• central vacuum system

NOTE: Connecting any of these to the HRV will

invalidate your warranty.

Clearances and Requirements

WARNING

Before installation, careful consideration must

be given to how this system will operate if

connected to any other piece of mechanical

equipment, i.e. a forced air furnace or air handler,

operating at a higher static. After installation, the

compatibility of the two pieces of equipment

must be confirmed, by measuring the air flows of

the ventilator, by using the balancing procedure

found in this manual.

CAUTION

It is always important to assess how the operation

of any HRV may interact with vented combustion

equipment (i.e. Gas Furnaces, Oil Furnaces,

Wood Stoves, etc.)

NEVER install a ventilator in a situation where its

normal operation, lack of operation or partial

failure may result in the backdrafting or improper

functioning of vented combustion equipment!!!

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, personal injury or loss of life.

Installation and service must be performed by a

qualified installer or service agency.

WARNING

Electric shock hazard. Can cause

injury or death. Before attempting to

perform any service or maintenance,

turn the electrical power to unit OFF

at disconnect switch(es). Unit may

have multiple power supplies.

Lint, dust or grease will collect in the HRV

damaging the unit.

Page 5

5

• At least 3' (1 m) away from the corner of the building*

• At least 3’ away from gas meter, electric meter or a

walkway where fog or ice could create a hazard*

• Not into a garage, workshop or other unheated space

When installing the weather hood, its outside perimeter

must be sealed with exterior caulking.

* Local code may require greater distances.

Intake Weather Hood Requirements

• Should be located upstream (if there are prevailing

winds) from the exhaust outlet

• At least 6' (2 m) from the exhaust weather hood *

• At least 6' (2 m) away from dryer vents and air handler

exhaust (medium or high efficiency furnaces)*

• A minimum of at least 6' (2 m) from driveways, oil fill

pipes, gas meters, or garbage containers, swimming

pools*

• At least 18" (457mm) above the ground, or above the

depth of expected snow accumulation*

• At least 3' (1 m) from the inside/outside corner of the

building*

• Do not locate in a garage, attic or crawl space

* Local code may require greater distances.

Weather Hood Clearances

Suspending the Unit using the

Provided Hanging Straps

CAUTION

Weatherhood Installation

Unit must be installed level to ensure proper

condensate drainage. Due to the broad range of

installation and operational conditions,

consideration must be given for the possibility

of condensation forming on the unit or

connecting ducting. Objects below the

installation may be exposed to condensate.

OUTSIDE CORNER

36" (1m)

recommended min.

36" (1m)

recommended min.

INSIDE CORNER

SCREEN

(sideview)

12"galvanized

pipesupplied

EXTERIOR

1/4"(6mm)SCREEN

(frontview)

WALL

1. ThermalCollarslidesovergalvanized

sleeveofWeatherhood.

2. FastenThermalCollartoBelt.

3. SlidetheInsulatedFlexibleDuctingover

theWeatherhood'sgalvanizedsleeveand

fastenittotheThermalCollar.

4. Hoodishingedtoallowforeasyaccess

forcleaningofbirdscreen.

COLLARISSUPPLIEDTO

ENSUREVAPOURBARRIER

IS100%SEALEDTO

WALLPLATE

INTAKE

18" (460mm) min.

6' (2m)

recommended min.

EXHAUST

18" (460mm) min.

CAUTION

Weatherhood arrangement - requires a minimum of 6'

(2m) separation and a minimum of 18" (460mm)

clearance above the higher of the grade or anticipated

Page 6

6

Stale Air Exhaust System

The stale air exhaust system is accomplished by the positive pressure created in the furnace ducting. The air

handler blower must be running for this system to be

effective.

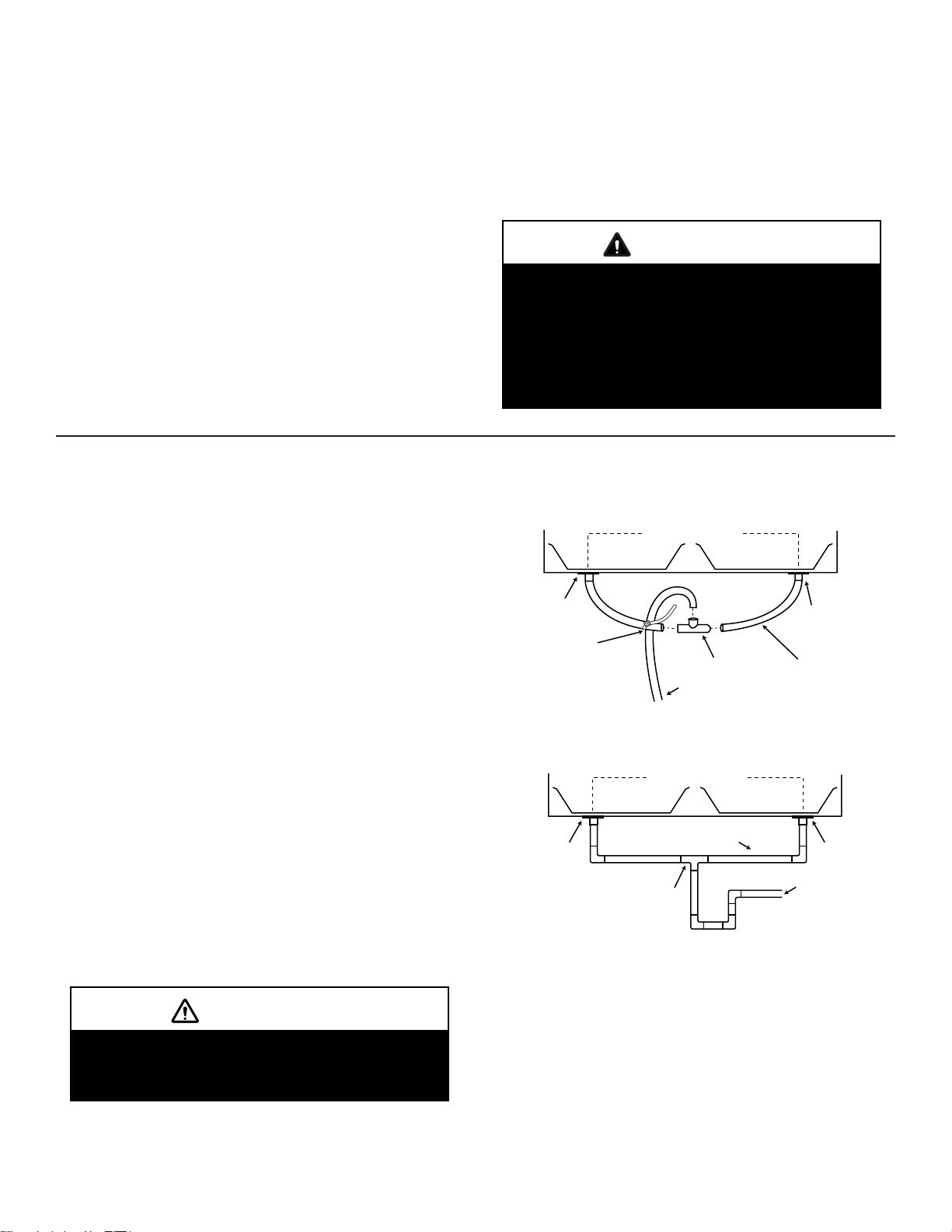

Drain Connection (HRV Only)

During a defrost cycle, the HRV may produce some condensation. This water should flow into a nearby drain, or

be taken away by a condensate pump.

