Page 1

CLEAN • FRESH • AIR

OPERATION AND

INSTALLATION MANUAL

®

For Models:

500DCS ControlAir 15

850FD/DDAnalog Controls

700FD/DD Analog Controls

1200FD/DD Analog Controls

500ERV ControlAir 15

700ERV Analog Controls

1200ERV Analog Controls

TO BE COMPLETED BY CONTRACTOR AFTER INSTALLATION

CAUTION

Before installation, careful consideration must be given to

how the system will operate if connected to any other piece

of mechanical equipment, i.e. a forced air furnace or air

handler, operating at a higher static. After

compatibility

confirmed, by measuring the airflow’s of the Heat/Energy

Recovery Ventilator (HRV/ERV), by using the balancing

procedure in this manual.

It is always important to assess how the operation of any

HRV/ERV may interact with vented combustion equipment

(ie. Gas Furnaces, Oil Furnaces, Wood Stoves, etc.).

NEVER install an HRV/ERV in a situation where its normal

operation, lack of operation or partial failure may result

in the backdrafting or improper functioning of vented

combustion equipment!!!

NOTE: ALTHOUGH SOME MODELS

DIFFER IN OPERATION, THE BASIC

STEPS ARE SIMILAR.

installation, the

of the two pieces of equipment must be

Installing Contractor

Telephone / Contact

Serial Number

Installation Date Model

* LEAVE FOR HOMEOWNER

NOTE: Due to ongoing research and product development, specifications,

ratings and dimensions are subject to change without notice.

TI-72C-NE

0105

Page 2

Table of Contents

INTRODUCTION

Introduction .................................................................... 2

ERV Questions and Answers ......................................... 3

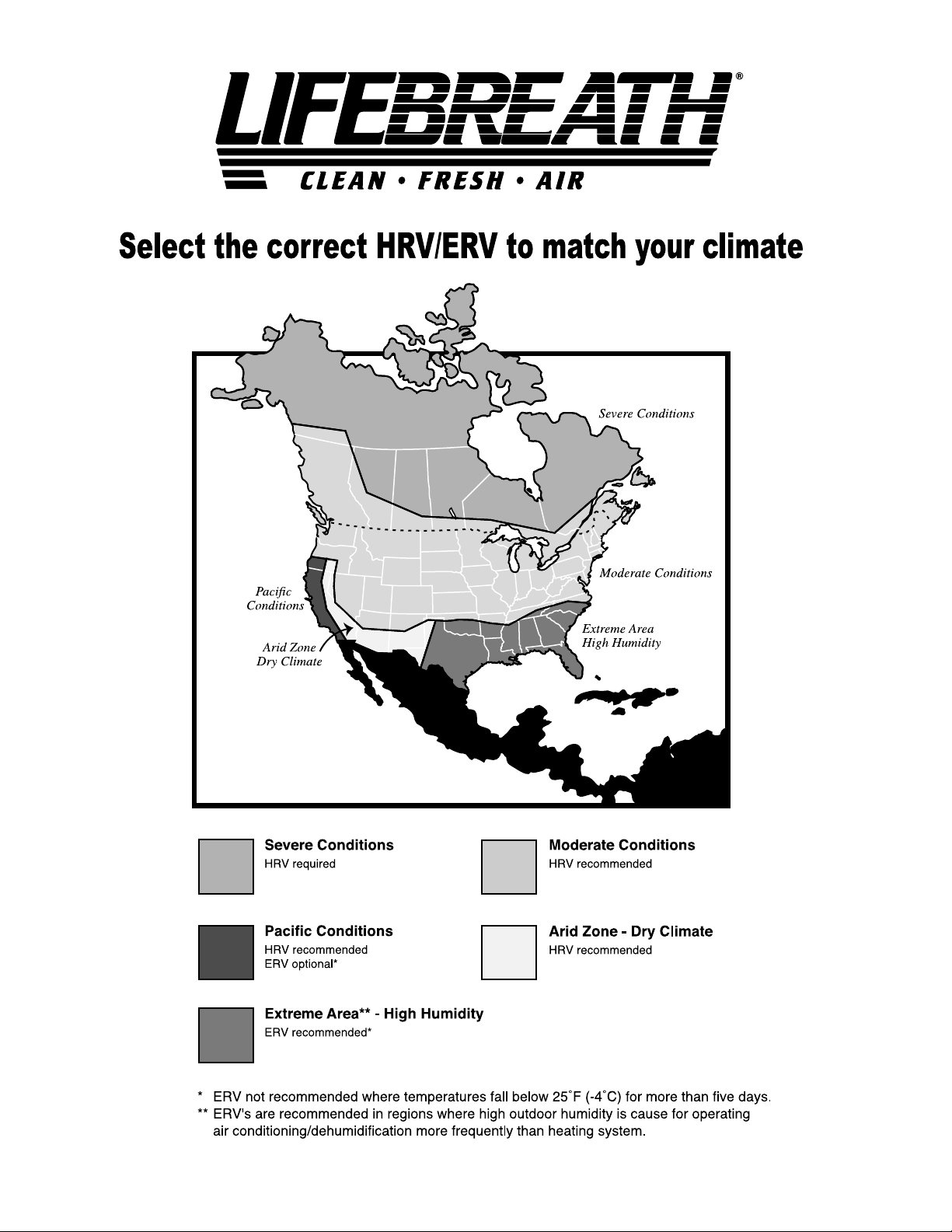

Select Correct HRV/ERV to Match Climate.....................4

Select the Correct Size HRV/ERV ................................ 5

Technical Data - Model 500DCS ................................... 6

Technical Data - Model 850FD/DD ............................... 7

Technical Data - Model 700FD/DD ............................... 8

Technical Data - Model 1200FD/DD ............................. 9

Technical Data - Model 500ERV ................................. 10

Technical Data - Model 700ERV ................................. 11

Technical Data - Model 1200ERV ............................... 12

Location for Mounting ................................................. 13

The Ductwork System ............................................. 13

Outside Weatherhoods ............................................... 14

Ducting from Weatherhoods ....................................... 14

Warmside Ducting - General ....................................... 14

Stale Air Return System ............................................. 14

Fresh Air Supply ......................................................... 15

The Integrated HVAC System ..................................... 15

Various Installation Types ........................................... 17

HRV - Aluminum Core

A Heat Recovery Ventilator (HRV) is designed to

provide fresh air into a building while exhausting

an equal amount of stale air. During the winter

months, the incoming cold fresh air is warmed by

utilizing the heat recovered from the stale air

before it is exhausted to the outdoors. During

summer months when the indoor space is air

conditioned, the Heat Recovery Ventilator will

help in cooling the incoming fresh air with the

stale air that is being exhausted.

ERV - Enthalpic Paper Core

An Energy Recovery Ventilator (ERV) is designed

to provide fresh air into a building while

exhausting an equal amount of stale air. An ERV

is designed for use in warm humid areas with

heavy air conditioning use. The ERV will transfer

both sensible and latent heat from the incoming

fresh air to the outgoing stale air thereby reducing

the load (due to ventilation) on the air

conditioning system.

Electrical Connections ............................................. 18

Fan Defrost (700, 850, 1200) ...................................... 18

Damper Defrost (700, 850, 1200)................................. 18

Self Test of Defrost Systems (700, 850, 1200) ............ 18

Speed Selection and Controls (700, 850, 1200) .......... 19

Optional Remote Controls (700, 850, 1200) ................ 19

ControlAir 15 (500 Only) ............................................. 20

Function And Control (500 Only) ................................ 21

Mode of Operation for ControlAir 15 (500 Only) ......... 22

Pitot Tube Air Flow Balancing ................................. 23

Service/Maintenance ................................................ 24

Motor ........................................................................... 24

HRV Core .................................................................... 24

ERV Core .................................................................... 24

Filters .......................................................................... 25

Condensate Drains ..................................................... 25

Duct Work ................................................................... 25

Damper Motor ............................................................. 25

Troubleshooting your HRV/ERV System ................ 26

ERVs are not suitable for climates where the

temperature drops below -4˚C (25˚F).

Wiring Diagrams ............................................. 27-29

Warranty .................................................................... 30

2

Page 3

ERV Questions & Answers

What is the difference between an HRV

and an ERV?

The core in an HRV (Heat Recovery Ventilator)

transfers heat from one air stream to the other. This is

called sensible heat. The term ERV (Energy Recovery

Ventilator) is usually used to describe a unit with an

enthalpic core that transfers moisture as well as heat

from one air stream to the other. This (moisture

transfer) is called latent heat.

Enthalpic - what does it mean?

Enthalpy is the term used to describe the energy

content of air. This energy is a combination of the

sensible and latent heat. Therefore, a core which

transfers energy is called an enthalpic core.

Is an ERV better than an HRV?

NOT NECESSARILY!! In cold climates such as most

of North America, an HRV works better than an ERV.

This is because the air inside the home during the

winter months will be more humid than the outside air.

An ERV would transfer the latent heat (humidity) from

the exhaust air back into the incoming airstream. This

will aggravate moisture problems in the home and

encourage the growth of mold and mildew. If the air in

the home is too dry for comfort, an ERV will not help. A

humidifier should be used to increase the humidity to

a comfortable level.

and damp situation. In fact, about 2/3 of the energy

used by the air conditioner system is to remove

moisture. Therefore, when ventilating in the summer,

less moisture brought into the home means less work

for the air conditioner, and energy savings for you.

During the winter, an ERV recovers some humidity

from the exhaust air, reducing the need for humidification

if the required ventilation rate would make the home

too dry.

,

What's the difference between this type of

core and a rotary type?

Here's a list of characteristics of the fixed plate core.

1. No rotating parts, so maintenance is easy and the

unit lasts a long time.

2. It is very flexible in terms of installation.

3. The core can easily be changed.

4. Because the supply and exhaust air streams are

completely separate, there is very little cross

leakage of any dust or germs.

Can the core become clogged with dust?

Because the surface of the core is a turbulent flow

area, dust sticks to it easily; however, because the

inside of the element is a laminar flow area, virtually no

dust sticks to it.

Where do you use an ERV instead

of an HRV?

An ERV is recommended for warm, humid areas with

heavy air conditioning use. As there is no defrost in an

ERV it is not recommended for areas where the

temperature drops below -4˚C (25˚F)

Why transfer moisture in the summer

(cooling season)?

The enthalpic core will allow moisture to be transferred

from a humid air flow to a dry air flow. This property is

useful in the cooling season if an air conditioning

system is used to lower the indoor humidity. You will

then have dry, cool air in the exhaust of the ERV, and

warm humid air in the supply stream. With these

conditions, the ERV will be able to transfer the

moisture and heat of the supply air to the exhaust air.

In this way, the ERV will supply to the home air which

is cooler and drier than outside. Remember that an

ERV is not a dehumidifier, and on its own will not take

moisture out of the air.

So why use an ERV?

A properly operating air conditioner will not only lower

the temperature in your house, but will also lower the

humidity level. This prevents an uncomfortable cold

What is the maintenance?

About once a year you should use a vacuum cleaner

to remove the dust from the core's surface. DO NOT

WASH WITH WATER!!

Is an air filter needed?

To prevent clogging of the core, an air filter should

always be installed on the supply and exhaust sides of

the core.

How much ventilation do I need?

During seasons when your windows and doors are

closed, the ERV should operate continuously when

the dwelling is occupied, and either continuously or

intermittently when not occupied.

