Page 1

Exhibition News

2 012

InnoTrans 2012

September 18 - 21 - Berlin

Liebherr-Transportation

Systems

Liebherr-Aerospace

© DB AG, Air bus

Page 2

22

Editorial

Francis Niss

Dear Reader,

InnoTrans in Berlin is an event of utmost importance for Liebherr. As in the past, we are participat-

ing with enthusiasm this year to present the products and the technologies we have developed

for the rail industry.

The industry is currently facing a downturn. Indeed, the global economic and financial conditions

restrain the implementation of new train projects and the replacement of rolling stock. Even in

China, the world’s most important market for the rail industry, several new programs have sud-

denly been frozen.

Nevertheless, we continue to experience sustainable growth thanks to our long-term develop-

ment strategy.

We have decided to concentrate our engineering skills at our main site in Korneuburg (Austria)

in order to consolidate efficiency. We have launched a promising process for product standard-

ization as well as for the reduction of lead-time and development cost. In Korneuburg, we are

establishing engineering and production expertise for highly efficient hydraulic systems derived

from the technologies we developed for the aerospace industry.

Of course, we continue to invest in environmentally friendly technologies such as air cycle and

CO

air conditioning as well as in other solutions for the reduction of noise emissions, on-board

2

weight and energy consumption.

A modern and competitive production center in Bulgaria and a joint venture in China complement

the Korneuburg site. Our customer service activities show substantial growth thanks to dynamic

commercial action and our global presence.

Thus, Liebherr is well prepared to meet the future challenges of the rail industry, which still shows

considerable growth potential in the medium and long term.

We hope you enjoy reading this new edition of our exhibition news and have a successful

InnoTrans 2012.

Best regards,

Francis Niss

President, Liebherr-Aerospace & Transportation SAS

Page 3

Contents

33

Editorial 2

Liebherr-Transportation Systems 4

A Strong Network ................................................... 6

Air Cycle Air Conditioning Technology ..................... 8

Electro-Hydraulic Actuation .................................... 10

Saline Provides Services

for Rail Vehicle Industry ......................................... 12

News From Around the World ............................... 14

Liebherr-Aerospace 16

Major Investments 18

Liebherr-Aerospace in the Americas ....................... 20

A Supplier to Airbus from the Very Beginning ........ 22

CSeries: Landing Gear and

Air Management Systems .................................... 24

AW189, Global 7000 / 8000 Program .................... 25

Vast Array of Products for the Aviation Industry .... 26

Liebherr Group News 28

Growth in the Business Year 2011 ......................... 30

Domestic Appliances Receive Awards ................. 33

New Liebherr T 284 Mining Truck ......................... 34

Publisher’s Address .............................................. 36

Page 4

© Bombardier Transportation

Liebherr-Transportation Systems

Page 5

Page 6

6

Transportation Systems

Liebherr’s Transportation Systems Division,

a Strong Network

The railway industry shows growth per-

spectives in the medium term, even if it

seems that the dynamics have slight-

ly slowed down in the last few months.

While countries that were hit particu-

larly hard by the current economic and

debt crisis cancelled or postponed sev-

eral projects, the railway industry as a

whole continues to grow.

The driving forces behind this growth

are new railway projects on the one

hand, and modernization measures in

the fields of long-distance traffic for

the main routes, subways and street-

cars on the other hand. Additionally,

this develop ment is supported by new

environmental protection requirements

and the highly congested transfer routes

in metropolitan areas.

Within its long-term strategy Liebherr-

Transportation Systems continues to

promote the expansion of its organiza-

tion in selected new markets or market

regions like North America, Russia or

Brazil with the aim of local presence. At

the same time Liebherr-Transportation

Systems has reinforced the sales

and service teams in its core markets

France, Germany and United Kingdom.

The process-based organization of

Liebherr-Transportation Systems has

been further developed in order to im-

prove smooth collaboration across the

different sites and to ensure that eve-

ry individual part of the organization re-

mains responsible for its tasks while

contributing to the achievement of the

company’s overall objectives. By en-

hancing simultaneous engineering the

lead time of the projects could be short-

ened even further. Thus, product quali-

ty, customer satisfaction and sustaina-

bility have been further increased.

Moreover, Liebherr-Transportation Systems

has started to concentrate all heating,

ventilation and air conditioning (HVAC)

product development activities at its

main site in Korneuburg (Austria). The

aim is to benefit from synergies that

the utilization of engineering resourc-

es and infrastructure, the standardiza-

tion of business processes, the existing

in-house production as well as test fa-

cilities offer.

Furthermore, the collaboration with

the development and project manage-

ment departments is being improved

in order to meet customer needs in an

even more suitable manner and to im-

plement the sales and service strategy,

which was defined for the entire trans-

portation field. Here the standardiza-

tion of processes across all Liebherr-

Transportation Systems sites has

especially proven its worth.

The organizational alignment of the

hydraulic systems area has been com-

pleted: Liebherr-Transportation Systems

further established its responsibility re-

garding marketing, sales and customer

service (including repair and overhaul) of

hydraulic systems and equipment,

in the framework of a close collabo

with Liebherr-

GmbH (Ger

ment of the manufacturing network,

which was kicked off some years ago,

was also further advanced.

Aero space Lindenberg

many). The strategic align-

with-

ration

Page 7

Transportation Systems

Liebherr-Transportation

Systems GmbH & Co KG

in Korneuburg, Austria

7

The manufacturing site of Liebherr-

Transportation Systems in Radinovo

(Bulgaria) has expanded its operation.

The local company called Liebherr-

Transportation Systems Marica EOOD

is in charge of the series production of

all large-scale European HVAC projects.

The joint venture in China’s Zhejiang

province, Liebherr Zhongche Transportation

Systems Co., Ltd., has successfully in-

creased its production program in the

field of HVAC systems for Chinese car

manufacturers, who contribute to pro-

jects in and beyond China.

In addition, the plant of Liebherr-

Transportation Systems GmbH & Co KG

in Korneuburg has been further devel-

oped in order to optimize performance

and quality, flexibility and high-speed re-

action time, which contributes to the di-

vision’s competitiveness. The range of

products manufactured in Korneuburg

is subsequently being enlarged.

Liebherr-Transportation Systems is be-

ing prepared to launch the assembly

and test of hydraulic products in the

near future, which will complement

the traditional HVAC systems railway

application.

All employees work hard to make one

vision come true: that of Liebherr-

Transportation Systems becoming a

global player and a worldwide reference

in the fields of HVAC, hydraulics and

power supply systems for the railway

industry. A major achievement in this

context was the renewal of the IRIS (Inter-

national Railway Industry Standard) cer-

tification of the Liebherr- Transportation

Systems’ sites in Korneuburg, Mannheim

and Radinovo in autumn 2011.

