Page 1

Liebherr Service Tools

for Excavator-Specific Maintenance

Page 2

Liebherr Mining Exchange Components

2

Attachment Tooling

• Cylinder Handling Tool

• Pin Puller 20t / 22 ton

• Pin Puller 30 t / 33 ton

• Cylinder Positioning Tool

Uppercarriage Tooling

• Jacking System

• Service Powerpack

• Pump Lifting Tool

• Vaccum Pump

Page 3

Liebherr Service Tools - Outline

A Wide Range of Tools

Liebherr customer support delivers a wide range of service tools for excavatorspecic maintenance: pump, cylinder, travel drive, track pad maintenance or

replacement, ensuring optimal working conditions no matter the size of the com-

ponent.

OEM Certified Solution

The close collaboration between the excavator R&D engineering team and service

tools development team ensures that the excavator design encapsulates bestpractice serviceability. The tooling design and product range evolve with the excavators.

High Operational Safety

Liebherr Service Tool development meets the most stringent EC and Australian

standards and delivers the same quality synonymous with Liebherr mining excavators.

Rugged Tooling

Before release, Liebherr tooling undergoes an intensive factory and eld testing

program to meet the challenges faced in the eld and exceed the expectations of

the end user.

Customer Benefits

With the Liebherr service tools solution, customers will benet from:

• An OEM-certied solution

• Maximized machine uptime

• Cost-efcient maintenance

• Easy machine serviceability

• Uncompromising operational safety

Undercarriage Tooling

• Track Press

• Track Condition Monitoring

• Track Roller Mounting Tool

• Travel Drive Mounting Tool

Customer Support

• Global network of Liebherr afliates

and exclusive representatives

• Customer specic requirement study

• Collaborative solution development

Liebherr Mining Exchange Components

3

Page 4

Liebherr Mining Exchange Components

4

Pin Puller 20t / 22 ton

With this tool Liebherr has designed the safest

solution for pressed pins extraction. This light

version of the 30t/33 ton Pin Puller is delivered in

own purpose built box for easy storage.

The extraction of the pin is done with the help

of the hydraulic hand pump, delivered with the

system.

Page 5

Attachment Tooling

Cylinder Handling Tool

Specially designed to handle and replace heavy hydraulic cylinders on the Liebherr R 995 and R 996 B front shovels, the Cylinder Handling Tool offers a safer

and more efcient alternative over cranes. The focus on maximum machine

uptime underpins Liebherr’s design philosophy.

Optimized for

Telescopic

Handlers

The Cylinder Handling Tool (CHT) has been designed to t

telescopic handlers and can be easily adapted to various

brands upon request. Its unique design removes cantilevered handling situations and provides a signicant advantage; in fact, only a standard 10 t / 11 ton telescopic handler

is required to handle hydraulic cylinders weighing up to 7,5

t / 8.3 ton. A side-shift function has been integrated into the

CHT for improved maneuverability.

Safe

Maneuverability

The unique shape of the CHT enables easy, underside access to cylinders installed on the excavator attachment.

Thanks to the adapted clamp jaws, the CHT enables secure

cylinder handling while protecting the cylinder pipes during

the entire component exchange operation. CHT makes cylinder handling easy.

Easy Control

and Operation

The CHT features a wireless remote control which enables

unimpeded mobility and allows precision control for effortless component positioning. The system can be either

controlled from the telescopic handler operator cabin or at

ground level.

Cylinder Handling Tool Specifications

Weight 2,5 t / 2.8 ton

Pin Puller 30 t / 33 ton

The Pin Puller provides unequaled

safety and simplicity when extracting

and inserting pressed pins into and

from the excavator’s attachment.

This tools is available in two others

sizes to extract pins from the R

9100 up to the R 9800.

Handling capacity (WLL) 7,5 t / 8.3 ton

Max. cylinder diameter 510 mm / 20.1 in

Cylinder Positioning Tool

The Cylinder Positioning Tool (CPT) is an

economical alternative to the sophisticated

Cylinder Handling Tool while offering the

same operational safety.

Available in two sizes to cover Liebherr mining excavators up to the R 9800, this tool

offers easy and safe serviceability when handling heavy cylinders. Simple to use, the CPT

is designed to t to a standard crane hook.