For most installations the ERV will normally be set to

operate continuously on low speed with the option of

going to high speed as the need arises. For example;

if you are entertaining and there is a large number of

people present (some may be smoking), the unit

should be switched to high speed.

Your ERV may be equipped with automatic or manual

switches, but all ERVs will have a manual speed

control override.

3

Page 4

4

Page 5

Selecting the Correct Size HRV/ERV

Commercial and Institutional Requirements

For outdoor air requirements, ASHRAE has produced the Ventilation Standard 62-1989 that

is used to determine acceptable ventilation rates. This standard is referenced directly or

used as “Good Engineering Practice” in most Code documents or design criteria.

Small restaurants, Donut Shops and Fast food stores

Seats 40

Employees 5

Total 45

ASHRAE requirement 20 cfm (10L/s) per person

Ventilation required 45 x 20 = 900 cfm (450 L/s)

Bar or Tavern

Seats 50

Employees 7

Total 57

ASHRAE requirement 30 cfm (15L/s) per person

Ventilation required 57 x 30 = 1710 cfm (855 L/s)

Classroom and School Portables

Seats 29

Teacher 1

Total 30

ASHRAE requirement 15 cfm (7.5L/s) per person

Ventilation required 30 x 15 = 450 cfm (255 L/s)

Beauty Salon

Customers 12

Employees 6

Total 18

ASHRAE requirement 25 cfm (12.5L/s) per person

Ventilation required 18 x 25 = 450 cfm (255 L/s)

Bank

Customers 25

Staff 9

Total 34

ASHRAE requirement 20 cfm (10L/s) per person

Ventilation required 34 x 20 = 680 cfm (320 L/s)

Bingo Hall

Customers 180

Staff 20

Total 200

ASHRAE requirement 30 cfm (15L/s) per person

Ventilation required 200 x 30 = 6000 cfm (3000 L/s)

Print Shop, Duplicating

Square footage of shop 2000 square ft (m

ASHRAE requirement 0.5 cfm/ft2 (2.5L/s - m

per person

Ventilation required 2000 x 0.5 = 1000 cfm (500 L/s)

Swimming Pools

Refer to “Pool” Models Installation Manuals.

2

)

2

)

MAKE UP HEAT REQUIREMENT at 1200 CFM (566L/s)

Nominal Nominal Nominal

Outdoor Temp. kW Req. for kW Req. for kW Req. for

C° F° 20°C (68°F) 25°C (77°F) 30°C (86°F)

Air Delivery Air Delivery Air Delivery

0 32 7 10 14

-10 14 10 14 17

-20 -4 12 15 19

-30 -22 15 19 22

-40 -40 17 21 24

5

Page 6

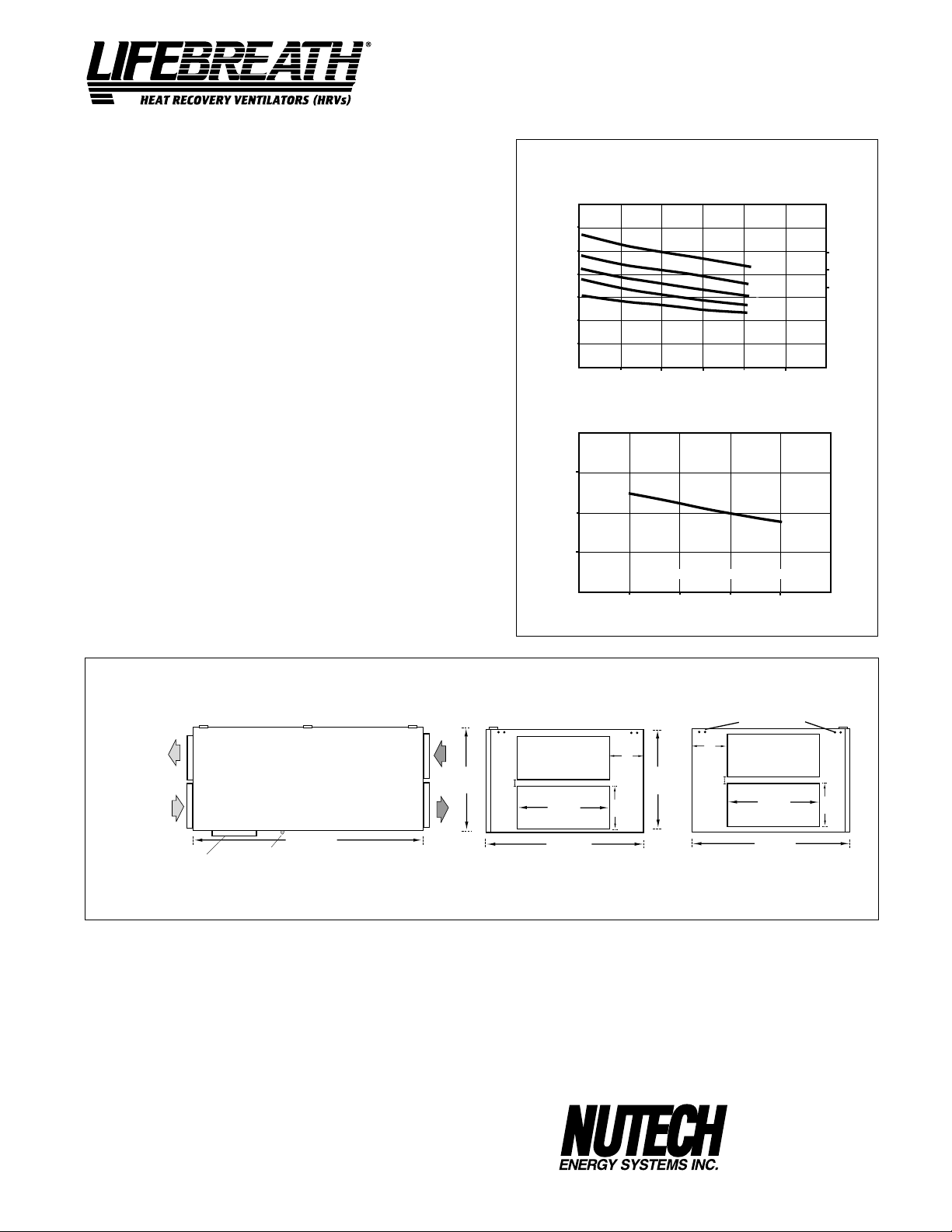

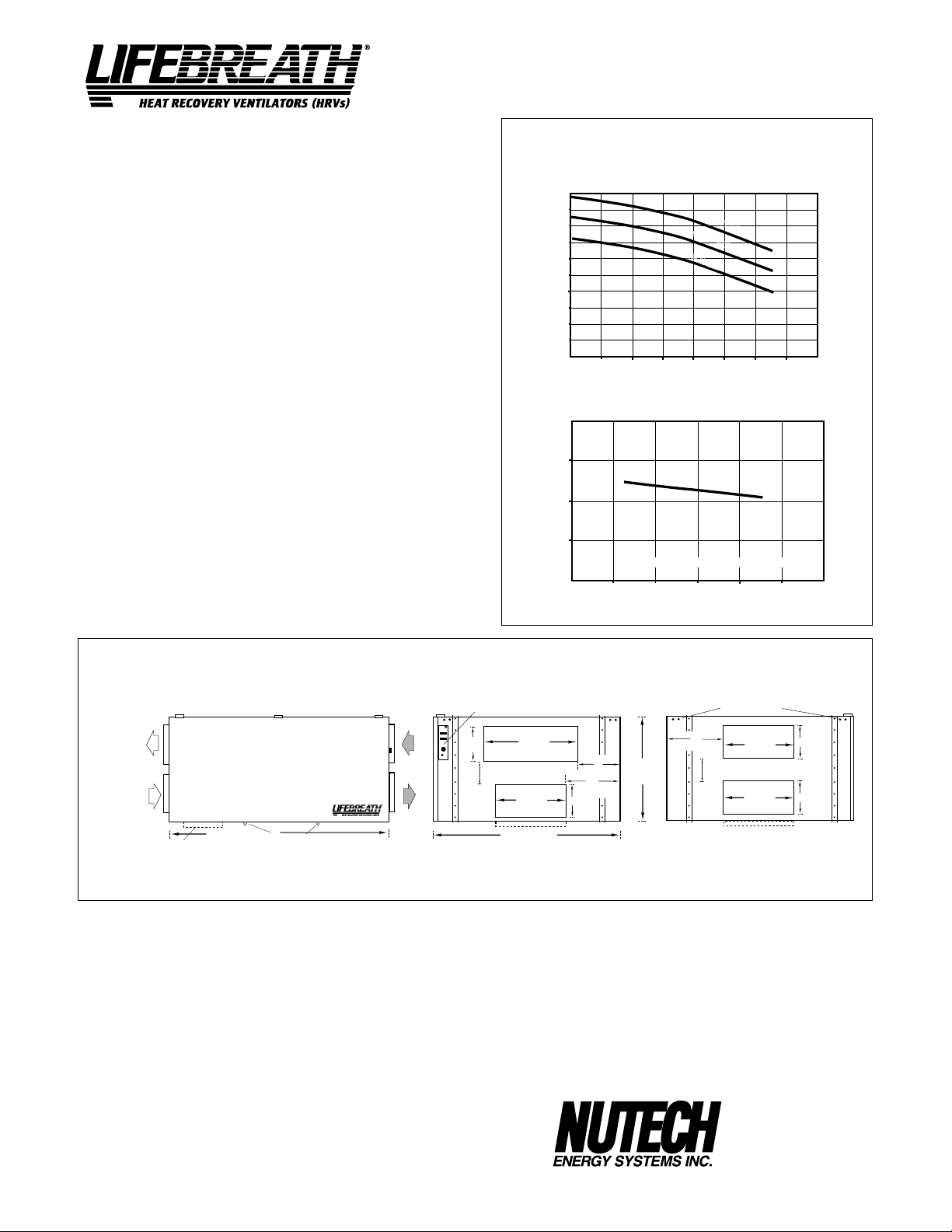

Model 500DCS

SPECIFICATIONS

CORES

Modular (4 section) patented aluminum heat recovery cores arranged

for high efficiency crossflow ventilation.

MOTORS

Two PSC, 5 speed double shafted, 120 VAC, 3.15 Amps each (6.3 total

on high speed). HP - 1/10, 1625 RPM. Watts - total on High Speed - 610.

FILTERS

Washable air filters in exhaust and supply air streams.

BLOWERS

Centrifugal type rated at 530 cfm (250 L/s) free air delivery. Each

air stream has two centrifugal blowers driven by two PSC motors.

CONNECTION DUCT SIZES

Four - 14" x 8" (356 mm x 200 mm).

MOUNTING

Unit to be set on support brackets hung by threaded rod type

apparatus (brackets and rods not included).

CASE

20 gauge prepainted galvanized steel (G60) for superior corrosion

resistance. Insulated with foil faced insulation duct liner where required to

prevent exterior condensation. Drain connection, One - 1/2" (12 mm) O.D.

CONTROLS ControlAir 15

DEFROST

Supply bypass damper routes indoor air to defrost cores.

WEIGHT 178 lbs. (81 kg) SHIPPING WEIGHT 203 lbs. (92 kg)

PERFORMANCE

AIRFLOWS (Each Air Stream)

282 (600)

235 (500)

190 (400)

143 (300)

94 (200)

AIRFLOW L/s (CFM)

42 (100)

25 (.1) 50 (.2) 75 (.3) 100 (.4) 125 (.5)

EXTERNAL STATIC PRESSURE IN PASCALS (in. W.C.)