The HRV cabinet has prepunched holes for the drain (see

below). Insert the drain spout through the hole in the drain

pan. Do not forget the “O ring” which seals each spout to

the pan. REMEMBER TO HAND TIGHTEN ONLY the

washer and lock nut which hold the drain spout in place.

Construct a P-Trap using the plastic tee connector. Cut

two lengths of hose and connect each piece to an end of

the “T” fitting, then connect the other ends to the two drain

spouts. Position the "T" fitting to point upward, andconnect

the drain line. Tape or fasten base to avoid any kinks. This

creates a “trap” which will hold some condensate and prevent odours from being drawn up the hose and into the

fresh air supply of the HRV.

"P" Trap (HRV only)

Note: Secondary drain pan may be required to

protect from condensate leakage.

Air Duct Design and Installation

A well designed and installed ducting system will allow the

HRV to operate at its maximum efficiency.

Always try to keep duct runs as short and straight as possible. See Installation Diagrams for various installation

options.

The inner and outer liners of the flexible insulated duct

must be clamped to the sleeve of the weather hoods (as

close to the outside as possible) and the appropriate port

on the HRV. It is very important that the fresh air intake

line be given special attention to make sure it is well

sealed. A good bead of high quality caulking (preferably

silicone sealant) will seal the inner flexible duct to both the

HRV port and the weather hood prior to clamping with a

large zip tie.

To minimize air flow restriction, the flexible insulated duct

that connects the two outside weather hoods to the HRV

should be stretched tightly and be as short as possible.

Twisting or folding the duct will severely restrict air flow.

See below for the recommended connection of flexible

insulated ducts to the the outside weather hoods and the

HRV.

WARNING

Include a short length of fabric flex duct or other

non-metallic connector in this hard ducted line

in order to keep the HRV separately grounded

(electrically) from the air handler. This will avoid

a possible shock hazard to service people if a

short to ground develops in one of the devices.

DRAIN HOSE PLUMBING

DRAIN PAN DRAIN PAN

DRAIN

SPOUT

ZIP TIE

HARD PIPE PLUMBING

DRAIN PAN DRAIN PAN

DRAIN

SPOUT

PRE-PUNCHED HOLES (2)

CONNECTOR

TO DRAIN

PRE-PUNCHED HOLES (2)

1/2" HARD PIPE

TEE

JOINT

TEE

DRAIN

SPOUT

1/2 " I.D.

DRAIN HOSE

DRAIN

SPOUT

TO DRAIN

CAUTION

The HRV and all condensate lines must be

installed in a space where the temperature is

maintained above the freezing point.

Page 7

7

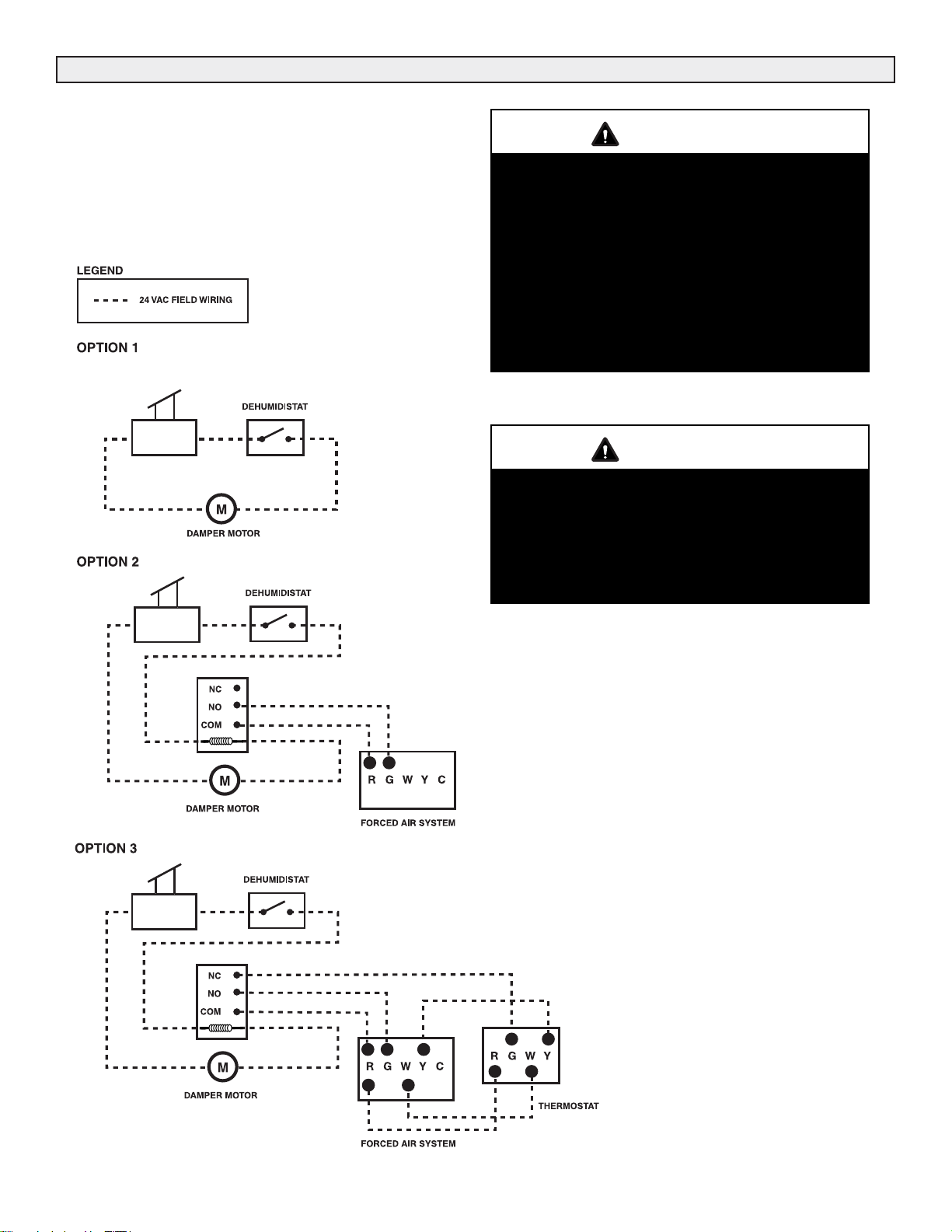

Remote Control Connections

Electrical connections should be made by a qualified service technician. Low voltage wires from the remote

controls are connected to the damper motor terminals.

Identify the appropriate installation type and connect as

per illustration.