Service specialists

checking an air

conditioning unit

Page 8

8

Transportation Systems

The Eco-Friendly Solution

for Air Conditioning in Trains

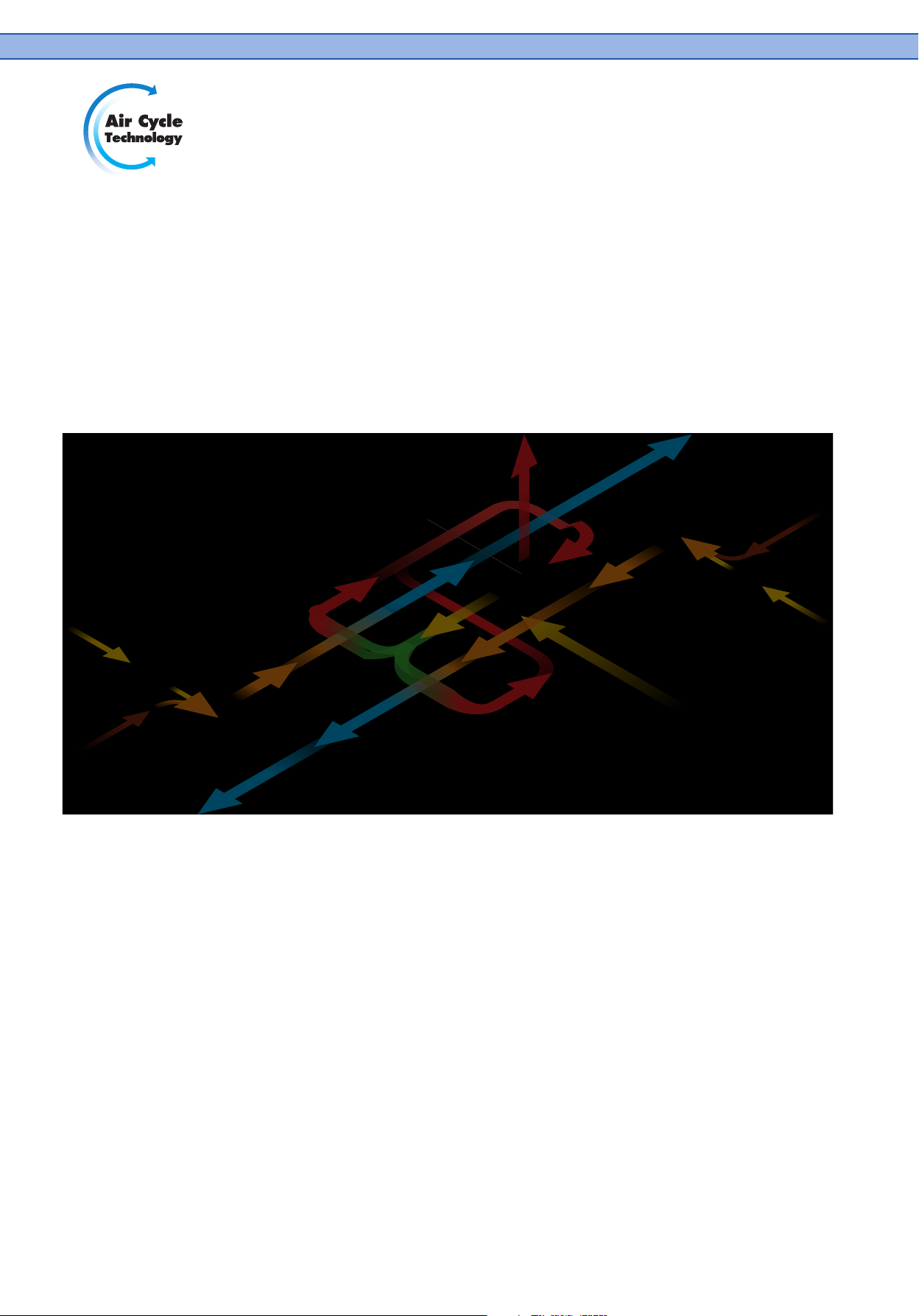

Liebherr’s air cycle air conditioning sys-

tem simply uses air as refrigerant to pro-

vide a comfortable climate for passen-

gers. The system operates with an open

loop process and draws the air required

for the cooling process from the environ-

ment. The air expands and thus cools.

Then the cool air runs through the heat

exchanger and is subsequently returned

to the ambience.

Fresh Air

Filter

When developing the system, Liebherr

took advantage of its long-term expe-

rience in the aircraft industry: air cycle

air conditioning systems made by

Liebherr have been installed on board of

numerous aircraft.

The system for application in rail vehicles

complies with all common passenger

comfort requirements such as UIC 553,

Exhaust

Process Air

Heater

MCT

EN13129 and EN14750, and – as a real

alternative to chemical refrigerants –

helps to reduce the greenhouse effect

according to worldwide HFC regulations.

As the system does not use any other re-

frigerant than air, there is no risk of refrig-

erant leakage and the compliance with

any future legislation regarding refriger-

ants in air conditioning systems is abso-

lute and unlimited.

Supply Air

Fan

Return Air

Filter

Fresh Air

Fresh Process Air

Return Air

Fan

Heater Heat Exchanger

Supply Air

Liebherr’s Air Cycle Air Conditioning Technology

Gives Proof of its Qualities

Liebherr-Transportation Systems’ cut-

ting-edge eco-friendly technology for air

conditioning of railway vehicles – the air

cycle air conditioning system – has prov-

en its outstanding performance in dai-

ly service. During the past seven years,

application in ICE 3 high speed trains

has demonstrated that this future-proof

technology derived from Liebherr’s

aerospace branch is superior to tradi-

tional vapor cycle air conditioning con-

cepts in terms of eco-friendliness, total

cost of ownership and enhanced pas-

senger comfort.

Liebherr's air cycle air conditioning tech-

nology features significantly reduced life

cycle costs compared to common vapor

cycle systems. Life cycle costs of tradition-

al air conditioning systems consist of sev-

eral items, the most significant ones be-

ing the direct maintenance on the system,

unscheduled vehicle downtime due to

system failure, spare part administration

and power consumption. Additional oper-

ating costs related to the refrigerant circuit

such as refrigerant handling and disposal,

retrofit of refrigerant in order to comply

with future regulations, or refrigerant emp-

tying / refilling times also contribute to the

high life cycle costs of traditional techno-

logies, increasing the attractiveness of the

air cycle technology.

Page 9

Transportation Systems

9

Thanks to the reduced number of its

key components, which is based on the

fact that the refrigerant channel does

not need to be sealed, the system offers

higher reliability. Moreover, failed com-

ponents can be isolated and exchanged

much faster on an air cycle system than

on a traditional system, which normally

requires the replacement of the complete

cooling unit. Therefore maintenance op-

erations are significantly simpler.

In all, the reliability of Liebherr’s air cy-

cle air conditioning system helps to save

direct maintenance costs and leads to

considerably reduced vehicle down-

times. In the case of maintenance the

reduced number of parts in the system

ease any maintenance and repair, while

simplified accessibility guarantees effi-

cient time-saving service. Maintenance

does not require EG 303/2008 refriger-

ant-trained and certified personnel any-

more. Moreover, storage, handling and

future accounting of refrigerant on site

are no longer necessary. Furthermore,

with a view to a future ban of chemical

refrigerants, the air cycle air condition-

ing units will not need to be retrofitted or

adapted, thus accounting for an addition-

al cost advantage when compared to va-

por cycle units.

A key advantage of the air cycle sys-

tem technology is its ability to continue

operating even when external tempera-

tures are extremely severe and beyond

normal operating conditions. For exam-

ple, it even continues generating cool

air under high external temperatures. In

contrast to this, the vapor cycle system

stops operating due to the refrigerant

overpressure switch. This key feature

guarantees that the air cycle air condi-

tioning systems works when it is most

needed, thus preventing inside cabin

temperatures from exceeding outside

temperatures.

Other benefits this technology offers to

passengers are the low measured noise

and vibration levels in the car and on

the platform. Liebherr-Transportation

Systems is the only supplier in the industry

to develop the air cycle machine / cooling

turbine in-house, which guarantees the

long-term availability of this next genera-

tion technology for railway applications.

From September 18 - 21, 2012, Liebherr-Transportation Systems will present

numerous innovative solutions at InnoTrans in Berlin (Germany) at booth no. 232

in hall 3.1. Energy-efficient and environmentally friendly air conditioning systems,

reliable hydraulic actuation systems and electronic compo-

nents, or a high-performance railroad excavator with rail bo-

gies – the variety of products and services on display represent

Liebherr’s comprehensive know-how in the transportation

sector.

Outdoor display

at InnoTrans

Page 10

10

Transportation Systems

Electro-Hydraulic Actuators −

an Intelligent Solution for Rail Transport

Electro-hydraulic actuators (EHA) work

as compact, high-performance “pow

houses” in rail vehicles, and are pro-

duced by Liebherr to meet specific cus-

tomer requirements in a wide range of

applications.

Twindexx Express

These applications include active lateral

suspension and active lateral centering

systems, car positioning systems, ac-

tive radial control, active wheelset control

and tilt technology. Among other attrib-

utes, EHA make a valuable contribution

to reducing the burden on the environ-

ment and preventing wear while increas-

ing performance.

Liebherr performs their assembly, fill-

ing and final testing under extremely

er

clean conditions and thus ensures they

will achieve many years of service in the

tough environment of rail transport. The

car manufacturer fits the Liebherr EHA

© Bombardier Transportation

to the vehicle and installs the cable con-

nection for the energy supply and con-

trol systems. The time-consuming in-

stallation work required on conventional

hydraulic systems to route the lines, fill

and vent the circuit is thus eliminated.