TEMPERATURE EFFECTIVENESS

100%

90%

EFFECTIVENESS

80%

94

(200)

143

(300)

AIRFLOW IN L/s (CFM)

SPEED

5

4

3

2

1

NOTE: Exhaust Relative Humidity (RH) at 40%

190

(400)

235

(500)

6.3 HIGH

3.8 MED

3.1 LOW

282

(600)

TOTAL CURRENT DRAW (AMPS) @ 120 VAC

DIMENSIONS 500DCS

EXHAUST AIR

TO OUTSIDE

NOTE:

Service clearance

is 760 mm (30 in.)

SUPPLY AIR

FROM OUTSIDE

DEFROST

DRAIN CONNECTION

1245 mm

(

49"

)

FRONT VIEW

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min. (3 wire)

99-105 Programmable Ventilation Control

99-109 Air Sentry™ Air Quality Monitor designed to accept

99-250 Ventilation Dehumidistat - Dehumidistat designed

DATE: __________________________

PROJECT: ________________________________________

MECHANICAL CONTRACTOR: ________________________________

includes Programmable Time Clock, Dehumidistat

and Air Sentry™

remotely mounted Control Pad

to accept remotely mounted Control Pad.

EXHAUST AIR

FROM BUILDING

475 mm

(

18 3/4"

SUPPLY AIR

TO BUILDING

6

32 mm

)

(

1 1/4")

INTERIOR DUCT

CONNECTION SIDE

All units conform to CSA and UL standards.

WARRANTY

Units carry a 15 year warranty on the heat recovery core and

a 2 year replacement parts warranty.

356 mm

(14")

717 mm

(

28 1/4 "

inches (mm)

150 mm

(

5 7/8"

)

200 mm

(8")

)

475 mm

(

18 3/4"

MOUNTING POINTS

150 mm

(

5 7/8"

)

35 mm

)

(

1 3/8"

)

EXTERIOR DUCT

CONNECTION SIDE

511 McCormick Blvd.

London, Ontario

Ph: (519) 457-1904

Fx: (519) 457-1676

Email: nutech@lifebreath.com

Website: www.lifebreath.com

356 mm

(14")

717 mm

(

28 1/4"

200 mm

(8")

)

N5W 4C8

TI-110-NE

0011

Page 7

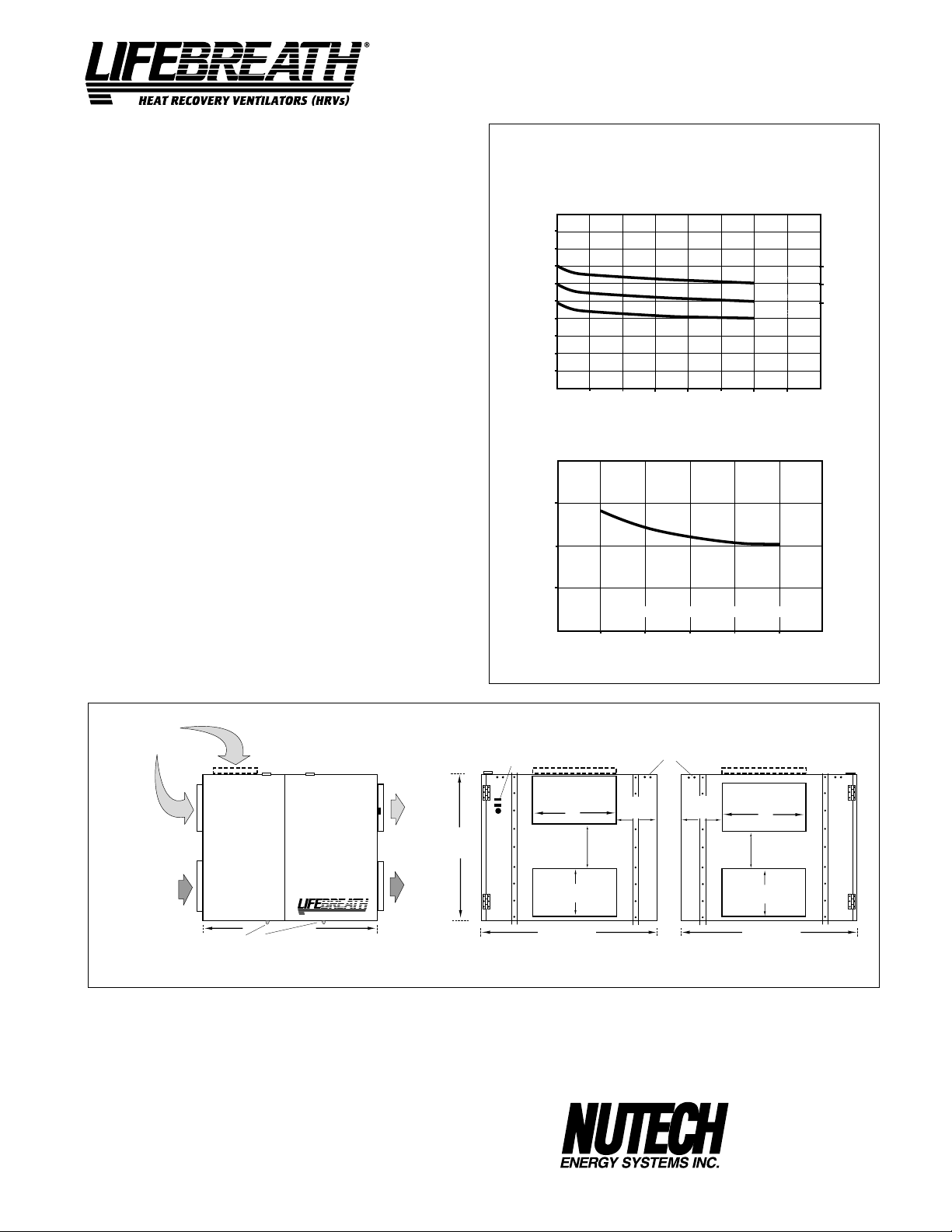

Model 850FD/DD

SPECIFICATIONS

CORES

Modular (6 section) patented aluminum heat recovery cores arranged for high

efficiency crossflow ventilation.

MOTORS

Two PSC, 3 speed double shafted, 120 VAC, 3.95 Amps each (7.9 total on

high speed). HP - 1/4, 1625 RPM. Watts - total on High Speed - 848.

FILTERS

Washable air filters in exhaust and supply air streams.

BLOWERS

Centrifugal type rated at 950 cfm (448 L/s) free air delivery. Each air stream

has one double shafted motor driving two centrifugal blowers.

CONNECTION DUCT SIZES

Three - 20" x 8" (508 mm x 200 mm).

Stale air intake - 26" x 8" (660 mm x 200 mm).

Model 850DD - additional 20" X 8" defrost port

MOUNTING

Unit to be set on support brackets hung by threaded rod type apparatus.

(brackets and rods not provided).

CASE

20 gauge prepainted galvanized steel (G60) for superior corrosion

resistance. Insulated with foil faced insulation where required to prevent

exterior condensation. Drain connections, Two - 1/2" (12 mm) O.D.

CONTROLS

Illuminated power switch, 3 speed blower control, low voltage (24 VAC)

terminals for connection of remote controls and defrost light indicating

automatic operation.

DEFROST CONTROLS

Model 850FD - Interrupts supply air while exhaust air defrosts core.

Model 850DD - Supply bypass routes indoor air to defrost core.

WEIGHT 255 lbs. (116 kg) SHIPPING WEIGHT 280 lbs. (127 kg)

PERFORMANCE

AIRFLOWS (Each Air Stream)

475 (1000)

425 (900)

378 (800)

329 (700)

282 (600)

235 (500)

190 (400)

143 (300)

94 (200)

AIRFLOW L/s (CFM)

42 (100)

25 (.1) 50 (.2) 75 (.3) 100 (.4) 125 (.5) 150 (.6) 175 (.7)

EXTERNAL STATIC PRESSURE IN PASCALS (in. W.C.)

TEMPERATURE EFFECTIVENESS

90%

80%

EFFECTIVENESS

70%

282

235

(600)

(500)

AIRFLOW IN L/s (CFM)

HIGH SPEED

MED SPEED

LOW SPEED

NOTE: Exhaust Relative Humidity (RH) at 40%

329

378

(700)

(800)

(900)

7.9 HIGH

7.0 MED

6.6 LOW

425

TOTAL CURRENT DRAW (AMPS) @ 120 VAC

DIMENSIONS 850

EXHAUST AIR

TO OUTSIDE

NOTE:

Service clearance

is 760 mm (30 in.)

SUPPLY AIR

FROM OUTSIDE

DEFROST AIR

DD MODELS ONLY

1188 mm

(46 3/4")

DRAIN CONNECTION

FRONT VIEW

OPTIONS

99-101 Sixty Minute Timer

99-130 Remote Wall Mount Dehumidistat Control

24 VAC only

DATE: __________________________

PROJECT: ________________________________________

MECHANICAL CONTRACTOR: ________________________________

EXHAUST AIR

FROM BUILDING

SUPPLY AIR

TO BUILDING

CONTROLS

200 mm

( 8")

172 mm

(6 3/4")

508 mm

1055 mm

(41 1/2")

INTERIOR DUCT

CONNECTION SIDE

All units conform to CSA and UL standards

WARRANTY

All units carry a 15 year warranty on the heat recovery cores

and a 2 year replacement parts warranty.

7

mm (inches)

660 mm

(26")

(20")

190 mm

(7 1/2 ")

263 mm

(10 3/8 ")

200 mm

(8")

625 mm

(24 5/8")

MOUNTING POINTS

263 mm

(

10 3/8"

508 mm

)

(20")

149 mm

(5 7/8")

508 mm

(20")

EXTERIOR DUCT

CONNECTION SIDE

511 McCormick Blvd.

London, Ontario

Ph: (519) 457-1904

Fx: (519) 457-1676

Email: nutech@lifebreath.com

Website: www.lifebreath.com

200 mm

(8")

200 mm

(8")