Electrical - Model 94-EXCHANGER-MD ONLY

OPTIONAL

TRANSFORMER

120 VAC

24 VAC

OPTIONAL

TRANSFORMER

120 VAC

OPTIONAL

TRANSFORMER

120 VAC

OPTIONAL RELAY (SPST)

OPTIONAL RELAY (SPST)

WARNING

In order to prevent electric shock when cleaning

or servicing the HRV, it is extremely important to

confirm the polarity of the power line that is

switched by the safety (disconnect) switch. The

hot line (black) is the proper line to be switched.

To confirm the proper polarity, use a voltmeter

or test lamp to ensure there is no power after

the switch when the door is open. Check

between that point and ground (on the cabinet).

Always make sure that the HRV is properly

grounded.

WARNING

On older thermostats, energizing the R and G

terminals at the forced air system has the effect

of energizing the Y terminal at the thermostat

and thereby activating the cooling system. If you

identify this type of thermostat, you must use

option 3.

Page 8

8

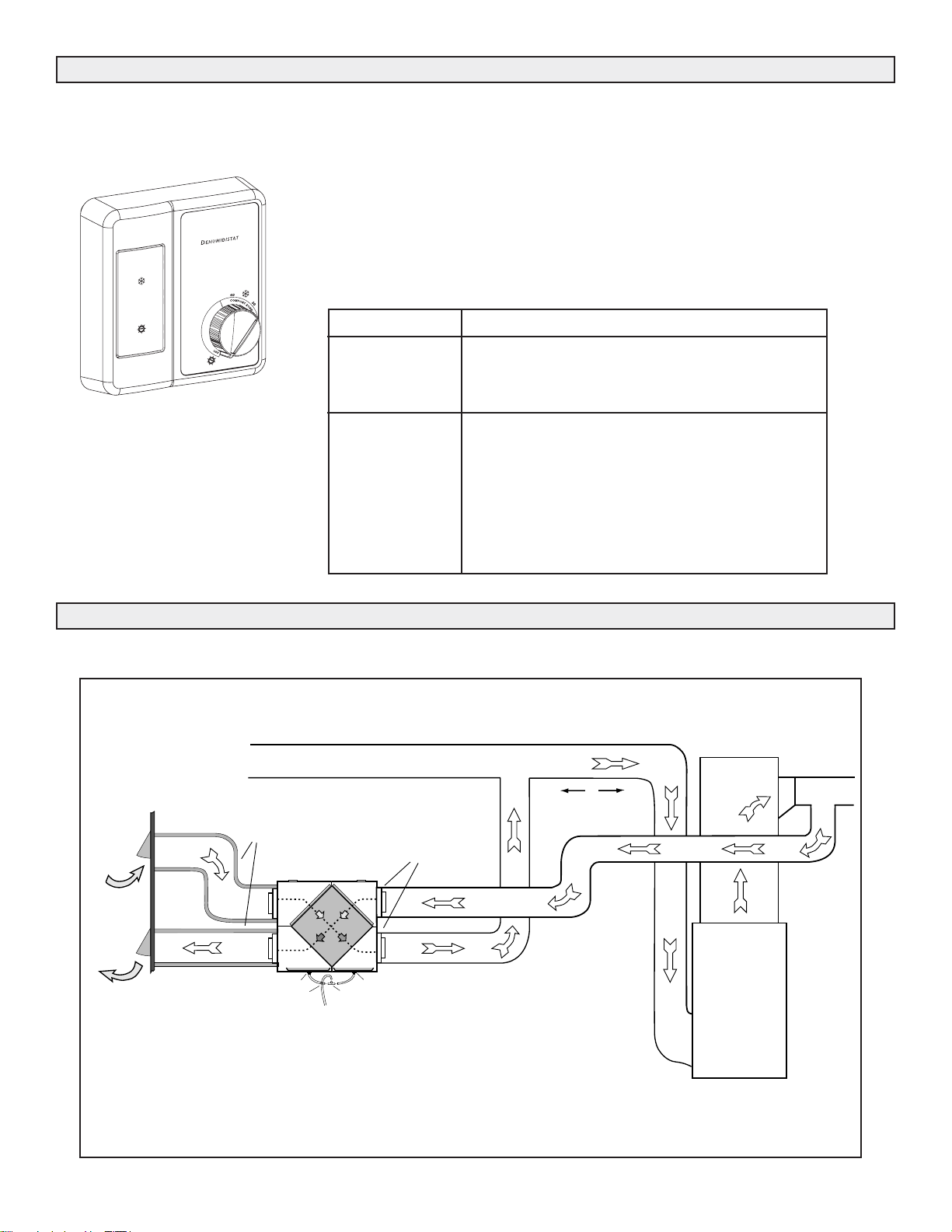

Installation

REMOTE DEHUMIDISTAT

*requires 2 wires

• anywhere humidity is a concern

• opens dampers to allow ventilation when humidity level exceeds

selected setting

Part No. 99-130

Dehumidistat Operation

Low Voltage - 24 VAC

PROBLEMS SOLUTIONS

Air is too dry • Increase humidity

• Switch ventilation mode from continuous

to intermittent

• Install a humidifier

Air is too humid • Reduce the humidity

• Verify if dryer is venting in basement

• Verify if heating wood is stored in basement

• Wait for outside temperature to change

Ex. Summer can be extremely humid

• Verify balancing of the HRV

• Run furnace blower continuously to increase

ventilation rate

tat

is

id

m

hu

e

D

e to

elativ

R

g

ettin

S

ns

itio

d

on

C

ide

ts

u

O

WINTER:

Set dehumidistat

between 30% to 40%.

If home is too dry,

adjust to higher setting.

If home is too humid,

adjust to lower setting.

SUMMER:

Set dehumidistat

to OFF.

Outdoors

NOTES:

1. Furnace blower is required to operate when ventilation is required.

2. Weatherhood arrangement is for drawing purposes only. Six feet (2 m) minimum separation required.

Eighteen inches (460 mm) above grade minimum.

3. Due to pressure differences in the equipment, airflows must be adjusted and confirmed on site.

4. Maintenance should be performed twice a year or more if required. Remove and wash filters and core and replace.

Outside hoods should be visually checked for blockage regularly.

5. Drain is required as shown above.

6. Built in balancing damper may require seasonal adjustments.

Insulated

Duct

DRAIN

SPOUT

TAPE

CONNECTOR

TO DRAIN

Built-in balancing damper*

in both air streams.

DRAIN

SPOUT

TEE

Return Air

3’

min.

recommended

Cool Air

*Unit is normally balanced with

furnace running at highest

operational speed

Return

Forced

Air

Furnace

Page 9

9

It is necessary to have balanced air flow in an HRV. The volume of air brought in from the outside must equal the volume

of air exhausted by the unit. If the air flow is not properly balanced, then:

• The HRV may not operate at its maximum efficiency

• A negative or positive air pressure may occur in the house

• The unit may not defrost properly

• Failure to balance HRV properly may void warranty

Excessive negative pressure

may have several undesirable

effects. In some geographic locations, soil gases such as

methane and radon gas may be drawn into the home through

basement/ground contact areas.

Read the Application Warning in Clearances & Requirements section of this manual!

Prior to balancing, ensure that:

1. All sealing of the duct system has been completed.

2. All of the HRV’s components are in place and

functioning properly.