This also removes the risk of contaminat-

ing the hydraulic fluid through incorrect

installation work and, as a result, dam-

aging the actuator. The system could

almost be described as having ‘plug and

play’ functionality.

EHA from Liebherr are fundamental-

ly maintenance-free. If, nevertheless, a

fault should occur, the entire unit can be

quickly replaced without any hydraulic

expertise, thus avoiding prolonged vehi-

cle downtime.

The innovative EHA systems are regulat-

ed by a controller which communicates

with the vehicle control unit via CAN bus.

This controller was also developed by

Liebherr.

Liebherr’s EHA can be adapted for all

customer requirements and ensure fast,

comfortable, and above all safe arrivals

at the destinations.

At train speeds of up to 350 km/h EHA

have to move heavy loads of several tons

into the position specified by intelligent

control units, or counteract vibrations

occurring on the vehicle. They not only

make faster train speeds possible, but

also increase passenger comfort.

A further key advantage of EHA is that

they reduce car and infrastructure wear

enormously. Initially rather high invest-

ment costs are recouped very quickly

through lower maintenance expenses,

reduced total energy costs and higher

carrying capacity compared with con-

ventional hydraulic systems. EHA are

self-contained hydraulic systems.

Above: Active yaw

damper system

Below: Actuator for

tilting technology

Page 11

The new Bombardier

V300 ZEFIRO high-speed train

© Bombardier Transportation

New Generation of Compact,

Transportation Systems

11

Reliable and Service-Friendly Actuators

Last year, Liebherr-Transportation Systems

developed a new type of electro-hydraulic

drive system for rail vehicles for

Bombardier Transportation. In the first

stage, concepts for two versions of this

new actuator type were drawn up. One

version is used for active roll compensa

on the new InterCity double-decker

coaches of Swiss Federal Railways

(SBB). The other version is used for active

yaw compensation on Bombardier’s new

V300 ZEFIRO Italia high-speed train.

The new actuator type is part of a new

platform strategy, for which Liebherr is

developing customer-specific actuators

for as broad a range of applications as

possible. These include elements for

active rotational damping, active later-

al suspension, lateral compensation, tilt

technology and level control.

The new generation of actuators differs

from the electro-hydraulic actuators de-

veloped by Liebherr in the past in that

the electronics are now integrated into

the device. They now assume the task

of regulating and monitoring the individ-

ual actuator. The computer in the vehi-

cle is merely responsible for coordinating

the individual actuators among each oth-

er. Communications with this computer

are conducted using a robust CAN bus

tion

signal, allowing the number of electrical

connections needed in the overall system

to be substantially reduced. Another ad-

vantage of bus communications is that

the parameters specific to the vehicle

or the actuator can be made available

through the bus system. Therefore an ac-

tuator can, for example, be used in dif-

ferent vehicles without any modifications

to its software. Equally, it is possible to

change the mechanical or hydraulic para-

meters of the actuator without software

modifications.

Another feature of Liebherr's new actu-

ator type is the complete integration

the bogie frame. The actuator is sim

sideways into the opening provided in

the frame. This guarantees optimal ac-

cessibility to the actuator when it is in-

stalled, and allows the complete elec-

tronics or individual hydraulic valves to

be exchanged within a very short space

of time without removal of the device.

Direct thermal contact means that the

bogie frame can also act as a cooler for

the actuator.

Not only in its installation attention was

paid to optimal service friendliness, but

also in its design. For example, all com-

ponents which could potentially fail can

be quickly and simply replaced. The num-

p ly slid

ber of parts subject to wear has been re-

duced to small assembly modules, and

a paint finish has been deliberately omit-

ted, keeping the follow-on costs incurred

during an overhaul to a minimum.

With the new generation of compact,

reliable and service-friendly actuators,

Liebherr-Transportation Systems has

developed a highly versatile basis for a

wide range of future applications. Funda-

mentally, these are configured as highly

dynamic, power-regulated components.

Versions with travel control circuit are,

however, also possible. The design was

configured to allow additional expansion

into

stages to be realized. That permits the

actuator to be expanded by a second

controlling element, for example, retain-

ing use of many individual components.

One actuator controlling element can

thus tilt the coach frame while the sec-

ond radially adjusts the axis to the spe-

cific radius of the bend.

Page 12

12

Transportation Systems

Liebherr Aerospace Saline, Inc. Provides Services

for Rail Vehicle Industry

Liebherr Aerospace Saline, Inc. is now also

engaged in servicing transportation sys-

tems. The company has recently estab-

lished a test area to service Liebherr’s level-

ing systems. By 2016, 706 rail cars will be

equipped with these systems and delivered

to the Chicago Transit Authority (CTA), which

operates the transit system of the Chicago

metropolitan area (Illinois, USA). The leve-

ling system adjusts the boarding height of

the vehicle to the station or platform. The

final assembly of the rail cars will be per-

formed by Bombardier Transportation in

Plattsburgh (New York, USA).

Liebherr Aerospace Saline, Inc. provides

technical support to Bombardier’s as-

sembly line and at the rail vehicle oper-

ators’ facilities as well as in-house repair

services. Over 40 maintenances have

been performed to date.

The Chicago metropolitan area dispos-

es of the second largest rail transit net-

work in the USA. Efficient functioning

of transport infrastructure is essential

to meet the needs of the approximate-

ly 10 million inhabitants. For this rea-

son, the Chicago Transit Authority has

started to modernize its transit system

and ordered 706 new vehicles from

Bombardier Transportation. These 5000

Series trains are the first ones anywhere

in North America to incorporate the ac-

tive hydraulic leveling systems built by

Liebherr-Aerospace Lindenberg GmbH

(Germany). This is the biggest single or-

der the company has ever won in the

transportation sector.

Each system consists of one hydraulic

unit, four hydraulically adjustable sus-

pension struts between the running

gear and the coach frame, four verti-

cal dampers, a control device and a hy-

draulic storage cylinder, the latter serv-

ing as an energy source in case of fault.

In addition to the supply and control

Chicago Transit

Authority (CTA) rail car

elements for the level-adjustment sys-

tem, the hydraulic unit incorporates an

independent supply for the brake sys-

tem including control and safety valves.

After the first leveling systems had been

approved of by the customer in spring

2008, Liebherr started producing them

in series (please refer to page 13).

© Bombardier

Transportation

Liebherr at Railway Interchange Exhibition

in Minneapolis

Liebherr-Transportation Systems partici-

pated in the Railway Interchange exhibi-

tion held at the Minneapolis Convention

Center (Minnesota, USA) from Septem-

ber 18 - 20, 2011. The company ex-

hibited as part of the “Made in Germa-

ny” booth which had been organized

and promoted by the German Ministry

of Economy and Technology. Although

Railway Interchange is an exhibition for

primarily railway infrastructure and sup-

port suppliers, Liebherr-Transportation

Systems made numerous contacts

at the exhibition and promoted other

Liebherr products illustrating the diver-

sified portfolio.

Railway Interchange offered various

technical forums as well as an indoor

and an outdoor exhibition on two sep-

arate sites. It was hosted by American

Railway Engineering & Maintenance-of-

way Association (AREMA), Railway Sup

ply

Institute (RSI), Railway Engineering-

Maintenance Suppliers Association

(REMSA), and Railway Systems Suppli-

ers Inc. (RSSI) – four organizations that

represent companies and individuals in-

volved in the railway and the rail industry.

Page 13

Order from Hungarian State Railways

Transportation Systems

13

In February 2012, Liebherr-Transportation

Systems received the order from the

Hungarian State Railways (MAV) to pro-

vide heating, ventilation and air condition-

ing systems (HVAC systems) for two new

prototype cars of the so called IC + train.

These coaches will be built in Szolnok,

about 100 km east of Budapest, and will

be ready by the end of the year 2012. The

contract considers an option of 48 addi-

tional coaches.

The IC+ train can operate with

a speed of up to 200 km/h

and is expected to be taken into

service in Hungary and on interna-

tional routes in 2013. The project is

supported by the European Union.

Heating, ventilation and

air conditioning (HVAC) unit

1,000th Leveling Actuator for Chicago Suburban Trains

Liebherr-Transportation Systems deliv-

ered the 1,000

active hydraulic level-adjustment system

of suburban train vehicles to Chicago

Transit Authority (CTA), Illinois (USA).