N5W 4C8

TI-111

0011

Page 8

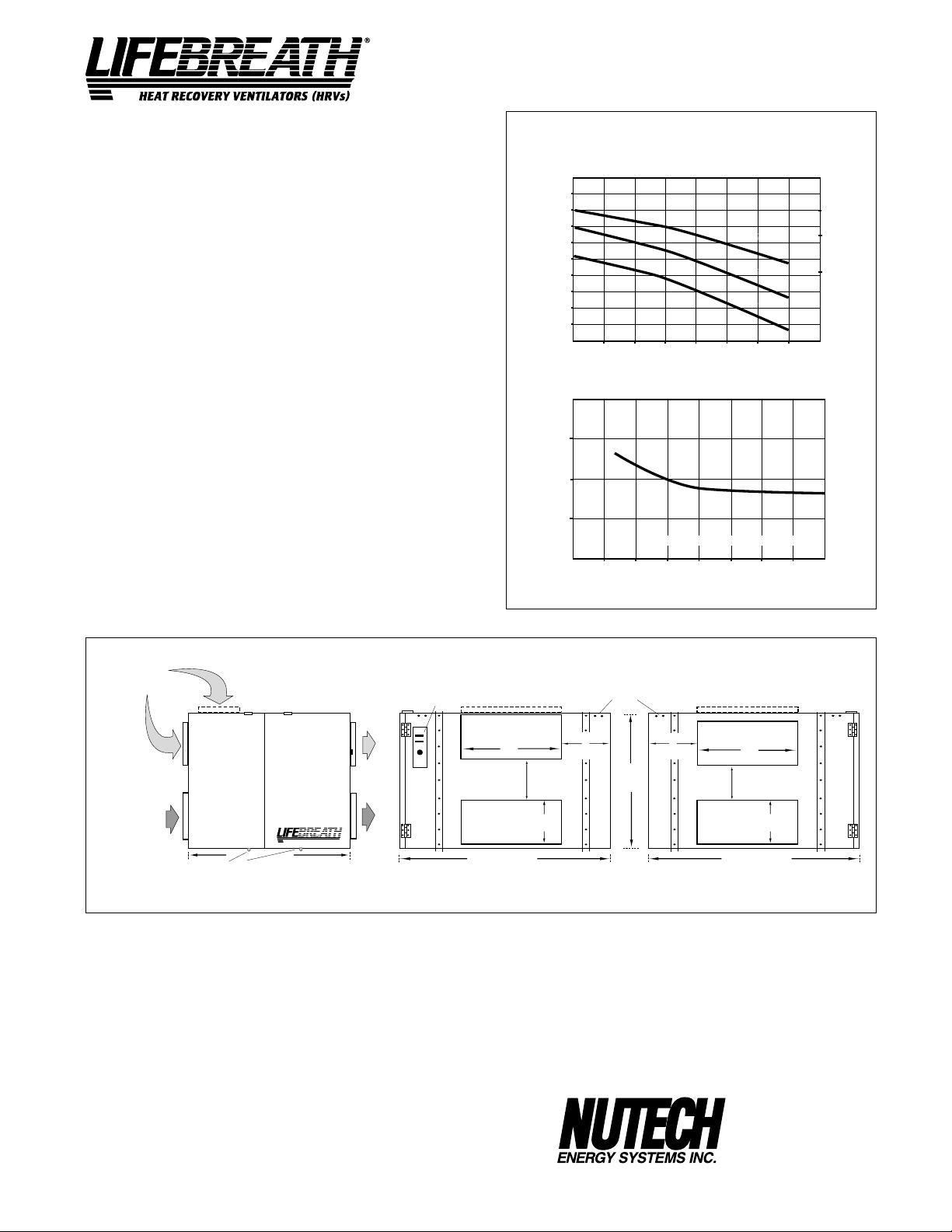

Model 700

FD/DD

SPECIFICATIONS

CORES

Modular (2 section) patented aluminum heat recovery cores

arranged for efficient cross-flow ventilation.

MOTORS

Two PSC, 3 speed single shafted, 120 VAC, 2.75 Amps each (5.5

total on high speed). HP - 1/10, 1625 RPM. Watts - total on high

speed - 648.

FILTERS

Washable air filters in exhaust and supply air streams.

BLOWERS

Centrifugal type rated at 329 L/s (700 CFM) free air delivery. Each

air stream has one single shafted motor driving a centrifugal blower.

CONNECTION DUCT SIZES

Four - 356 mm x 200 mm (14" x 8" ).

MOUNTING

Unit to be set on support brackets hung by threaded rod type

apparatus (brackets and rods not provided).

CASE

20 gauge prepainted galvanized steel (G60) for superior corrosion

resistance. Insulated with foil faced insulation where required to

prevent exterior condensation. Drain connections; two - 12 mm

(1/2") O.D.

CONTROLS

Illuminated power switch, 3 speed blower control, low voltage (24

VAC) terminals for connection of remote controls and defrost light

indicating automatic operation.

DEFROST CONTROLS

MODEL 700 FD - Interrupts supply air while exhaust air defrosts core.

MODEL 700DD - Supply bypass routes indoor air to defrost core.

WEIGHT 64.4 kg (142 lbs.) SHIPPING WEIGHT 75.8 kg (167 lbs.)

PERFORMANCE

MODEL 700FD, 700DD

AIRFLOWS (Each Air Stream)

423 (900)

378 (800)

329 (700)

282 (600)

235 (500)

190 (400)

143 (300)

94 (200)

AIRFLOW L/s (CFM)

42 (100)

25 (.1) 50 (.2) 75 (.3) 100 (.4) 125 (.5) 150 (.6) 175 (.7)

EXTERNAL STATIC PRESSURE IN PASCALS (IN. W.C.)

TEMPERATURE EFFECTIVENESS

70%

60%

50%

EFFECTIVENESS

143

(300)

HIGH SPEED

MED SPEED

LOW SPEED

NOTE: Exhaust Relative Humidity (RH) at 40%

190

(400)

AIRFLOW IN L/s (CFM)

235

(500)

(600)

282

329

(700)

5.5 HIGH

5.0 MED

4.7 LOW

TOTAL CURRENT DRAW (AMPS) @ 120 VAC

SUPPLY AIR

FROM OUTSIDE

FD MODEL ONLY

NOTE:

Service clearance

is 760 mm (30 in.)

from front

access doors

EXHAUST AIR

FROM BUILDING

OPTIONS

DD MODEL ONLY

DRAIN CONNECTION

FRONT VIEW

753 mm (29 5/8")

DIMENSIONS 700

EXHAUST AIR

TO OUTSIDE

625 mm

(24 5/8 ")

HEAT RECOVERY VENTILATORS (HRVs)

¤

SUPPLY AIR

TO BUILDING

CONTROLS

DISCHARGE SIDE

All units conform to CSA and UL standards.

99-101 Sixty Minute Timer

WARRANTY

99-130 Remote Wall Mount Dehumidistat Control

24 VAC only

All units carry a 15 year warranty on the heat recovery cores

and a 2 year replacement parts warranty.

DATE: __________________________

PROJECT: ________________________________________

MECHANICAL CONTRACTOR: ________________________________

8

mm (inches)

356 mm

(14")

200 mm

(8")

730 mm

(28 3/4")

210 mm

(8 1/4")

165 mm

MOUNTING POINTS

(6 1/2")

165 mm

(6 1/2")

356 mm

(14")

159 mm

(6 1/4")

200 mm

(8")

730 mm

(28 3/4")

INLET SIDE

511 McCormick Blvd.

London, Ontario

Ph: (519) 457-1904

Fx: (519) 457-1676

Email: nutech@lifebreath.com

Website: www.lifebreath.com

N5W 4C8

TI-103

0011

Page 9

Model 1200FD/DD

SPECIFICATIONS

CORES

Modular (3 section) patented aluminum heat recovery cores arranged

for efficient cross-flow ventilation.

MOTORS

Two PSC, 3 speed double shafted, 120 VAC, 4 Amps each (8.1 total on

high speed). HP - 1/4, 1625 RPM. Watts - total on high speed - 972.

FILTERS

Washable air filters in exhaust and supply air streams.

BLOWERS

Centrifugal type rated at 1200 cfm (566 L/s) free air delivery. Each air

stream has one double shafted motor driving a centrifugal blower.

CONNECTION DUCT SIZES

Four - 20" x 8" (508 mm x 200 mm).

MOUNTING

Unit to be set on support brackets hung by threaded rod type

apparatus. (brackets and rod not provided).

CASE

20 gauge prepainted galvanized steel (G60) for superior corrosion

resistance. Insulated with foil faced insulation where required to

prevent exterior condensation. Drain connections; two - 1/2" (12 mm) O.D.

CONTROLS

Illuminated power switch, 3 speed blower control, low voltage (24

VAC) terminals for connection of remote controls and defrost light

indicating automatic operation.

DEFROST CONTROLS

MODEL 1200FD - Interrupts supply air while exhaust air defrosts core.

MODEL 1200DD - Supply bypass routes indoor air to defrost core.

WEIGHT 191 lbs. (87 kg) SHIPPING WEIGHT 215 lbs. (98 kg)

AIRFLOW L/s (CFM)

613 (1300)

566 (1200)

518 (1100)

472 (1000)

423 (900)

378 (800)

329 (700)

282 (600)

235 (500)

70%

60%

EFFECTIVENESS

50%

PERFORMANCE

AIRFLOWS (Each Air Stream)

8.1 HIGH

518

(1100)

7.8 MED

7.1 LOW

566

(1200)

HIGH SPEED

MED SPEED

LOW SPEED

25 (.1) 50 (.2) 75 (.3) 100 (.4) 125 (.5) 150 (.6) 175 (.7)

EXTERNAL STATIC PRESSURE IN PASCALS (in. W.C.)

TEMPERATURE EFFECTIVENESS

NOTE: Exhaust Relative Humidity (RH) at 40%

235

(500)

282

(600)

AIRFLOW IN L/s (CFM)

329

(700)

378

(800)

423

(900)

472

(1000)

TOTAL CURRENT DRAW (AMPS) @ 120 VAC

SUPPLY AIR

FROM OUTSIDE

FD MODEL ONLY

NOTE:

Service clearance

is 760 mm (30 in.)

from front

access doors

EXHAUST AIR

FROM BUILDING

DD MODEL ONLY

DRAIN CONNECTION

FRONT VIEW

DIMENSIONS 1200

EXHAUST AIR

TO OUTSIDE

HEAT RECOVERY VENTILATORS (HRVs)

759 mm (29 7/8")

¤

SUPPLY AIR

TO BUILDING

CONTROLS

DISCHARGE SIDE

mm (inches)

508 mm

(20")

1055 mm

(41 1/2")

OPTIONS

All units conform to CSA and UL standards

99-101 Sixty Minute Remote Timer

99-130 Remote Wall Mount Dehumidistat Control

24 VAC only

DATE: __________________________

PROJECT: ________________________________________

MECHANICAL CONTRACTOR: ________________________________

WARRANTY

All units carry a 15 year warranty on the heat recovery cores

and a 2 year replacement parts warranty.

9

172 mm

(6 3/4")

200 mm

(8")

MOUNTING POINTS

263 mm

(10 3/8")

625 mm

(24 5/8 ")

263 mm

(10 3/8")

508 mm

(20")

149 mm

(5 7/8")

200 mm

(8")

1055 mm

(41 1/2")

INLET SIDE

511 McCormick Blvd.

London, Ontario

Ph: (519) 457-1904

Fx: (519) 457-1676

Email: nutech@lifebreath.com

Website: www.lifebreath.com

N5W 4C8

TI-120

0011

Page 10

CLEAN • FRESH • AIR

®

Model 500ERV

SPECIFICATIONS

LATENT RECOVERY (MOISTURE) TRANSFER CORES

Modular (4 section) 2- Enthalpic, 2 Aluminum arranged for high

efficiency crossflow ventilation.

MOTORS - Two PSC, 5 speed double shafted, 120 VAC, 3.15 Amps

each (6.3 total on high speed). HP - 1/10, 1625 RPM. Watts - total on

High Speed - 610.

FILTERS - Washable air filters in exhaust and supply air streams.

BLOWERS - Centrifugal type rated at 530 cfm (250 L/s) free air

delivery. Each air stream has two centrifugal blowers driven by two

PSC motors.

CONNECTION DUCT SIZES Four - 14" x 8" (356 mm x 200 mm).

MOUNTING - Unit to be set on support brackets hung by threaded

rod type apparatus (brackets and rods not included).

DEFROST - Damper defrost system.

CASE - 20 gauge prepainted galvanized steel (G60) for superior

corrosion resistance. Insulated with foil faced insulation duct liner

where required to prevent exterior condensation. Drain connection,

One - 1/2" (12 mm) O.D.