3. Balancing dampers are fully open.

4. Unit is on HIGH speed.

5. Air flow in branch lines to specific areas of the house

should be adjusted first prior to balancing the unit. A

smoke pencil used at the grilles is a good indicator of

each branch line's relative air flow.

6. After taking readings of both the stale air to the HRV duct

and fresh air to the house duct, the duct with the lower

CFM ([L/s] velocity) reading should be left alone, while the

duct with the higher reading should be dampered back to

match the lower reading.

7. Return unit to appropriate fan speed for normal operation

8. A field-supplied balancing damper for the stale air side

is required for system balancing.

Balancing Procedure

The following is a method of field balancing an HRV using a

Pitot tube, which is advantageous in situations when flow stations are not installed in the duct system. Procedure should

be performed with the HRV on high speed.

The first step is to operate the air handler on high speed. This

will provide the maximum pressure that the HRV will need to

overcome, and allow for a more accurate balance of the unit.

Drill a small hole in the duct (about 3/16"), three feet downstream of any elbows or bends, and one foot upstream of any

elbows or bends. These are recommended distances but the

actual installation may limit the amount of straight duct.

The Pitot tube should be connected to a magnehelic gauge or

digital manometer capable of reading from 0 to 0.25 in. (0-62

Pa) of water, preferably to 3 digits of resolution. The tube

coming out of the end of the Pitot is connected to the high

pressure side of the gauge. The tube coming out of the

branch of the Pitot is connected to the low pressure or reference side of the gauge.

Insert the Pitot tube into the duct; pointing the tip into the air

flow.

For general balancing it is sufficient to move the Pitot tube

around in the duct and take an average or typical reading.

Repeat this procedure in the other (supply or return) duct.

Determine which duct has the highest air flow (highest reading on the gauge). Then damper that air flow back to match

the lower reading from the other duct. The flow should now

be balanced.

Actual air flow can be determined from the gauge reading.

The value read on the gauge is called the velocity pressure.

The Pitot tube comes with a chart that will give the air flow

velocity based on the velocity pressure indicated by the

gauge. This velocity will be in either feet per minute or meters

per second. To determine the actual air flow, the velocity is

multiplied by the cross sectional area of the duct being measured.

This is an example for determining the air flow in a 6" duct.

The Pitot tube reading was 0.025 inches of water.

From the chart, this is 640 feet per minute.

The 6" duct has a cross sectional area of

= [3.14 x (6"÷12)

2

]÷4

= 0.2 square feet

The air flow is then:

640 ft./min. x 0.2 square feet = 128 cfm

For your convenience, the cross sectional area of some com-

mon round duct is listed below:

DUCT DIAM. (inches) CROSS SECTION AREA (sq. ft.)

5 0.14

6 0.20

7 0.27

The accuracy of the air flow reading will be affected by how

close to any elbows or bends the readings are taken.

Accuracy can be increased by taking an average of multiple

readings as outlined in the literature supplied with the Pitot

tube.

Air Flow Balancing

CAUTION

Ensure balanced air flow in HRV. Excessive

positive pressure may drive moist indoor air into

the external walls of the building where it may

condense (in cold weather) and degrade

structural components. May also cause key

holes to freeze up.

WARNING

Ensure balanced air flow in HRV. Excessive

negative pressure may also cause the backdrafting of vented combustion equipment.

Page 10

10

Placement of Pitot Tube HRV

Pitot Tube and Gauge

Pitot Tube Air Flow

Balancing Kit

with magnehelic gauge,

Pitot tube, hose and

carry case.

NOTE:

Graphic is for illustrative purposes only.

Duct connection ports may vary.

NOTE: Apply use of balancing dampers as required.

AGNEHELIC

M

Outdoors

*Unit is normally balanced with

furnace running at highest

operational speed

Built-in balancing damper*

in both air streams.

C

I

L

E

H

E

N

G

A

M

Return Air

C

I

L

E

H

E

N

G

A

M

Cool Air

Return

Forced

Air

Furnace

Page 11

11

1. Inspect Exterior Hoods at least once a month.

Make sure exhaust and fresh air supply hoods are not

blocked or restricted by leaves, grass, or snow. In winter, it

is especially important to make sure snow is not blocking

the hoods or that frost has not built up on the wire mesh

(bird screen).

WARNING:

Blockage of hoods may cause an imbalance.

2. Clean Air Filters - Twice a Year

The standard filters equipped with your HRV are removable and washable.

a) simply open access door and slide core out

b) remove filter clips

c) once clips are removed filters can be taken off the

core to be rinsed with water or a combination of mild

soap and water. Do not clean in the dishwasher

d) to re-assemble, place clean filter(s) (wet or dry) back

into their positions against the core and return clips to

their original position

e) slide core back into its original position

3. Clean Core - Twice a Year

a) open access door

b) carefully grip ends of core and pull evenly outward.

-core may be snug, but will slide out of the channel

c) once removed from the cabinet remove filters

d) wash core in warm soapy water

(do not use dishwasher)

e) install the clean filters

f) install clean core

Note: Core installation label on the outer end of the core.

To install the clean core:

a) first mount the bottom flange of the core guide into the

bottom H channel approximately 1/4” (6mm)

b) mount the left or right side flange of the core guide

approximately 1/4” (6mm) followed by the other side

c) mount the top flange of the core guide into the top H

channel approximately 1/4” (6mm)

d) with all four corners in place and the core straight and

even, push hard in the center of the core until the core

stops on the back of the cabinet

NOTE: Core will appear to stick out from cabinet approximately 1/8” (3mm). This is designed this way so that the

access door will fit tight against the core.

4. Drain (condensate) Line - Clean Once a Year

Inspect drain line, drain spout and “P” trap for blockage,

mold or kinks. Flush with warm soapy water and replace if

worn, bent or unable to clean.

5. Clean Duct System if Required

The duct system running to and from the HRV may accumulate dirt. Wipe and vacuum the duct once every year.

You may wish to contact a Heating/Ventilation company to

do this.

6. General Maintenance - Twice a Year

Wipe down the inside of the cabinet with a damp cloth to

remove dirt, bugs and debris that may be present.

Maintenance HRV

Page 12

12

Date Maintenance Performed Contractor

Notes

Maintenance Record

Note: It is important to maintain this product regularly to ensure optimal performance.

Page 13

12

Date Entretien effectué Entrepreneur

Notes

Fiche d’entretien

Remarque : pour un fonctionnement optimal, il importe d’entretenir ce produit régulièrement.

Page 14

11

1. Inspectez les capuchons extérieurs au moins une

fois par mois

Vous devez vous assurer que les capuchons d’évacuation

de l’air vicié et d’admission de l’air neuf ne sont pas blo-

qués ou obstrués par des feuilles, de l’herbe ou de la

neige. En hiver, il est particulièrement important de veiller

à ce que la neige ne bloque pas ces orifices et à ce que la

gelée ne s’accumule pas sur le treillis métallique (grillage

pour les oiseaux).

AVERTISSEMENT :

L’obstruction de ces ouvertures peut

provoquer un déséquilibre du système.