Liebherr was awarded the contract to de-

velop and supply this hydraulic system

after Bombardier Transportation had re-

ceived, in 2006, from CTA the order to

supply the suburban train vehicles. The

fleet is equipped with a special system

th

leveling actuator for the

for level-adjustment that makes board-

ing and de-boarding easier, for disabled

people in particular.

justment of the entrance height of the

carriages to each station or platform

the train approaches.

This was the first significant order in

the field of active hydraulic leveling sys-

tems won by Liebherr-Transportation

Systems. The leveling-system was de-

veloped and is manufactured at the

It enables the ad-

company’s facilities in Lindenberg

(Germany).

Suspension strut and

hydraulic power unit

New Office

in Paris

On September 15, 2011, Liebherr-

Transportation Systems opened a

new office in Gennevilliers, near Paris

(France). The team in Paris has been

supporting customers in South Eu-

rope and Latin America for the past

five years, building up close relation-

ships with car manufacturers and rail-

way operators.

The five specialists that belong to the team

cover the fields of marketing and sales,

project management, engineering support

and customer service. They work closely

with Liebherr-Transportation Systems’

headquarters in Korneuburg (Austria).

The establishment of a larger office in

Paris is a strong signal of the compa-

ny's long-term commitment to provide

train manu facturers and operators with

an even better level of support and re-

activity and meet each customer’s indi-

vidual requirements.

Left to right:

Managing D irector Liebher r-Transporta tion Sy stems Gmb H & Co KG

Purchas ing and As set Investments, Liebhe rr-Aerospace & Transp ortation SA S

Managing D irector and Chief O peratin g Offi cer, Produc tion,

Managing D irector Liebher r-Transporta tion Sy stems Gmb H & Co KG

Christian Rauscher

President Liebherr-Aerospace & Transportation SAS

Eléonor Borrallo-Gautier

Head of Pa ris Office, SW E urope & La tin Amer ica,

Liebherr-Transport ation Sy stems GmbH & Co KG

Francis Niss

Josef Gropper

Dirk Junghans

Page 14

14

Transportation Systems

Air Conditioning Systems for Variotrams in London

© Stadle r Pankow G mbH

Liebherr Supplies Bombardier

Low-Floor Trams

Railway vehicle manufacturer Bombardier

Transportation awarded Liebherr-

Transportation Systems with a contract

to supply 48 lightweight roof-mounted

air conditioning units for low-floor trams

to its site in Bautzen (Germany).

In August 2011, German railway

vehicle manufacturer Stadler

Pankow GmbH selected Liebherr-

Transportation Systems as suppli-

er of air conditioning systems for six

Variotrams. The trams will be op-

erated by Tramlink in the south of

London (UK).

These trams will be operated by the

Rhein-Neckar-Verkehr GmbH (RNV),

the Oberrheinische Eisenbahngesells-

chaft (OEG) and the Rhein-Haardt-

Bahn (RHB).

The package includes twelve saloon

rooftop air conditioning units and six

driver cab air conditioning units.

This is the sixth call-off order of the exist-

ing framework contract between Stadler

and Liebherr-Transportation Systems.

To date, air conditioning systems for

84 vehicle sets have been ordered.

© Bombardier

Transportation

Electro-Hydraulic Actuators for V300 ZEFIRO

High-Speed Trains

In December 2011, Liebherr-Transportation

Systems has received an order from

Bombardier’s bogies center of excel-

© Bombardier Transportation

lence in Siegen (Germany) to supply 800

electro-hydraulic actuators for the active

lateral suspension in the V300 ZEFIRO*

high-speed trains. By 2017 50 train sets

are to be equipped with 16 actuators

each. The first two devices were deliv-

ered on schedule in June 2012.

The electro-hydraulic actuators will ena-

ble the further improvement of the run-

ning characteristics of the FLEXX* speed

bogies, while reducing wear on wheel

and rail.

For Liebherr-Transportation Systems this

order represents another important mile-

stone in the successful implementation of

active damping systems in the rail sector.

* Trademark of Bombardier Inc. or its subsidiaries

Page 15

Supplying Swiss Railways’ Double-Decker

Transportation Systems

15

Liebherr-Transportation Systems has

recently been selected by Bombar-

dier's bogies business unit to supply

the roll compensation and lateral sus-

pension systems for Swiss Railways’

next generation double-decker inter-

city

service. This project will feature

© Bombardier Transportation

Bombardier FLEXX* Tronic WAKO*

technology which is an innovative me-

chatronic system for the compensation

of the natural roll movement of a car

body. Integrated into the existing sec-

ondary suspension, it allows a speed

increase of ~15 % in curves and, as a

result, shorter journey times with lower

investment in infrastructure.

Liebherr’s scope of supplies for this

system covers electro-hydraulic actu-

ators with integrated power electron-

ics for 59 trains. The parts will be de-

livered to Bombardier's bogies site in

Siegen (Germany). With this innovative

project Liebherr has proven once more

that the company is a reliable partner

for the railway industry with extensive

experience in the field of integrated hy-

draulic systems.

* Trademark of Bombardier Inc. or its subsidiaries

Delivery of Additional Air Conditioning Systems

to Slovakian Passenger Intercity Coaches

In May 2012, Liebherr-Transporta-

tion Systems has started to supply

the Slovakian railway vehicle man-

ufacturer and maintenance compa-

ny ZOS Trading s.r.o., based in Vrutky,

with ten additional air conditioning sys-

tems for passenger intercity coaches.

ZOS Trading s.r.o. had received the or-

der from Slovakian railway operator

ZSSK. The contract includes ten inter-

city coaches of the latest generation

Ampeer and Bmpeer series, with an

option for another 30 vehicles.

Liebherr has already delivered 75 sys-

tems for this type of coaches and is

proud to contribute to the Slovakian

railways’ and to ZOS Vrutky’s further

development and increased success

by supplying innovative air condition-

ing systems.

Liebherr-Transportation Systems Delivers

HVAC Units for Class 158 Series

Railway Projects Limited, Derby (UK),

awarded Liebherr a contract for the de-

livery of additional air conditioning sys-

tems for its Class 158 Express Sprinter

diesel multiple units.

These trains are operated by First

ScotRail Ltd. of Scotland and owned by

Angel Trains, a leading asset manage-

ment and train leasing company in the

UK, which finances the purchase and in-

stallation of the new systems.

The two-car trains will be retrofitted with

a total of 20 Liebherr heating, ventilation,

air conditioning (HVAC) units. In addition

to two separate air conditioning units for

installation in the roof area at both ends

of the carriage, the package includes an

underfloor-mounted hydraulically driven

alternator in the middle of the car and a

cab kit, which supplies conditioned air

to the driver’s cabin. The units are con-

trolled by existing HVAC controllers.

Page 16

Page 17

Liebherr-Aerospace

© Airbu s

Page 18

18

Aerospace

Looking Ahead: Liebherr-Aerospace Invests in

Infrastructure, Research and Development

At Liebherr-Aerospace’s birthplace in Lindenberg (Germany) new facilities will be constructed in the years

to come. The areas for production and customer service will be enlarged to meet the aircraft manufac-

turers' growing demand, and a new administration building will be erected to house Liebherr-Aero space

Lindenberg GmbH in the future. Other examples for the ongoing investment in infrastructure, research and

development are Liebherr- Aerospace’s new facilities in Russia and the test and development center “ISA”

inaugurated in Toulouse in 2011.

Liebherr-Aerospace’s Expansion

Program in Lindenberg

In February 2012, the Board of Manage-

ment of Liebherr-Aerospace Lindenberg

GmbH informed the public about further

expansion plans. Due to the increase

in air traffic figures and the demand for

Liebherr-Aerospace products and sys-

tems growing accordingly, the production

capacities and assembly lines need to

be enlarged considerably. Customer ser-

vice also requires more space for main-

tenance, repair and overhaul. In addition,

the systems Liebherr-Aerospace de-

velops and manufactures in Lindenberg

have larger dimensions than ever before.

The nose landing gear for the long-range

Airbus A350 XWB, for example, is the

largest landing gear system that Liebherr-

Aerospace has ever developed.

The participation in this Airbus program

therefore makes the expansion of the

workshops and the areas for production

and assembly as well as for testing and

development indispensable.