CONTROLS - ControlAir 15

WEIGHT 178 lbs. (81 kg) SHIPPING WEIGHT 203 lbs. (92 kg)

PERFORMANCE

AIRFLOWS (Each Air Stream)

282 (600)

235 (500)

190 (400)

143 (300)

94 (200)

AIRFLOW L/s (CFM)

42 (100)

25 (.1) 50 (.2) 75 (.3) 100 (.4) 125 (.5)

EXTERNAL STATIC PRESSURE IN PASCALS (in. W.C.)

TEMPERATURE EFFECTIVENESS

100%

90%

EFFECTIVENESS

80%

94

(200)

143

(300)

AIRFLOW IN L/s (CFM)

SPEED

5

4

3

2

1

NOTE: Exhaust Relative Humidity (RH) at 40%

190

(400)

235

(500)

6.3 HIGH

3.8 MED

3.1 LOW

282

(600)

TOTAL CURRENT DRAW (AMPS) @ 120 VAC

DIMENSIONS 500ERV

EXHAUST AIR

TO OUTSIDE

NOTE:

Service clearance

is 30 in. (760 mm)

SUPPLY AIR

FROM OUTSIDE

DEFROST

ENTHALPIC CORE ALUMINUM CORE

49"

DRAIN CONNECTION

(1245 mm)

FRONT VIEW

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min. (3 wire)

99-105 Programmable Ventilation Control includes

Programmable Time Clock, Dehumidistat and

Air Sentry™

99-109 Air Sentry™ Air Quality Monitor designed to

accept remotely mounted Control Pad

DATE: __________________________

PROJECT: ________________________________________

MECHANICAL CONTRACTOR: ________________________________

EXHAUST AIR

FROM BUILDING

18 3/4"

(475 mm)

SUPPLY AIR

TO BUILDING

10

1 1/4"

(32 mm

)

INTERIOR DUCT

All units conform to CSA and UL standards.

WARRANTY

Units carry a 5 year warranty on the energy recovery cores,

a 15 year warranty on aluminum cores and a 2 year

replacement parts warranty.

ERVs are not recommended for regions where the

design temperature is below 25°F (-4°C)

inches (mm)

14"

(356 mm)

28 1/4 "

(717 mm)

CONNECTION SIDE

5 7/8"

(150 mm)

8"

(200 mm)

18 3/4"

(475 mm)

MOUNTING POINTS

5 7/8"

(150 mm)

1 3/8"

(35 mm)

EXTERIOR DUCT

14"

(356 mm)

28 1/4"

(717 mm)

CONNECTION SIDE

511 McCormick Blvd.

London, Ontario

Ph: (519) 457-1904

Fx: (519) 457-1676

Email: nutech@lifebreath.com

Website: www.lifebreath.com

8"

(200 mm)

N5W 4C8

TI-130

0105

Page 11

CLEAN • FRESH • AIR

®

Model 700ERV

SPECIFICATIONS

LATENT RECOVERY (MOISTURE) TRANSFER CORES

Modular (2 section) enthalpic (moisture) transfer cores

arranged for efficient cross-flow ventilation.

MOTORS

Two PSC, 3 speed single shafted, 120 VAC, 2.75 Amps each

(5.5 total on high speed). HP - 1/10, 1625 RPM. Watts - total

on high speed - 648.

FILTERS

Washable air filters in exhaust and supply air streams.

BLOWERS

Centrifugal type rated at 700 CFM (329 L/s) free air delivery.

Each air stream has one single shafted motor driving a

centrifugal blower.

CONNECTION DUCT SIZES

Four - 14" x 8" (356 mm x 200 mm)

MOUNTING

Unit to be set on support brackets hung by threaded rod type

apparatus (brackets and rods not provided).

CASE

20 gauge prepainted galvanized steel (G60) for superior

corrosion resistance. Insulated with foil faced insulation

where required to prevent exterior condensation.

CONTROLS

Illuminated power switch, 3 speed blower control, low voltage

(24 VAC) terminals for connection of remote controls.

WEIGHT 142 lbs (64.4 kg) SHIPPING WEIGHT 167 lbs. (75.8 kg)

PERFORMANCE

AIRFLOWS (Each Air Stream)

423 (900)

378 (800)

329 (700)

282 (600)

235 (500)

190 (400)

143 (300)

94 (200)

AIRFLOW L/s (CFM)

42 (100)

25 (.1) 50 (.2) 75 (.3) 100 (.4) 125 (.5) 150 (.6) 175 (.7)

EXTERNAL STATIC PRESSURE IN PASCALS (IN. W.C.)

TEMPERATURE EFFECTIVENESS

70%

60%

50%

EFFECTIVENESS

143

(300)

HIGH SPEED

MED SPEED

LOW SPEED

NOTE: Exhaust Relative Humidity (RH) at 40%

190

(400)

AIRFLOW IN L/s (CFM)

235

(500)

(600)

282

329

(700)

5.5 HIGH

5.0 MED

4.7 LOW

TOTAL CURRENT DRAW (AMPS) @ 120 VAC

DIMENSIONS 700ERV

SUPPLY AIR

FROM OUTSIDE

NOTE:

Service clearance

is 30 in. (760 mm)

EXHAUST AIR

FROM BUILDING

ENTHALPIC CORE

29 5/8"

(753 mm)

HEAT RECOVERY VENTILATORS (HRVs)

EXHAUST AIR

TO OUTSIDE

¤

SUPPLY AIR

TO BUILDING

24 5/8 "

(625 mm)

FRONT VIEW

OPTIONS

99-101 Sixty Minute Remote Timer

All units conform to CSA and UL standards.

DATE: __________________________

PROJECT: ________________________________________

MECHANICAL CONTRACTOR: ________________________________

CONTROLS

DISCHARGE SIDE

WARRANTY

Units carry a 5 year warranty on the energy recovery cores

and 2 year replacement parts warranty.

ERVs are not recommended for regions where the design

temperature is below 25°F (-4°C)

11

inches (mm)

14"

(356 mm)

8"

(200 mm)

28 3/4"

(730 mm)

8 1/4"

(210 mm)

6 1/2"

(165 mm)

MOUNTING POINTS

6 1/2"

(165 mm)

14"

(356 mm)

6 1/4"

(159 mm)

8"

(200 mm)

28 3/4"

(730 mm)

INLET SIDE

511 McCormick Blvd.

London, Ontario

Ph: (519) 457-1904

Fx: (519) 457-1676

Email: nutech@lifebreath.com

Website: www.lifebreath.com

N5W 4C8

TI-131

0105

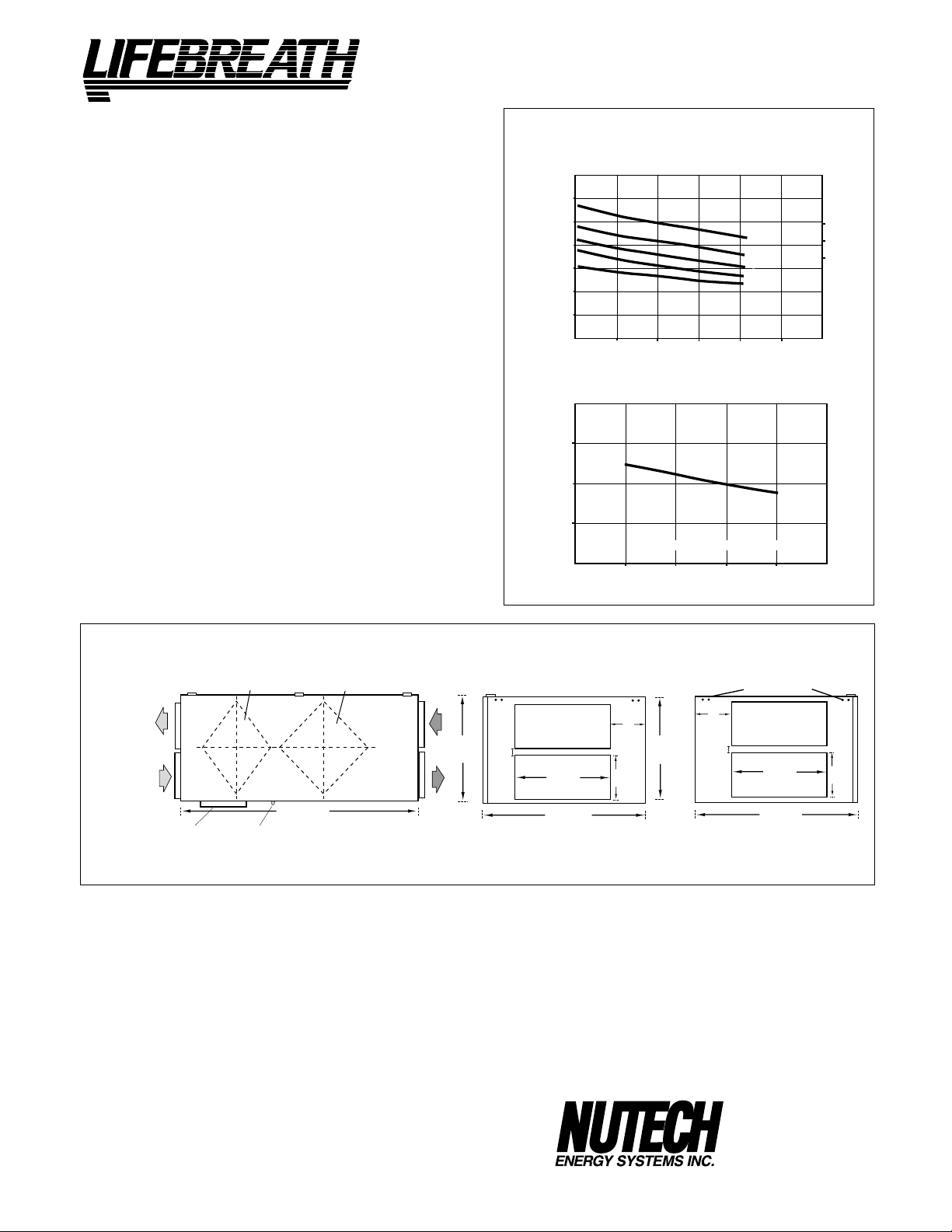

Page 12

®

CLEAN • FRESH • AIR

SPECIFICATIONS

LATENT RECOVERY (MOISTURE) TRANSFER CORES

Modular (3 section) latent recovery (moisture) transfer cores

arranged for efficient cross-flow ventilation.

MOTORS

Two PSC, 3 speed double shafted, 120 VAC, 4 Amps each

(8.1 total on high speed). HP - 1/4, 1625 RPM. Watts - total

on high speed - 972.

FILTERS

Washable air filters in exhaust and supply air streams.

BLOWERS

Centrifugal type rated at 1200 cfm (566 L/s) free air delivery.

Each air stream has one double shafted motor driving a

centrifugal blower.

CONNECTION DUCT SIZES

Four - 20" x 8" (508 mm x 200 mm).

MOUNTING

Unit to be set on support brackets hung by threaded rod type

apparatus. (brackets and rod not provided).

CASE

20 gauge prepainted galvanized steel (G60) for superior

corrosion resistance. Insulated with foil faced insulation

where required to prevent exterior condensation.

CONTROLS

Illuminated power switch, 3 speed blower control, low voltage

(24 VAC) terminals for connection of remote controls.

WEIGHT 191 lbs. (87 kg) SHIPPING WEIGHT 215 lbs. (98

kg)

Model 1200ERV

PERFORMANCE

AIRFLOWS (Each Air Stream)

613 (1300)

566 (1200)

518 (1100)

472 (1000)

423 (900)

378 (800)

329 (700)

AIRFLOW L/s (CFM)

282 (600)

235 (500)

25 (.1) 50 (.2) 75 (.3) 100 (.4) 125 (.5) 150 (.6) 175 (.7)

EXTERNAL STATIC PRESSURE IN PASCALS (in. W.C.)