2. Nettoyez les filtres à air deux fois par année

Les filtres à air standard dans votre VRC sont amovibles

et lavables.

a) Ouvrez simplement la porte d’accès et sortez le noyau

échangeur.

b Enlevez les pinces qui retiennent les filtres.

c) Une fois les attaches enlevées, vous pouvez sortir les fil-

tres du noyau pour les rincer simplement à l’eau ou bien

avec de l’eau savonneuse. Ne tentez pas de les nettoyer

dans un lave-vaisselle.

d) Après ce nettoyage, remettez les filtres (humides ou secs)

en place contre le noyau et remettez les pinces où elles se

trouvaient auparavant.

e) Remettez le noyau à l’endroit où il était.

3. Nettoyez le noyau deux fois par année

a) Ouvrez la porte d’accès.

b) Saisissez prudemment les extrémités du noyau et tirez

également vers l’extérieur. Même si le noyau vous semble

un peu serré, il vous sera possible de le sortir de sa

coulisse.

c) Une fois que vous l’avez sorti de l’armoire, enlevez les fil-

tres.

d) Lavez le noyau échangeur avec de l’eau savonneuse mod-

érément chaude. (Ne vous servez jamais du

lave-vaisselle).

e) Remettez les filtres propres en place.

f) Réintroduisez le noyau nettoyé.

Remarque :

L’étiquette d’installation du noyau doit être à

son extrémité extérieure.

Pour installer le noyau nettoyé :

a) Introduisez d’abord le rebord inférieur du guide-noyau

dans le profilé en H du bas, sur une distance d’environ 1/4

po (6 mm).

b) Insérez son rebord de gauche ou de droite environ 1/4 po

(6 mm), puis passez à l’autre côté.

c) Insérez le rebord supérieur du guide-noyau dans le profilé

en H du haut, environ 1/4 po (6 mm).

d) Lorsque les quatre coins sont bien en place et que le

noyau est droit et uniforme, poussez fortement dans le

centre du noyau, jusqu’à ce qu’il soit arrêté par l’arrière de

l’armoire.

REMARQUE :

Vous noterez que le noyau dépasse d’env-

iron 1/8 po (3 mm) hors de l’armoire. C’est là une

précaution pour que la porte d’accès soit bien ajustée

contre le noyau lui-même.

4. Nettoyez le tube d’évacuation (de condensation)

une fois par année

Examinez le tube d’évacuation, la goulotte d’égouttement

et le siphon en P, en cas d’obstruction, de moisissure ou

de tortillement. Rincez bien le tube avec de l’eau savon-

neuse modérément chaude. Remplacez-le s’il est trop

usé, faussé ou impossible à nettoyer.

5. Nettoyez les canalisations au besoin

Il pourrait y avoir une accumulation de saleté dans les

canalisations reliées au VRC. En plus de vous servir d’un

aspirateur, essuyez les canalisations une fois par année.

Vous pourriez aussi confier cette tâche à une entreprise

spécialisée en chauffage et climatisation.

6. Effectuez un entretien général deux fois par année

Essuyez l’intérieur de l’armoire avec un chiffon humide,

afin d’enlever la saleté, les insectes morts et les débris

qu’il pourrait y avoir.

Entretien VRC

Page 15

10

Placement du tube de Pitot (VRC)

Tube de Pitot et débitmètre

Nécessaire d’équilibrage

des débits d’air

avec tube de Pitot incluant

un débitmètre à hélice,

un tuyau flexible et

une mallette.

N.B. :

Ce schéma n’est offert qu’à des fins d’illustration. Les

orifices de raccordement pour les canalisations peuvent varier.

N.B. : On utilise des registres d’équilibrage selon les besoins.

Page 16

9

Dans un VRC, il est essentiel que le volume des circuits d’air soit équili-

bré. La quantité d’air provenant de l’extérieur doit égaler la quantité

évacuée par l’appareil. Les conséquences d’un déséquilibre des débits

d’air pourraient être les suivantes :

• Le VRC ne fonctionnera peut-être pas à son efficacité maximale

• La maison pourrait subir une pression d’air négative ou positive

• Le dégivrage de l’appareil pourrait être insuffisant

• La garantie offerte par le fabricant pourrait être annulée si le VRC n’est

pas correctement équilibré

Une pression négative excessive

pourrait avoir plusieurs effets sec-

ondaires indésirables. Dans certaines régions, il est possible que des gaz

provenant du sol, tels que le méthane et le radon, soient aspirés dans la

maison.

Lisez bien l’avertissement dans la section des dégagements et

exigences de ce manuel !

Avant de procéder à l’équilibrage, n’oubliez pas de vérifier les points

suivants :

1. Tout le réseau de conduites doit avoir été complètement scellé.

2. Tous les composants du VRC doivent être en place et en bon état de

marche.

3. Les registres d’équilibrage doivent être complètement ouverts.

4. L’appareil doit être réglé à sa GRANDE vitesse.

5. Les débits d’air dans les canalisations secondaires qui atteignent des

endroits spécifiques de la maison devraient être ajustés d’abord, avant

d’équilibrer l’appareil. Pour déterminer le débit d’air relatif de chaque

canalisation secondaire, vous pouvez vous servir d’une poire à fumée

près de la grille correspondante.

6. Après avoir effectué une lecture pour la conduite qui ramène l’air vicié

au VRC et pour la conduite qui distribue l’air neuf dans la maison, la

conduite où la vélocité (en pieds cubes/minute ou en litres/seconde)

est la plus basse ne demande aucun ajustement. Par contre, vous

devez vous servir du registre de l’autre conduite pour réduire son débit

au même niveau.

7. Rétablissez la vitesse normale de fonctionnement de l’appareil.

8. Un registre d’équilibrage fourni sur place sur le côté de l’air vicié est

requis pour équilibrer le système.

Marche à suivre pour l’équilibrage

Nous vous proposons une méthode d’équilibrage du VRC sur les lieux à

l’aide d’un tube de Pitot. Elle est vraiment avantageuse dans les situa-

tions où l’on ne pose pas de colliers de débit dans les canalisations. Ce

travail d’équilibrage devrait être effectué alors que le VRC marche à

grande vitesse.

Premièrement, on doit faire marcher l’armoire de traitement d’air à

grande vitesse. On obtiendra ainsi la pression maximale que le VRC

devra surmonter et il sera alors possible d’équilibrer l’unité avec plus de

précision.

Percez un petit trou (environ 3/16 po) dans le conduit, à trois pieds en

aval et à un pied en amont de n’importe quel coude. Il s’agit là de dis-

tances recommandées mais, en réalité, le genre d’installation pourrait

limiter la longueur de conduit droit.

Le tube de Pitot devrait être connecté à un débitmètre à hélice ou à un

autre manomètre capable de faire une lecture de 0 à 0,25 pouce d’eau (0

à 62 Pa), de préférence avec une précision allant jusqu’à trois chiffres.

Le tube qui sort du sommet du tube de Pitot est raccordé au côté à

haute pression du manomètre. Le tube qui sort du côté du tube de Pitot

est connecté au côté à basse pression ou référence du manomètre.

Introduisez le tube de Pitot à l’intérieur du conduit, en dirigeant

l’extrémité de ce tube de Pitot dans la circulation de l’air.