In recent years, Liebherr-Aerospace has

experienced a positive development of its

order situation. In addition to the system

for the A350 XWB program, Liebherr-

Aerospace Lindenberg GmbH develops

and manufactures the complete land-

ing gear systems for the COMAC C919,

the largest aircraft ever built in China,

and the new Bombardier CSeries fam-

ily. Moreover the company supplies

flight control / actuation systems for

diverse Airbus aircraft as well as the

Eurocopter and AgustaWestland helicop-

ters. These new orders pose a real chal-

lenge to the production site in Lindenberg.

So, in the future, the manufacturing of

the prototypes and the preparation for

the series production will be separat-

ed from the series production. Further-

more, the infrastructure of the site needs

to be enhanced. A parking garage, a new

administration building and other facili-

ties will be built from 2012 to 2018. The

area occupied by Liebherr-Aerospace

Lindenberg GmbH will be expanded from

127,000 m² to 160,000 m², and the floor

space will be increased from currently

55,000 m² to 75,000 m².

Liebherr-Aerospace

in Lindenberg

Page 19

Aerospace

Nizhny Novgorod: A New Plant for the Russian Market

19

In 2011, the production network of

Liebherr's division Aerospace and

Transportation Systems was enlarged

by a new Russian plant in Dzerzhinsk

close to the city of Nizhny Novgorod.

The company OOO Liebherr-Aero-

space Nizhny Novgorod provides di-

rect access to the Russian aviation

market.

One of the first local customers was

Sukhoi Civil Aircraft Company, which

manufactures the SuperJet 100 for

airlines in the East and the West.

Liebherr-Aerospace supplies the com-

plete fly-by-wire flight control system

as well as the integrated air manage-

ment system for this regional jet.

OOO Liebherr-Aerospace Nizhny

Novgorod has a 3,200 m² production

area. The Liebherr Group has anoth-

er company on its 120 hectare site

in Dzerzhinsk: OOO Liebherr-Nizhny

Novgorod, which is responsible for the

manufacturing and assembly of con-

struction machinery and components.

New Test Center in Toulouse Fully Working

Liebherr-Aerospace Toulouse SAS,

Liebherr’s center of excellence for

aerospace air management systems,

held the opening ceremony of its new

test and development center on Sep-

tember 23, 2011.

taken into operation step by step

throughout the year 2011.

The test center was

Spread over 5,600 m² the new facilities

substantially expand Liebherr’s capabili-

ty of simulating the operating conditions

of its airborne systems, such as engine

temperature and pressure, or acous-

tic environment. It allows full-scale as

well as digital model testing of technol-

ogies related to vibrations, cabin noise

and the concept of the More Electric Air-

craft. These latest generation test facil-

ities significantly contribute to reducing

development cost and optimizing the

performance of future air management

systems.

The test center accounts for a 27 Mil-

lion Euro investment, part of which is

borne by the French Government and

the Region of Midi-Pyrénées.

The building’s environmental footprint

was subject to particular attention during

its design and construction phases.

Key parameters such as energy con-

sumption, water consumption and noise

emissions show considerable reductions

compared to previous test facilities.

Page 20

20

Aerospace

Liebherr-Aerospace in the Americas

For more than 20 years, Liebherr-Aero space has been operating its own customer service company in Saline

(Michigan, USA) as well as a customer service facility in Laval near Montreal (Canada). The plant in Guaratinguetá

(Brazil) burned down in 2011, but will be re-erected. As far as possible, production was relocated to other facilities

within the global production network.

Expanding in Canada

Following the official announcement made

at Farnborough International Airshow in

July 2010, Liebherr-Aerospace Canada

expanded its facility in 2011 in order to ac-

commodate the final assembly and test-

ing of the landing gear for the Bombardier

CSeries aircraft. This project will account

for an investment of more than 3.8 million

Canadian Dollars of capital expenditure

(2.9 million EUR) when completed.

Liebherr’s activities in the fields of aero-

space and transportation in Canada date

back to 1993 when Liebherr-Aerospace

Toulouse SAS was selected as a sup-

plier of the air management system for

Bombardier Aerospace’s Global Express

aircraft. This was the starting point of a

fruitful relationship between Bombardier

and Liebherr in North America.

supporting the division’s activities in North

America. In 2001, Liebherr-Aero space

Canada along with Liebherr- Canada’s

other divisions moved to its current loca-

tion in a new building in Laval (Quebec).

With a population of nearly 400,000,

Laval is the third largest city in Que-

bec. Strategically situated close to

Bombardier’s sites in Montreal and Mi-

rabel, Liebherr-Aerospace Canada cur-

rently provides technical, logistics and

engineering support to the customer’s

final assembly lines.

Further, Liebherr-Transportation Systems

in North America is based at this facility.

The local team provides sales and mar-

keting as well as customer support func-

tions to the rail industry.

The supply of the air management sys-

tem and the landing gear system to the

CSeries aircraft has created new oppor-

tunities for Liebherr-Aerospace Canada.

Bombardier Aerospace’s CSeries final

assembly line will be in Mirabel, approxi-

mately 35 km from Liebherr’s Laval facility.

Liebherr- Aerospace Canada will be re-

sponsible for expanded logistics as well

as final assembly and testing of the land-

ing gear system. This will further optimize

the flow of parts from the global supply

base and shorten reaction time to cus-

tomer requests.

The Laval facility was expanded by

1,400 m² in October 2011. The new build-

ing will house six final assembly cells as

well as test facilities for the CSeries land-

ing gear, thus enabling Liebherr to man-

age just-in-time deliveries directly to the

aircraft assembly line, and to contribute to

a peak production rate of one aircraft per

day. In addition, one part of the building

will be dedicated to maintenance activities

for rail industry customers.

Liebherr-Aerospace Canada works

closely with the European Liebherr OEMs

to procure tooling and other equipment.

Later this year, the recruiting and train-

ing process for the additional activities

will be commenced. The expansion is

part of Liebherr’s commitment towards

Bombardier.

Liebherr-Aerospace Canada was created

in 1997 within the Liebherr Group’s Cana-

dian sales and service company, Liebherr-

Canada Ltd., Burlington, with the aim of

Page 21

Liebherr Aerospace Saline, Inc. Opens Expansion

Aerospace

21

On June 14, 2012, Liebherr Aerospace

Saline, Inc. inaugurated the expansion

of its customer service center for the

Americas. In Saline (Michigan, USA),

Liebherr-Aerospace maintains air man-

agement systems, flight control / ac-

tuation systems as well as landing

gear systems for airframe manufactur-

ers such as Airbus, AgustaWestland,

ATR, Bombardier, Dassault, Embraer,

Eurocopter and Gulfstream. The compa-

ny currently completes more than 1,000

repairs per month and also has a small

manufacturing section where helicopter

flight controls are assembled.

With this expansion, which is the fourth

extension in the history of the compa-

ny, Liebherr-Aerospace has increased

The expansion will also allow the servic-

ing of A350 XWB nose landing gear and

CSeries landing gear in due course.

Moreover, the company is now capa-

ble of extending its support packag-

es in the fields of flight control / actua-

tion systems as well as air management

systems for rotorcraft. The main cus-

tomers of Liebherr Aerospace Saline,

Inc. in this field are AgustaWestland

and Eurocopter.

Liebherr-Aerospace

in Saline

The facilities of Liebherr Aerospace

Saline, Inc. came into operation in 1991.

Today the company employs more than

140 staff supporting Liebherr-Aerospace

customers in the Americas in the fields of

sales, inventory, repair and technical ser-

vices. For equipment the company has

no in-country service capability, it per-

forms a liaison function between the cus-

tomer and Liebherr’s Original Equipment

Manufacturers in Europe, which includes

exchanges and repair management.

Left to right: Alex Vlielander

(President Liebherr Aerospace Saline, Inc.),

Gretchen Driskell (Mayor of Saline),

Philipp Liebherr, Francis Niss (President

Liebherr-Aerospace & Transportation SAS)

its workspace in Saline by more than

3,000 m

measuring over 9,000 m2 including

workshop, warehouse and offices.

Further, a part of the new building will

be used to create a training facility for

Liebherr Aerospace Saline employees.