TEMPERATURE EFFECTIVENESS

70%

60%

EFFECTIVENESS

50%

235

(500)

NOTE: Exhaust Relative Humidity (RH) at 40%

282

329

(700)

(800)

(600)

AIRFLOW IN L/s (CFM)

378

HIGH SPEED

MED SPEED

LOW SPEED

423

(900)

472

(1000)

518

(1100)

8.1 HIGH

7.8 MED

7.1 LOW

TOTAL CURRENT DRAW (AMPS) @ 120 VAC

566

(1200)

DIMENSIONS 1200ERV

EXHAUST AIR

HEAT RECOVERY VENTILATORS (HRVs)

TO OUTSIDE

¤

SUPPLY AIR

TO BUILDING

CONTROLS

(1055 mm)

DISCHARGE SIDE

20"

(508 mm)

41 1/2"

WARRANTY

SUPPLY AIR

FROM OUTSIDE

NOTE:

Service clearance

is 30 in. (760 mm)

from front

access doors.

EXHAUST AIR

FROM BUILDING

OPTIONS

ENTHALPIC CORE

29 7/8"

(759 mm)

FRONT VIEW

Units carry a 5 year warranty on the energy recovery cores

99-101 Sixty Minute Remote Timer

and 2 year replacement parts warranty.

ERVs are not recommended for regions where the design

All units conform to CSA and UL standards.

temperature is below 25°F (-4°C)

DATE: __________________________

PROJECT: ________________________________________

MECHANICAL CONTRACTOR: ________________________________

12

inches (mm)

10 3/8"

(263 mm)

6 3/4"

(172 mm)

8"

(200 mm)

(625 mm)

24 5/8 "

10 3/8"

(263 mm)

20"

(508 mm)

5 7/8"

(149 mm)

8"

(200 mm)

41 1/2"

(1055 mm)

INLET SIDE

511 McCormick Blvd.

London, Ontario

Ph: (519) 457-1904

Fx: (519) 457-1676

Email: nutech@lifebreath.com

Website: www.lifebreath.com

N5W 4C8

TI-132

0105

Page 13

Location for Mounting

The Ductwork System

The HRV/ERV must be located in a conditioned

space where the surrounding air temperature

does not fall below 60˚F (16˚C). The unit must be

mounted level (horizontal). The warranty will be

void if these conditions are not met.

Typically the HRV/ERV is positioned close to

an outside wall or the roof to simplify the

connections and keep the length of insulated

ducting required for the fresh air intake to a

minimum.

A minimum clearance of 36 inches (90 cm) in

front of the HRV/ERV is recommended to service

the ventilator. The HRV/ERV may be mounted on

an equipment platform providing the drain hoses

are clear and there is sufficient space to open the

doors for servicing.

Install the drain pans in the bottom of the

HRV/ERV so the drain (not on all models)

connections protrude through the holes provided.

Use drain hoses with hose clamps to connect the

drain pan outlets to a floor drain or standpipe.

Make sure the drain line slopes down to the

outlet. If this is not possible a condensate pump

will be required for positive removal of the water.

Protect the drain line from freezing.

A properly designed ducting system will allow the

HRV/ERV to operate at its maximum efficiency.

(Air flow will be restricted by undersized ducting,

use of too many elbows, tees, bends, etc.).

Always try to keep duct runs as short and

straight as possible.

NOTE: Fully insulated ducting with an integral

vapour barrier must be used on all runs

passing through unheated areas in order

to avoid condensation problems and

energy losses from the air steams.

All joints must be airtight, sealed and impervious

to moisture. See specification sheets for each

unit for exact duct sizes and location.

To minimize pressure drop and noise, galvanized

metal ducts, properly sized, are recommended.

Keep ducting as short as possible and use a

minimum of elbows and tees. Connecting sections

and shorter runs may be flexible ducting one size

larger than the metal equivalent. Use flexible duct

connectors at the

transmission.

All duct joints must be secured with screws,

rivets or duct sealant and sealed with aluminum

duct tape to prevent leakage.

HRV/ERV

to avoid noise

DRAIN

SPOUT

Forming the “P” Trap

TAPE

HRV CABINET

DRAIN

SPOUT

TEE

CONNECTOR

TO DRAIN

13

Page 14

Outside Weatherhoods

The weatherhoods must have built-in “bird” screen with

1/4 in (63.5 mm) minimum mesh to prevent birds and

rodents from entering into the ductwork. Do not

smaller mesh as it will be very susceptible to plugging

up. Gravity dampers at the vents must not be used as

they will restrict air flow and often “seize up”. The

preferred location of the outside weatherhoods is:

• no less than 10 ft. (3 m) apart from each other

• at least 18 in ( 46 cm) above snow line or

ground level

• away from sources of contaminants, such as

automobile exhaust fumes, gas meters,

garbage cans, containers, etc.

• not exposed to prevailing winds, whenever

reasonable possible

The outside perimeter of the weatherhood must be

caulked to prevent leakage into the building.

The design and size of the weatherhoods or louvres

chosen by the installer must allow for adequate free

area. Water and debris penetration of the system is

minimized when the airflow does not exceed 1000 FPM

(5.08 m/s) free area velocity.

use

Ducting from the Weatherhoods

All duct joints must be fastened with screws, rivets or

duct sealant and wrapped with a quality duct tape to

prevent leakage. We recommend aluminum foil tape.

Stale Air Return System

The stale air return system is used to draw air from the

points in the building where the worst air quality

problems occur. Balancing dampers and/or adjustable

grilles are recommended on all return air lines which

are used during installation to help balance the “draw”

from different areas of the building.

Alternately, the stale air may be drawn directly from

the return air duct. When this system is used, the air

handler’s blower must constantly operate. The exhaust

takeoff connection must be at least a 3 ft (1 m) from

a directly connected HRV/ERV supply duct if both are

connected to the same duct run. Static pressure of the

air handlers return system should be noted and

compensated for if, it is apparent that the static

pressure of the return in the air handler will exceed

.1 to .15” W.C.

A damper located just prior to the HRV/ERV is

required to balance the stale air exhausted with the

fresh air supply entering the building.

Galvanized sheet metal ducting with sufficient cross

section with an integral single piece vapour barrier should

be used to connect the HRV/ERV to the weatherhoods.

All ducting must meet UL Class 1 requirements.

A minimum R value of insulation should be equal to

4 (RSI 0.75)

A good bead of high quality caulking (preferably acoustical sealant) and taping with a high quality aluminum foil

tape is recommended to seal the duct to both the

HRV/ERV and the weatherhood.

Warmside Ducting - General

Ducting from the HRV/ERV to the different areas in the

building should be galvanized metal whenever possible.

To minimize airflow losses in the ductwork system, all

ducts should be as short as possible and with as few

bends or elbows as possible. 45° elbows are preferred

to 90° elbows. Use “Wye” (Y) fittings instead of “Tees”

(T) whenever possible.

Return air suction points should be located on the

opposite side of the room from the fresh air inlet. The

inlets may be located in the ceiling or high on the walls

and fitted with inlet grilles.

Many commercial activities produce air contaminants in

the form of dusts, fumes, mists, vapours and gases.

Contaminants should be controlled at the source so that

they are not dispersed through the building nor allowed

to increase to toxic concentration levels. The ventilator

allows for economical operation of the HVAC system

while effectively removing contaminants from the space.

In designing the exhaust portion of the system

the exhaust grilles are placed so as to remove the

contaminants while not allowing them to enter the

breathing zone of the occupants.

For contaminants that are lighter than air, grilles should

be located high on the wall. If contaminants are heavier

than air, a lower placement of the grilles will be

required. Information on a contaminants specific gravity

and toxicity should be available from chemical data

sheets.

14

Page 15

Fresh Air Supply System

The Integrated HVAC System

The fresh air supply ductwork from the HRV/ERV may

be directly connected to the return air duct of the

forced air system. Check the air flow balance of the

HRV/ERV with the air handler blower both “ON” and

“OFF” to determine that it does not imbalance the

HRV/ERV more than 10%. Also, it is advisable to

include a short length of flex duct or other non-metallic

connector in this hard ducted line in order to keep

the HRV/ERV acoustically isolated and separately

grounded (electrically) from the air handler. This will

avoid a possible shock hazard to service people if a

short to ground develops in one of the devices.

It may be necessary to install a separate fresh air supply

ductwork system if the heating is other than forced air.

When installing an HRV/ERV, the designer and

installer should be aware of local codes that may

require smoke detectors and/or firestats in the HVAC

or HRV/ERV ductwork.

Because an HRV/ERV is designed to bring fresh air

into the building, structures may require supply voltage

interrupt when smoke or flame sensors are triggered,

or when a central fire alarm system is activated.

Supply air grilles may be ceiling or high wall mounted.

Avoid locating incoming fresh air grilles that could

cause a direct draft on the occupants as the incoming

air may be below room temperature. A reheat duct

heater can be installed to improve occupant comfort.

The use of balancing dampers or adjustable grilles to

balance the flow rates into various rooms is

recommended.

The use of balancing dampers or adjustable grilles

as supply air diffusers and air exhaust covers are

recommended. TECHGRILLES™ are round, efficient,

sound absorbing devices available in 4”, 5”, 6” and 8”

(100, 125, 150, and 200 mm) models.

Figure A and B

The HRV/ERV has become an integral component of

the HVAC system. Figure A shows an HRV/ERV unit

providing fresh air directly to the return air plenum of a

rooftop heat/cool unit.

In the balanced airflow system, the HRV/ERV exhaust

removes stale room air (eg. from lunch room, storage

or copy area) and returns to the space an equal

amount of fresh outdoor air, making the use of an

economizer obsolete in conjunction with an HRV/ERV.

Many buildings have ceiling return air plenum as

in Figure B. Fresh air from the HRV/ERV can be

introduced directly into the ceiling space but this

should occur near the air handler’s intake.

By operating the HRV/ERV on a 24 hour/7 day battery

backed timer, the unit can be set to operate only when

occupancy or indoor conditions require the air

exchange.

In installations where it is satisfactory to provide

general exhaust from the space, the air to be

exhausted may be taken directly from the return air

plenum to the HRV/ERV as it is drawn back to the air

handler. Fresh air supplied by the HRV/ERV is then

introduced directly into the return air plenum but at a

location closer to the air handler. The air handler

would have a constant running blower to effectively

distribute the fresh air and remove the stale air.

Balancing dampers would be located in both the

HRV/ERV supply and exhaust ducts between the

return air plenum and the HRV/ERV.

NOTE: At no time should the air handler T.E.S.P. on

the return duct exceed that of the HRV/ERV .

TECHGRILLE

(optional)

schematic

AIR FLOW

SUPPLY

AIR FLOW

EXHAUST

15

Page 16

The Integrated HVAC System

ROOFTOP

ECONOMIZER

UNIT

FRESH AIR

SUPPLY

STALE AIR

EXHAUST

Figure A

HRV/ERV UNIT

RETURN AIR DUCT or

BREATHER T

B.D.

B.D.

HRV/ERV FRESH

AIR SUPPLY

SUPPLY DUCT

STALE AIR

EXHAUST TO HRV/ERV

Example only - Duct connections not typical

ECONOMIZER

FRESH AIR

SUPPLY

STALE AIR

EXHAUST

Figure B

ROOFTOP

ROOF DECK

CEILING RETURN AIR PLENUM

12" BREATHER

HRV/ERV UNIT

B.D.