Pour obtenir un équilibrage général, il suffit de déplacer le tube de Pitot

dans le conduit (de distribution ou de retour) pour prendre une lecture

moyenne ou typique. Procédez de la même façon dans l’autre conduit.

Déterminez quel conduit a le plus grand débit d’air en vous basant sur la

lecture du manomètre. Ensuite, réduisez ce débit pour qu’il corresponde

au débit le moins élevé. Les deux débits devraient maintenant être en

équilibre.

Le débit d’air réel peut être déterminé à partir de la lecture du

manomètre. L’indication du manomètre est appelée la pression due à la

vitesse. Le tube de Pitot est fourni avec un tableau qui donne la vitesse

de circulation de l’air basée sur la pression de vitesse indiquée par le

manomètre. Cette vitesse est exprimée en pieds par minute ou en

mètres par seconde. Pour déterminer le débit d’air réel, il faut multiplier

la vitesse de l’air par la surface de la section transversale du conduit qui

a été mesuré.

Voici un exemple dans lequel on détermine le débit d’air dans un conduit

de 6 pouces :

La lecture du tube de Pitot a été de 0,025 pouce d’eau.

Le tableau fourni indique que cela équivaut à 640 pieds par minute.

Le conduit de 6 pouces a une surface transversale de

[3,14 x (6 ÷ 12)

2

] ÷ 4 = 0,2 pied carré

Le débit d’air est donc de 640 pieds par minute x 0,2 pied carré = 128

pieds cubes par minute.

Pour vous faciliter la tâche, vous trouverez ci-dessous la surface trans-

versale de quelques conduits ronds souvent utilisés :

DIAMÈTRE DU CONDUIT (pouces) SURFACE TRANSVERSALE (pi. ca.)

5 0,14

6 0,20

7 0,27

L’exactitude de la lecture du débit d’air sera affectée par la position du

tube de Pitot, c’est-à-dire par sa proximité à n’importe quel coude dans

le conduit. On peut donc obtenir un chiffre plus précis en prenant une

moyenne de plusieurs lectures, comme l’explique la documentation

fournie avec le tube de Pitot.

Équilibrage des circuits d’air

AVERTISSEMENT

ATTENTION

un refoulement dans des appareils de combustion ventilés.

VRC. Une pression négative excessive pourrait aussi causer

Veillez à ce que les débits d’air soient équilibrés dans le

trous des serrures.

air humide pourrait provoquer une congélation dans les

une détérioration des composants structuraux. De plus, cet

pourrait ensuite s’y condenser (par temps froid) et causer

intérieur humide dans les murs extérieurs du bâtiment. Il

Une pression positive excessive pourrait entraîner l’air

Veillez à ce que les débits d’air soient équilibrés dans le VRC.

Page 17

8

Installation

DÉSHUMIDISTAT À DISTANCE

*qui exige deux fils

• s’emploie partout où il y a beaucoup d’humidité

• ouvre les registres pour assurer la ventilation lorsque

l’humidité dépasse le niveau prévu

Pièce N

O

99-130

Fonctionnement du déshumidistat

Basse tension - courant alternatif de 24 volts

PROBLÈMES SOLUTIONS

L’air est trop sec • Augmentez le taux d’humidité

• Passez du mode de ventilation continu à intermittent

• Installez un humidificateur

L’air est trop humide • Réduisez le taux d’humidité

• N’évacuez pas l’air de la sécheuse au sous-sol

• Vous pourriez devoir sortir le bois de chauffage du

sous-sol

• Attendez que la température extérieure change.

Ex. : l’été peut s’avérer très humide

• Vérifiez l’équilibrage du VRC

• Faites fonctionner la soufflante de la fournaise en

permanence pour accroître le taux de ventilation

fonctionne à sa plus haute vitesse.

équilibré alors que la fournaise

*L’appareil est normalement

isolée

Conduite

6. Il se pourrait être nécessaire d’ajuster le registre d’équilibrage d’une saison à l’autre.

5. On doit prévoir un système d’égouttement tel qu’illustré ci-dessus.

remettre en place. Vous devez examiner les capuchons extérieurs régulièrement pour vous assurer qu’ils ne sont pas obstrués.

4. Il faut entretenir le système une fois par année, ou même plus souvent au besoin. Retirez et lavez les filtres et le noyau avant de les

3. À cause des différences de pression entre les appareils, les débits d’air doivent être ajustés et confirmés sur place.

(2 mètres) est requis. Ils doivent aussi être posés à au moins 18 pouces (460 mm) au-dessus du niveau du sol.

2. L’agencement ci-dessus des capuchons anti-intempéries n’est que pour les fins du dessin. En réalité, un écartement d’au moins 6 pieds

1. Il faut que la soufflante de la fournaise fonctionne lorsqu’on a besoin de ventilation.

REMARQUES :

to OFF.

Set dehumidistat

SUMMER:

adjust to lower setting.

If home is too humid,

adjust to higher setting.

If home is too dry,

between 30% to 40%.

Set dehumidistat

WINTER:

O

u

ts

ide

C

on

d

itio

ns

S

ettin

g

R

elativ

e to

D

e

hu

m

id

is

tat

Page 18

7

Connexions pour télécommandes

Les raccordements électriques devraient être effectués

par un technicien compétent. Les fils à basse tension

provenant des télécommandes sont connectés aux

bornes du moteur du registre.

Identifiez le type d’installation approprié et raccordez tel

qu’illustré.

Alimentation électrique - Modèle 94-EXCHANGER-MD seulement

thermostat, vous devez utiliser l’option 3.

refroidissement. Si vous identifiez ce genre de

conséquent, d’actionner le système de

borne jaune (Y) au thermostat et, par

système à air pulsé a pour effet d’exciter la

tension des bornes rouge (R) et verte (G) au

Sur les thermostats plus anciens, la mise sous

AVERTISSEMENT

assurer que le VRC est bien mis à la terre.

terre (sur l’armoire). Vous devez toujours vous

l’interrupteur. Vérifiez entre ce point et la prise de

électrique est vraiment coupé au delà de

assurer que, lorsque la porte est ouverte, le courant

voltmètre ou d’une lampe de vérification pour vous

que la polarité est appropriée, servez-vous d’un

est la ligne qui doit être commutée. Pour confirmer

(sectionneur) de sécurité. Le fil sous tension (noir)

d’énergie qui est commutée par l’interrupteur

important de confirmer la polarité de la ligne

nettoyage ou l’entretien du VRC, il est extrêmement

Pour éliminer les risques de choc électrique durant le

AVERTISSEMENT

Page 19

6

Système d’évacuation de l’air vicié

Le rendement du réseau d’évacuation de l’air vicié est

basé sur la pression positive créée dans les canalisations

de la fournaise. Pour que ce système soit efficace, il

faut que la soufflante de l’appareil de traitement de

l’air soit en marche.

Raccord d’écoulement (VRC seulement)

Durant un cycle de dégivrage, le VRC pourrait produire un

peu de condensation. Cette eau devrait être acheminée

vers un renvoi à proximité ou éliminée par une pompe à

condensat.