Liebherr Mining Exchange Components

5

Page 6

Liebherr Mining Exchange Components

6

Service Powerpack

Fixed to the undercarriage and connected to a

generator set, this additional module provides

hydraulic power to separate the undercarriage

from the uppercarriage.

The Service Powerpack offers full control of the

undercarriage including track chain tensioning

and release of the travel brakes.

Page 7

Uppercarriage Tooling

Jacking System

With its all new Jacking System, Liebherr delivers a cost-effective solution to lift

the excavator uppercarriage for easy swing ring maintenance or replacement. The

jacking system is a safer and more efcient alternative to the complex crane lift.

An OEM

Certified Solution

This system includes four synchronous hydraulic columns

with integrated power unit and mechanical locking system,

a lifting frame and a bucket rolling device. These elements

work in perfect harmony and provide optimal weight distribution resulting in safe load suspension.

Easy Usability

Once the cylinder pins are removed, the lifting frame is installed and the swing ring bolts unfastened, the lifting operation can be carried out by a single person. In only 15

minutes, the uppercarriage reaches its maximum height

which is sufcient to walk out the undercarriage.

Safe Control

The ergonomic and compact wireless remote control provides unimpeded movement. Via the integrated LCD display, the user can view the health of the Jacking System on

demand.

Wide

Compatibility

The Jacking System is compatible with Liebherr mining backhoes and face shovels from the R 9250 up to the R 9800.

Jacking System Specifications

Lifting capacity 640 t / 705 ton

Cylinder stroke 1.133 mm / 3’8’’

Pump Lifting Tool

The Pump Lifting Tool has been specically designed to handle hydraulic

pumps installed on Liebherr mining

excavators without removing the compartment housing or any components.

This solution allows for fast and efcient

maintenance.

The Pump Lifting Tool is available

in two sizes:

• Pump Lifting Tool for 100t series

•

Pump Lifting Tool for R 9250 up to R 9800

(

with adapters to t different sizes of pumps)

Power supply 24 kW / 32 HP

For Even More

Efficiency

To complete this innovative solution and increase machine

uptime, Liebherr has developed the Service Powerpack to

separate the undercarriage from the uppercarriage.

Vacuum Pump

Connected to the hydraulic tank, the

Vacuum Pump enables easy maintenance

of the hydraulic system without the need to

drain the tank of its oil.

This tool is available in three sizes across the

entire range of Liebherr mining excavators:

• Vacuum Pump 30 for R 9100 and R 984 C

• Vacuum Pump 60 for R 9100 up to R 9400

• Vacuum Pump 120 for R 9100 up to R 9800

Liebherr Mining Exchange Components

7

Page 8

Liebherr Mining Exchange Components

8

Track Condition Monitoring

With the Track Condition Monitoring system,

Liebherr provides all specialized electronic and

mechanical measurement tools to monitor the

wear of the track chain and its components.

This system is delivered with dedicated software

to track wear of components and facilitate forecasting of spare parts.

Page 9

Undercarriage Tooling

Track Press

The Liebherr-designed Track Press allows for easy, safe and efcient opening of

the track chain by pushing out one of the pressed pins.

Strong Design

Utilizing high performance hydraulics, the Track Press delivers a force up to 500 t / 551 ton enabling smooth and safe

pin removal.

Hydraulic Power

Unit Options

The Track Press energy is supplied by the Hydraulic Power Unit available in either gasoline or electric variants. The

electric version can be adapted to suit various voltages and

frequencies in order to comply with your regions specica-

tions.

Wide

Compatibility

To cover the Liebherr mining excavator product range up to

the R 9400, Liebherr has developped two Track Press sizes:

• Track Press 200 t / 220 ton for the R 9100 up to the R 9150

• Track Press 500 t / 551 ton for the R 9100 up to the R 9400

In addition each Track Press is delivered with several adapters to t various pin sizes.

Track Press Specifications

Track Press size 200 t / 220 ton 500 t / 551 ton

Weight 500 kg / 1,102 lb 2.000 kg / 4,409 lb

Track Roller Mounting Tool

(TRMT)

Available in four sizes for the entire

mining excavators range, the Track

Roller Mounting Tool enables easy track

roller replacement without the need to

dismantle the track chain.