HRV/ERV FRESH

AIR SUPPLY

Example only - Duct connections not typical

16

UNIT

SPACE

B.D.

STALE AIR EXHAUST

SUPPLY DUCTWORK

Page 17

Figure 7A

Saddle Installation

Various Installation Types

NOTE: When installing your HRV/ERV

flexible duct connectors should

be installed between the HRV/ERV

and the galvanized duct work.

Vibration Isolators

Threaded

rod and U channel

(Supplied by others)

(Supplied by others)

Hang unit with suspended rods

and "U" channel members.

Figure 7C

Suspended

PVC Support Straps

(Supplied by others)

Figure 7B

Curb Mounted

Curb is wood or metal

(Supplied by others)

Mount unit on wooden or metal

curb assembly. Unit must be raised

an adequate height for installation

and slope of drain lines.

May be anchored to

floor,leaving space

for drain connections

Vibration Isolators

(Supplied by others)

Unit Suspended using

Polyester reinforced PVC support straps.

17

Page 18

Electrical Connections

It is recommended that a licensed electrician make all

electrical connections. It is very important that the

unit be properly grounded. It is recommended that a

separate 15 amp/120 volt circuit be used.

accumulation. After the defrost period, the fresh air

supply fan automatically returns to the normal speed

and fresh outside air continues to be drawn into the

building. Water from the melted frost collects in the

bottom drip pans and drains out through the bottom

W

ARNING: In order to prevent electric shock when

cleaning or servicing the HRV/ERV, it is extremely

important to confirm the polarity of the power line that is

drain connections. The defrost cycle repeats

automatically until the air temperature rises

above 27˚F(-3˚C).

switched by the safety (disconnect) switch whose control

arm is located on the outside of the electrical control box

area. The hot line (black) is the proper line to be switched.

DAMPER DEFROST

To confirm the proper polarity, use a voltmeter or test lamp

to make sure there is no power after the switch when the

Models 700DD, 850DD, 1200DD

door is open. Check between that point and ground (on the

cabinet). This must be done as occasionally some

buildings are improperly wired. Always make sure the

HRV/ERV is properly grounded.

These damper defrost HRV’s have an electronically

controlled damper defrost mechanism. If the outside

temperature drops below 27˚F(-3˚C ), the defrost timer

is activated. A motor driven damper door mechanism

opens the defrost port and at the same time closes off

the supply air from outside. After approximately 3

minutes, the damper operates in the opposite direction

to close off the defrost port and reopen the fresh air at

the supply port. The 27.5 minute wait time and 3

minute defrost cycle repeat until the temperature again

Line

Black

White

Power Supply

Cord

rises above 27˚F (-3˚C).

Black

Neut.

Power

Terminal

Block.

Green

Self Test of Defrost Systems

Models 700, 850, 1200

GND.

If confirmation of the defrost system is needed,

complete the following steps.

1. Disconnect power to the unit and open access/

Electrical Connection

2. Locate the “snap disc” type temperature sensor

FAN DEFROST

3. Disconnect the two wires from the HRV to the

Models 700FD, 850FD, 1200FD

4. Using a jump wire with alligator clips, join two

Fan defrost HRV’s are equipped with an electronically

controlled fan defrost system to remove frost that

collects on the warm air side of the aluminum heat

transfer surfaces of the heat exchanger core. When

the outside air temperature drops below 27˚F(-3˚C),

defrost is activated which provides for an automatic

defrost cycle. During the automatic defrost cycle the

fresh air supply is shut off while the exhaust fan contin

ues to operate. This allows warm inside air to

flow through the heat exchanger core melting frost

5. Close access doors and power the unit.

This procedure will simulate a defrost that would occur

automatically in the field when the outside temperature

drops below -3˚C (27˚F).

maintenance doors.

mounted in the upper left hand corner (cold air

stream) of the HRV.

sensor, at the sensor.

wires from the HRV together.

18

Page 19

Speed Selection and Controls

Model 700, 850 and 1200 HRV/ERV only

These models are equipped with a 3 speed

control, low medium and high, as well as a

lighted on/off switch and a 4 screw terminal strip.

The terminal strip can be used to connect any

low voltage device which will then jump the unit

to high speed from whatever setting the speed

control was on. The terminal strip can also be

wired to allow the unit to be turned off from a

ON

OFF

ON/OFF ONLY

LOW

HIGH

LOW/HIGH ONLY

SWITCHING FROM REMOTE LOCATION

*Supplied and Installed by Contractor*

remote location as well as from high to low from

a remote location. To wire the unit in this

configuration you would need two electrical on/off

switches to be installed at the remote location

into a double gang electrical enclosure or side by

side. One should be labeled on/off and the other

should be labeled high/low.

ON/OFF SWITCH

ON

OFF

LOW

HIGH

ON/OFF/LOW/HIGH

COMMON

3 SPEED CONTROL

HIGH

ON/OFF

Optional Remote Controls

RED BLACK ORANGE

DEHUMIDISTAT VENTILATION

CONTROL (DVC)

PART NO. 99-116

•Turns ERV ON/OFF

• Dehumidistat increases

ventilation when required

DEHUMIDISTAT

PART NO. 99-130W

•Provides high speed

ventilation when humidity

level exceeds setting

Dehumidistat

Setting Relative to

Outside Conditions

WINTER:

Set dehumidistat

between 30% to 40%.

If home is too dry,

adjust to higher setting.

If home is too humid,

adjust to lower setting.

SUMMER:

Set dehumidistat

to OFF.

Off

10

20

60

50

30

40

60 MINUTE CRANK TIMER

PART NO. 99-101

•Provides high speed

ventilation for 60 minutes

This style of remote switching began

approximately July 1997

19

Page 20

ControlAir 15

OPTIONAL REMOTE CONTROLS Model 500 Only

PROGRAMMABLE VENTILATION CONTROLLER (PVC)

LOCATION: Hallway, kitchen, office

& work place

(connect 1/unit only)

• Advanced digital remote.

• Digital dehumidistat.

• Full fan speed control.

AIR SENTRY™

•

Recirculation mode (on compatible

•

Air Quality Sensor built-in.

HRV/ERVs).

• 7 day, 24 hour programmable timer.

• Digital display and status lights.

• 100' (30 m) maximum wire length.

PART NO. 99-105

Connects to RED, ORANGE, GREEN and YELLOW terminals.

*NOTE: This device is NOT compatible with the Air Sentry.

NEW! VENTILATION DEHUMIDISTAT

LOCATION: Central location in house.

• Dehumidistat activates high speed

VENTILATION

DEHUMIDISTAT

over-ride when humidity level in home

exceeds setting.

• Knockout designed to accept Control

Pad when remotely mounted, giving full

HRV/ERV functionality & control from

remote location.

NEW!

AIR SENTRY™ AIR QUALITY SENSOR

LOCATION: Kitchen, basement,

work place

• Digital Air Quality Monitor.

™

ENTRY

S

IR

A

ENSOR

S

UALITY

Q

IR

A

IGITAL

D

• Status light indicates fan speed.

(connect 1/unit only).

• Increases ventilation to remove

odours and contaminants.

• Among gases detected are

FAN SPEED INDICATOR

cigarette smoke and formaldehyde.

• 100' (30 m) maximum wire length.

• Knockout designed to accept Control

Pad when remotely mounted.

PART NO. 99-109

Connects to RED, GREEN and YELLOW terminals.

*NOTE:

This device is NOT compatible with the PVC.

ControlAir 15

Control Module

Control Pad

• All controls wire to

matching colour on

the Control Module.

• Control Pad can be

removed and mounted

in a remote location.

PART NO. 99-250

Connects to BLACK, RED, GREEN and YELLOW terminals.

*Replaces 99-116 DVC & 99-230 VRD.

*Only compatible with ControlAir 15 electronics.

DIGITAL ELECTRONIC TIMER (DET)

LOCATION: Bathrooms & kitchen

Connect up to 8 on 300

•

If a PVC or Air Sentry is used, connect

•

up to 5 on 300

' wire max.

• Touch pad operation.

• 20/40/60 minute status lights.

• Compact wall mount unit.

• Mounts in 2x4 box.

Shown with “decora” cover plate

•

PART NO. 99-104

Connects to RED, GREEN and YELLOW terminals.

' (91 m) wire max.

(99-107W).

•

Control Pad mounts

in a 2”x 4” box or can

be mounted in the

optional Ventilation

Dehumidistat or

Air Sentry.

• Full fan speed control.

•

Three Modes of Operation

- Standby/ON

- 20 ON / 40 OFF

-

Recirculation

(on compatible HRV/ERVs)

*See individual control instructions for more details.

20

0011

Page 21

FUNCTION & CONTROL

Model 500 Only

Operating the ControlAir 15

Plugging in the HRV/ERV energizes the unit. A self test

function will be performed every time the HRV/ERV is

energized (refer to “Self Test” for more details). After

the self test has completed successfully the HRV/ERV

will default to Speed 1. This is the factory default

setting. Follow the instructions found on the HRV/ERV

door to select desired mode and speed, or refer to the

instructions found on the following page.

Control Module

Control Pad

ControlAir 15

Exploded view

Self Test

Each time the

test function will automatically initiate. During the self

test the

available (1-5), test the damper motor operation and will

default back to the previous mode/speed selection,

(factory default is Speed 1). Total self test duration is

approximately 1 min. 30 sec.

HRV/ERV

HRV/ERV

is powered/energized the self

will cycle through all the speeds

Automatic Defrost Operation

(Not on all models)

The advanced technology of the digital microprocessor

automatically activates the defrost system only as it is

needed. To be an efficient heat recovery device, the

HRV/ERV must effectively provide for core defrost as well

as providing efficient heat exchange. As outdoor

conditions cool, the temperature sensor (thermistor) tracks

the supply air temperature. The thermistor then sends its

signal to the microprocessor (circuit board) which initiates

only the defrost cycle time required to clear the core. On

recirculating defrost models, the core is defrosted when

the supply air port is automatically blocked off and exhaust

air is redirected back through the HRV/ERV. On damper

defrost models, the core is defrosted when the supply air

port is automatically blocked off and the warm air

surrounding the HRV/ERV is drawn in through the defrost

port. The mode indicator will flash RED during the defrost

cycle. This dramatic advance makes more energy

available for recovery as the unit spends less time in

defrost mode. By optimizing the defrost cycle, the

HRV/ERV combines money saving performance with a

well designed and reliable control system.

Removing and relocating the

Control Pad

The Control Pad can be removed and installed in a

remote location (100’ wire length max). The Control Pad

can be installed in a 2x4 box with a “Decora” type cover

plate or can be installed in the optional “Ventilation

Dehumidistat” or “Air Sentry”. When the Control Pad is

installed in a remote location, all optional controls will still

be wired to the Control Module on the

remotely mounted on its own, the Control Pad is wired to

the Control Module by 3 wire (min. 20 gauge). Connect

the colour coded terminals to the corresponding terminals

on the Control Module. When the Control Pad is remotely

mounted in the Ventilation Dehumidistat or Air Sentry,

refer to optional controls page for wiring requirements.

HRV/ERV

. When

21

Glossary

DEFROST MODE - to ensure reliable operation during cold

weather, the HRV/ERV will automatically cycle through its

defrost mode as needed. (not on all models)

DEHUMIDISTAT - a control device that senses the amount of

moisture in the air and will activate high speed fan operation

when the air moisture level exceeds the control setting. The

optimum air moisture level (or relative humidity [Rh]) in the

typical home is in the range of 30 to 40% Rh.