Au fond du coffre du VRC, il y a des trous déjà percés

pour les raccords du bac d’écoulement (dessin ci-après).

Introduisez chaque goulotte d’écoulement dans son trou

dans le bac. N’oubliez pas le joint torique qui forme un

joint étanche entre le raccord et le bac. RAPPELEZ-

VOUS DE SERRER UNIQUEMENT AVEC VOS DOIGTS

la rondelle et le contre-écrou qui retiennent le raccord

d’écoulement en place.

Formez un siphon en P en vous servant du té de rac-

cordement en plastique. Coupez deux longueurs de tube

et connectez chaque raccord d’écoulement à une

extrémité du té, puis raccordez les autres bouts aux deux

goulottes d’égouttement. Veillez à ce que la sortie cen-

trale du té soit dirigée vers le haut et raccordez le tuyau

d’évacuation. Enrubannez ou attachez la base pour éviter

les tortillements. Le “piège” ainsi créé retiendra un peu

d’eau de condensation et empêchera les odeurs

désagréables de remonter dans le tube et le VRC.

Siphon en P (VRC seulement)

N.B. : Il faudra peut-être utiliser un bac d’écoulement secondaire

comme protection contre les fuites d’eau de condensation.

Le VRC et tous les tubes pour l’eau de condensation

doivent être dans un endroit où la température est

maintenue au-dessus du point de congélation.

ATTENTION

Conception et pose des conduites d’air

Quand l’ensemble de canalisations est bien conçu et cor-

rectement installé, on peut compter sur l’efficacité

maximale du VRC.

Il faut toujours s’efforcer de garder les canalisations aussi

courtes et aussi droites que possible. Consultez les

Schémas d’installation pour vous familiariser avec

diverses options d’installation.

Les revêtements intérieur et extérieur de la gaine flexible

isolée doivent être solidement attachés au manchon des

capuchons anti-intempéries (aussi près que possible du

dehors) et à l’orifice approprié sur le VRC lui-même. Il faut

s’assurer que la canalisation de la prise d’air pur est bien

scellée. Un bon cordon de calfeutrant de haute qualité (de

préférence un scellant à base de silicone) permettra de

sceller la gaine flexible intérieure, aussi bien à l’orifice du

VRC qu’au capuchon anti-intempéries, avant son serrage

avec une grande attache zip.

Pour entraver aussi peu que possible la circulation d’air,

la gaine flexible isolée (qui raccorde les deux capuchons

anti-intempéries extérieurs au VRC) devrait être bien

étirée et aussi courte que possible.

Quand la conduite est tortillée ou pliée, la circulation de

l’air est sérieusement limitée. On présente ci-dessous la

meilleure façon de raccorder les gaines flexibles isolées

aux capuchons anti-intempéries extérieurs et au VRC.

AVERTISSEMENT

protégés contre les chocs possibles.

l’entretien et aux réparations seront alors mieux

circuit à la terre dans les dispositifs, les préposés à

de l’appareil de traitement de l’air. Advenant un courtséparées la mise à la terre (électrique) du VRC et celle

dans cette conduite rigide. Son but est de garder

tissu souple ou tout autre connecteur non métallique

Vous devez intercaler un court tronçon de gaine en

Page 20

5

Positionnement et installation des capuchons

Le kit comprend deux capuchons anti-intempéries à cou-

vercle fixe avec un grillage à mailles de 1/4 po (6 mm).

Exigences pour le capuchon d’évacuation

• À au moins 6 pieds (2 mètres) de distance de la prise d’air

de ventilation *

• Au moins 18 pouces (457 mm) au-dessus du sol, ou au-

dessus de l’accumulation prévue de neige *

• À au moins 3 pieds (1 mètre) de distance du coin de l’édi-

fice *

• À au moins 3 pieds (1 mètre) du compteur de gaz, du

compteur d’électricité ou d’une allée piétonnière si la brume

ou la glace pourrait présenter des risques *

• Jamais dans un garage, un atelier ou un autre endroit non

chauffé

Lorsque vous posez un capuchon anti-intempéries, son

périmètre extérieur doit être calfeutré avec un produit appro-

prié.

* Il se pourrait que le code local stipule des distances plus

considérables.

Exigences pour le capuchon d’admission

• Il doit être situé en amont de la direction normale des vents

dominants (le cas échéant) et de l’orifice d’évacuation

• À au moins 6 pieds (2 mètres) du capuchon anti-intem-

péries d’évacuation *

• À au moins 6 pieds (2 mètres) de tout évent de sécheuse et

de la sortie d’un appareil de traitement de l’air (fournaise à

efficacité moyenne ou élevée) *

• À au moins 6 pieds (2 mètres) des voies d’accès, des

canalisations de remplissage du mazout, des compteurs de

gaz, des bacs à ordures ou de toute piscine *

460 mm

460 mm

neige en hiver.

Dégagements pour les

capuchons anti-intempéries

Pour suspendre l’appareil en utilisant

les bandes de suspension fournies

Installation des capuchons anti-intempéries

• À au moins 18 pouces (457 mm) au-dessus du sol, ou au-

dessus de l’accumulation prévue de neige *

• À au moins 3 pieds (1 mètre) de tout coin extérieur ou

intérieur du bâtiment *

• Il ne doit jamais être dans un garage, un grenier ou un vide

sanitaire

* Il se pourrait que le code local stipule des distances plus

considérables.

(460 mm) au-dessus du sol ou du niveau prévu pour la

capuchons, et un espace libre d’au moins 18 pouces

un écartement d’au moins 6 pieds (2 mètres) entre les

L’agencement des capuchons anti-intempéries exige

ATTENTION

humidité.

de l’appareil pourraient donc être exposés à cette

canalisations. Les objets qui se trouvent en dessous

accumulation de condensation sur l’appareil ou les

d’utilisation, il faut prévoir la possibilité d’une

donné la diversité des conditions d’installation et

bon écoulement de l’eau de condensation. Étant

L’appareil doit être installé de niveau pour assurer un

ATTENTION

Page 21

4

Choix de l’emplacement

Le VRC doit être placé dans un endroit chauffé où il sera

possible de l’entretenir facilement. Normalement, le VRC

devrait être installé dans la chambre des appareils

mécaniques ou dans un endroit près du mur extérieur sur

lequel on posera les capuchons anti-intempéries. Si la

maison n’a pas de sous-sol ou s’il ne convient pas à ce

genre d’installation, vous pouvez installer l’appareil dans

la buanderie-chaufferie ou dans une autre pièce sem-

blable.

En général, on déconseille les installations dans

le grenier :

A) à cause des travaux compliqués requis,

B) pour prévenir le gel,

C) pour faciliter l’entretien et le nettoyage.

Le VRC doit être installé en position horizontale, de la

manière illustrée ci-dessous. L’appareil devrait être sus-

pendu à l’aide des bandes de suspension fournies. Si

c’est nécessaire, on peut installer l’appareil sur une plate-

forme. Cependant, son armoire devrait être isolée de

cette plate-forme, afin de prévenir toute transmission de la

vibration. L’appareil doit être de niveau. Il faut laisser un

espace libre suffisant devant l’appareil, afin de pouvoir

facilement atteindre les filtres à air et le noyau. On recom-

mande un dégagement d’au moins 25 pouces (635 mm)

pour qu’il soit possible d’ouvrir la porte. Quatre bandes de

suspension en polyester à renfort de chlorure de

polyvinyle sont utilisées pour suspendre le VRC aux

solives du plancher dans le sous-sol.