• TRMT 400 t for R 9250 up to R 9400

• TRMT 450 t for R 995

• TRMT 670 t for R 996 B

• TRMT 800 t for R 9800

Working pressure 700 bar / 10,152 psi

Hydraulic Power

Unit options

Electric: 400 V / 50 Hz, 220 V / 50 Hz, 115 V / 60 Hz

Gasoline: 3 kW / 4 HP

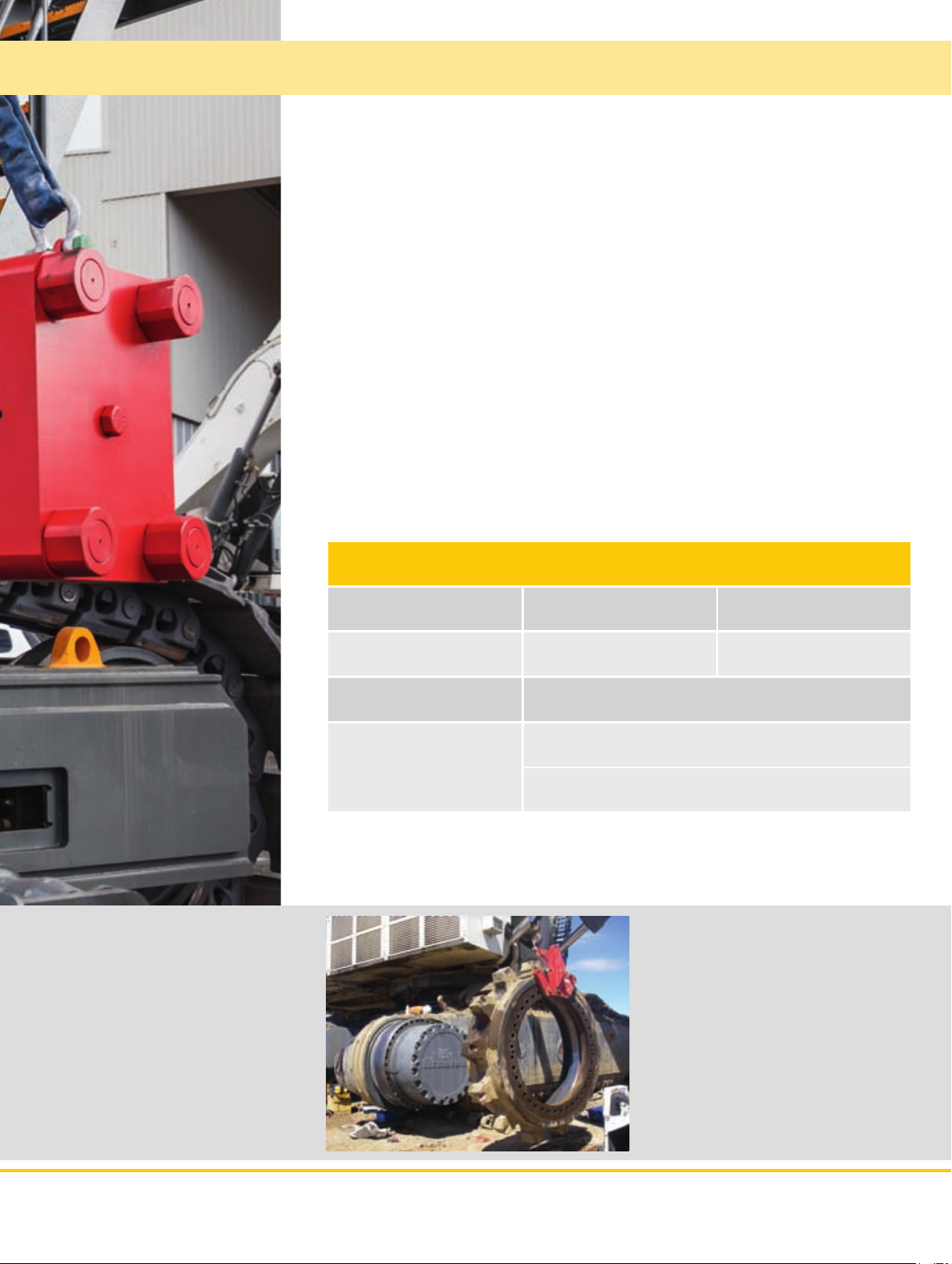

Travel Drive Mounting Tool (TDMT)

The Travel Drive Mounting Tool combined

with the Hydraulic Sprocket Puller offer the

safest way to assemble and maintain the

travel drive and its components.