RESET - whenever resetting of the HRV/ERV is required,

simply disconnect power for 30 seconds.

STANDBY MODE - the HRV/ERV is energized and waiting for fan

operation to be initiated by a remote device or manual override.

THERMISTOR

measures electrical resistance in a known manner, as

outdoor temperatures fluctuate.

- the

HRV/ERV

's temperature sensor which

Page 22

To select mode of operation for ControlAir 15

Model 500 Only

Press and hold the fan selection button on the Control Pad. After 5 seconds the control will

begin to cycle each mode holding each for 2 seconds. Release the button when the desired

mode of operation is reached.

Modes of Operation LED Indication

OFF No LED’s illuminated HRV/ERV is off, no controls will

initiate operation.

Standby / On Steady Green LED and Yellow LED to indicate speed

HRV/ERV will run at speed selected in ventilation mode.

Standby mode is indicated by no speed indicator

illuminated. Optional remote controls will override standby

or selected speed into high speed.

20 On / 40 Off Flashing Green LED and Yellow LED to indicate speed

HRV/ERV will operate in ventilation mode at speed selected

for 20 minutes and OFF for 40 minutes.

To select speed

Momentarily press fan selection button and release. HRV/ERV will move into next speed.

OFF is indicated by no yellow LED illuminated. Speed 1 is the first yellow LED. Speed five is

indicated by a flashing speed 4 LED.

Automatic Defrost

During cold outdoor conditions the

function, which will prevent ice from forming on the core. Defrost is indicated by a flashing Red

LED indicator.

HRV/ERV

will occasionally go into an automatic defrost

22

Page 23

PITOT TUBE AIR FLOW BALANCING

It is necessary to have balanced air flows in an HRV/ERV. The volume

of air brought in from the outside must equal the volume of air exhausted

by the unit. If the air flows are not properly balanced, then;

• The HRV/ERV may not operate at its maximum efficiency

• A negative or positive air pressure may occur in the house

• The unit may not defrost properly

• Failure to balance HRV/ERV properly may void warranty

For general balancing it is sufficient to move the pitot tube around in

the duct and take an average or typical reading. Repeat this procedure

in the other (supply or return) duct. Determine which duct has the highest airflow (highest reading on the gauge). Then damper that airflow

back to match the lower reading from the other duct. The flows should

now be balanced. Actual airflow can be determined from the gauge

reading. The value read on the gauge is called the velocity pressure.

The Pitot tube comes with a chart that will give the air flow velocity

Excessive

walls of the building where it may condense (in cold weather) and

degrade structural components. May also cause key holes to freeze up.

positive pressure may drive moist indoor air into the external

based on the velocity pressure indicated by the gauge. This velocity

will be in either feet per minute or metres per second. To determine the

actual airflow, the velocity is multiplied by the cross sectional area of the

duct being measured.

Excessive

In some geographic locations, soil gases such as methane and radon

gas may be drawn into the home through basement/ground contact

areas. Excessive negative pressure may also cause the backdrafting of

vented combustion equipment.

Read the Application Warning on the front of this manual!

Prior to balancing, ensure that:

1. All sealing of the ductwork system has been completed.

All of the HRV/ERV's components are in place and functioning properly.

2.

3. Balancing dampers are fully open.

4. Unit is on HIGH speed.

5. Air flows in branch lines to specific areas of the house should be

negative pressure may have several undesirable effects.

This is an example for determining the airflow in a 6" duct.

The Pitot tube reading was 0.025 inches of water.

From the chart, this is 640 feet per minute.

The 6" duct has a cross sectional area of =

The airflow is then:

640 ft./min.

For your convenience, the cross sectional area of some common

round duct is listed below:

DUCT DIAM. (inches) CROSS SECTION AREA (sq. ft.)

adjusted first prior to balancing the unit. A smoke pencil used at the

grilles is a good indicator of each branch line's relative air flow.

6. After taking readings of both the stale air to the

HRV/ERV

duct and

fresh air to the house duct, the duct with the lower CFM ([L/s]

velocity) reading should be left alone, while the duct with the higher

reading should be dampered back to match the lower reading.

7. Return unit to appropriate fan speed for normal operation

The accuracy of the air flow reading will be affected by how close to

any elbows or bends the readings are taken. Accuracy can be

increased by taking an average of multiple readings as outlined in the

literature supplied with the Pitot tube.

[

3.14 x(6"÷12)

= 0.2 square feet

X

0.2 square feet = 128 cfm

5 0.14

6 0.20

7 0.27

2

]

÷4

BALANCING PROCEDURE

The following is a method of field balancing an

HRV/ERV

using a Pitot tube,

Pitot tube and gauge

advantageous in situations when flow stations are not installed in the ductwork. Procedure should be performed with the

HRV/ERV

The first step is to operate all mechanical systems on high speed,

have an influence on the ventilation system, i.e. the

on high speed.

HRV/ERV

itself and

which

the forced air furnace or air handler if applicable. This will provide the

maximum pressure that the

HRV/ERV

will need to overcome, and allow

for a more accurate balance of the unit.

Drill a small hole in the duct (about 3/16"), three feet downstream of

any elbows or bends, and one foot upstream of any elbows or bends.

These are recommended distances but

the actual installation may limit the

Place pitot tube a minimum of 18" from blower or elbows

amount of straight duct.

The Pitot tube should be connected to a

magnehelic gauge or other manometer

capable of reading from 0 to 0.25 in. (062 Pa) of water, preferably to 3 digits of

resolution. The tube coming out of the

top of the pitot is connected to the high

pressure side of the gauge. The tube

coming out of the side of the pitot is connected to the low pressure or reference

side of the gauge.

Insert the Pitot tube into the duct; point-

Magnehelic

gauge

MAGNEHELIC

Pitot

tube

ing the tip into the airflow.

AIR FLOW

Pitot tube

Magnehelic gauge

Magnehelic

gauge

MAGNEHELIC

MAGNEHELIC

DUCT

Pitot Tube Air Flow

Balancing Kit

c/w magnehelic gauge,

Pitot tube, hose and

carry case.

PART NO. 99-167

Outdoors

Pitot

tube

Note: Duct connections may vary,

depending on model.

23

TI-74-2C

0105

Page 24

SERVICE/MAINTENANCE

Servicing your HRV/ERV on a regular schedule will

result in optimum operating efficiencies and

prolonged life of the equipment.

Due to numerous applications in which this

equipment can be installed, it is difficult to predict

servicing intervals. In certain situations where there

is heavy smoke, servicing the equipment every one two months may be needed; whereas ventilating a

meeting room for example for carbon dioxide may

only need service every six months to a year.

MOTOR

Access to the motor is through the front service

doors. Note heat exchanger core can be removed to

provide more room. See CORE in this section.

The motor is a permanent split capacitor type (PSC)

which uses a sleeve mechanism to steady the shaft.

There is an oil wick beside the sleeve which supplies

oil to it on a continuous basis.

If the motor does not have oil tubes, no maintenance

is required.

Access to the wick is through oil tubes, (two per

motor) located in the motor case itself. These oil

tubes are either capped with yellow plugs, (which

need to be removed for oiling) or have clear tubes

protruding from them.

In either case an oiling device such as an “Oil

Telespout” filled with 20 S.A.E. non-detergent electric

motor oil should be used to put oil inside the tubes. A

couple of drops of oil once a year will do.

DO NOT OVER OIL!

HRV CORE (HRV only)

The heat exchange core is accessible through the

front service door. Special care and attention should

be given to this component as the edges may be

sharp, and the core itself susceptible to damage

if dropped.

When removing the core, the location it is removed

from should be noted.

The core is removed by carefully pulling the core

outward from the unit, sliding it evenly along its “H

channel” supports found in each corner of the core.

Note the core may have some resistance when

sliding out. Avoid tilting the core as this will result in

its edges catching the H channel and temporarily

preventing its removal.

In most cases, washing the core in a mild

detergent and warm water will be all that

is needed to completely clean them. Do not use

harsh chemicals as this may cause corrosion in the

HRV. The time between core service will depend

on the application the HRV has been installed in.

It can be as often as one - two months or at the very

least, cleaned every six months. When reinstalling

the core you must note foam location and drip

edge location for proper core placement.

See diagram below.

ERV CORE (ERV only)

Remove core and vacuum or use low pressurized

clean core. Do not wash or submerse in water.

With the core in its proper position, place the

bottom flange, (approximately 1/4”) into its H channel

support, then place the left side, the right side and

finally the top flange into place in the same fashion.

Once all four corners are in place, push the core

evenly into the cabinet until it reaches the back. Be

sure the drip edges are overlapping the drip trays.

Note the core will protrude slightly out from the front

of the cabinet, this is so the access door, when

closed, ensures a tight fit.

air to

FRONT VIEW

Models 700, 1200 Model 500

FILTER

DOUBLE

DRIP EDGE

CORE

FILTER

DRAIN PANS (not on all models) DRAIN PANS (not on all models)

Note location and arrangement of cores and filters when removing.

DOUBLE

DRIP

EDGES

FILTER

SINGLE

DRIP EDGE

CORE

Model 850

DOUBLE

DRIP EDGE

CORE

24

FILTER

DOUBLE

DRIP

EDGES

FILTER

LEFT DRIP

EDGE

SINGLE DRIP

EDGE CORE

DRAIN

PAN

RIGHT DRIP

EDGE

FILTER

Page 25

FILTERS

Open front service door to access the filters

located in both supply and exhaust air streams.

Note to remove and install filters, it may be easier

to first remove the core(s). See CORE.

The filters are designed to stop large particles

from entering in the core. The filters are fastened

in place by a metal spring rod. To remove filters

from core(s) simply pull the rod from one end,

outward until free from core lip, and remove.

Only use warm water with a mild detergent to

wash the filters. Do not use harsh chemicals.

The time between filter service will depend on the

application the HRV/ERV has been installed in. It

can be as often as one - two months or at the

very least, cleaned every six months.

CONDENSATE DRAINS

The condensate drains consist of two drain pans

which may collect water after the HRV/ERV

initiates a defrost cycle, and a drain line to

remove the condensate.

Maintenance on this portion of the system should

be done as often as possible and should not

exceed six months. Note bacterial growth in

standing water is a major concern to healthy

indoor air quality, and should be avoided whenever

possible.

To clean these components, open the front

service door and flush the pans with water.

Ensure that the pans drain completely and in a

reasonable amount of time. Note if the water

does not drain right away, check for blockage in

the drain line, also check that the drain line has a

good slope to it. (1/8 - 1/4” per foot)

DUCT WORK

It is a good idea to inspect ducting, outside

weather hoods (wall caps), and grilles for blockage

and dirt buildup, at least every six months.

Outside weather hoods should be protected by a

rodent screen which can plug up with debris.

Also, it is a good idea to visually confirm that

the fresh air supply is free from any sources of

contamination, such as other vented combustion

equipment added after the fact.

DAMPER MOTOR

The damper motor, (if applicable) is a self

contained motor and does not require service.

The damper door attached to the motor could use

a little lithium grease on the shaft opposite the

motor, where it enters its holder, once every

two - three years.

General Maintenance

As a final step in a routine maintenance

schedule, it is a good idea to confirm operation of

the system, checking speed control functions and

remote control operation, if applicable.

Wipe the inside of the cabinet to remove dust and

cob webs as needed.