These expansion measures enable the

plant to meet the increasing demand

for landing gear servicing from 2013

and 2014 onwards: Liebherr Aerospace

Saline, Inc. will continue its Embraer

ERJ overhauls well into 2014, and in

addition to that expects an increase in

workload for the successful EJet family.

2

and now possesses an area

Rebuilding of Liebherr-Aerospace

Facilities in Brazil

On July 5, 2011, a blaze destroyed

the plant of Liebherr Aerospace Brasil

Ltda. based in Guaratinguetá. This

plant specialized in the manufactur-

ing of parts for Liebherr’s landing gear,

flight control and air management

systems.

That day, Liebherr immediately set up

a recovery plan, which involved far-

reaching action such as immediate

additional machine investment, imple-

mentation of three-shift and week-end

shift, activation or reactivation of addi-

tional supply sources, and transfer of

Liebherr-Aerospace’s Brazilian work-

ers to the European plants. Thanks

to this recovery plan, and to the sup-

port of the customers, it was possible

to ensure Liebherr’s deliveries to the

airframers’ assembly lines. No aircraft

delivery date was impacted.

Liebherr decided to rebuild the plant,

which underlines the company’s com-

mitment to its Brazilian customers and

employees. The construction will be

completed by the end of 2012.

Page 22

22

Aerospace

A Supplier to Airbus from the Very Beginning

From the earliest days of Airbus in

1969, Liebherr-Aerospace has been

on board of this unparalleled Euro-

pean aviation initiative. The compa-

ny has equipped the Airbus A300,

the A310, the A320 family, the

A330 / A340 and the A380 – in short,

all families of Airbus aircraft – with

components and systems in the

fields of flight control / actuation, air

management and landing gear. The

A350 XWB will soon be supplied too.

In the course of their long-standing

business relationship, Airbus has

awarded many prizes to Liebherr-

Aero space. The latest recognition

was the Bronze Award 2011, which

Liebherr-Aerospace Toulouse SAS

received for its improved perfor-

mance despite the complete loss

of the Liebherr-Aerospace facility in

Guaratinguetá (Brazil) during a cata-

strophic fire.

Liebherr-Aerospace Delivers

First Components for A350 XWB Flap System

Recently, the first ship set of the load-

sensing drive strut for the A350 XWB flap

system, developed and manufactured by

Liebherr-Aerospace Lindenberg GmbH

(Germany), was delivered to the Airbus

system test bench in Bremen (Germany).

The set consists of a strut for the flap sta-

tions 1 and 4 and the associated harness-

es. This mechanical-electronic compo-

nent is installed four times in each aircraft.

The load-sensing drive struts signal to

the high-lift controller if there are unac-

ceptably high loads between the actu-

ation system and the flaps, which may

occur in case of certain faults. The con-

troller then causes the flap system to en-

ter the so called fail-safe mode, by turn-

ing it off. Airbus simulates one wing side

of the aircraft on the system test bench.

At the same time, Liebherr-Aerospace’s

qualification test bench in Lindenberg

© Airbu s

was successfully put into operation

with a load-sensing drive strut to con-

duct the usual tests for technical perfor-

mance, endurance, fatigue, vibration and

environmental sustainability.

Load-sensing

drive struts

Page 23

Airbus Partially Delegates Responsibilities

to Liebherr-Aerospace

Aerospace

23

Airbus has recently started to share more

responsibilities within the design, build,

verification and validation process of its

aircraft with risk sharing partners. Airbus

performed assessments and audits to

check the process definitions and their

application in its suppliers’ daily business.

As a result of this analysis, Liebherr-

Aero space Lindenberg GmbH has re-

ceived its first official approval from

Airbus for the so called “Management

and Cascade of the Organization

Authority & Signatory”. The scope of

activities Airbus Design Organization

has delegated to Liebherr-Aerospace

Lindenberg GmbH is defined by

a “Design Organization Interface

Document”.

In addition to the signatory rights

ed internally, experienced

Liebherr-Aerospace Lindenberg GmbH

have been granted rights to sign specif-

ic documents towards the authorities.

delegat-

employees of

Liebherr-Aero space Lindenberg GmbH

was turned from a line organization di-

vided into different disciplines into a

process-oriented company.

management system is focused on six

business processes describing the pro-

cedure from predefined required inputs,

through the process and its methods to

achieve defined outputs.

Delivery of MSN5000 Airbus A320 Family −

a Milestone for Liebherr-Aerospace

In January 2012, Airbus delivered

MSN5000 of the single-aisle program,

an A320, to Middle East Airlines based

in Beirut (Lebanon).

Since the start of this program Liebherr-

Aerospace has supplied more than

40,000 flap gear rotary actuators, 15,000

rudder surface control actuators, 50,000

slat rotary actuators, 10,000 air condi-

tioning packs, 40,000 engine bleed air

valves as well as a vast array of other

components.

Producing close to 40 units of its A320

aircraft per month, Airbus relies on a

high-performance supply chain to feed

its final assembly line with quality pro-

ducts delivered on time. As a result, this

program generates significant work-

loads at Liebherr-Aerospace’s produc-

tion facilities.

As over 270 airlines operating these

aircraft worldwide require efficient

support, Liebherr-Aerospace provides

customer services from its facilities in

Toulouse (France), Lindenberg (Germany),

Saline (Michigan, USA), Singapore and

Shanghai (China) 24 hours a day and

7 days a week all year round.

Today’s

Middle East Airlines received

MSN5000 of Airbus’

single-aisle program

© Airbu s

Page 24

24

Aerospace

© Image pr ovide d cour tesy of Bom bardi er Inc.

CSeries: Landing Gear and Air Management

Systems by Liebherr-Aerospace

Liebherr-Aerospace develops and sup-

plies the highly integrated nose and main

landing gear systems, including all me-

chanical, hydraulic and electrical hard-

ware and software applications, as well

as the complete air management system

to Bombardier’s CSeries* program.

The jet airliner family is specifically de-

signed for the 100 to 149 seats segment.

With a 15-percent operating cost advan-

tage compared to other aircraft sched-

uled for entry into service in 2013, it sets

new standards.

Liebherr puts high demands on its prod-

ucts, which are clean and simplified,

service and maintenance friendly. They

are of light weight and robust with high

reparability. Noise reduced, they meet

future acoustic regulations. Furthermore

the main landing gear features an inno-

vative main fitting.

For the development of the CSeries

systems a team of more than 120

engineers was set up. Located in

Lindenberg (Germany), Toulouse (France)

and Montreal (Canada) they ensure

both highest efficiency and custom-

er proximity.

Air conditioning pack

on its test bench

The supply chain is arranged to meet

the demands of a global aircraft pro-

gram; the systems are assembled in

Lindenberg, Toulouse and in Montre-

al, and completed with parts sourced

in North America. This competitive con-

cept, and the market potential related to

it, will strengthen Liebherr’s presence in

the North American aircraft market.

* Trademark of Bombardier Inc. or its subsidiaries

Page 25

Liebherr-Aerospace Contributes with

Three Product Lines to the AW189

Aerospace

25

The AW189 is an 8-ton class multi-role

rotorcraft designed and produced by

AgustaWestland. It is capable of meet-

ing the requirements of challenging op-

erations such as off-shore, corporate and

VIP transport.

With its three product lines − air man-

agement systems, flight control / actua-

tion systems and landing gear systems

− Liebherr-Aerospace is a major supplier

to the AW189. From its air management

system product line Liebherr delivers the

cabin air conditioning system which fea-

tures a vapor cycle system. Two electri-

cally driven compressors developed and

manufactured by Liebherr are installed

in the engine compartment and power

a two-zone cabin and cockpit air cool-

ing system. In cold conditions either the

heating system fed by air bled on the en-

gines or the auxiliary power unit (APU)

provides passengers with warm air.

Liebherr-Aerospace supplies all compo-

nents of the system, including heat ex-

changers, valves, controller and cockpit

panel. The AW189 cabin

and cockpit air distribu-

tion, com

valves, fans, diffusers and

gaspers, is also provided

by Liebherr.

From its flight control ac-

tuation system product

line Liebherr supplies a

complete fly-by-wire ac-

tuation for main and tail rotors of the

AW189. These actuators are hydraulical-

ly powered.

Liebherr also delivers the complete

landing gear system of the AW189.