With the assistance of a crane, the TDMT offers easy handle of Liebherr mining excavator travel drives up to the R 9800.

Liebherr Mining Exchange Components

9

Page 10

Liebherr Mining Exchange Components

10

Liebherr Mining Training System

The most qualied workforce is the one that

is best informed. The Liebherr Mining Training

System increases learning retention by providing access to online content and assessments

before and after class sessions.

• Online learning programs

• Factory sessions

• Simulator training

• On-site sessions

Page 11

Customer Support

As a global mining solutions provider, Liebherr is more than a mining equipment

manufacturer. Ensuring a permanent dialogue with each machine owner, Liebherr

provides tailored assistance to customer specic projects and site requirements.

Proactive Service Supplying

Liebherr Mining

Network

With a truly global network composed of Liebherr afliates

and exclusive representatives, Liebherr’s worldwide presence enables the highest level of service support irrespective of equipment location. Using advanced forecasting

techniques and in-depth knowledge of regional populations, Liebherr service centers ensure that customers always have timely access to spare parts.

Customized

Service Support

Liebherr tailored support solutions integrate component exchange and management agreements, service and maintenance on site or maintenance management agreements. Liebherr’s highly-trained service personnel ensure preventive and

scheduled maintenance tasks and provide emergency service.

Service

Engineering

Support

Machine and component reliability data are collected and

monitored through the Liebherr maintenance management

system. Liebherr’s sales and service organization and product engineering groups provide fast and proactive support

over the lifetime of the machine and promote mutual benet

for all involved.

Customer Value Management

Liebherr Mining

Exchange

Components

The Liebherr Mining Exchange Components program enables customers to minimize the total machine’s Owning

and Operating Cost while maintaining peak productivity and

reliability. Through 15 Liebherr-certied component rebuild

facilities worldwide, customers can take advantage of this

program regardless of the equipment location or eet size.

Liebherr Mining Exchange

Components

Exchange and repair programs for

components are conducted by Liebherrcertied rebuild facilities using the latest

OEM rebuild specications and the

complete range of genuine Liebherr

parts to ensure:

• Value: signicantly reduce total cost

of ownership

• Quality: guaranteed as-new perfor mance and reliability

• Availability: global network of

components rebuild facilities

Complete Training

Programs

The Liebherr Mining Training System provides operator and

maintenance staff blended training sessions that encourage

productive, cost-effective and safe mining operation. The Liebherr Mining Training System employs online learning programs, factory and on-site sessions and simulator training.

From-Cradle-To-Grave Support

• Customer specic requirement study

• Collaborative solution development

• On-site machine assembly

• On-site machine settings

• Training program on / off site

• Machine performance monitoring

• Spare parts supply

• Parts remanufacturing facilities

Liebherr Mining Exchange Components

11

Page 12

The Liebherr Group of Companies

Wide Product Range

The Liebherr Group is one of the largest construction

equipment manufacturers in the world. Liebherr’s

high-value products and services enjoy a high reputation

in many other fields. The wide range includes domestic

appliances, aerospace and transportation systems,

machine tools and maritime cranes.

Exceptional Customer Benefit

Every product line provides a complete range of models

in many different versions. With both their technical

excel lence and acknowledged quality, Liebherr products

offer a maximum of customer benefits in practical

application.

State-of-the-art Technology

To provide consistent, top quality products, Liebherr

attaches great importance to each product area, its

components and core technologies. Important modules

and components are developed and manufactured

in-house, for instance the entire drive and control

techno logyfor construction equipment.

Worldwide and Independent

Hans Liebherr founded the Liebherr family company in

1949. Since that time, the enterprise has steadily grown

to a group of more than 120 companies with over

35,000employees located on all continents. The corporate

headquarters of the Group is Liebherr-International AG

inBulle, Switzerland. The Liebherr family is the sole owner

of the company.

www.liebherr.com

Printed in Germany by Typodruck BK-RP LEC 11490345-1-09.12 Subject to technical modications. Illustrations may include optional equipment and accessories.

Liebherr-Mining Equipment Colmar SAS

49 rue Frédéric Hartmann, FR-68025 Colmar Cedex

+33 369 49 20 00, Fax +33 369 49 23 18

www.liebherr.com, E-Mail: info.lec@liebherr.com

Loading...

Loading...