Pour suspendre l’appareil

Les bandes de suspension devraient être attachées à

l’appareil aux quatre coins. (Les vis de montage se trou-

vent déjà sur le coffre du VRC). Fixez solidement l’autre

extrémité des bandes aux solives à l’aide de clous à tête

large (qui ne sont pas fournis). N’oubliez pas que

l’appareil doit RESTER DE NIVEAU. Les bandes ont été

conçues pour diminuer la possibilité de bruit, de réso-

nance ou d’harmoniques. C’est pourquoi on vous

conseille d’utiliser la pleine longueur des bandes entre le

VRC et les solives de plancher.

Installation

Raccordement d’appareils au VRC

Les appareils suivants ne devraient jamais être connectés

au VRC :

• sécheuse à linge

• dessus de cuisinière

• ventilateur de dessus de poêle

• système central d’aspiration

N.B. : Si l’un des appareils mentionnés ci-dessus est rac-

cordé au VRC, la garantie est alors annulée.

Dégagements et exigences

plusieurs sources d’énergie électrique.

sectionneur(s). L’appareil pourrait avoir

l’alimentation électrique (OFF) au(x)

réparation ou d’entretien, coupez

mort. Avant d’effectuer tout travail de

pourrait être cause de blessures ou de

Risque de secousse électrique. Le choc

AVERTISSEMENT

compétent ou une entreprise spécialisée.

d’entretien doivent être effectués par un installateur

même des pertes de vie. Les travaux d’installation et

entraîner des dommages matériels, des blessures ou

modification, de réparation ou d’entretien peut

Toute erreur d’installation, de réglage, de

AVERTISSEMENT

l’appareil.

s’accumuler dans le VRC et endommager

La mousse, la poussière et la graisse peuvent

ATTENTION

AVERTISSEMENT

ces appareils de combustion ventilés !!!

délétères ou un mauvais fonctionnement de

pourrait entraîner un refoulement de gaz

période d’inutilisation ou une panne partielle

situation où son fonctionnement normal, une

N’installez JAMAIS un ventilateur dans une

fournaises au mazout, poêles à bois, etc.).

de combustion ventilés (fournaises au gaz,

de chaleur pourrait affecter d’autres appareils

fonctionnement d’un ventilateur à récupération

Il est toujours important d’évaluer comment le

manuel.

méthode d’équilibrage qu’on trouve dans ce

débit d’air du ventilateur, au moyen de la

appareils doit être confirmée en mesurant le

Après l’installation, la compatibilité des deux

fonctionne à une pression statique plus élevée.

air pulsé ou un appareil de traitement d’air, qui

équipement mécanique, tel qu’une fournaise à

fonctionnera s’il est raccordé à tout autre

tenir compte de la façon dont ce système

Avant de procéder à l’installation, il faut bien

Page 22

3

Assemblage du registre motorisé

Montez le moteur du registre en alignant les quatre (4)

trous de la plaque de montage avec ceux de la plaque se

trouvant sur le dessus de l’appareil. Ceci contribuera à

aligner automatiquement le raccord du moteur et l’axe du

registre.

Alignez le registre en position complètement fermée.

Utilisez une clé Allen de 1/8 po pour serrer la vis de fixa-

tion.

Les registres devraient maintenant être en position

entièrement fermée, mais sans courant électrique.

Identifiez le schéma de câblage approprié dans ce guide.

En activant le moteur du registre, les volets devraient

s’ouvrir à 90°.

Page 23

2

MODÈLE 94-EXCHANGER-MD — Comprend un registre motorisé à 24 volts

Fiche technique - VRC

Dimensions du VRC

en pouces (mm)

Dimensions du VRC

en pouces (mm)

GARANTIE :

Garantie à vie sur le noyau d’échange de chaleur en

aluminium. Garantie de cinq ans pour toutes les autres

pièces.

MODÈLE 94-EXCHANGER — Pas de registre. Un kit optionnel (99-MD-KIT) peut lui être ajouté

Le débit d’air habituel se situe entre 0 et 130 pieds cubes par minute.

Le débit d’air habituel se situe entre 80 et 130 pieds cubes par minute.

Date : __________________________________________

Étiquette : ________________Qté :___________________

Projet : _________________________________________

Ingénieur : _______________________________________

Entrepreneur : ____________________________________

Fournisseur : _____________________________________

Soumission N

o

:___________________________________

Presentée par : ___________________________________

1204

®

Page 24

Outils requis pour l’installation

• cisailles de ferblantier • grandes attaches zip

• divers tournevis • gaine flexible en tissu - classe II

• perceuse électrique • ruban mastic

• marteau • ruban en papier d’aluminium

• dénudeur de fil • attaches zip

• couteau • boyau de vidange de 1/2 po

diam. int.

• pistolet à calfeutrer

• poire à fumée

Outils requis pour l’équilibrage

• ensemble d’équilibrage à tube de Pitot [coffret, 8 pieds

de tube en vinyle, tube de Pitot, débitmètre à hélice

(0 - 0,25 po) et plaque de montage]

ou

• tube de Pitot avec instructions et manomètre numérique

(avec résolution de 0 à 0,25 po - on doit indiquer jusqu’à un

centième de pouce)

Les ventilateurs à récupération de chaleur (VRC) ont été

conçus pour fournir de l’air neuf tout en expulsant une

quantité égale d’air vicié.

Le VRC est muni d’un noyau en aluminium. Cet appareil

utilise l’air vicié qu’on expulse pour conditionner l’air neuf

qui arrive.

Ces instructions ne constituent qu’un guide général et ne

remplacent aucunement les exigences des codes en

vigueur. Consultez les autorités locales compétentes avant

de commencer les travaux d’installation.

Outils requis......................................................................1

Utilisation ..........................................................................1

Généralités .......................................................................1

Fiche technique VRC........................................................2

Assemblage du registre motorisé .....................................3

Dégagements et exigences .............................................4

Installation .....................................................................4-6

Alimentation électrique

- Modèle 94-EXCHANGER-MD seulement ......................7

Fonctionnement du déshumidistat....................................8

Équilibrage des circuits d’air........................................9-10

Entretien ........................................................................11

Utilisation

Généralités

Table des matières

Outils requis

* LAISSEZ CE MANUEL CHEZ LE PROPRIÉTAIRE

N.B. : À cause de notre programme continu de recherches et de perfectionnement

des produits, les caractéristiques, les puissances nominales et les dimensions peu-

vent être modifiées sans préavis.

TI -FAE-001-F

1207

MODÈLES 94-EXCHANGER, 94-EXCHANGER-MD, 99-MD-KIT

Voir page 3 pour l'installation de l'ensemble

99-MD-KIT

ATTENTION

®

INSTRUCTIONS D’INSTALLATION POUR L’ÉCHANGEUR D’AIR

Loading...

Loading...