It includes everything from the con-

trol panel, whose lever is installed in

the cockpit, down to the wheels and

brakes installed on the retractable

landing gear legs. Moreover, Liebherr

is responsible for the landing gear ex-

tension and retraction system with ac-

tuators and hydraulic valves as well as

position switches. One key character-

istic of this landing gear is its crash

posed of ducts,

© AgustaWestland

worthiness that allows an exceptional

landing sinking speed.

The order for the AW189 systems is

another milestone in Liebherr-Aerospace’s

highly successful cooperation with the

rotorcraft manufacturer, which started

more than ten years ago with the landing

gear and the air conditioning system for

the AW139. Since then AgustaWestland

and Liebherr have steadily intensified their

collaboration. Today Liebherr-Aerospace

is proud to supply all of AgustaWestland’s

latest platforms, and intents to further de-

velop this valuable relationship.

Liebherr-Aerospace Selected for Bombardier’s

Global 7000 and Global 8000 Aircraft Programs

Liebherr-Aerospace has been awarded

the contract to supply the integrated air

management system for Bombardier’s

© Image pr ovide d cour tesy of Bom bardi er Inc.

newest members of the Global* air-

craft family, the Global 7000* and the

Global 8000* ultra long-range jets. This

system comprises the bleed air system,

the airframe ice protection system, the

air conditioning system and the cabin

pressure control system, and features

lightweight, high reliability pneumatic

and mechanical components with in-

tegrated controls. It will be developed,

qualified and manufactured in Tou-

louse (France) by Liebherr-Aerospace

Toulouse SAS, Liebherr’s center of ex-

cellence for aero space air management

systems. Bombardier will thus again

benefit from Liebherr’s unmatched

experience in integrated air manage-

ment systems for business aviation.

Liebherr also supplies integrated air

management systems for the other air-

craft of the Global family, the Global

5000* and the Global 6000* jets, as

well as for several other of Bombardier’s

commercial and business aircraft. The

award of the Global 7000 and Global

8000 aircraft integrated air management

system is another milestone in the 20

years of Bombardier’s and Liebherr’s

business relationship.

* Trademarks of Bombardier Inc. or its subsidiaries

Page 26

26

Aerospace

Flexibility and a Vast Array of Products

for the Aviation Industry

From business jets over the latest helicopter programs and regional jets to special military applications: the

vast array of Liebherr-Aerospace products is a result of an over five decades lasting success story as a major

supplier in the global aviation industry.

Air-to-Air Refueling with New

Liebherr Hose Drum Drive System

When UK-based Cobham Mission Equip-

ment planned their future air-to-air re-

fuelling equipment, they chose Liebherr

to develop the core motor control subsys-

tem in 2007. The hose drum drive system

(HDDS), based on Liebherr-Aerospace’s

proven power electronic technology, pro-

vides the motive force to trail and rewind

the refuelling hoses.

It comprises a 10 kW electric motor con-

trol unit, a dump resistor pack for dissi-

pating power during regenerative electric

braking and a geared motor unit to drive

the hose drum.

The HDDS is a joint development by

Liebherr-Aerospace Lindenberg GmbH

and Liebherr-Elektronik GmbH in Lindau

(Germany). Liebherr-Aerospace in

Lindenberg concentrated on the em-

bedded system and motion control work

encompassing electronic systems, de-

velopment of control laws, airborne soft-

ware development and electric motor

development. Liebherr in Lindau focused

on airborne hardware development and

airborne equipment qualification.

The overall system integration was per-

formed by Liebherr-Aerospace to pro-

Motor control unit

vide Cobham with a fully integrated sub-

system for wing refuelling pods and fuse-

lage refuelling systems.

The HDDS is currently certified for the

A330 MRTT application, and serial de-

livery has started. Certification for the

A400M platform is the next program

milestone.

Liebherr-Aerospace Selected for KC-390’s Bleed System

In February 2012, Embraer Defense and

Security, based in São José dos Cam-

pos (Brazil) selected Liebherr-Aero-

space to provide the bleed controller

and bleed valves of the KC-390 military

transport aircraft.

The latest-generation bleed system

features the most advanced com-

pact electro-pneumatic bleed technol-

ogy, which has gained an unmatched

experience in operation on a wide ar-

ray of aircraft models across the world.

It provides high reliability, optimized

safety and comfort conditions as well

as proven robustness under all operat-

ing conditions. The integration into the

aircraft and the system-performanc-

es will be further strengthened by the

test rig that will be set up at Liebherr-

Aerospace’s recently opened test center

in Toulouse, France.

Liebherr-Aerospace Toulouse SAS will

develop and manufacture the system

that features integrated control archi-

tecture with high-reliability, high-per-

formance, lightweight pneumatic and

mechanical components. This new

partnership in defense and security

further expands the already long last-

ing relationship between Embraer and

Liebherr-Aerospace.

© Embraer

Page 27

Aerospace

Signing of Master Contract for Chinese Aircraft C919

27

On February 14, 2012, Commercial

Aircraft Company of China (COMAC),

based in Shanghai, and Liebherr-

Aerospace

for the

The contract covers

two major systems on

board this aircraft:

the landing gear and

the integrated air

management system.

The C919 is not the first par-

ticipation of Liebherr-Aerospace in a

Chinese aircraft program. Liebherr al-

ready supplies the landing gear system

and the integrated air management sys-

tem for the ARJ21 regional jet.

The landing gear system is to be de-

veloped, supplied and serviced by

Liebherr-Aerospace Lindenberg GmbH

(Germany). The system includes the main

landing gear and nose landing gear, ex-

tension and retraction system, nose

wheel steering system as well as the po-

sition and warning system.

For development and production

Liebherr-Aerospace has entered into a

joint venture with Chinese AVIC member

signed a master contract

C919 program.

Landing-Gear Advanced Manufacturing

Co., Ltd. (LAMC) in Changsha, Province

of Hunan.

The contract award is proof of Liebherr-

Aerospace's competence as a supplier

of competitive, future-oriented landing

gears for commercial transport aircraft.

Moreover, the new program participa-

tion is a possibility to further broad-

en Liebherr’s expertise in this field of

technology.

The integrated air management system

of the C919 will be developed, supplied

and serviced by Liebherr-Aerospace

Toulouse SAS. It includes the bleed air

system, the air conditioning system,

the air distribution system, the cabin

pressure control system, the wing an-

ti-ice system and the avionics ventila-

tion system.

The focus is on developing a very high

level of integration for all functions. For

example, there will be only two central-

ized controllers to manage all air-related

functions.

Liebherr-Aerospace has set up a co-

operation with Nanjing Engineering In-

stitute of Aircraft Systems (NEIAS) for

the development and manufacturing of

some of the air management system’s

components.

Liebherr-Aerospace and NEIAS agreed

on a work share based on each part-

ner’s best capabilities. The goal of this

cooperation is to deepen the relation-

ship with NEIAS. The institute has been

selected by Liebherr as a key partner in

order to set up a work share model suit-

able for future programs.

Sukhoi SuperJet100 EASA Certified

In February 2012, the Sukhoi Super-

Jet 100 received its type certificate

validated by the European Aviation

Safety Agency (EASA). This certifi-

cate authorizes the commercial oper-

ation of the Russian regional jet in the

European Union as well as in coun-

tries whose aviation authorities have

specific recognition agreements with

EASA. Liebherr-Aerospace is on board

the SuperJet 100 and supplies the in-

tegrated fly-by-wire flight control system

and the air management system. With-

in the SuperJet 100 program, Liebherr-

Aerospace has demonstrated – for the

first time in the history of aircraft sys-

tem suppliers – its ability to support an

airframer in the full certification process

of an integrated flight control system:

Liebherr-Aerospace designed, manufac-

tured and supported the complete flight

control system including flight control

computers and cockpit controls. Liebherr

congratulates Sukhoi Civil Aircraft Cor-

poration for this major achievement and

is proud to continue to contribute to the

success of the SuperJet 100 program.

Page 28

Page 29

Liebherr Group News

Page 30

30

Liebherr Group News

The Liebherr Group Grew Considerably

in the Business Year 2011

The Liebherr Group was able to increa-

se its turnover in the 2011 financial year

by 747.0 million euros or 9.8 % to 8,334.0

million euros. Once again, almost all the

Group’s divisions contributed to this

growth. Turnover from construction ma-

chinery and mining equipment recorded

an above-average increase. In these pro-

duct lines Liebherr boosted turnover by

642.4 million euros or 13.5 % to a total

of 5,386.6 million euros. The proporti-

on of the Group’s total turnover accoun-

ted for by these areas rose from 62.5 %

to 64.6 %.

In the earthmoving division, the Group

was able to increase its turnover by 448.6

million euros or 27.9 % to 2,058.8 mil-

lion euros. In the mining division, sales

revenues were boosted by 209.5 milli-

on euros or 26.1 % to 1,012.0 million

euros. Following an upturn in 2010,

turnover in the mobile crane division fell

slightly by 73.2 million euros or 4.0 % to

1,738.6 million euros. Liebherr’s overall

Page 31

Liebherr Group News

31

turnover in the construction cranes and

mixing technology division was 577.2 mil-

lion euros, which represents an increase

of 57.5 million euros or 11.1 %.

From activities outside the construction

machinery and mining equipment areas,

the Liebherr Group achieved a turnover

of 2,947.4 million euros, 104.6 million eu-

ros or 3.7 % higher than in the previous

year. Sales revenues for other products

and services fell by 113.4 million euros or

36.8 % to 195.1 million euros. All other

product areas increased their turn over:

The maritime cranes division boosted its

turnover by 78.4 million euros or 10.7 %

and therefore its sales revenue by 808.0

million euros. The aerospace and trans-

portation systems division also recorded

a significant turnover increase to 913.4

million euros, 94.1 million euros or 11.5

% above the same period in 2010. The

machine tool and automation systems

division increased its turnover by 20.8

million euros or 12.6 % to 186.4 million

euros. The domestic appliances division

boosted its total turnover to 844.5 milli-

on euros, an increase of 24.7 million eu-

ros or 3.0 %.

the modernisation of existing ones and

the expansion of the sales and service

network.

The growth of the Liebherr Group led to

a distinct increase in the workforce du-

ring the year under review. At the end of

2011 Liebherr employed 35,333 peop-

le worldwide. In total, Liebherr created

2,354 new jobs.

The Liebherr Group will also maintain its

course for growth in 2012. Increases are

realistic in all divisions. The Group antici-

pates an increase in total turnover in the

order of 10 %. The current view is that an

improved result is possible in comparison

to the previous year.

The investment total increased by 125.0

million euros or 23.0 % to 669.1 million

euros. These funds were devoted to the

construction of new production facilities,

Page 32

32

Liebherr Group News

New LH 80 M Litronic Material Handler Features

Prize-Winning Energy Recovery Cylinder (ERC)

The LH 80 M Litronic is the first materi-

al handler of a new generation of mobile

machines designed specifically for ma-

terial handling. It is powered by a 313-hp

(230-kW) Liebherr 6-cylinder in-line engi-

ne, which is also a new development and

complies with Stage IIIB / Tier 4i exhaust

emission limits.

The energy recovery cylinder (ERC) is a

prize-winning innovation which boosts

the performance of the LH 80 M Litronic

even further. Installed as standard equip-

ment on the LH model series, this pa-

tented Liebherr development takes the

form of a third hoist cylinder. It is moun-

ted between the two hoist cylinders and

filled with nitrogen gas. By compressing

the nitrogen, the ERC system stores the

energy released as the working equip-

ment is lowered. During the next lifting

movement, the nitrogen expands and

the stored energy is added to the power

exerted by the hoist cylinders. Since the

energy recovery cylinder contributes up

to 80 kW of additional energy, less pow-

er is needed from the diesel engine. This

innovative device makes machine opera-

ting cycles smoother, more powerful and

above all faster. Consequently, the ma-

chine performs even more economically.

R 950 SME: New Heavy Duty Crawler Excavator

Liebherr presented the new R 950 SME

crawler excavator for the first time at

the 2012 Intermat trade show in Paris

(France). This newly developed heavy

duty machine complies with Stage IIIB /

Tier 4i exhaust emission standards and

was specifically designed to increase

productivity in tough stone-quarrying

applications.

The ‘SME’ acronym stands for ‘Super

Mass Excavation’, the machine is for in-

stance equipped with a reinforced un-

dercarriage featuring crawler-track

components from the larger R 956.

In conjunction with a heavier counter-

weight, this construction ensures higher

stability, allowing the use of a larger bu-

cket. The equipment of the R 950 SME

was optimized for higher tear-out and

breakout forces.

Compared with the standard version, the

R 950 SME has a higher engine output.

Its new 6-cylinder common-rail diesel en-

gine produced at the Liebherr Compe-

tence Centre for Diesel Engines in Bulle

(Switzerland) delivers 300 hp (220 kW)

from a displacement of 10.5 liters. It com-

plies with Stage IIIB/Tier 4i exhaust emis-

sion standards, for which purpose its

specification includes an external exhaust

gas recirculation system and a diesel par-

ticulate filter with active regeneration.

The higher dynamic performance of the

R 950 SME is not only derived from the

engine power and the new hydraulic sys-

tem. Travel speed is 20 % higher and,

coupled with a 7 % increase in drawbar

pull, it makes the new excavator distinct-

ly more manoeuvrable across rough ter-

rain. Working cycles are improved by a

7 % increase to 211 kN in tear-out force,

and a 9 % increase to 255 kN in break-

out force.

Page 33

Liebherr Domestic Appliances

Receive Several Plus X Awards

Liebherr Group News

33

Liebherr has recently been honoured

with three “Plus X Awards” for refrige-

rators and freezers from its current ran-

ge as well as with the 2012 “Specialized

Trade Brand of the Year” award.

A renowned jury of experts grants the

Plus X Awards once a year. The as-

sessment criteria are innovation, de-

sign, quality, ease of use, ergonomics

and ecology. The seal of “The Best

Product of the Year” is awarded for

outstanding achievement within a pro-

duct category.

This year Liebherr won the annual Plus

X Award in three categories: The WTes

5872 multi-temperature wine cabinet, the

TP 1760 table-top refrigerator as well as

the GP 1486 table-top freezer were each

honoured as “The Best Product of the

Year” in their respective categories. In

addition, these three appliances received

Plus X Awards for “High Quality, Design

and Ease of Use”.

The specialized trade brand prize was

awarded for the first time this year. The

jury voted for their preferred brands in

different categories, which resulted in

Liebherr being honoured as the 2012

“Specialized Trade Brand of the Year”

in the product group of “Large Home

Appliances”. The reasons why the

award was granted to Liebherr were

Liebherr’s particularly fair distribution

structure and commercially attractive

product portfolio.

Liebherr Rotary Loading System:

The Entry-Level Solution for Unmanned Production

Liebherr’s automation systems’ product

range has recently been extended by the

RLS 800 rotary loading system, which

completes the existing PHS linear pallet

handling system. This new system is ide-

al for users who are looking for a cost-

effective entry to high-efficiency produc-

tion for one to two machines. It enables

spindle utilization of more than 90 % and

is available in two sizes.

The pallet storage capacity of the new

RLS is ideal for automation of up to two

machining centers combined with a very

small footprint. The layouts of the mani-

pulator and storage racks allow up to 24

pallet storage locations in a minimal area

– a basic requirement for operation with

very few operators or completely unat-

tended operation.

installed on a rotary module and docked

to the system in exchange of two shelf

units. Up to 18 storage locations per to-

wer can be added with a minimal foot

print. The storage tower can also be used

to link two individual RLS

units to form one combined

system.

Another machine can be

added without difficulty at

a later time. Thanks to its

shape, the storage modu-

le can be integrated in dif-

ferent positions, depen-

ding on the space available.

Therefore it is ideal for ins-

tallation in existing produc-

tion cells, where space is

limited.

If production requires a larger number of

pallets or if storage capacity is not ade-

quate, the latter can be increased with

the Liebherr RST storage tower. It is

Page 34

34

Liebherr Group News

New Gas Engine Model Series

er output from 245 hp to 335 hp (180 kW

to 246 kW) and is equipped with a turbo-

charger and charge-air cooler.

Unlike existing models, the new model

series, which is based on the Liebherr

diesel short block engines of emission

level IIIB, features a self-contained sys-

tem. The compressor inlet and turbine